Spring, preparation method thereof and mold assembly used for preparing spring

A mold and component technology, applied in the field of spring processing, can solve the problems of operator's misjudgment, difficult integral molding, uncontrollable shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

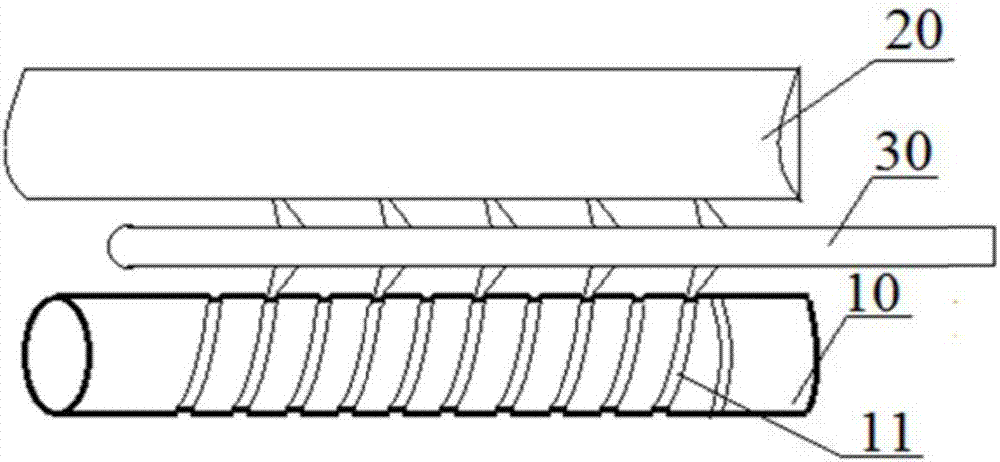

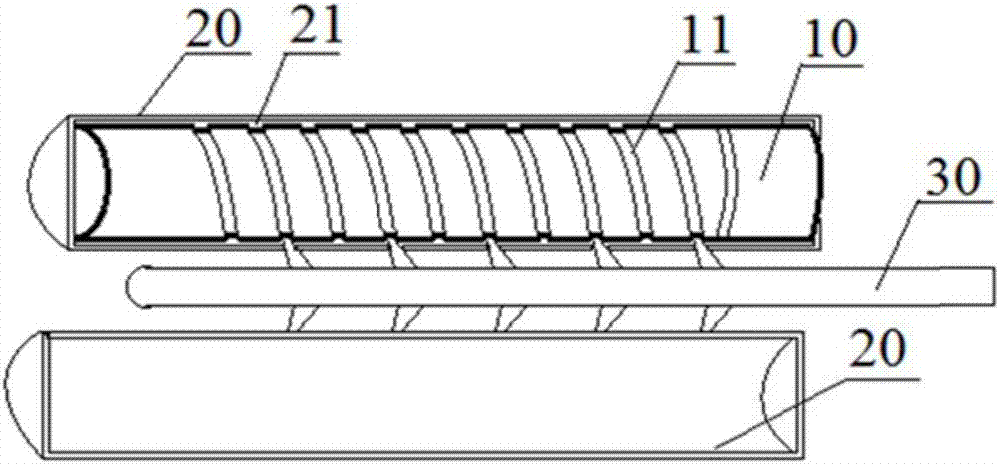

[0044] In addition, the present invention also provides a method for preparing a spring, which includes the following steps: S1, providing a molten metal capable of forming a bulk amorphous alloy with a critical dimension greater than 1mm (preferably greater than 10mm); (amorphous The measurement method of the critical size of the alloy is as described above, and will not be repeated here), and the master alloy ingot is melted to form a molten metal; S2, under the pouring condition, the molten metal is injected into the present invention through the sprue In the mold assembly, the spring is formed; S3. Open the mold assembly, take out the spring precursor with the mandrel built in, and cut off the excess part of the surface of the spring precursor after cooling, to obtain the spring precursor with the built-in mandrel. The spring of the mandrel; S4. Under corrosive conditions, the spring with the mandrel built in is placed in an corrosive solution to corrode the mandrel to obta...

preparation example 1 to 4

[0060] One, preparation example 1 to 4, be used for illustrating the mold assembly that the present invention prepares spring

[0061] The test items and test methods involved in the following preparation examples 1 to 4 are as follows:

[0062] (1) Vickers hardness: measured with reference to the standard of ASTM E90-82. Specifically, a test block with a length, width, and height of 20×20×2mm is formed by casting a copper mold at room temperature and pressure, using HVS-10Z digital Vickers hardness tester (Shanghai Precision), diamond diamond indenter, and a pressure of 15 under 3KG. Seconds, the hardness value is calculated by measuring the diagonal length of the diamond indentation.

