Patents

Literature

1827results about How to "Exquisite design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

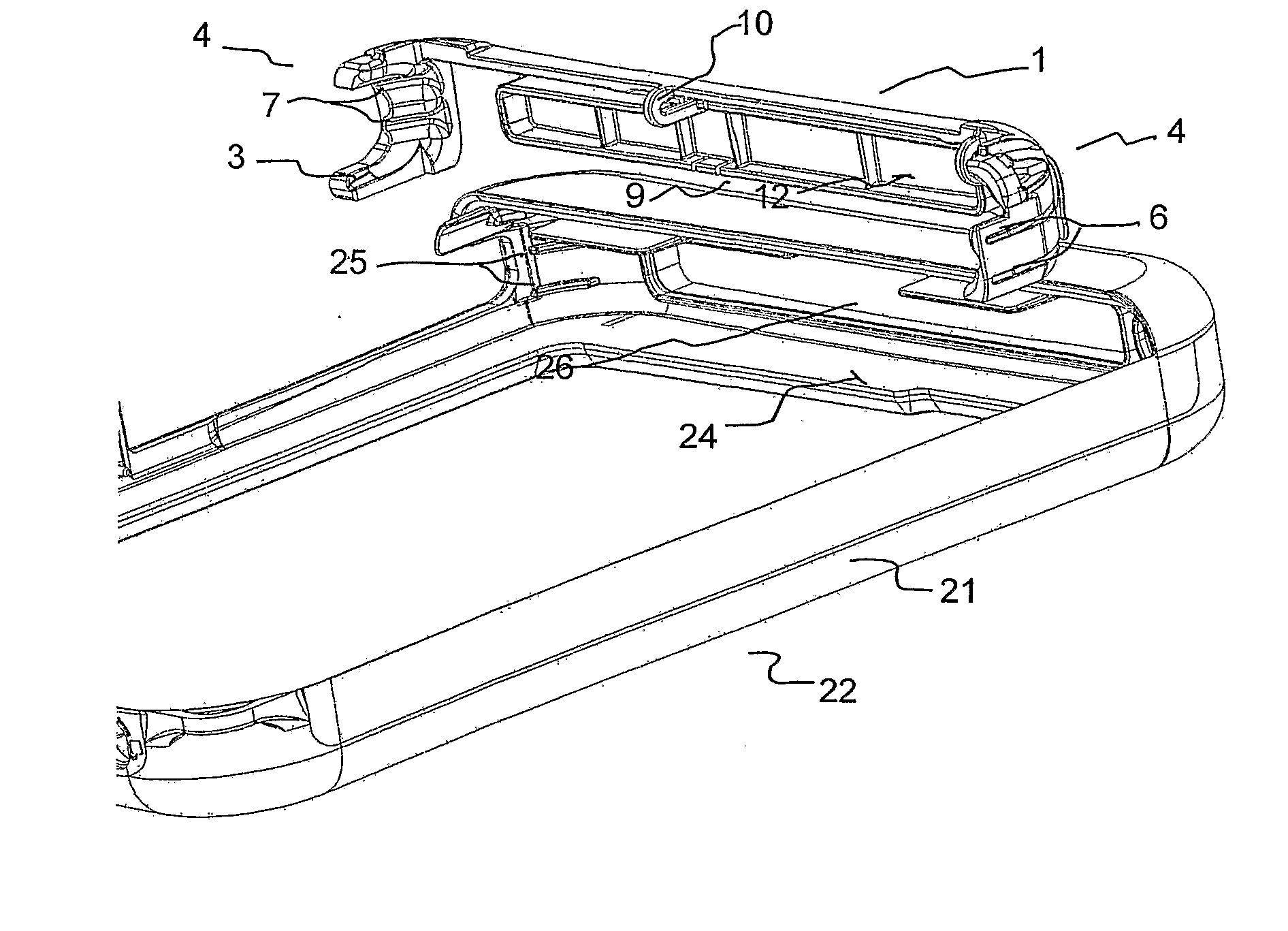

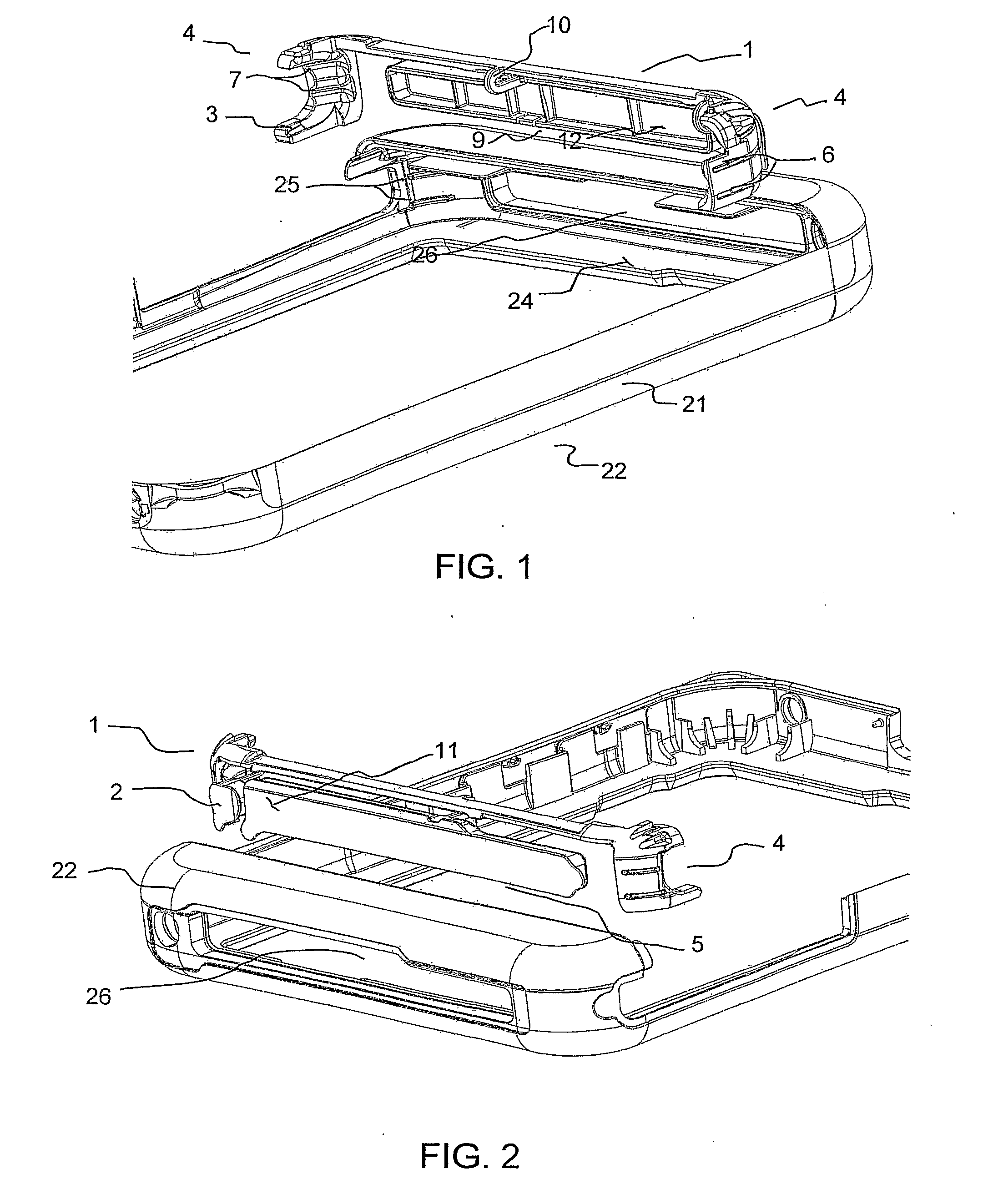

Impact-resistant case with sealable opening

InactiveUS20070158220A1Cost-effectiveEasy to customizeClosed casingsDigital data processing detailsPagerHand held

The present invention is a cost effective impact-absorbing insert which combines multiple functionality with parts consolidation and ease of customization that allows wide application anywhere tailored impact protection is desired. The impact-absorbing insert of the present invention mates with a user defined enclosure to produce a protective case for any fragile articles that are used in a portable environment, for example portable electronic devices such as cameras (35 mm and digital), instrumentation, tools, PDAs, web tablets, hand held computers, cell phones, pagers, gaming devices, electronic music players, voice recorders, global positioning systems (GPS), and the like.

Owner:CLEEREMAN ROBERT J +2

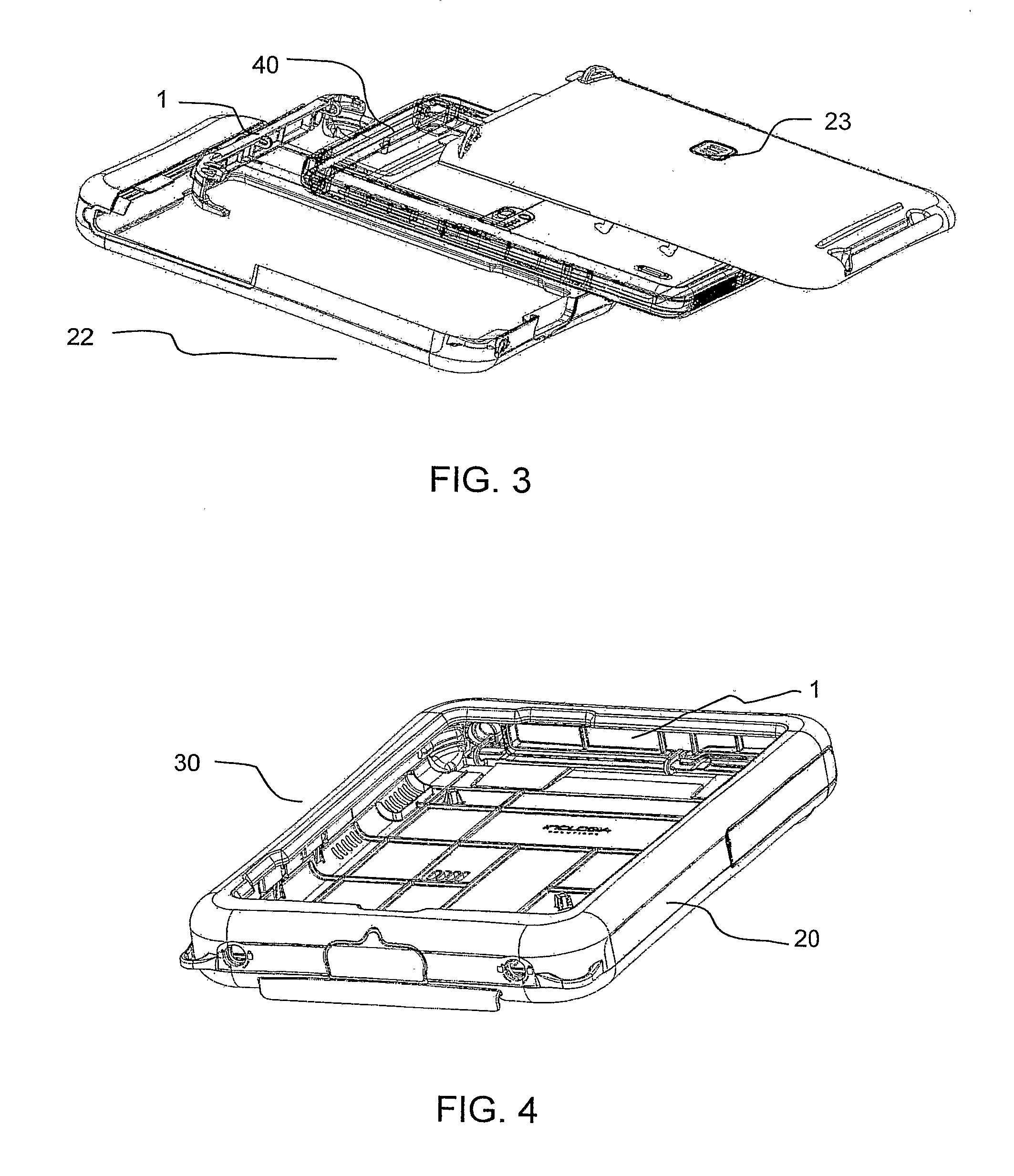

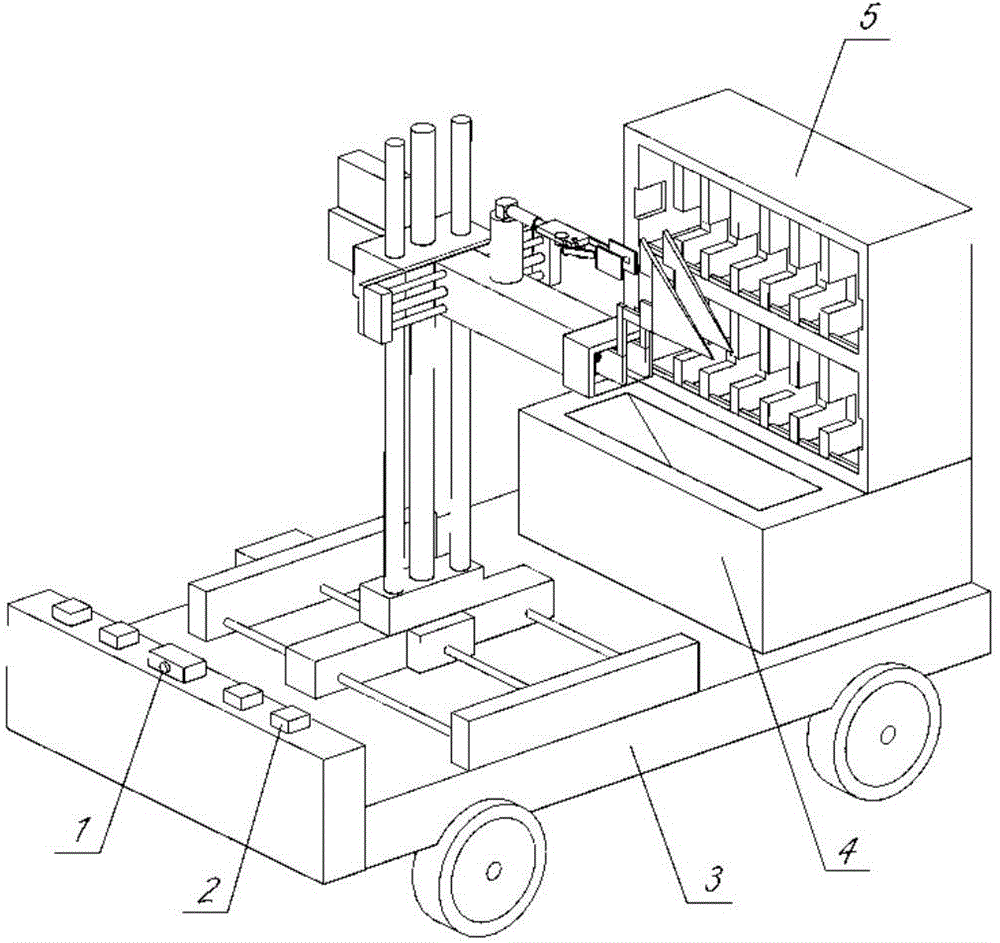

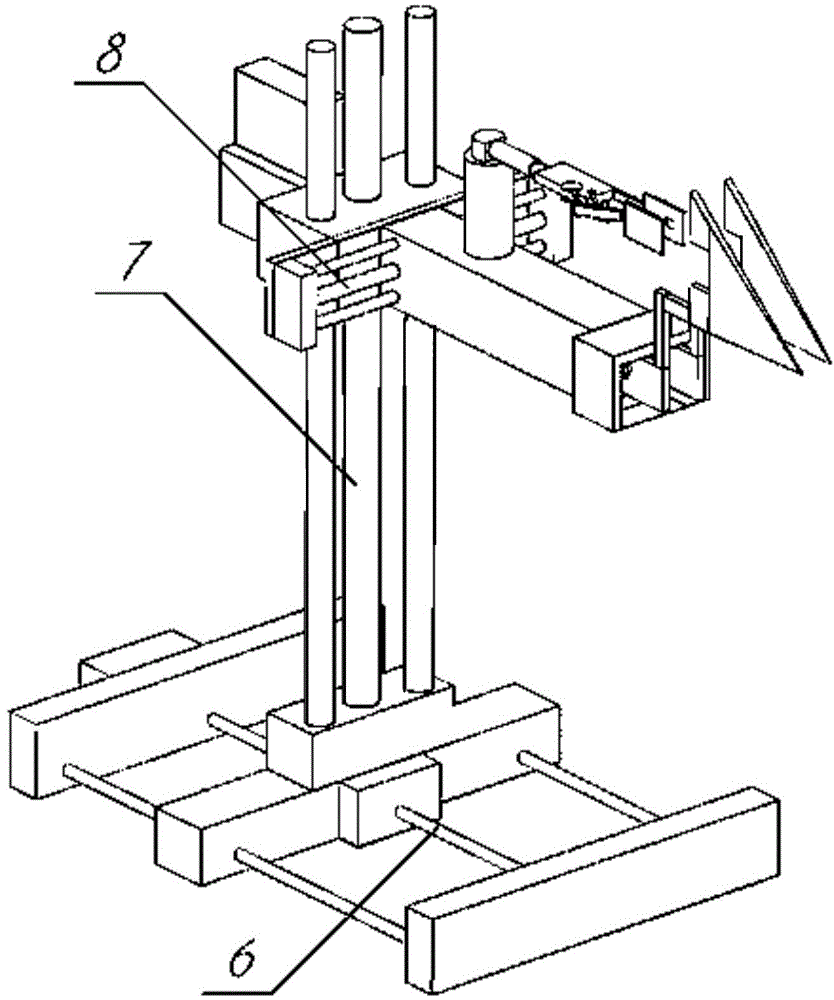

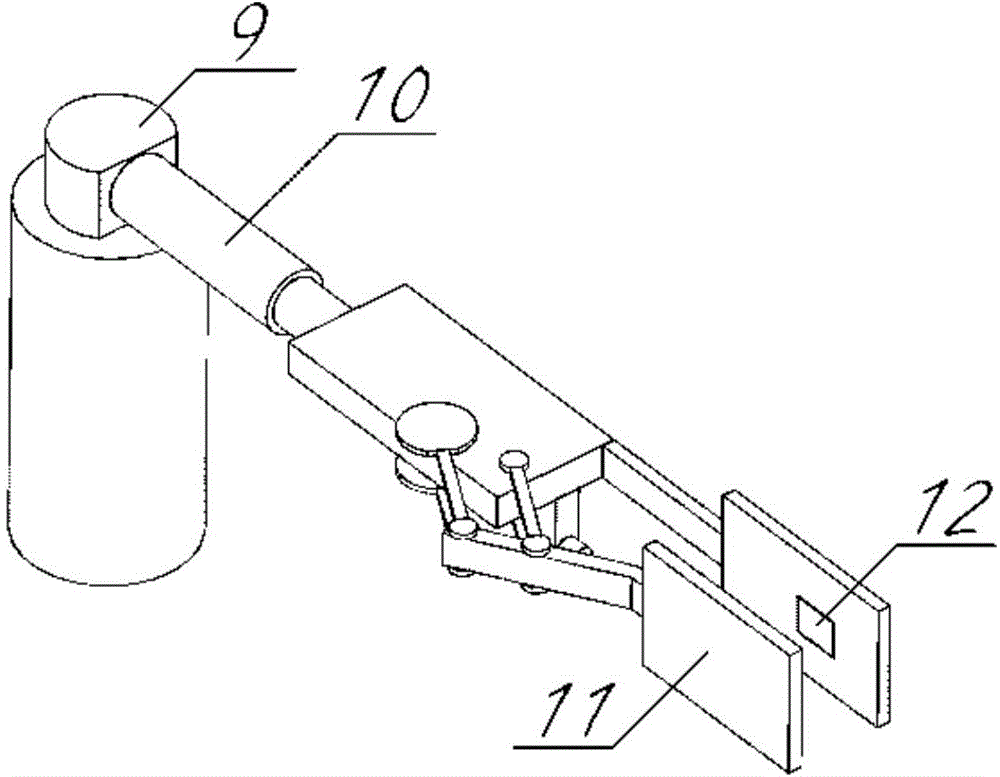

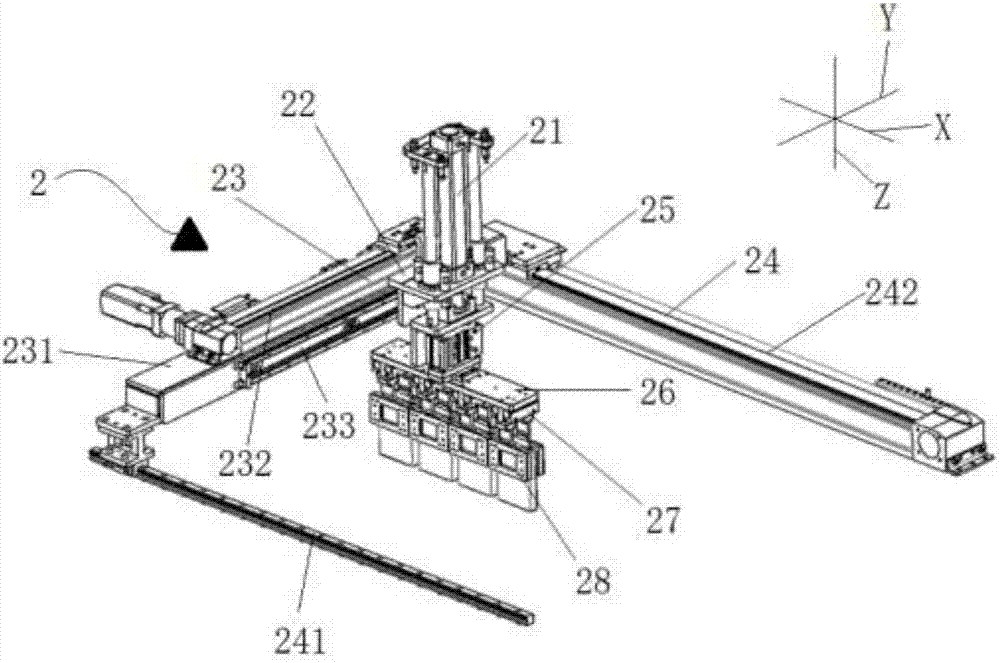

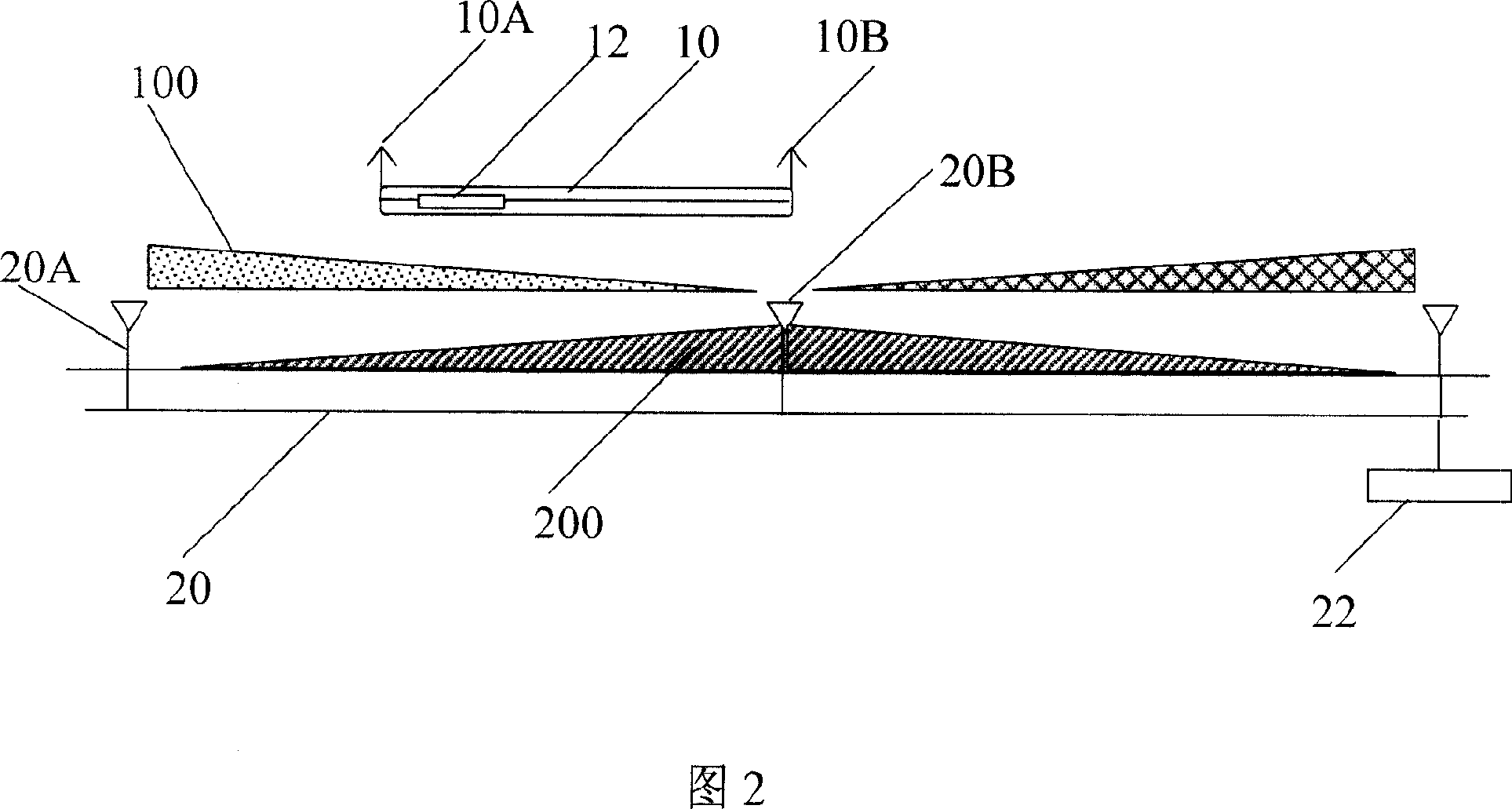

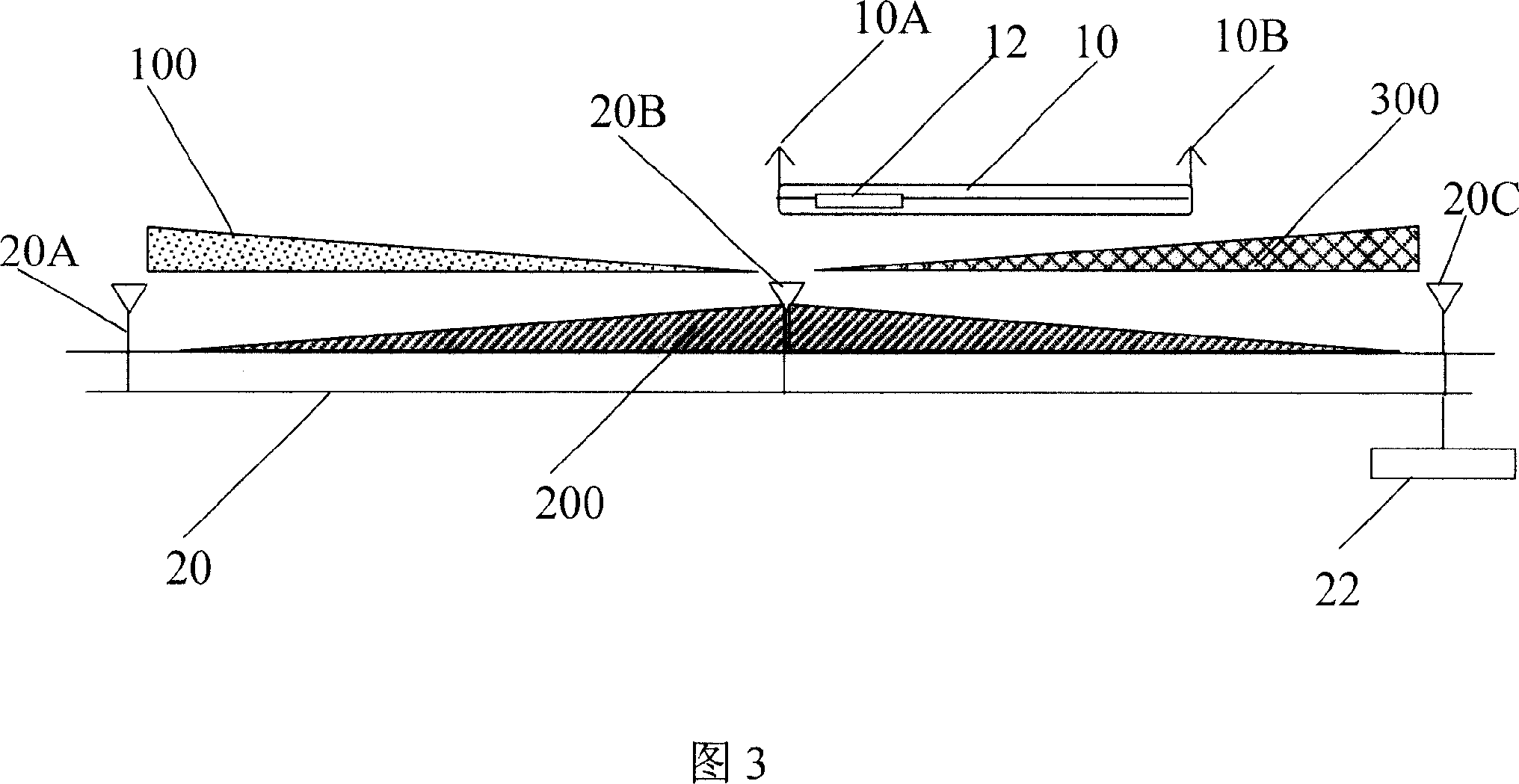

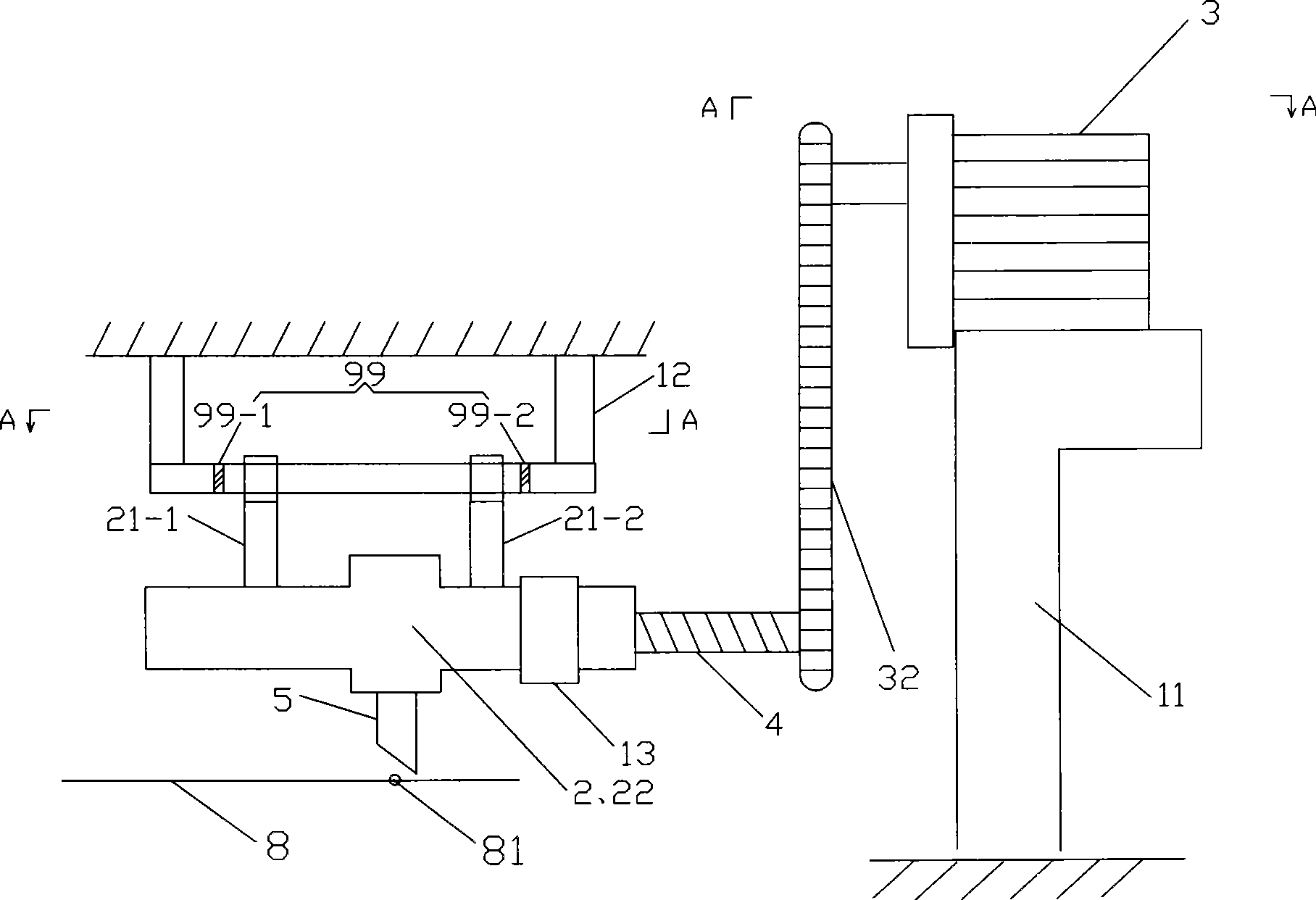

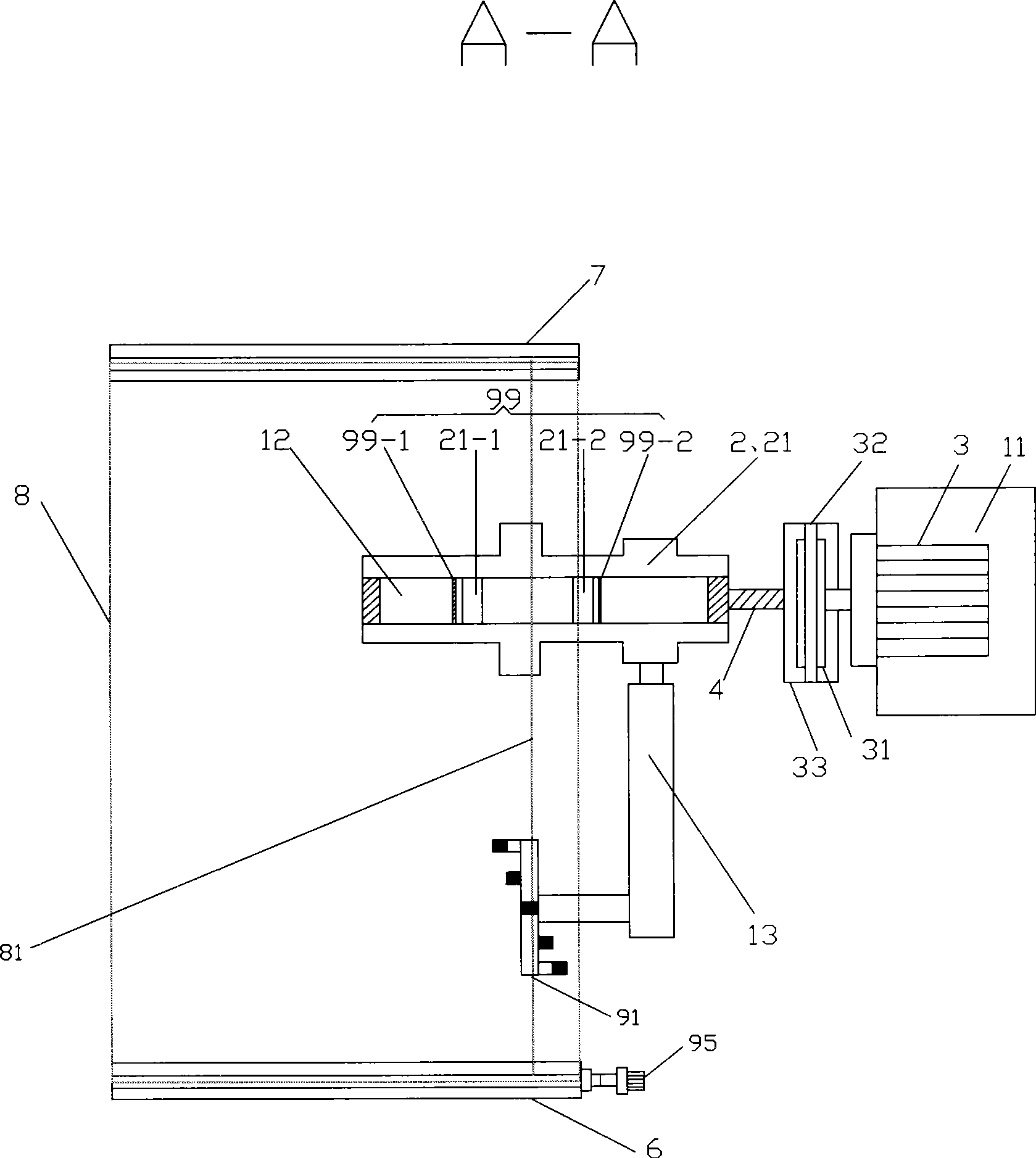

Intelligent book management robot

ActiveCN104875177AMechanism design is exquisite and practicalRealization is likely to be largeManipulatorManipulatorEngineering

The invention provides an intelligent book management robot for fully automatically borrowing, returning and arranging of books of a library. The intelligent book management robot comprises an automatic moving trolley for polling and avoiding a barrier, a storing bookshelf, a book basket, a book picking and storing mechanism and a control device. The intelligent book management robot is characterized in that the moving trolley can move according to a ground mark and a mark line; a mechanism for avoiding the barrier and polling is mounted at a head part of the trolley; the storing bookshelf is of a special structure and is in the same direction as the trolley marching direction; the book picking and storing mechanism moves up and down, left and right and front and back based on the combination of guide rails; a composite manipulator consisting of a book expanding arm and a book picking arm is arranged at the tail end of the mechanism and has the functions of telescoping, expanding and clamping; the books can be picked and stored under the effects of imaging of a camera and controlling of a computer. The intelligent book management robot has the advantages that the book is automatically managed without reconstructing the bookshelf of the library, and thus the labor intensity of workers in the library can be reduced.

