Patents

Literature

37 results about "Treatment resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1. rejection or resistance on the behalf of a person to accept psychological or medical remediation or unwillingness to adhere to the therapy professional. TREATMENT RESISTANCE: "Treatment resistance is common in couples therapy by one partner or the other.".

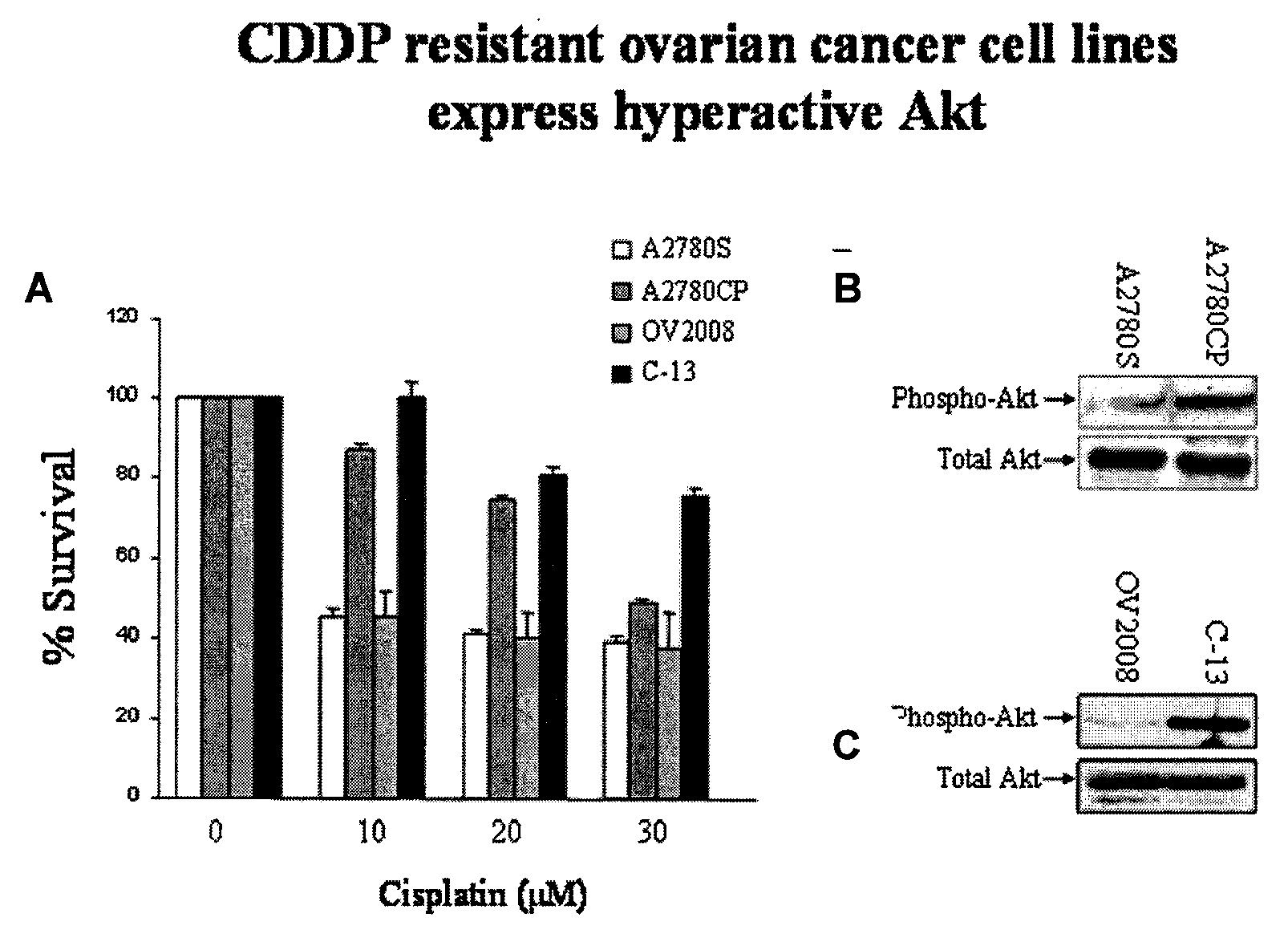

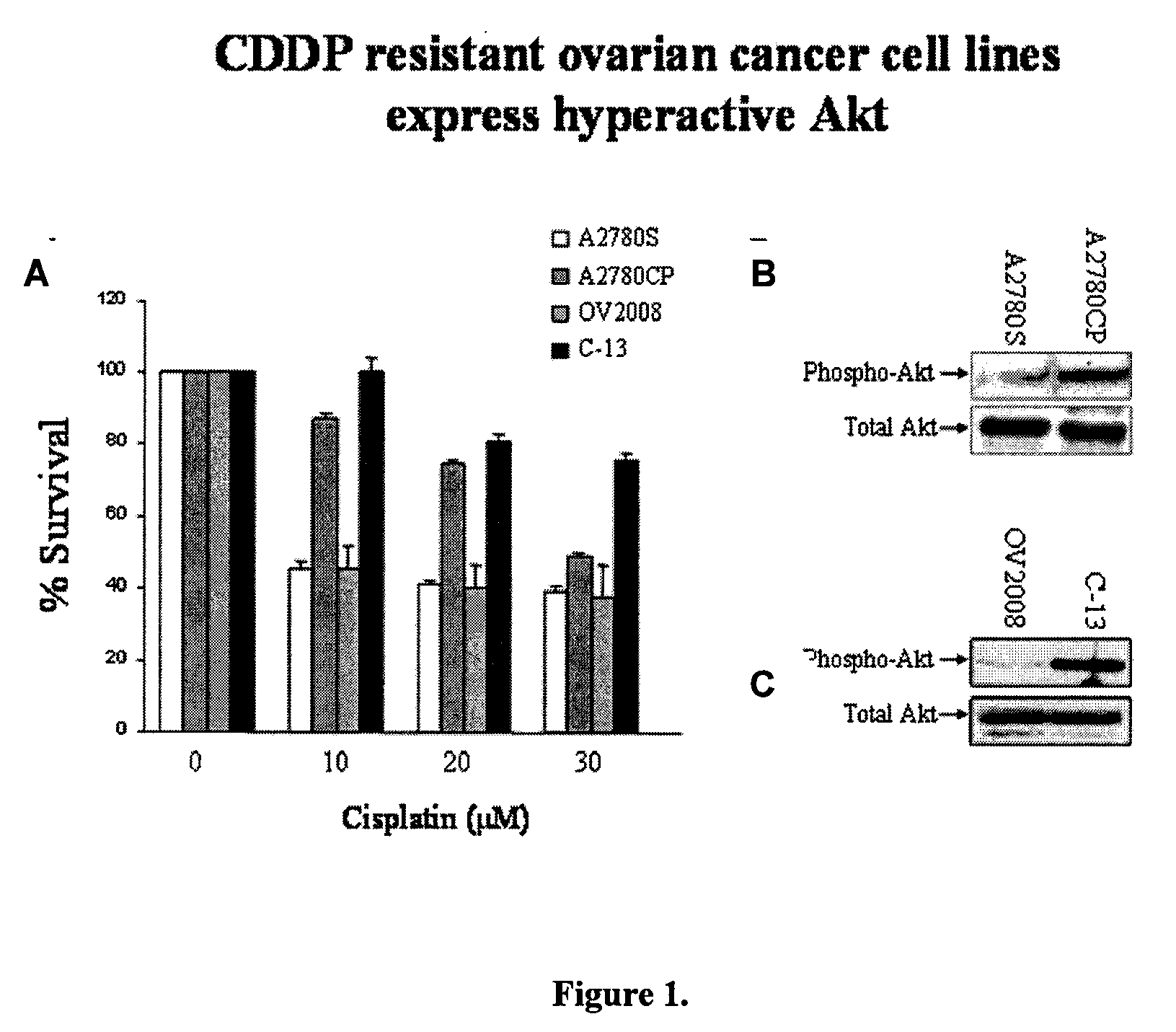

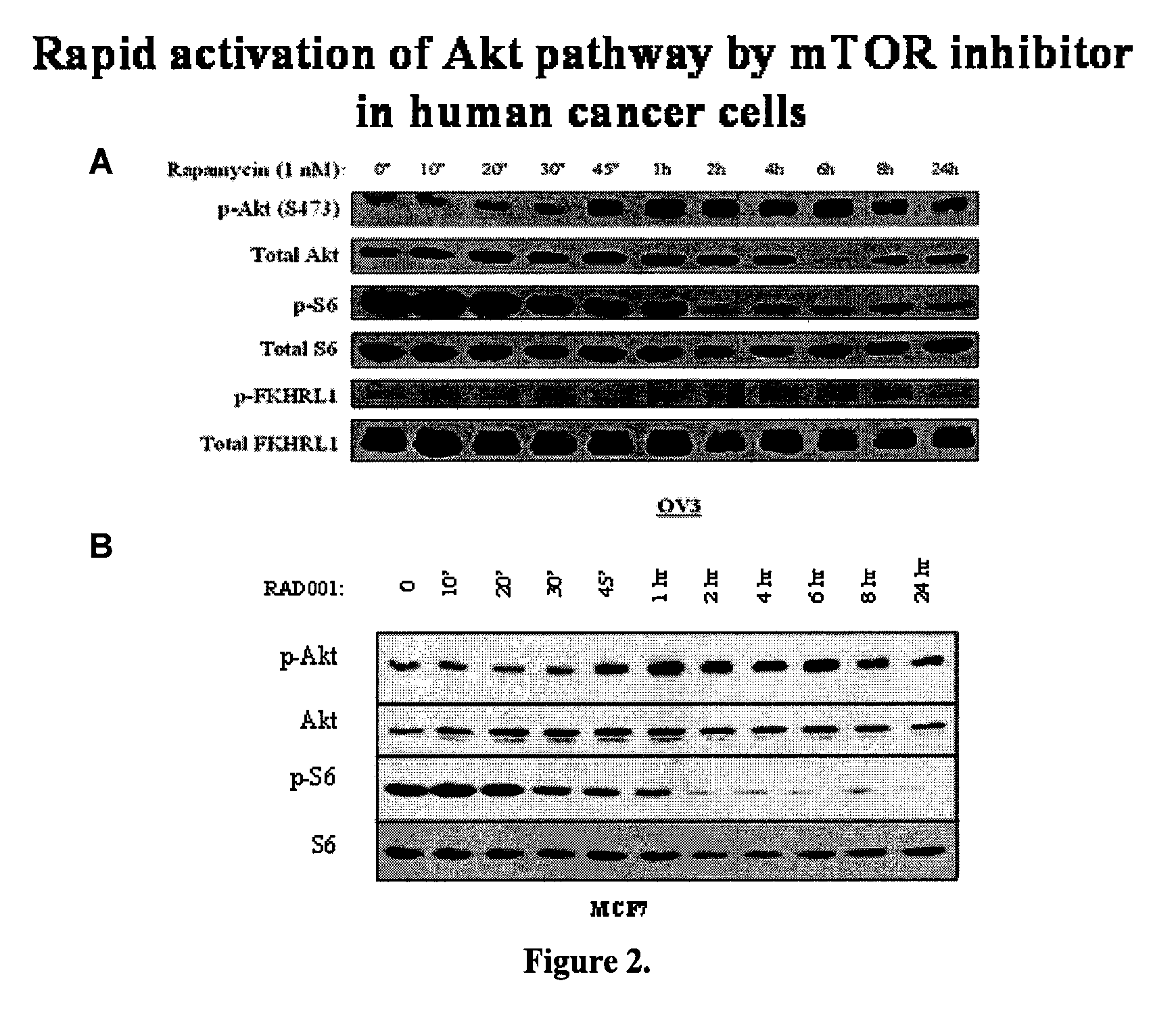

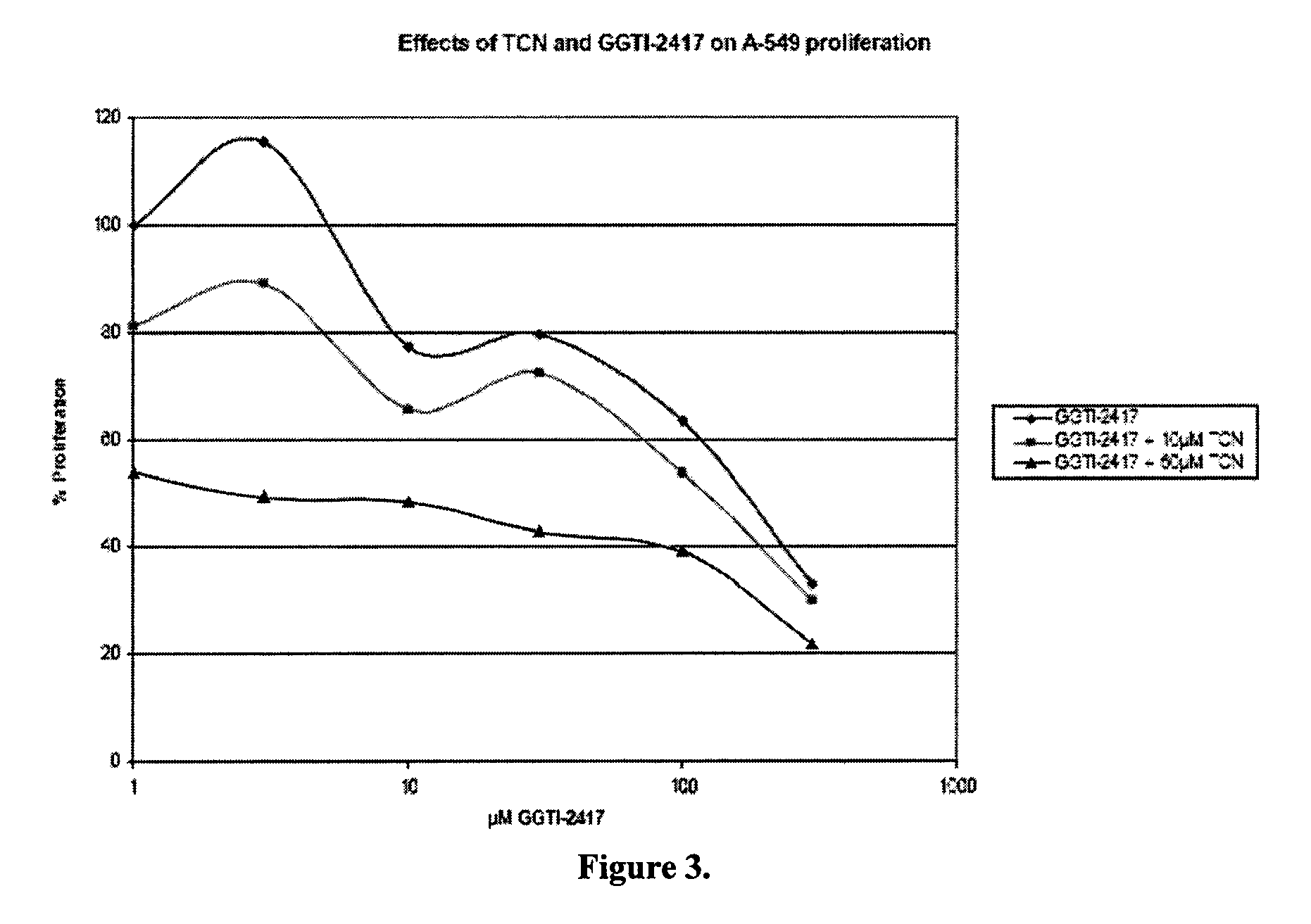

Akt sensitization of cancer cells

ActiveUS20080131526A1Broaden spectrumEffective treatmentHeavy metal active ingredientsAntibody ingredientsLung cancerTriciribine

Most human tumors find ways to resist anticancer drug monotherapy. Akt is considered a likely peptide providing such monotherapy drug resistance. Data indicates that Akt chemoresistance is induced in a p53-dependent manner and that inhibition of Akt may be an effective means of overcoming chemoresistance in cancer cells expressing wild-type p53. Breast, ovarian, lung cancer and leukemia cells lines were treated with combinations of Akt activation inhibitor Triciribine (TCN) or Triciribine phosphate (TCNP) and chemotherapeutic drugs to determine the efficiency of combination therapy. Additionally, cells were introduced into xenograft models to determine in vivo effects of combination treatment. Combining TCN or TCNP with other anticancer drugs overcame cytotoxic or treatment resistance. Thus, TCN and TCNP are shown to broaden the spectrum of human tumors that can be effectively treated.

