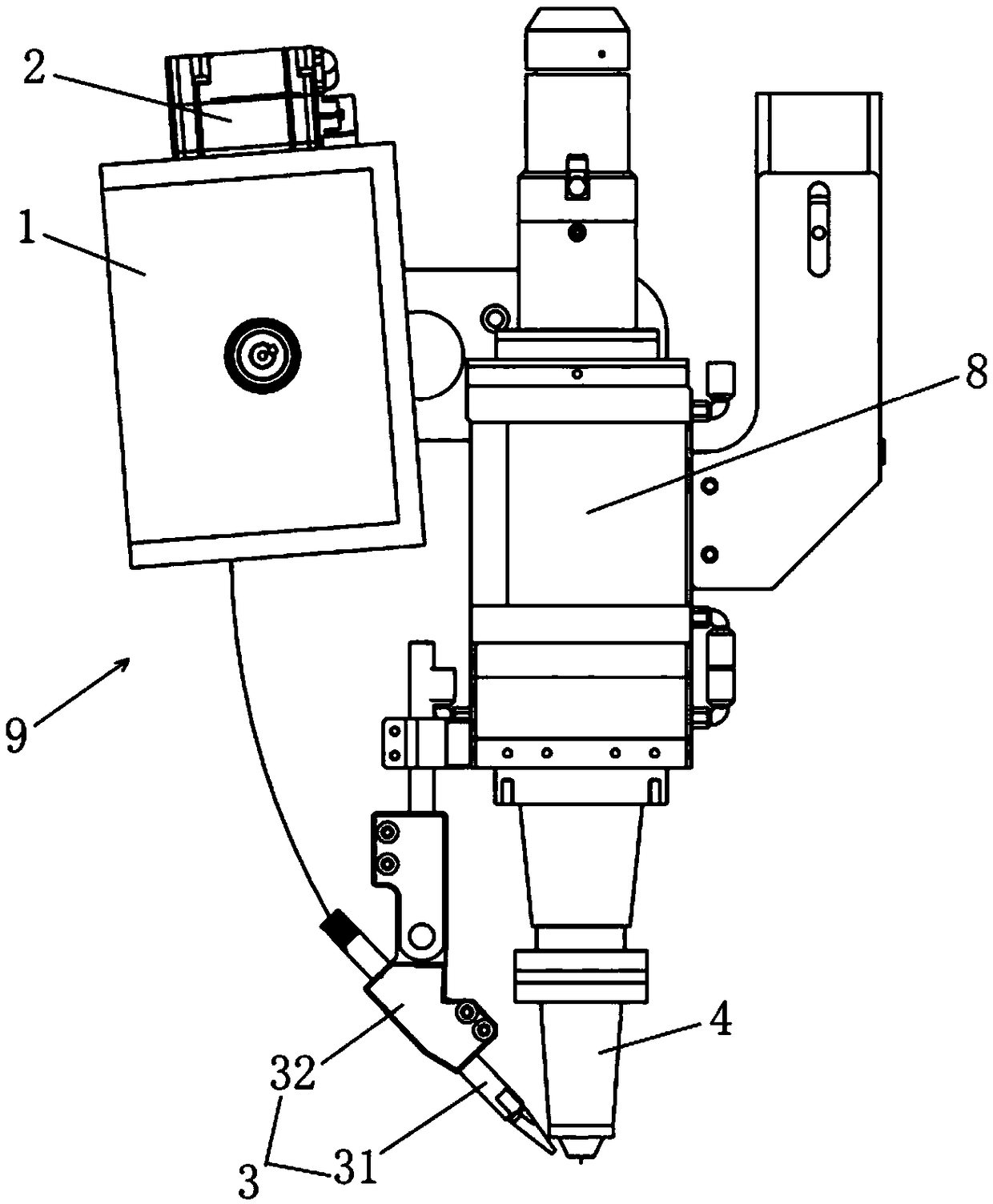

Laser wire filing welding device and method

A technology of laser wire filling and welding device, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of undercut, wire clamping, leakage welding, etc., to ensure stability and reliability, and improve product qualification rate and efficiency, the effect of good weld formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