Owner:SHANGHAI JIAO TONG UNIV

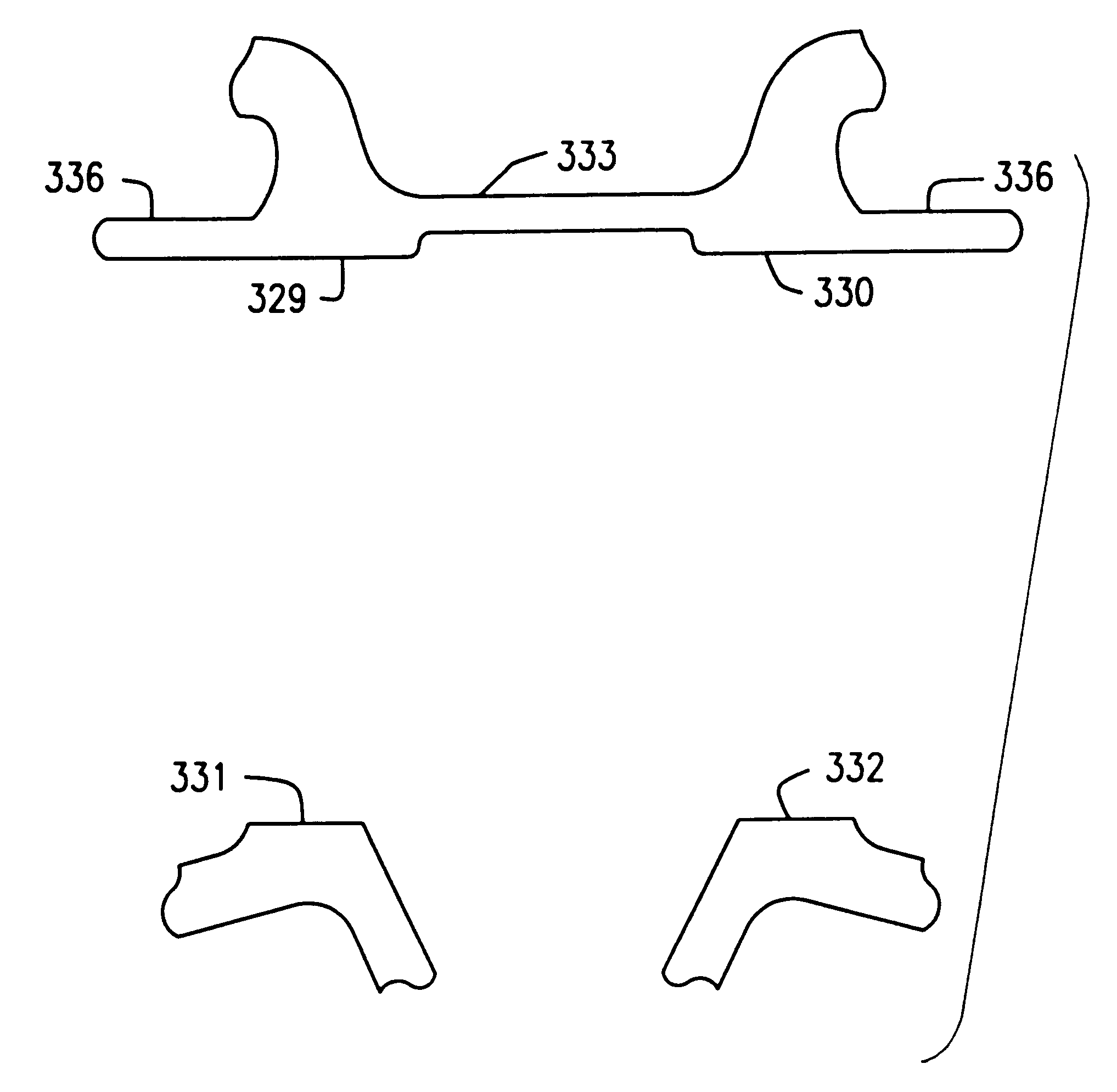

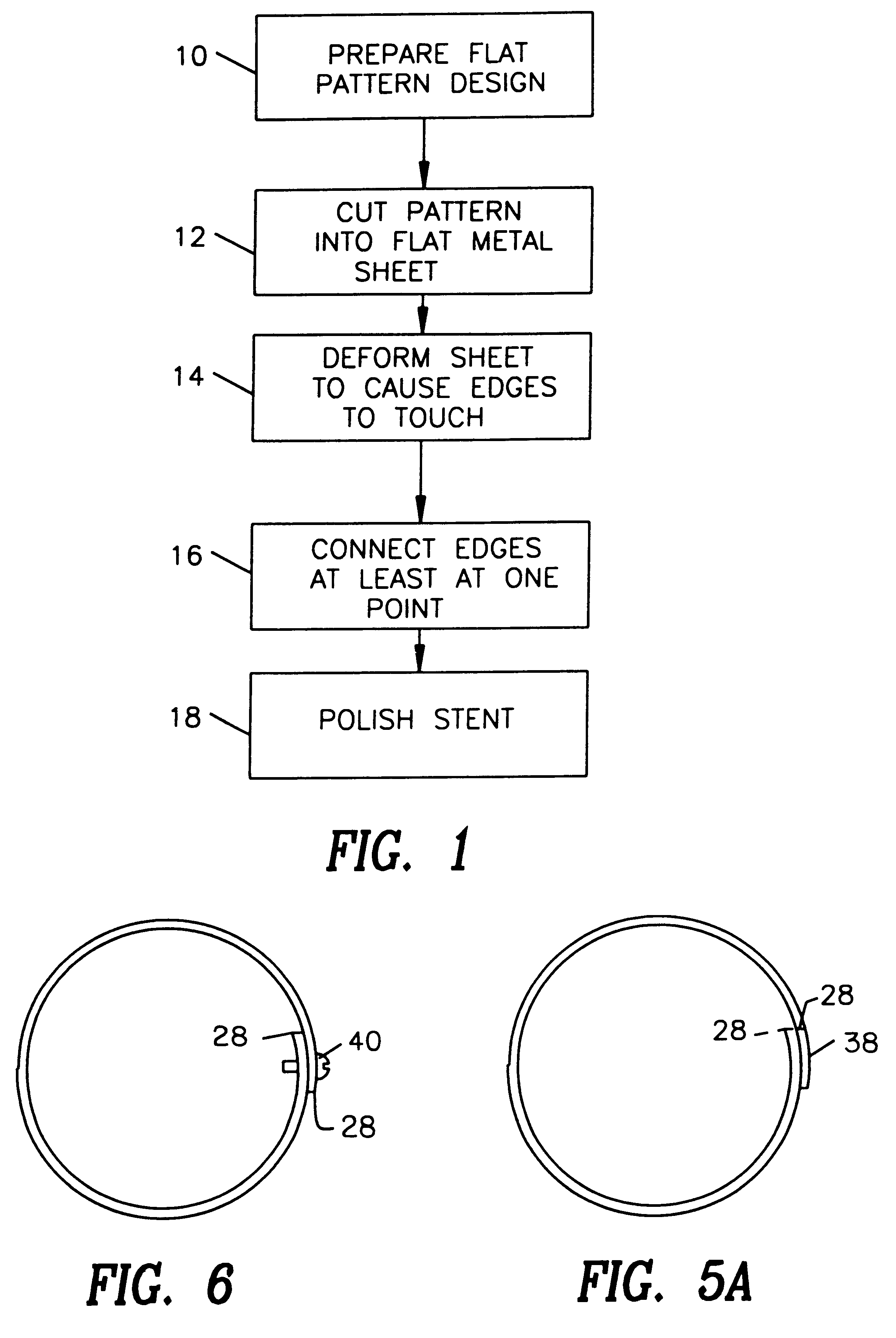

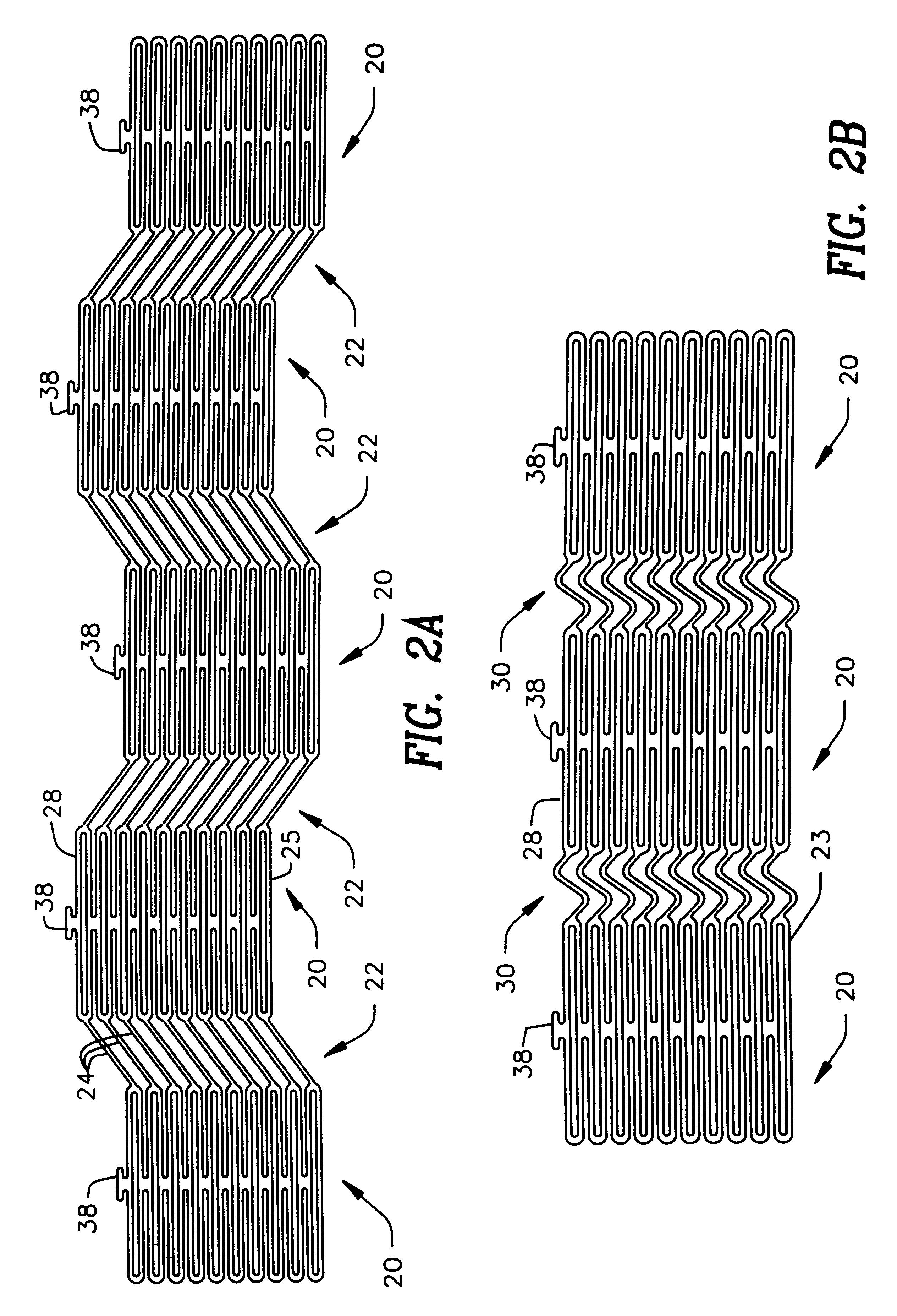

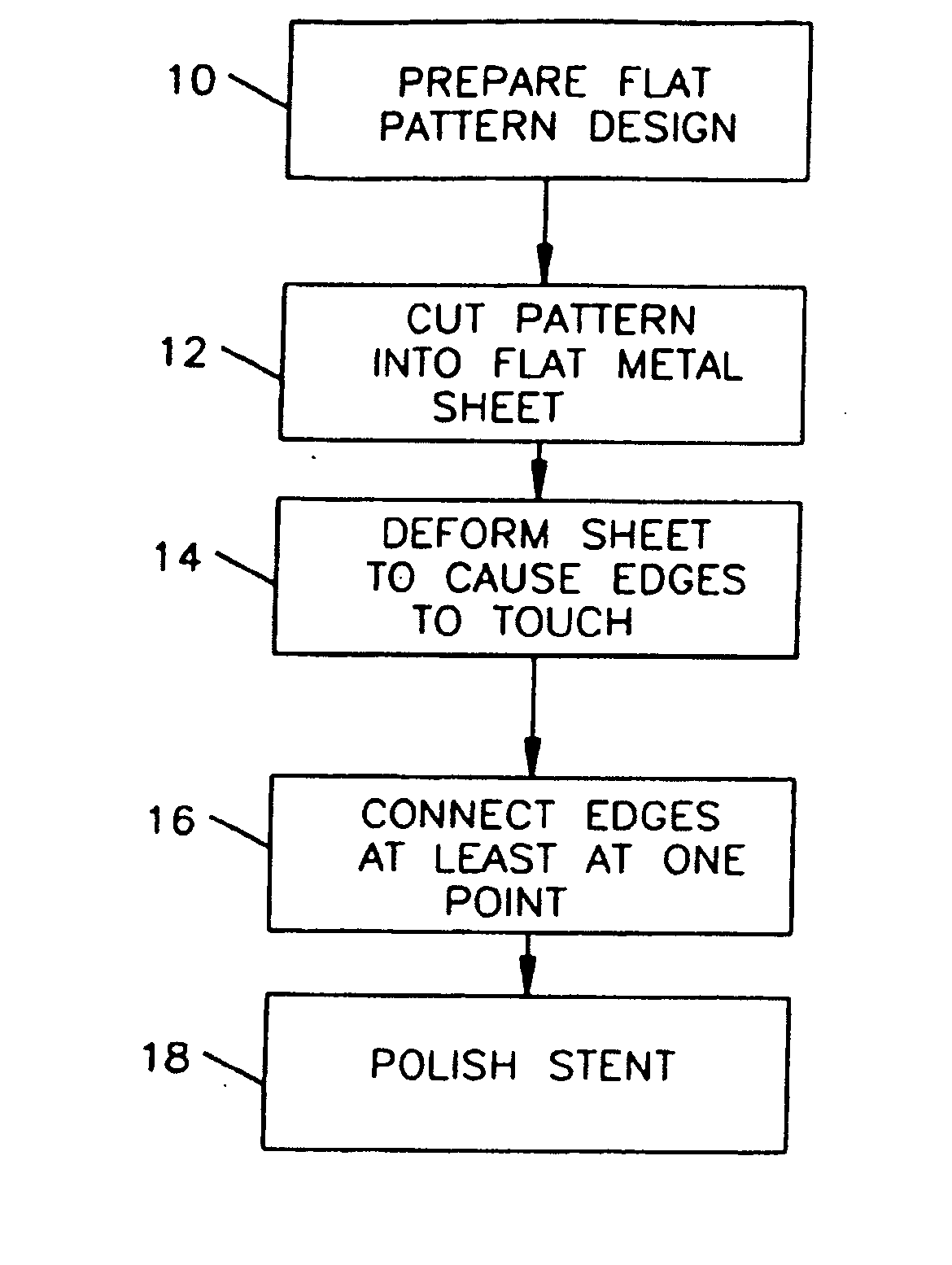

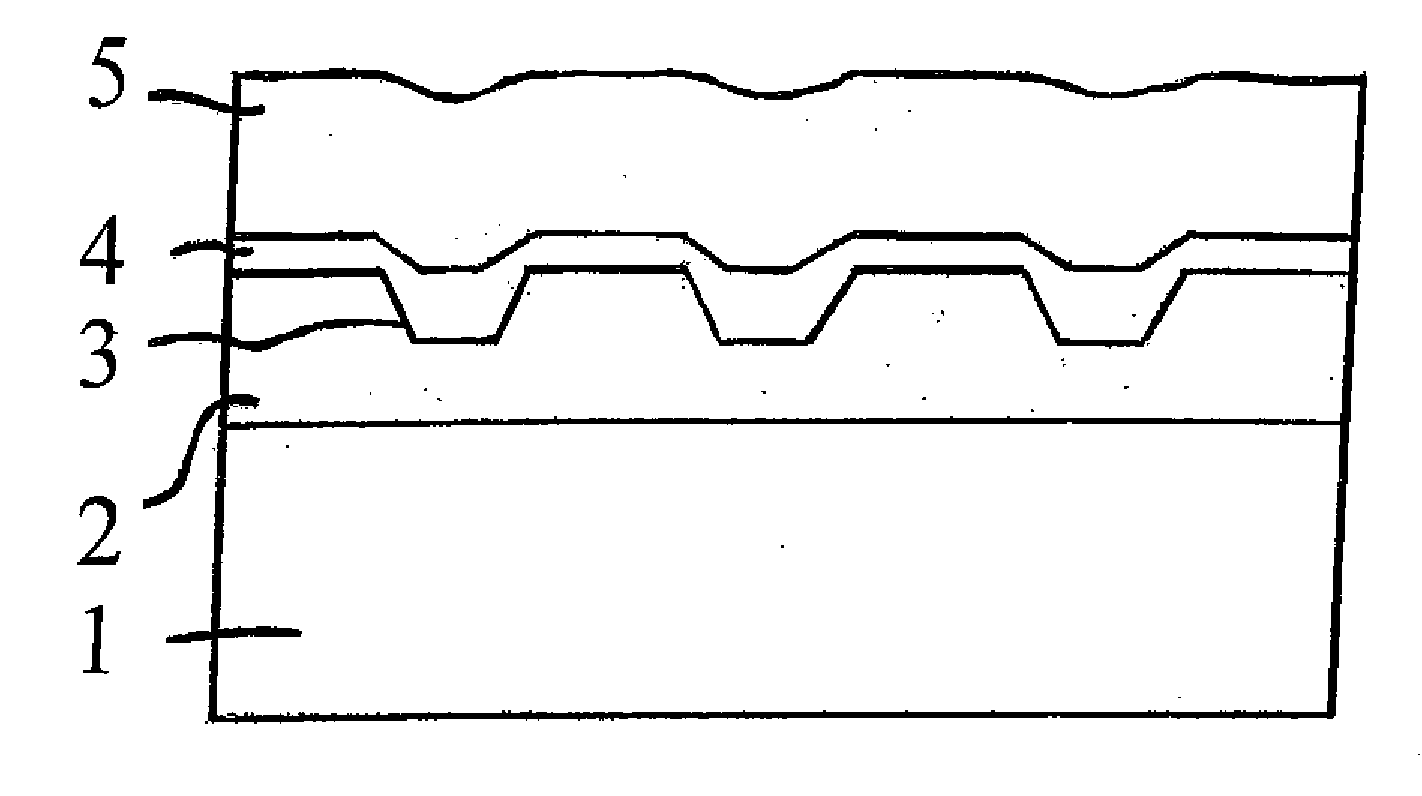

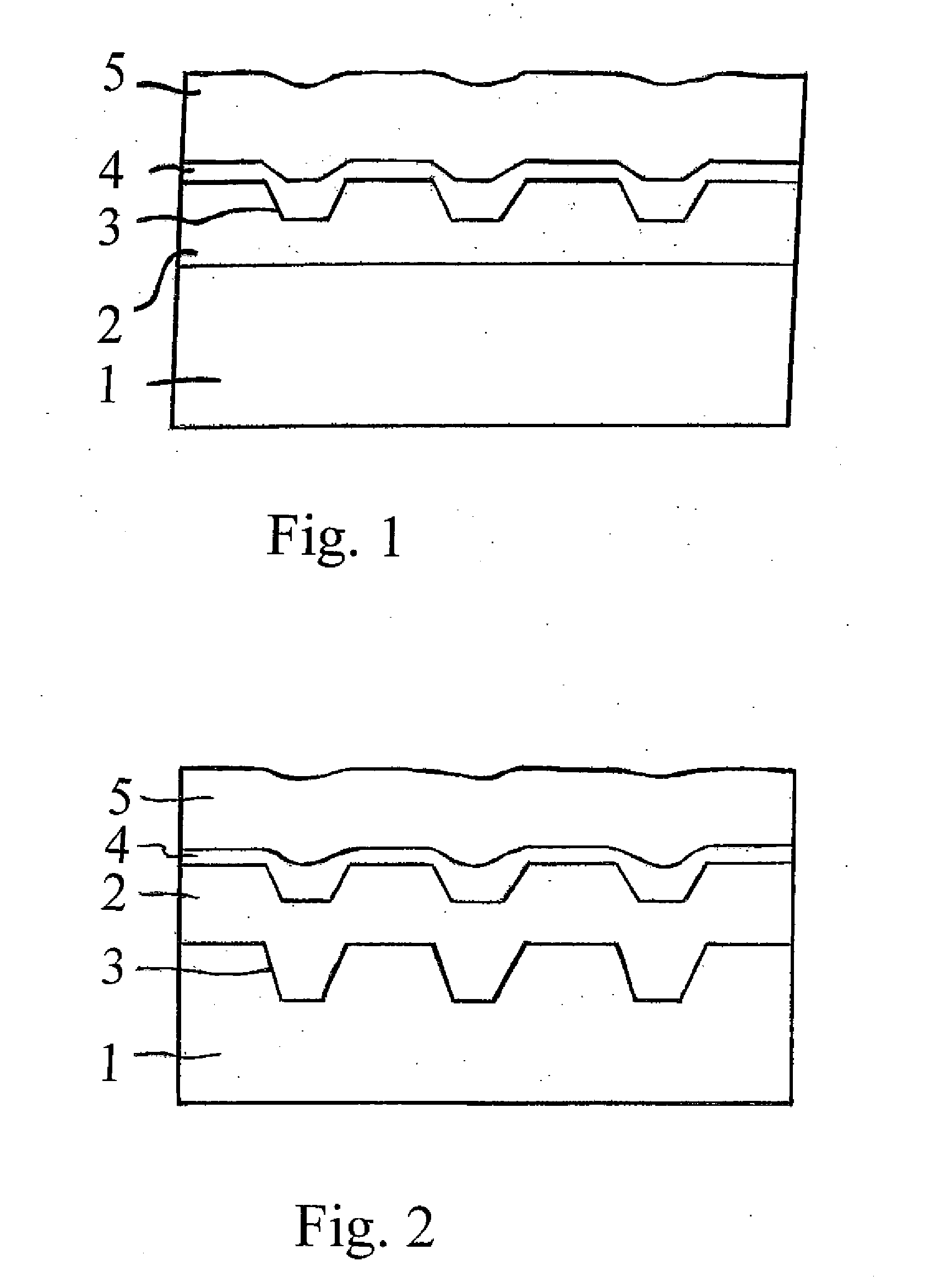

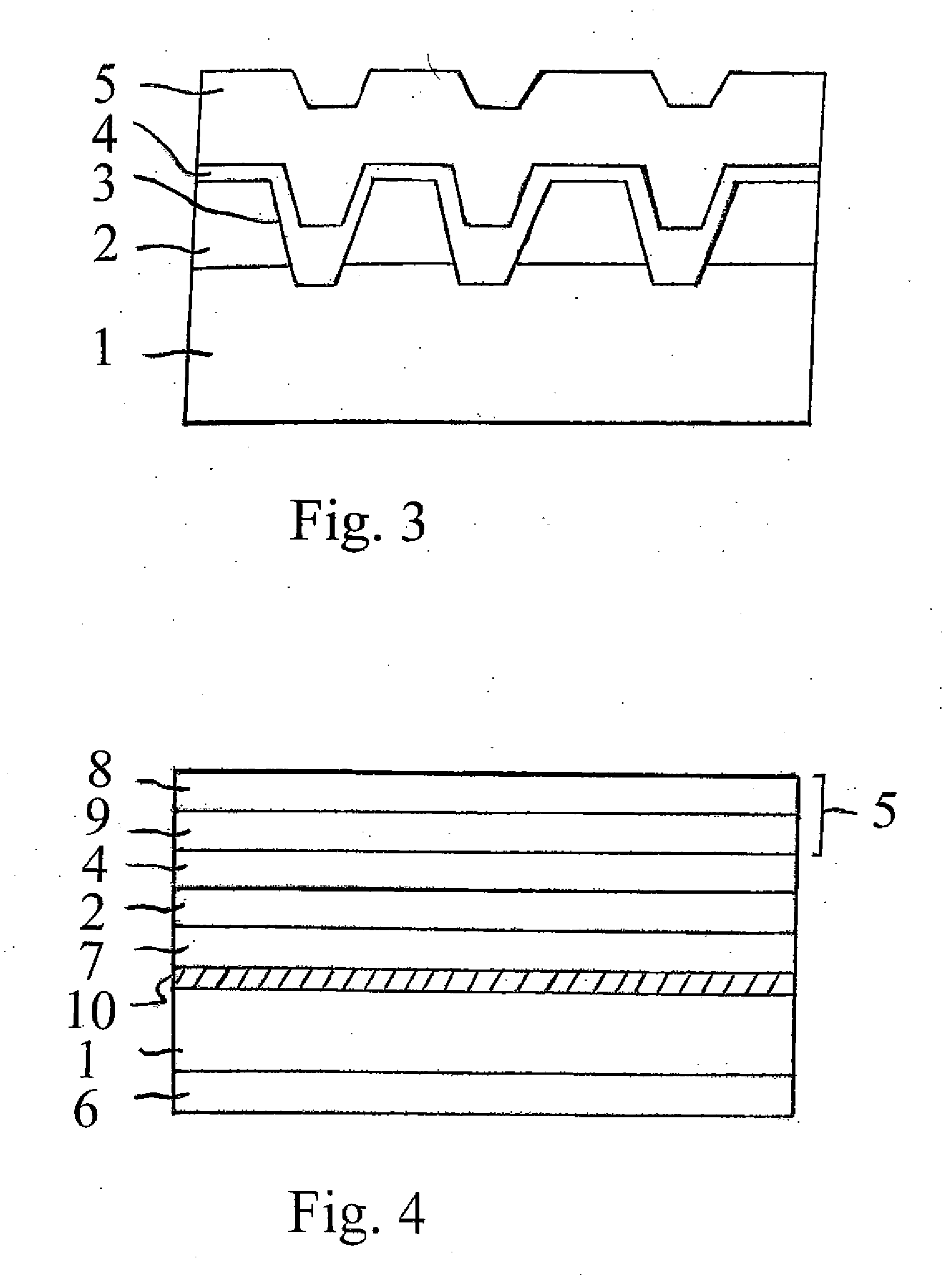

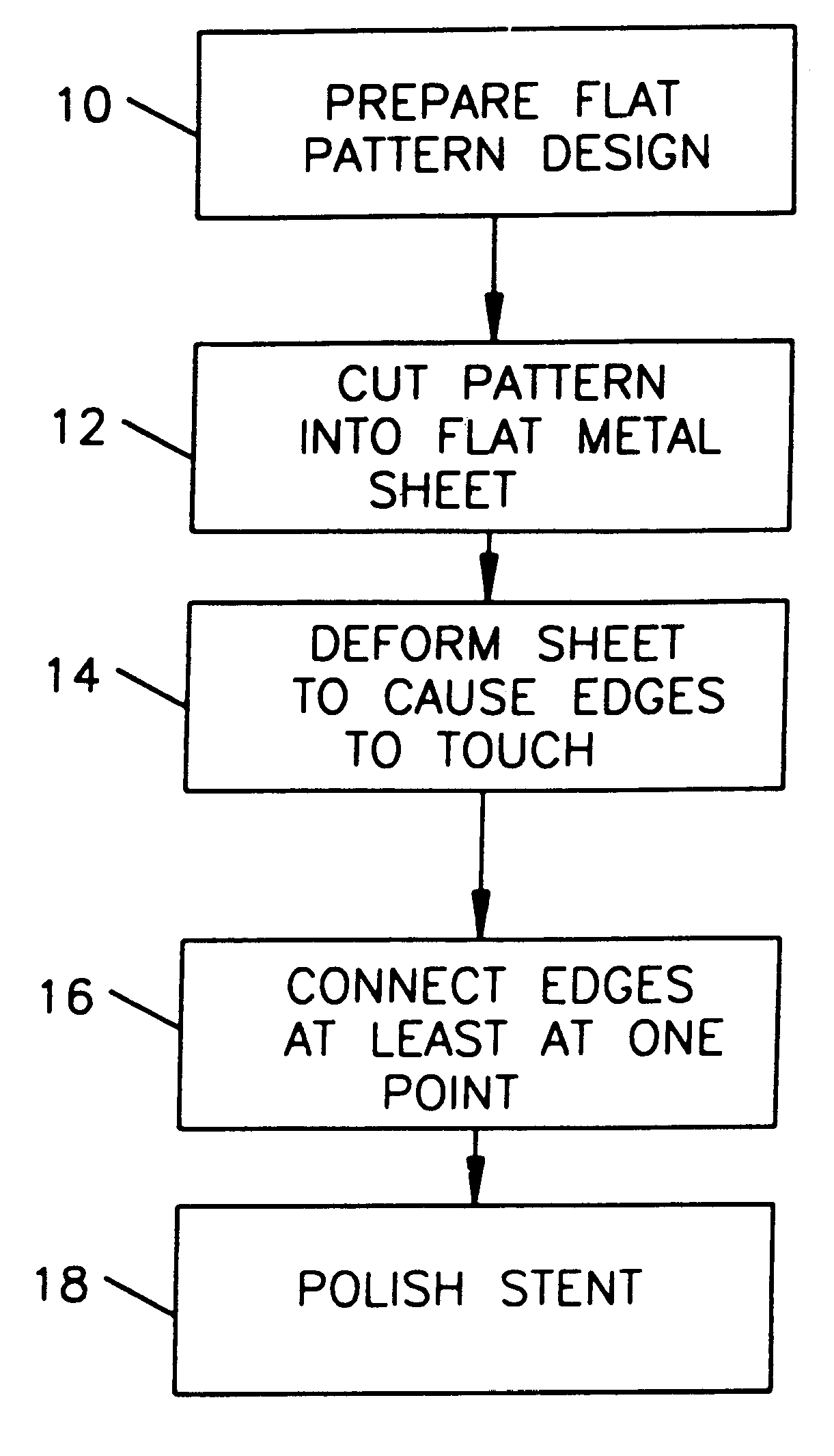

Stent

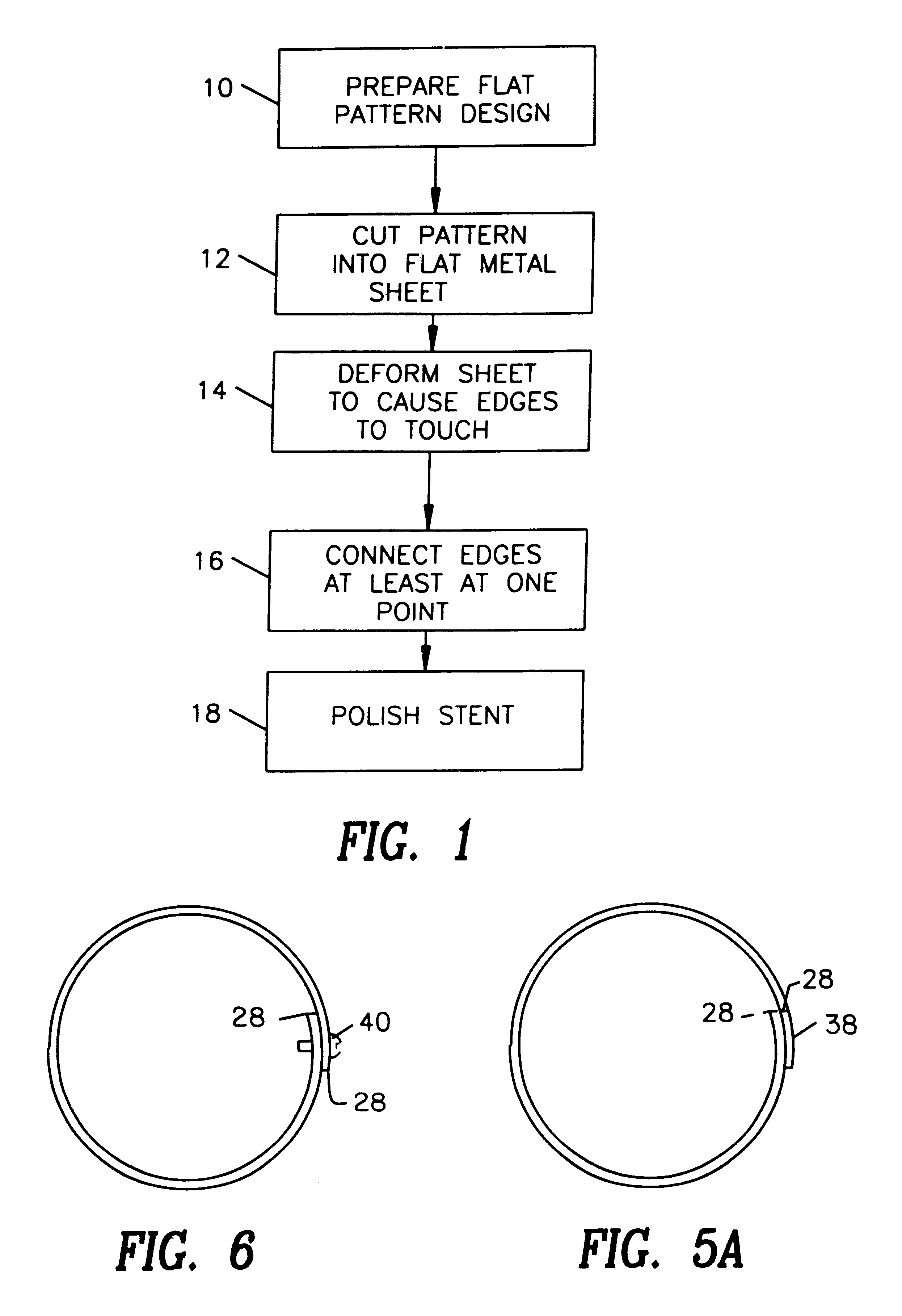

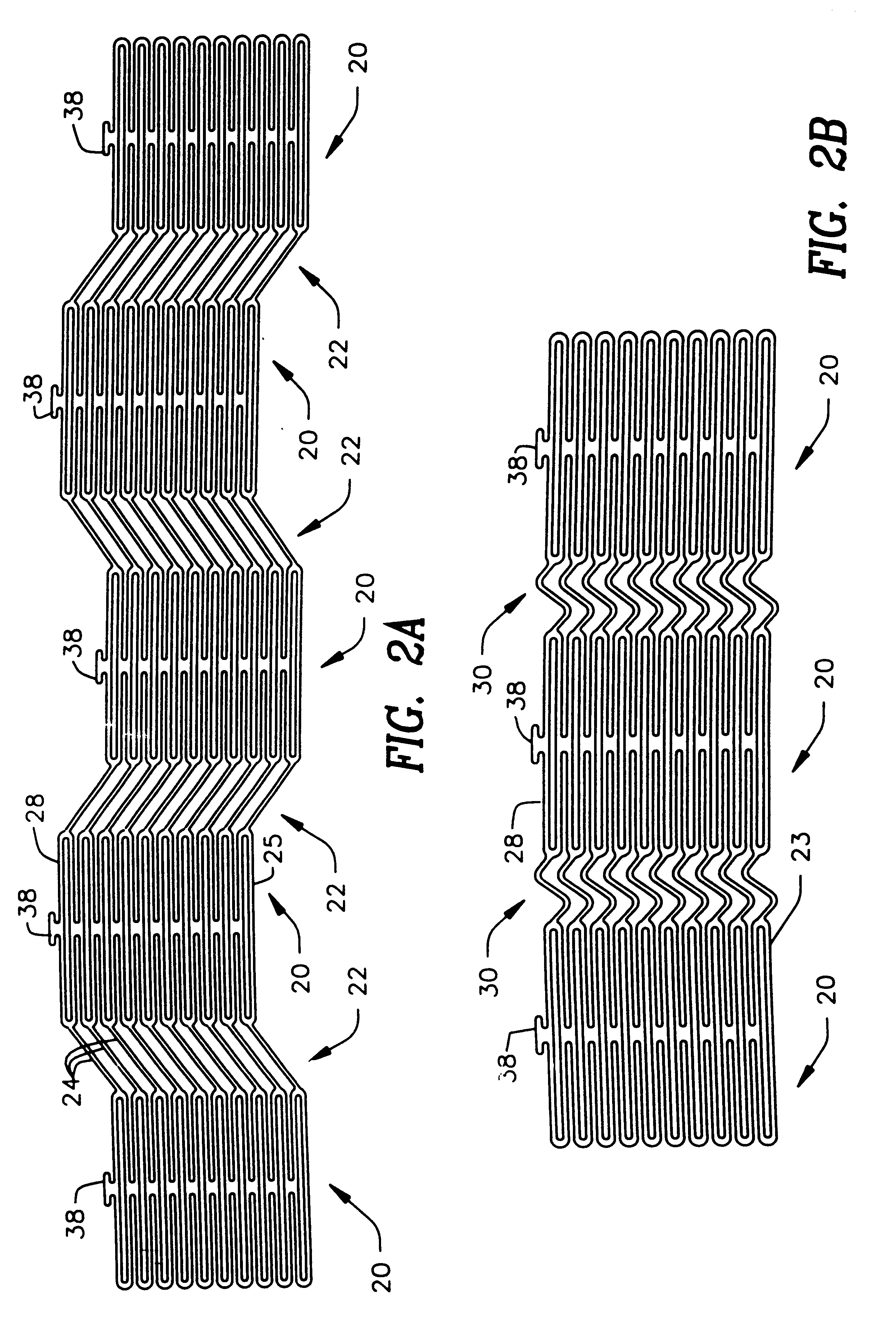

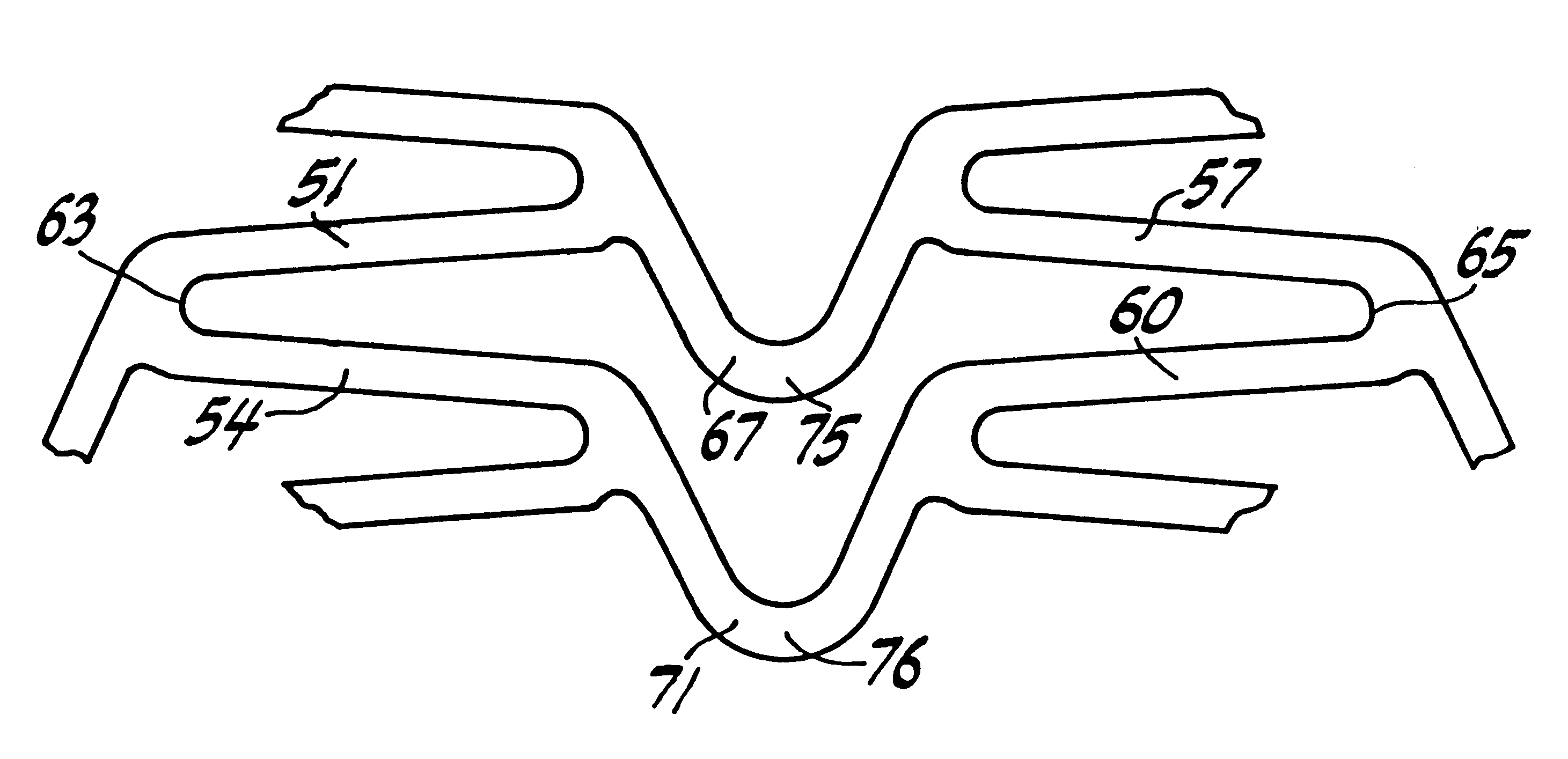

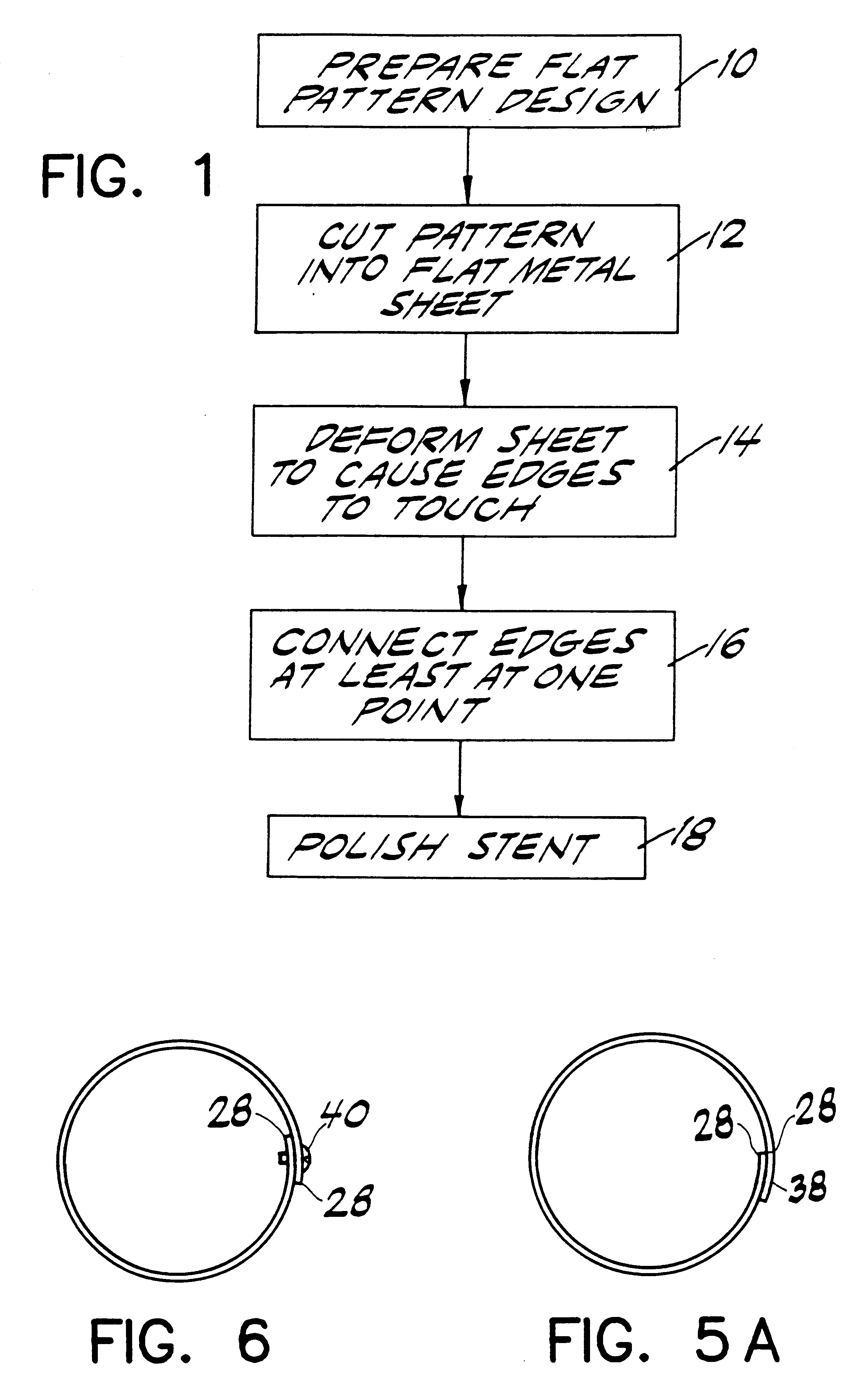

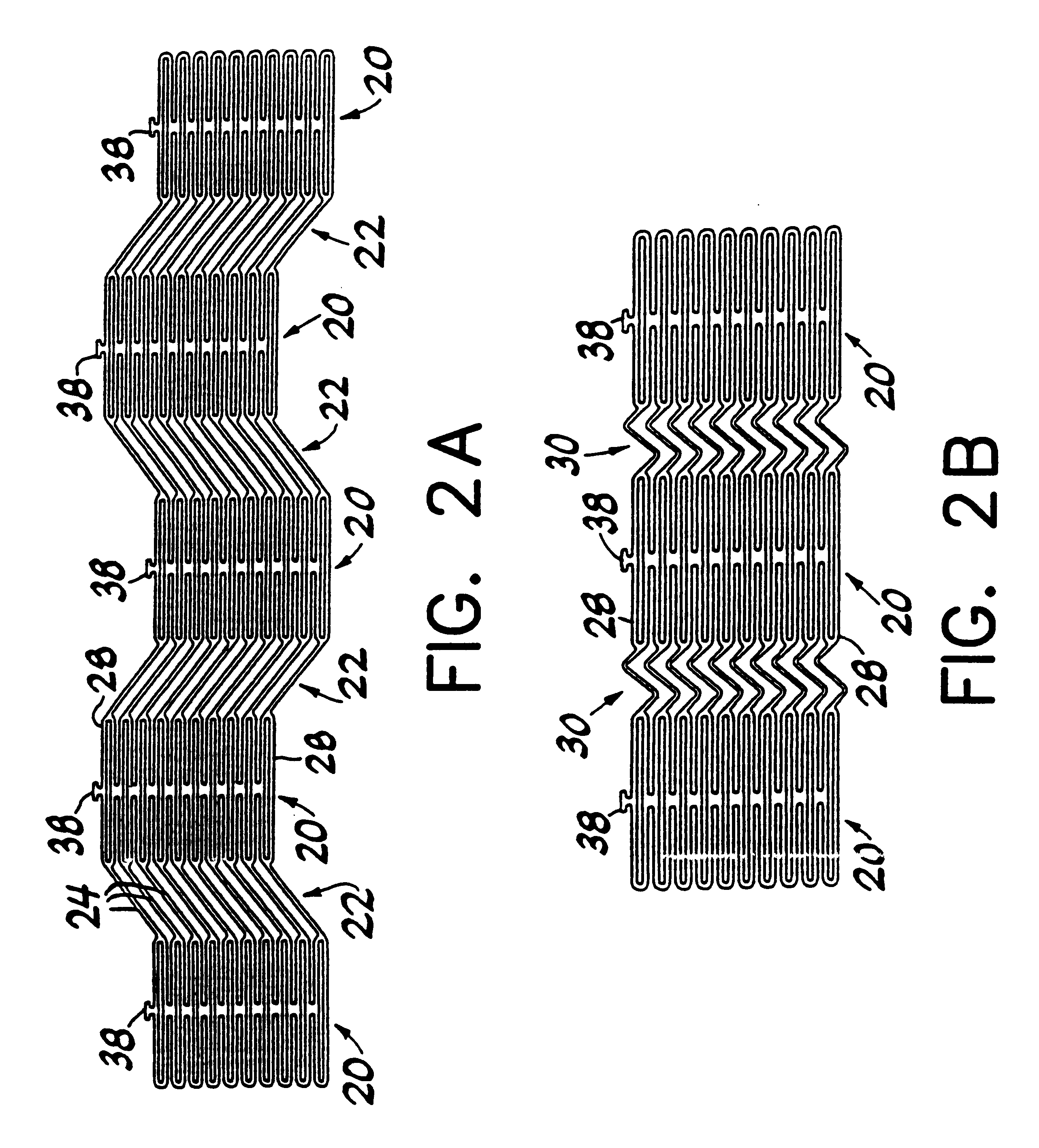

A stent and a method for fabricating the stent are disclosed. The stent has an originally flat pattern and connection points where the sides of the flat pattern are joined. The method includes the steps of a) cutting a stent pattern into a flat piece of metal thereby to produce a metal pattern, b) deforming the metal pattern so as to cause two opposing sides to meet, and c) joining the two opposing sides at least at one point. Substantially no portion of the stent projects into the lumen of the stent when the stent is expanded against the internal wall of a blood vessel.

Owner:MEDINOL LTD

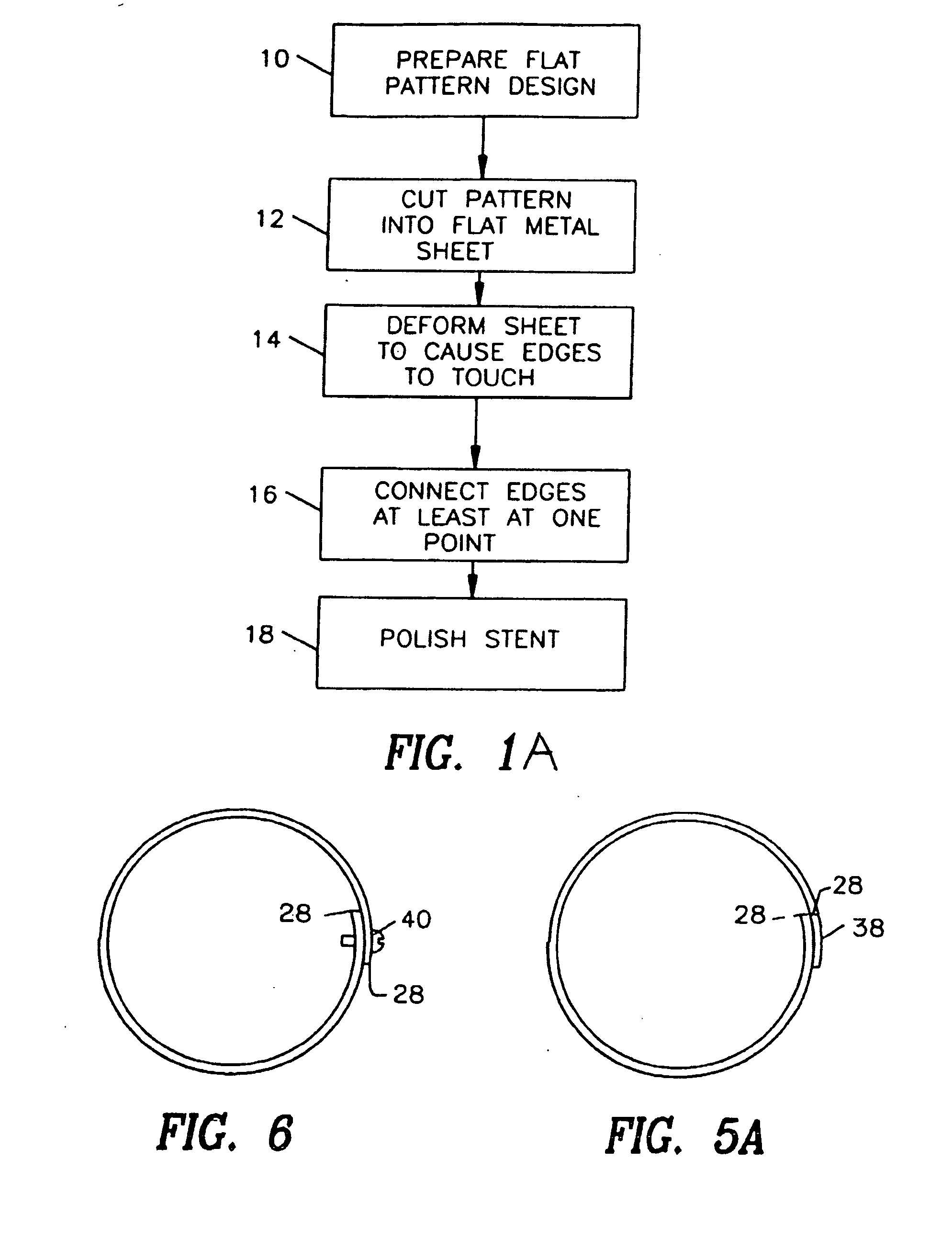

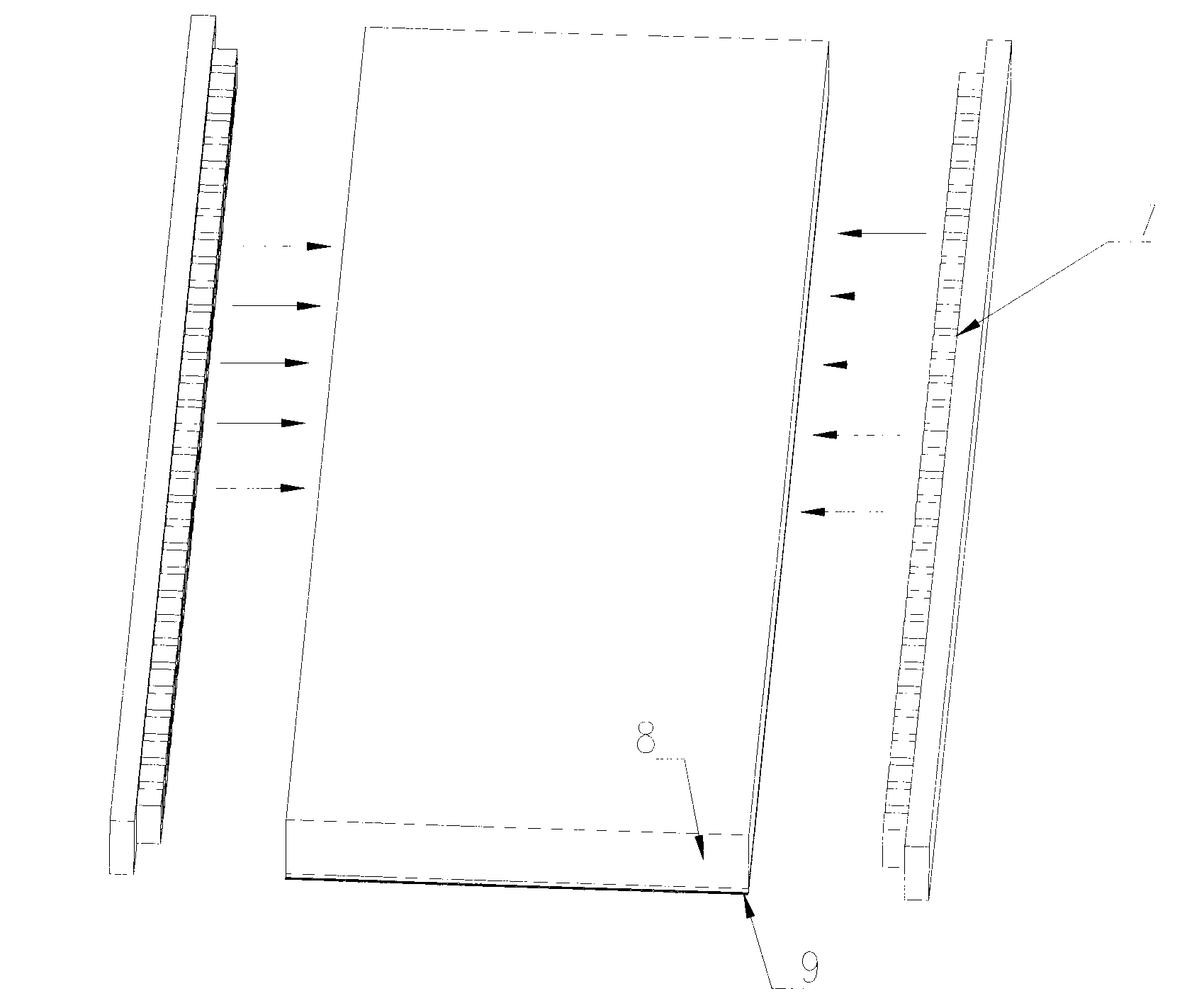

Flat process of drug coating for stents

InactiveUS20070077347A1Electropolishing step can be eliminatedExquisite designStentsSurgeryInsertion stentDrug-Coated Stents

A drug-coated stent and a method for fabricating the stent are disclosed. The stent has an originally flat pattern and connection points where the sides of the flat pattern are joined. The method includes the steps of a) cutting a stent pattern into a flat piece of metal thereby to produce a metal pattern, b) spraying the flat metal stent pattern with a polymer and a drug, c) deforming the metal pattern so as to cause two opposing sides to meet, and d) joining the two opposing sides at least at one point. Substantially no portion of the stent projects into the lumen of the stent when the stent is expanded against the internal wall of a blood vessel.

Owner:MEDINOL LTD

Surface covering panel

