Patents

Literature

147results about How to "High elastic limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

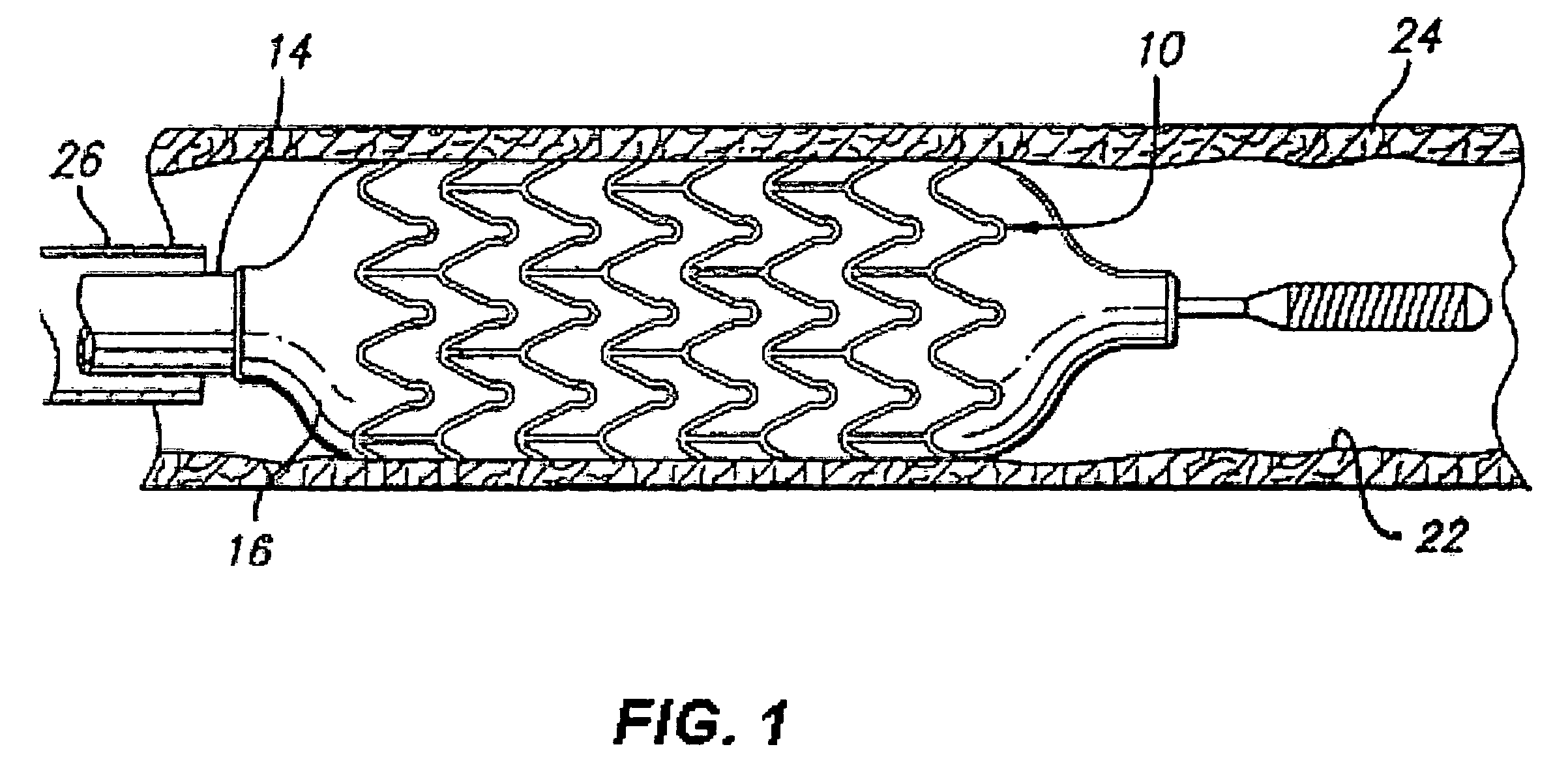

Bulk metallic glass medical instruments, implants, and methods of using same

InactiveUS20020162605A1Good mri signatureHigh susceptibilityIncision instrumentsSurgical needlesMri guidedMetal

MRI-compatible medical instruments and appliances are made using bulk metallic glass alloys. MRI-guided methods include the use of articles that include bulk metallic glass alloys.

Owner:UT BATTELLE LLC

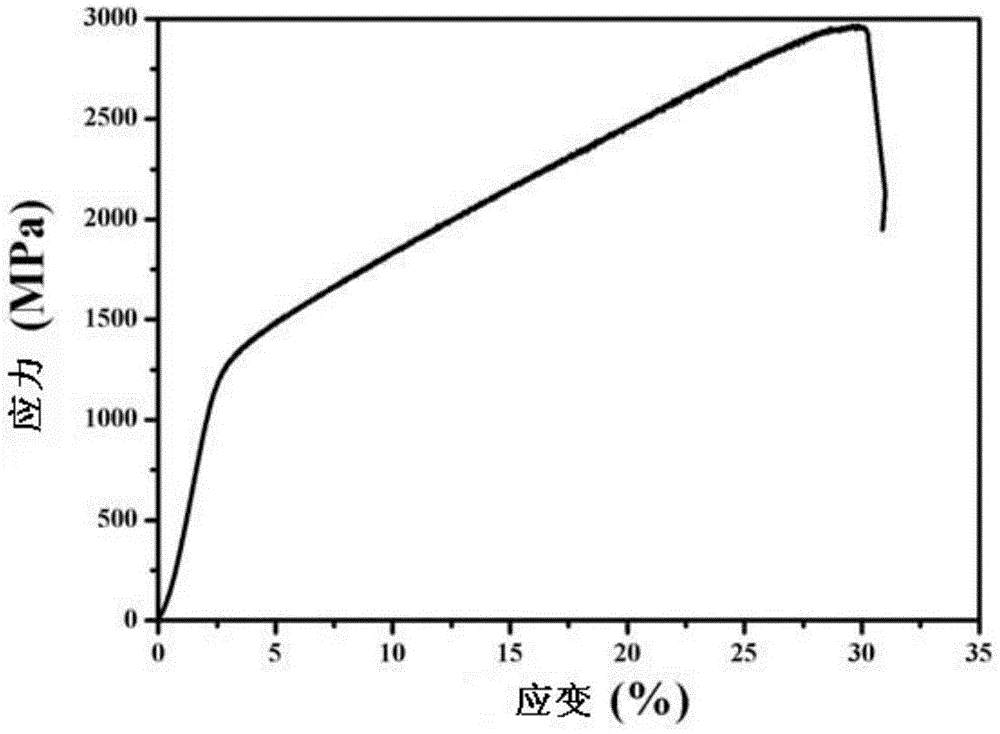

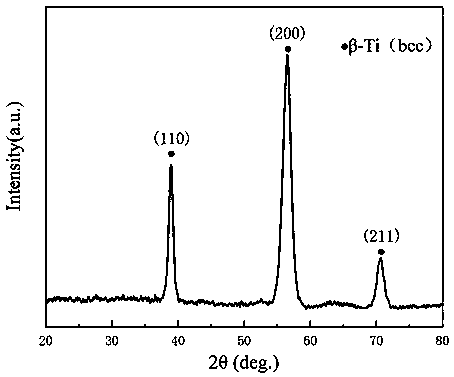

High-strength high-toughness ultrafine-grained high-entropy alloy and preparation method thereof

The invention belongs to the technical field of alloy material, and discloses a high-strength high-toughness ultrafine-grained high-entropy alloy and a preparation method thereof. The high-strength high-toughness ultrafine-grained high-entropy alloy is composed of the following elements according to the atomic percentage: 20%-25% of Ni, 18%-20% of Fe, 18%-22% of Co, 18%-20% of Cr, and 20%-24% of Al; the microstructure takes a body-centered cubic disordered solid solution phase rich in Ni and Al elements as a matrix phase, and takes a face-centered cubic disordered solid solution phase rich in Fe and Cr elements as a reinforcing phase. The preparation method of the alloy comprises the steps: elemental powders with the atomic percentages are subjected to powder mixing and high-energy ball milling to prepare an amorphous composite powder, and the amorphous composite powder is sintered to obtain the high-strength high-toughness ultrafine-grained high-entropy alloy. The prepared high-entropy alloy has the advantages of large size and good comprehensive mechanical properties, and can be used in the fields of aeronautics and astronautics, military industry, electrons, instruments and apparatuses and the like.

Owner:SOUTH CHINA UNIV OF TECH

Bulk metallic glass medical instruments, implants, and methods of using same

InactiveUS20030111142A1Reduce capacityLow corrosion rateIncision instrumentsSurgical needlesMri guidedAlloy

MRI-compatible medical instruments and appliances are made using bulk metallic glass alloys. MRI-guided methods include the use of articles that include bulk metallic glass alloys.

Owner:HORTON JOSEPH A JR +1

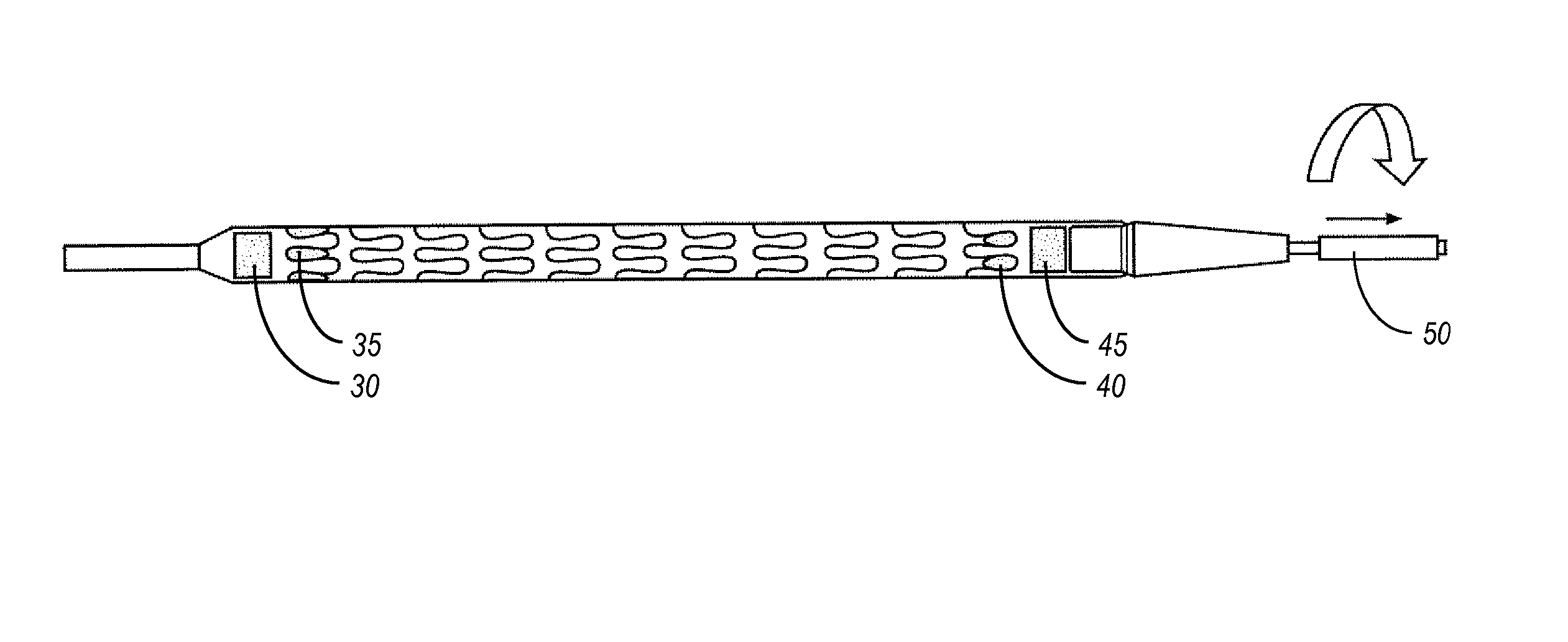

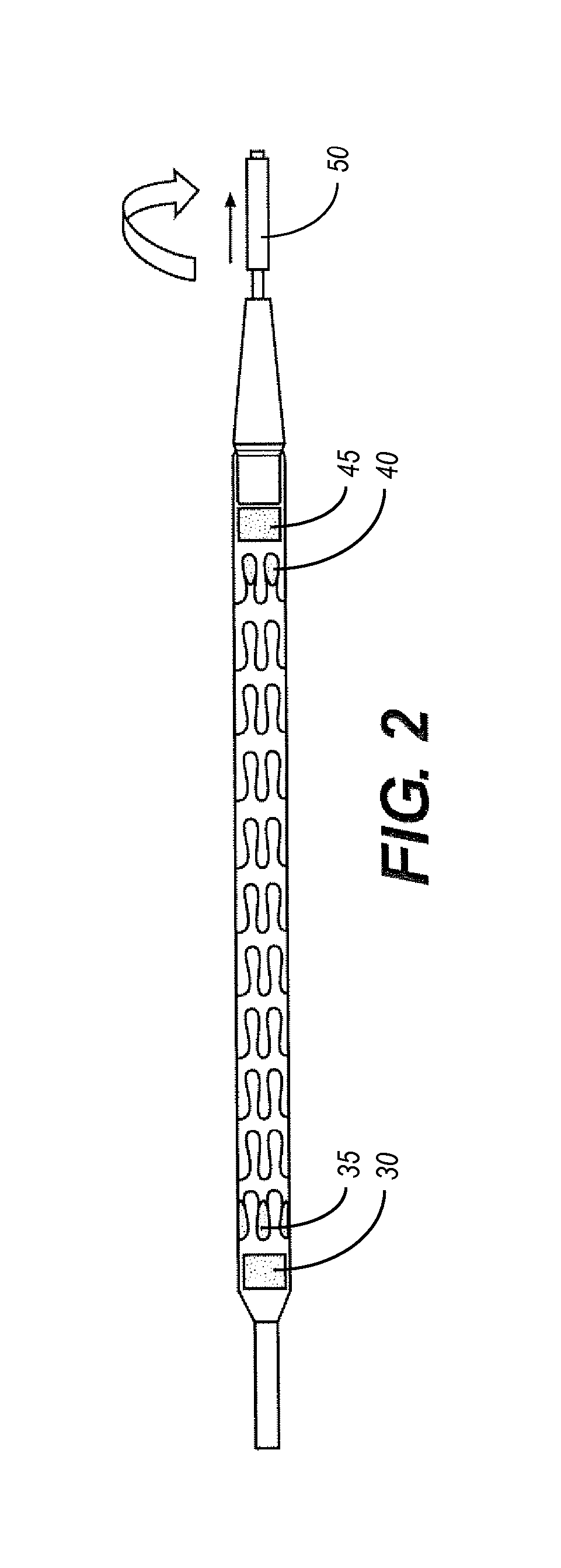

Radiopaque markers and medical devices comprising binary alloys of titanium

There is disclosed medical devices, such as stents, guidewires and embolic filters, comprising a binary alloy of titanium and one binary element selected from platinum, palladium, rhodium, and gold. There is also disclosed a radiopaque marker comprising the disclosed binary alloy, as well as medical devices having the radiopaque marker attached thereto. Methods of attaching the radiopaque marker to the medical devices, such as by welding, are also disclosure also disclosed.

