Municipal sludge drying device

A technology of municipal sludge and oblique placement, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of poor dehumidification efficiency, frequent use, and inconvenient maintenance, and achieve the effect of reliable operation, high work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

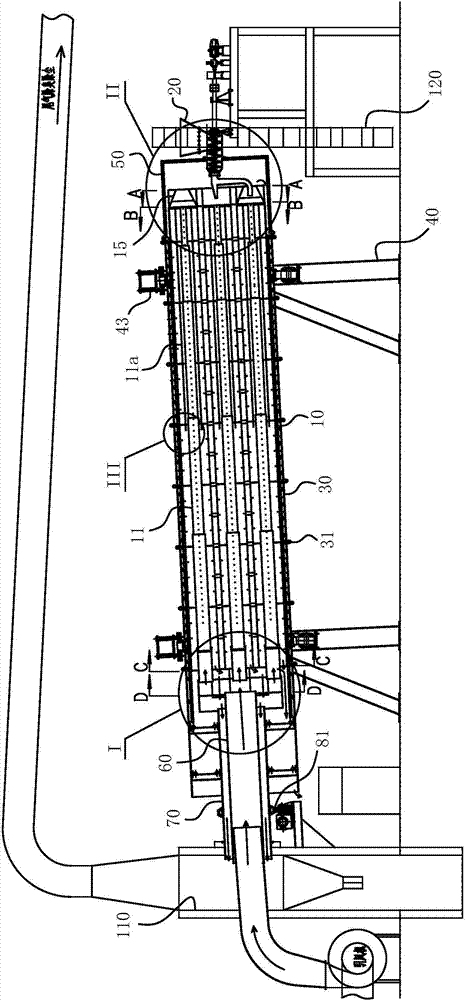

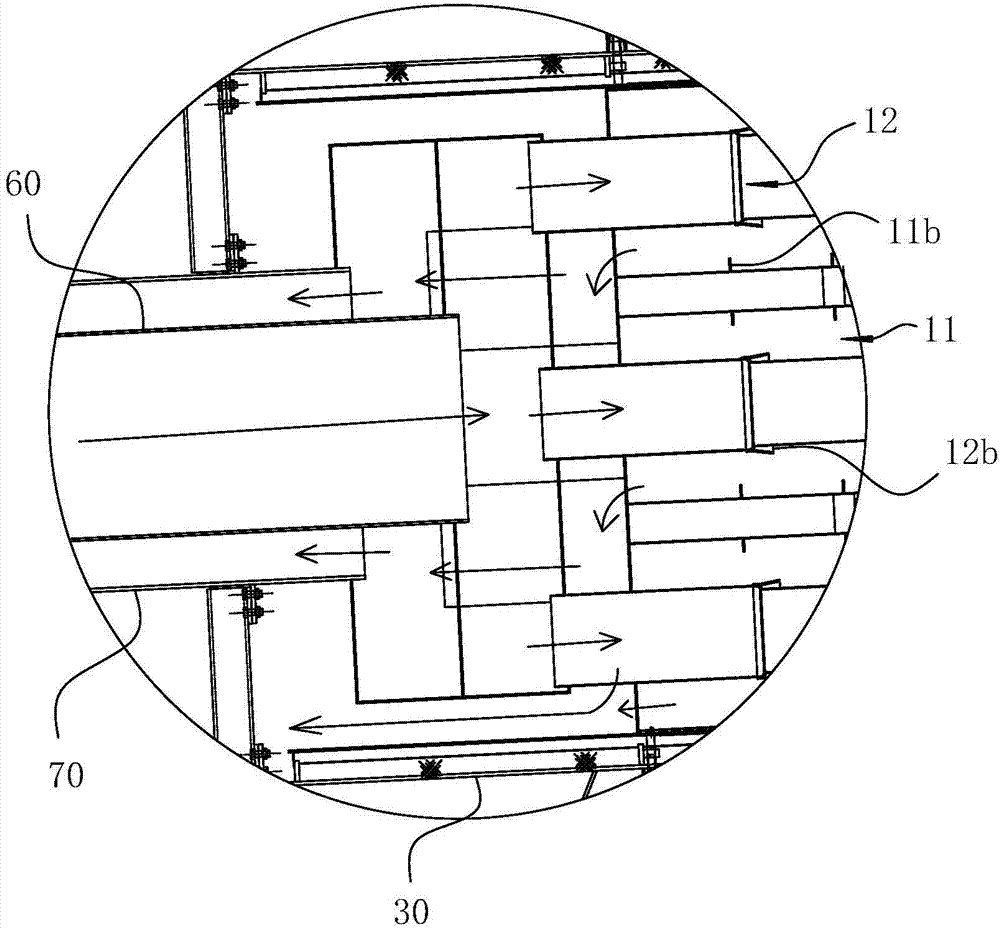

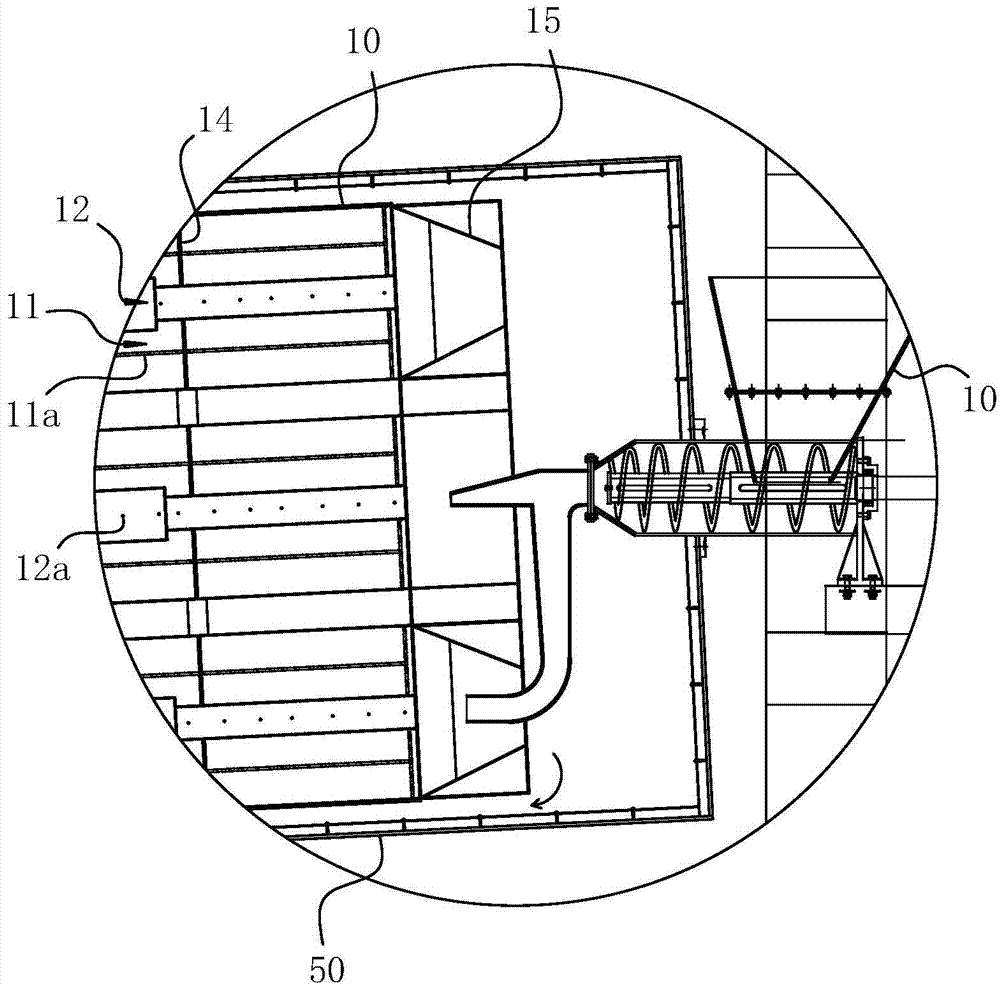

[0041] For ease of understanding, combined here Figure 1-8 Specifically set forth the component structure of the present invention and its specific work flow:

[0042] Actual finished product of the present invention, can refer to figure 1 As shown, it usually includes an outer drum (that is, an outer casing 30), and a support frame 40 is arranged outside the outer drum 30, and a rolling support roller assembly is correspondingly provided at the support frame 40, including a support roller 42 and a support roller 41, and the support roller The assembly is arranged on the column of the support frame 14 , and at the same time, the support frame 14 is also provided with directional wheels 43 to ensure the actual rolling guidance of the drum 10 . A return air cover 50 is arranged at a height of one end of the cylinder body of the outer drum, and the return air cover 50 is connected with the shell at the end of the outer drum. cavity), a mud supply machine is arranged at the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com