InactiveUS20080176039A1Sharper, deeper, more defined and detailed textured designExquisite designLamination ancillary operationsCovering/liningsBiomedical engineeringSurface cover

Owner:CHEN HAO A +1

Stent fabrication method and apparatus

A method is provided for electropolishing a stent. A stent is mounted on a rack having electropolishing mounts. Each of the mounts has a base and an electrically conductive first member having a first end and a second end. The first end is connected to the base and the second end contacts the external surface of the stent. Each of the mounts also has a non-electrically conductive second member having a first end and a second end. The first end of the second member is attached to the base and the second end is placed in the bore of the stent. The second ends of the first and second members bias towards each other to secure the stent between them. The stent is immersed in an electropolishing bath and an electrical current is applied to the first member.

Owner:MEDINOL LTD

Stent fabrication method

Owner:MEDINOL LTD

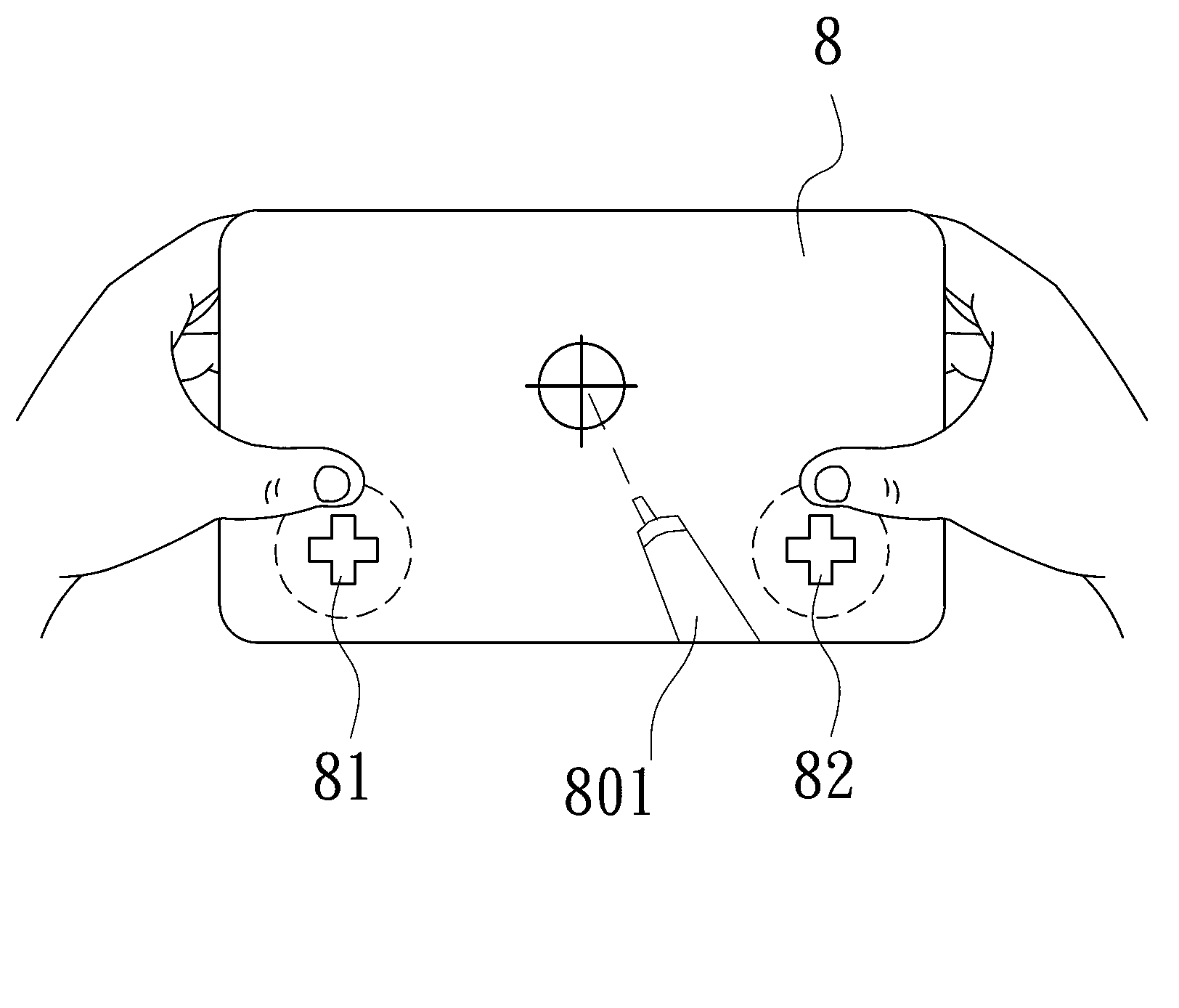

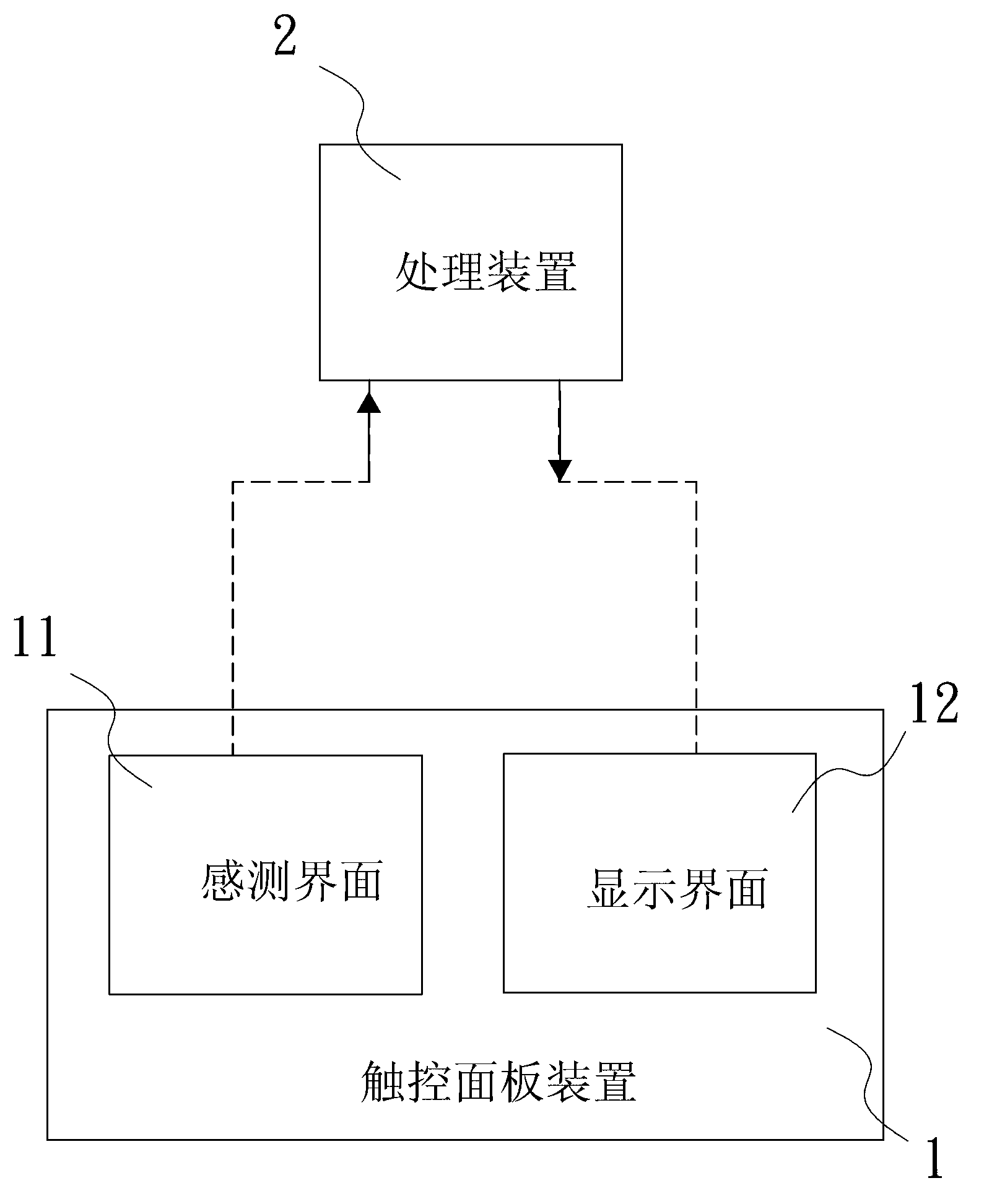

Game controlling method for use in touch panel medium and game medium

ActiveCN103252087AExquisite designImprove convenienceVideo gamesInput/output processes for data processingHuman–computer interactionTouch panel

The present invention provides a game controlling method for use in a touch panel medium. The medium includes a touch panel device and a processor device. The game includes a controlled virtual object displayed on the touch panel device, and the processor device is loaded with different programs specifically corresponding to different numbers of the initial points of touch. Upon receiving a touch signal indicative of the number of the initial points of touch from the touch panel device, one of the programs specifically corresponding to the number of the initial points of touch is executed to make the controlled virtual object demonstrate a specific activity. At least one of the programs should make the controlled virtual object continue to demonstrate the activity for a predetermined period of time after the touch is released.