Owner:ABBOTT LAB INC

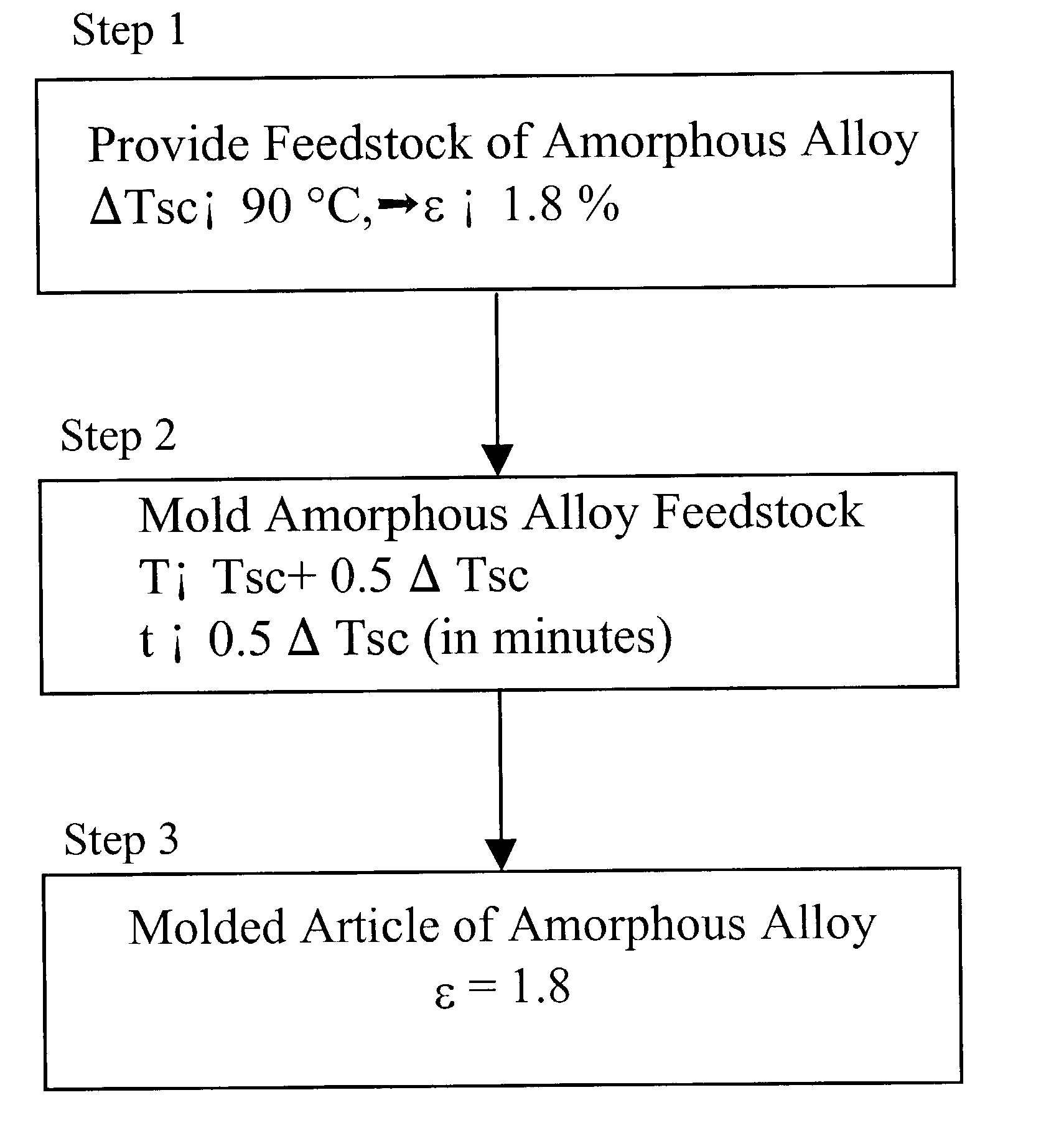

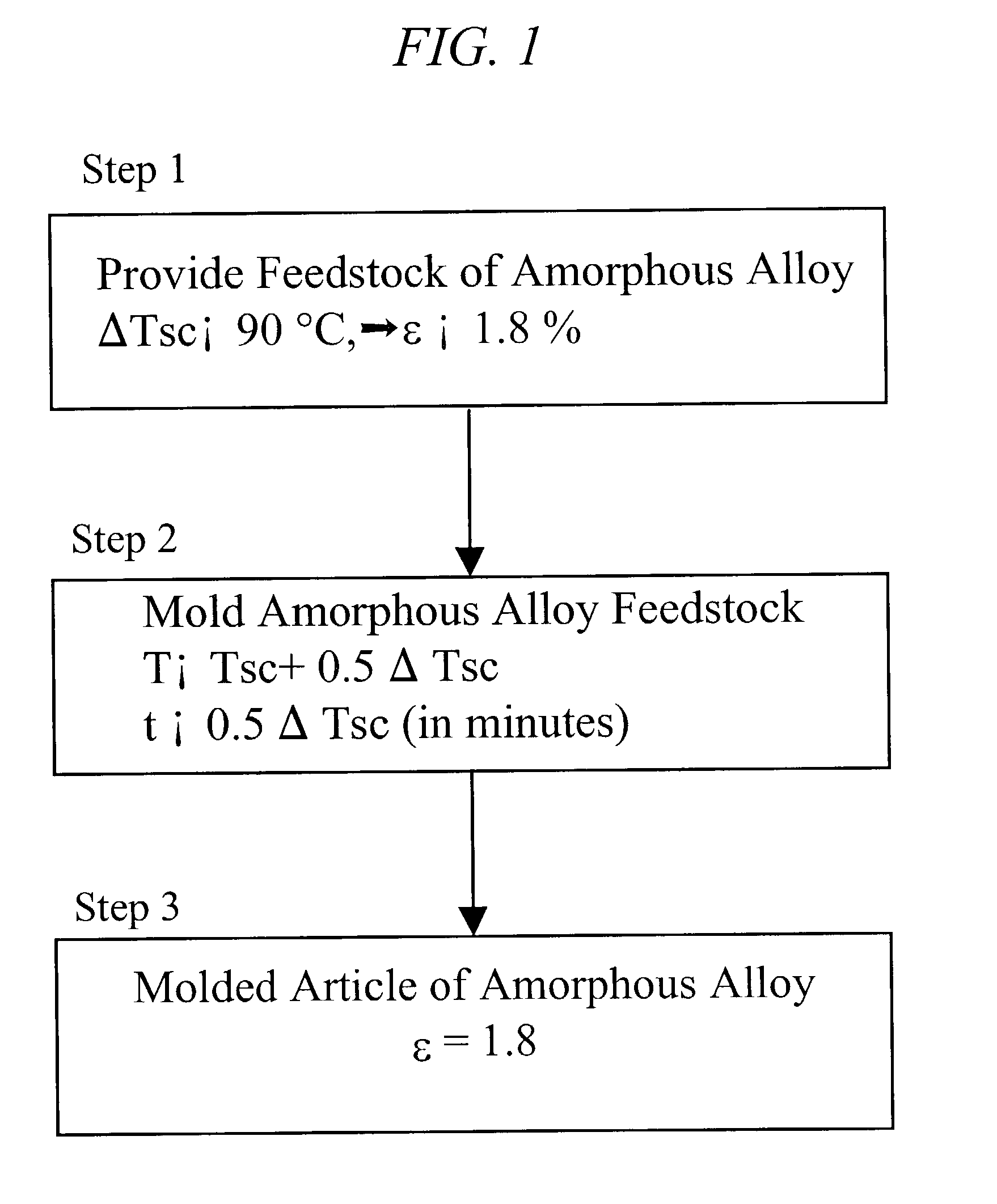

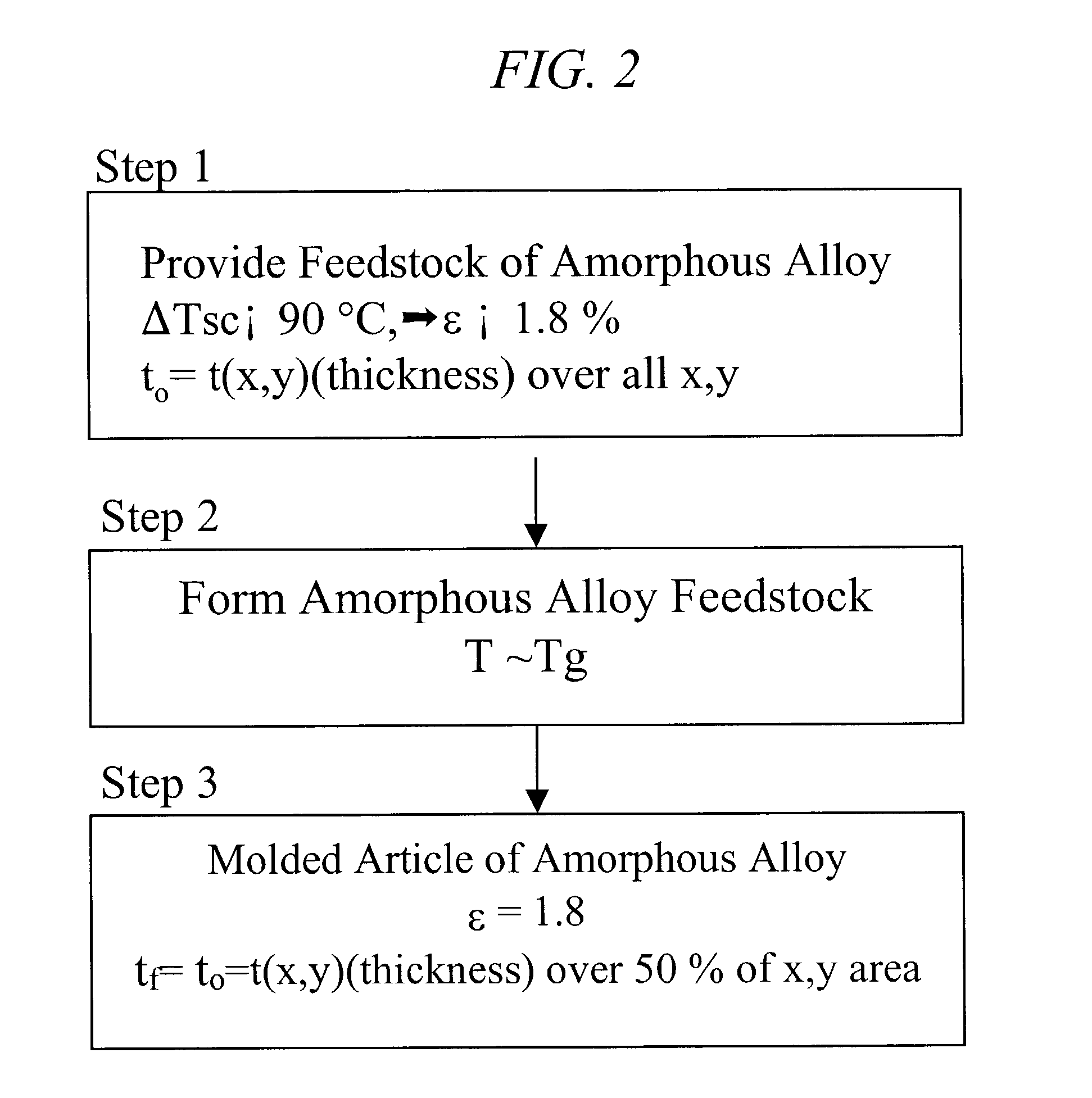

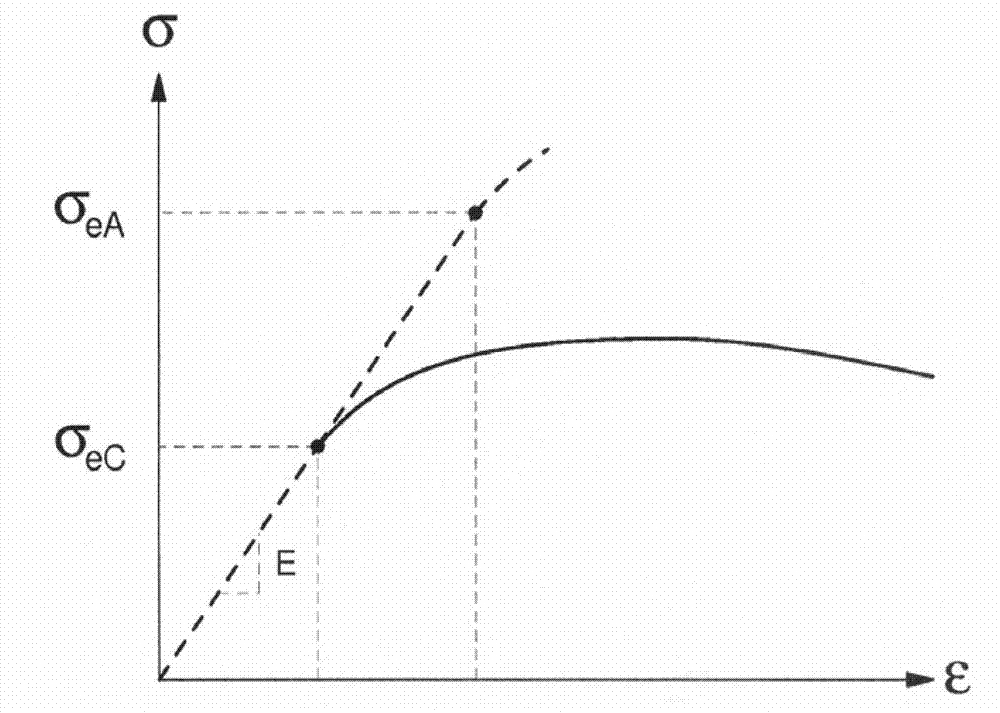

Method of forming molded articles of amorphous alloy with high elastic limit

A method for forming molded articles of bulk-solidifying amorphous alloys around the glass transition range, which preserves the high elastic limit of the bulk solidifying amorphous alloy upon the completion of molding process is provided. The method comprising providing a feedstock of bulk solidifying amorphous alloy, then molding the amorphous alloy feedstock around the glass transition range to form a molded article according to the current invention which retains an elastic limit of at least 1.2%.

