Ice cream machine with restart and regeneration functions

An ice cream machine and ice cream technology, applied in frozen sweets, food science, applications, etc., can solve the problems of ice cream hardness and taste deterioration, achieve the effect of accelerating the cooling speed, ensuring stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

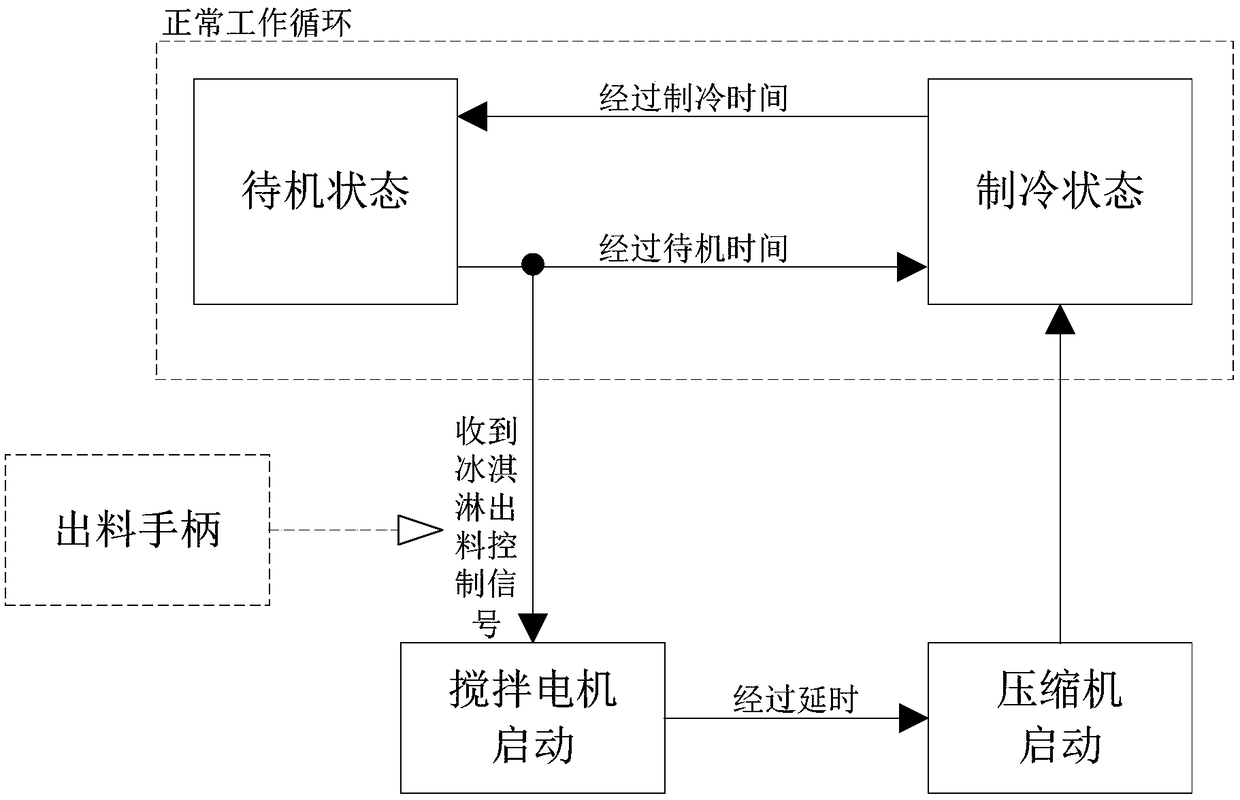

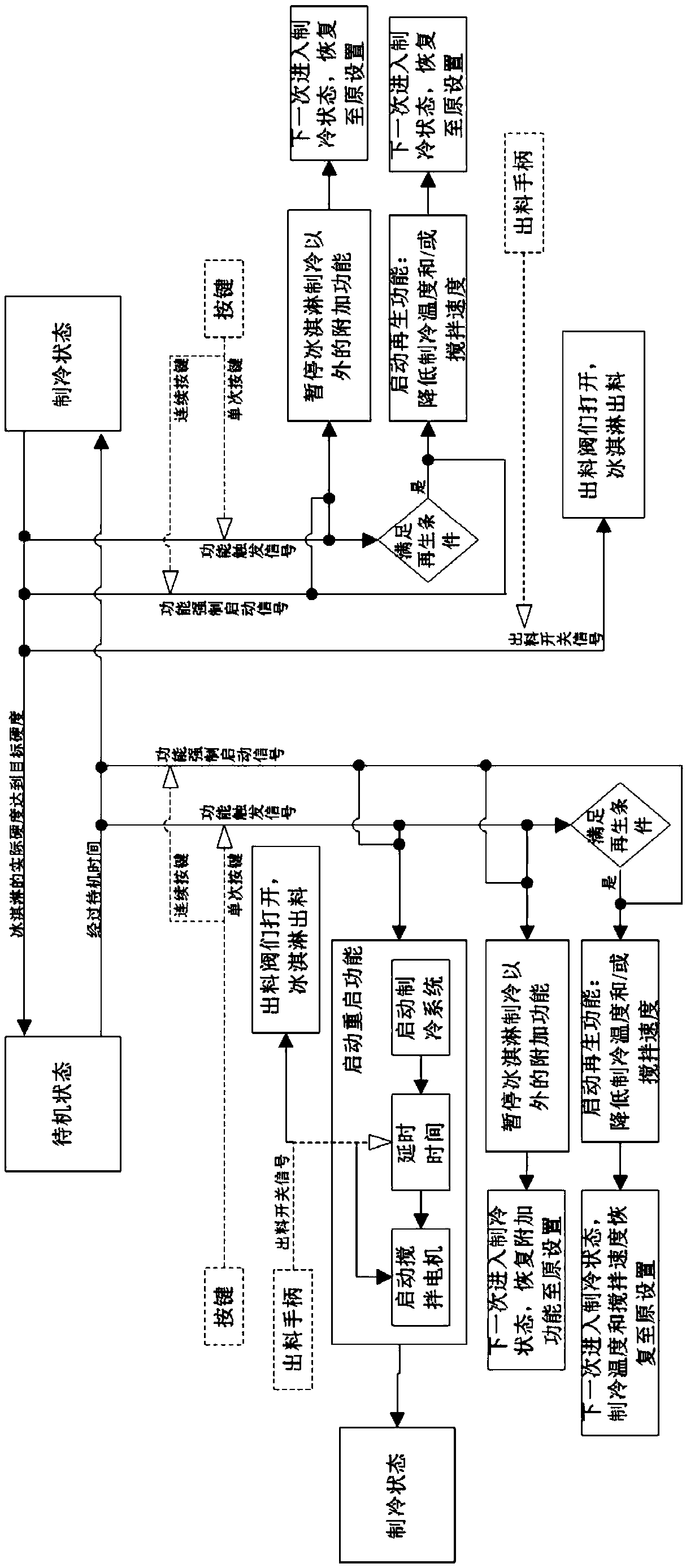

[0043] Such as figure 2 As shown, the present invention discloses an ice cream machine with restart and regeneration functions, which is equipped with a freezing cylinder, a refrigeration system, a stirring motor, a discharge handle and a control system, and the refrigeration system can provide ice cream in the freezing cylinder Refrigeration, the power output by the stirring motor is used to stir the ice cream in the freezing cylinder, the discharge handle can control the discharge valve to open, so that the ice cream in the freezing cylinder is discharged through the discharge valve , and the control system can receive the discharge switch signal when the discharge valve is opened; the control system controls the ice cream machine to alternately cycle between the cooling state and the standby state, wherein in the cooling state In the standby state, the refrigeration system and the stirring motor are all started; in the standby state, the refrigeration system and the stirri...

Embodiment 2

[0054] On the basis of the first embodiment above, in the second embodiment, when the regeneration function is started, the control system directly adjusts the hardness value of the ice cream to which the target hardness is set.

Embodiment 3

[0056] On the basis of the above-mentioned embodiment 1, this embodiment 3 adopts a method different from the above-mentioned embodiment 2 to realize the regeneration function, that is, adopts the following preferred measures:

[0057] The control system is preset with multiple hardness levels, and a corresponding ice cream hardness value is set corresponding to each hardness level, wherein, the higher the hardness level, the greater the corresponding ice cream hardness value; The control system can be controlled to set the ice cream machine to work at one of the hardness levels, and record the hardness level at which the ice cream machine works as the set hardness level, so that the control The system sets the ice cream hardness value corresponding to the set hardness level as the target hardness;

[0058] The implementation of the regeneration function is as follows: increasing the hardness gear at which the ice cream machine works, so that the target hardness is set to incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com