Owner:FOURIER INFORMATION

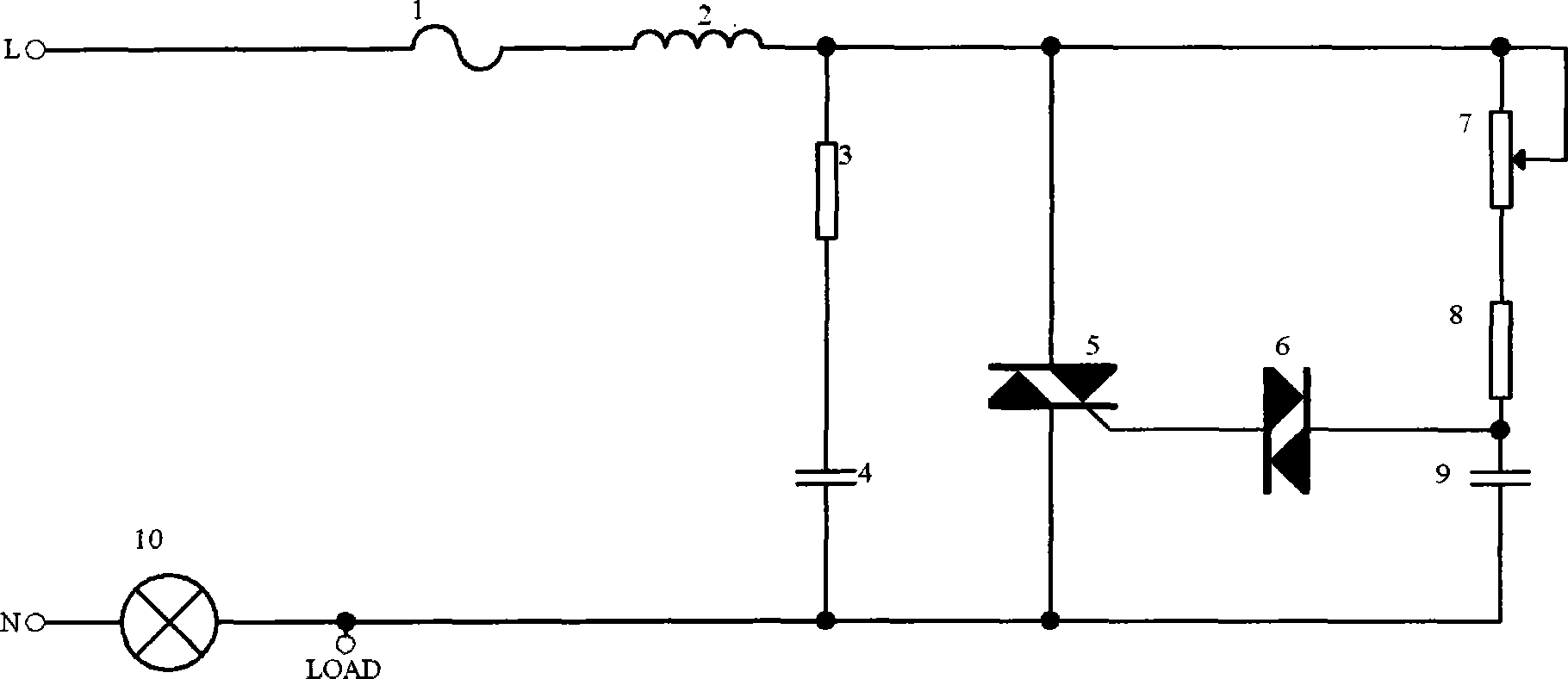

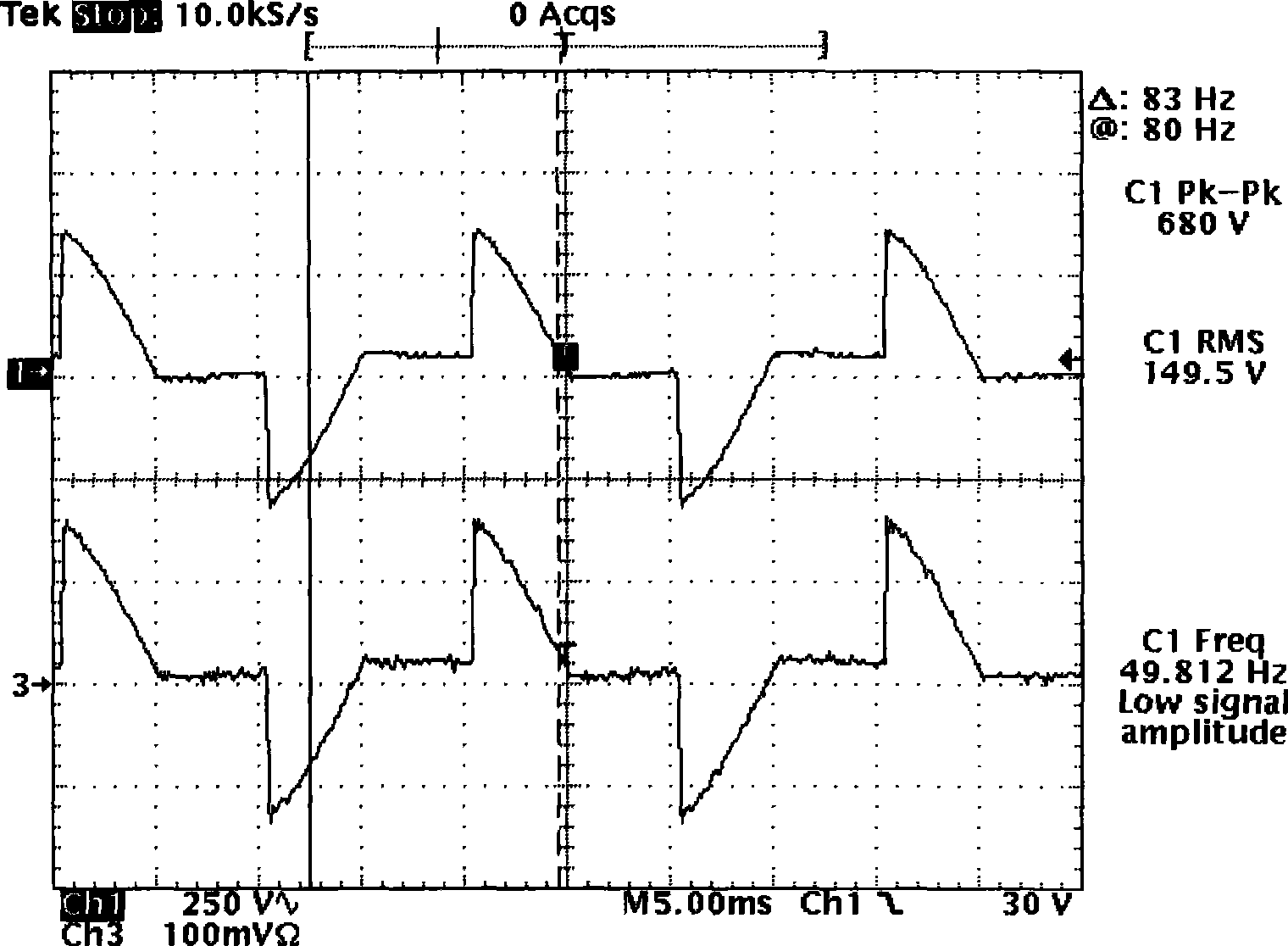

LED light modulating apparatus suitable for light modulator

InactiveCN101505568AExquisite designGood dimming effectAc-dc conversion without reversalElectric light circuit arrangementTransformerDimmer

The invention relates to an LED dimming device for a dimmer, which comprises a rectifier, a booster, a preamp voltage detecting circuit and a post voltage detecting circuit, a main control chip, a primary transformer, a secondary transformer, a secondary rectification and secondary filter circuit, and a diode switch. The LED dimming device for the dimmer can realize the brightness control of an LED bulb by using a controlled silicon dimmer and a transistor dimmer, and make the use of the energy-saving and environment-friendly LED more widely.

Owner:CIVILIGHT SHENZHEN SEMICON LIGHTING

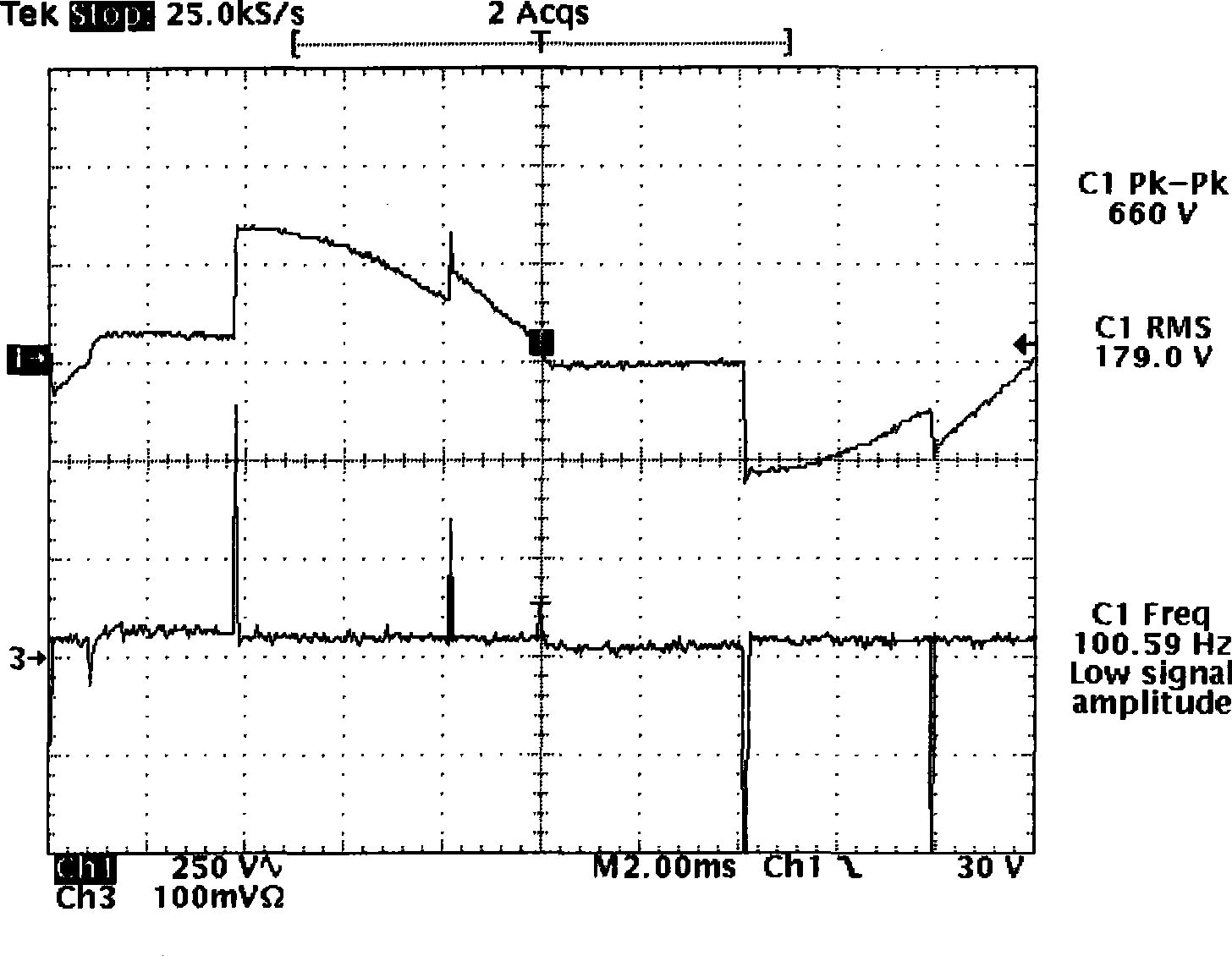

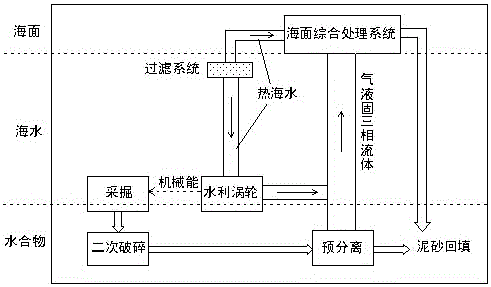

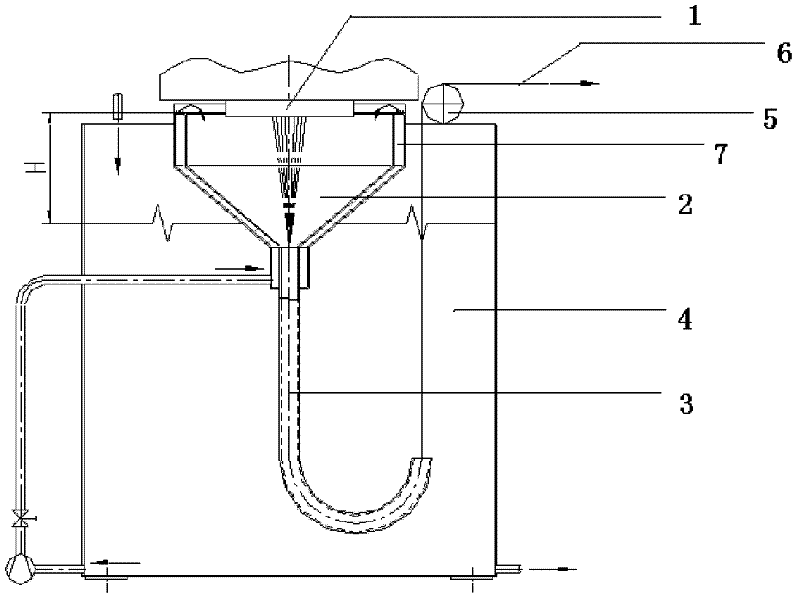

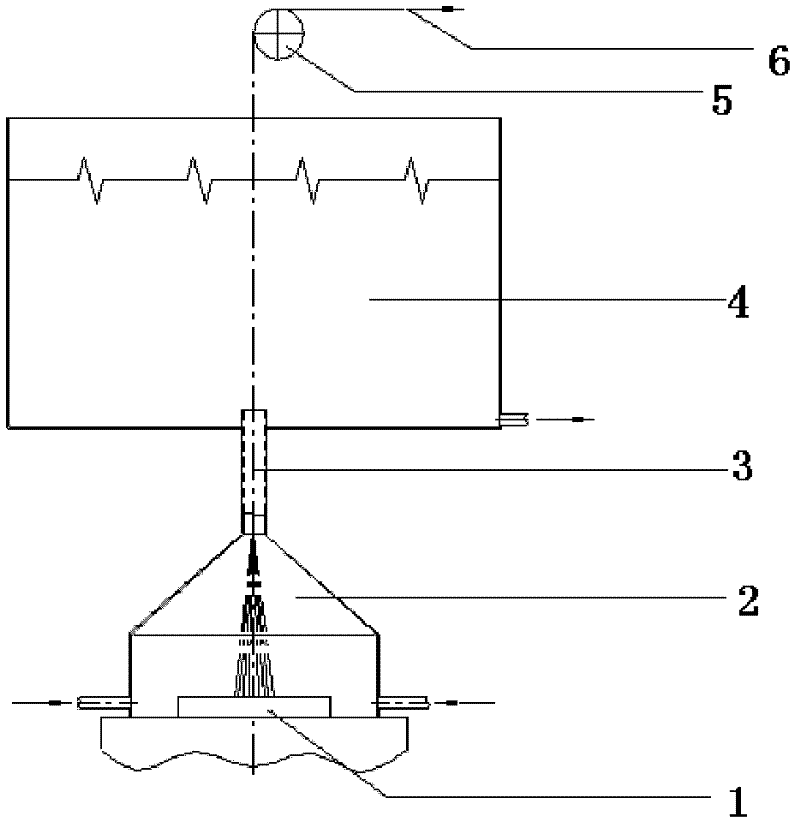

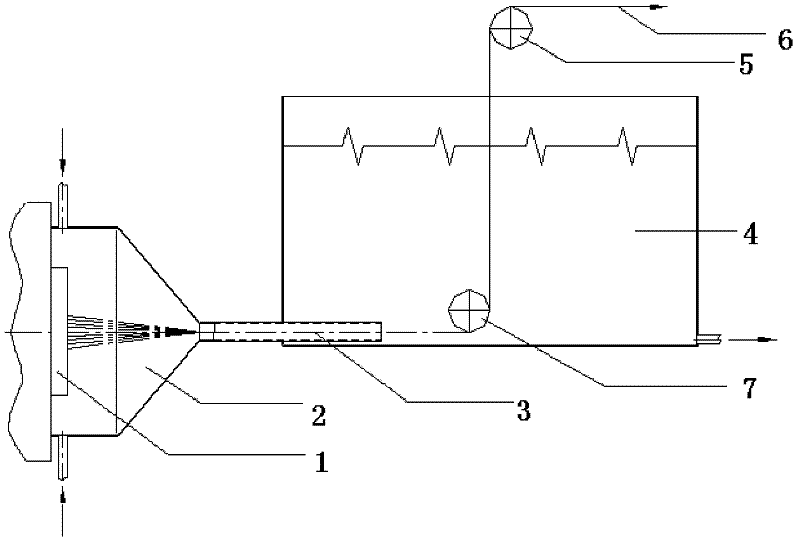

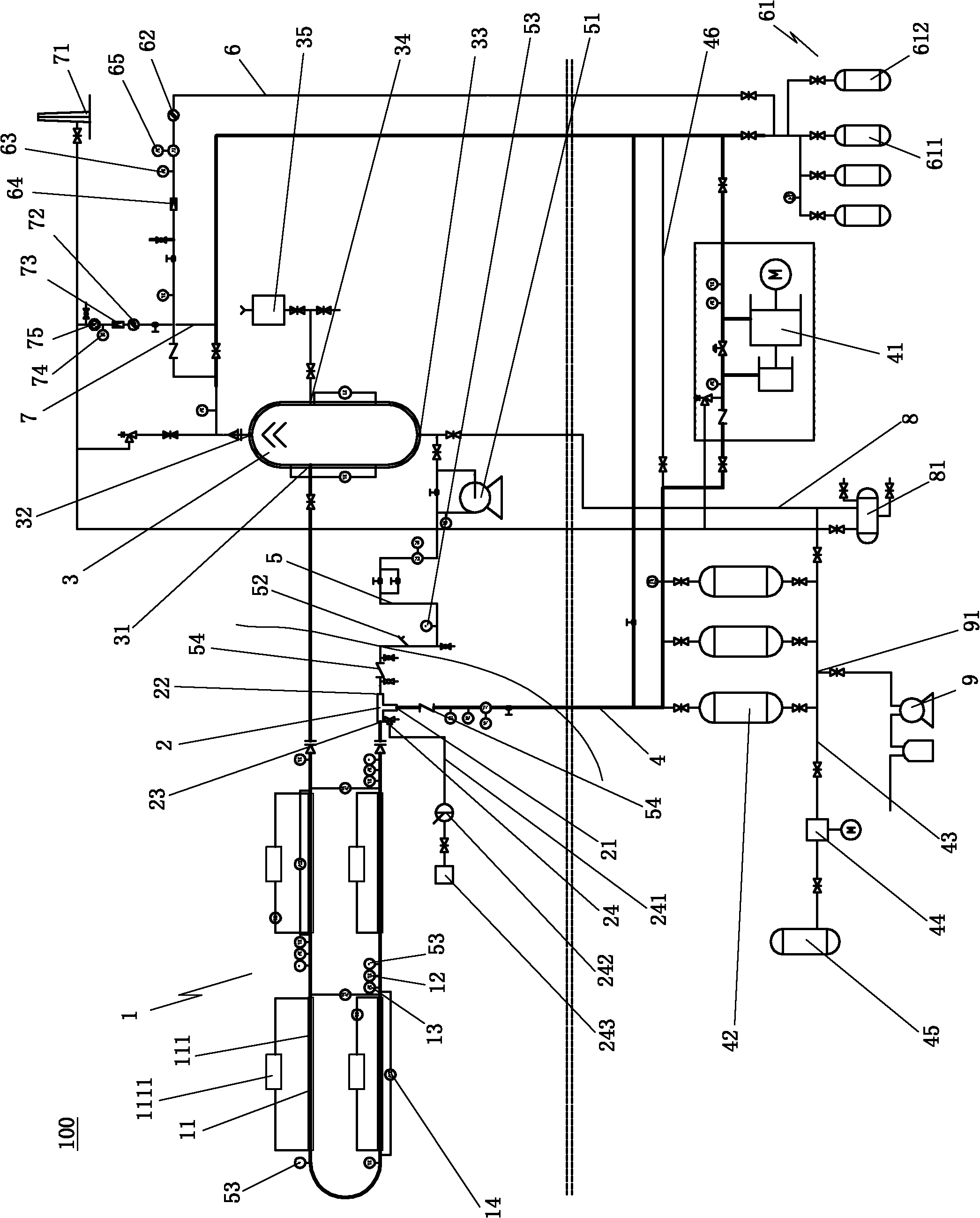

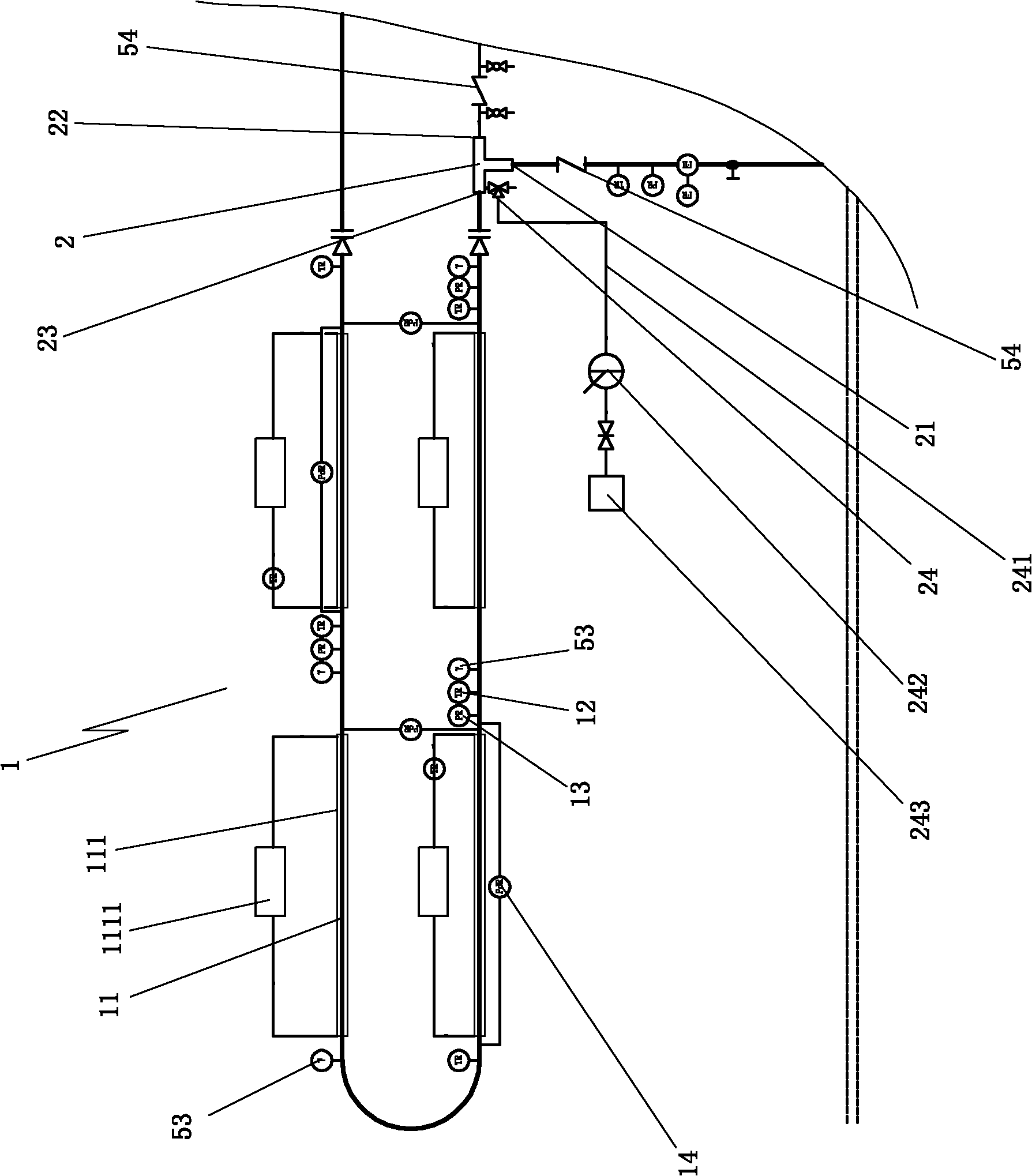

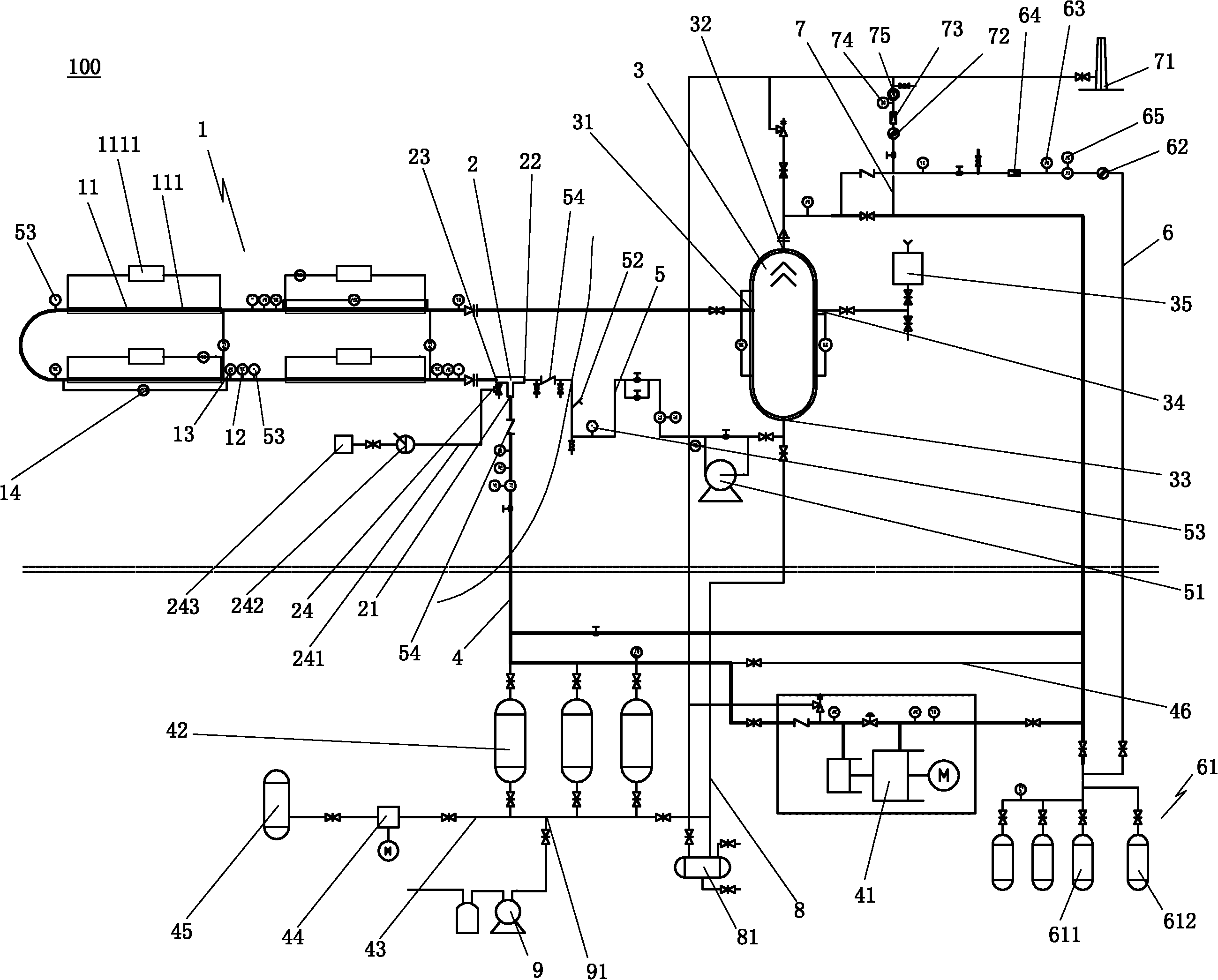

Method for green extraction of seabed unstratlfied rock natural gas hydrate

ActiveCN105064959ADoes not change temperatureDoes not change the pressureFluid removalExternal energySeawater

The invention discloses a method for green and energy-saving extraction of a seabed unstratlfied rock natural gas hydrate and belongs to the technical field of natural gas extraction. The method comprises the steps of pre-treatment of the natural gas hydrate, pre-collection of the natural gas hydrate, separation of the natural gas hydrate, and collection of the natural gas hydrate. The working principle is that on the premise that the ambient temperature and pressure of a natural gas hydrate formation are not changed, natural gas hydrate solid sediment is extracted through submarine mining, phase change is conducted on the natural gas hydrate by means of hot seawater to generate an airlift effect, and then the natural gas hydrate is lifted the sea surface to be processed and natural gas is collected finally. Meanwhile, the airlift effect serves as the power source of an extraction head, external energy consumption is reduced, and sea pollution is avoided. The method is a green natural gas collection method.

Owner:SOUTHWEST PETROLEUM UNIV

Cellulose fiber, preparation method thereof and equipment

ActiveCN102477591AHigh strengthSmall denierArtificial filaments from cellulose solutionsArtificial thread manufacturing machinesPolymer scienceSpinning

The invention relates to the field of chemical fibers, in particular to a cellulous fiber, a preparation method thereof and equipment. The cellulose fiber mainly comprises cellulous, is prepared by the solidifying liquid co-current drawing and spinning technology, and meets the following conditions that the tension breakage strength of the fiber is higher than or equal to 2.0cN / dtex, the fineness of the fiber is equal to or smaller than 1.67dtex, the content of S elements in the fiber is smaller than or equal to 100ppm, the fibrillation index (F.I.) of the fiber is smaller than or equal to 2. In addition, the cellulose fiber is free of chemical compositions relevant to fibrillation treatment resistance. The invention further relates to the preparation method of the cellulous fiber and the equipment. The cellulose fiber is high in strength, low in fineness and free of fibrillation tendency, the preparation method is simple, and is easy to control and applicable to large-scale industrialized production, and the equipment is simple in structure, skillful in design and stable in condition.

Owner:CHINESE TEXTILE ACAD

Stereoscopic vision detection machine for parts and detection method thereof

PendingCN106872474AAvoid damageExquisite designOptically investigating flaws/contaminationProgramme control in sequence/logic controllersControl systemEngineering

The invention discloses a stereoscopic vision detection machine for parts and a detection method thereof. The detection machine comprises a rotating disc, six shooting stations and a control system, wherein the rotating disc is used for bearing a to-be-detected part and driving the to-be-detected part to rotate; the six shooting stations are used for acquiring six-face images of the to-be-detected part; the control system is at least used for judging whether the to-be-detected part is qualified or unqualified according to the image acquired at each shooting station; when the to-be-detected part is determined to be unqualified, projections of a circular ring formed by a subsequent movement track of the to-be-detected part and a circular ring formed by an initial movement track of the part on the same plane parallel to the rotating disc are concentric and do not coincide with each other. By virtue of the rotating disc made of an optical transparent material, an extra delivery structure does not need to be increased to enable the to-be-detected part to be suspended, and possible damage caused by up-and-down movement of the to-be-detected part is avoided. Moreover, a complicated delivery structure is not needed, the structure is greatly simplified, and partitioned discharging is realized by a dislocation device and a discharging mechanism.

Owner:张天山

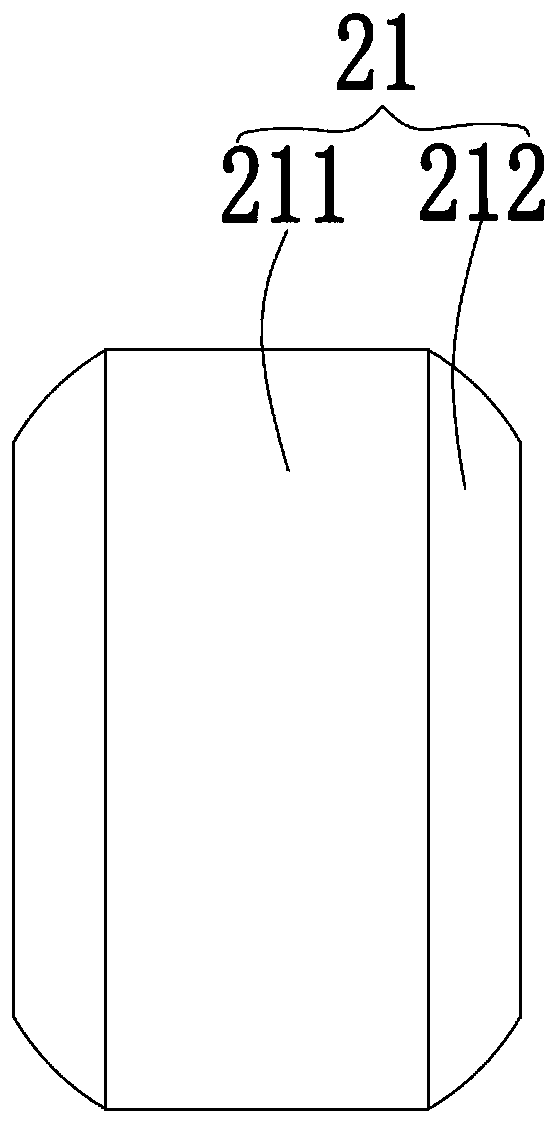

Battery cell appearance visual inspection equipment and detection method thereof

PendingCN107402219ASatisfy the pipeline online detectionExquisite designMaterial analysis by optical meansVisual inspectionAssembly line

The invention discloses battery cell appearance visual inspection equipment and a detection method thereof. The battery cell appearance visual inspection equipment comprises a first shooting station, a battery cell clamping and conveying mechanism, a second shooting station and a battery cell conveying and rotating mechanism, wherein the bottom surface or top surface of a battery cell is subjected to image acquisition by a shooting module at the first shooting station; the battery cell clamping and conveying mechanism is at least used for clamping at least one battery cell and driving the battery cell to move to the upper side or lower side of the first shooting station; other five surfaces of the battery cell are subjected to image acquisition twice by virtue of three shooting modules at the second shooting station; and the battery cell conveying and rotating mechanism can fix and drive the battery cell positioned thereon to rotate and convey the battery cell to a blanking station after the image is acquired at the second shooting station. According to the battery cell appearance visual inspection equipment disclosed by the invention, the requirement for detecting the six surfaces of the battery cell can be met by adopting the four shooting modules, partial shooting modules are saved, and the equipment cost is greatly reduced. Moreover, when six-surface detection of the battery cell is met, the assembly line type online detection of the battery cell is effectively met by the conveying mechanism, and the detection efficiency is improved.

Owner:SUZHOU JEE INTELLIGENT EQUIP CO LTD

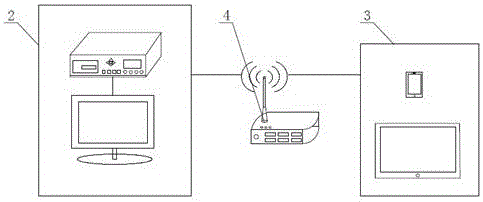

Plant management system and method for garden and landscape engineering based on two-dimensional codes

InactiveCN105844408AImprove confidentialitySolve the problem of limited display contentResourcesRecord carriers used with machinesAgricultural engineeringLandscape engineering

The invention discloses a plant management system and method for garden and landscape engineering based on two-dimensional codes. The system comprises: nameplates which are provided with two-dimensional codes and are fixed on trees for identifying the trees; a big data platform which is provided with configuration software and is used for receiving, processing, storing and outputting tree information corresponding to the two-dimensional codes; multiple user sides which are provided with configuration software and two-dimensional code scanning function, and are used for reading tree information in the big data platform through different permissions and / or scanning two-dimensional codes, inputting tree information into the big data platform and downloading applications from the big data platform; and a network which is used for interactive communication between the big data platform and user sides. According to the system and the method, the two-dimensional code technology is combined with the big data platform technology which helps users obtain comprehensive information of trees so that the problem that display content is limited by the limitation of nameplate area is solved; and planter information is kept secret to prevent information leakage.