Owner:CRUCIBLE INTPROP LLC

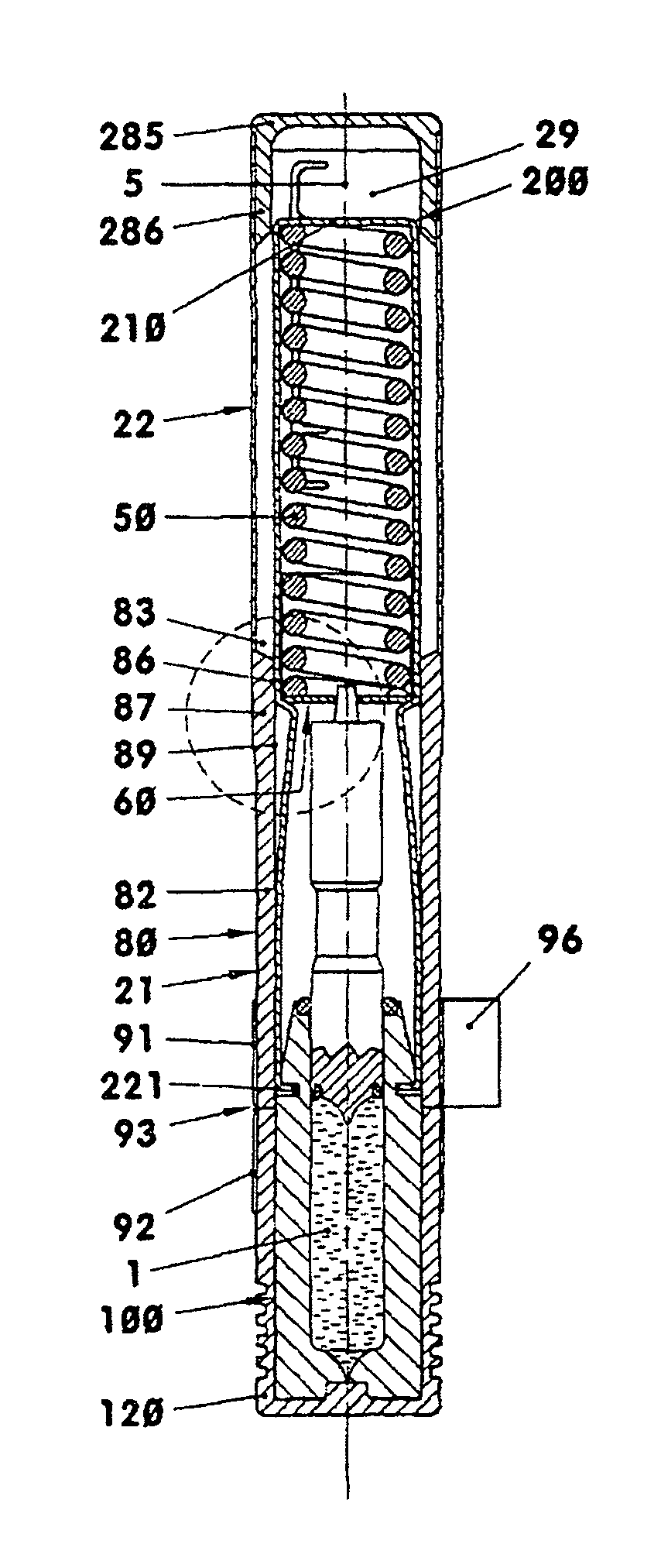

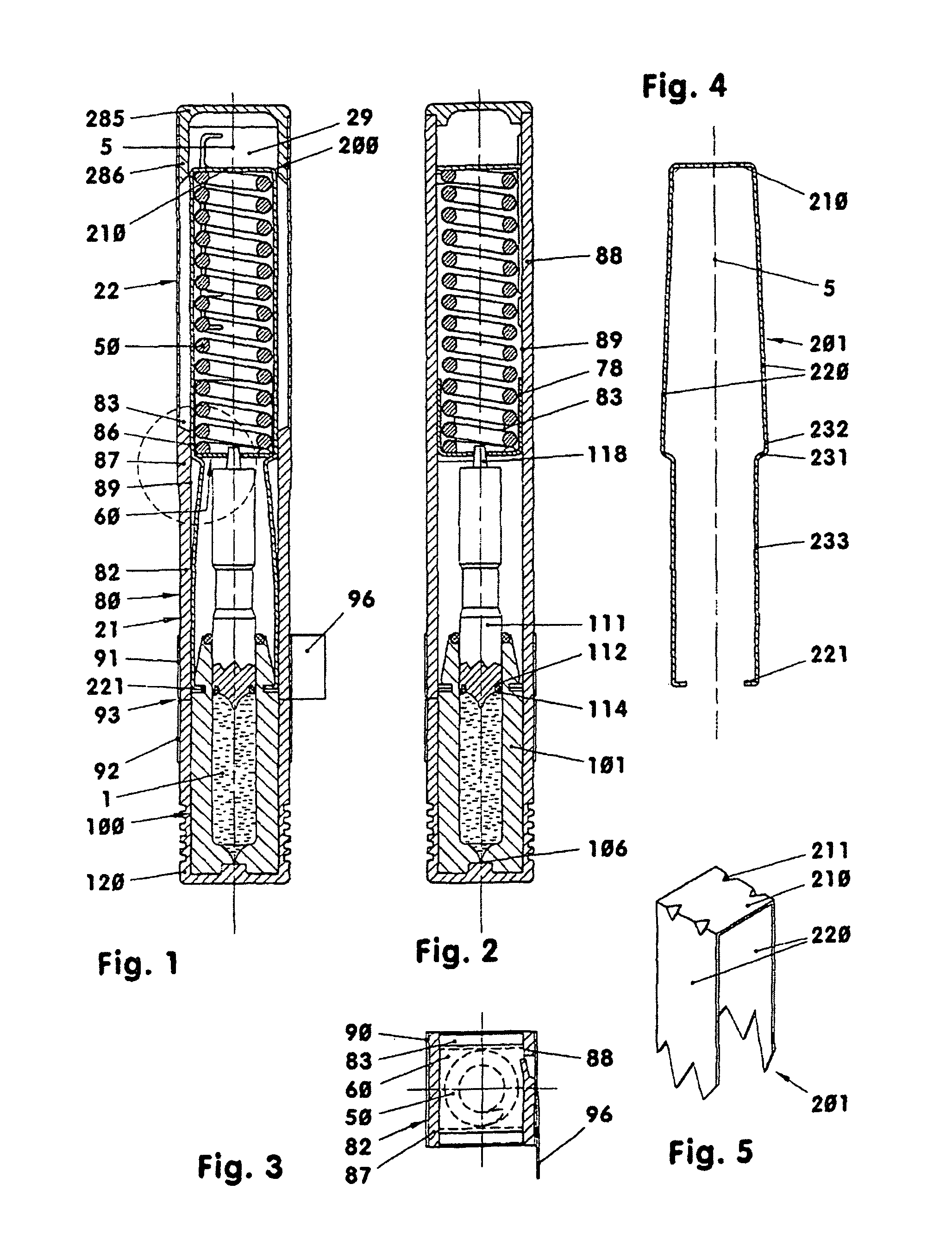

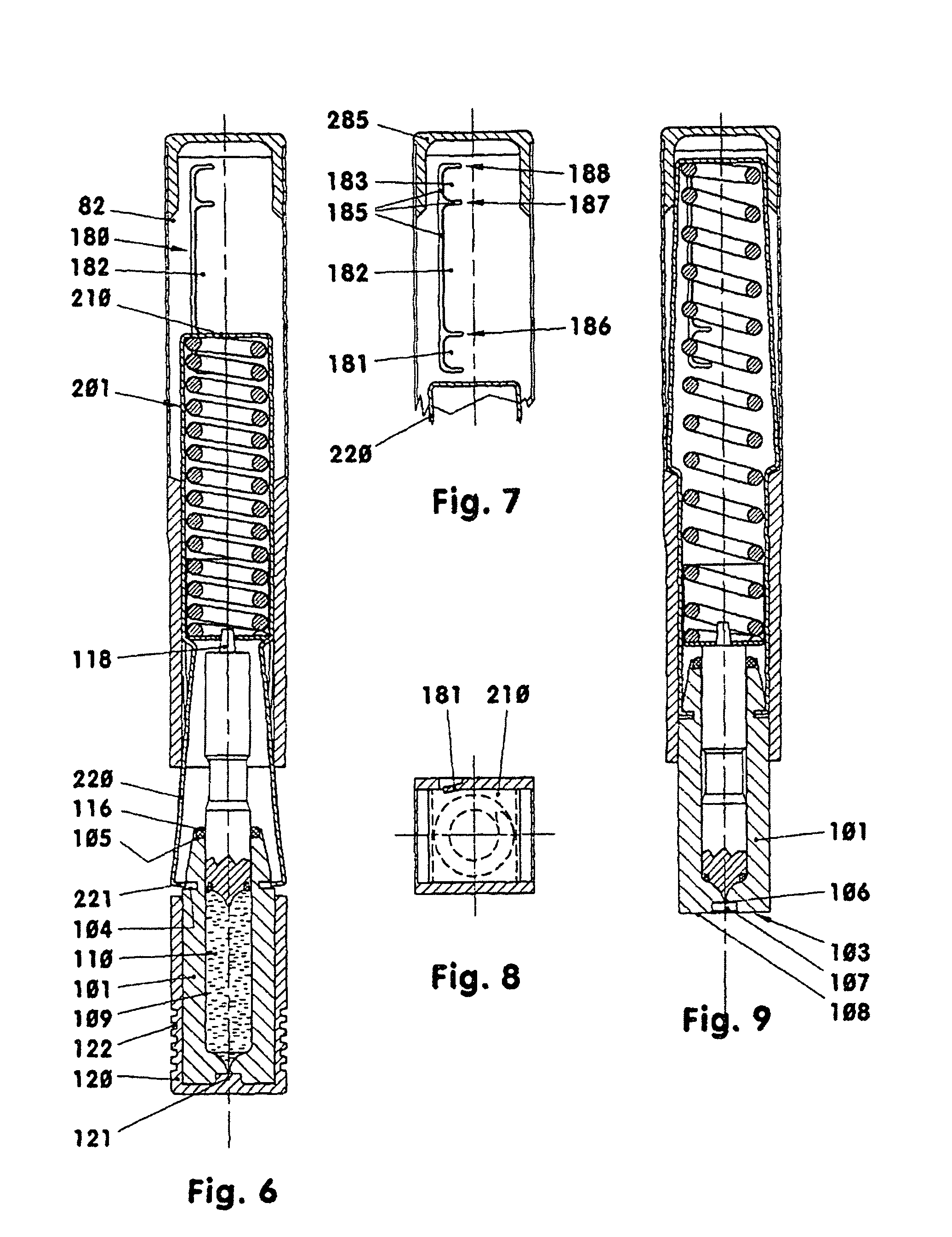

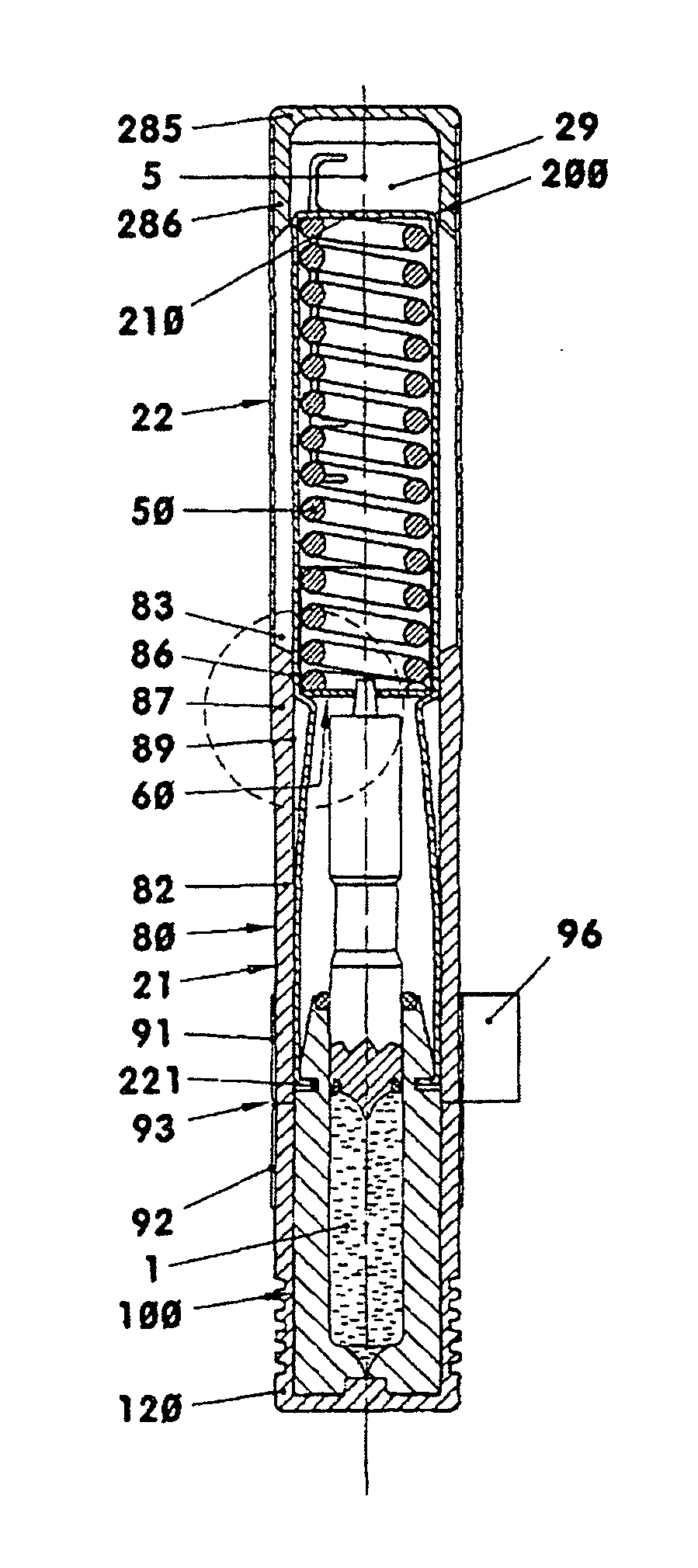

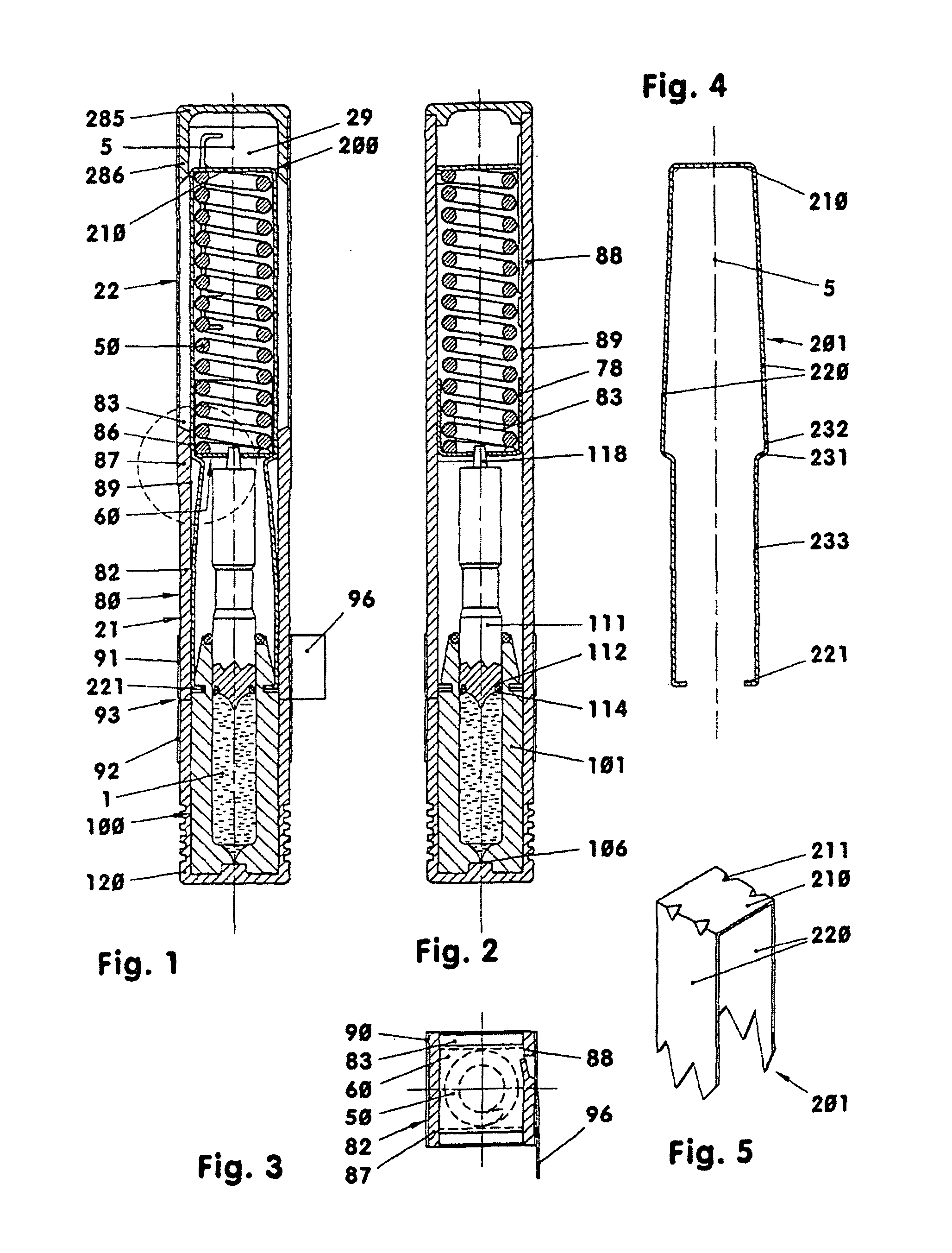

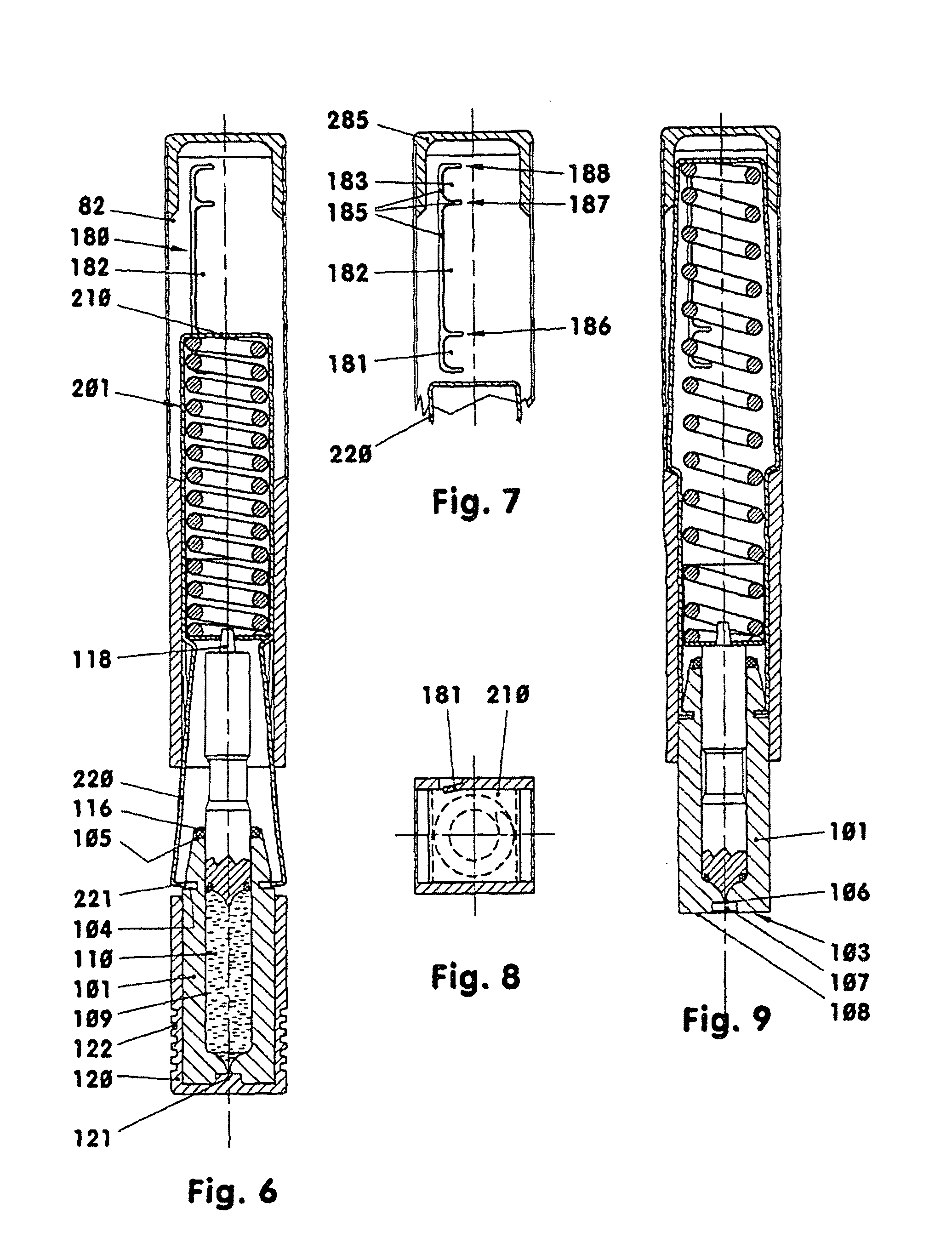

Single-use injector having a flexurally elastic housing

ActiveUS8105271B2Low costHigh elastic limitJet injection syringesAutomatic syringesMetal sheetEngineering

A housing of the injector is made from a thin-walled sheet-metal part. The sheet-metal part has at least two branches or legs. Each branch has, at the free end thereof, an angled retaining element or a recess as a means of receiving the cylinder of a cylinder / piston unit. The branches are elastic flexural beams which, in the middle area, are each bent in a Z-shape or S-shape to form a supporting portion for the piston-actuating ram. The contact zone situated between an individual supporting portion and the piston-actuating ram represents a wedge gear pairing that forces the respective branch outwards. The trigger unit comprises at least a trigger element which is slidably supported on the metal sheet, wherein the support section or, respectively the contact sections extend outwardly into longitudinal grooves. The branches may be provided with a locking tongue to engage corresponding openings in the trigger element to lock the housing in position as desired.