Owner:UNIV OF SOUTH FLORIDA

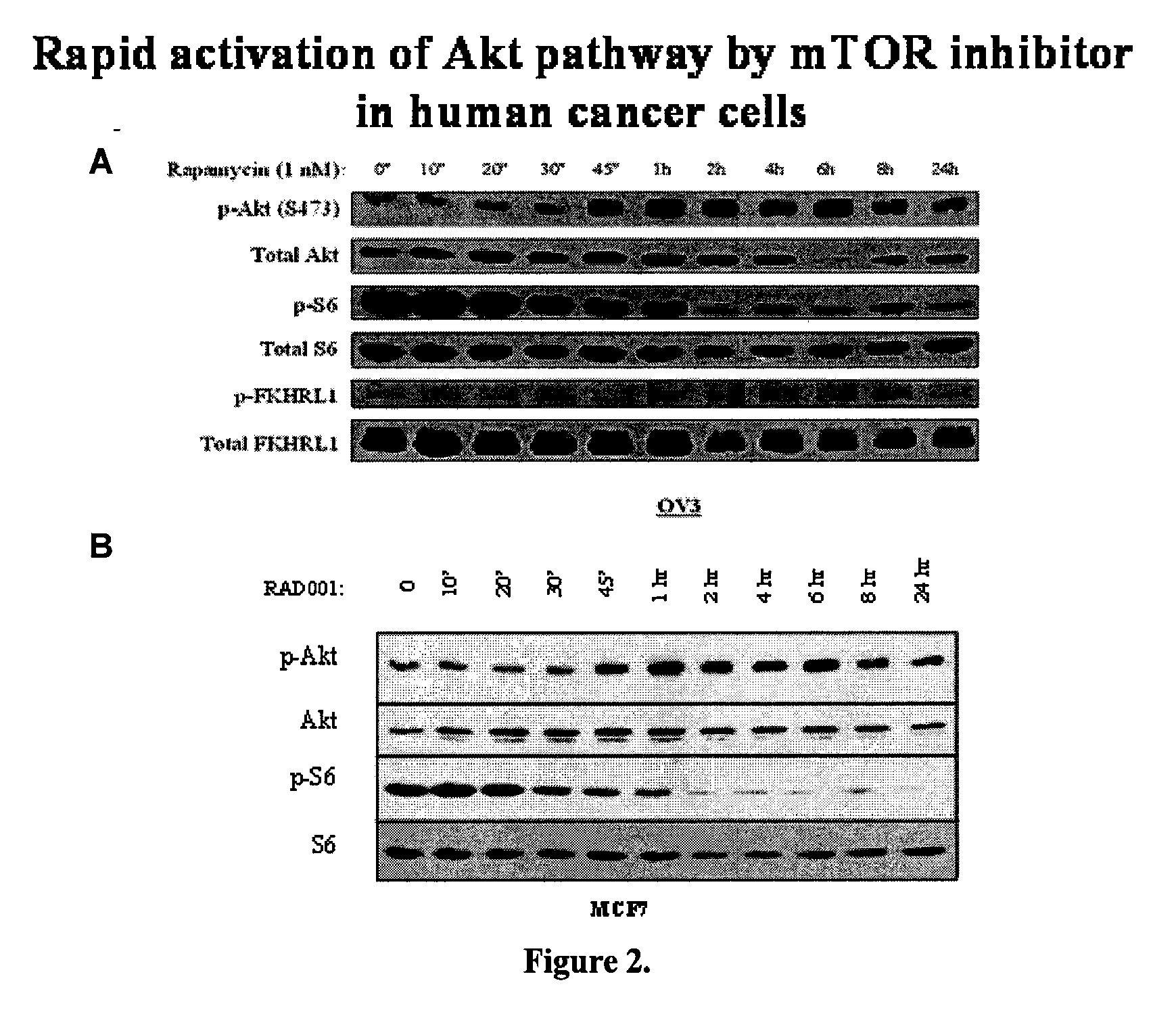

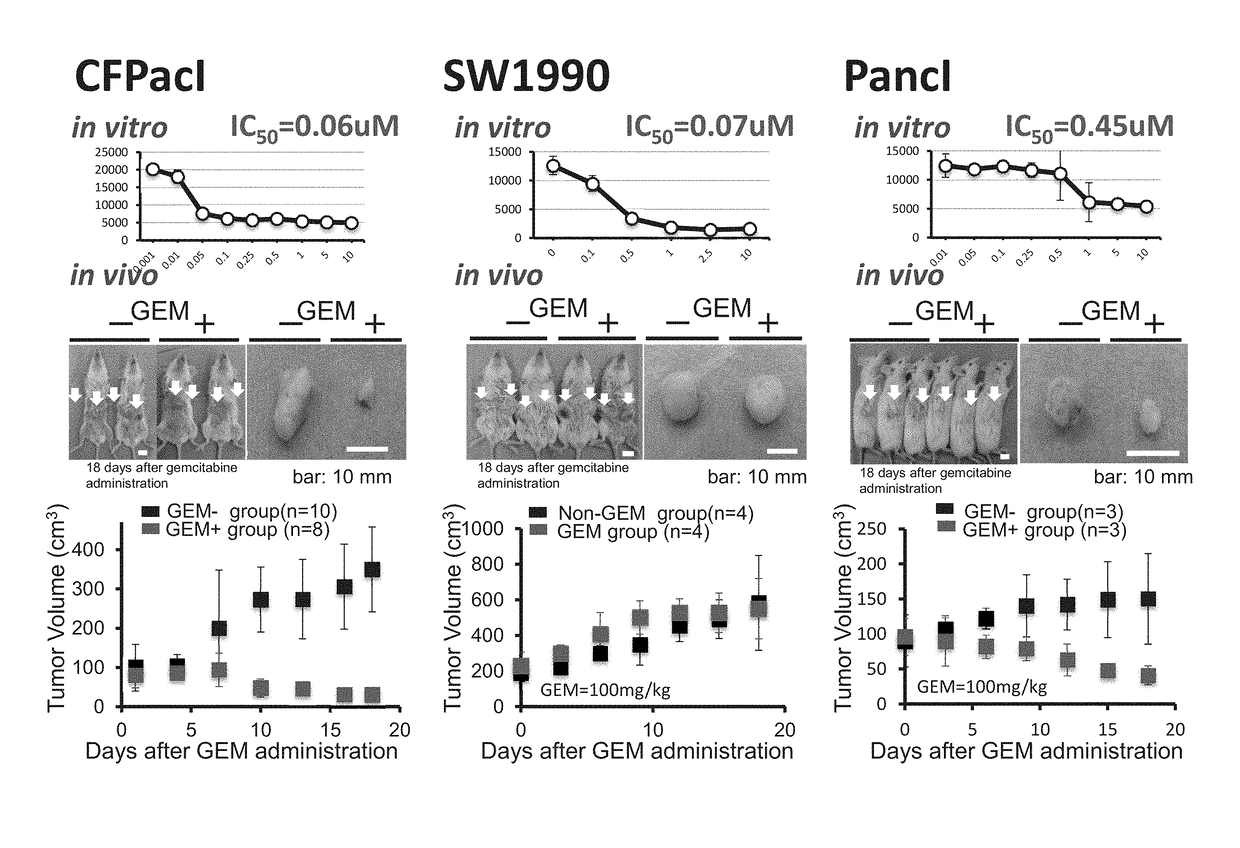

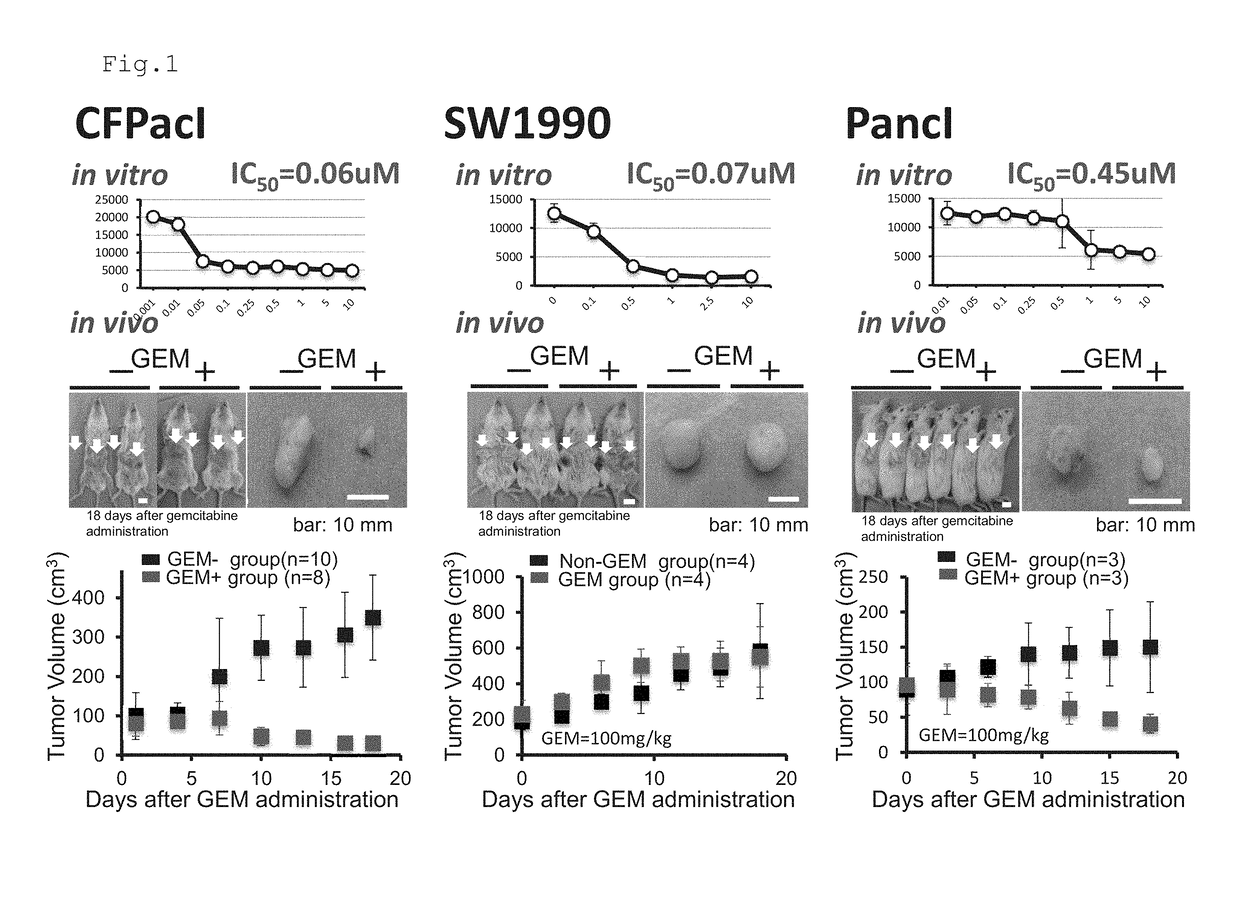

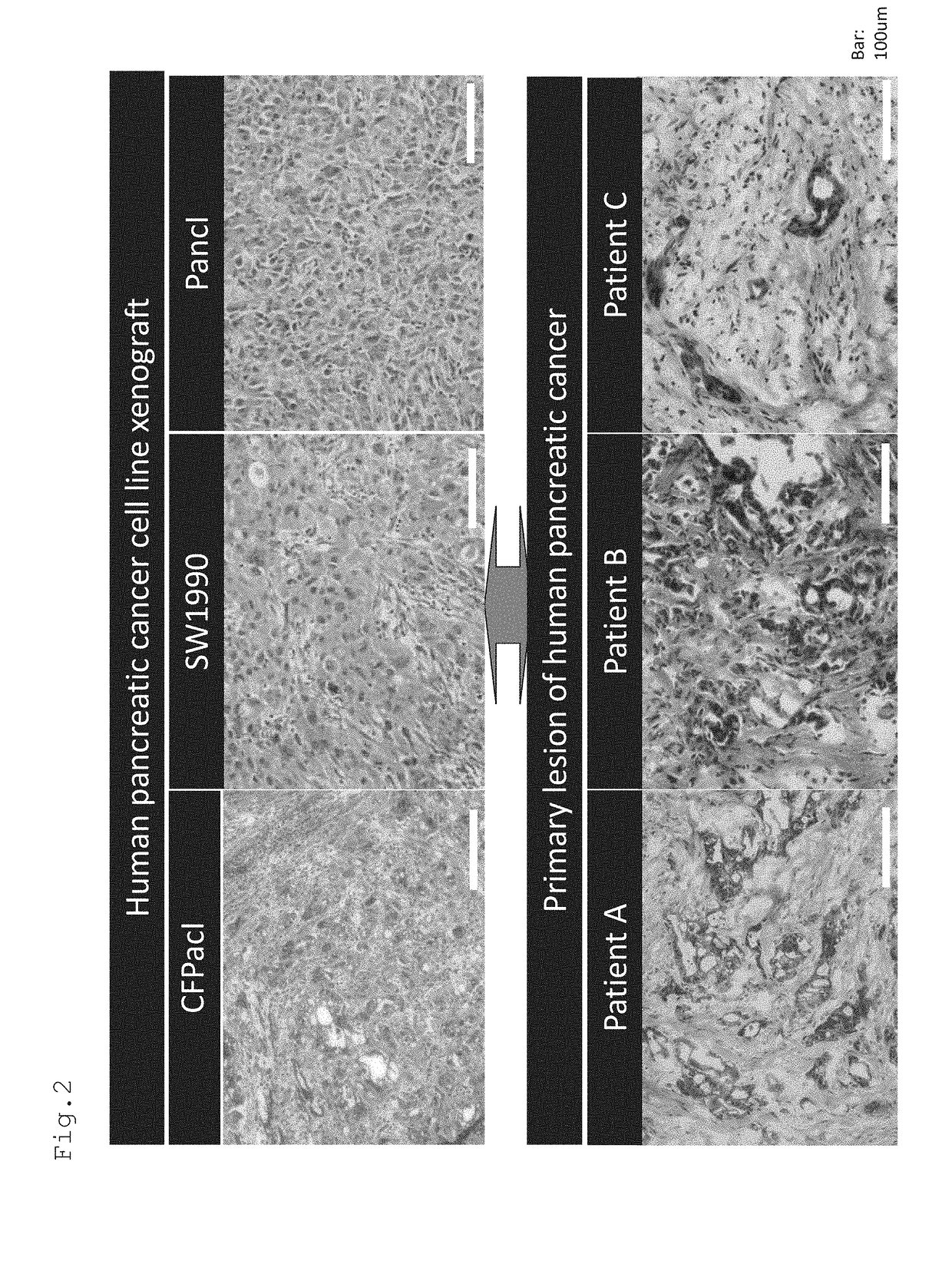

Method for reconstituting tumor with microenvironment

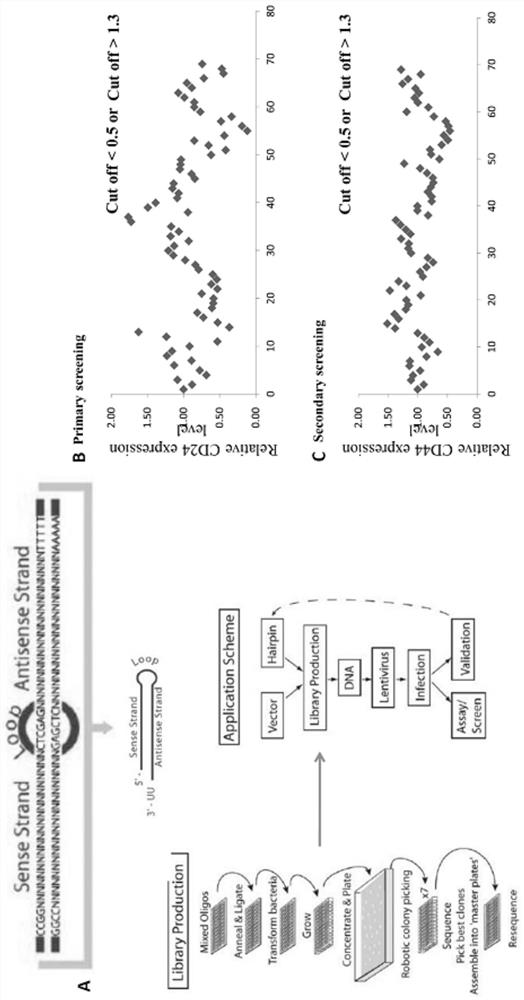

PendingUS20170285002A1Reduce sensitivityGenetically modified cellsPancreatic cellsHuman tumorPrognostic prediction

It is intended to develop a technique that can reproduce a microenvironment of cancer tissue and to construct a novel drug discovery screening system of high precision. It is also intended to provide a method for reconstituting human cancer tissue using primary human cancer cells that retain the properties of human tumor. The present invention provides a reconstituted cancer organoid reproducing a cancer microenvironment. The present invention also provides a method for preparing a cancer organoid from cancer tissue, a xenograft prepared from the cancer organoid, a method for preparing the xenograft, a method for evaluating treatment resistance of cancer, a method for evaluating invasion or metastasis of cancer, a method for evaluating recurrence of cancer, and a method for conducting prognostic prediction of cancer.

Owner:PUBLIC UNIV CORP YOKOHAMA CITY UNIV

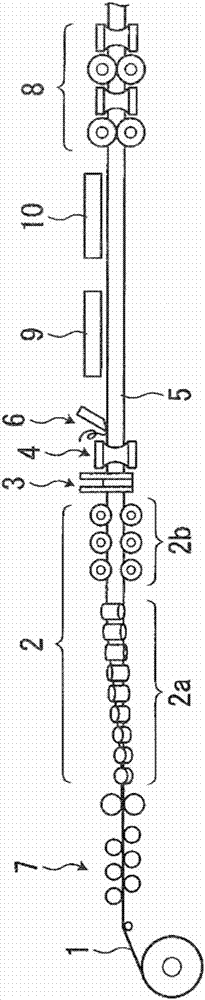

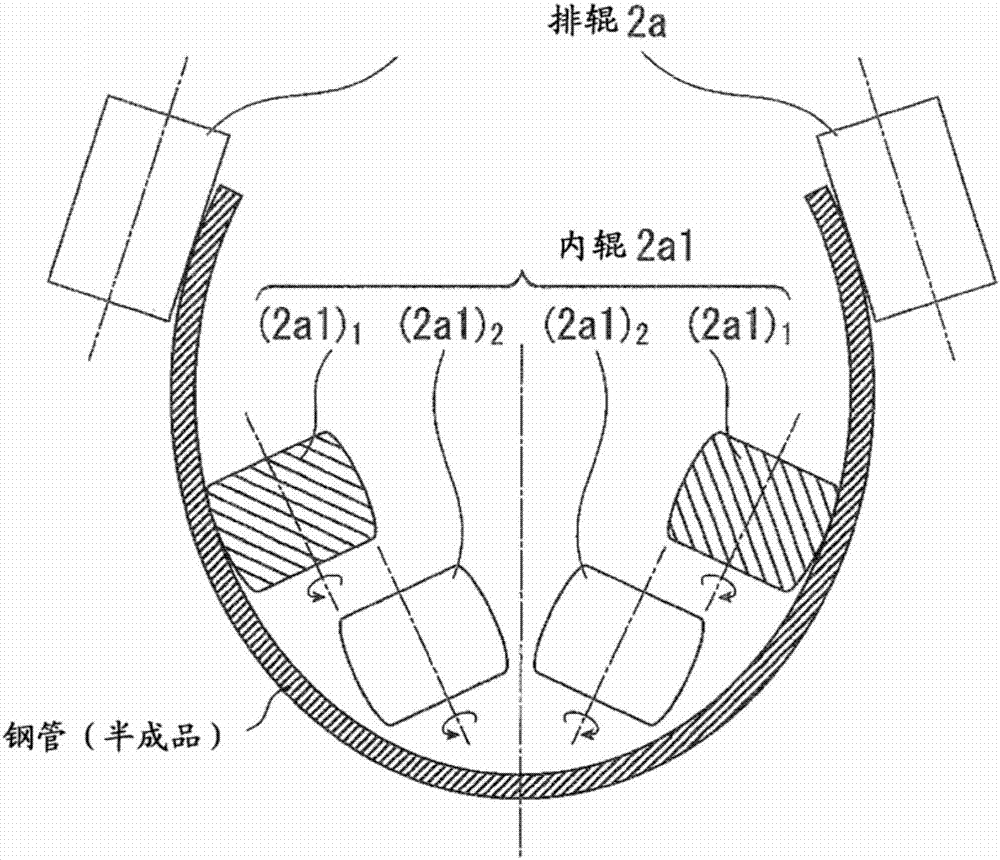

High-strength thick-walled electric resistance welded steel pipe for conductor casing for deep well, production method therefor, and high-strength thick-walled conductor casing for deep well