Owner:SUZHOU GREEN PLANT FULL STACK INFORMATION TECH CO LTD

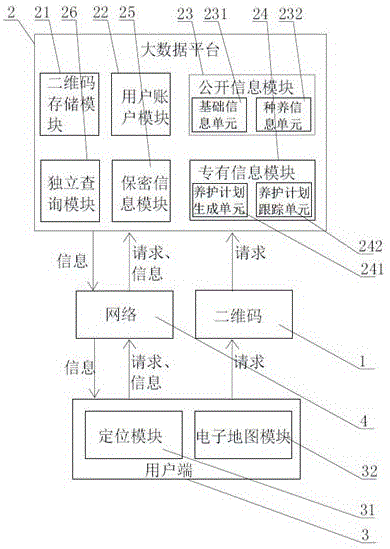

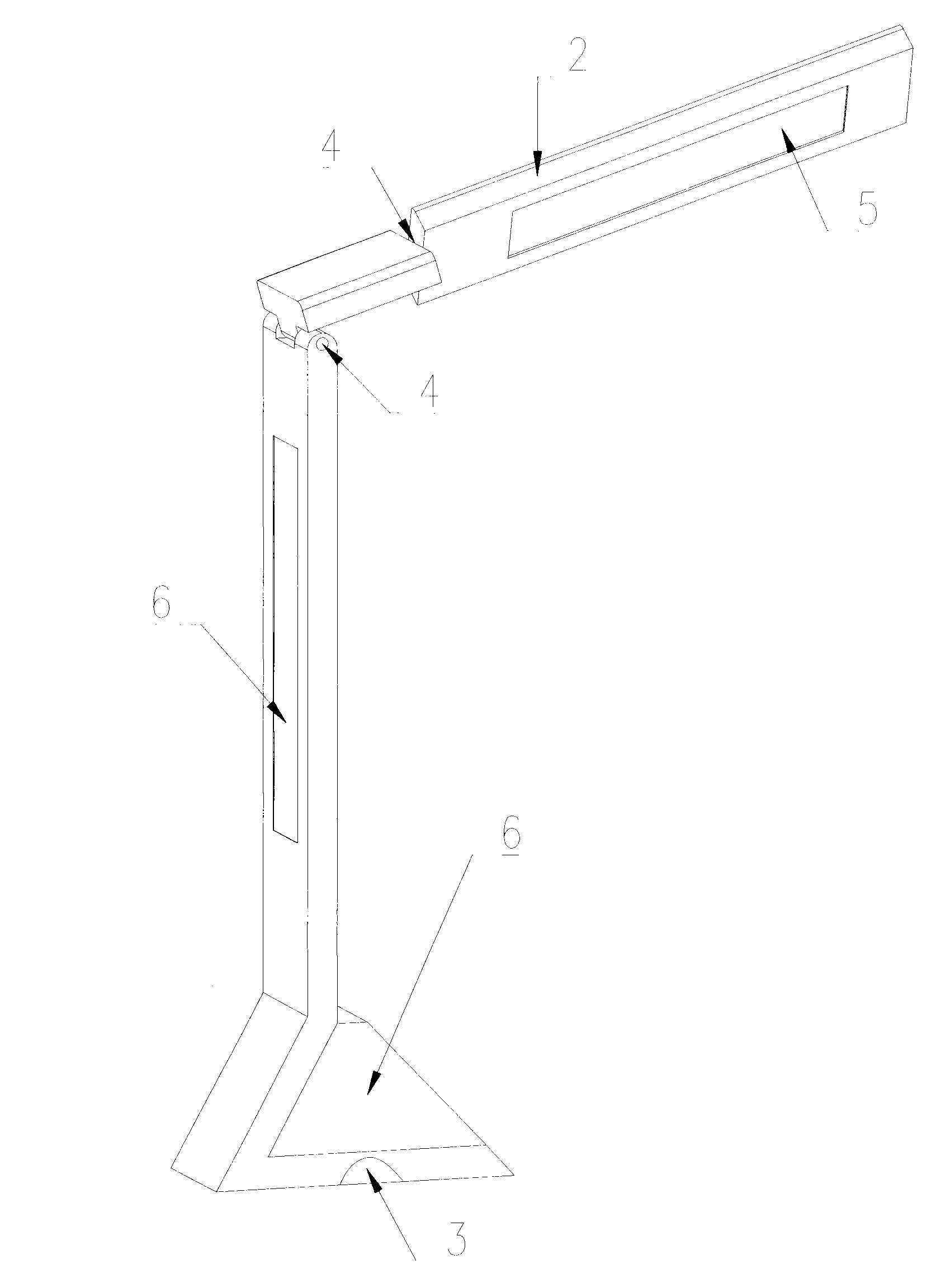

Light-emitting diode (LED) eye-protecting lamp with multiple illuminators

InactiveCN103133967AExquisite designHas an aesthetic effectMechanical apparatusLighting support devicesLow voltageEffect light

The invention provides a light-emitting diode (LED) eye-protecting lamp with multiple illuminators which comprises an LED area light source, a heat dissipating shell, a rotating shaft structure matched with a natural light sensor and a low-voltage direct current drive controller used for adjusting brightness. The LED eye-protecting lamp with multiple illuminators has the advantages that adjustment control function is intelligent, low-voltage input is safe, appearance of the eye-protecting lamp can be designed variously, problems of direct glare of the light source illuminators and indirect glare of the lighting device are solved under the condition that high-light of the eye-protecting lamp is ensured, structure is reasonable and compact, manufacturing is convenient, purposes of energy-efficient, environmental protection, conscious, flicker-free, no radiation, no glare, no shadows and no light pollution are achieved truly, and the LED eye-protecting lamp with multiple illuminators has high social benefits and economic benefits.

Owner:吴明番

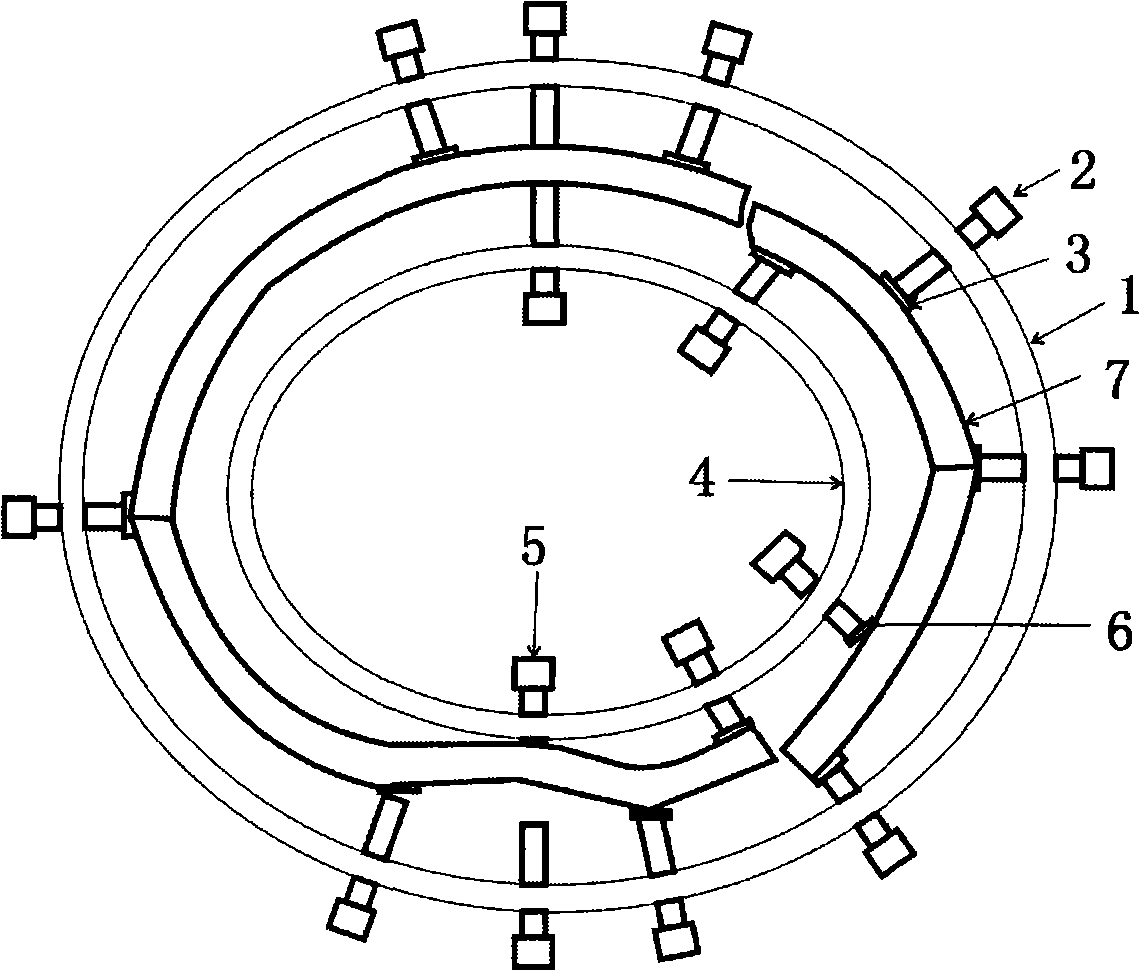

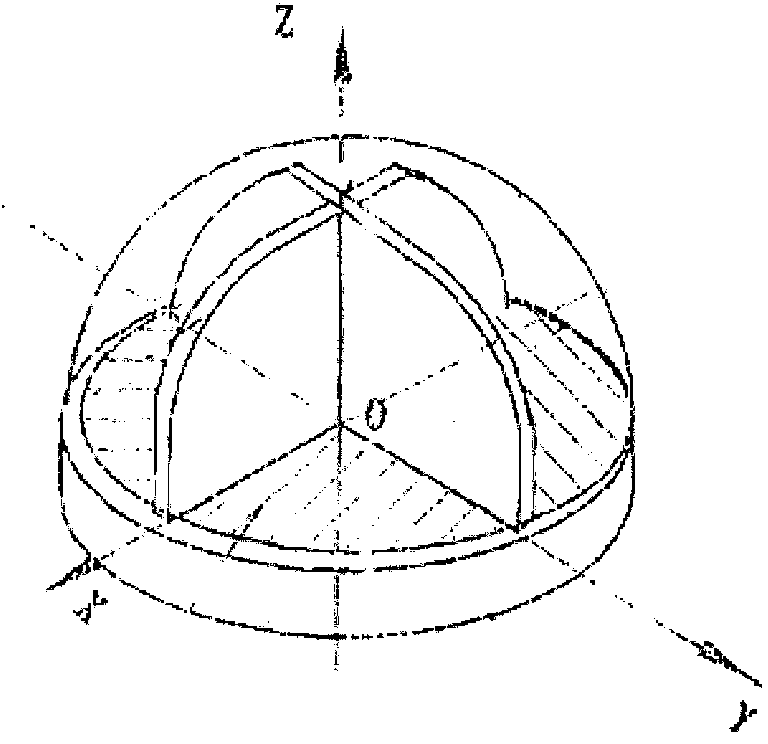

Damaged deformation bronze ware correcting locating and repairing device and method thereby

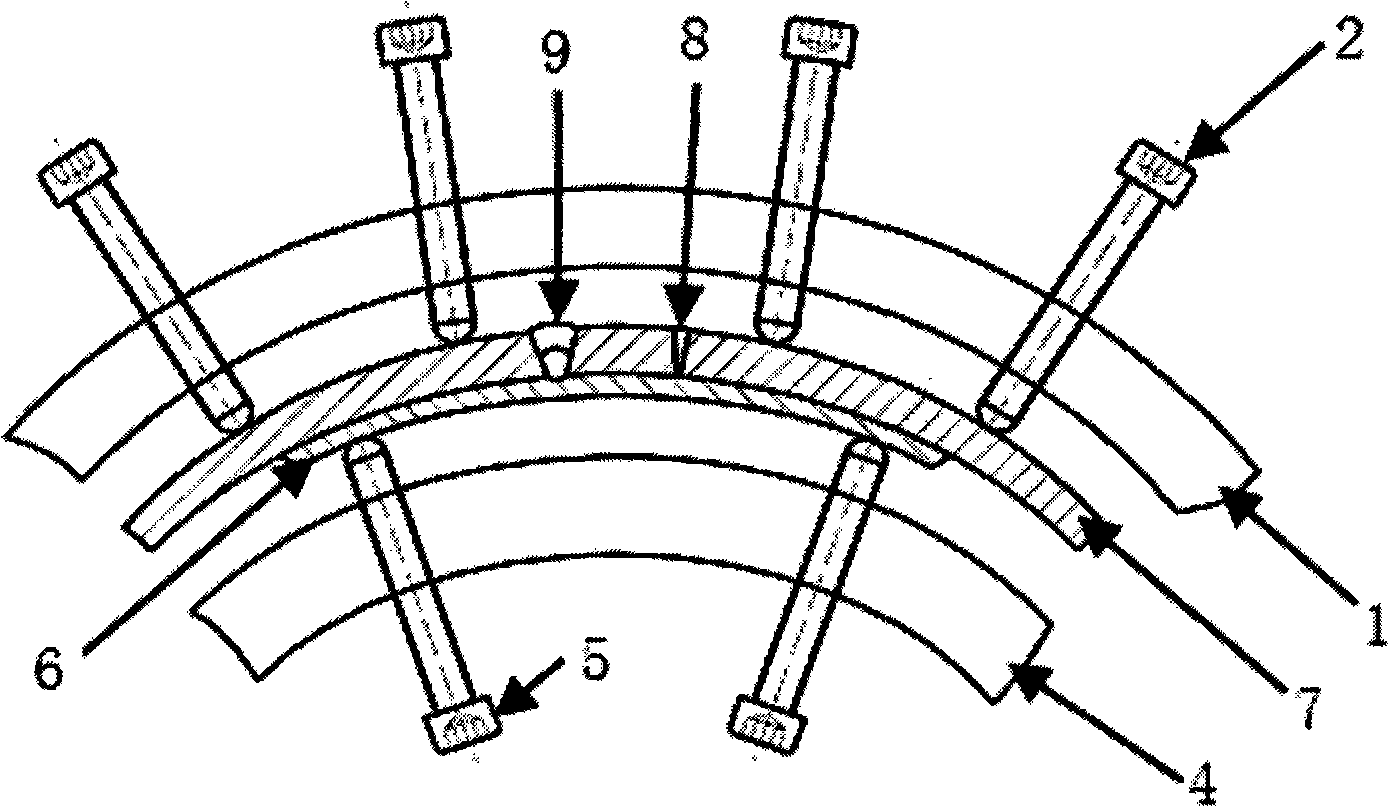

InactiveCN101264562ASimultaneous recoveryGuarantee smooth implementationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringBronze

The invention discloses a reparation device and a method thereof for the shape-righting and positioning of damaged and distorted bronze ware, belonging to the technical field of relic restoration, which is characterized in that an inner ring (4) is arranged in a damaged and distorted bronze ware (7); an inner adjusting bolt is connected with an inner gasket (6) on the inner wall of the damaged and distorted bronze through a plurality of screw holes on the inner ring (4); an outer ring (1) is arranged outside the damaged and distorted bronze ware (7); an outer adjusting bolt is connected with an outer gasket (3) on the outer wall of the damaged and distorted bronze through a plurality of screw holes on the outer ring (1); the screw holes on the outer ring (1) and the inner ring (4) are evenly distributed. The reparation device and method for the shape-righting and positioning of damaged and distorted bronze ware has an advantage that shape-righting and positioning of seriously damaged and distorted bronze ware are realized to ensure successful laser welding reparation.

Owner:湖北省博物馆

Wax deposition experimental device

InactiveCN102062744AReasonable structureExquisite designParticle size analysisInvestigating phase/state changeWax depositionEngineering

The invention relates to a wax deposition experimental device. The experimental device comprises an experimental pipeline, wherein on end of the experimental pipeline is communicated to an outlet of a gas and liquid mixer; the other end of the experimental pipeline is communicated to a liquid return port of the gas and liquid separator; a gas inlet of the gas and liquid mixer is communicated to an exhaust port of the gas and liquid separator through a circulation compressor; a liquid inlet of the gas and liquid mixer is communicated to a liquid discharging port of the gas and liquid separator through a multiphase pump; a pipeline between the multiphase pump and the liquid inlet of the gas and liquid mixer is also provided with a laser particle size analyzer and an on-line gamma phase fraction instrument; the experimental pipeline is provided with a plurality of measuring sections at intervals; each measuring section can be detachably serially connected to the experimental pipe, the outer sides of the pipeline of all measuring sections are respectively provided with a temperature control water bath jacket; and the inlet end of each measuring section of the pipeline is respectively provided with one on-line gamma phase fraction instrument. The experimental device has the characteristics of reasonable structure, ingenious design, advanced experimental equipment, wide application range, accurate measurement and the like and can save the experimental cost and reduce emission of harmful gas.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

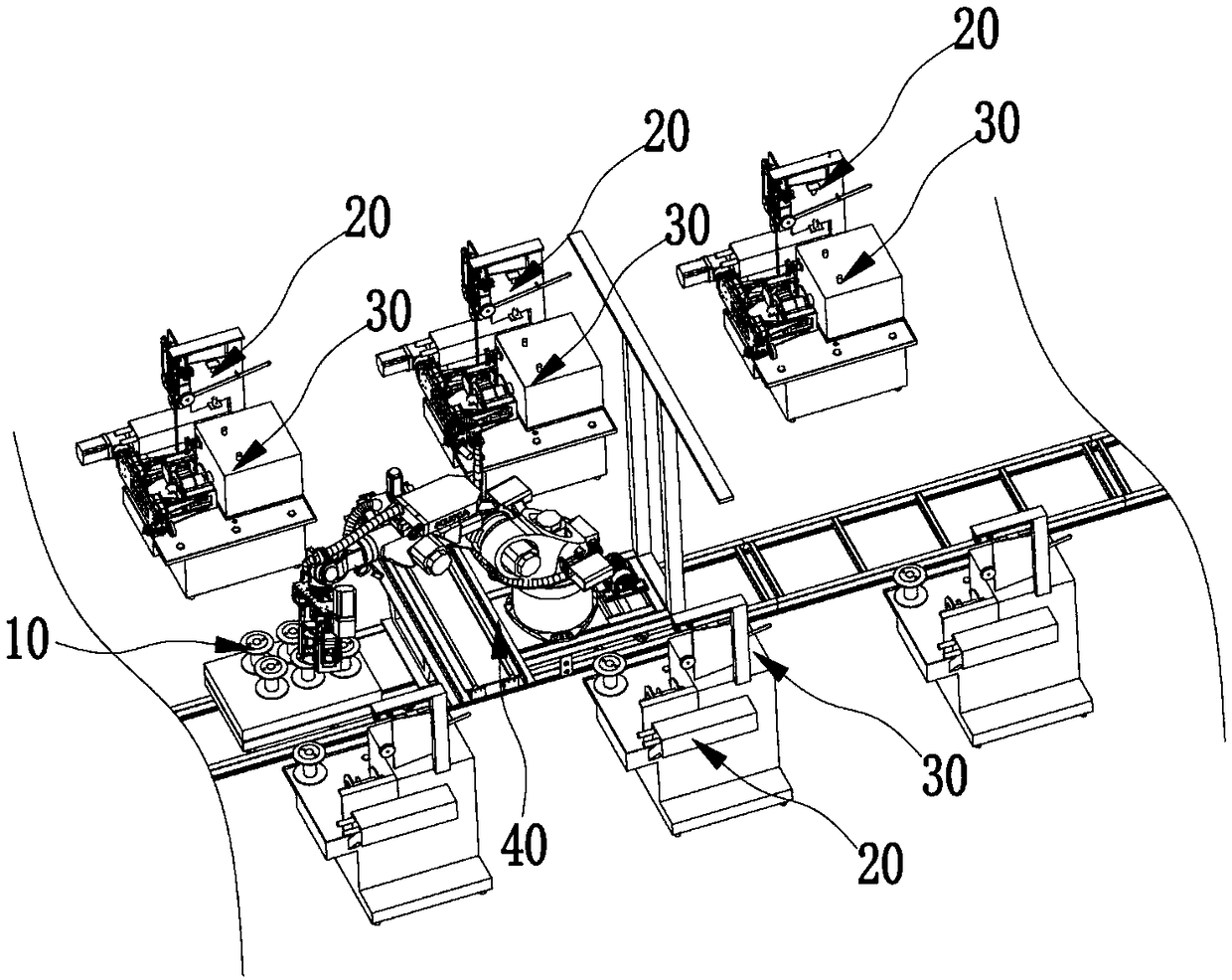

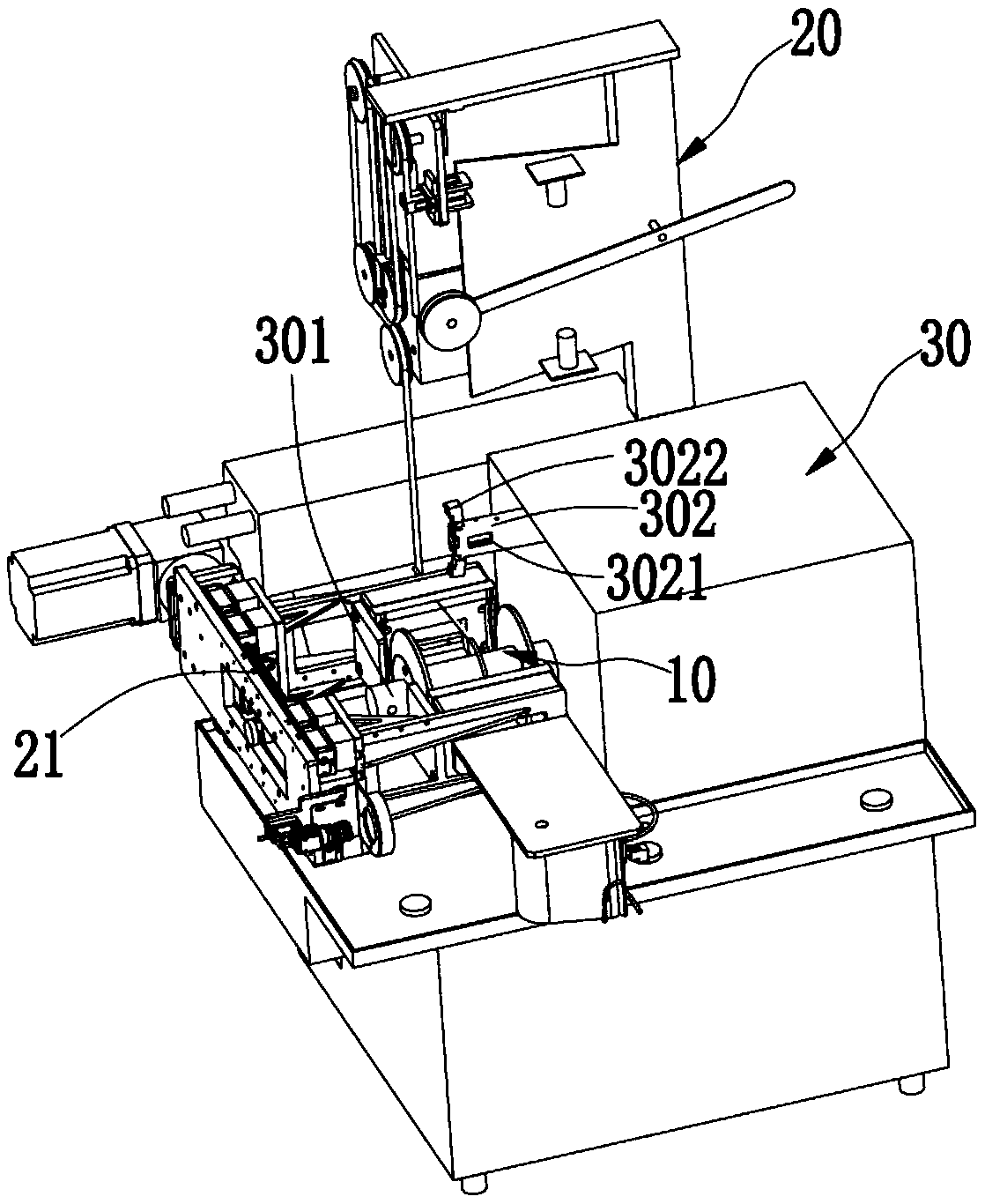

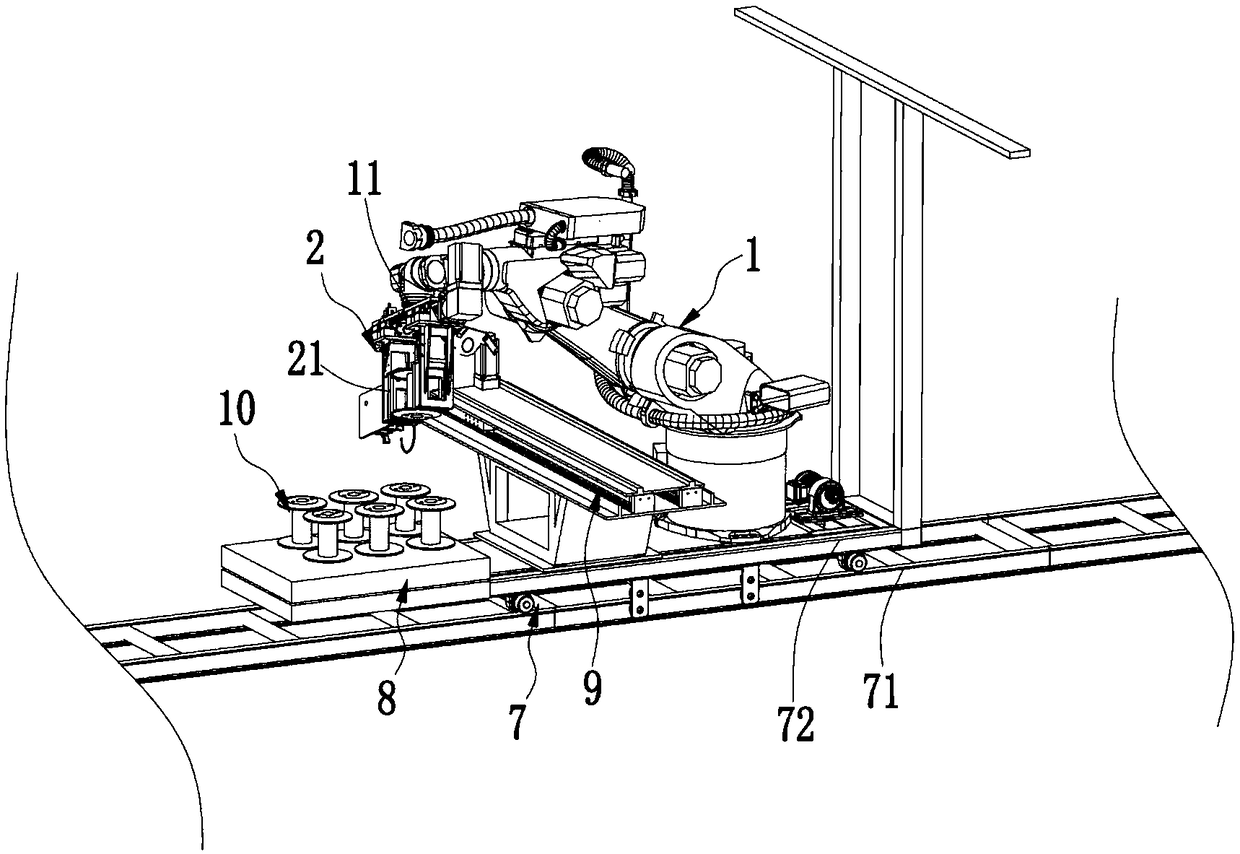

Full-automatic winding production line and processing method thereof

PendingCN109436951ASimple structureIncrease flexibilityFilament handlingProduction lineWinding machine

The invention discloses a full-automatic winding production line and a processing method thereof. The full-automatic winding production line comprises at least one automatic feeding machine, at leastone winding machine and an automatic winding disc feeding and discharging robot, wherein the automatic feeding machine is used for supplying a filament-shaped body; the winding machine is used for fixing a winding disc and driving the winding disc to rotate; and the automatic winding disc feeding and discharging machine can move the winding disc onto the winding machine and taking the winding discdown from the winding machine, and the position of the filament-shaped body can be determined visually when the filament-shaped body is grabbed and cut off. According to the scheme, the automatic winding disc feeding and discharging robot cooperates with the automatic feeding machine and the winding machine, so that the whole process of feeding, winding and discharging is achieved automatically,and the novel full-automatic winding production line which is simple in structure and capable of controlling the winding process easily is provided; in addition, the visual positioning technique can effectively and accurately determine the position of the filament-shaped body, so that automatic grabbing and shearing are made possible; and the visual positioning technique is good in flexibility andhigh in accuracy and efficiency, so that the winding efficiency is improved.

Owner:WUXI MINGONG TECH

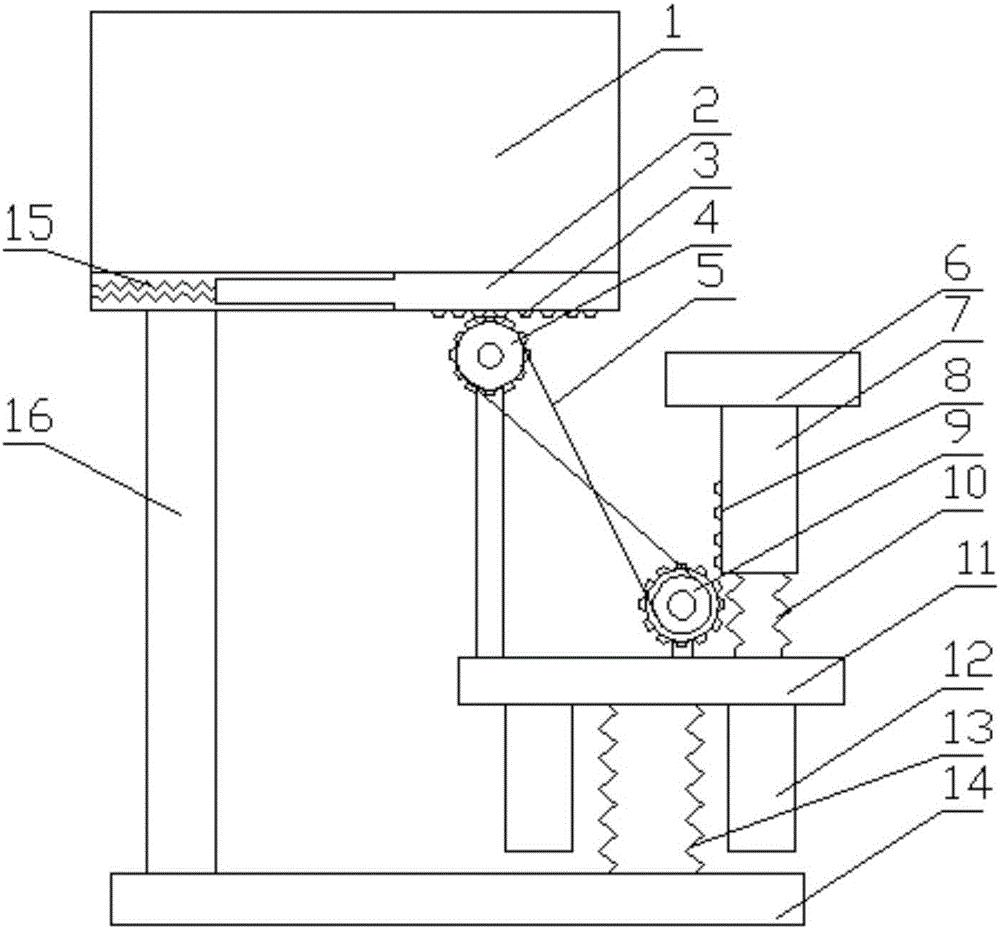

Poultry feeding device with continuous quantitative feeding function

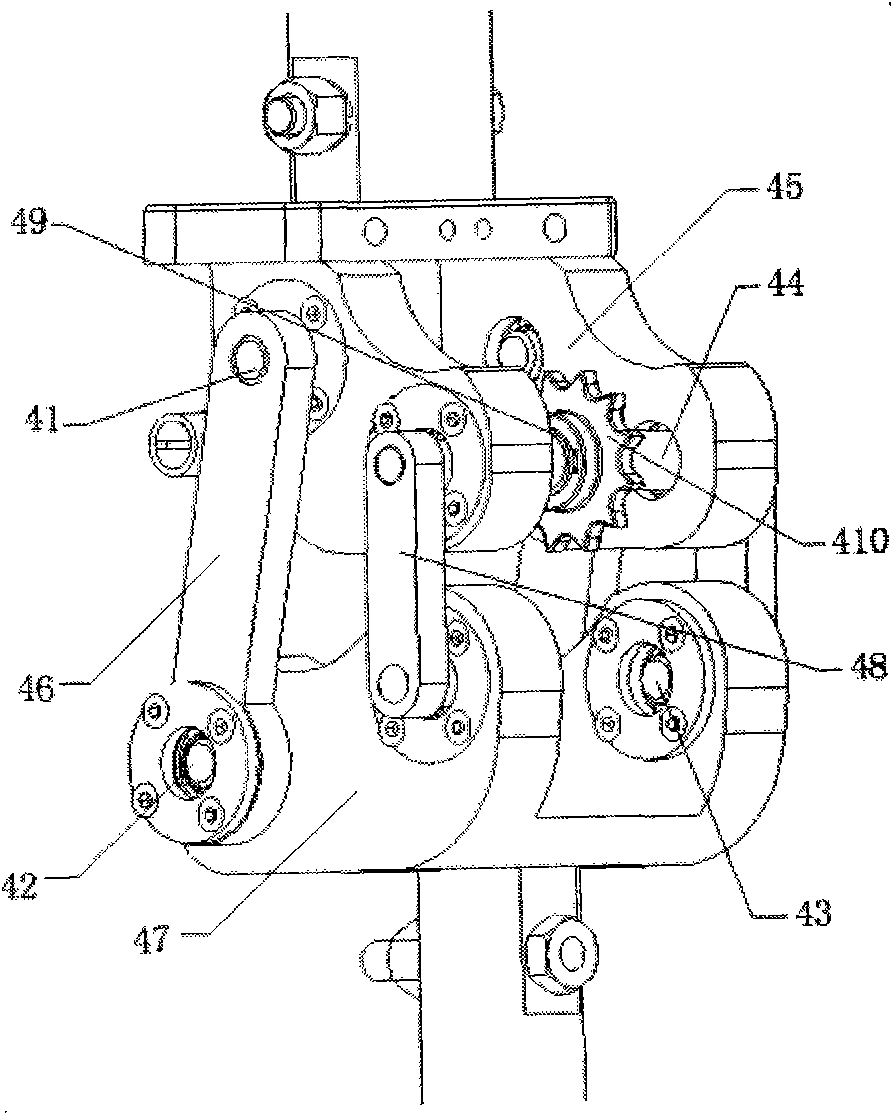

ActiveCN106069848AWith continuous quantitative feeding functionExquisite designAnimal feeding devicesAvicultureGear wheelEngineering

The invention relates to a poultry feeding device with a continuous quantitative feeding function. The poultry feeding device comprises a feed bin, a supporting rod, a base plate and a treading mechanism, wherein the feed bin is fixed above the base plate by virtue of the supporting rod, the feed bin comprises a bin body, a sliding plate and a first strip-shaped gear, and the treading mechanism comprises a pedal, a first stop block, a first spring, a second strip-shaped gear, a first circular gear, a second circular gear, a supporting plate, a second stop block and a second spring. The poultry feeding device with the continuous quantitative feeding function is delicate in design and smart in structure, and when livestock treads the pedal, firstly the first spring with relatively low elasticity is compressed, the sliding plate slides away and feed in the feed bin is given out, and then the second spring with relatively high elasticity is compressed, so that the first circular gear is separated from the first strip-shaped gear, the sliding plate is reset, and the feed bin is closed. Therefore, food is continuously thrown in, the condition that too much food is thrown in at a time can not appear, the livestock can take more exercise, and health degree of the livestock is improved.