Owner:LTS LOHMANN THERAPIE-SYST AG

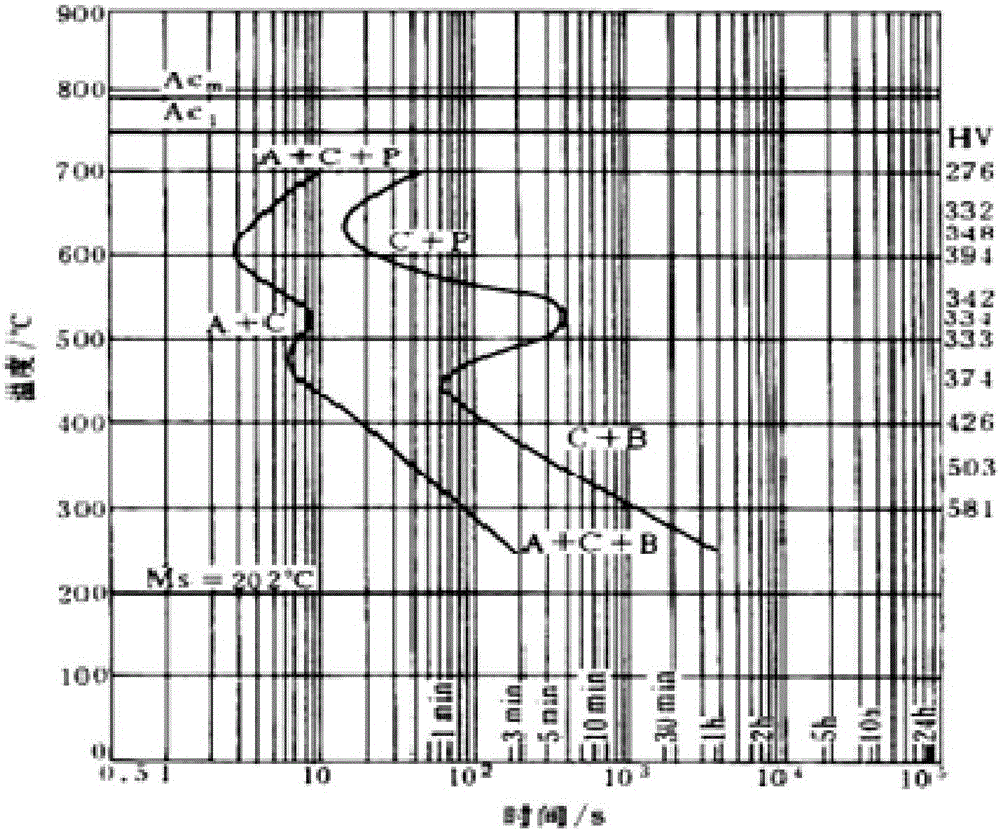

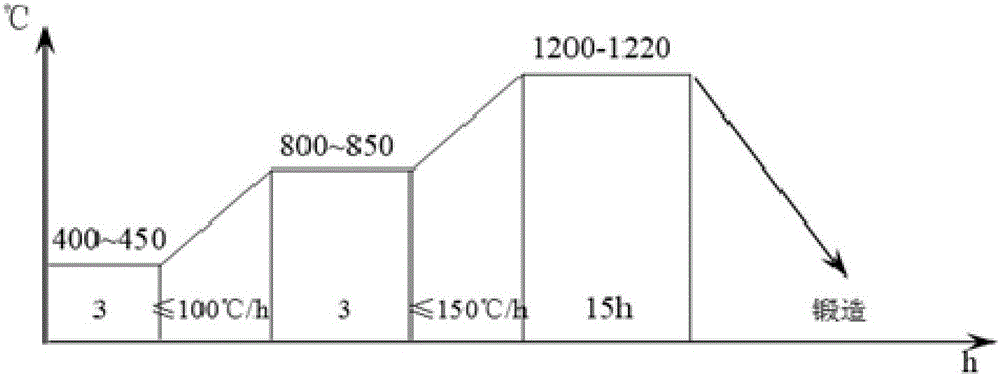

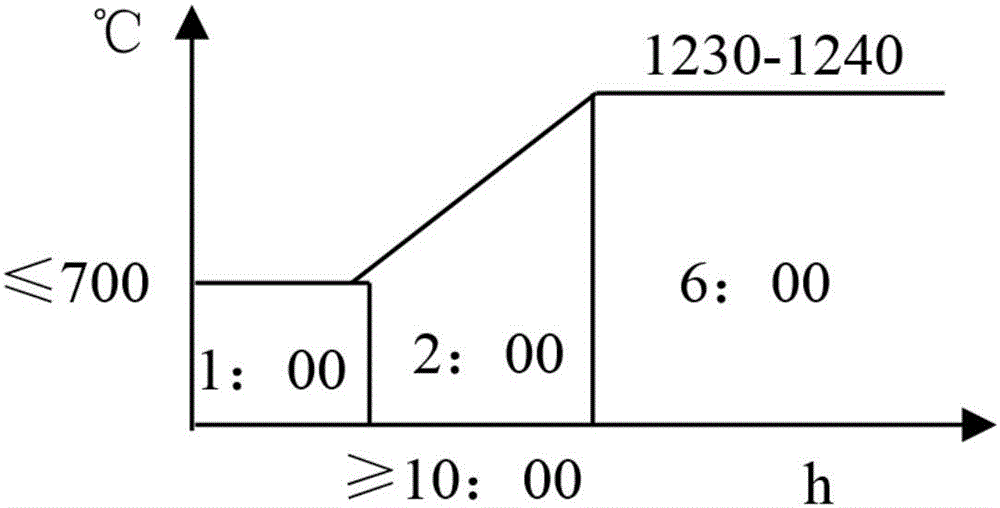

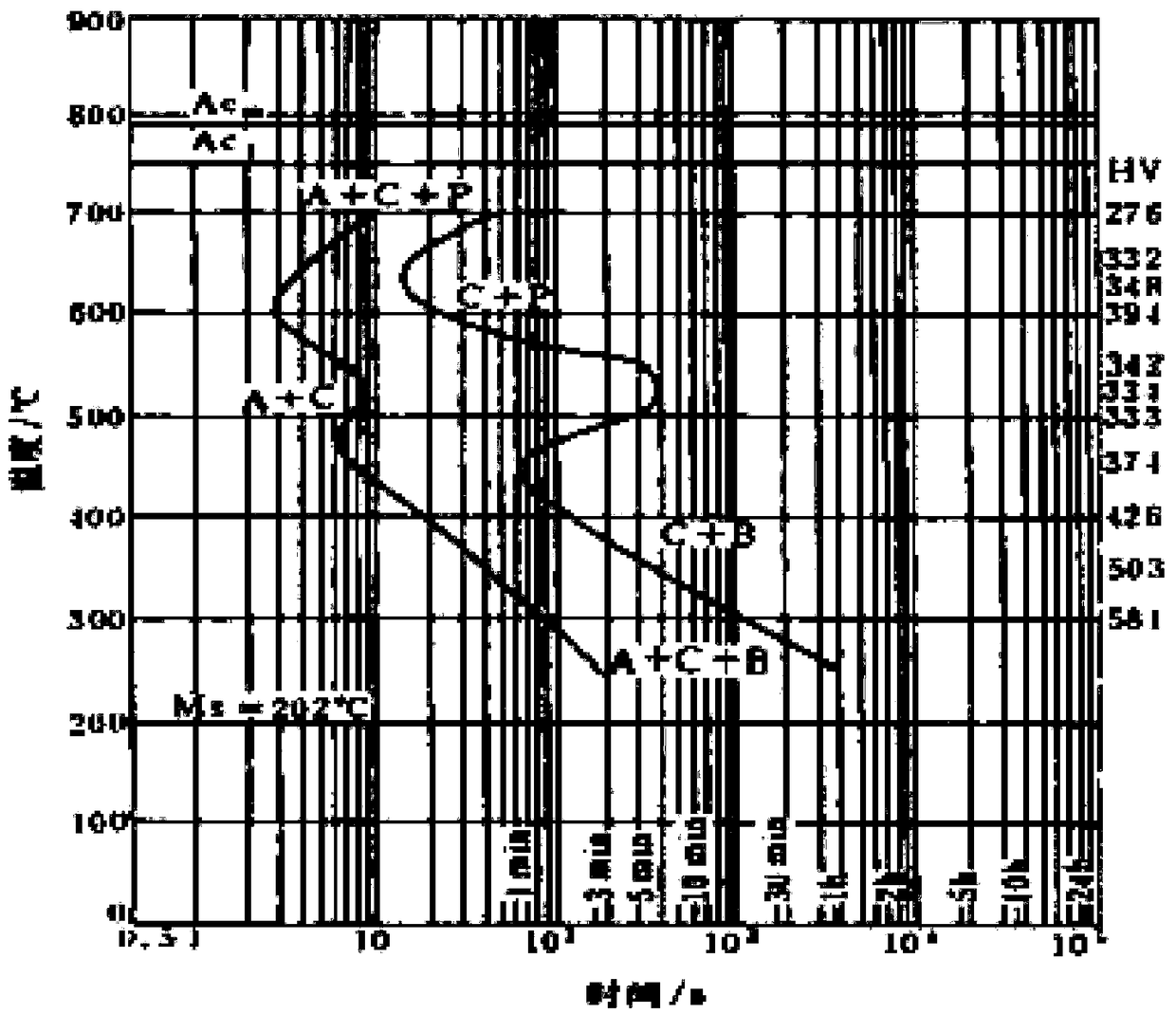

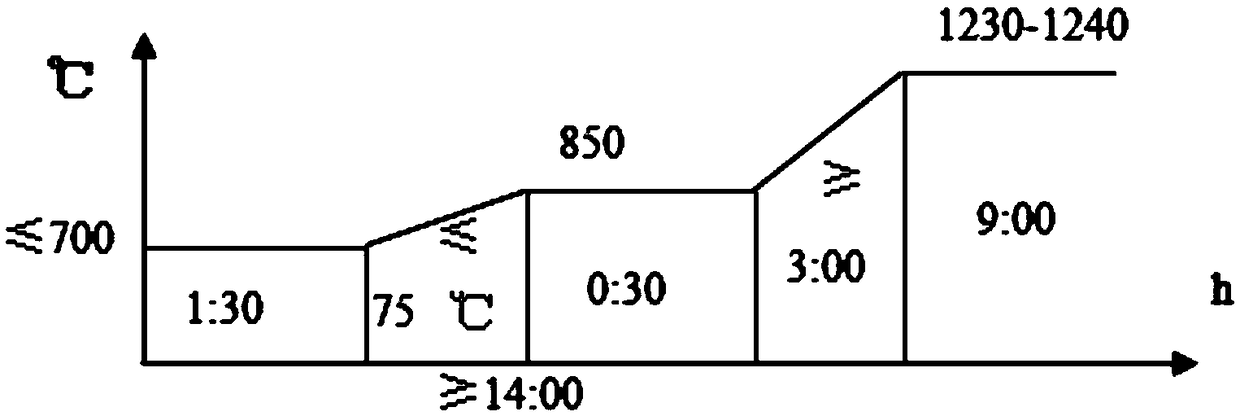

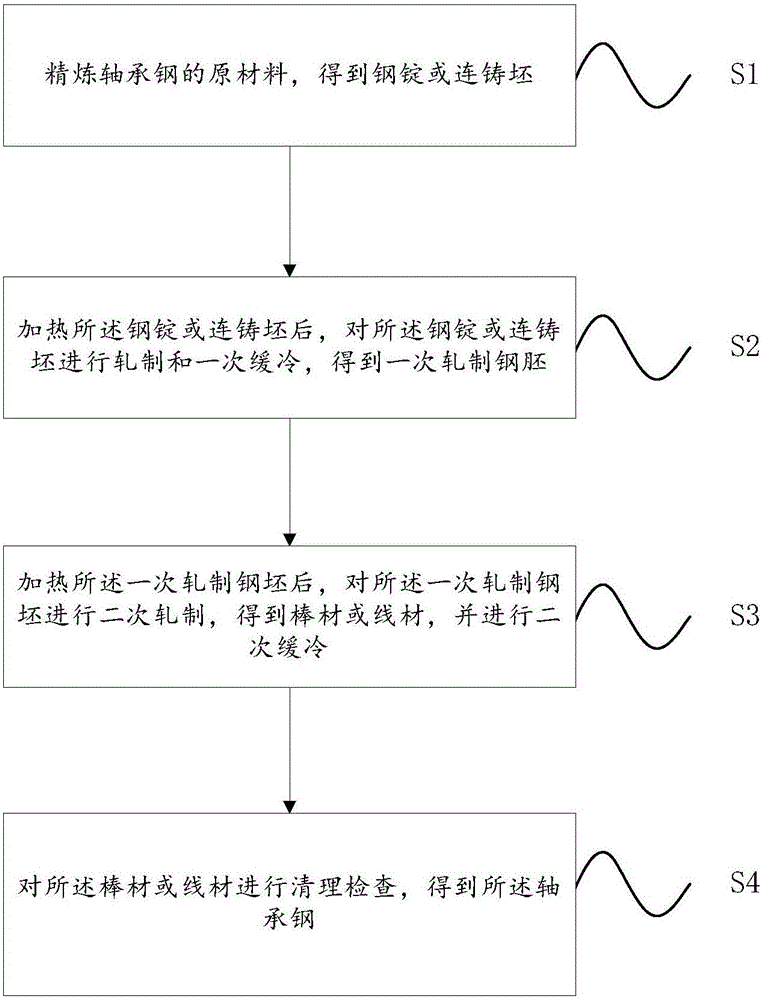

Bearing steel material with long service life and machining method thereof

The invention discloses bearing steel material with long service life and a machining method thereof. The bearing steel material with the long service life comprises, by weight percentage, 0.95-1.05% of C, 0.15-0.35% of si, 0.25-0.45% of Mn, 1.40-1.60% of Cr, 0.05-0.09% of Ni, 0.02-0.05% of M0, smaller than or equal to 0.05% of Al, 0.05-0.08% of Cu, smaller than or equal to 0.01% of P, smaller than or equal to 0.008% of S, smaller than or equal to 0.0025% of Ti, smaller than or equal to 0.002% of O, smaller than or equal to 0.04% of As, smaller than or equal to 0.03% of Sn, smaller than or equal to 0.005% of Sb, smaller than or equal to 0.002% of Pb, smaller than or equal to 0.001% of Ca and the balance Fe. The bearing steel material with the long service life has high elastic limit, tensile strength and contact fatigue strength, has high hardening capacity and necessary hardenability so that the high wear resistance can be guaranteed, has certain impact toughness, has good dimensional stability or structure stability, can resist chemical corrosion and can effectively reduce the phenomena of fatigue flaking, jamming, ferrule breakage, wear and corrosion.

Owner:建龙北满特殊钢有限责任公司

High-end bearing steel material for machine tool and production process thereof

ActiveCN110257716AImprove purityEvenly distributedProcess efficiency improvementElectric furnaceRare-earth elementNumerical control

The invention relates to a high-end bearing steel material for a machine tool and a production process of the high-end bearing steel material, and belongs to the technical field of special steel smelting. The high-end bearing steel material for the machine tool and the production process of the high-end bearing steel material aim to solve the problem that the properties such as wear resistance and contact fatigue strength of an existing bearing steel material cannot meet the requirements of a high-end numerical control machine tool, and the production process comprises electric furnace treatment, LF refining and VD process, die casting, hot delivery / cover cooling, primary heating rolling cogging, slow cooling, secondary heating rolling and spheroidizing annealing. Ni, Mo and rare earth elements are added on the basis of existing bearing steel, the content of Al and Cu is strictly controlled, and a good mechanical property index is provided for steel materials, and the produced bearing steel material has high elasticity limit, tensile strength, contact fatigue strength and wear resistance, can effectively reduce the phenomena of material fatigue flaking, clamping and the like and is applicable to manufacturing a bearing ring and a rolling body and needle with the wide size range for the machine tool.

Owner:建龙北满特殊钢有限责任公司

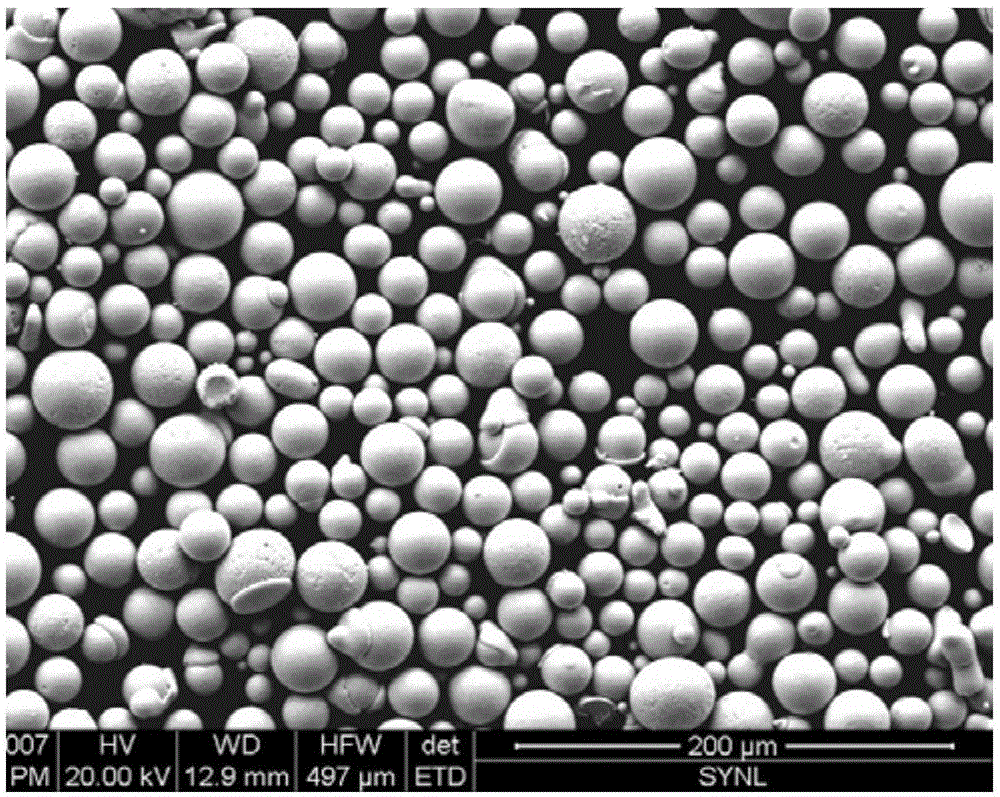

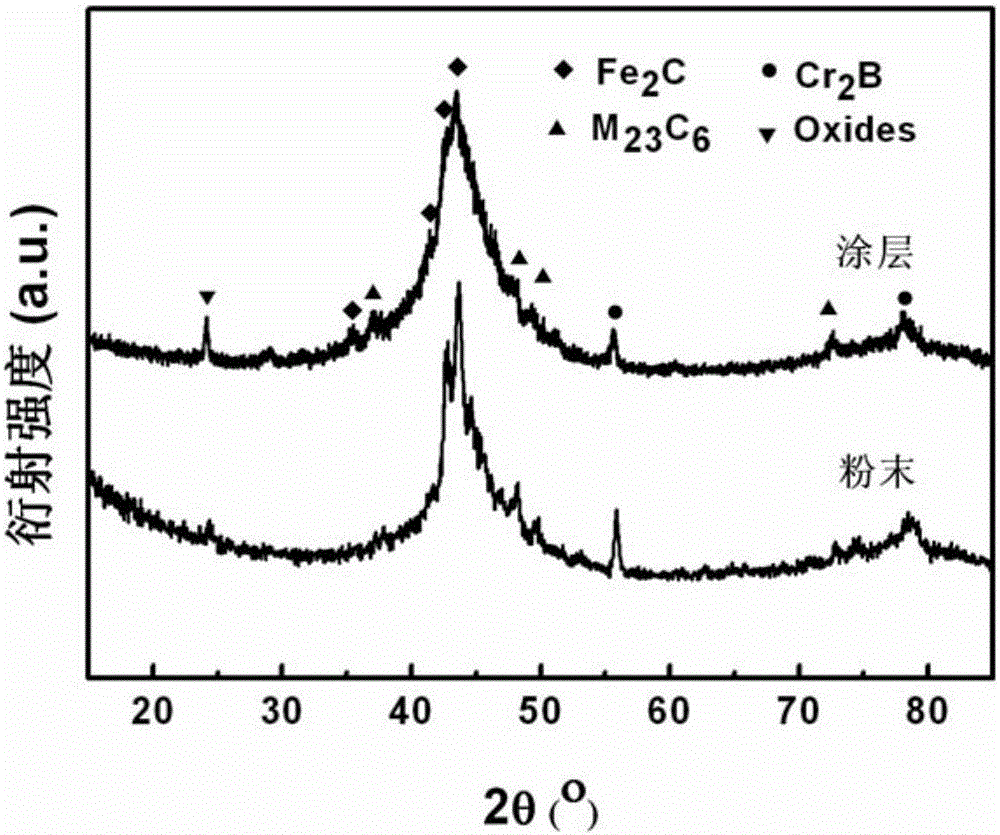

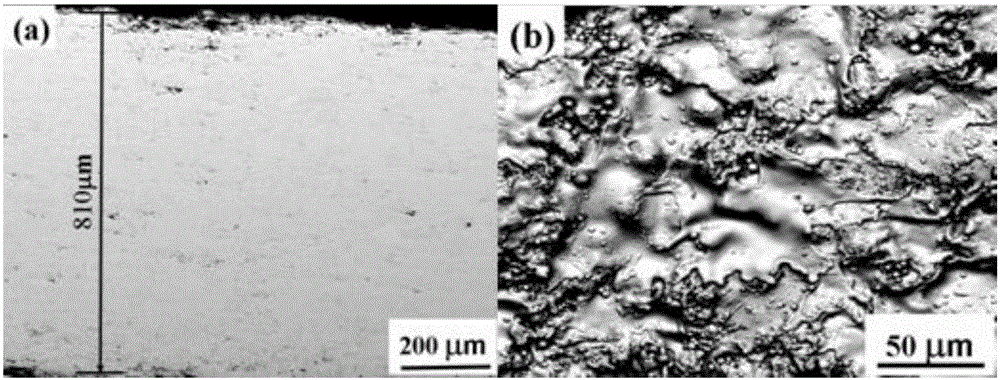

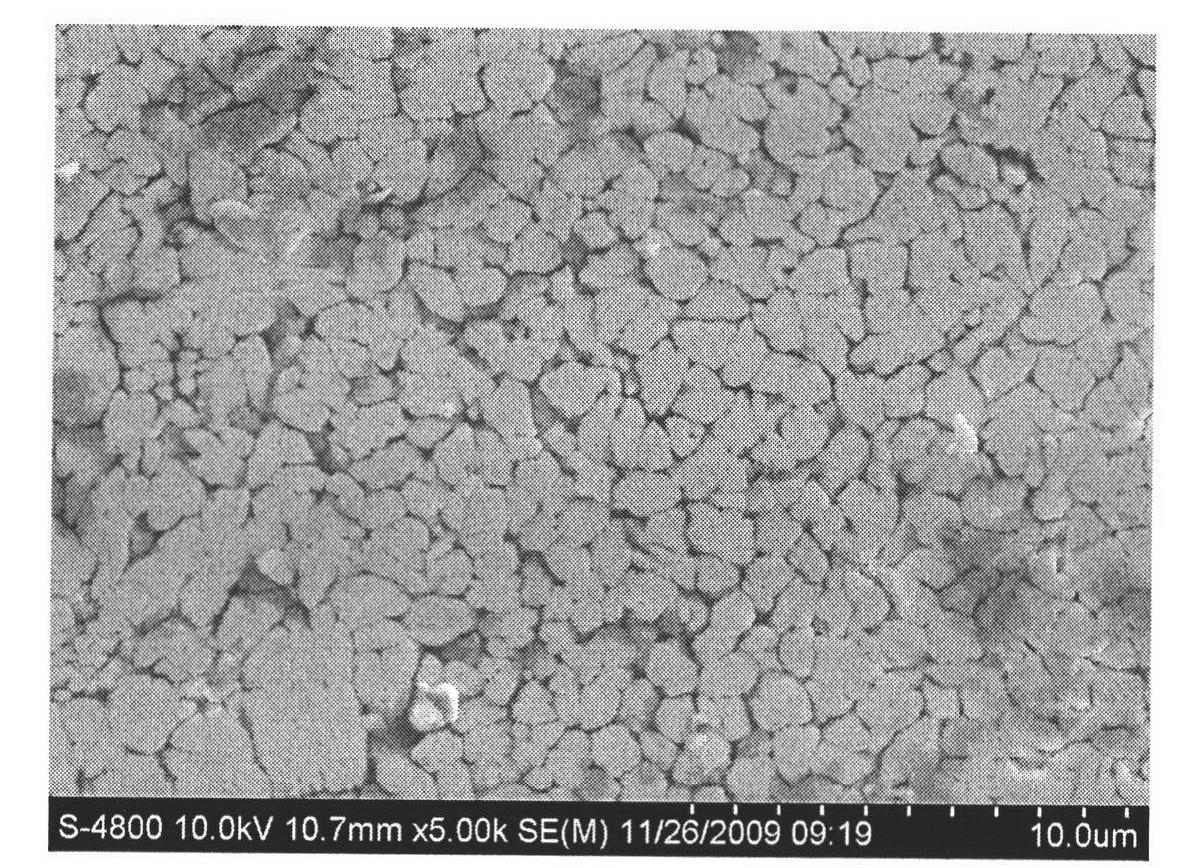

Iron-based amorphous alloy powder and preparing method and application thereof

The invention relates to iron-based amorphous alloy powder and a preparing method thereof. The alloy powder is prepared from, by weight, 40-65% of Fe, 15-25% of Cr, 10-20% of Mo, 2-8% of W, 1-5% of Mn, 1-4% of B, 0-4% of Si, 0-3% of C, 0-2% of Ce, and 0-2% of Y, wherein at least two elements of Si, C, Ce and Y should exist simultaneously, and the total mass percentage is larger than or equal to 1%. The mobility and the filling performance of the iron-based amorphous alloy powder are excellent, the content of an amorphous phase is larger than or equal to 50%, the powder serves a thermal spraying raw material to prepare a coating which is compact and uniform in structure, low in porosity, few in unmelted particles, low in oxygen content, high in amorphous-phase content, free of magnetism, high in substrate-bonding strength, high in Vickers hardness, resistant to corrosion and excellent in friction resistance, and thus the iron-based amorphous alloy powder has multiple purposes.