ActiveCN107109567AHigh strengthSimple and cheap to manufactureFurnace typesMetal rolling arrangementsElectrical conductorThick wall

Provided is an electric resistance welded steel pipe that has high strength, high toughness, and excellent post-welding heat treatment resistance. A hot-rolled steel sheet comprising the following is used as a starting material: a composition containing 0.01-0.12% of C, 0.05-0.50% of Si, 1.0-2.2% of Mn, 0.03% or less of P, 0.005% or less of S, 0.001-0.10% of Al, 0.006% or less of N, 0.010-0.100% of Nb, and 0.001-0.050% of Ti; and a structure that comprises 90% by volume or more of a main phase that is a bainitic ferrite phase and 10% or less (including 0%) by volume of a second phase, in which the average particle size of the bainitic ferrite phase is 10 [mu]m or less and extremely fine Nb deposits having a particle size of less than 20 nm are dispersed at a rate that, when calculated in terms of Nb, is equal to or less than 75% by ratio (%) of the total amount of Nb. The starting material is formed to have a substantially circular cross section by roll forming and subsequently subjected to electric resistance welding in order to obtain an electric resistance welded pipe, the electric resistance welded section of the electric resistance welded pipe is subjected to inline heat treatment, and the result is subjected to diameter reduction rolling so that the deviation from roundness of a steel pipe end section is 0.6% or less.