Owner:樱源有限公司

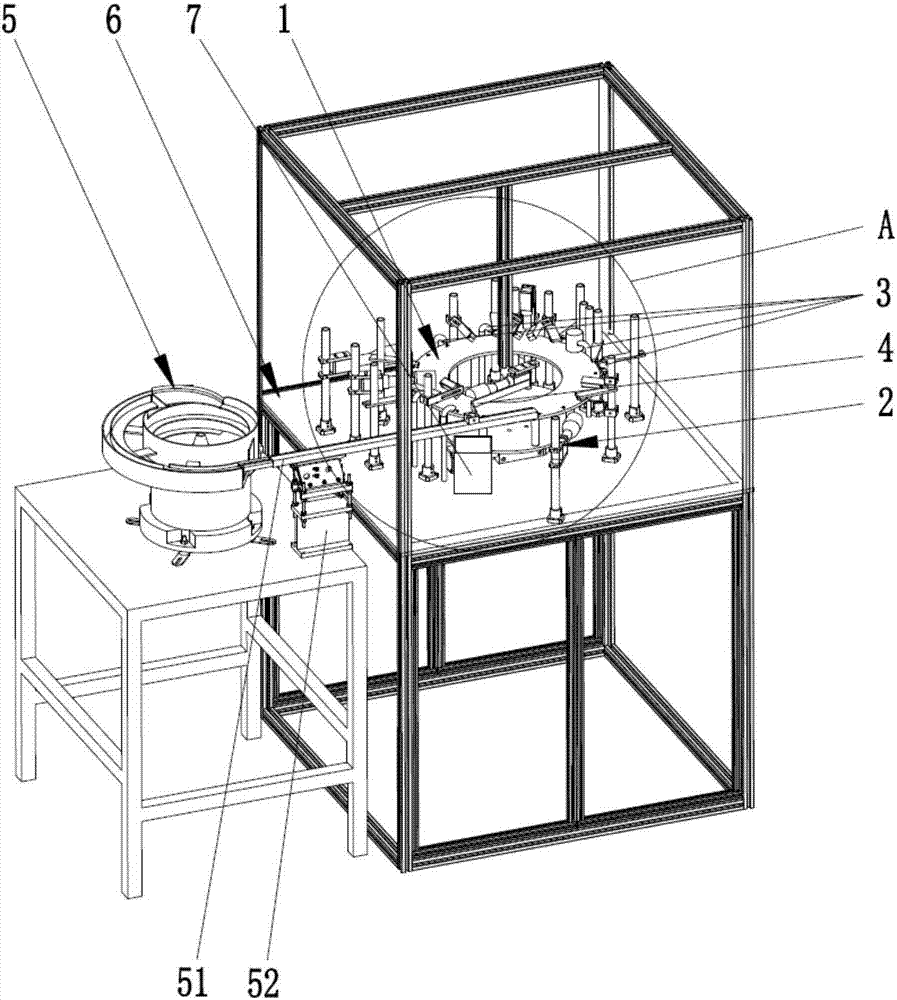

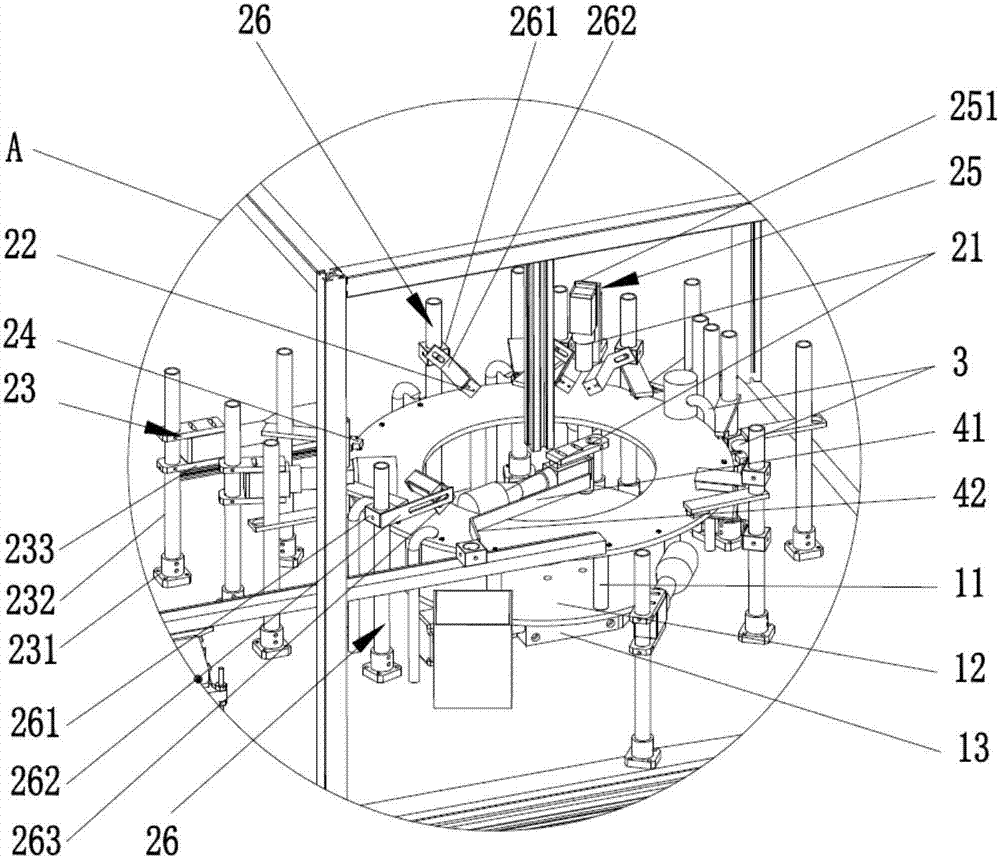

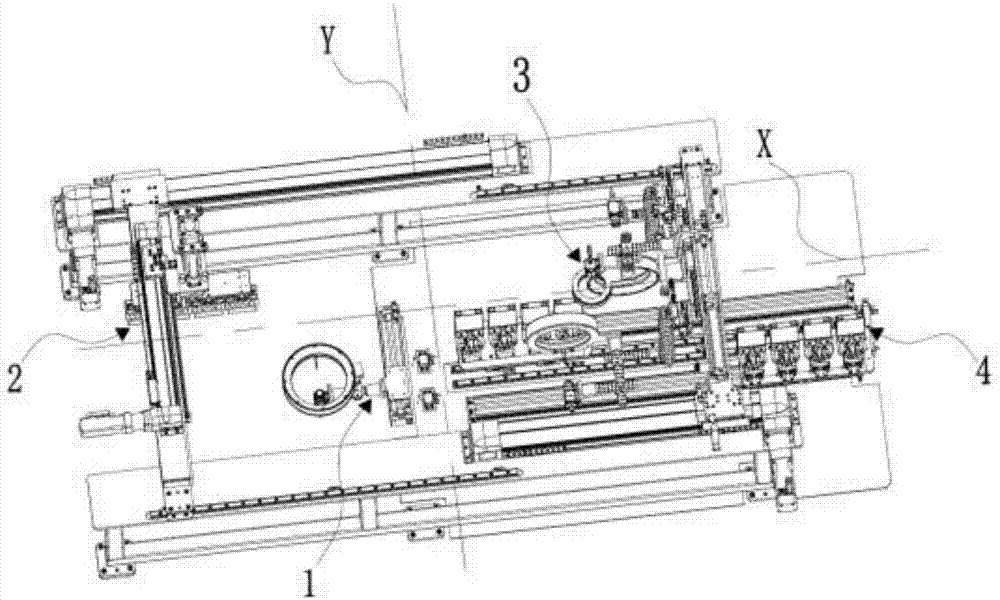

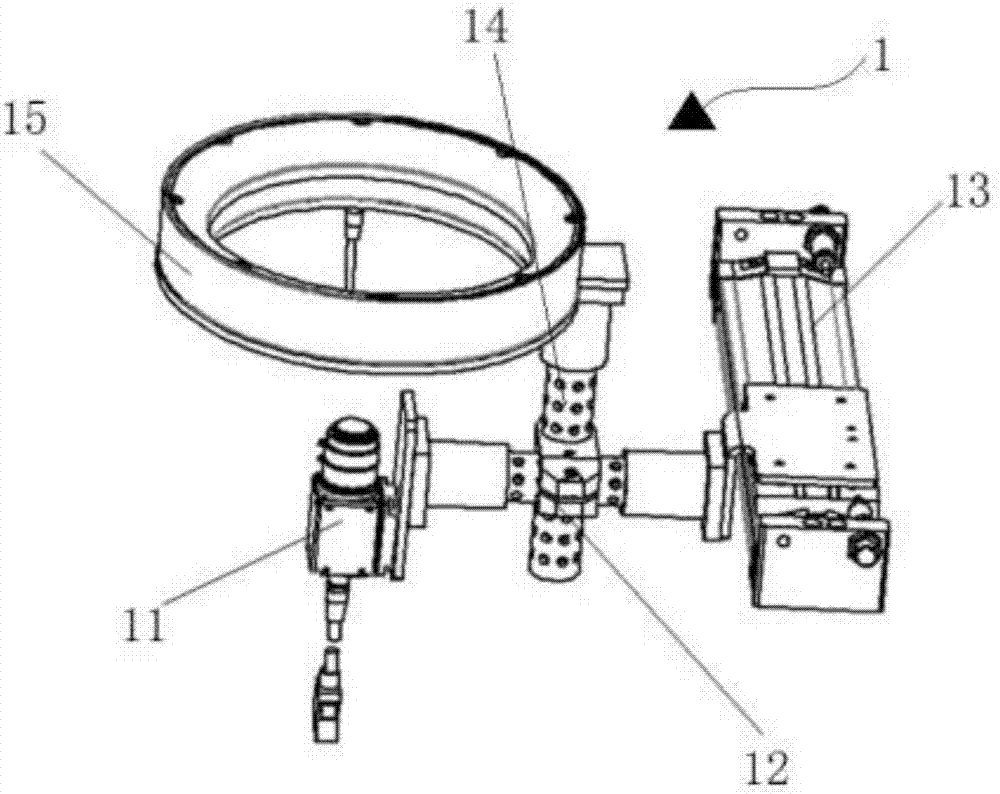

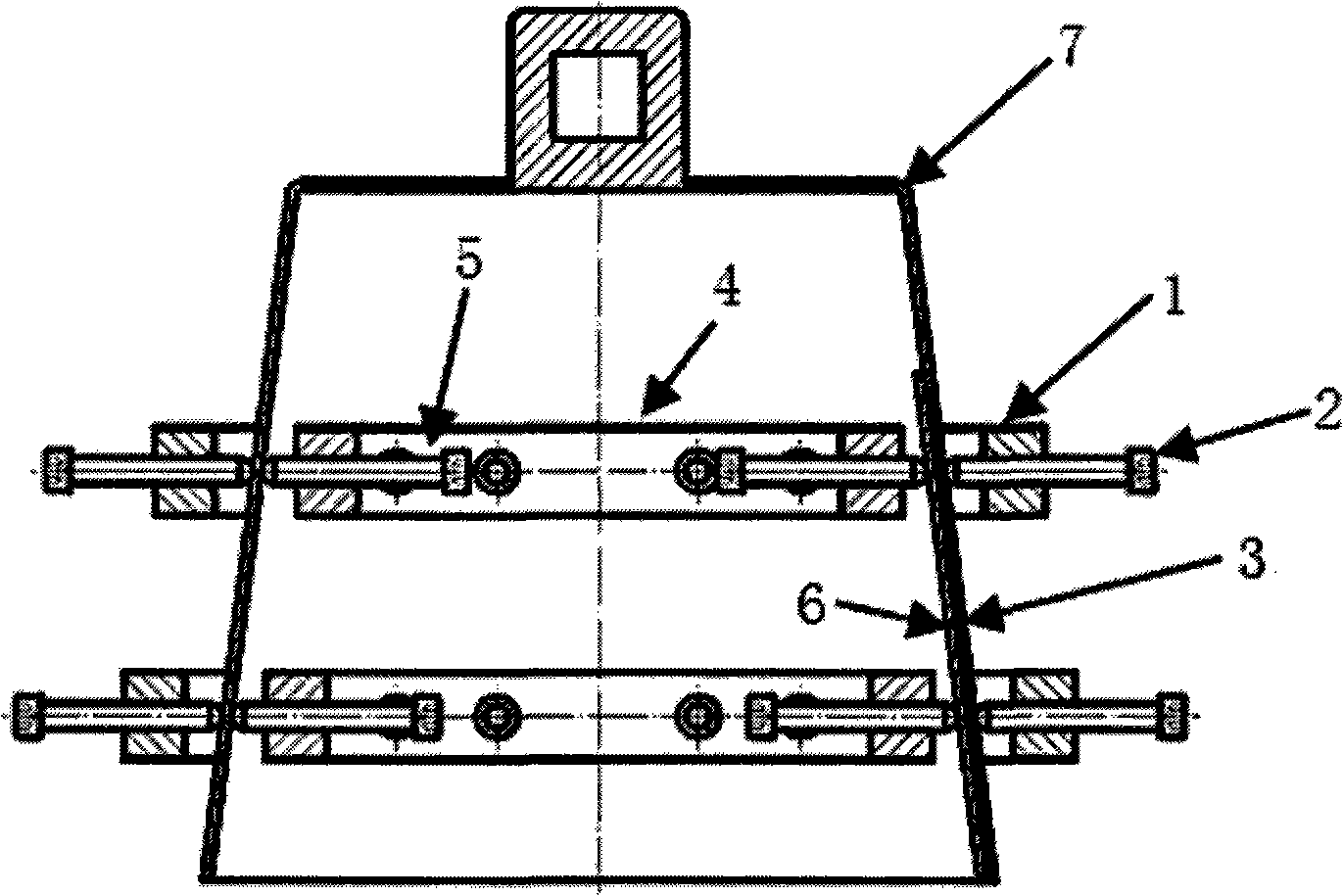

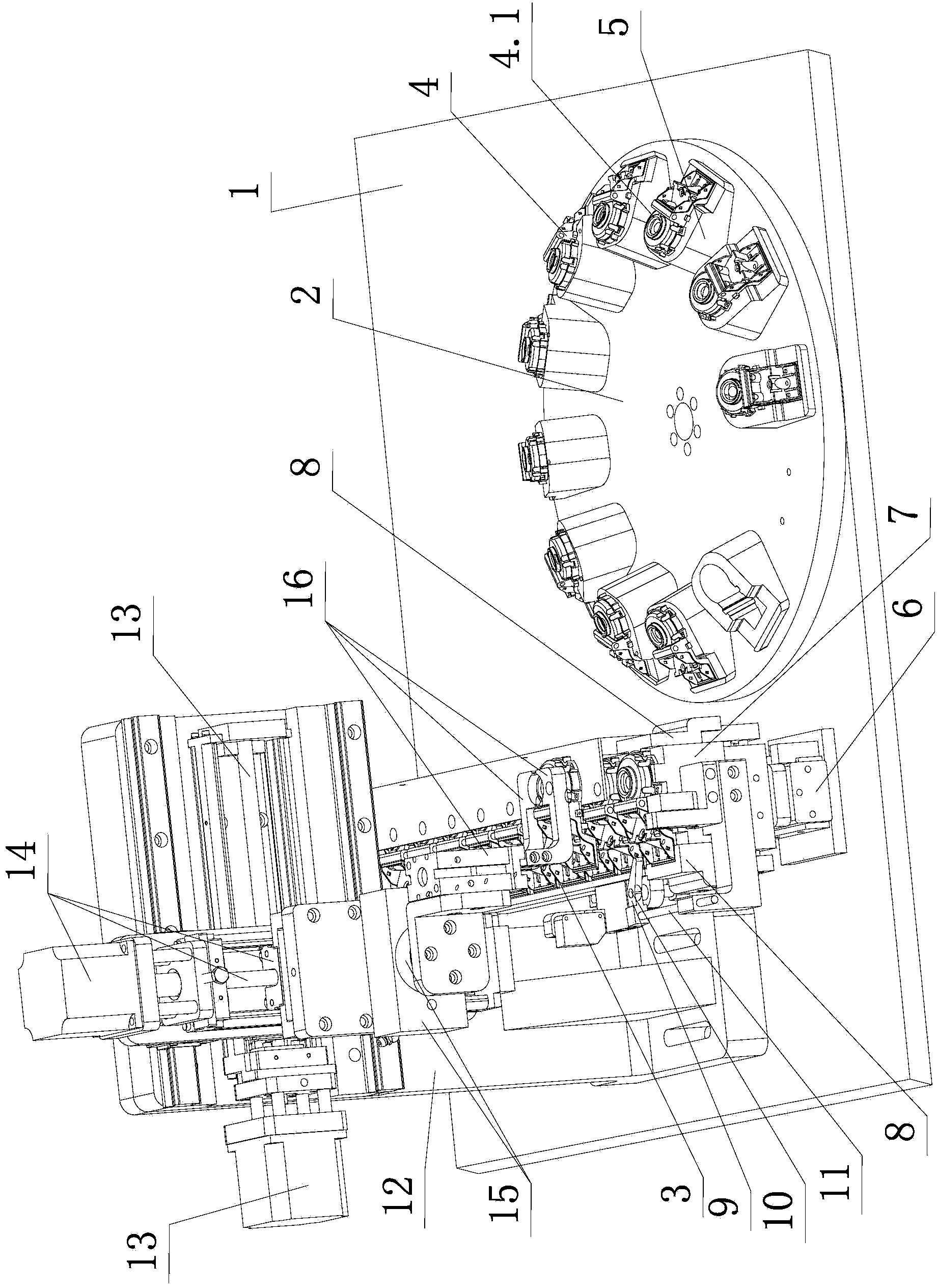

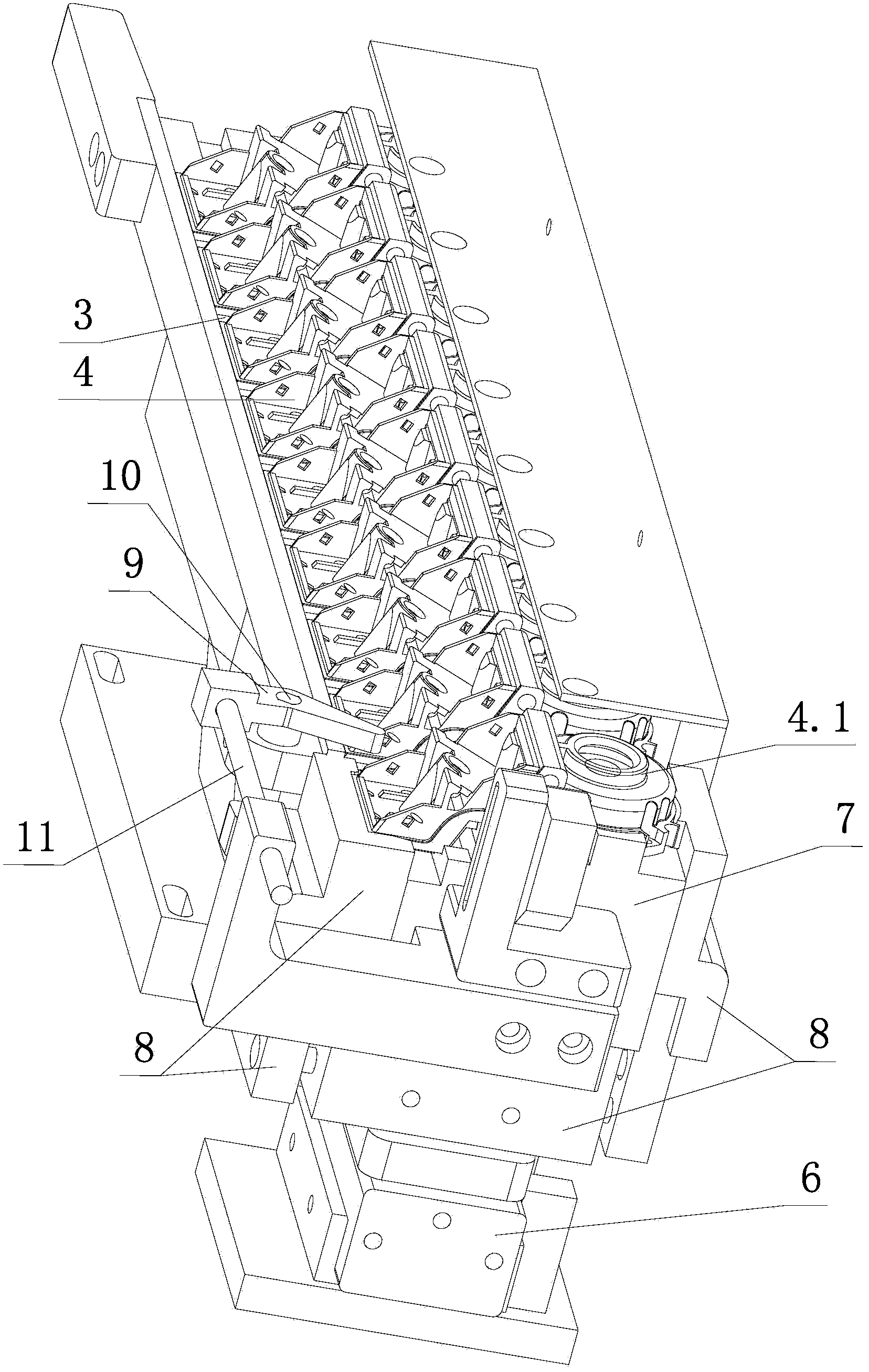

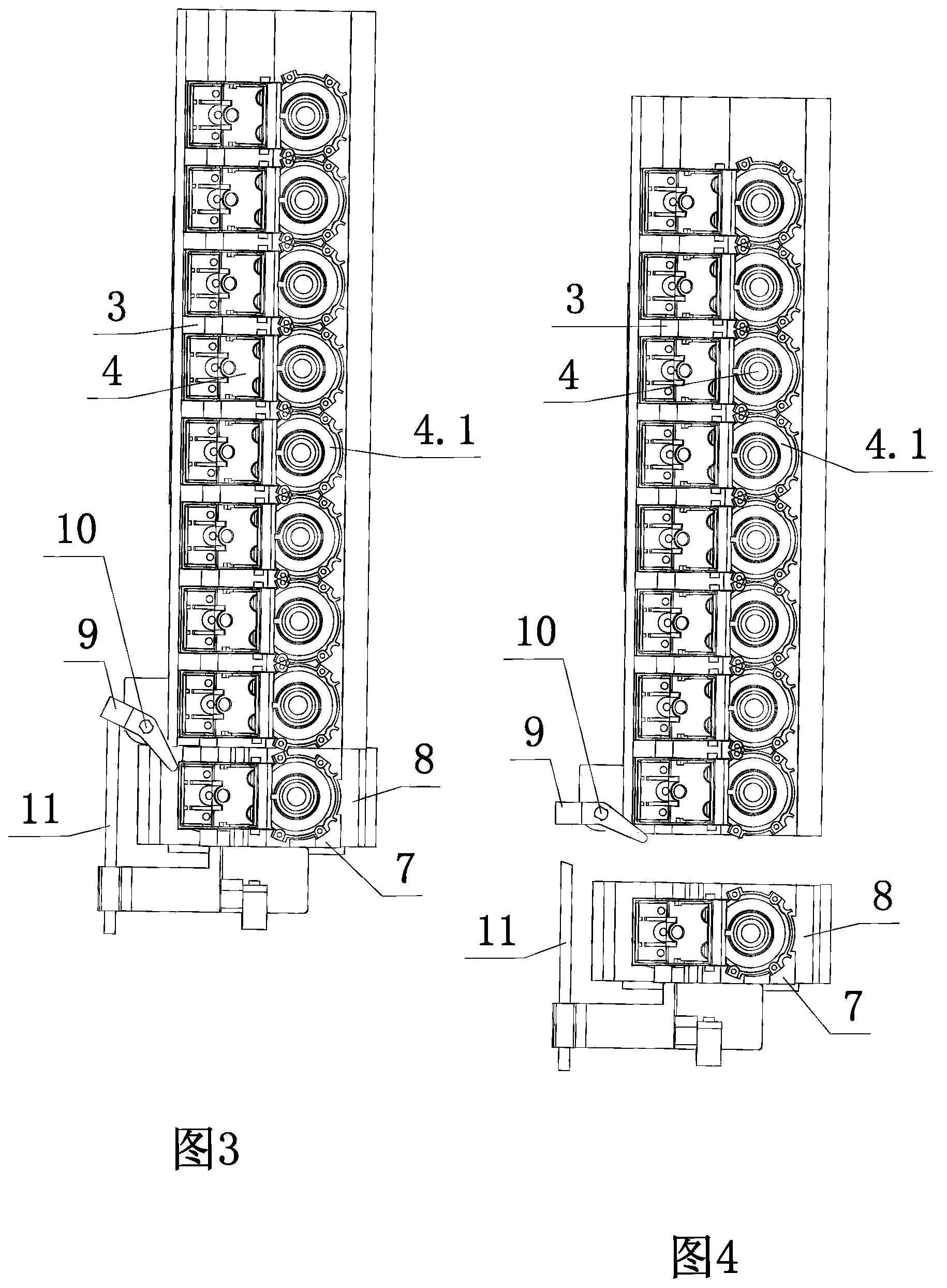

Full-automatic steel ball assembling machine

ActiveCN104015040AAchieve separationPrecise positioningMetal working apparatusEngine lubricationSteel ballEngineering

The invention discloses a full-automatic steel ball assembling machine which comprises a machine frame (1). A transition section material groove (7) is formed in the machine frame (1). The tail end of an automatic feeding groove channel (3) is hinged with a blocking plate (9). When the transition section material groove (7) is separated from the tail end of the automatic feeding groove channel (3), the front end of the blocking plate (9) abuts against a workpiece (4) at the forefront end on the automatic feeding groove channel (3). When the transition section material groove (7) abuts against the tail end of the automatic feeding groove channel (3), a top rod (11) of the transition section material groove (7) stops the front end of the blocking plate (9) from preventing the workpiece (4) from moving forward. A feeding arm is arranged on the machine frame (1). The machine further comprises a steel ball discharging device, a down-pressing device and an oil injection device. The machine can achieve automatic feeding of the workpiece (4), the workpiece is conveyed to a down-pressign working position quickly, accurately and efficiently, a steel ball can be automatically conveyed into a mounting hole of the workpiece (4), the steel ball can be pressed automatically, and automatic oil injection can be carried out to the steel ball.

Owner:NINGBO JINGCHENG CAR IND

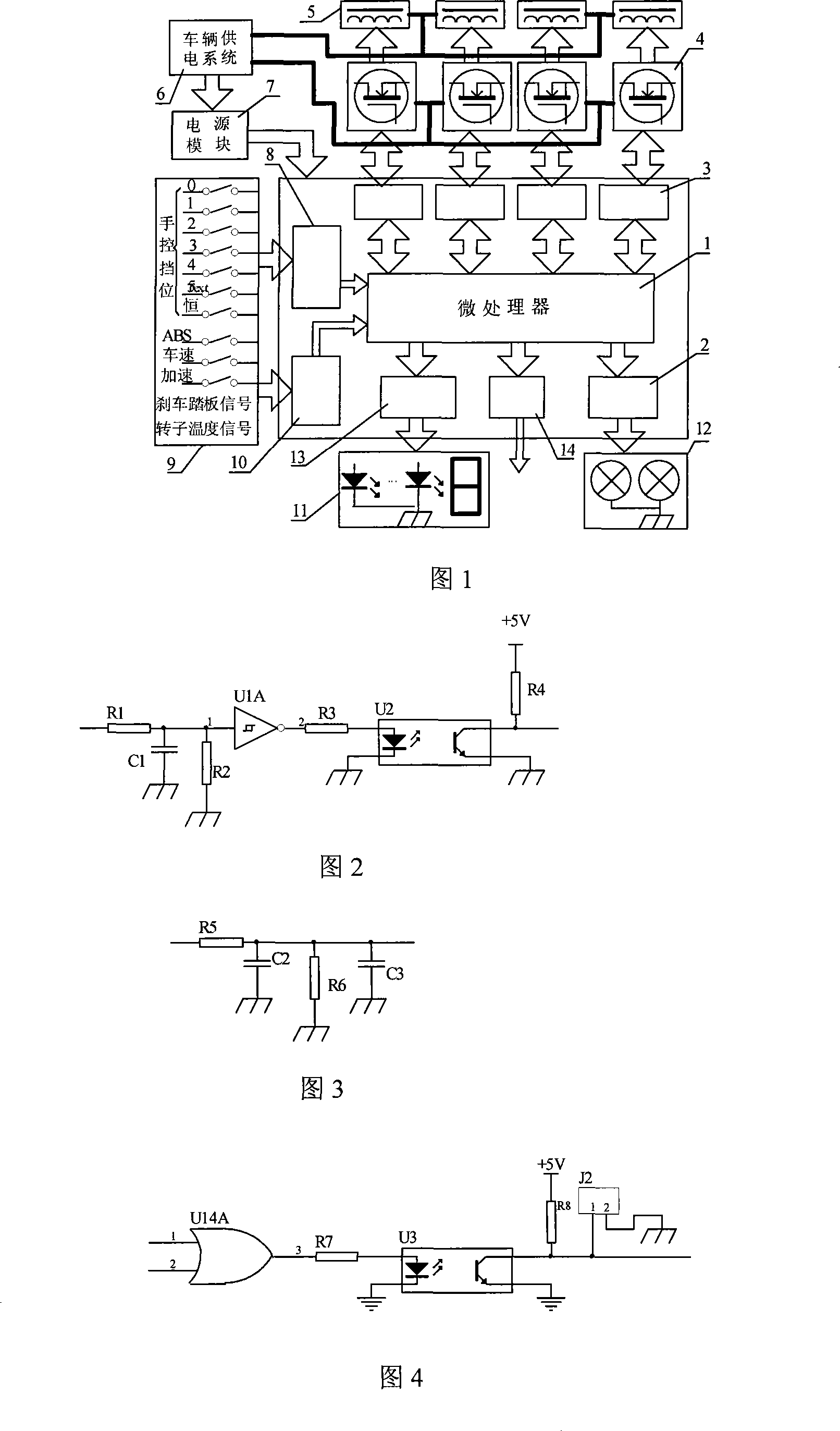

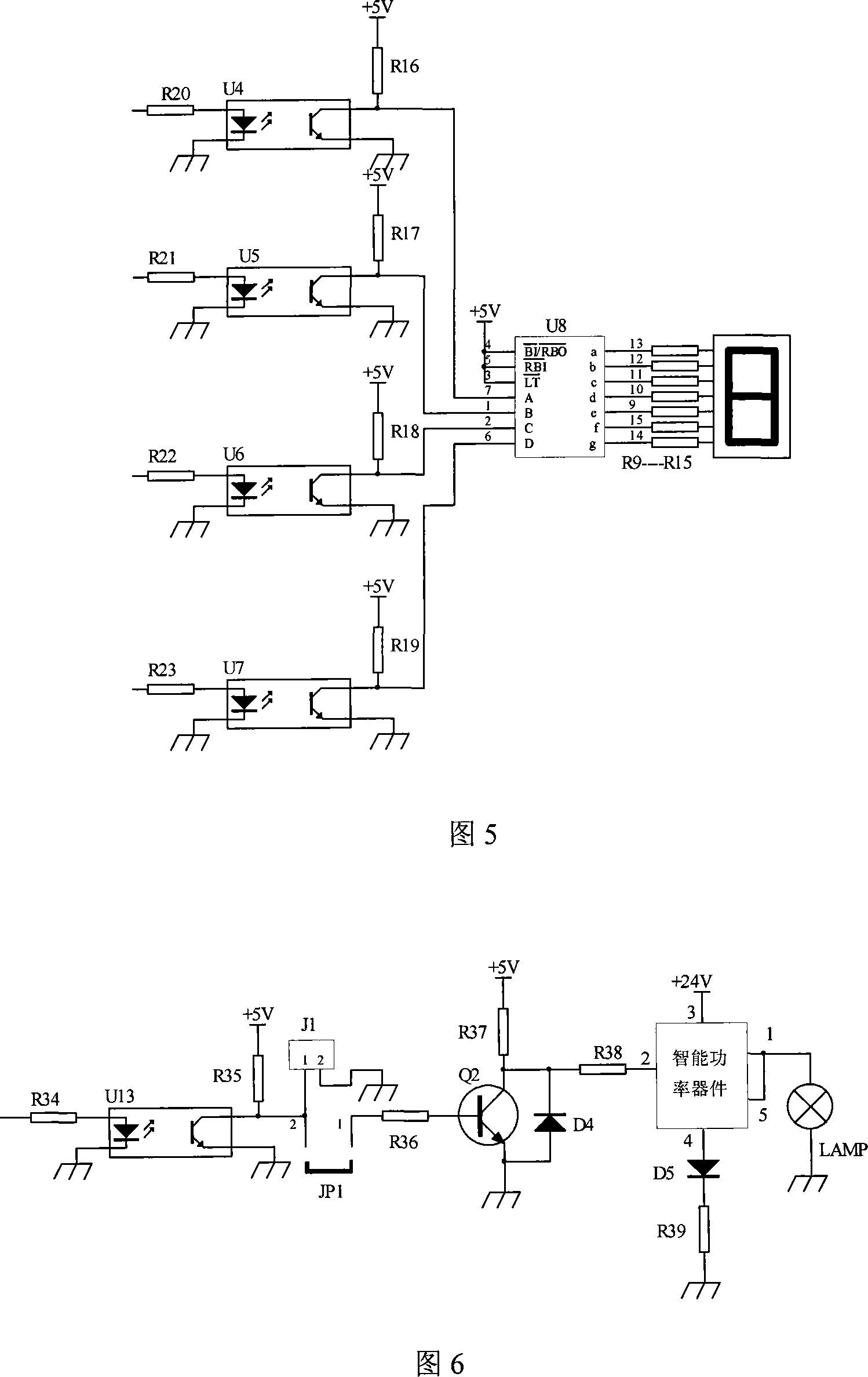

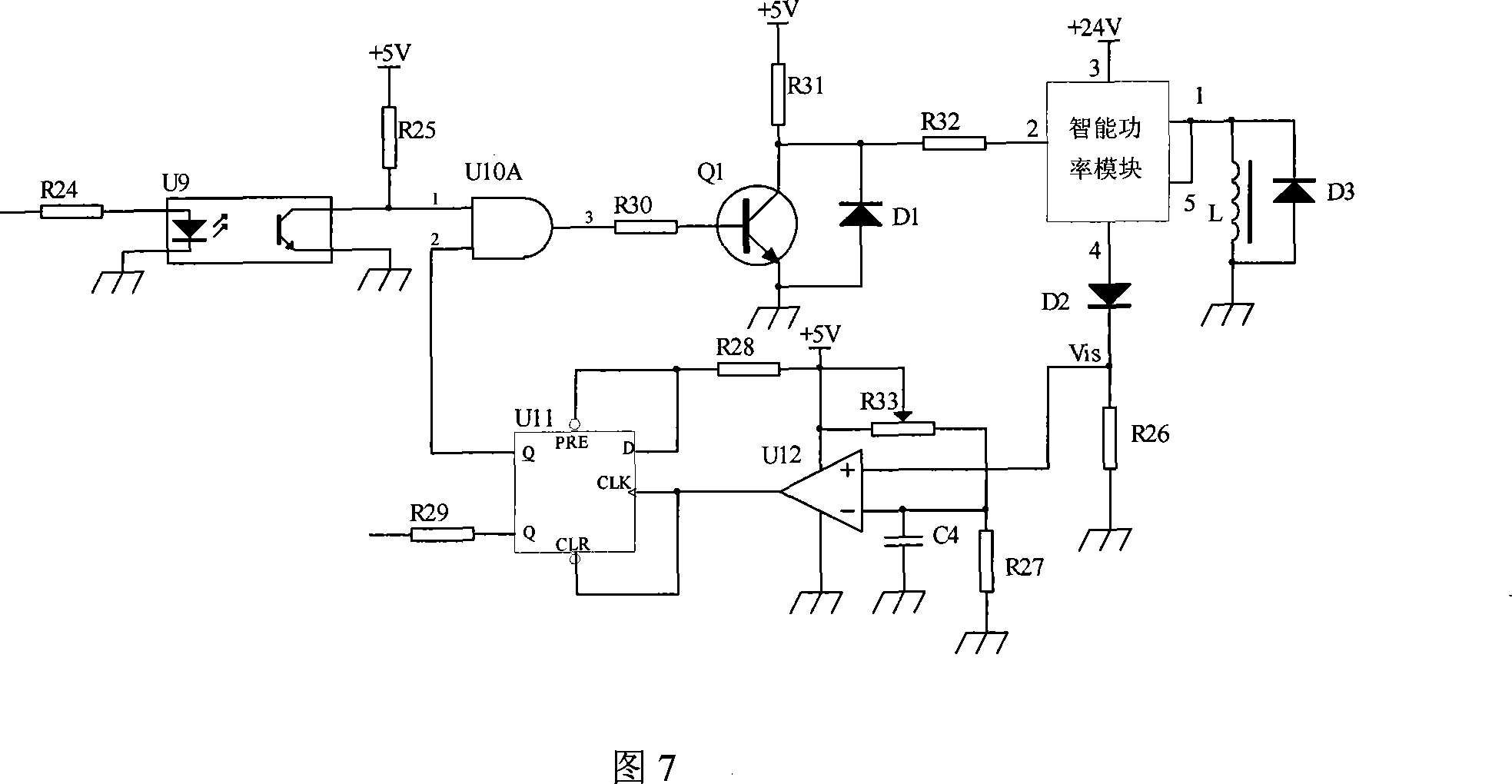

Intelligent control driver for electric eddy speed damper and its control method

InactiveCN101239590AThe working status display is intuitive and eye-catchingExquisite designElectrodynamic brake systemsElectric machinesWrong directionControl theory

The invention discloses an intelligent control drive and the control method for an eddy current retarder. Switching signals includes switch signals which has 7 manual shifts: neutral, 1 block, 2 block, 3 block, 4 block, 5 block, constant rate, ABS switch signals, vehicle speed switch signals and acceleration pedal switch signals; analog signals includes: braking pedal analog signals and rotor temperature analog signals. A microprocessor gathers signals at real time, counts braking moment whose size is needed by the braking and outputs PWM signals of duty rate corresponding to the braking moment, simultaneously, instructs circuits, drive circuits of the microprocessor and brake light drive circuits, and speeds up pedal redundant wrong direction output circuit to send out corresponding control orders; the invention uses a discrete structure, causes a electrically controlled unit and a power module to be separated respectively, and has the advantages of saving space, easy installation and that coils are not easily damaged; rotor disk is not deformed by uniform stress; the life of the eddy current retarder is improved.

