Reverse control valve, reverse dosing filling machine and filling method thereof

A technology of reversing control valve and filling machine, which is applied in the field of reversing control valve and reversing quantitative filling machine, can solve the problem of failing to achieve the best use effect and work efficiency, and it is difficult to achieve fast and effective accurate control, unfavorable production cost and production efficiency, etc., to achieve the effect of improving control accuracy, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

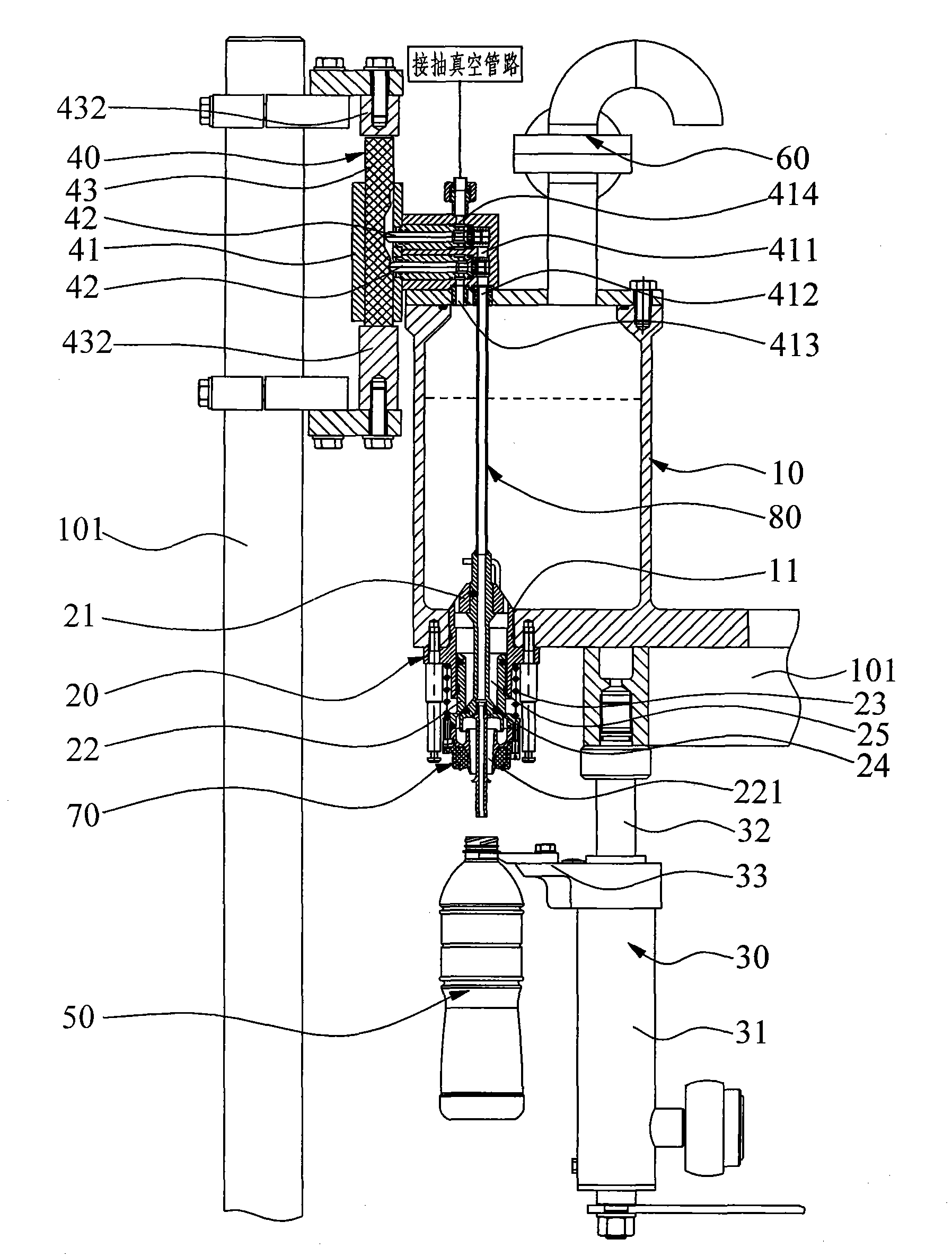

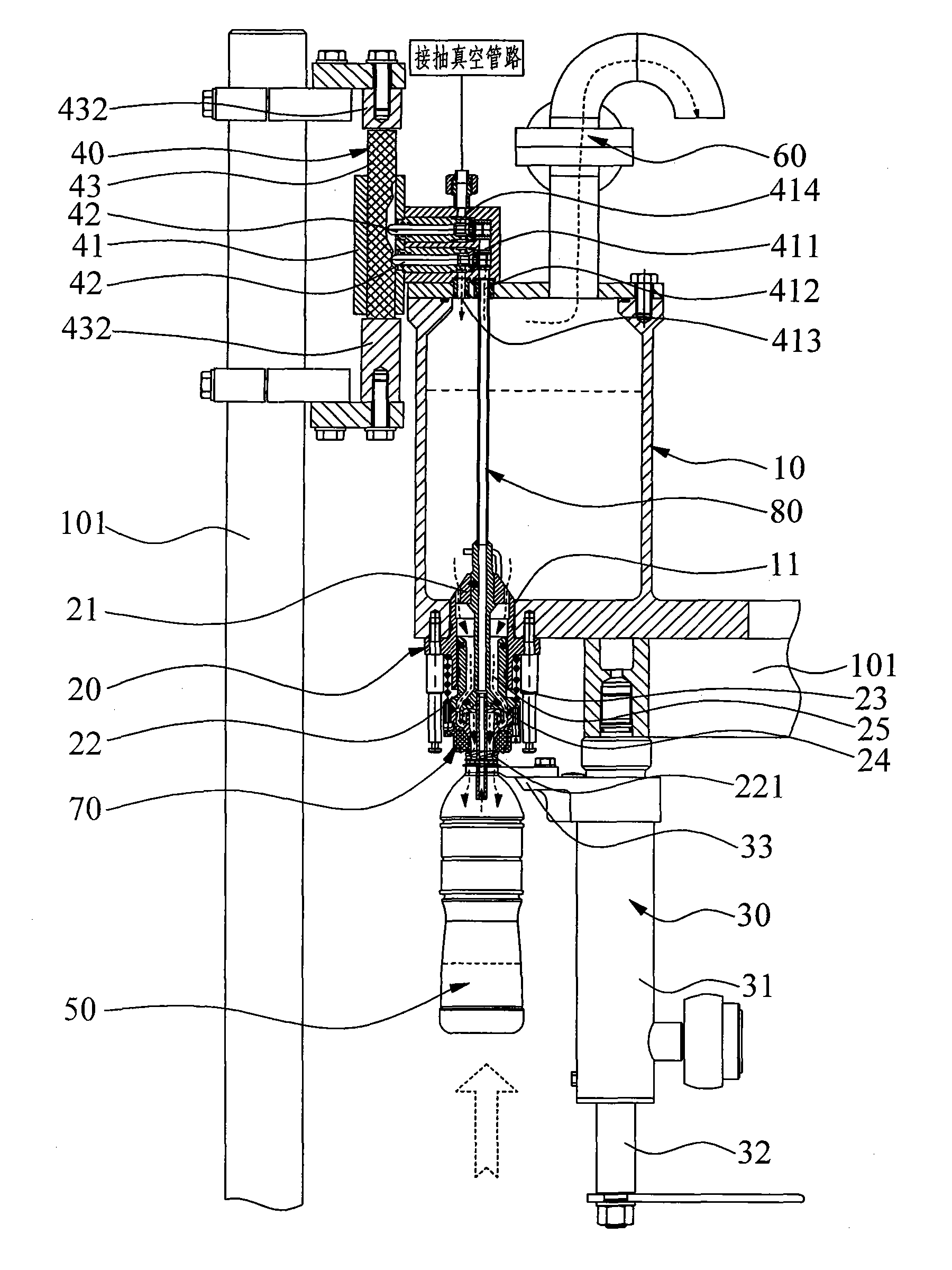

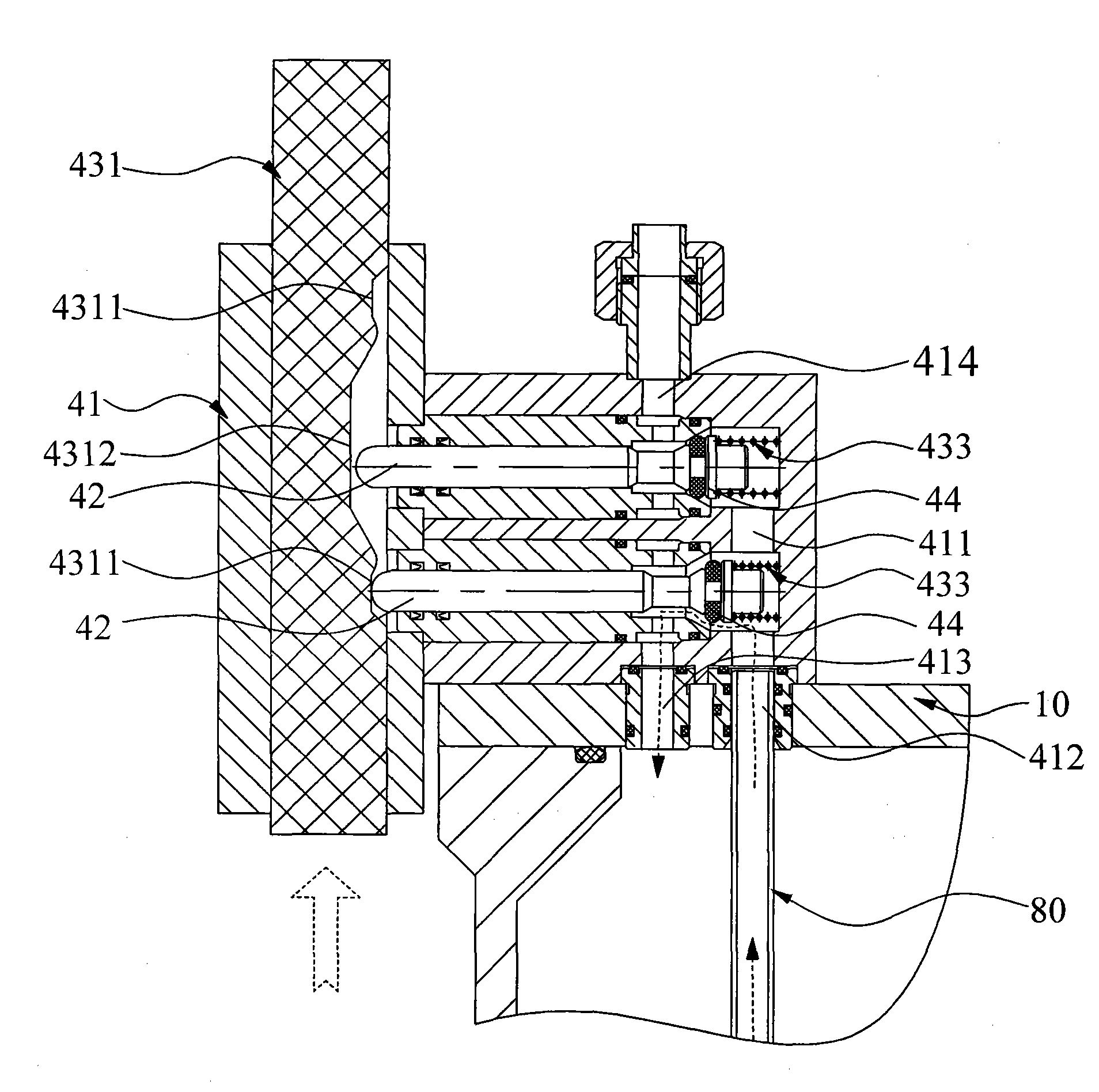

[0049] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of a preferred embodiment of the present invention, including a liquid storage tank 10 , a filling control valve 20 , a bottle lifting device 30 , and a reversing control valve 40 .

[0050]Wherein, the liquid storage tank 10 is fixedly installed on the machine base 101, and the liquid storage tank 10 is used as a component of a liquid supply device to store various water, fruit juice, beverages or cola that need to be filled into the bottle body 50. and other materials. A discharge port 11 is provided at the lower end of the liquid storage tank 10, and a total exhaust valve 60 is further provided above the liquid storage tank 10, and the total exhaust valve 60 communicates with the inside of the liquid storage tank 10 for filling. total exhaust.

[0051] The filling control valve 20 is installed below the discharge port 11 of the liquid storage tank 10 for controlling the opening and clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com