Owner:JFE STEEL CORP

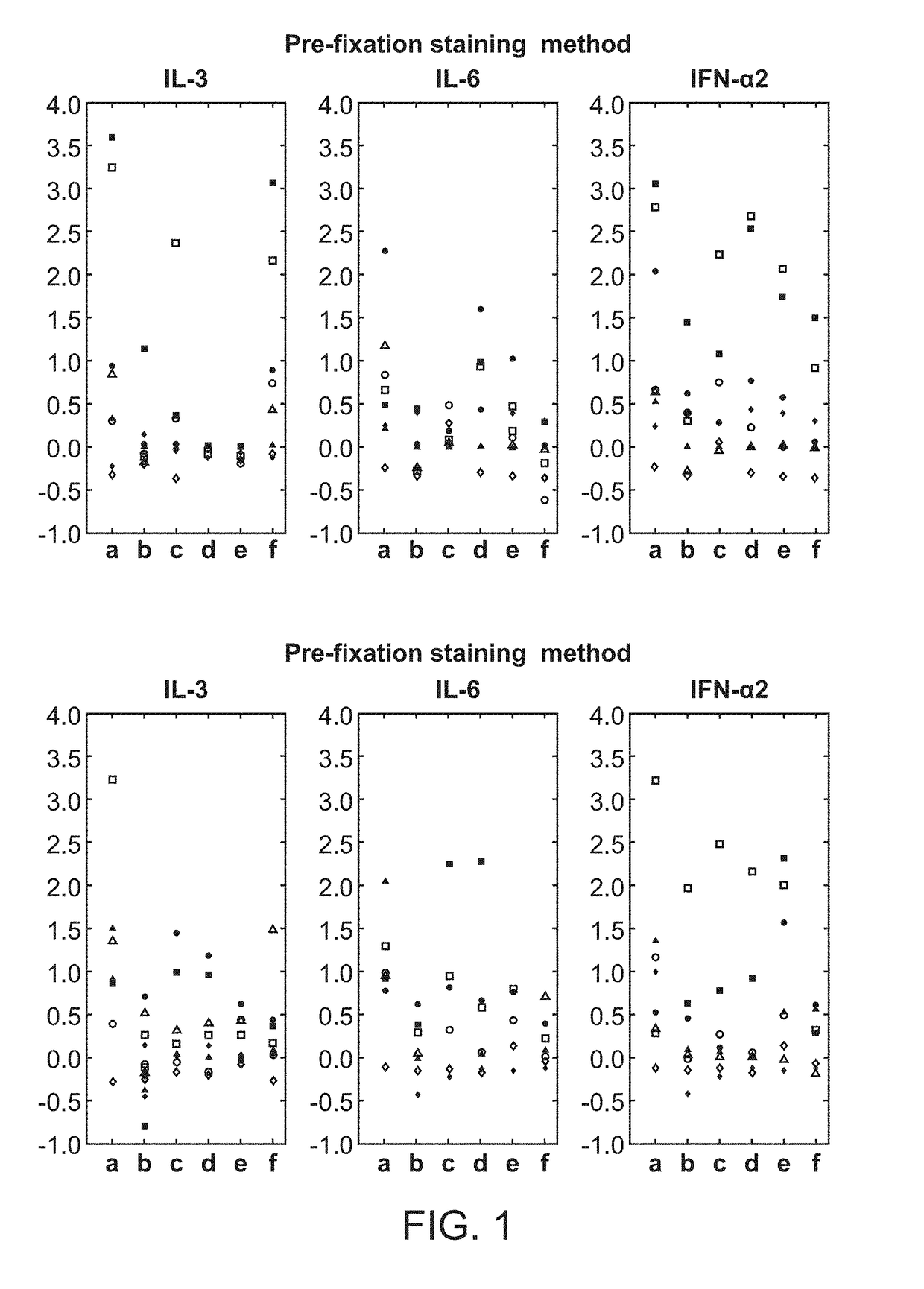

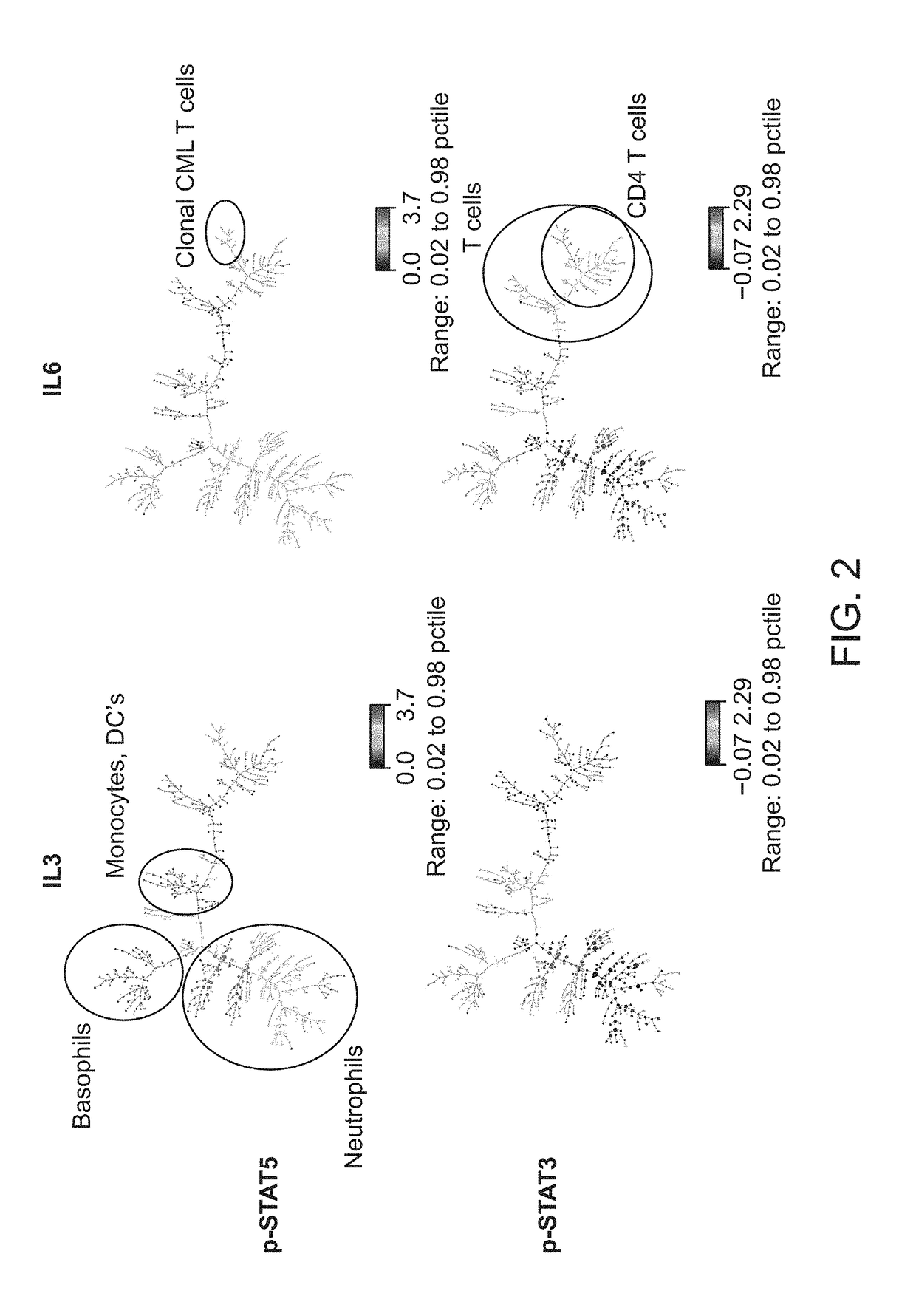

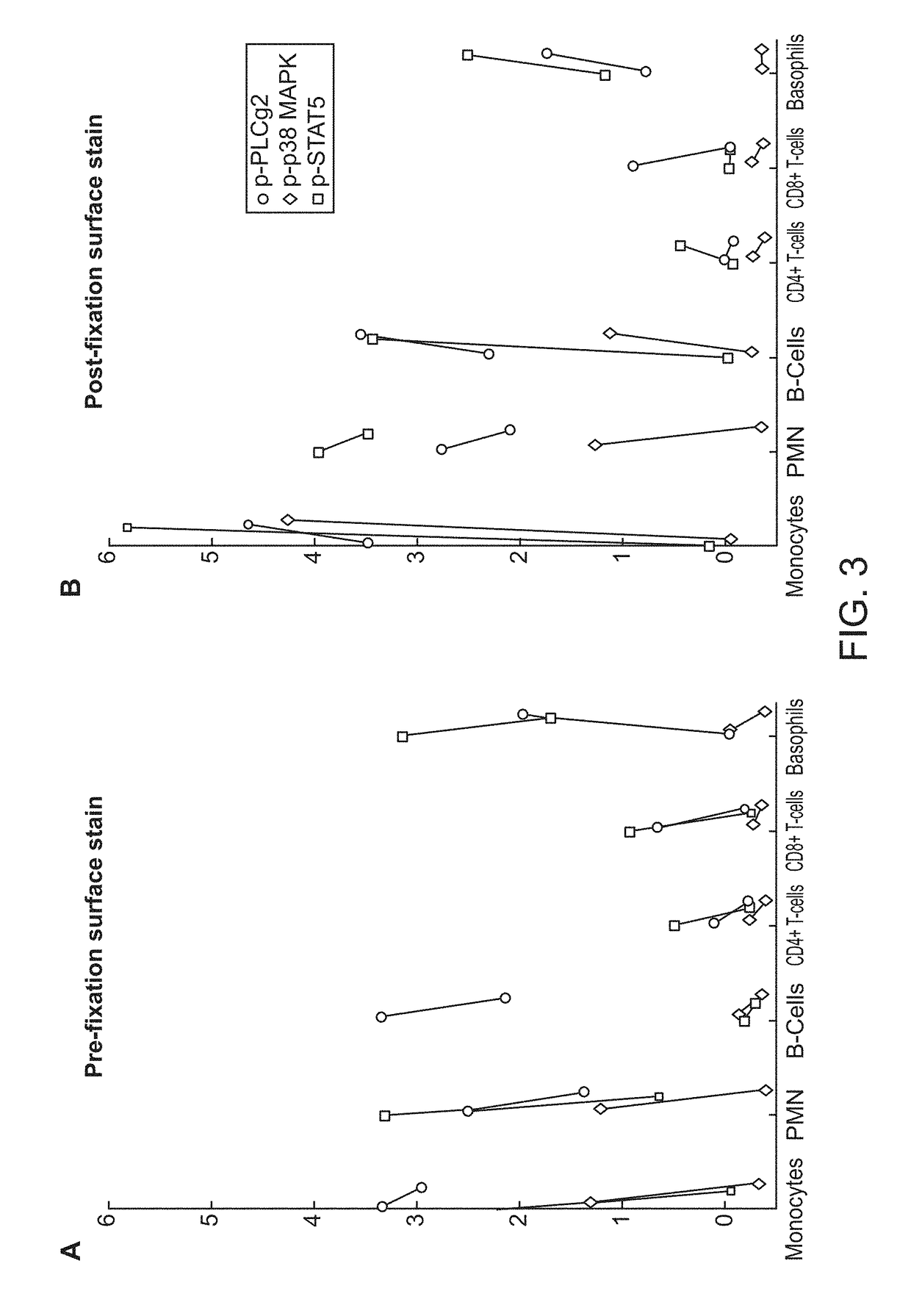

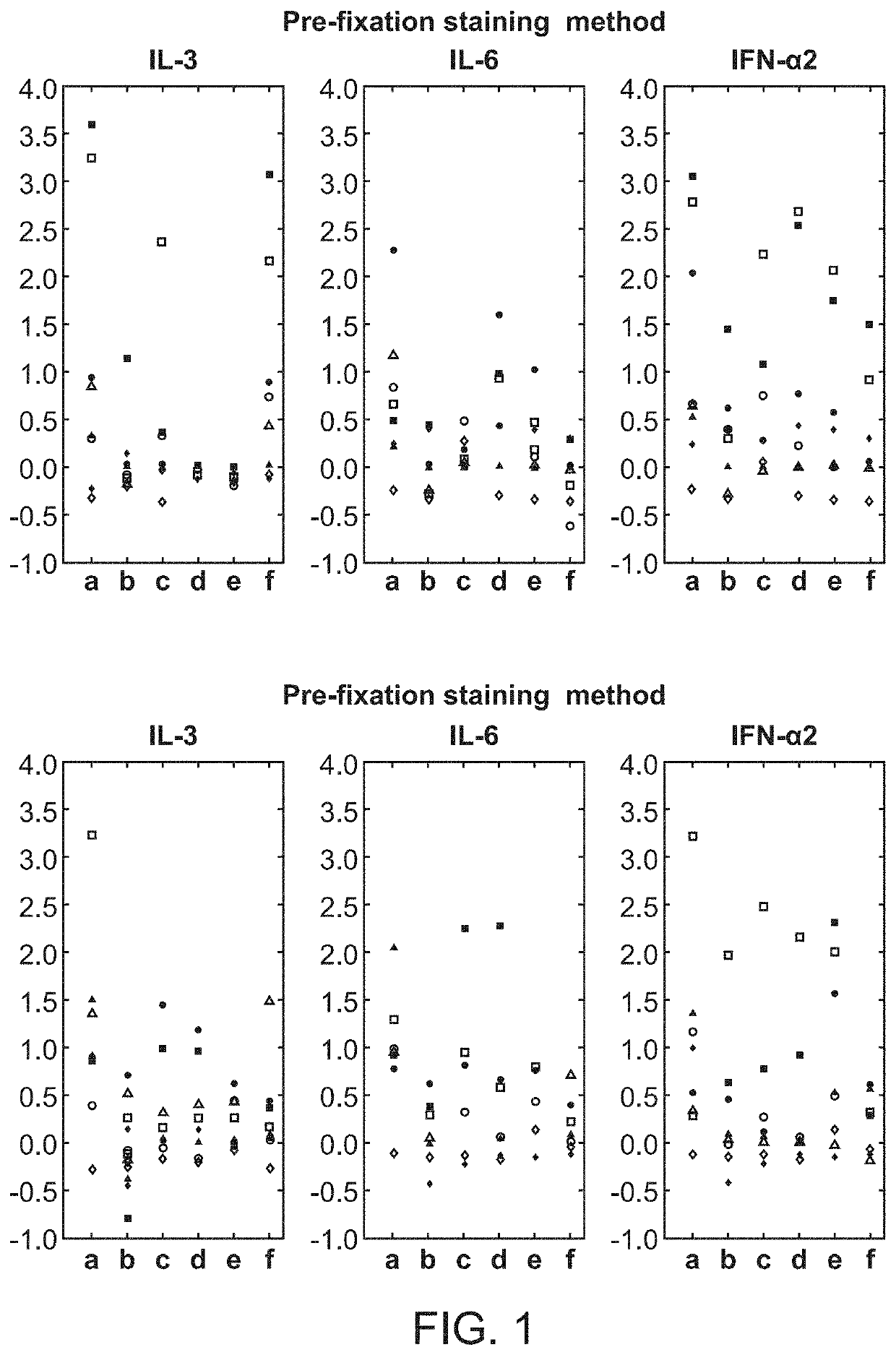

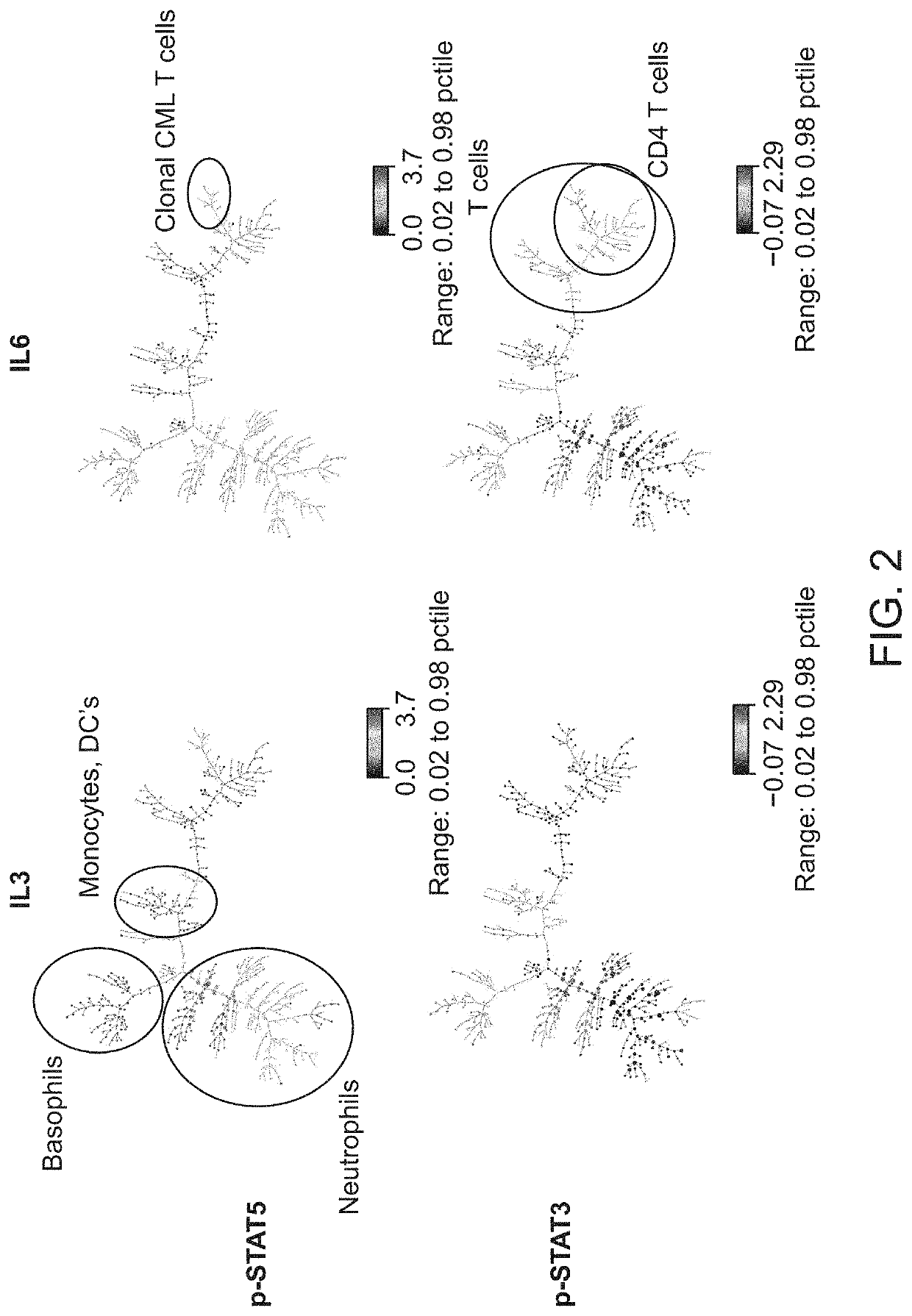

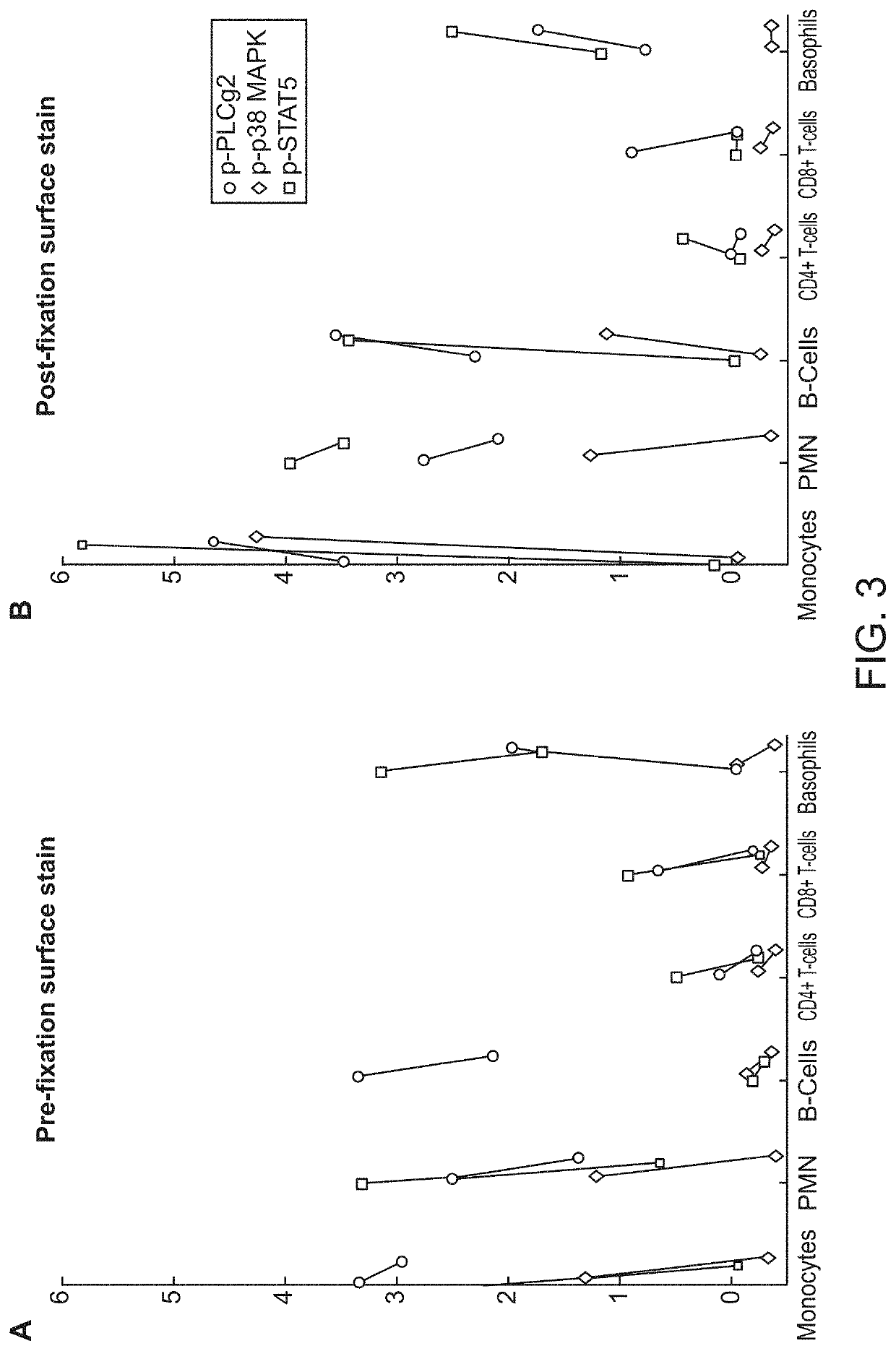

Cell-specific signaling biomarker analysis by high parameter cytometry; sample processing, assay set-up, method, analysis

ActiveUS20180252708A1Facilitate data interpretationEasy to explainDisease diagnosisIndividual particle analysisMarker selectionProgenitor cell

The present invention recognizes that current clinical laboratory testing methods for multiparametric single cell analysis are limited to analysis of intact live cells, and are insufficient for identification of signaling activation profile defining certain cell types, including but not limited to neoplastic and immunologically activated cell subsets. One aspect of the present invention generally relates to marker selection in panels to include proteins routinely assessed in standard FCM, while preferably also incorporating markers for surface receptor proteins within activated signaling cascades. A further aspect of the present invention generally relates to panel design for the following indications in neoplastic and non-neoplastic clinical applications as examples of the technology: (a) identification of CML progenitor cell subsets in the setting of disease recurrence after treatment discontinuation or relapse due to treatment resistance, and (b) characterization of activated basophils to predict the severity of an allergic response. Another aspect of the present invention generally relates to methods to measure levels of surface and IC biomarkers in separate or combined assays for robust characterization of each or select cell compartment, and data analysis based on results from each or all method(s) used for optimal detection of the markers. A further aspect of the present invention generally relates to the identification and profiling of cell subpopulations based on analysis of surface markers including those associated with lineage and maturation of cell types and receptor proteins, and the corresponding IC phosphoproteins including those in activated signaling cascades to predict certain disease states or response to treatment.