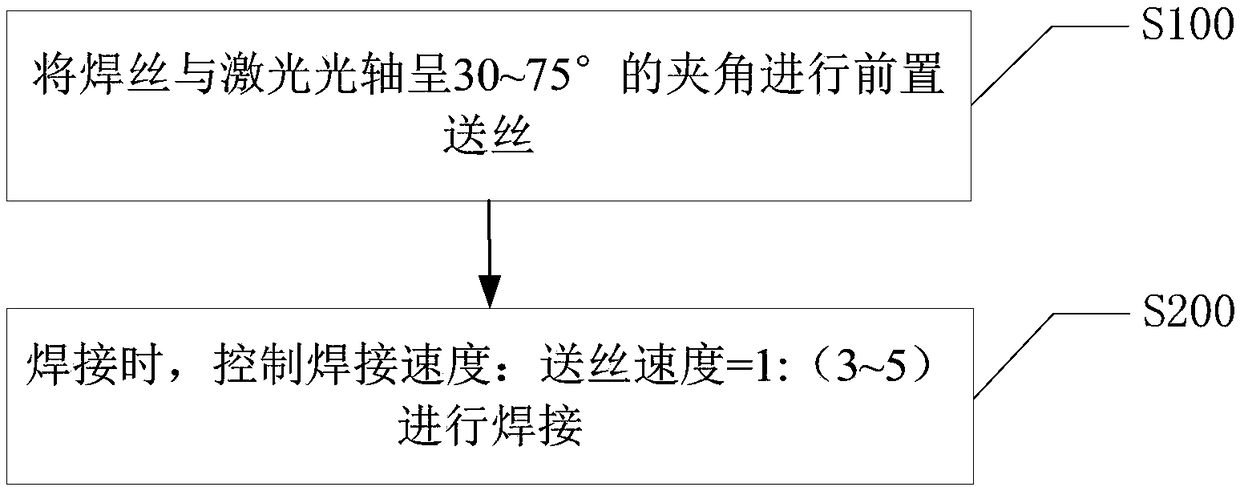

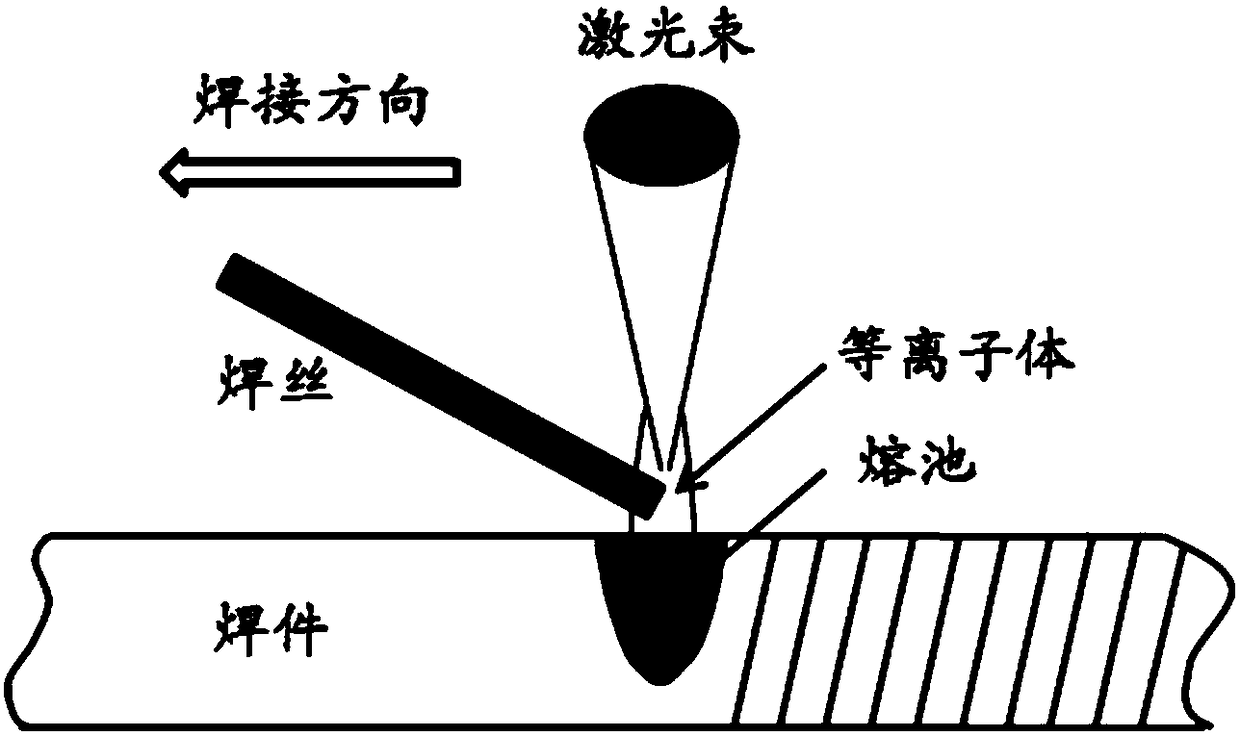

Embodiment 1

[0050] This embodiment is aimed at overlay welding of SUS304 stainless steel sheet. During the test, the surface of the stainless steel plate was polished with 600-grit sandpaper, and then cleaned with absolute ethanol to remove the surface oxide layer and oil stains. During the laser welding process, the weldment is clamped with a piano-type fixture to prevent wave-like deformation of the welded specimen. The laser welding machine used in the test is the WFD2500 semiconductor laser welding machine independently developed by Han's Laser, and the welding wire is 0.6mm ER304 stainless steel wire. The configuration of the external optical path for laser welding requires a fiber core diameter of 400um, a collimation of 70mm, and a focus of 150mm. Welding process parameters are: output power 2300W, welding speed 20mm / s, wire feeding speed 60mm / s, spot diameter 0.6mm, wire spacing D=0.5mm, wire feeding angle a=35°, front wire feeding. Argon gas is used for protection during weldin...

Embodiment 2

[0052] This embodiment is aimed at overlay welding of SUS304 stainless steel sheet. During the test, the surface of the stainless steel plate was polished with sandpaper, and then cleaned with absolute ethanol to remove the surface oxide layer and oil stains. During the laser welding process, the weldment is clamped with a piano-type fixture to prevent wave-like deformation of the welded specimen. The laser welding machine used in the test is the WFD2500 semiconductor laser welding machine independently