Owner:CHINA SHIP DEV & DESIGN CENT

Alloy for producing cold rolled working roll and method for producing same

The invention relates to an alloy for cold-rolling worker rollers and its preparing process, wherein the alloy comprises the main chemical constituents of: C 0.9-1.2%, Si 0.85-1.25%, Mn 0.40-0.60%, Cr 2.50-5.50%, Ni 0.25-0.45%, Mo 0.25-0.45%, V 0.05-0.155 and balancing Fe.

Owner:BAOSTEEL ROLL SCI & TECH

Spring, preparation method thereof and mold assembly used for preparing spring

InactiveCN107541682AEasily brokenFailure to be foundFoundry mouldsFoundry coresShort range orderMultiple use

The invention discloses a spring, a preparation method thereof and a mold assembly used for preparing the spring. The spring is an integrally formed amorphous alloy element. Compared with conventionalcrystal materials, by utilizing structural characteristics of short range order and long range disorder of an amorphous alloy, the spring has the excellent mechanical properties of relatively high elastic limit, high strength, high hardness and the like, and therefore the phenomenon of flabby stiffness is not prone to occurring after the spring is used many times. Meanwhile, by utilizing the characteristics of no typical deformation mechanism such as dislocation slipping and twin crystal of the integrally formed amorphous alloy, the spring is broken rapidly once exceeding use limit so that anoperator can easily find out and timely handle with the situation that the spring fails.

Owner:BYD CO LTD

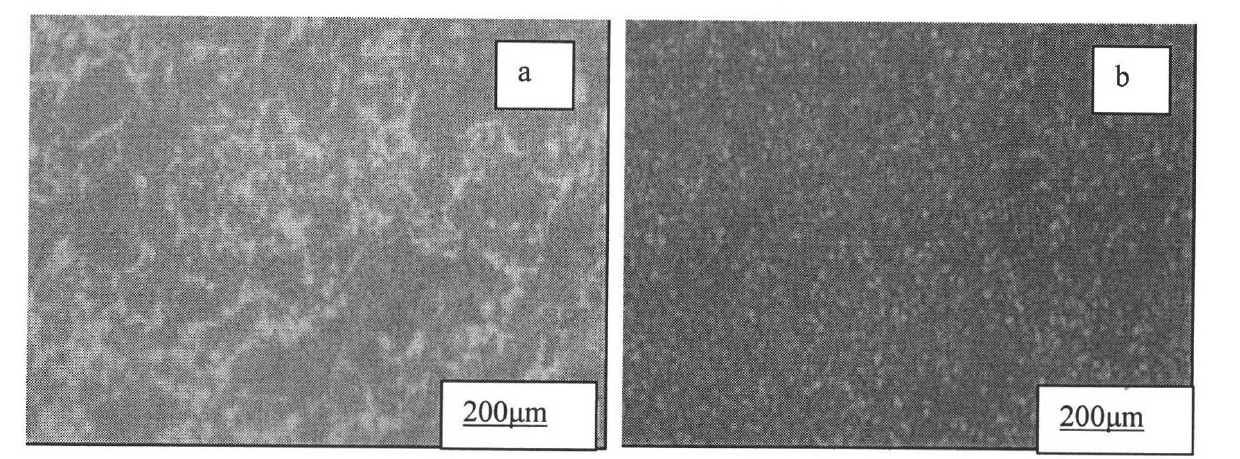

Method for preparing inoculant for refining as-cast structure of spring steel and application method thereof

ActiveCN102168220AEasy dispersive distributionUniform grain refinementSpring steelMechanical property

The invention discloses a method for preparing an inoculant for refining an as-cast structure of spring steel and an application method thereof, and relates to alloy steel. The preparation method comprises the following steps of: preparing materials in a molar ratio of Fe:V:Nb:Al of (3.2-5.6):(0.5-1.5):(1.9-4.3):(1.5-3.5), melting, and centrifuging and rapidly quenching and melt-spinning to obtain a flaky rapidly-solidified FeVNbAl intermediate alloy inoculant with the average thickness of between 0.1 and 0.3mm, the average width of between 1 and 2.5mm and the average length of between 3 and 8mm, namely the inoculant for refining the as-cast structure of the spring steel. The application method comprises a step of using the inoculant for refining the as-cast structure of the spring steel by a metal melt casting method. The inoculant has a remarkable effect of refining matrix grains and structures of the spring steel, so that the comprehensive mechanical properties and the service performance of a spring steel material are further improved.

Owner:HEBEI UNIV OF TECH

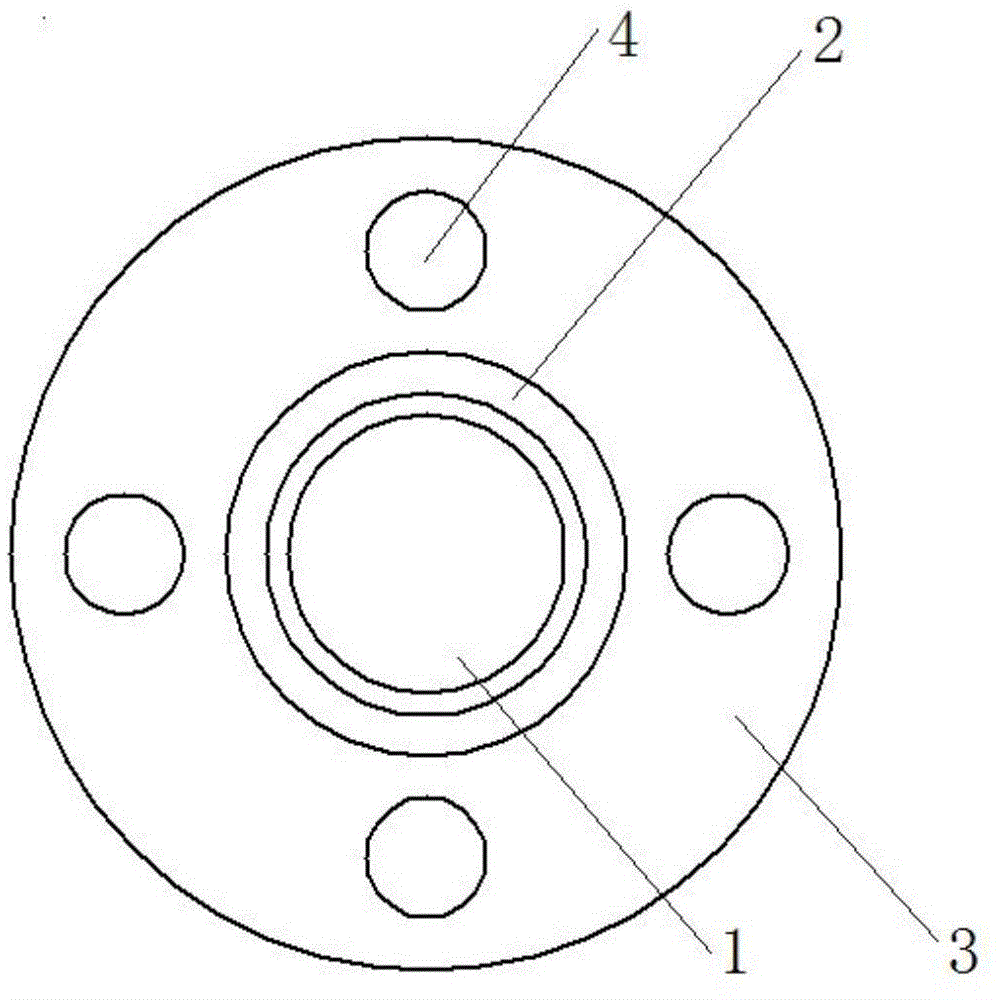

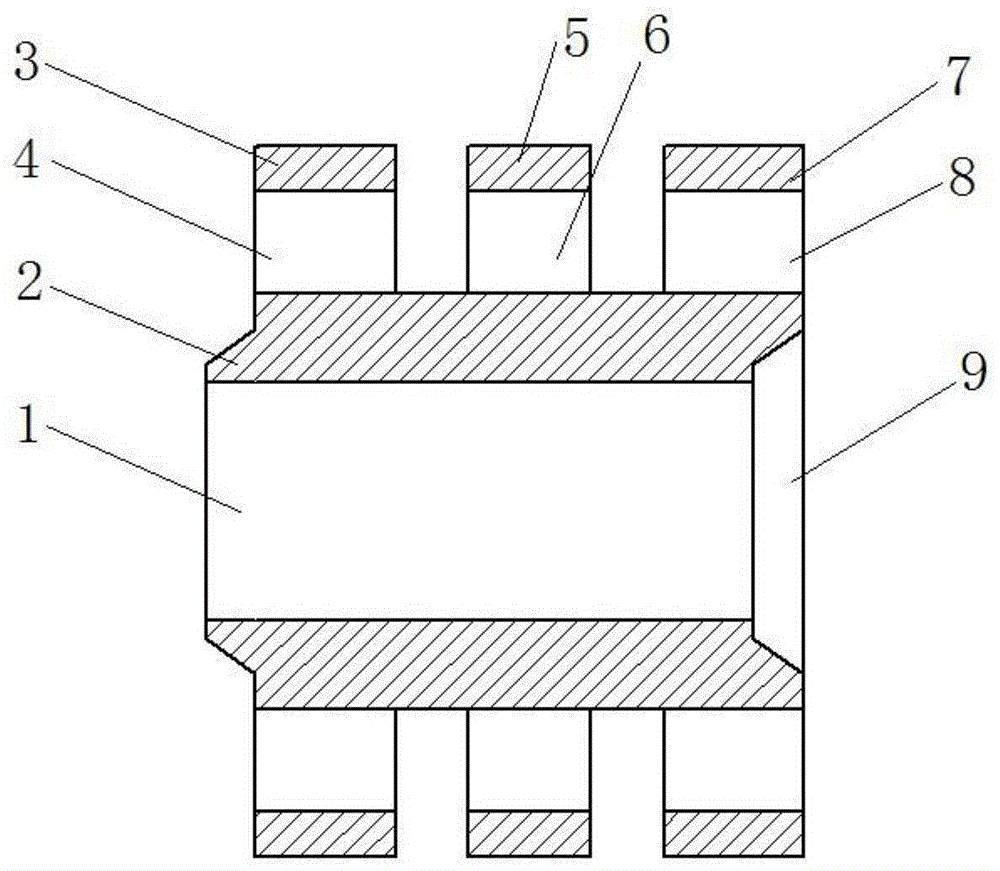

F304/F304L double-standard stainless steel flange and production process thereof

ActiveCN104791562AReasonable structureExquisite designFlanged jointsCircular discSS - Stainless steel

The invention discloses an F304 / F304L double-standard stainless steel flange. The F304 / F304L double-standard stainless steel flange comprises a through hole and a flange plate. The flange plate is of a disc structure, the through hole is formed perpendicular to the flange plate with the center axis of the flange plate serving as the center line, and the edges of the two ends of the through hole are provided with a boss and a groove respectively. The flange plate comprises a front flange plate body, a middle flange plate body and a rear flange plate body which are sequentially arranged in parallel, the diameters of the front flange plate body, the middle flange plate body and the rear flange plate body are equal, the thicknesses of the front flange plate body and the rear flange plate body are equal, at least four fixing holes are evenly formed in each flange plate body, the hole diameters of the front fixing holes, the middle fixing holes and the rear fixing holes are equal, and the positions of the front fixing holes, the middle fixing holes and the rear fixing holes correspond. The invention further discloses a production process of the F304 / F304L double-standard stainless steel flange. The F304 / F304L double-standard stainless steel flange is high in rigidity and strength, resistant to corrosion, ingenious in structural design, high in practicality and long in service life.

Owner:WUXI HUAERTAI MACHINERY MFG

Rare earth microalloying bearing steel and preparation method thereof

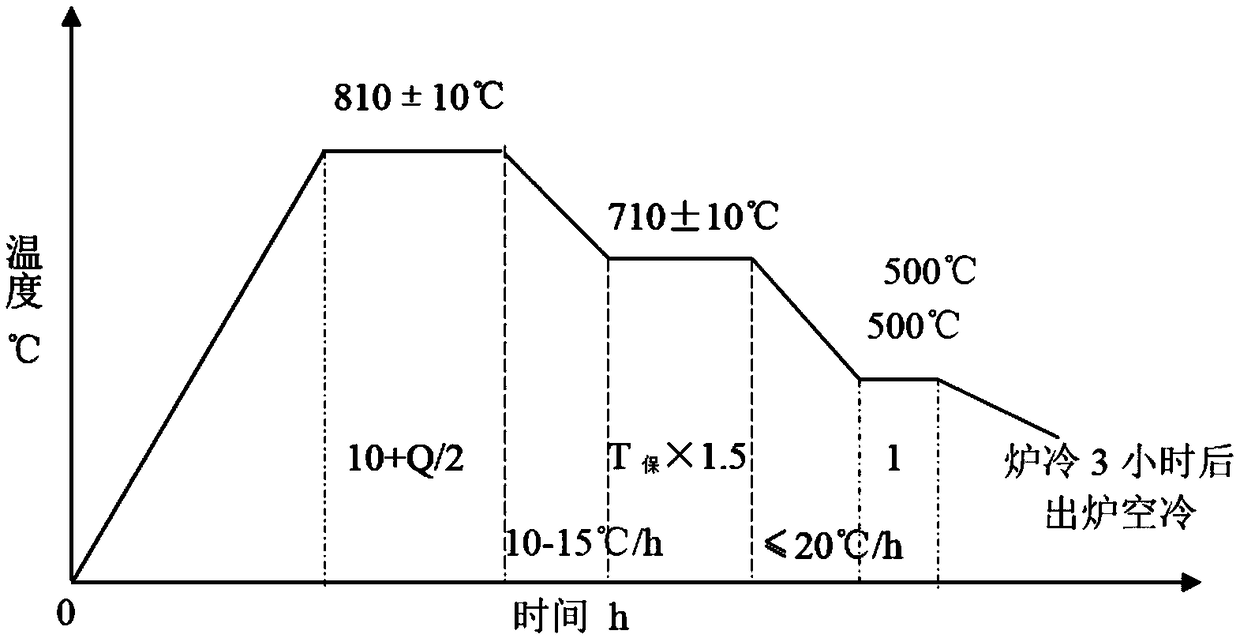

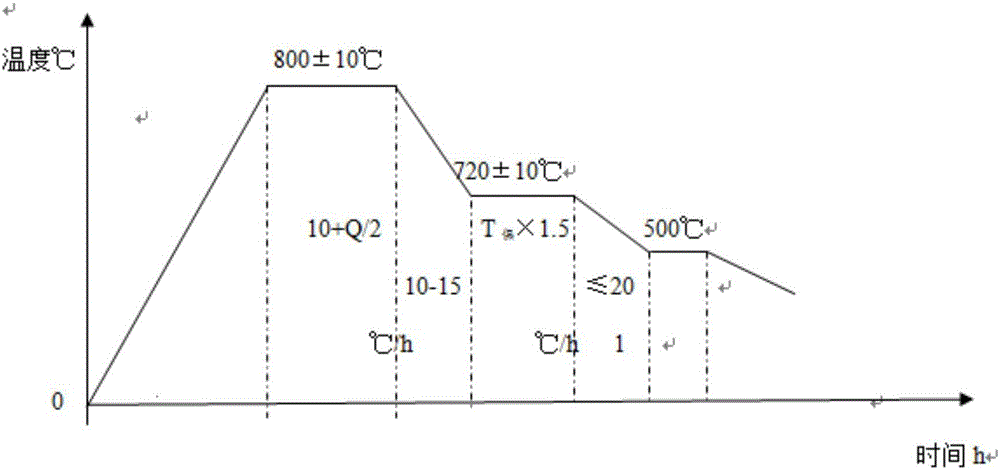

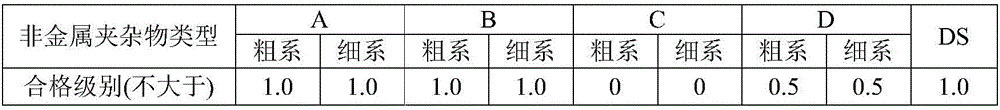

ActiveCN109457081AHigh elastic limitImprove hardenabilityFurnace typesHeat treatment furnacesSlow coolingMaterials science

The invention discloses rare earth microalloying bearing steel and a preparation method thereof and belongs to the technical field of bearing steel manufacturing. According to the technical aim, the performance of the bearing steel is improved. According to the rare earth microalloying bearing steel, converter, LF-RH refining and square billet continuous casting are carried out, electroslag remelting is carried out after scaling of a prepared continuous casting billet, then cover cooling and pit cooling are carried out, and then primary heating rolling cogging is carried out; after annealing or slow cooling is carried out, checking and cleaning are carried out, and a primary rolled steel billet is prepared and subjected to secondary heating rolling; and after stack cooling or slow coolingis carried out, a secondary rolled steel billet is prepared and subjected to spheroidizing annealing, straightening, polishing or scaling, flaw detection, cleaning and checking are carried out, and then the rare earth microalloying bearing steel is prepared. The content design ingredient of Nb ranges from 0.010% to 0.45%, and the rare earth microalloying bearing steel is suitable for being used for manufacturing various bearing rings and rolling elements and roller pins within a wide size range.