Owner:DEEPATH MEDICAL

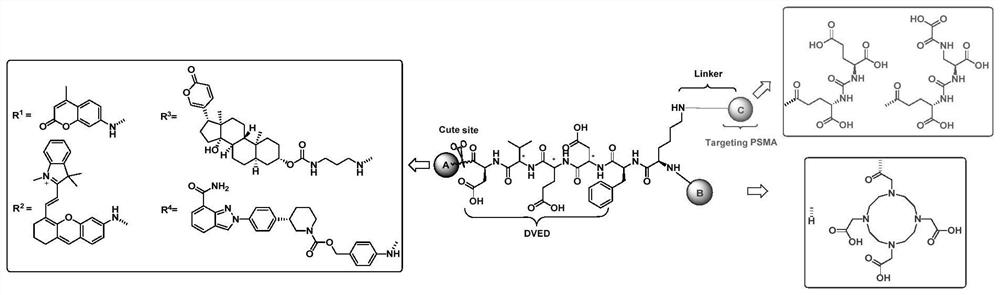

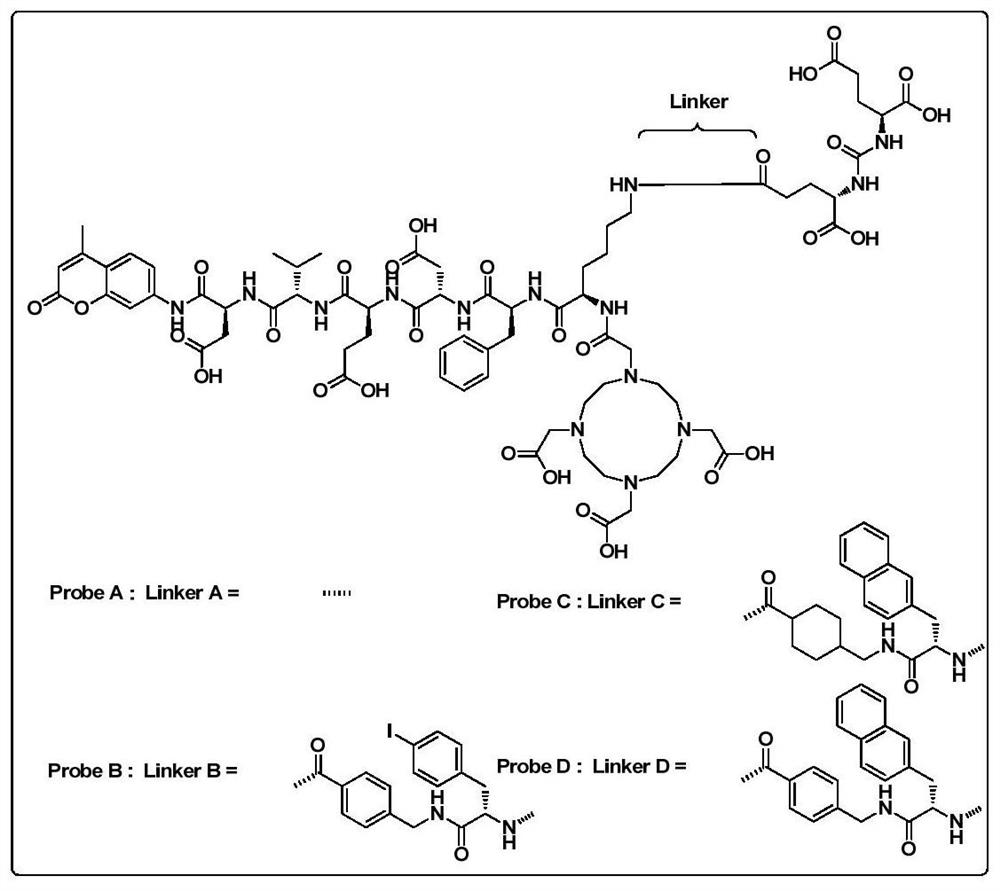

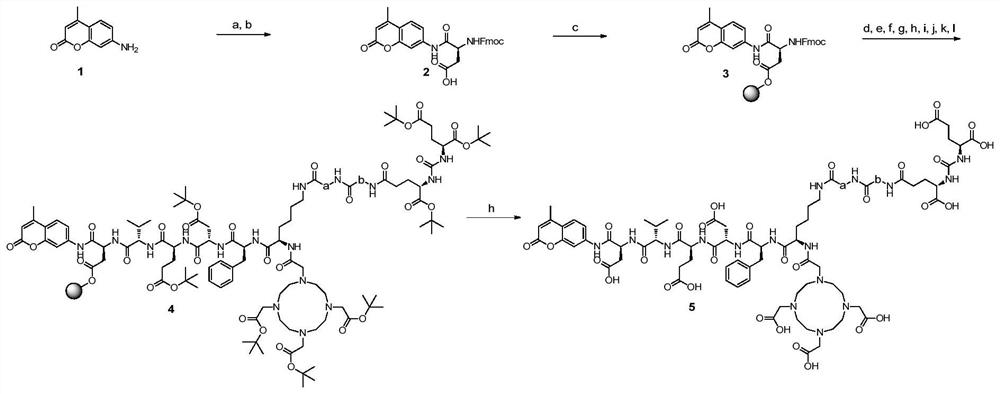

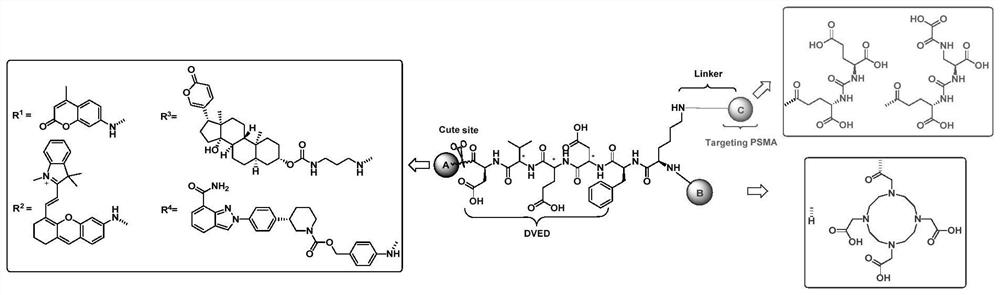

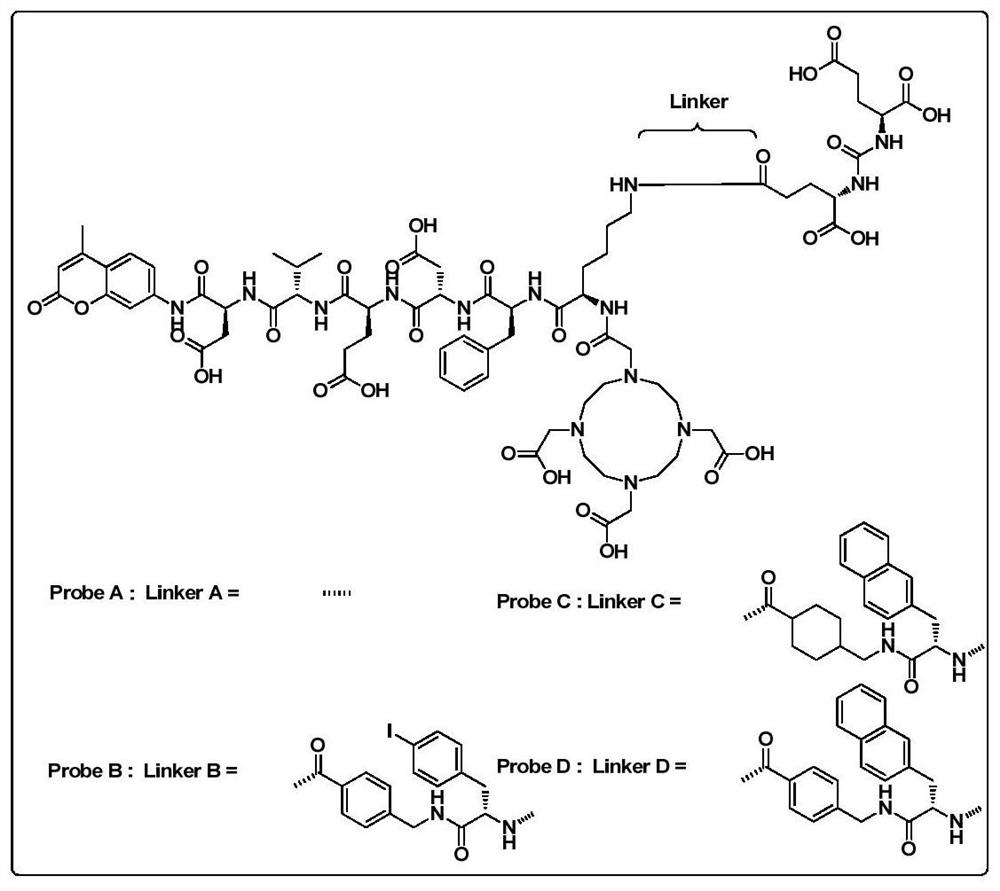

Double-enzyme system probe and application thereof

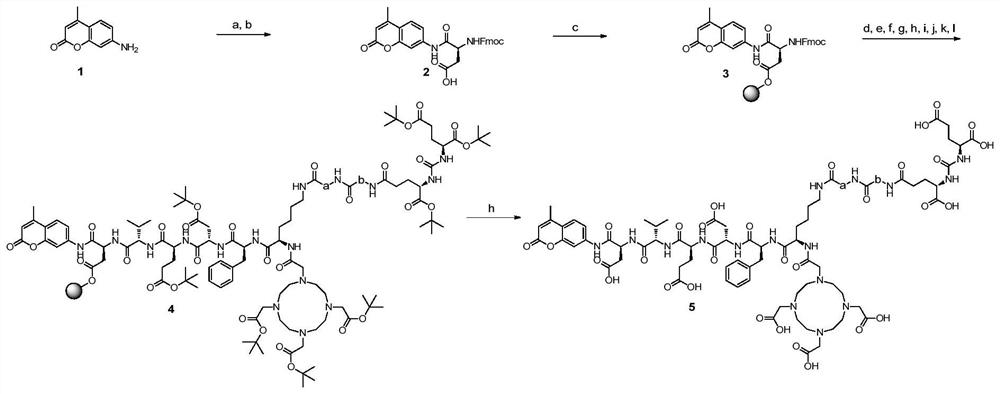

ActiveCN112574280AAddress resistanceResolve Healing EffectsRadioactive preparation carriersPeptide preparation methodsAntigenProstate specific membrane

The invention belongs to the field of nuclear medicine, and relates to a double-enzyme system probe and application thereof. The probe has a structure shown as a formula I, and QD is a fluorophore ora drug group; L is a linker and has a structure as shown in a formula II; T is a PSMA specific targeting group; and Z is H, a nuclide chelating group, radionuclide or a nuclide chelating group chelated with radionuclide. The double-enzyme system nuclear medical probe for delivering drug molecules based on prostate specific membrane antigen PSMA targeting and Caspase-3 recognition strategies can target prostate cancer to perform radiotherapy sensitization treatment, is beneficial to solving the problems of radiotherapy resistance, targeted nuclide treatment resistance and the like of castration-resistant prostate cancer patients, and is expected to realize navigation in prostate cancer surgery. More efficient tools are provided for detection and treatment of tumor treatment, and wide application prospects are achieved.