Owner:江蕴梅

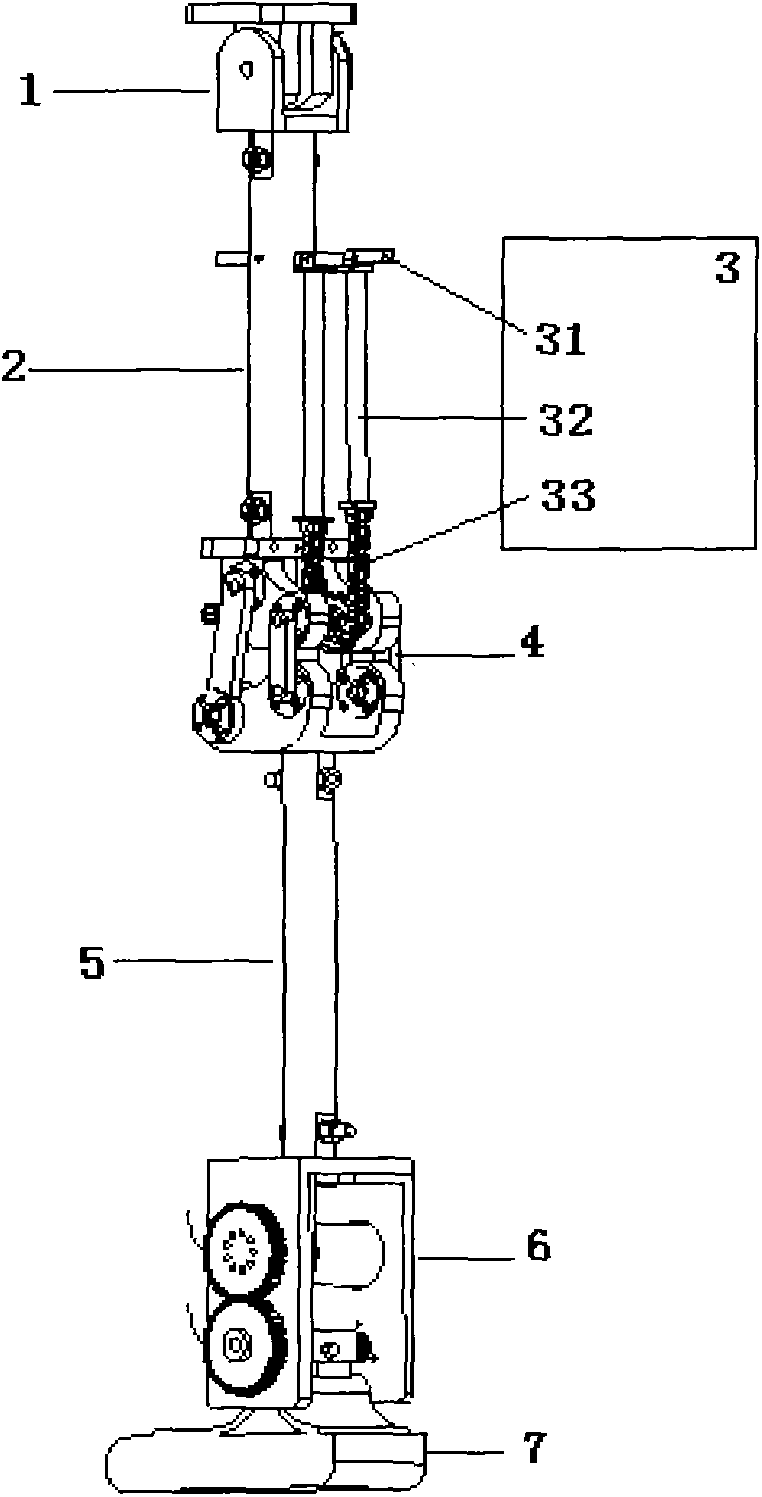

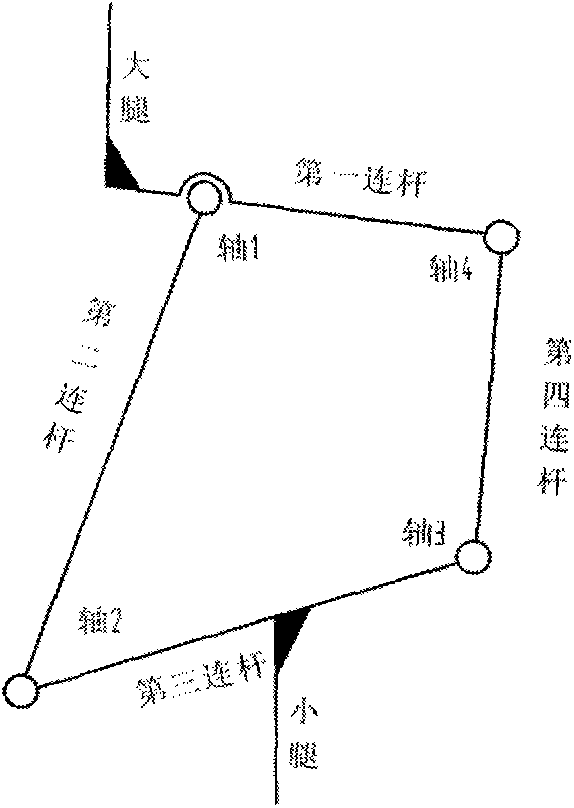

Two-leg robot leg mechanism based on driving of artificial muscles

InactiveCN103707951AEffective simulationShorten the lengthVehiclesPhysical medicine and rehabilitationDrive shaft

The invention discloses a two-leg robot leg mechanism based on driving of artificial muscles. The two-leg robot leg mechanism comprises a single-shaft hip joint, thigh rods, a pneumatic artificial muscle driving mechanism, bionic knee joints, crus rods, ankle joint transmission mechanisms and artificial flexible feet, wherein the single-shaft hip joint is connected with the thigh rods, the thigh rods are connected with the bionic knee joints, the bionic knee joints, the crus rods, the ankle joint transmission mechanisms and the artificial flexible feet are sequentially connected, the pneumatic artificial muscle driving mechanism comprises a transverse rod, the transverse rod is perpendicularly fixed in the thigh rods, two pneumatic artificial muscles are arranged in parallel, one ends of the two pneumatic artificial muscles are fixedly connected with the transverse rod, the other ends of the two pneumatic artificial muscles are connected to each other through a chain, the chain is connected with a driving shaft of the bionic knee joints through a chain wheel, and driving is achieved through opposite pulling of the pair of pneumatic muscles. The two-leg robot leg mechanism has the advantages of being natural in walking gait, high in adaptability to road conditions, small in motion impact, high in walking speed, small in energy consumption, capable of achieving flexible motion of joints, simple in structure and delicate in design.

Owner:NORTHEASTERN UNIV +1

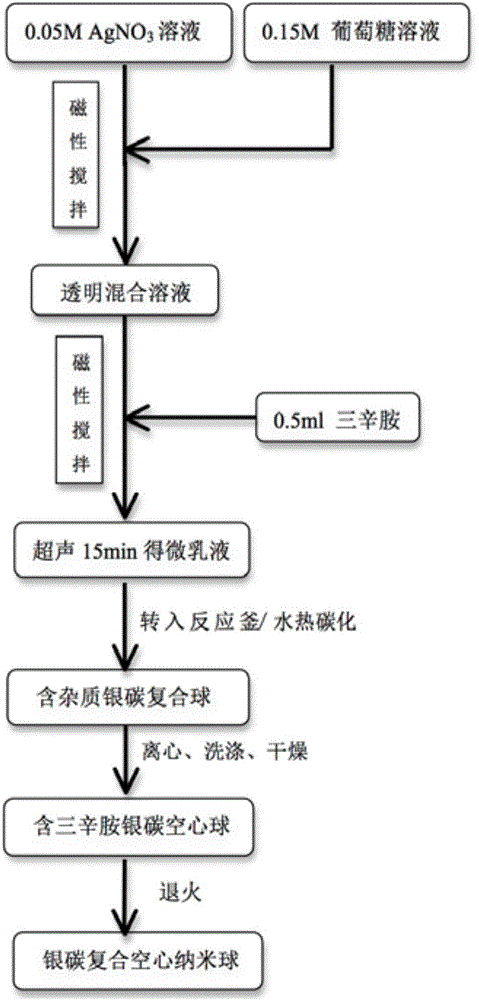

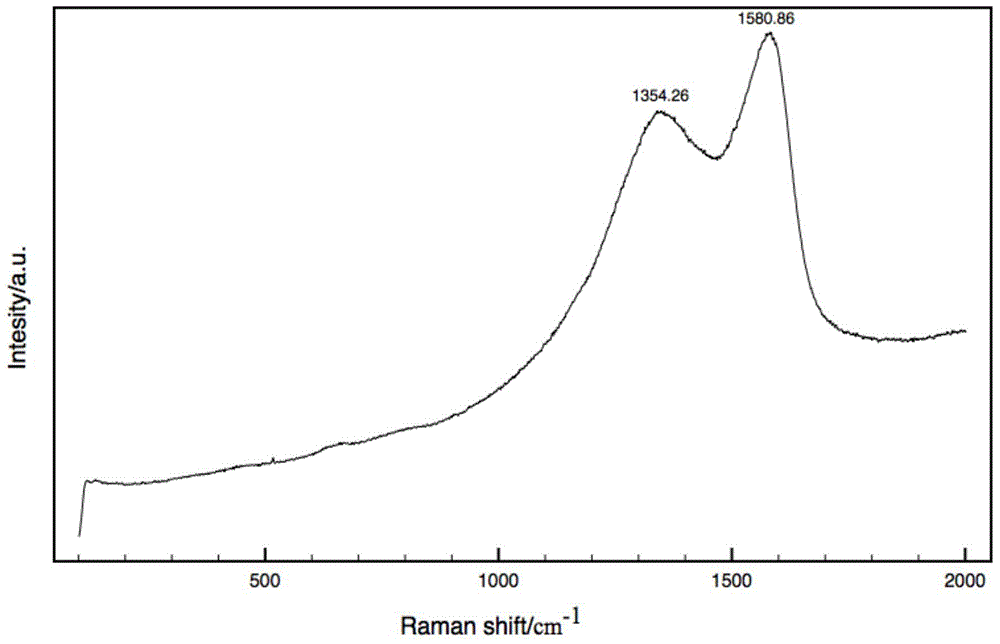

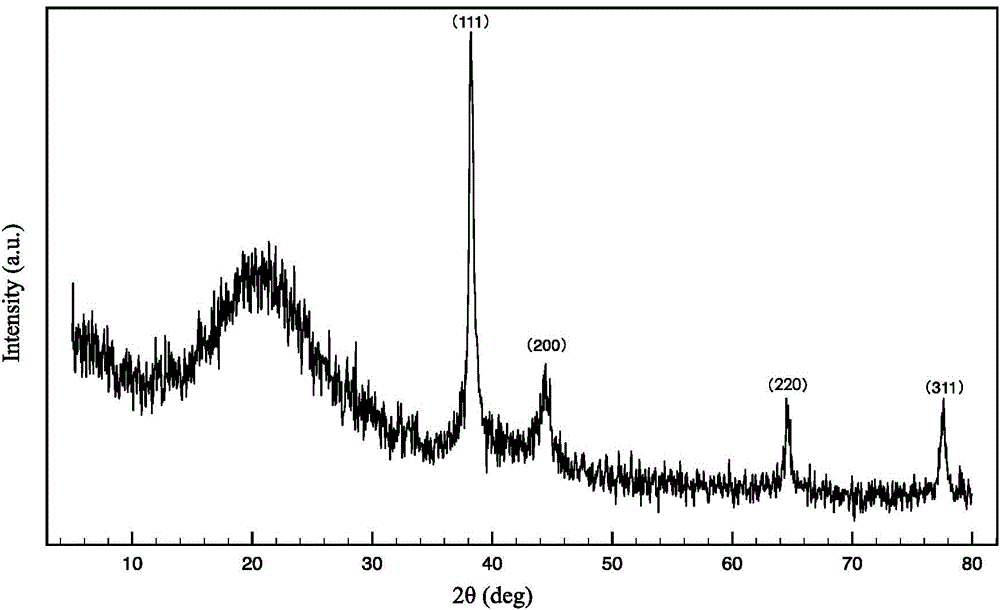

Preparation method of silver/carbon composite hollow nanospheres

ActiveCN104857902AExquisite designEasy reunionMicroballoon preparationMicrocapsule preparationCarbon compositesSolid particle

The invention discloses a preparation method of silver / carbon composite hollow nanospheres. According to the method, under a stirring condition, a glucose solution is added into a silver nitrate aqueous solution; a proper amount of trioctylamine is slowly dropped in while stirring is carried out; the mixed solution is subjected to ultrasonic dispersion, such that a milky while solution is obtained; the emulsion obtained after ultrasonic treatment is delivered into a reaction kettle, and a hydrothermal reaction is carried out; when the reaction is finished, the obtained product is cooled to room temperature; centrifugal separation is carried out, such that black solid particles are obtained; washing and drying are carried out; and annealing is carried out under the protection of argon gas, such that the composite hollow nanospheres are obtained. The material has good application prospects in the aspects of surface-enhanced Raman scattering, antibiosis and the like.

Owner:NANJING UNIV OF SCI & TECH

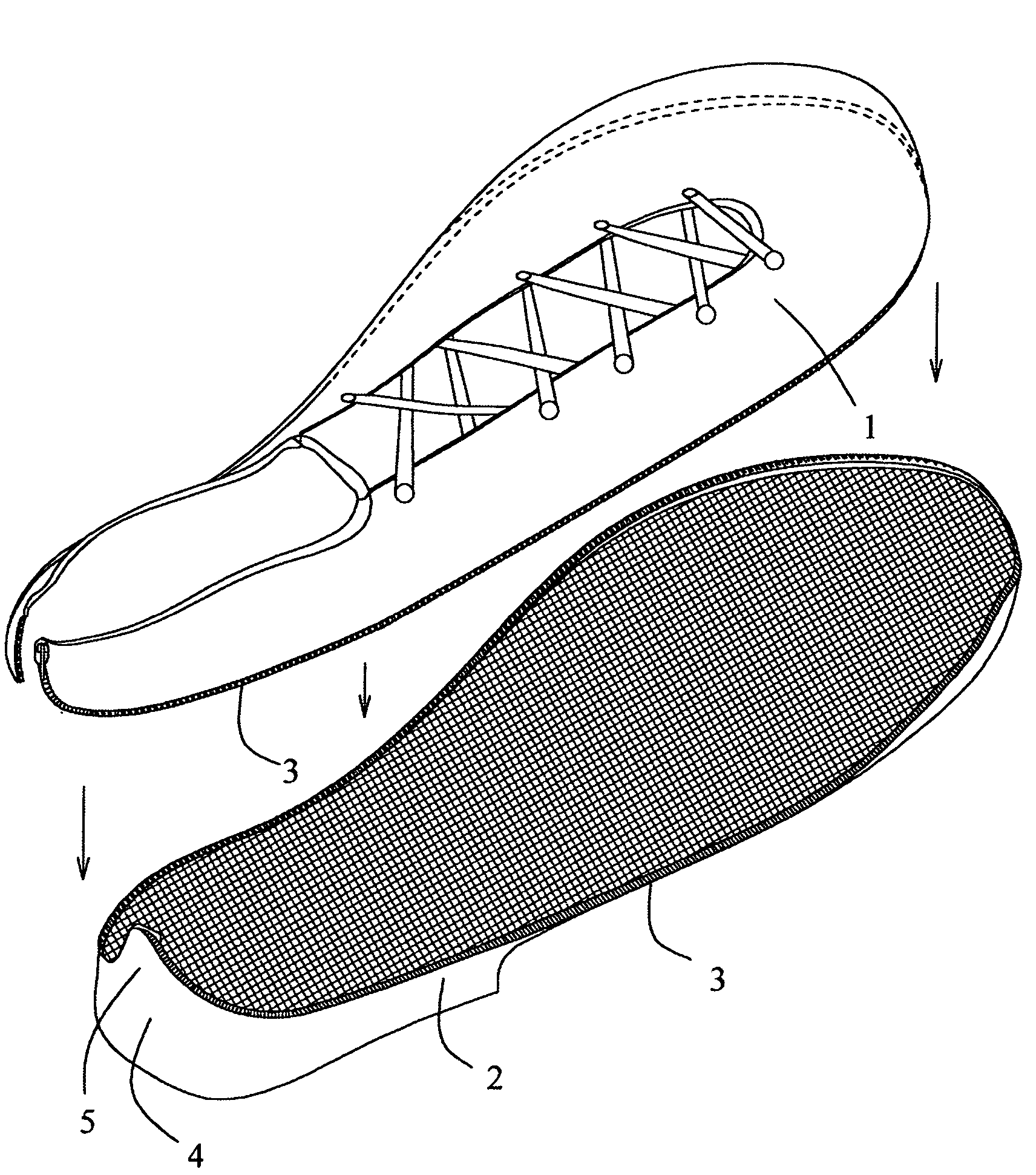

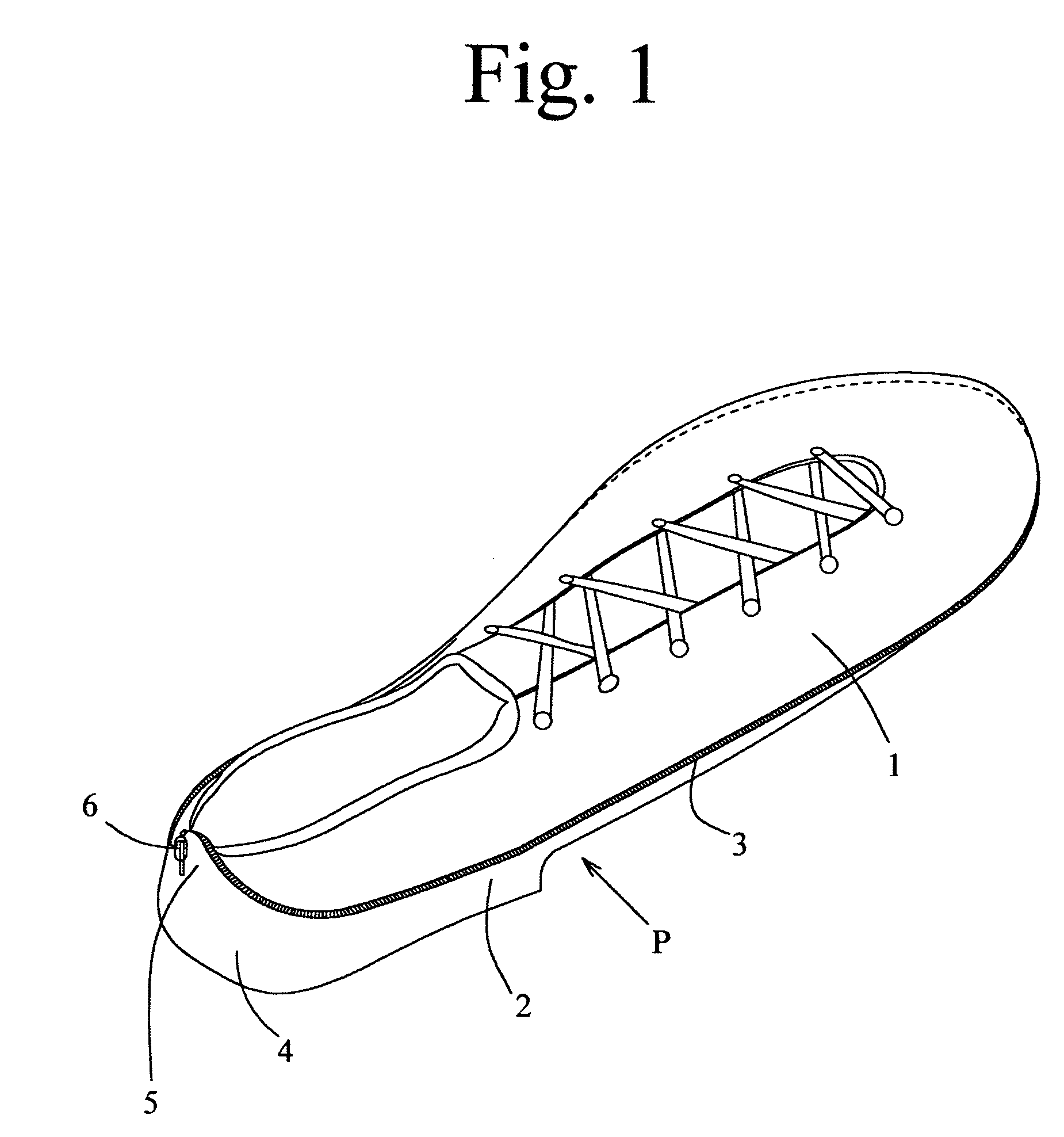

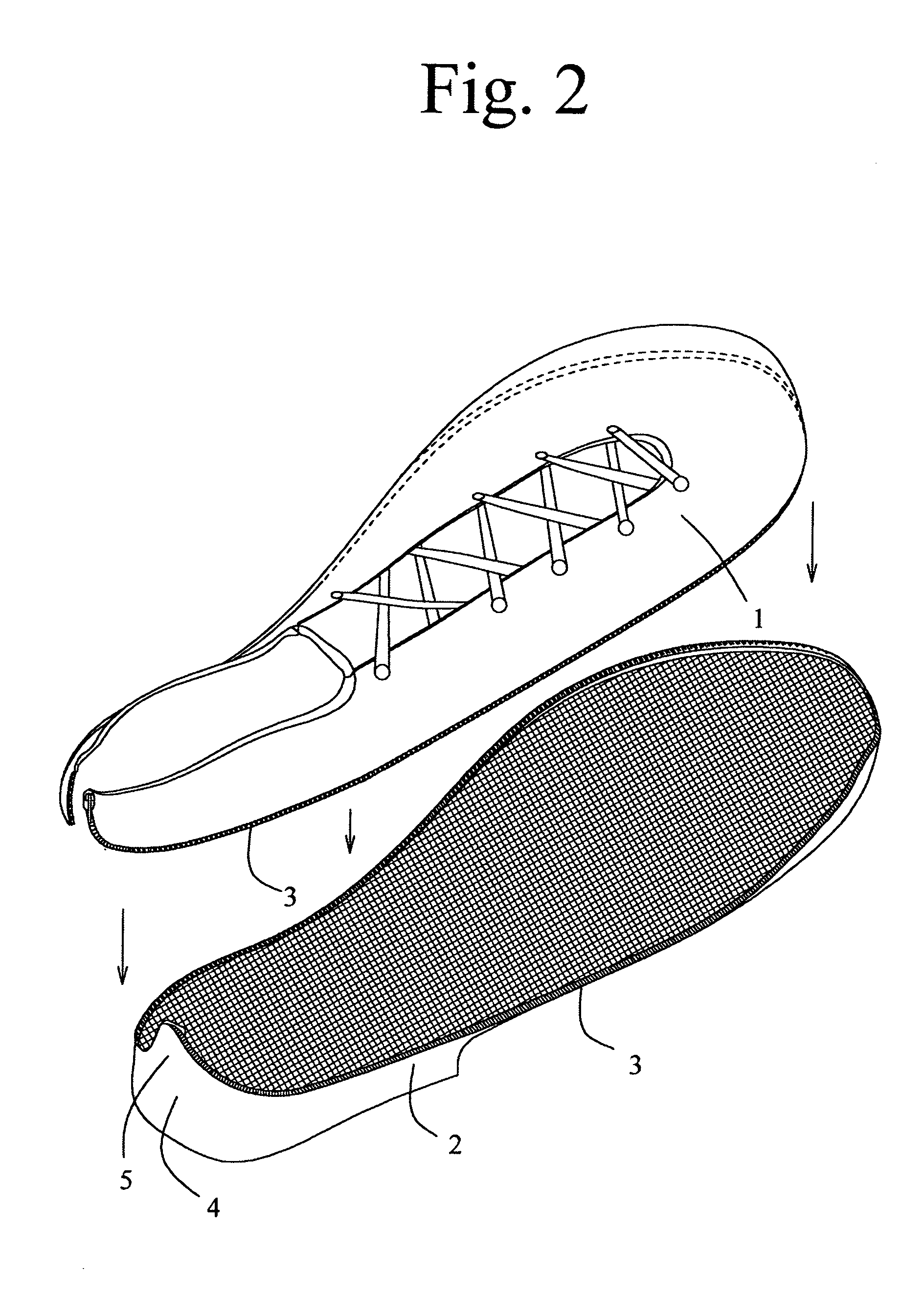

Footwear wear exchangeable upper and sole portions

InactiveUS7013587B2Avoid any damage and accidentSophisticated designSolesWear-resisting attachmentsFastenerBiomedical engineering

Footwear characterized by comprising an upper portion (1), a shoe sole (2), and a fastener (3) that connects them, wherein a plurality of kinds of upper portions are exchangeably used by being connected by the fastener (3) with respect to the shoe sole that is made the basis. The footwear is arranged so that the shoe sole (2) is used by being connected by the fastener in such a manner that the kind of the upper portion is changed according to the purpose of use of the shoe. A cover depending from the upper portion or a cover (7) rising from the shoe sole covers the fastener; the fastener is a slide fastener encircling the shoe except the heel of the shoe sole; and the initial end and a portion adjacent the terminal end of the fastener (3) encircling the shoe sole (2) meet each other.

Owner:YAMA HIROMITSU +1

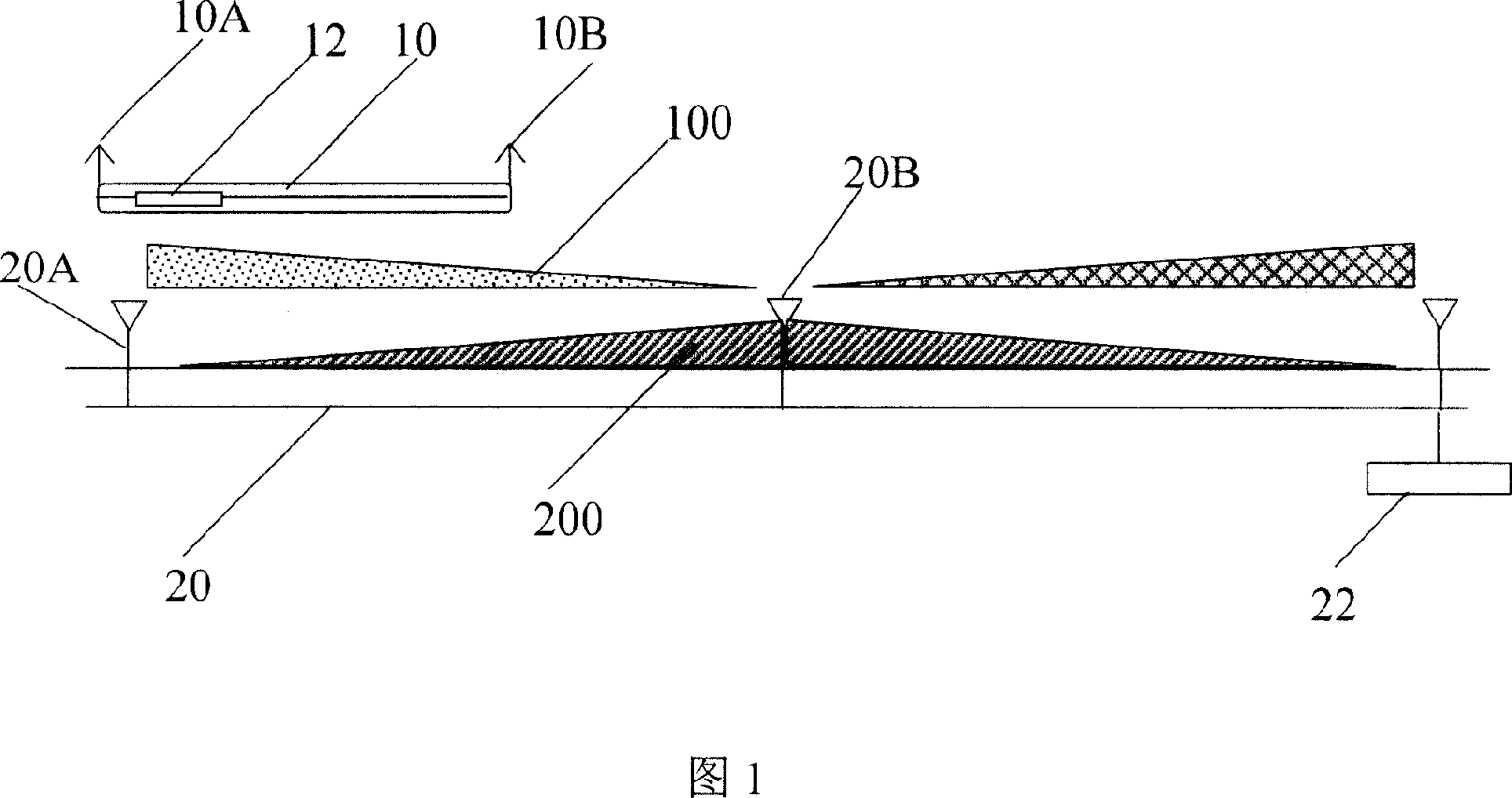

Trans zone quick switching method for rail communication radio local area network

InactiveCN1946228AQuick switchSimple structureData switching by path configurationRadio/inductive link selection arrangementsTransceiverCommunication link

This invention relates to a method for quick switch of cross the region of WLAN used in railway communication, which sets up train-ground communication between train-carrier radio transceiver set on the orbit train and that set beside the orbit characterizing in setting at least two train-carried radio transceivers on the train and said transceivers set by the side of orbit are distributed along the orbit , the train-carried device tests the signal strength of the adjacent by-the-side of the orbit devices timely, and a pair with the strongest signal sets up a train-ground working link for communication, when the signal strength is smaller than a scheduled one, it reselects a pair with the strongest signal as a new train-ground communication link, when the new one is started up to work to begin transmitting communication services carried by the original link, the original link is closed down so as to realize seamless quick cross the region switch.

Owner:SHANGHAI UNIV

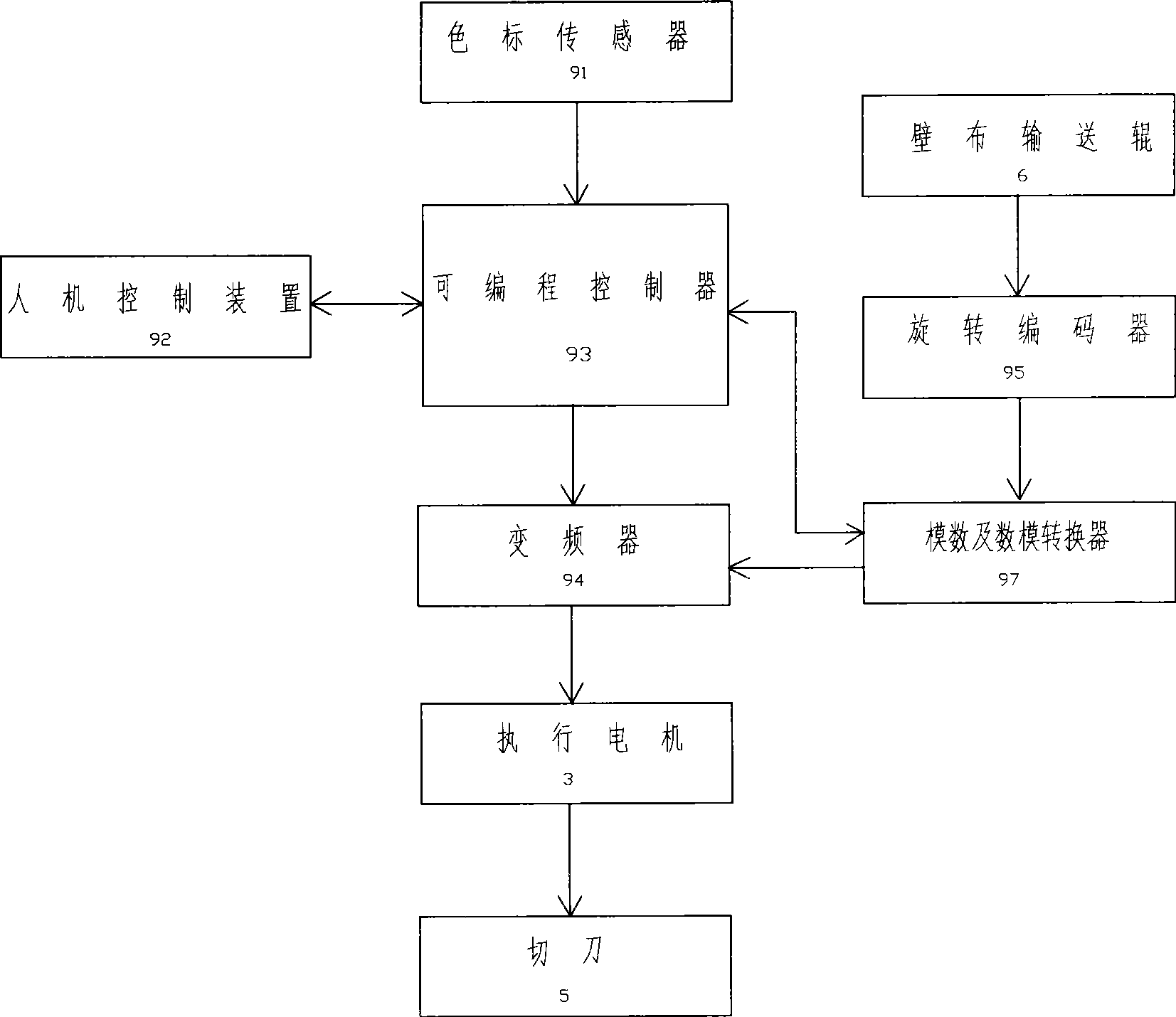

Glass fiber wall cloth edge-cutting electronic error-correcting apparatus

InactiveCN101368327AHigh degree of automationImprove quality and efficiencySevering textilesControl using feedbackColor ScaleGlass fiber

The invention discloses an electronic deviation rectifying device used in glass fiber wallhanging cut trimming, consisting of a control system and an execution system. The control system comprises at least two colour mark sensors, a programmable controller, a transducer, and a revolving coder, and the execution system is composed of an execution motor frame, a slide bar frame, a sensor frame, a cutter saddle, an execution motor, a screw mandrel and a cutter. After any of the colour mark sensors detects color streak which serves as a colour mark inlayed along the edge on the upper surface at one side of the edge to be cut of the wallhanging, the colour mark sensor sends the location information to the programmable controller to control the movement of the cutter so as to rectify deviation. The signals of the colour mark sensors can be used in high speed deviation rectification and low speed deviation rectification. The revolving coder feeds back the detected speed of the threads of the wallhanging to the programmable controller to control the movement speed of the cutter so as to ensure constant ratio of deviation rectification to the speed of the threads of the wallhanging. The electronic deviation rectifying device realizes automated control to deviation rectification and is high in rectification precision, stable in performance, simple in operation and installation and low in making cost.