Owner:建龙北满特殊钢有限责任公司

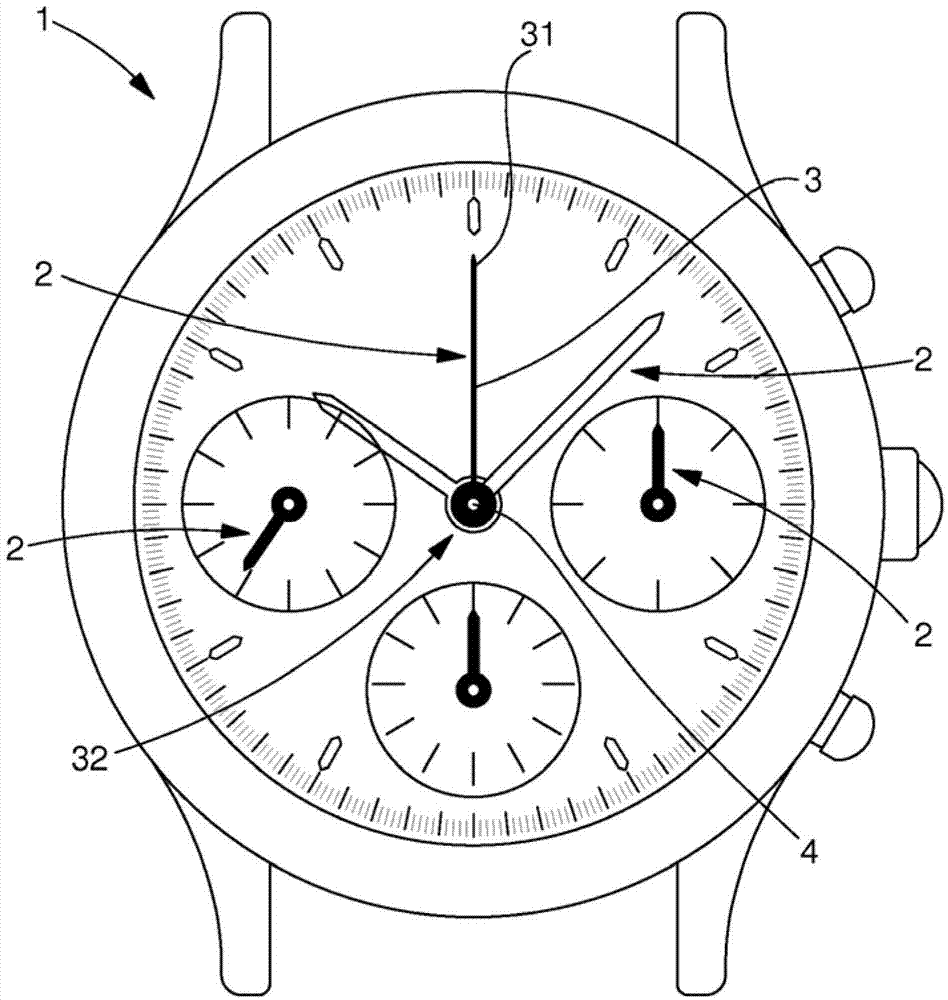

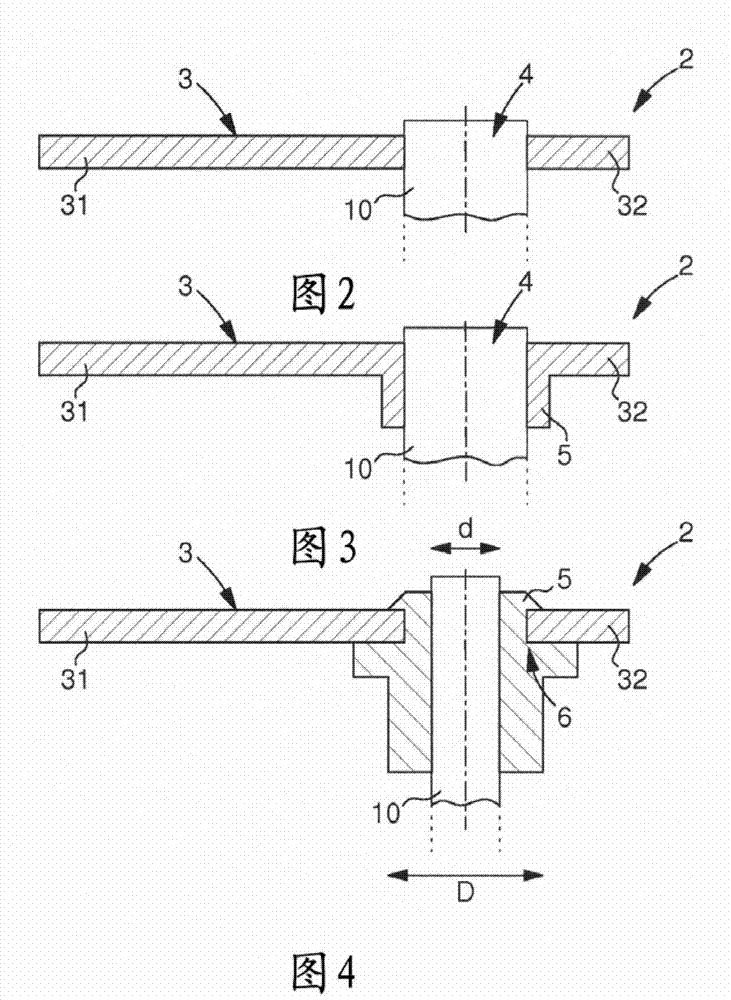

Timepiece hand

InactiveCN103097967AInteresting elastic propertiesHigh elastic limitVisual indicationFoundry mouldsMechanical engineeringAmorphous metal

The invention relates to a special hand for sudden acceleration. Said hand (2) is mounted such that it can pivot about an axis (10) so as to be able to indicate a piece of information. Said hand is produced from an at least partially amorphous metal alloy.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

High-end bearing steel material for machine tool bearing ring and manufacturing method of high-end bearing steel material for machine tool bearing ring

ActiveCN110257717AImprove mechanical propertiesImprove purityElectric furnaceProcess efficiency improvementRare-earth elementNumerical control

The invention relates to a high-end bearing steel material for a machine tool bearing ring and a manufacturing method of the high-end bearing steel material for the machine tool bearing ring, and belongs to the technical field of special steel smelting forging. The high-end bearing steel material aims to solve the problem that the performance of the steel material cannot meet the requirement of a high-end numerical control machine tool due to the fact that the carbide inside the steel material for the bearing ring is segregated and distributed in a mesh mode, the steel material is caused not to meet the requirement of the high-end numerical control machine tool, the invention provides the high-end bearing steel material for the machine tool bearing ring and the manufacturing method of the high-end bearing steel material for the machine tool bearing ring, and comprises the following steps of electric furnace, LF refining and VD process, die casting, hot charging / cover cooling, heating rolling, slow cooling, and spheroidizing annealing. According to the steel material and the method, Ni, Mo and rare earth element are added on the basis of existing bearing steel, the content of Al and Cu is strictly controlled, and a good mechanical property index is provided for the steel material; the carbide in the manufacturing process is effectively diffused, the carbide level of the steel material is improved, the steel material for the bearing ring of the machine tool has a high elastic limit, tensile strength, contact fatigue strength and wear resistance, and can effectively reduce the phenomena of fatigue peeling, blocking and the like.

Owner:建龙北满特殊钢有限责任公司

Gas-shielded flux-cored wire for welding of SUS316L austenitic stainless steel deep-cooling low-temperature storage and transportation container and device

ActiveCN107971657AAdjust the melting pointAdjustable viscosityArc welding apparatusWelding/cutting media/materialsManganeseSodium titanate

The invention discloses a gas-shielded flux-cored wire for welding of a SUS316L austenitic stainless steel deep-cooling low-temperature storage and transportation container and device and the preparation method thereof. The as-shielded flux-cored wire comprises a steel strip and a flux core wrapped in the steel strip, and the flux core comprises the following components of, by weight, 4.25-5.85 parts of natural rutile, 0.8-1.9 parts of quartz sand, 0.7-1.8 parts of sodium titanate, 0.25-0.3 part of sodium fluoride, 0.125-0.275 part of calcined alpha alumina, 0. 27wt% of calcined alpha aluminaand 0.025-0.15 part of nitrogen-containing ferrochromium, 0.085-0.05 part of spray silicon iron, 1.05-1.45 parts of electrolytic manganese, 3.6-4.85 parts of metal chromium, 6.42-6.85 parts of atomized iron powder, 1. 9-2.5 parts of nickel powder, and 1.0-1.35 parts of molybdenum. The gas-shielded flux-cored wire has the advantages that efficient semi-automatic and automatic welding technologies are achieved, the welding efficiency is high, splashing is low, the appearance is attractive, the welding current is wide, and the voltage adaptability strong.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

