Sludge drying equipment

A sludge drying and equipment technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of poor dehumidification efficiency, inability to dry thoroughly, and no proper dust separation measures, etc., and achieve high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

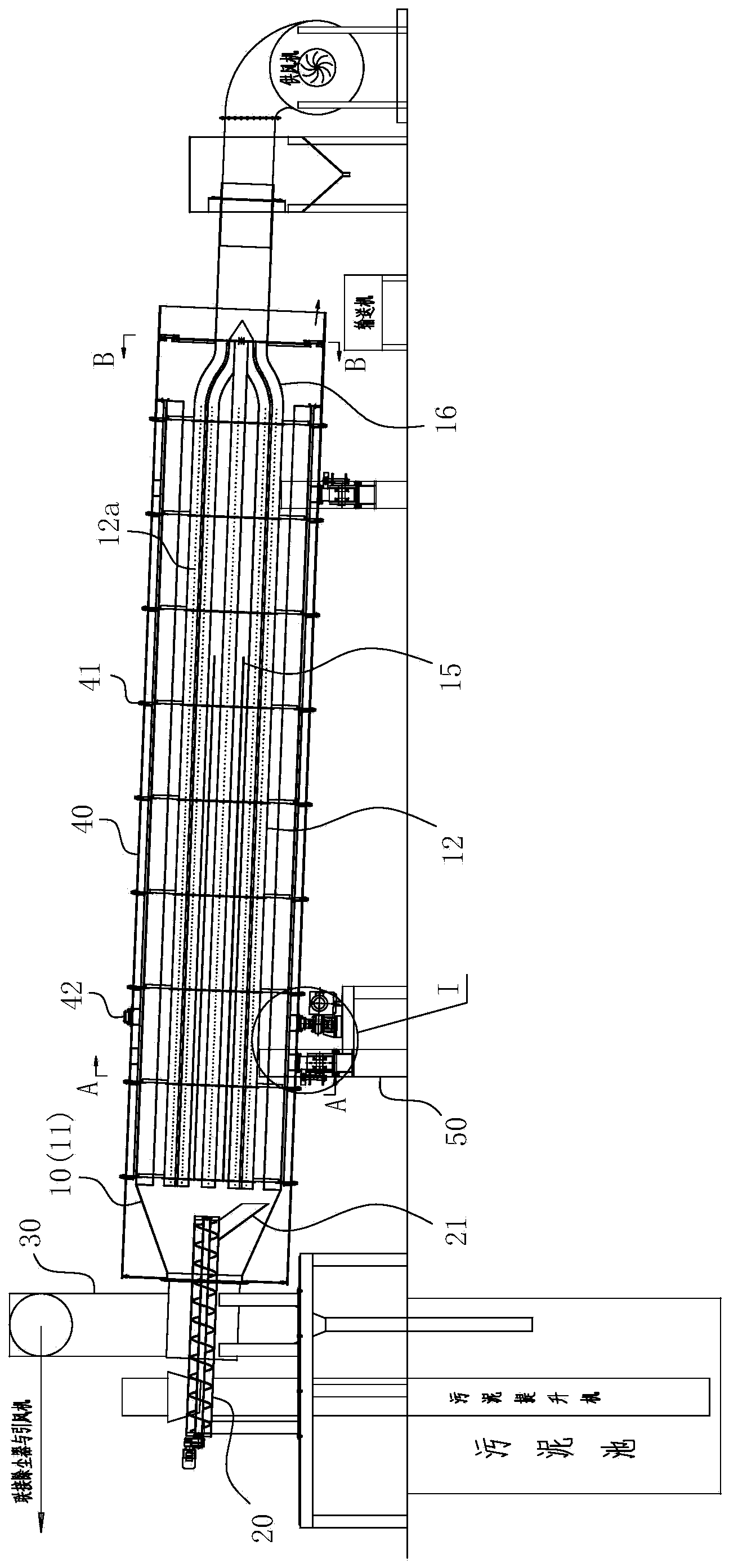

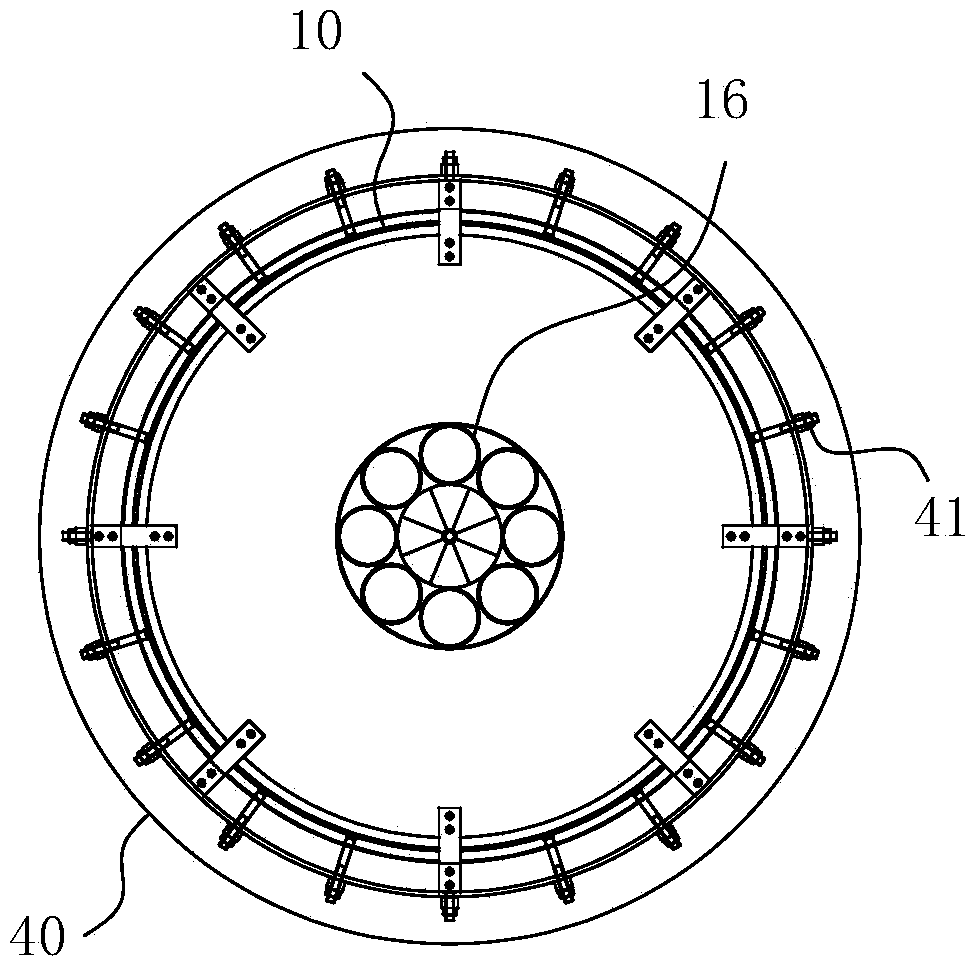

[0038] For ease of understanding, combined here Figure 1-4 Specifically set forth the component structure of the present invention and its specific work flow:

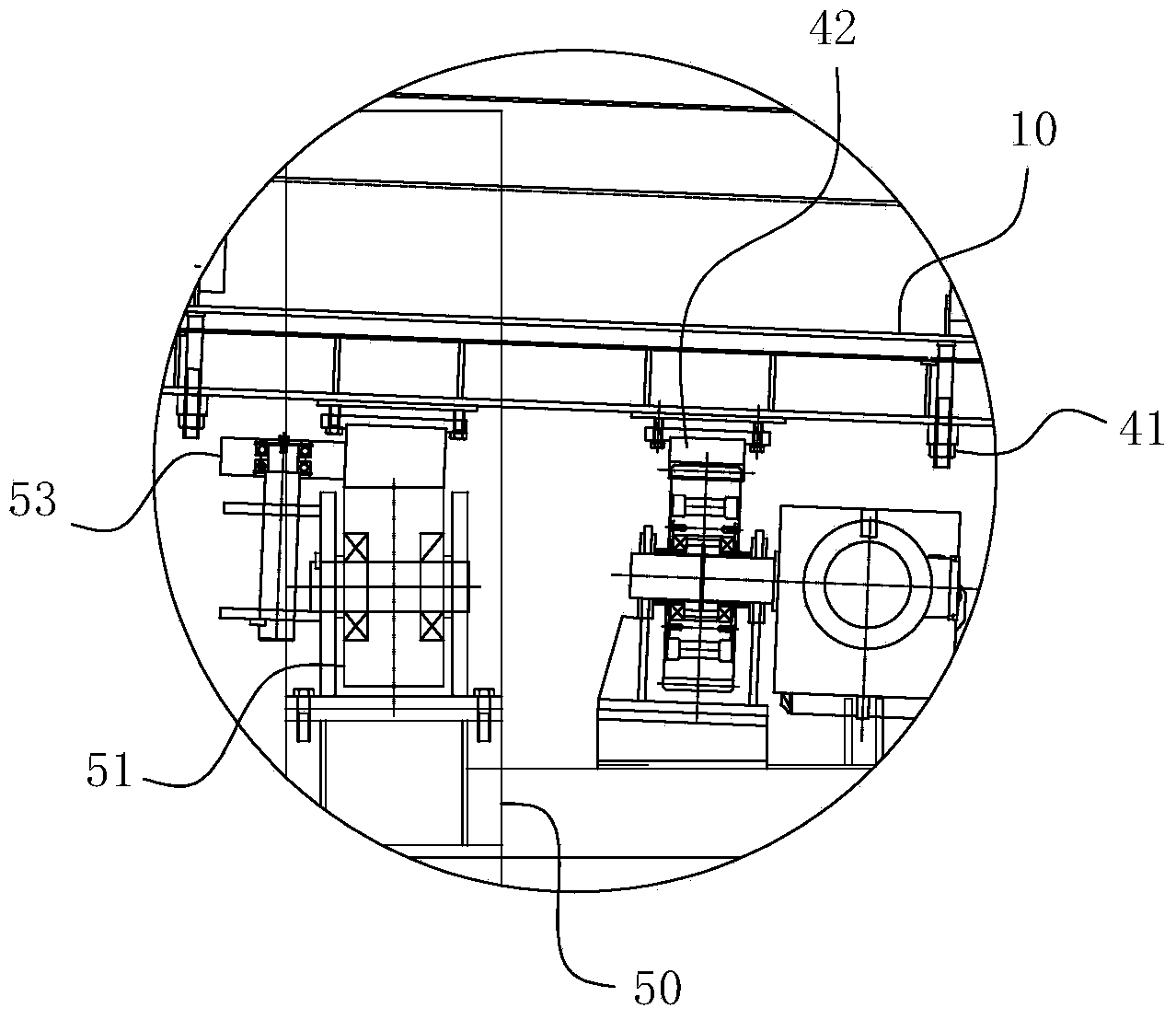

[0039] Concrete structure of the present invention, as Figure 1-4 As shown, it generally includes an outer shell 40, a support frame 50 is arranged on the outer wall of the outer shell 40, and a rolling support roller assembly is correspondingly arranged at the support frame 50, including a support roller 52 and a support roller 51, and the support roller assembly is arranged on the support frame 50 on the column, while the support frame 14 is positioned at the side of the supporting roller 52 and the supporting roller 51, and an orientation wheel 53 is also arranged to ensure the actual rolling guide of the cylinder 10. A mud feeder is arranged at the high end of the outer shell 40, and a screw conveyor 20, etc. are used for specific operations; the mud feeder penetrates the outer shell 40 to communicate with the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com