[0063] (2) Immersion corrosion test (corrosion rate): measured according to the standard of JB / T 7901-1999 "Metal Material Laboratory Uniform Corrosion Full Immersion Test Method", specifically, the length, width and height are formed by copper mold casting under normal temperature and normal...

Embodiment 1

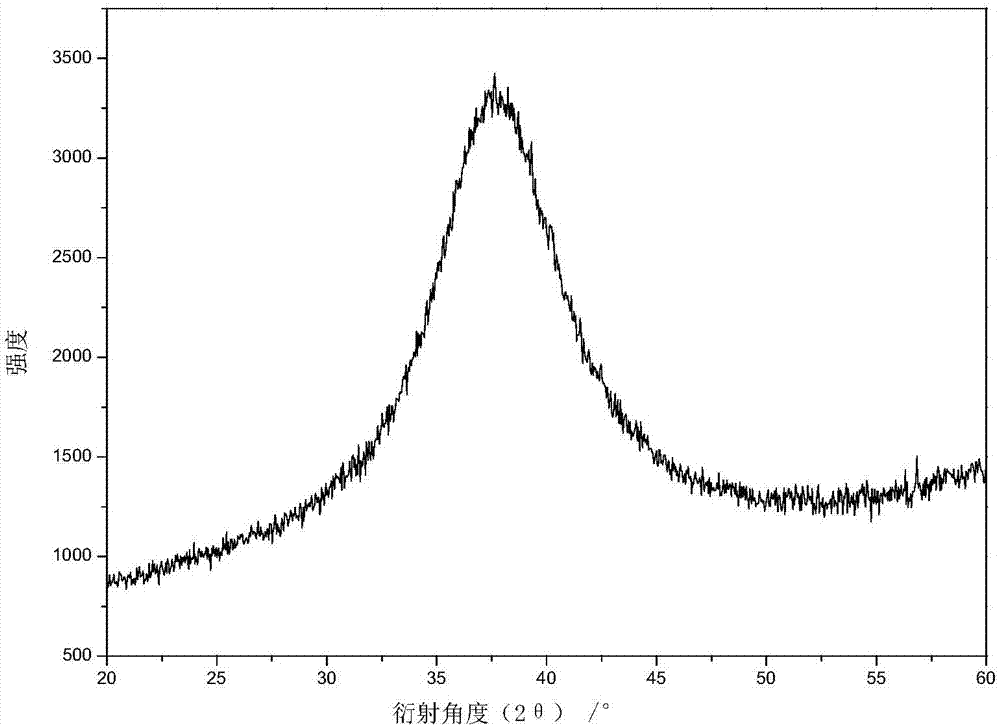

[0086] Embodiment 1 (Zr 55 Al 10 Cu 30 Ni 5 Amorphous alloy spring)

[0087] Zr 55 Al 10 Cu 30 Ni 5 Performance testing of amorphous alloy materials:

[0088] It can be seen from the test that the Zr 55 Al 10 Cu 30 Ni 5 The critical size of the amorphous alloy is greater than 10mm, which belongs to the bulk amorphous alloy; and the Zr 55 Al 10 Cu 30 Ni 5 Other performance test results of amorphous alloy materials are shown in the following table:

[0089]

[0090] The preparation method of the spring is as follows:

[0091] (1) The general formula is Zr 55 Al 10 Cu 30 Ni 5 Put the master alloy ingot into the feeding device of the horizontal 160T die-casting machine, and put it into the melting device of the die-casting machine from the feeding device; the vacuum degree of the die-casting machine is 200Pa. Melting the master alloy ingot by induction heating to form a molten soup, the temperature of the molten soup is 980°C;

[0092] (2) The metal molten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical dimension | aaaaa | aaaaa |

| Critical dimension | aaaaa | aaaaa |

| Critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com