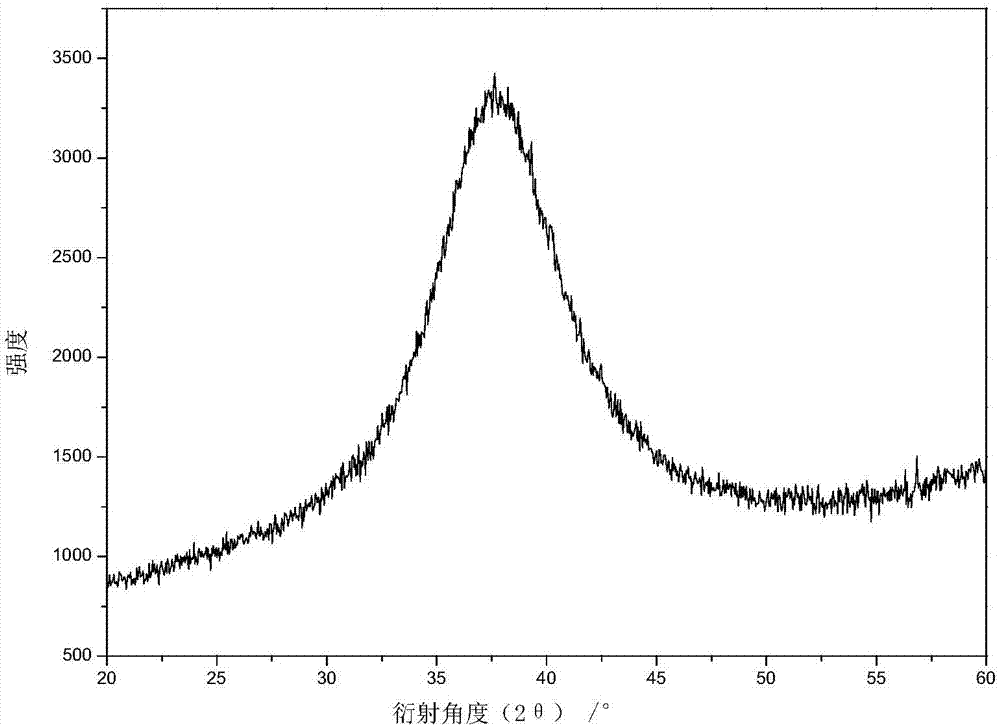

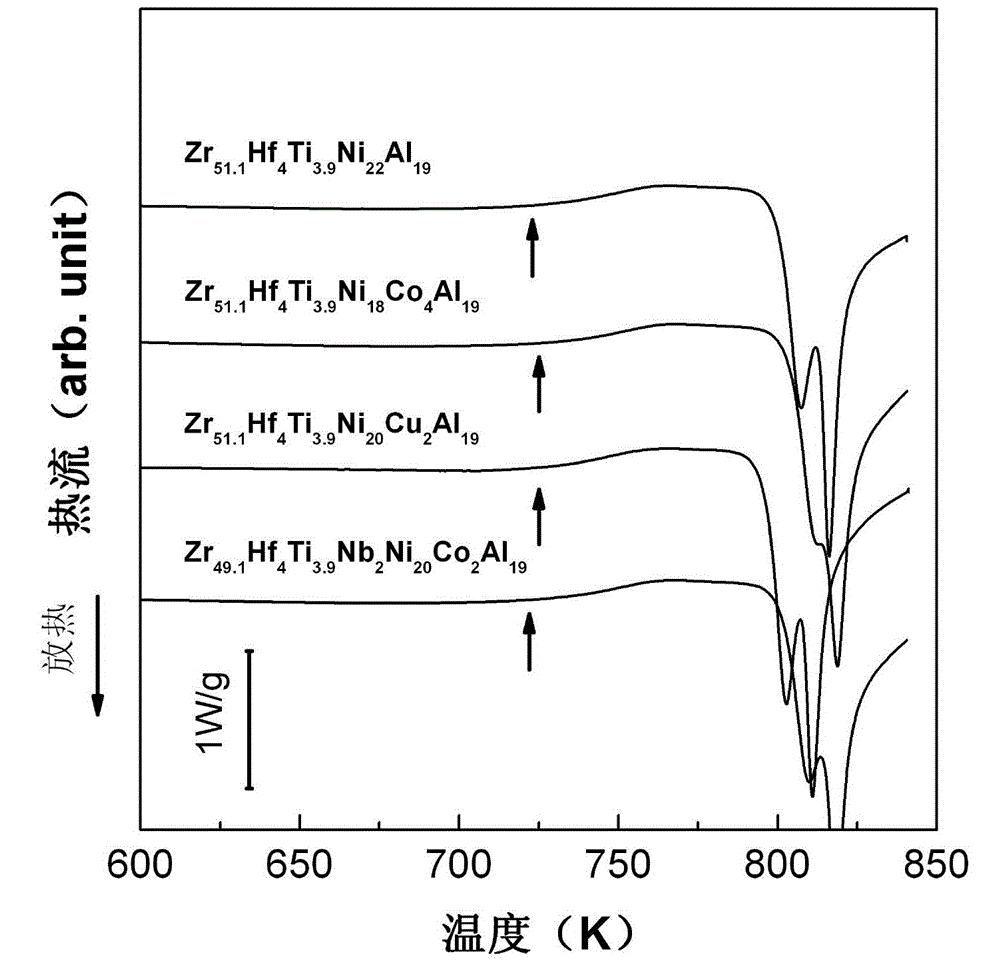

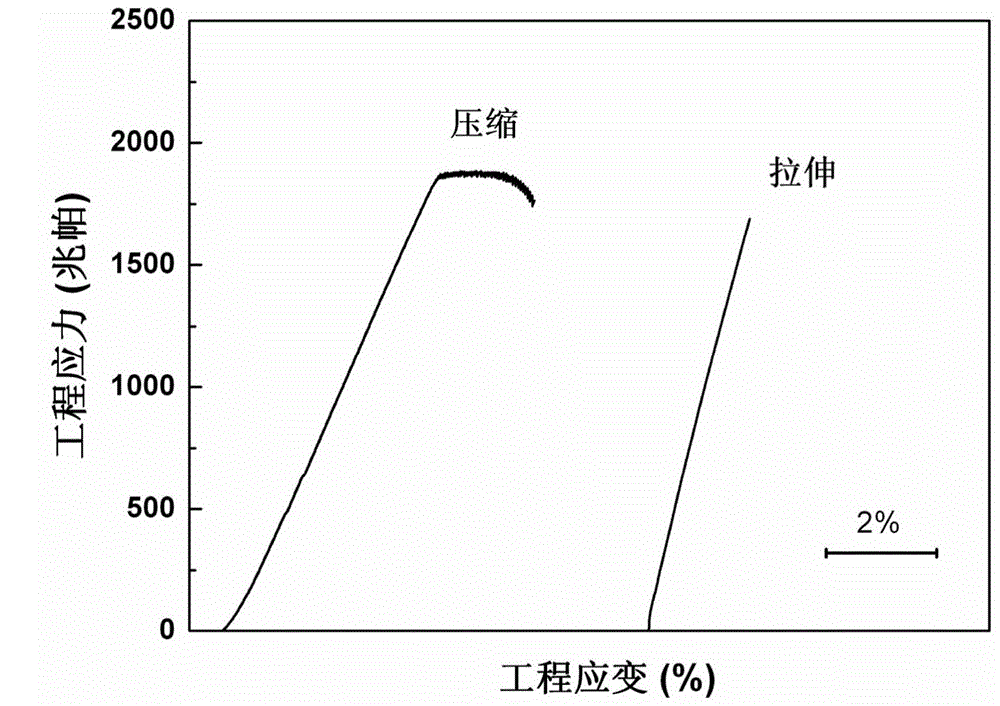

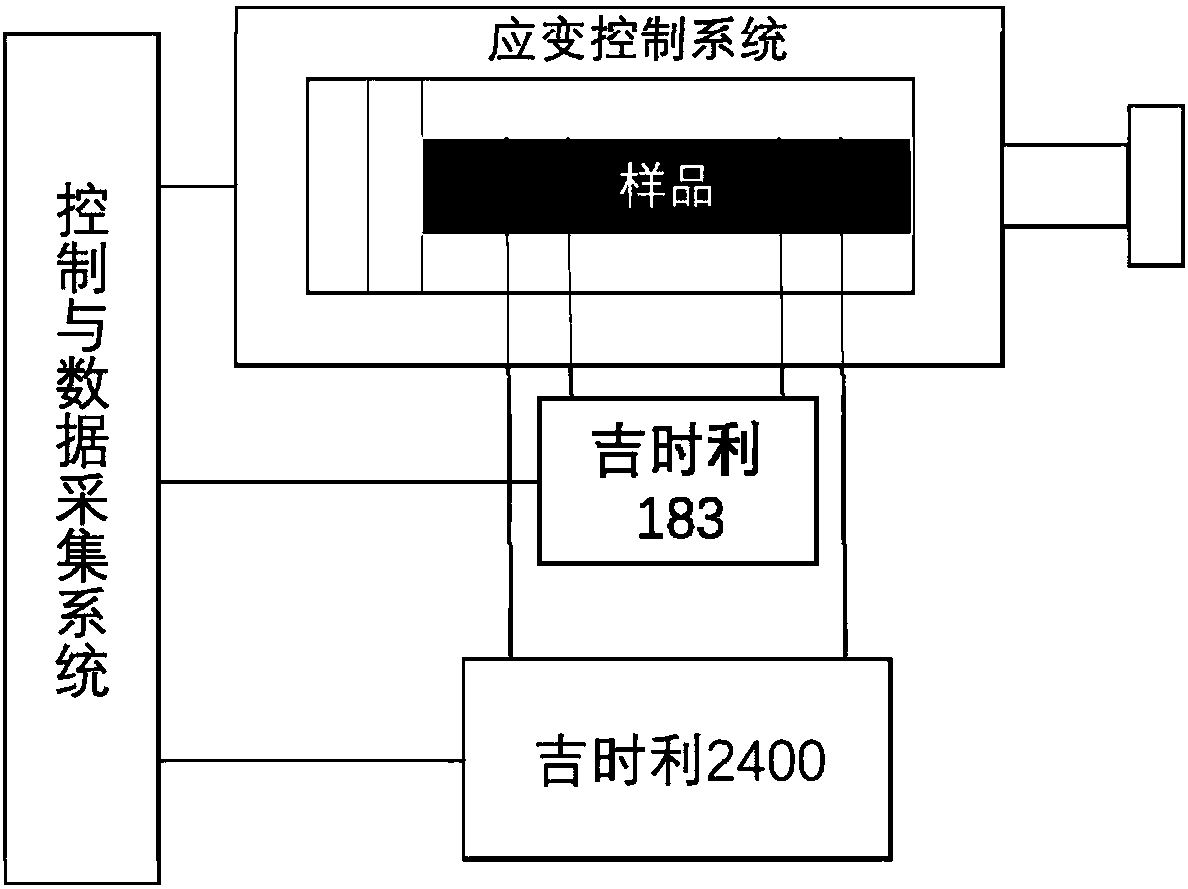

Zr-based amorphous alloy having strong glass-forming ability

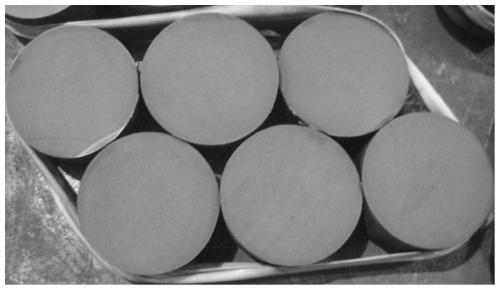

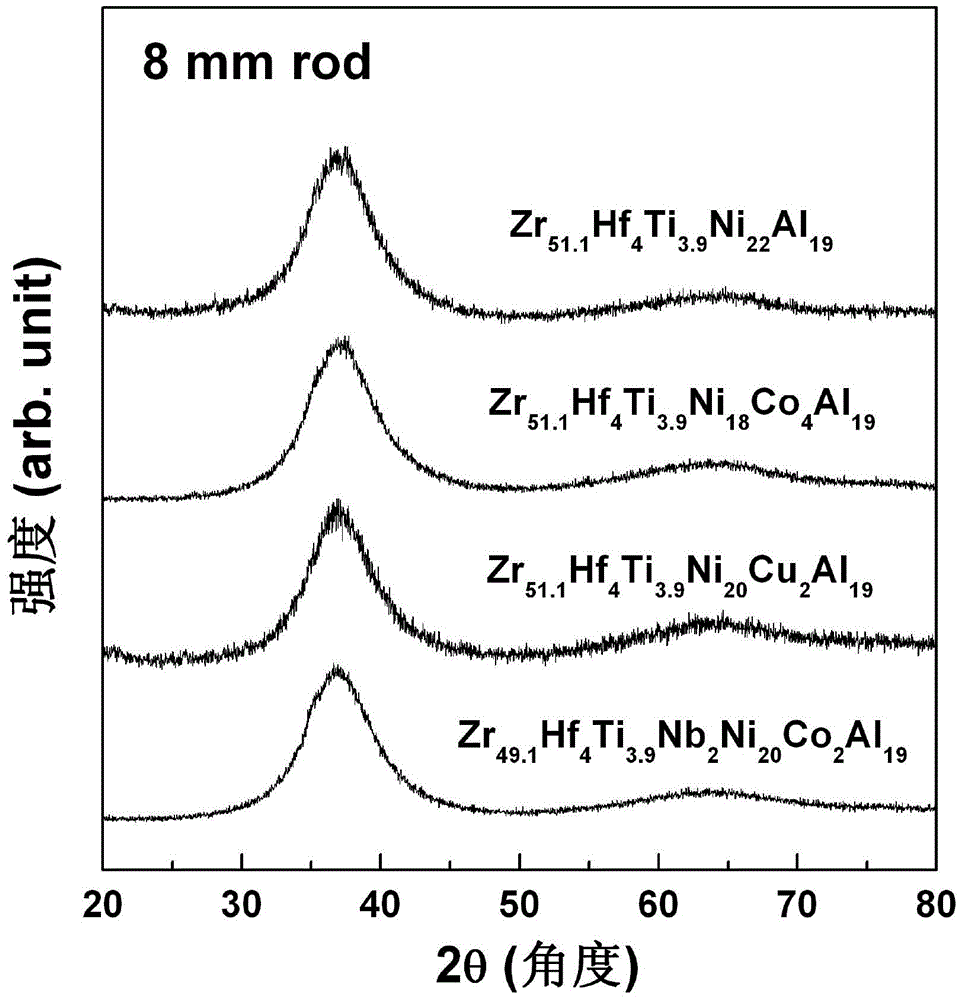

The invention aims to provide a Zr-based amorphous alloy having a strong glass-forming ability, and is characterized in that the alloy is composed of five elements of Zr, Hf, Ti, Ni and Al; the component expression formula of the alloy is Zra-Hfb-Tic-Nid-Ale, wherein the atomic percentages (at.%) of the elements comprise: a=48-56, b=1.5-8, c=1.5-8, d=19-25, e=17.1-21, and a+b+c+d+e=100. The critical diameter of a completely amorphous bar material formed by the preferred components under copper mold casting conditions can reach 8 mm, and after an alloy melt in the composition range is subjected to copper mold casting, bulk materials with an amorphous structure or parts can be formed. At the same time, the alloy has the characteristics of high fracture strength, high elastic limit, high fracture toughness, corrosion resistance and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Flexible resistance type strain sensor

ActiveCN108332647ALarge measuring strain rangeGood performance and stabilityElectrical/magnetic solid deformation measurementElectrical resistance and conductanceStress–strain analysis

The invention relates to a flexible resistance type strain sensor comprising an insulating flexible substrate and a metal glass film. The metal glass film as a strain sensitive material is deposited on the flexible substrate. According to the flexible resistance type strain sensor, because of the metal glass film as the strain sensitive material, the flexible resistance type strain sensor has advantages of high sensitivity, large measuring strain range, small resistance temperature coefficient, and simple preparation method and the like; and thus the sensor can be used as a basic unit of the electronic skin and can be applied to fields of the stress-strain analysis and the like widely.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

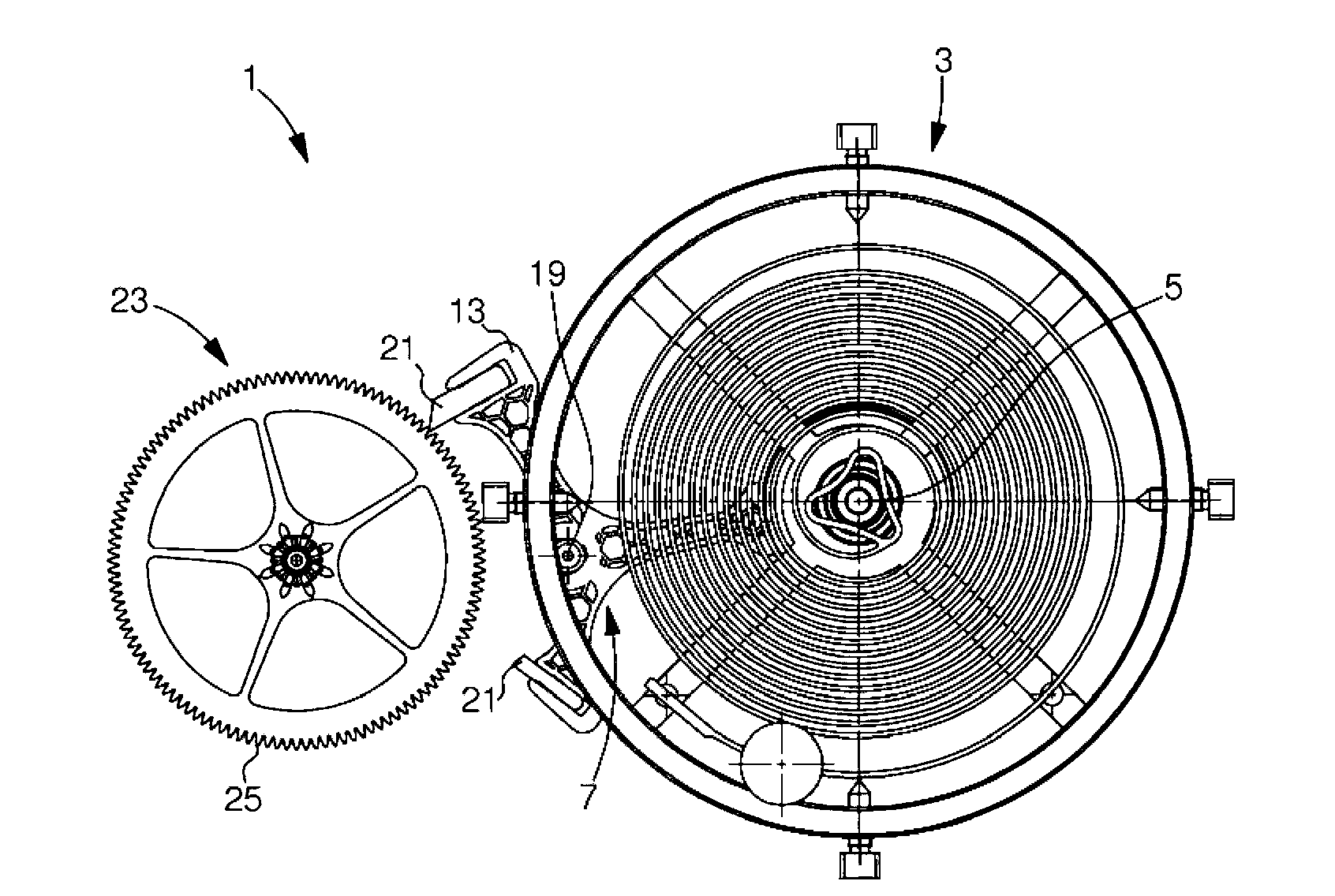

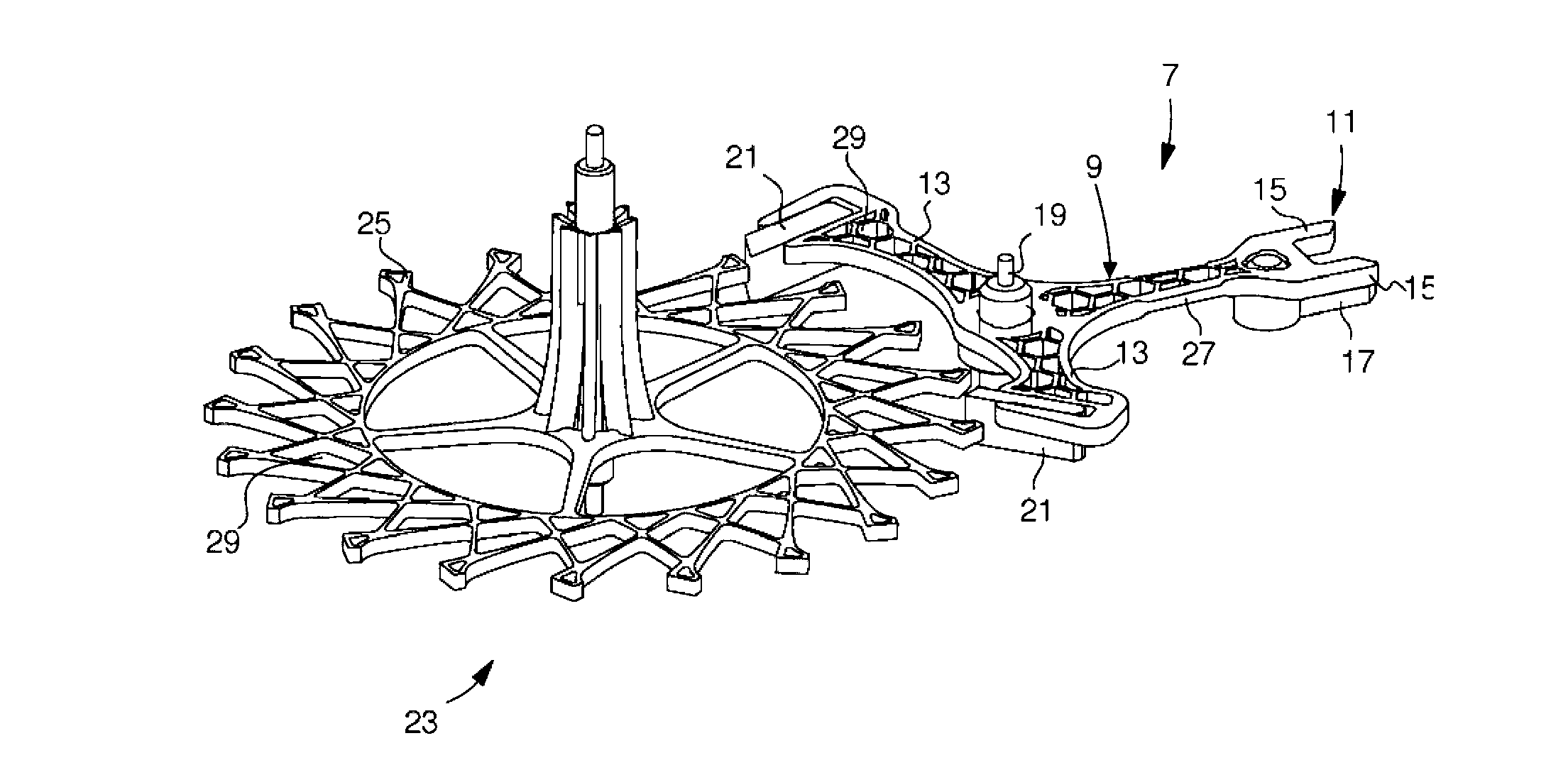

Escapement system for a timepiece

InactiveCN103026303AGood energy recovery coefficientHigh elastic limitEscapementsEngineeringAmorphous metal

The invention relates to an escapement system (1). This system comprises a pallet (7) equipped with a fork intended to collaborate with a pin mounted on a plate (5), and with a rod comprising arms intended to accept pallet stones (21) so as to collaborate with at least one escapement wheel (23). Part of the escapement system is made of an at least partially amorphous metal alloy.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Long-life bearing steel and manufacturing method thereof

The invention provides long-life bearing steel. The long-life bearing steel comprises 0.96wt%-1.03wt% of carbon, 0.15wt%-0.35wt% of silicon, 0.25wt%-0.45wt% of manganese, 1.4wt%-1.6wt% of chromium, 0.05wt%-0.09wt% of nickel, 0.02wt%-0.08wt% of molybdenum, 0.007wt%-0.030wt% of aluminum, 0.04wt%-0.08wt% of copper, 0.002wt%-0.030wt% of yttrium, less than 0.01wt% of phosphorus, less than 0.008wt% of sulphur, less than 0.0025wt% of titanium, less than 0.0008wt% of oxygen, less than 0.012wt% of arsenic, less than 0.002wt% of tin, less than 0.005wt% of antimony, less than 0.002wt% of lead, less than 0.001wt% of calcium, and the balance iron. The long-life bearing steel has better performance by strictly controlling the content of the elements in the bearing steel.

Owner:龙南天宇蓝龙新材料有限公司

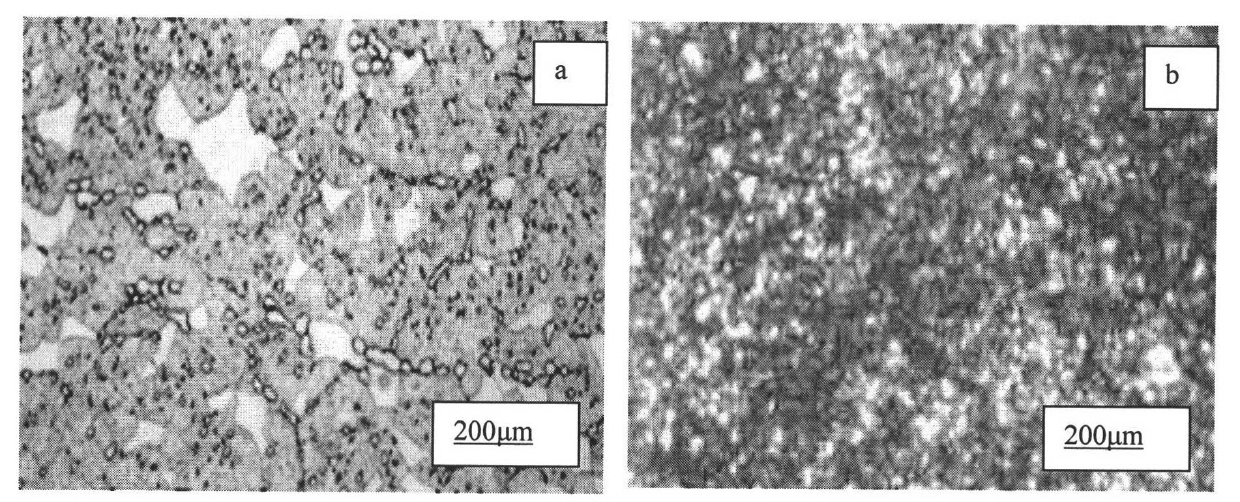

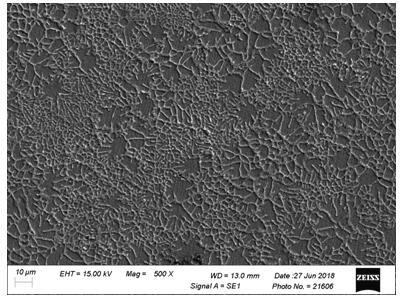

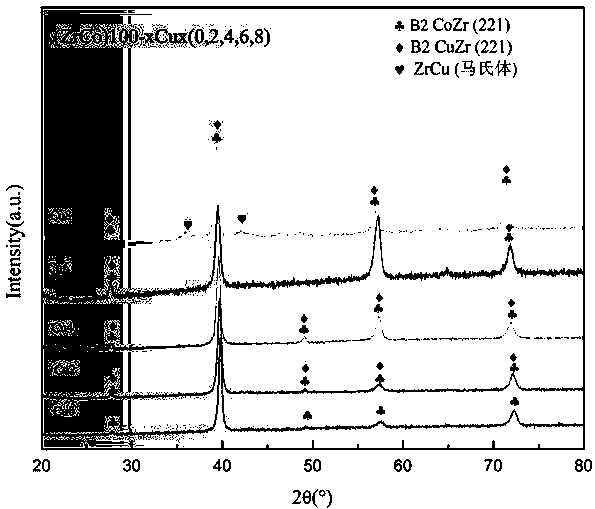

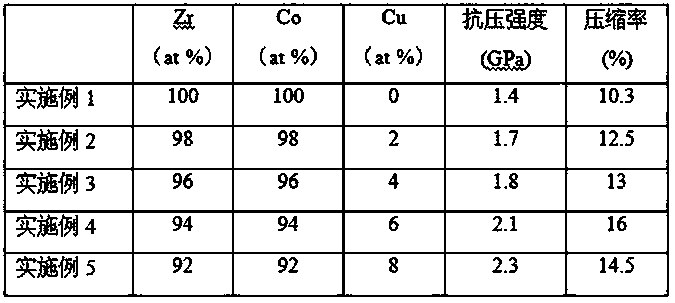

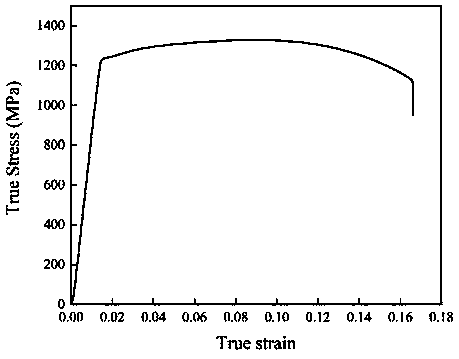

B2 phase toughened non-crystal composite and preparation method thereof

InactiveCN109371338AImprove plastic toughnessImprove the defects of poor plasticityCu elementRoom temperature

The invention relates to a B2 phase toughened non-crystal composite and preparation method thereof, and belongs to the technical field of non-crystal composites. The atomic ratio of the B2 phase toughened non-crystal composite is (ZrCo)<100-x>Cu<x>, wherein x is 0-8. The preparation method comprises the following steps of preparing materials according to (ZrCo)<100-x>Cu<x>, placing each metal ingredient in an arc melting furnace for melting, and then performing quick cooling on an alloy to room temperature at a cooling speed being 1000 K / s; then overturning alloy ingots, and performing meltingagain for at least four times, so as to obtain a master alloy; and performing remelting on the master alloy, so as to obtain block-shaped (ZrCo)<100-x>Cu<x> non-crystal composites through copper moldsuction molding. According to the preparation method disclosed by the invention, Cu elements in the ZrCoCu alloy are adjusted; and by a water cooled copper mold method, during quick solidification, the ZrCoCu alloy can produce a B2 ( CsCl structure ) CuZr phase and a CoZr phase, and then the plastic toughness of the non-crystal composite can be increased.