Owner:PEKING UNIV FIRST HOSPITAL

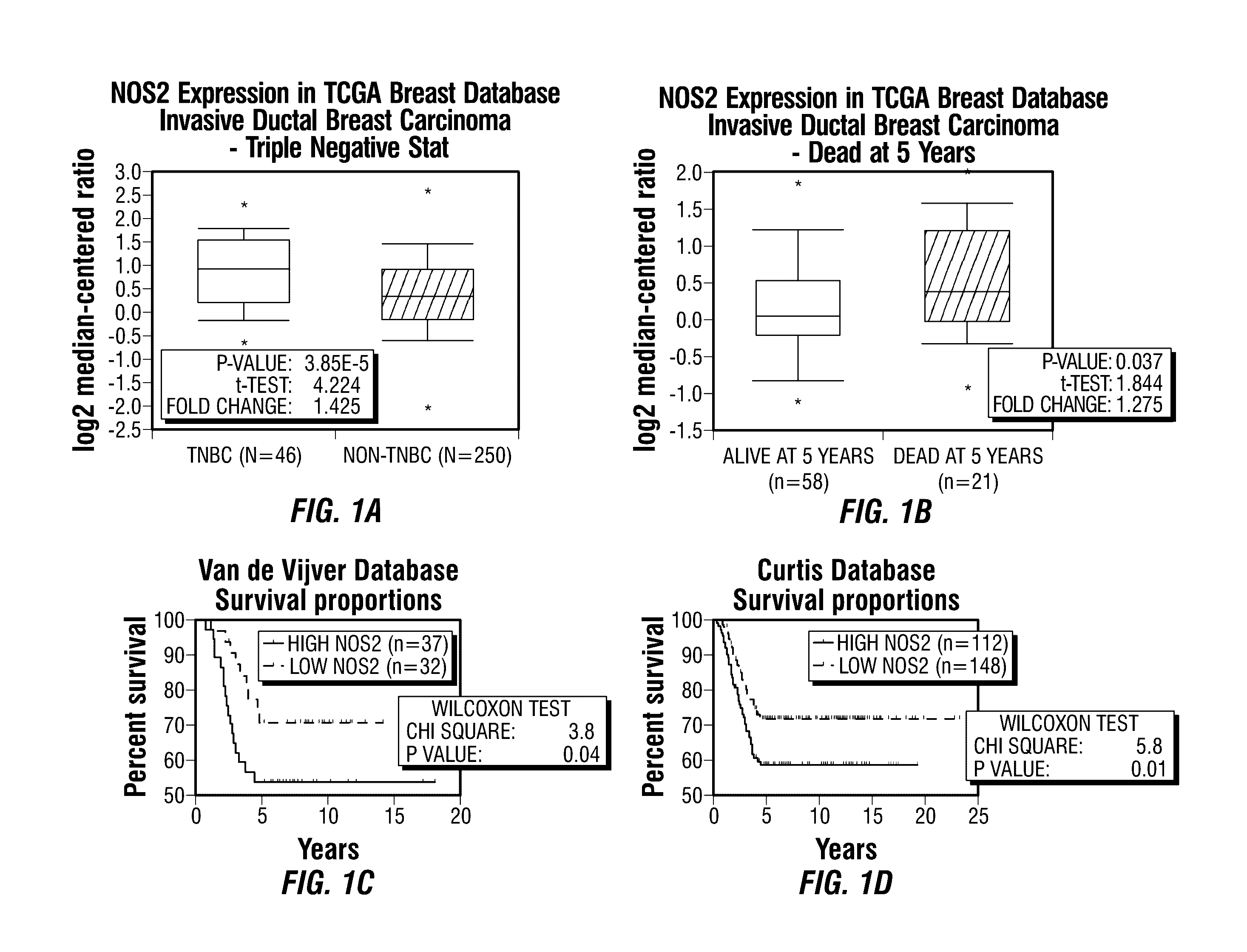

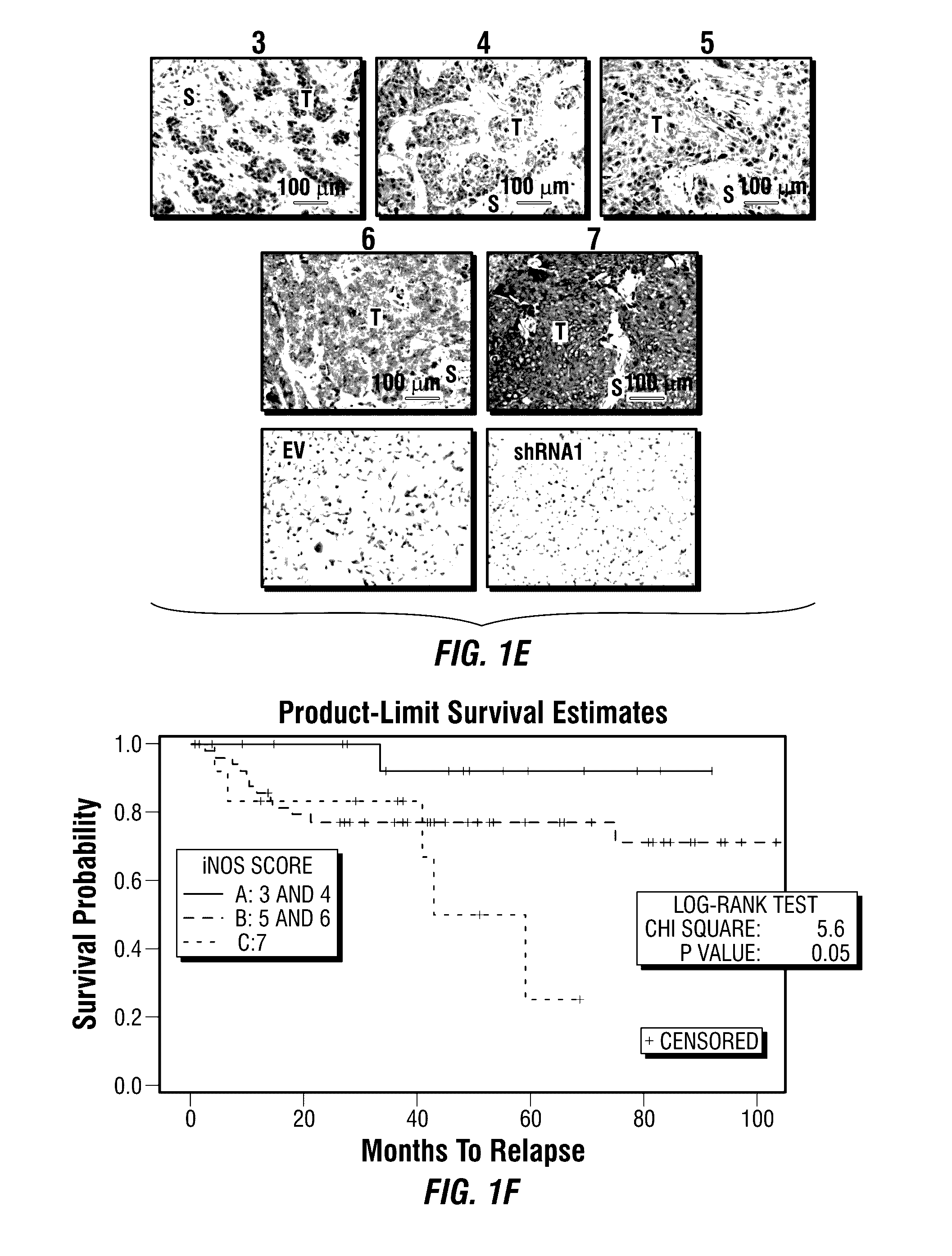

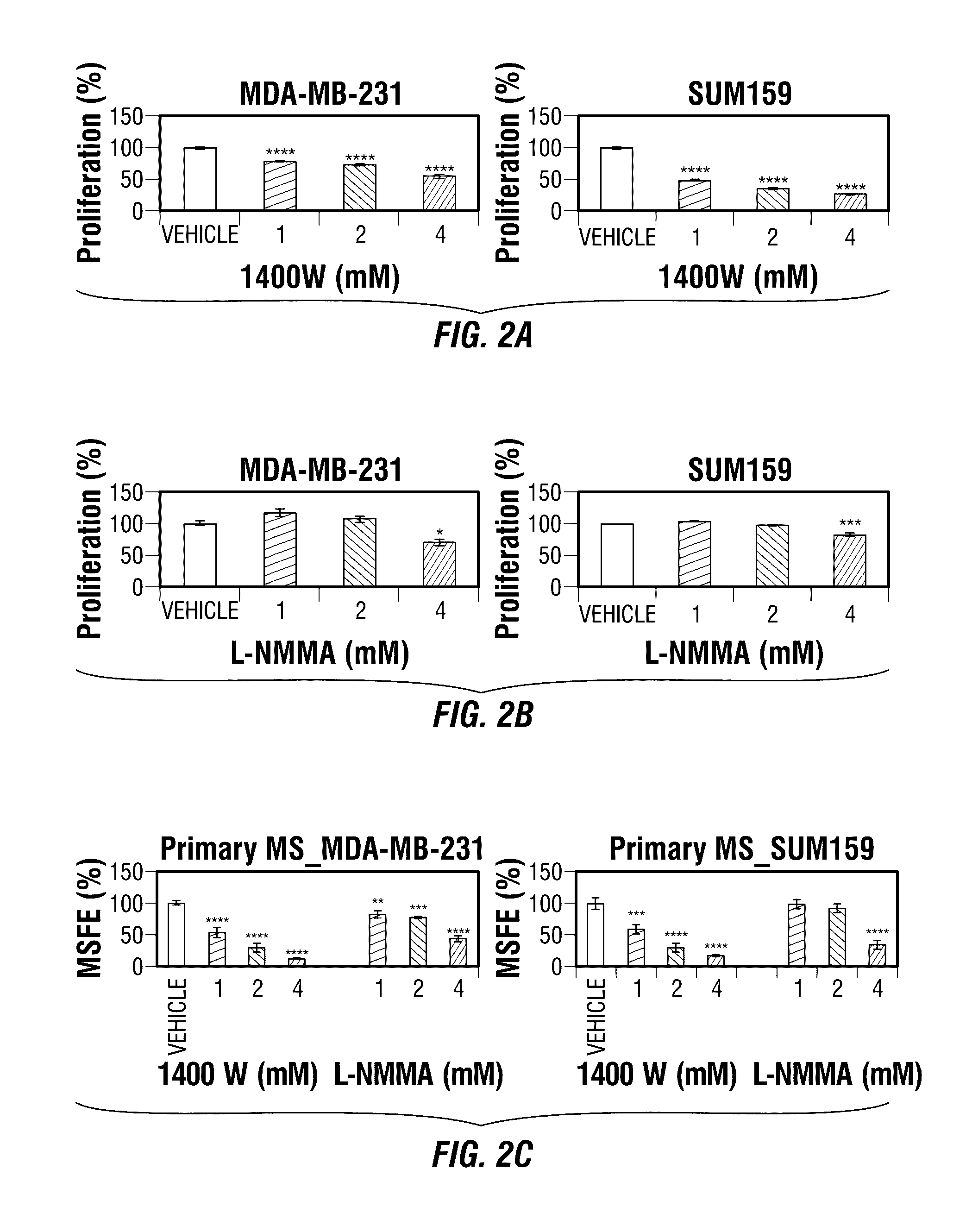

Inos-inhibitory compositions and their use as breast cancer therapeutics

InactiveUS20170020835A1Unexpected benefitEasy to useInorganic active ingredientsAntibody ingredientsRefractoryHuman breast

Disclosed are methods for treating one or more mammalian cancers, and in particular, methods for treating human breast cancer employing one or more iNOS pathway-inhibitory compounds, either alone, or in combination with one or more selected antihypertensive agents, including calcium channel antagonists, either alone, and further in combination with one or more conventional chemotherapeutic or anti-cancer regimens. Also disclosed are particular therapeutic formulations including these compositions, and methods for their use in treating refractory, metastatic, and relapsed cancers, and for managing or reversing treatment resistance in human triple-negative breast cancers in particular.

Owner:THE METHODIST HOSPITAL

Resistance furnace with adjustable cooling rate

InactiveCN105219933AQuality improvementAvoid enteringFurnace typesHeat treatment furnacesElectrical resistance and conductanceTemperature control

A resistance furnace with an adjustable cooling rate is composed of a furnace body (1) and a furnace door (2), a hearth inlet of the furnace body (1) is connected with the furnace door (2), heating elements (4) are arranged in the furnace body (1), circulation fans (5) are arranged at the top of the furnace body (1), and a chimney (6) is arranged at the top of the furnace body (1). The resistance furnace is characterized in that an electromagnetic butterfly valve (7) is arranged at the bottom of a flue of the chimney (6), a separation outlet is arranged at the position, above the electromagnetic butterfly valve (7), of the flue and connected with a pipeline (8) of an induced draft fan (9); and a filter hood (10) is arranged at the top of the flue. The resistance furnace is convenient and easy to operate, automatic temperature rising control, automatic constant temperature control and automatic cooling control of the heat treatment resistance furnace are organically combined together through the additionally-arranged chimney and induced draft fan, the cooling speed is effectively controlled, and the quality of high heat treatment workpieces is greatly improved; and meanwhile the situation that waste gas directly enters the air and pollutes the air can be avoided well.

