Amorphous composite and method for preparing flexible coupling diaphragm by using amorphous composite

An amorphous composite material, flexible coupling technology, applied in elastic couplings, couplings, mechanical equipment and other directions, can solve problems such as poor corrosion resistance, elastic limit, etc., to achieve high commercial use price, high Elasticity and fatigue resistance, effect of excellent elasticity and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

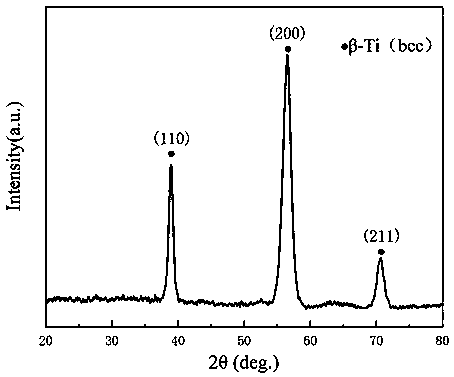

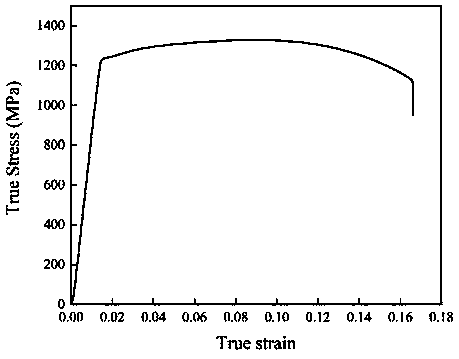

[0043] This embodiment is a Ti x -Zr-V-Cu-Be (x=40~62) series amorphous composite material.

[0044] This embodiment is a Ti x -Zr-V-Cu-Be (x=40~62) system amorphous composite material is composed of five elements: Ti, Zr, V, Cu, and Be, the Ti-Zr-V-Cu-Be system amorphous composite The atomic percentage of the material is Ti 60 Zr 13 V 13 Cu 4 Be 10 Among them, Ti, Zr, V, Cu, Be are synthesized by smelting bulk Ti, Zr, Cu with purity ≥99.999%, bulk Be with purity ≥99.9%, and V after HCL pickling.

[0045] The preparation process of the diaphragm of the Ti-Zr-V-Cu-Be series amorphous composite flexible coupling proposed in this example is as follows:

[0046] Step one, pre-treatment: the raw materials required for the preparation of amorphous composite materials are cleaned with a grinder to clean the surface oxides, and then the samples are placed in an ultrasonic cleaning equipment containing absolute ethanol for ultrasonic cleaning for 20-30 minutes to remove The oil and impuritie...

Embodiment 2

[0072] This embodiment is a Ti x -Zr-V-Cu-Be (x=40~62) series amorphous composite material.

[0073] This embodiment is a Ti x -Zr-V-Cu-Be (x=40~62) system amorphous composite material is composed of five elements Ti, Zr, V, Cu, and Be, the Ti-Zr-V-Cu-Be system amorphous composite The atomic percentage of the material is Ti 46 Zr 20 V 12 Cu 5 Be 17 Among them, Ti, Zr, V, Cu and Be are synthesized by smelting bulk Ti, Zr, Cu with purity ≥99.999%, bulk Be with purity ≥99.9%, and V after HCL pickling.

[0074] The preparation process of the diaphragm of the Ti-Zr-V-Cu-Be series amorphous composite flexible coupling proposed in this example is as follows:

[0075] Step one, pre-treatment: the raw materials required for the preparation of amorphous composite materials are cleaned with a grinder to clean the surface oxides, and then the samples are placed in an ultrasonic cleaning equipment containing absolute ethanol for ultrasonic cleaning for 20-30 minutes to remove Oil stains and impu...

Embodiment 3

[0096] This embodiment is a Ti x -Zr-V-Cu-Be (x=40~62) series amorphous composite material.

[0097] This embodiment is a Ti x -Zr-V-Cu-Be (x=40~62) system amorphous composite material is composed of five elements Ti, Zr, V, Cu, and Be, the Ti-Zr-V-Cu-Be system amorphous composite The atomic percentage of the material is Ti 48 Zr 18 V 12 Cu 5 Be 17 Among them, Ti, Zr, V, Cu and Be are synthesized by smelting bulk Ti, Zr, Cu with purity ≥99.999%, bulk Be with purity ≥99.9%, and V after HCL pickling.

[0098] The preparation process of the diaphragm of the Ti-Zr-V-Cu-Be series amorphous composite flexible coupling proposed in this example is as follows:

[0099] Step one, pre-treatment: the raw materials required for the preparation of amorphous composite materials are cleaned with a grinder to clean the surface oxides, and then the samples are placed in an ultrasonic cleaning equipment containing absolute ethanol for ultrasonic cleaning for 20-30 minutes to remove Oil stains and impu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com