Owner:KUNMING UNIV OF SCI & TECH

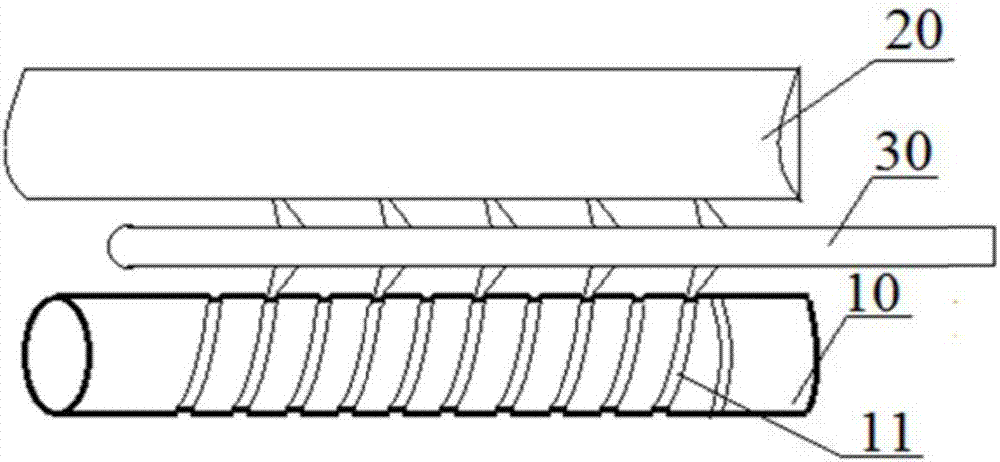

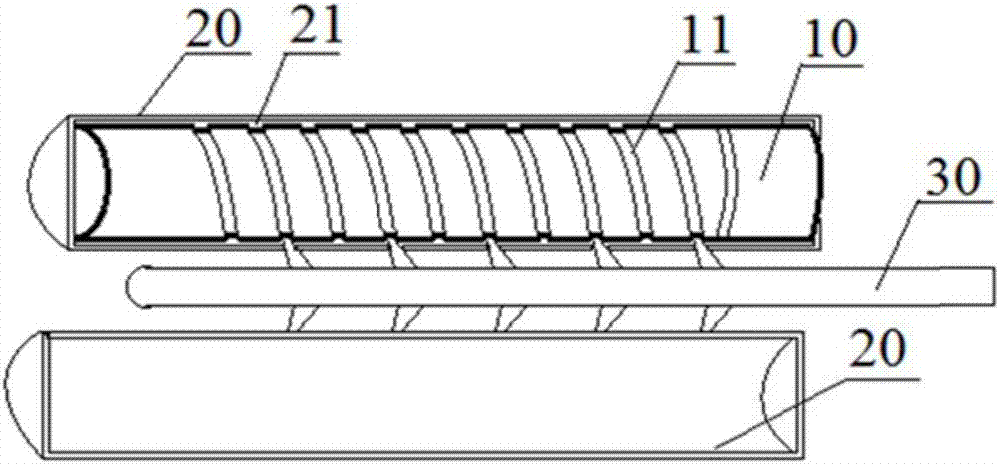

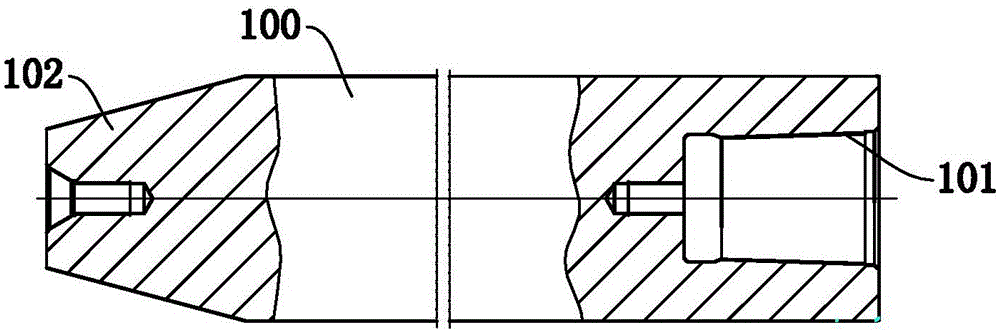

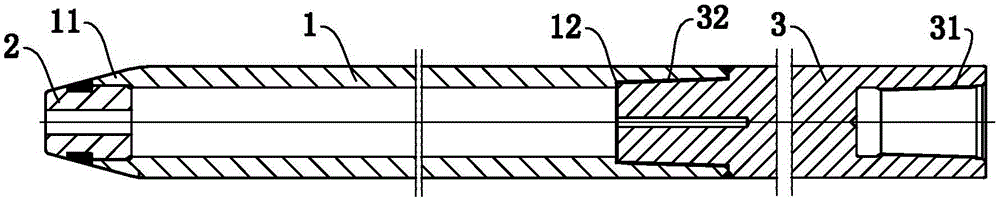

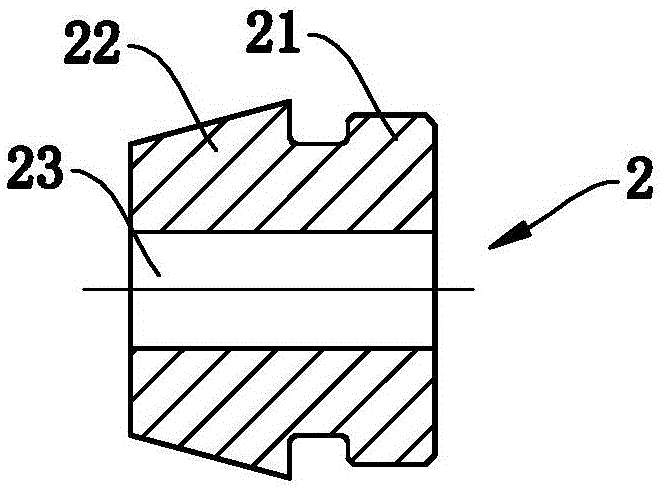

Alloy steel, retained mandrel and production method of retained mandrel

InactiveCN104998905AImprove purityImprove wear resistanceMandrelsMetal rolling arrangementsAlloy steelHeat treated

The invention discloses alloy steel and belongs to the technical field of continuous rolling units. The alloy steel comprises components in percentage by mass as follows: 0.27%-0.31% of C, 0.60%-0.80% of Si, 0.7%-0.9% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.005% of S, 3.50%-3.70% of Cr, 0.20%-0.30% of Ni, 0.40%-0.50% of V, 0.50%-0.58% of Mo, smaller than or equal to 0.025% of Al and the balance of iron and impurity elements. The invention discloses a retained mandrel adopting the alloy steel. The retained mandrel comprises a plug, a connecting rod and a hollow cylindrical retained mandrel body. The invention further discloses a production process for manufacturing the retained mandrel. The process comprises steps of steel making, rolling, heat treatment, machining and assembling. On the premise that the use requirements are met and the product quality is guaranteed, the cost is reduced.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

Supporting hanger for grooved cable bridge and preparation process of supporting hanger

ActiveCN104862608AHigh elastic limitIncrease yield pointSolid state diffusion coatingCable trayElectric cables

The invention discloses a supporting hanger for a grooved cable bridge. The supporting hanger comprises the following constituents: C, Cr, B, Ni, N, Mo, Cu, Al, V, W, Si, Mn, Nb, Ti, S, P, and the balance of Fe and inevitable impurities. The invention further provides a preparation process of the supporting hanger for the grooved cable bridge. The preparation process is simple and feasible, low in manufacture cost and pollution-free in the manufacture process, and the prepared supporting hanger is abrasion-proof, corrosion resistant, high in strength and long in service life.

Owner:KINGSHORE NEW RESOURCES ELECTRIC JIANGSU

Casting method of rare earth alloy copper strip

The invention discloses a casting method of a rare earth alloy copper strip; the specific of the casting method is as follows: charging-covering-smelting-blending and dregs catching-warming a converter and pouring copper water-adding rare earth-horizontally continuous casting; wherein the additive amount of the compound rare earth accounts for 0.03-0.05% of the weigh of copper material; the compound rare earth comprises lanthanum and chromium which account for 0.01-0.07% of the weigh of the rare earth; zinc accounts for 0.5-5.0% of the weigh of the rare earth; chromium accounts for 0.5-5.0% of the weigh of the rare earth; and zirconium accounts for 0.5-5.0% of the weigh of the rare earth. The casting method effectively removes various complex harmful impurities brought about by waste material and plating white material by adding compound rare earth into a heating preserving furnace. The casting method can effectively improve the form, size and distribution of sulfide, improves the machining operation performance, causes the copper strip to have good welding performance, the mechanical property of the copper strip to be increased, and the overall performance of the phosphor bronze strip to be better.

Owner:MAANSHAN TIANCHENG COPPER IND

Single-use injector having a flexurally elastic housing

ActiveUS20110251549A1Low costHigh tensile strengthJet injection syringesAutomatic syringesMetal sheetEngineering

A housing of the injector is made from a thin-walled sheet-metal part. The sheet-metal part has at least two branches or legs. Each branch has, at the free end thereof, an angled retaining element or a recess as a means of receiving the cylinder of a cylinder / piston unit. The branches are elastic flexural beams which, in the middle area, are each bent in a Z-shape or S-shape to form a supporting portion for the piston-actuating ram. The contact zone situated between an individual supporting portion and the piston-actuating ram represents a wedge gear pairing that forces the respective branch outwards. The trigger unit comprises at least a trigger element which is slidably supported on the metal sheet, wherein the support section or, respectively the contact sections extend outwardly into longitudinal grooves. The branches may be provided with a locking tongue to engage corresponding openings in the trigger element to lock the housing in position as desired.

Owner:LTS LOHMANN THERAPIE-SYST AG

Steel ball special for large-sized offshore wind turbine generator bearing and manufacturing process of steel ball

ActiveCN102865301AIncrease the secondary stable tempering technologyAdd NDTFinal product manufactureBearing componentsSteel ballQuenching

The invention relates to a steel ball special for a large-sized offshore wind turbine generator bearing and a manufacturing process of the steel ball. The roundness of the steel ball is less than or equal to 0.8 mum, the hardness is 59-64 HRC, the single-grain hardness grain difference is less than or equal to 0.8 HRC, the batch hardness difference is less than or equal to 1.2 HRC, the core hardness is 54-60 HRC, the retained austenite is 8-13 percent, the metallographic structure is 2-3 grade, the surface roughness is less than or equal to 0.8 mum, and the crush load and the compression ratio of the steel ball are 1.2 times greater than international crush load and compression ratio. By selecting raw materials, adopting hot extrusion continuous forming during ball billet forming, adopting a water soluble quenching agent to perform multi-stage quenching during thermal treatment, increasing a secondary stable tempering technology, increasing various technologies such as eddy current nondestructive flaw detection in a process flow, the steel ball has the characteristics of good high contact fatigue strength, high wear resistance, high elastic limit, proper hardness, high impact toughness, good dimensional stability and the like.

Owner:JIANGSU LIXING GENERAL STEEL BALL

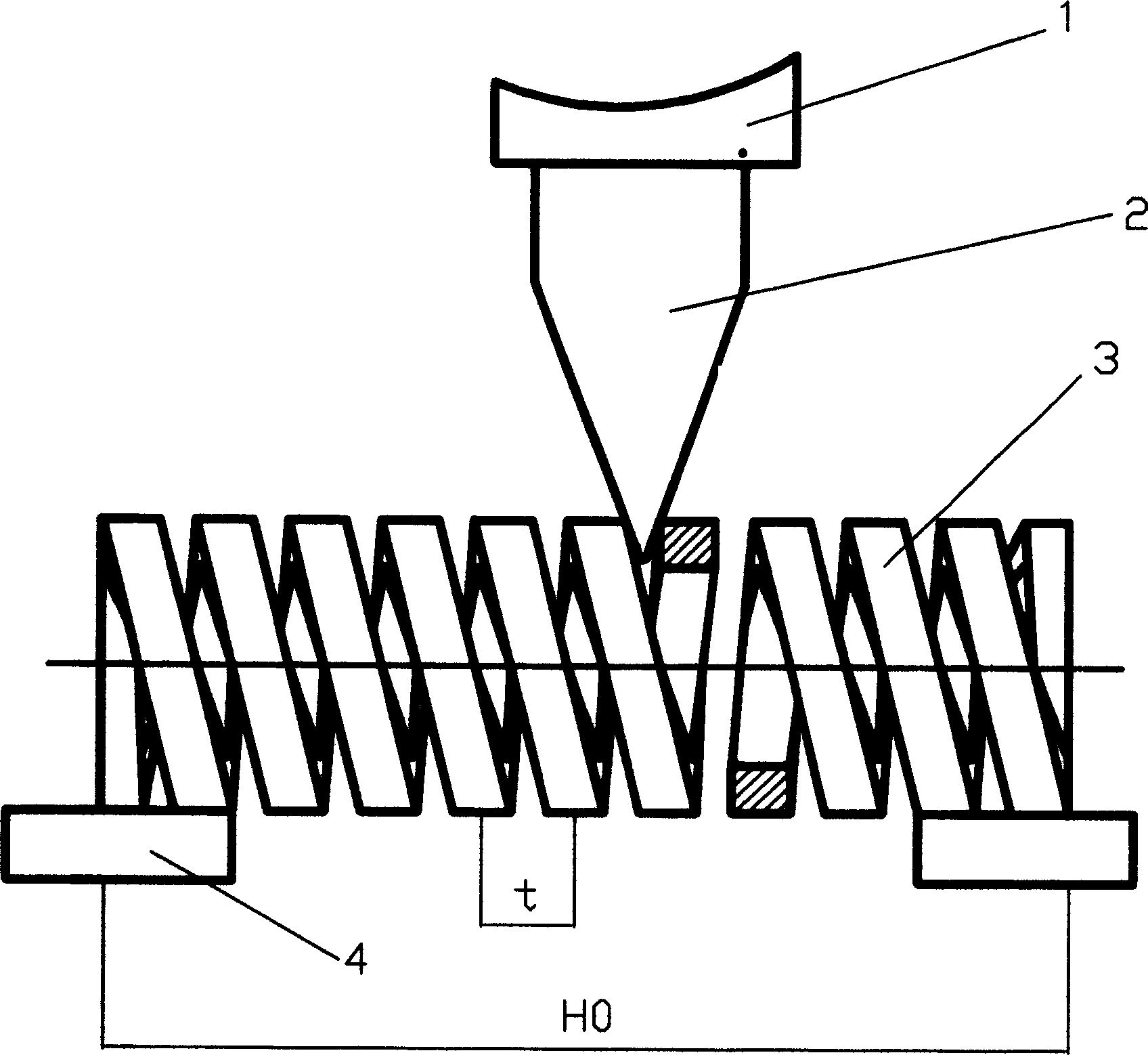

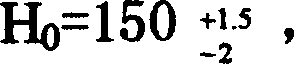

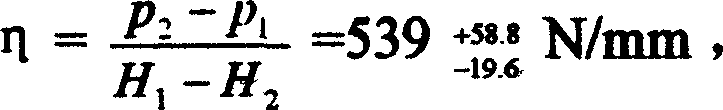

Amorphous composite and method for preparing flexible coupling diaphragm by using amorphous composite

The invention discloses an amorphous composite and a method for preparing a flexible coupling diaphragm by using the amorphous composite, and belongs to the technical field of application of amorphouscomposites. The flexible coupling diaphragm is made of a Ti-based amorphous composite or a Zr-based amorphous composite. According to the flexible coupling diaphragm made of the amorphous composite,an amorphous composite master ingot is smelted by using a vacuum arc furnace, a plate-shaped amorphous composite is subjected to suction casting by using a copper mold, heat treatment is performed before and after rolling, two-dimensional high-temperature rolling and room-temperature rolling for pre-deformation are performed, rough and finish machining is performed, and the diaphragm with the required size is obtained. The flexible coupling diaphragm made of the amorphous composite has the advantages of high elasticity (the elastic limit is 1.5%-1.7%), high strength, high toughness, high hardness, excellent corrosion resistance, fatigue resistance, long service life and the like.

Owner:TAIYUAN UNIV OF TECH

Explosion-proof type fixed ammonia gas detection probe and manufacturing method thereof

InactiveCN105039787AHigh elastic limitIncrease yield pointMaterial analysisRare-earth elementPhysical chemistry

The invention discloses an explosion-proof type fixed ammonia gas detection probe used on an ammonia gas detector. The explosion-proof type fixed ammonia gas detection probe comprises a displayer and a probe tube extending out of the displayer. The probe tube comprises the following components of C, Mn, P, S, Mo, Ni, Cu, Si, Ti, Cr, Mn, Fe, Pb, Nb, V, rare earth elements and the balance Al. The rare earth elements comprise La, Y, Sc, Gd, Sm, Ho, Tb and the balance lanthanide. The invention further provides a manufacturing method for the explosion-proof type fixed ammonia gas detection probe. The manufacturing method is simple and easy to implement, manufacturing cost is low, pollutants cannot be generated in the manufacturing process, the corrosion resistance of the manufactured fixed ammonia gas detection probe is good, the explosion-proof performance is good, service life is prolonged, and cost is reduced.

Owner:JIANGSU JINDI ELECTRONICS TECH

Repairing method for mechanical machine-lathed compression spring

InactiveCN1869254AImprove manufacturing pass rateImprove acceptance rateFurnace typesHeat treatment process controlTorsion springMachining

The invention discloses a mending method for mechanism processing compression spring that includes the following steps: taking spring backfire and controlling the rigidity at HRC44-HRC48; strutting every pitch of the spring; taking heating process of to the spring and ensuring the rigidity between HRC50-HRC53 after heating process; snapping 24hours and finishing mending. The invention could improve mechanism processing compression spring yield and sharply decrease produce cost.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com