Owner:常州华碧宝特种新材料有限公司

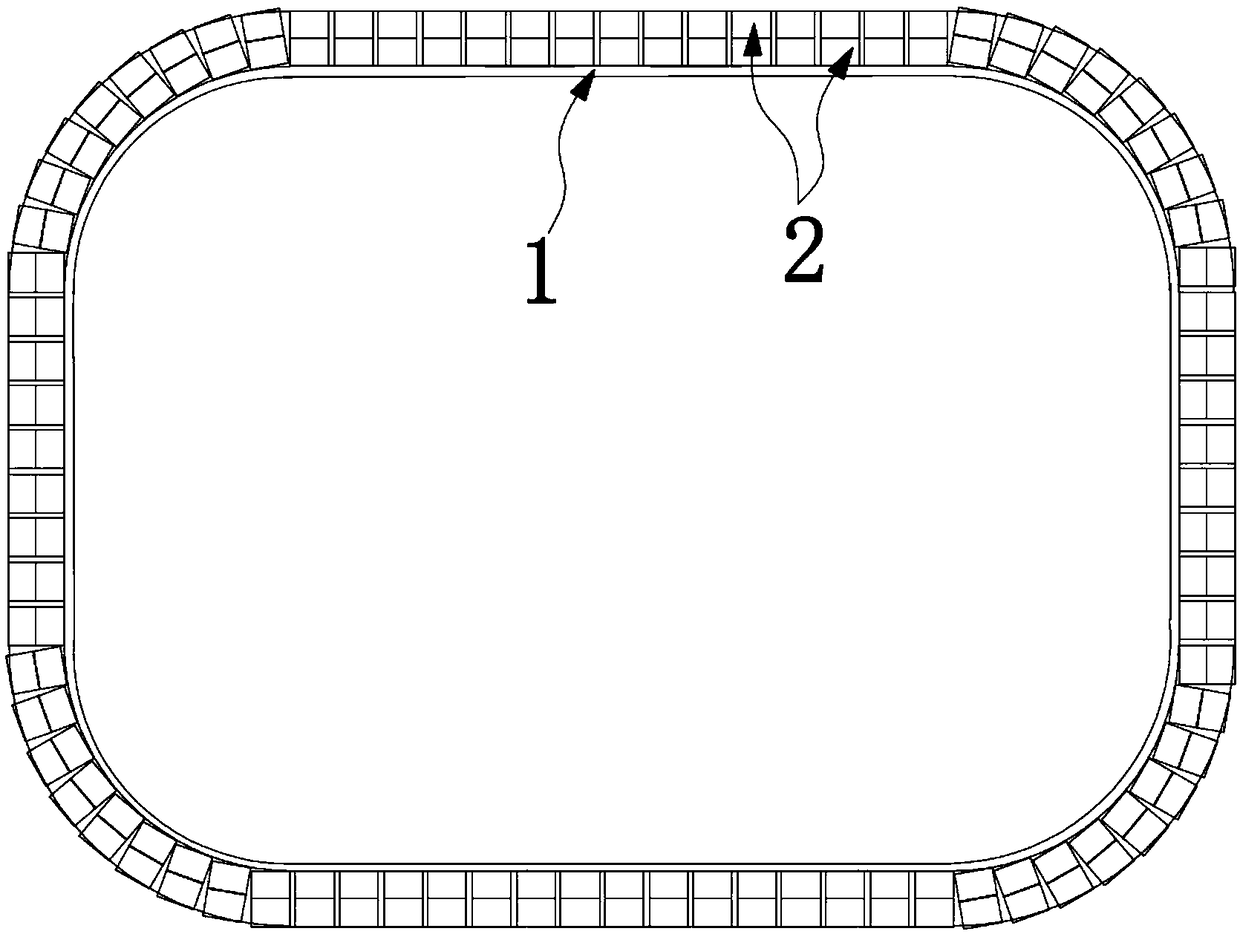

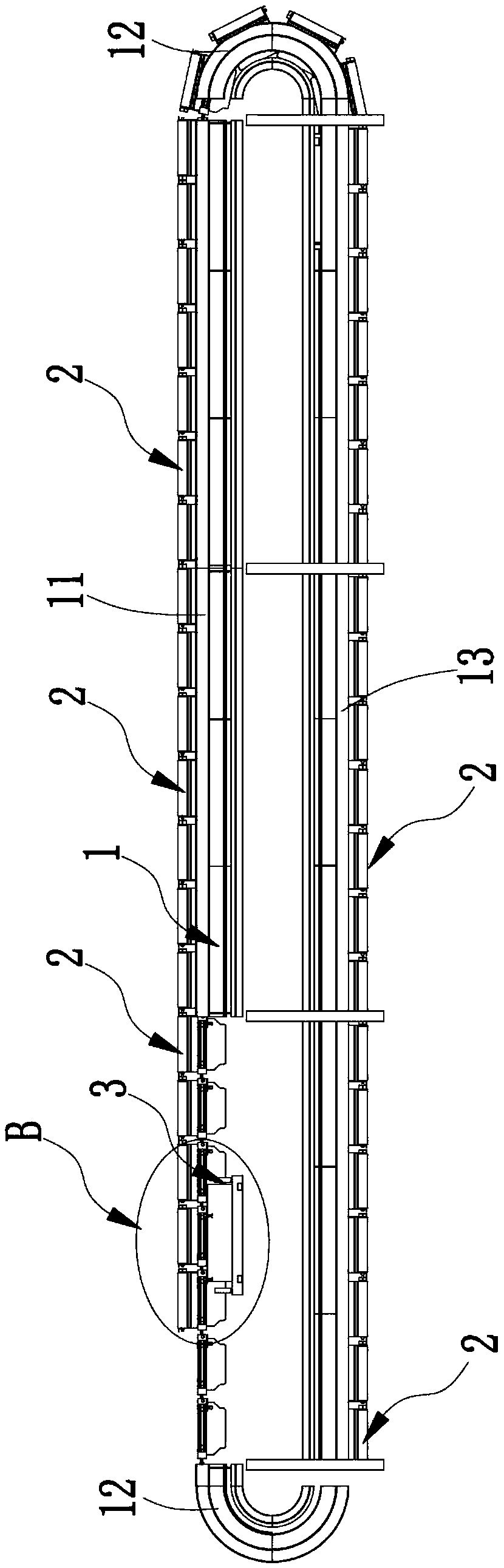

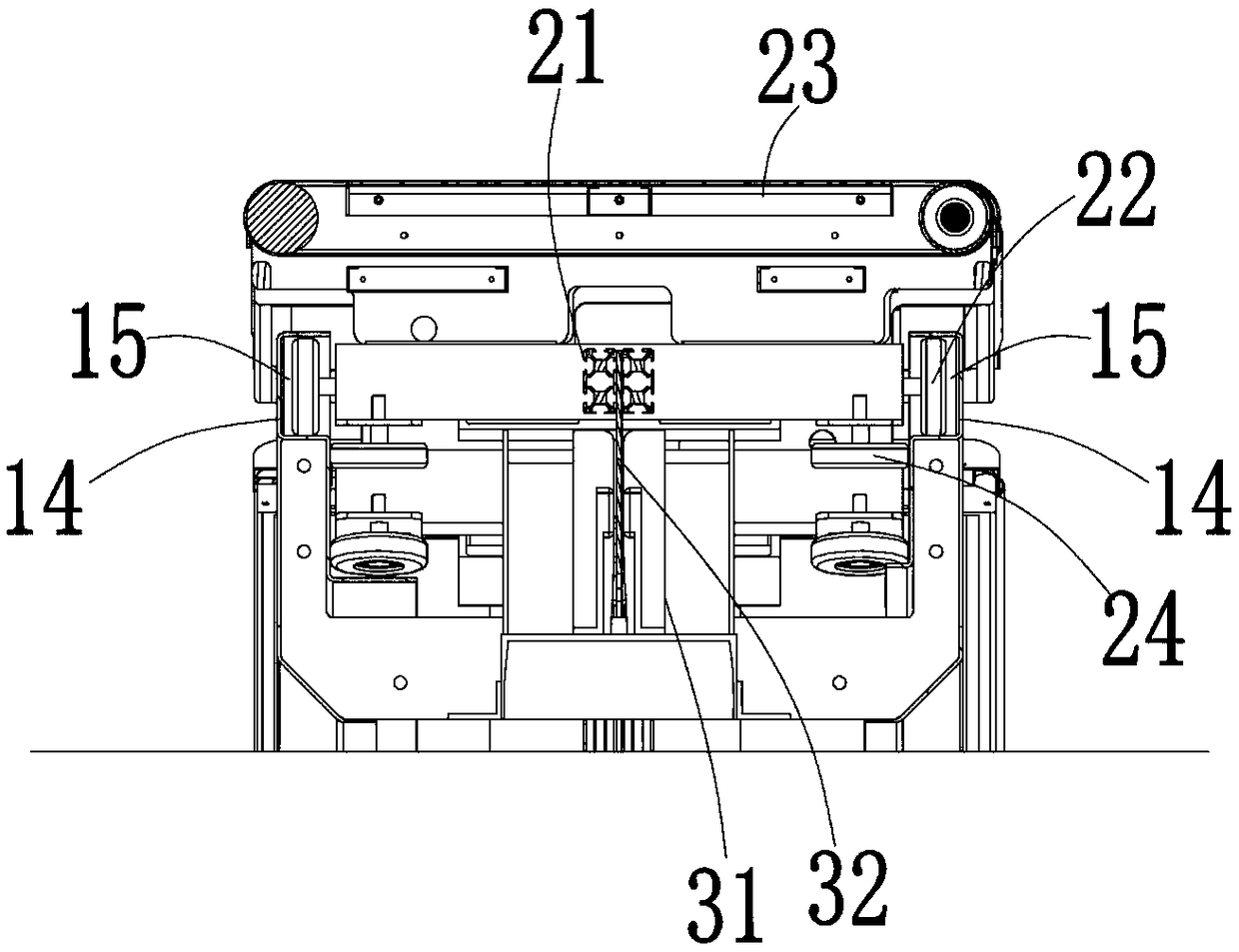

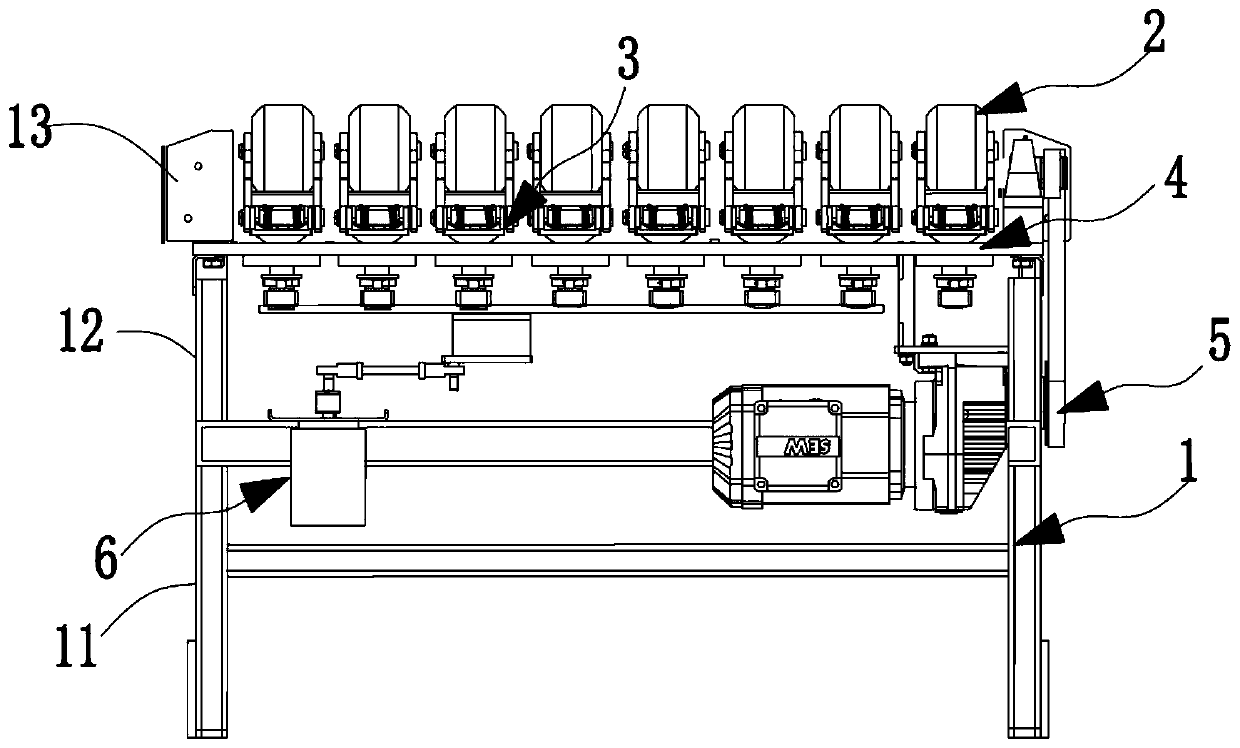

Double-loop-line intersected belt sorting machine, intersected belt sorting system and sorting method thereof

PendingCN109335538AReduce vacancy rateIncrease the number ofPackagingConveyor partsEngineeringMechanical engineering

The invention discloses a double-loop-line intersected belt sorting machine, an intersected belt sorting system and a sorting method thereof. The double-loop-line intersected belt sorting machine comprises at least one annular rail, two sets of intersected belt cars for forming two conveying loop lines circularly rotated on the annular rails side by side, and a power device for driving the two sets of intersected belt cars to move along the annular rails. The double-loop-line intersected belt sorting machine is delicate in design and simple in structure; as two sets of cars are used in one annular rail, the number of the intersected belt cars is increased by using internal space of the loop lines under the precondition of not increasing the floor area to multiply the sorting capacity, theuse efficiency of the sorting machine is improved, and the equipment cost is reduced; and meanwhile, parcels can be transferred between two conveying annular intersected belt cars, so that the idlingrate of the cars can be reduced, meanwhile, the parcel loading flexibility is improved, and the arrangement requirements and the occupied space of a particle loading line are reduced.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

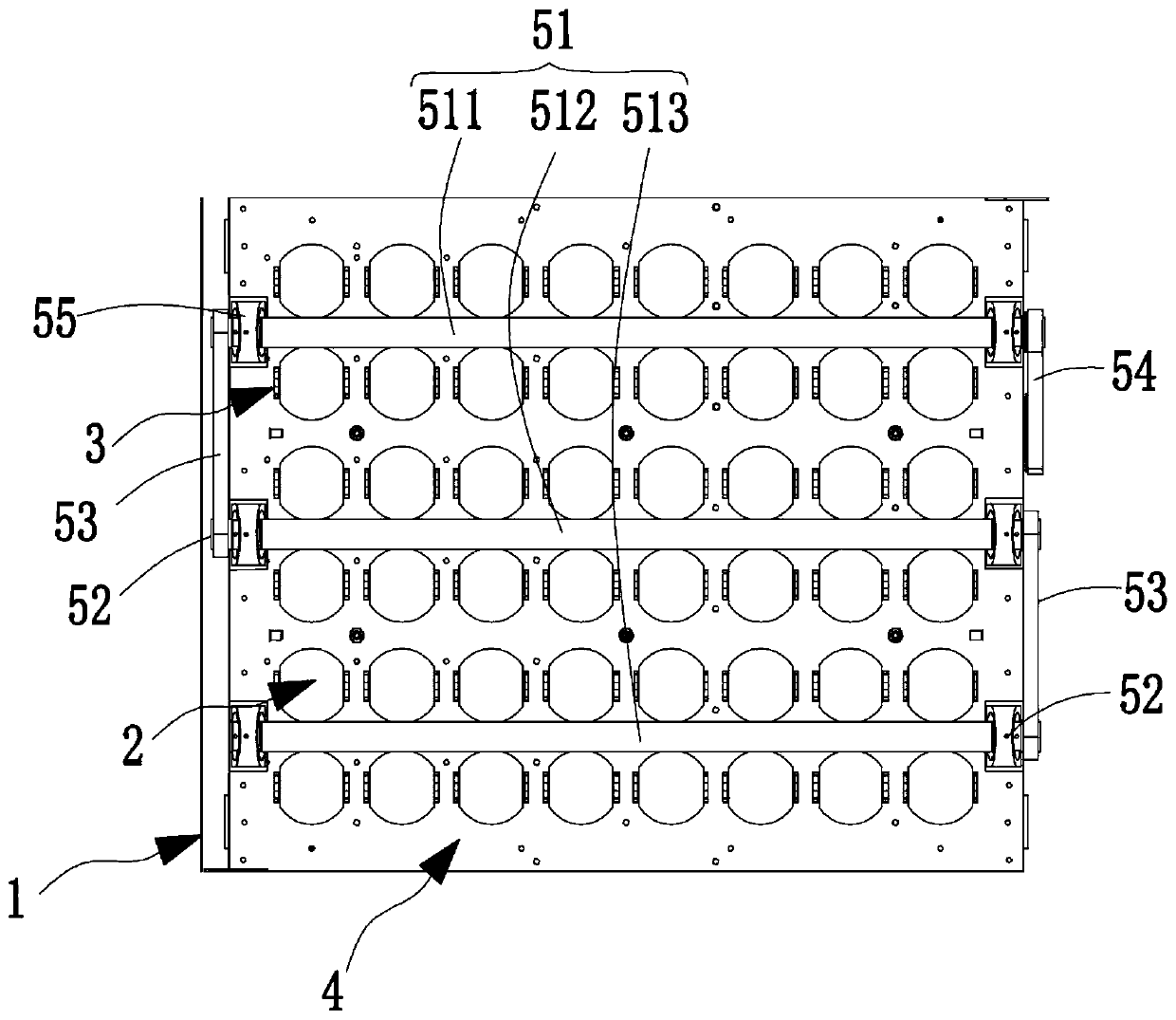

Wheel type conveying line

PendingCN110015540AEasy to assembleGuaranteed reliabilityConveyor partsRoller-waysSelf adaptiveFriction force

The invention discloses a wheel type conveying line which comprises a rack. Multiple rows of eccentric rotating wheels are arranged on the rack in an equal height manner. The axes of all the eccentricrotating wheels are parallel to one another and are parallel to the horizontal plane. Each eccentric rotating wheel is arranged on an installing frame located on the rack in the manner of rotating around the axis of the eccentric rotating wheel. The eccentric rotating wheels on each row are attached to a driving roller, the driving roller makes contact with the lower semicircle of each eccentricrotating wheel, the driving roller is affected by upward elastic force, and thus the eccentric rotating wheels are attached to the driving roller in a self-adapting manner, or the driving roller makescontact with the upper semicircle of each eccentric rotating wheel, the eccentric rotating wheels are affected by the upward elastic force, and the eccentric rotating wheels are attached to the driving roller in a self-adapting manner. The driving roller rotates under the driving of a first power source, and the eccentric rotating wheels are driven to rotate through friction force. According to the wheel type conveying line, the design of the scheme is elaborate, the eccentric rotating wheels or the driving roller are affected by the upward elastic force, thus the eccentric rotating wheels always keep being attached to the driving roller, after abrasion is caused or when the installing position precision is poor, self-adaptive adjusting is achieved, rotating between the eccentric rotatingwheels and the driving roller is effectively ensured, and the conveying stability is improved.

Owner:SUZHOU GP LOGISTICS SYST

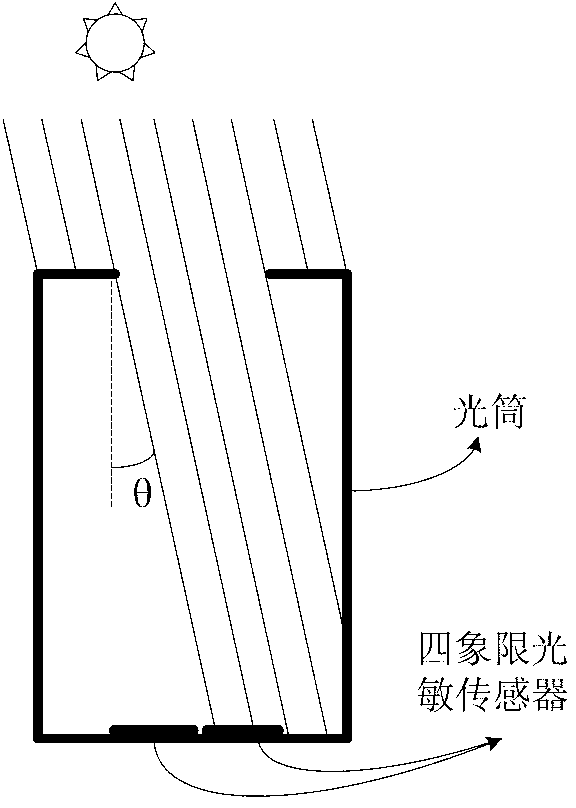

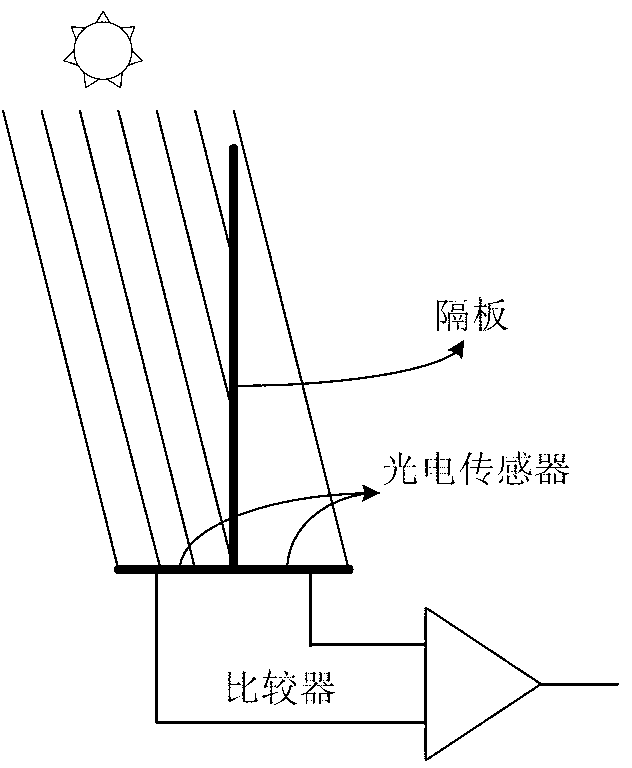

Sunlight tracking sensor

InactiveCN103277922AImplement trackingLow costSolar heating energySolar heat collector controllersLight signalSunlight

The invention provides a sunlight tracking sensor at least comprising a light signal detector fixed on a photovoltaic component and facing to the same direction with the photovoltaic component. The light signal detector comprises multi-quadrant light sensors and a controller. Each multi-quadrant light sensor comprises a signal output end corresponding to each quadrant and a shielding structure. The multi-quadrant light sensors are partitioned according to each quadrant. The controller is connected to the light signal detector and a motor device, and is used for receiving and processing electrical signals outputted by each output end of the light signal detector. Sunlight tracking by the photovoltaic component is realized by the motor device controlled according to correspondence of current values of the light sensor. The sunlight tracking sensor is low in cost, simple in structure, high in tracking accuracy, more sensitive to light with a small incident angle, and large in accurate tracking range, and can be applied in the field of sunlight tracking on a large scale.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

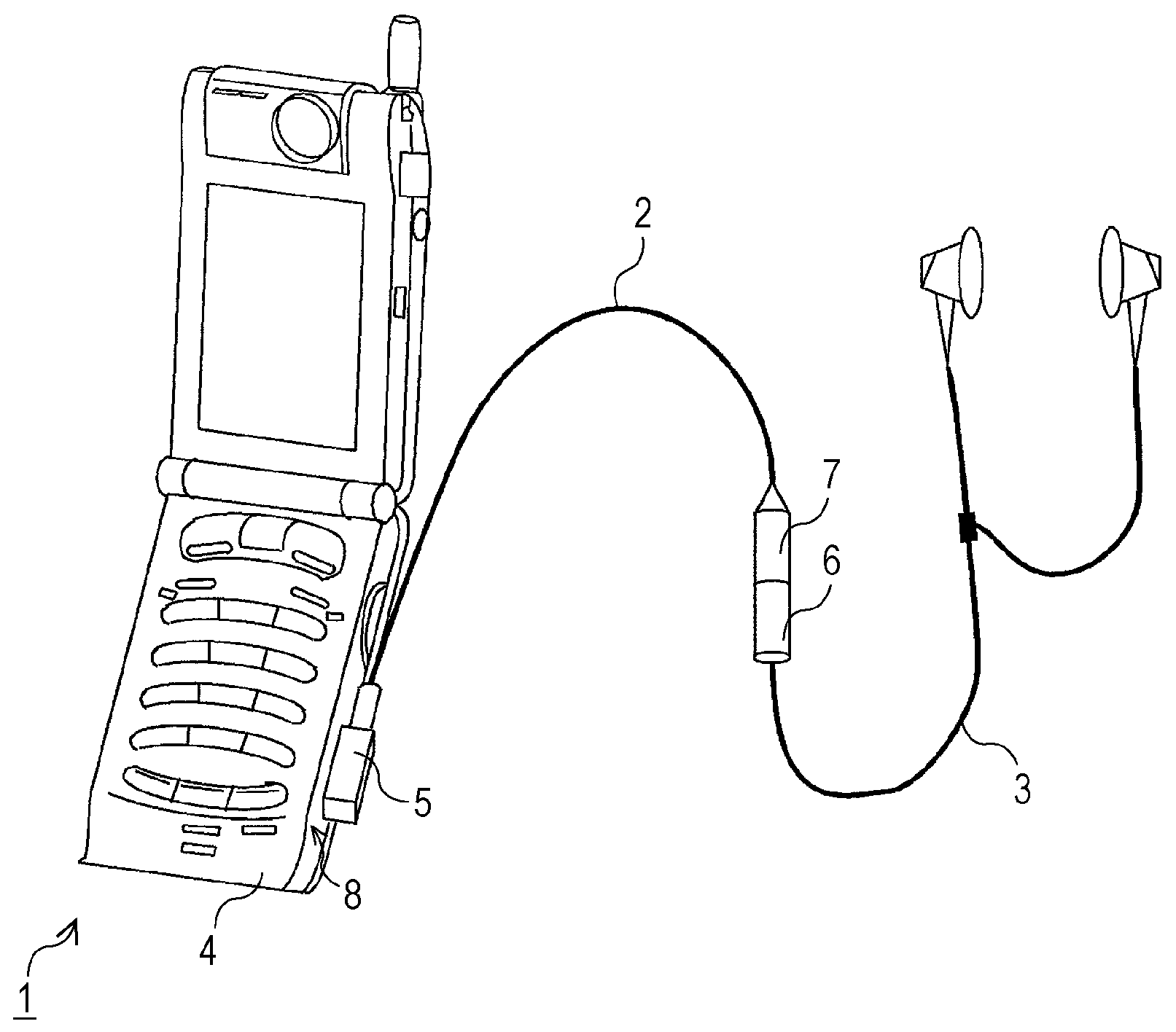

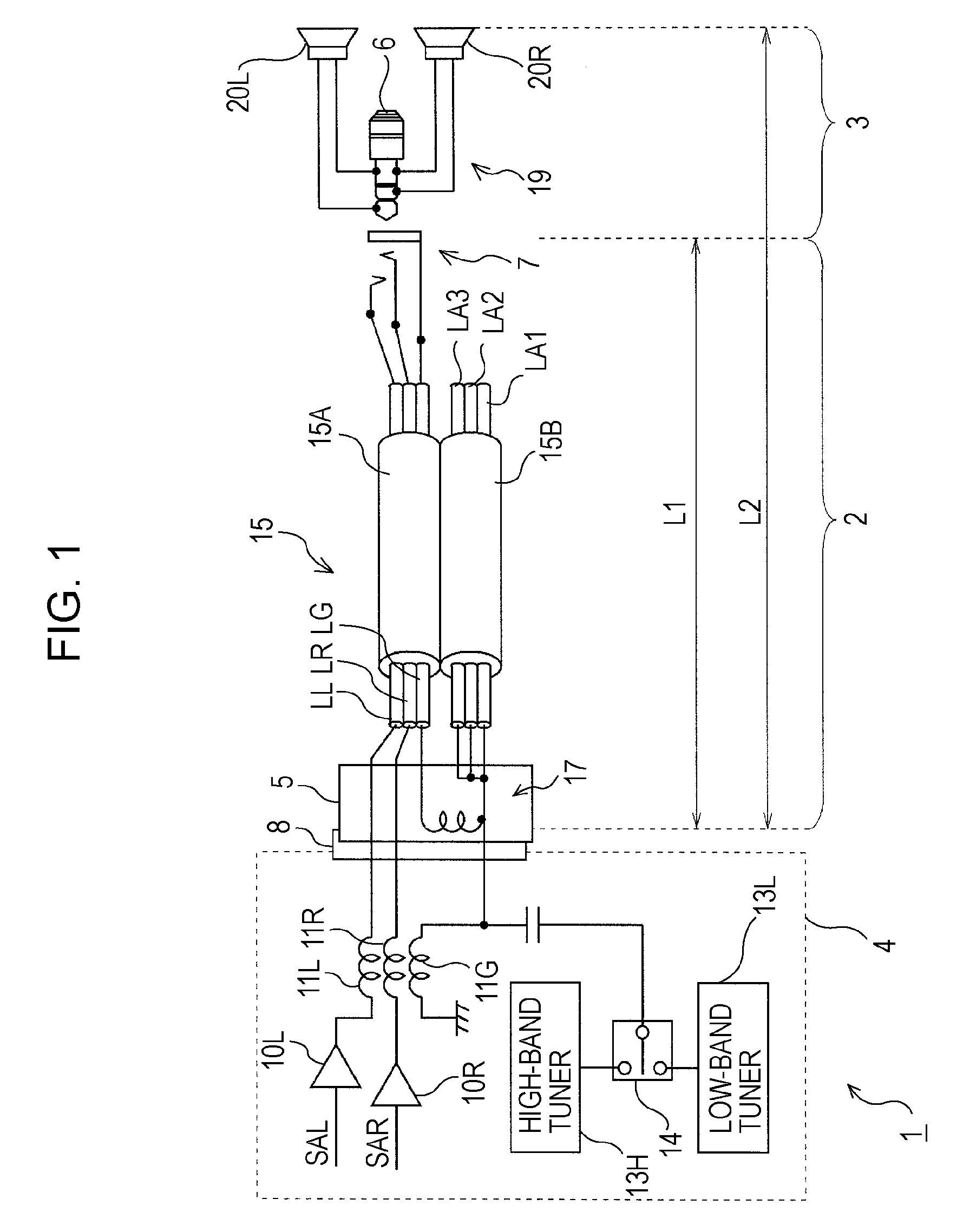

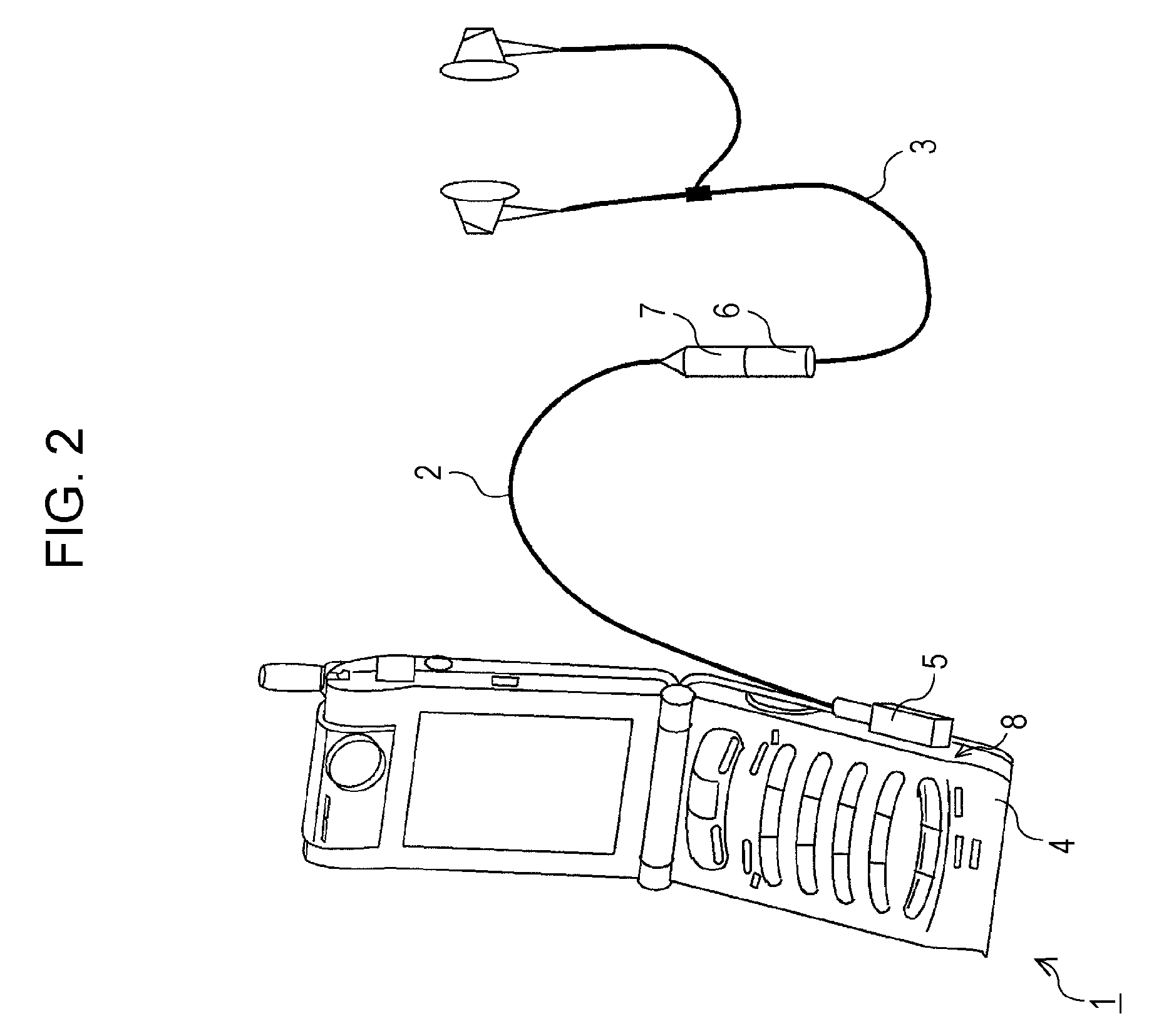

Reception device, antenna, and junction cable

ActiveUS20080254831A1Simple designImprove performanceSubstation equipmentElongated active element feedElectric powerHigh frequency

A reception device including a transmission part having transmission cables transmitting a signal and / or power of a main-body device, an antenna part provided along the transmission cables from main-body-device-side ends of the transmission cables to a point between the main-body-device-side ends and the other ends of the transmission cables so that a high-frequency-signal-transmission path is formed, a high-frequency-elimination circuit provided at the main-body-device-side ends, which eliminates entry of the high-frequency signal to the main-body device, and a tuner that connects one of ends of the antenna part, the end being provided on the main-body-device side, to an antenna-input terminal and that receives a broadcast wave falling within the first frequency band corresponding to the antenna part's length is provided. The other end of the antenna part is an open end.

Owner:SONY SEMICON SOLUTIONS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com