developed by Han's Laser, and the welding wire is 0.6mm ER304 stainless steel wire. The configuration of the external optical path of laser welding requires a fiber core diameter of 400um, a collimation of 70mm, and a focus of 200mm. Welding process parameters are: output power 2000W, welding speed 30mm / s, wire feeding speed 100mm / s, spot diameter 0.6mm, wire spacing D=0mm, wire feeding angle a=70°, front wire feeding. Argon gas is used for protection during welding, and the ...

Embodiment 3

[0054] In this embodiment, welding is performed on a SUS304 stainless steel sheet. The thermal conductivity of SUS304 stainless steel is small, the linear expansion coefficient is large, the lateral displacement of the workpiece caused by thermal shrinkage during the welding process, and the joint gap is too large or too small during connection, etc., it is difficult to guarantee the welding quality, and the most likely to occur in butt welding The defect is burn through. During the test, the two boards were butted along the length direction, and the butt end and upper surface were polished with 600-grit sandpaper, and then cleaned with absolute ethanol to remove the surface oxide layer and oil stains. During the laser welding process, the weldment is clamped with a piano-type fixture to ensure that the assembly gap between the two plates is as small as possible to prevent the wavy deformation of the welded test piece. The laser welding machine used in the test is the WFD2500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Spot size | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com