Owner:江苏邦泰炉业有限公司

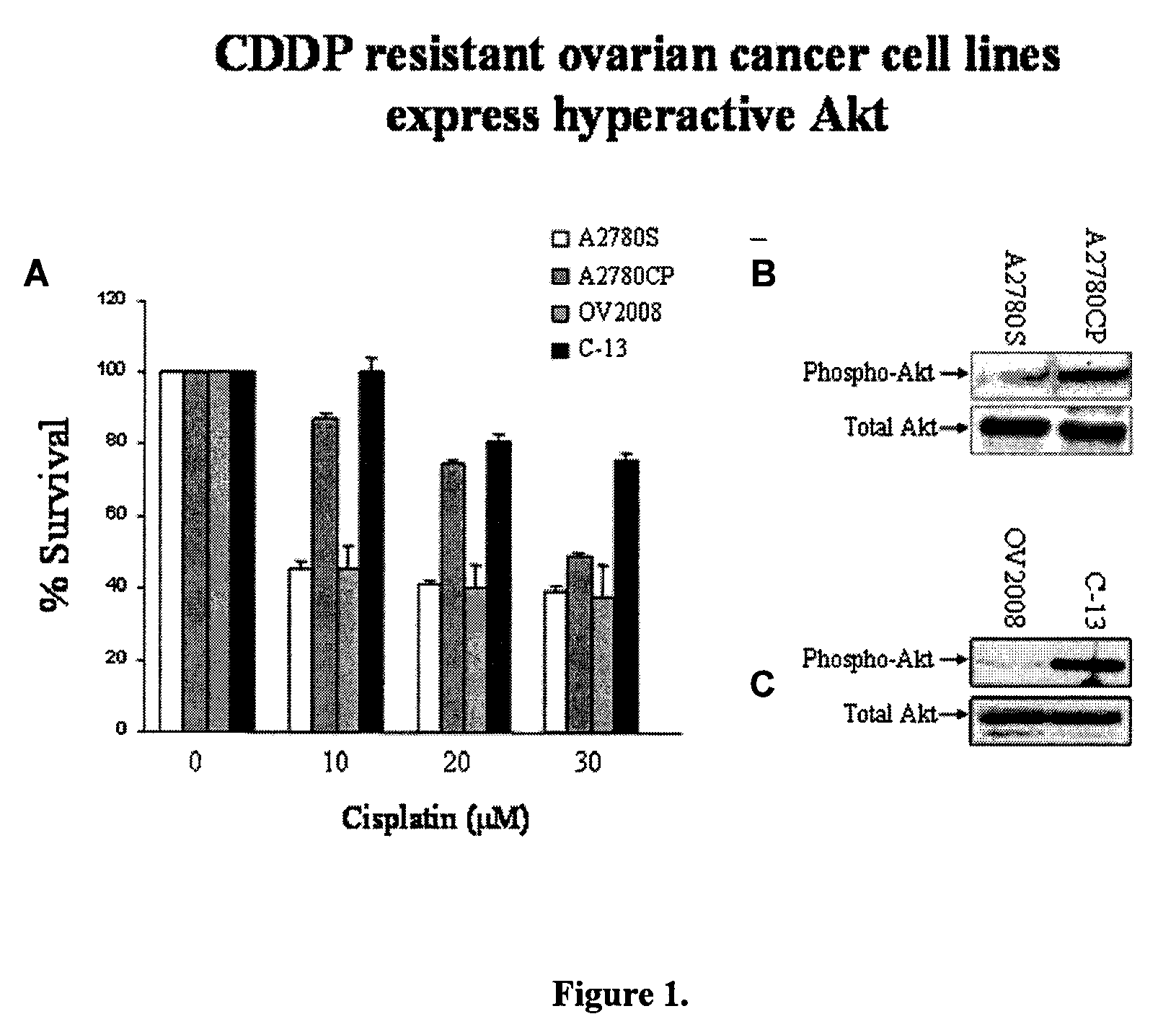

Akt sensitization of cancer cells

ActiveUS8828451B2Broaden spectrumEffective treatmentBiocideHeavy metal active ingredientsLung cancerTriciribine

Most human tumors find ways to resist anticancer drug monotherapy. Akt is considered a likely peptide providing such monotherapy drug resistance. Data indicates that Akt chemoresistance is induced in a p53-dependent manner and that inhibition of Akt may be an effective means of overcoming chemoresistance in cancer cells expressing wild-type p53. Breast, ovarian, lung cancer and leukemia cells lines were treated with combinations of Akt activation inhibitor Triciribine (TCN) or Triciribine phosphate (TCNP) and chemotherapeutic drugs to determine the efficiency of combination therapy. Additionally, cells were introduced into xenograft models to determine in vivo effects of combination treatment. Combining TCN or TCNP with other anticancer drugs overcame cytotoxic or treatment resistance. Thus, TCN and TCNP are shown to broaden the spectrum of human tumors that can be effectively treated.

Owner:UNIV OF SOUTH FLORIDA

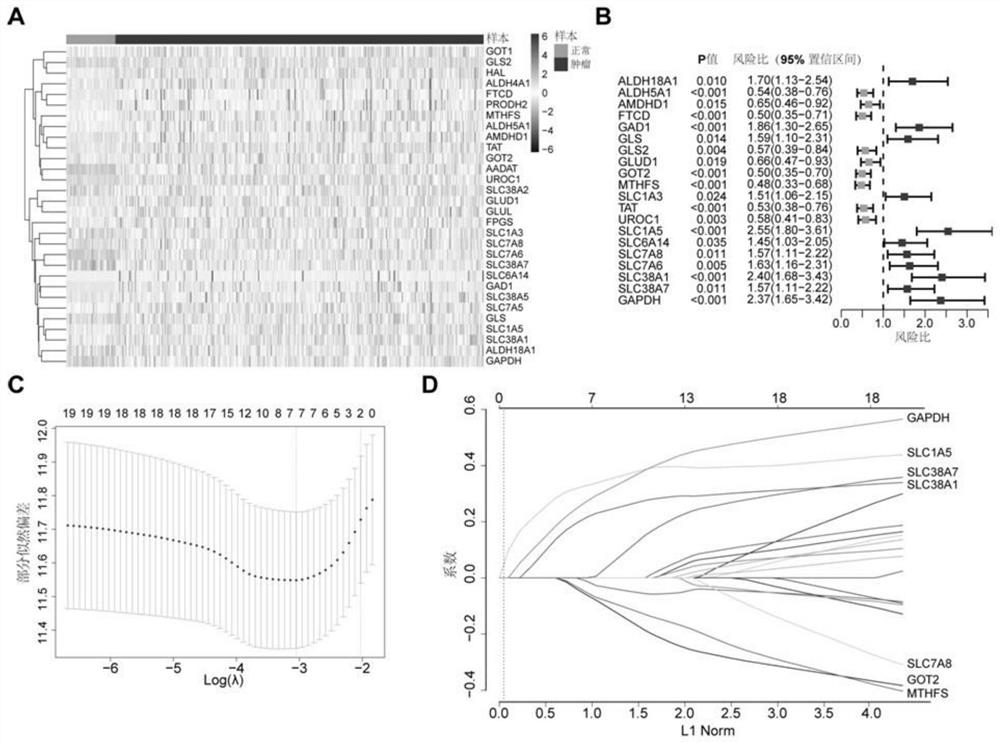

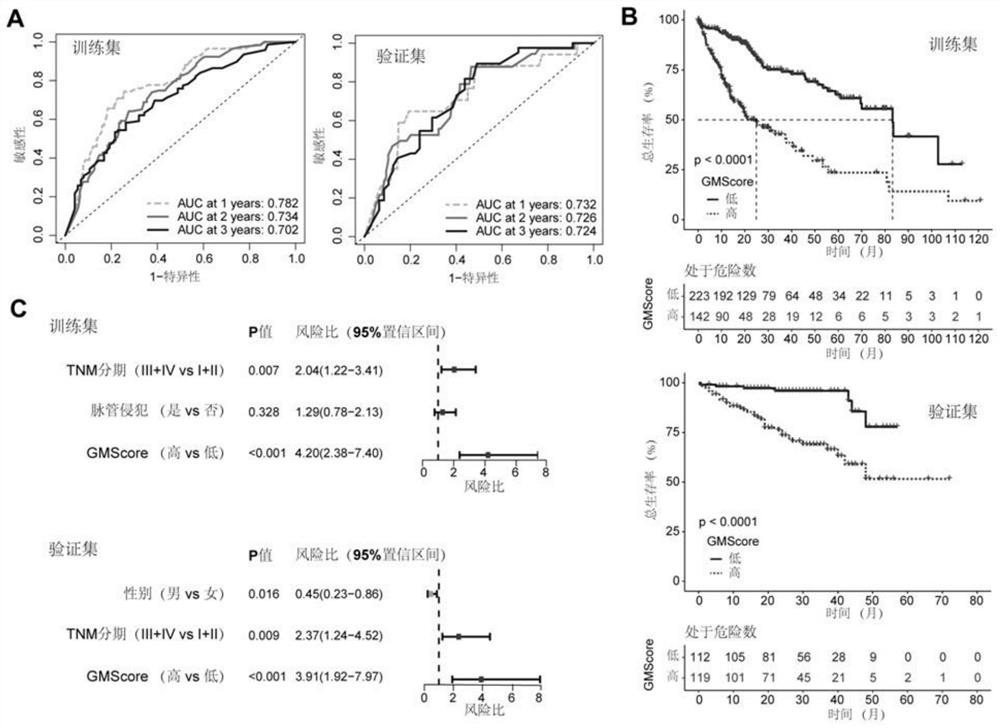

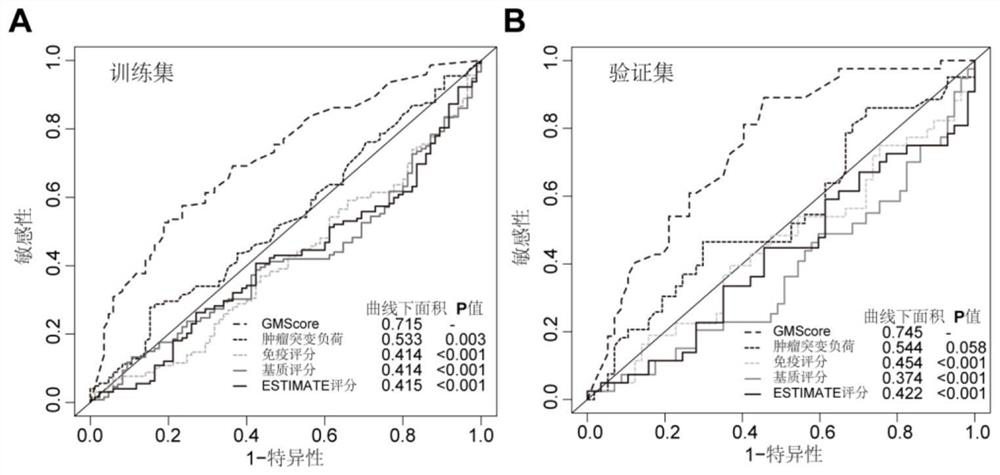

Glutamine metabolism gene tag scoring system for predicting prognosis and treatment resistance of hepatocellular carcinoma

ActiveCN113930506AObjective assessment of overall survivalAids in treatment resistanceMicrobiological testing/measurementProteomicsOncologyChemo therapy

The invention discloses a glutamine metabolism gene tag scoring system for predicting prognosis and treatment resistance of hepatocellular carcinoma, and belongs to the technical field of biological medicine. By detecting the expression level of seven specific glutamine metabolism related genes of a hepatocellular carcinoma patient, a model can be used for judging the total lifetime of the patient, evaluating the treatment resistance of a postoperative transcatheter arterial chemoembolism patient and evaluating the immune cell infiltration degree in a tumor and the immune escape potential of a tumor cell, and the prediction capability on the liver cancer immunotherapy reaction is improved. Meanwhile, the model provided by the invention can improve the prediction accuracy of the three-year total lifetime of hepatocellular carcinoma, and compared with the prediction of the prognosis of the patient directly through the existing next-generation sequencing technology, the number of genes needing to be detected is reduced, the efficiency is improved, and the cost is reduced. As a molecular marker capable of objectively and accurately evaluating hepatocellular carcinoma treatment resistance and tumor immune state, accurate prediction and precise implementation of hepatocellular carcinoma treatment prognosis can be realized.

Owner:AFFILIATED HOSPITAL OF JIANGSU UNIV

Pressure vessel steel plate having excellent post weld heat treatment resistance, and manufacturing method therefor

ActiveUS20180371567A1Increase resistanceImprove toughnessFurnace typesProcess efficiency improvementTreatment resistanceImpurity

The present disclosure relates to a middle high temperature pressure vessel steel plate having excellent resistance against a post weld heat treatment (PWHT) and a manufacturing method therefor. The pressure vessel steel plate includes 0.05 to 0.17 wt % of C, 0.50 to 1.00 wt % of Si, 0.3 to 0.8 wt % of Mn, 1.0 to 1.5 wt % of Cr, 0.3 to 1.0 wt % of Mo, 0.003 to 0.30 wt % of Ni, 0.003 to 0.30 wt % of Cu, 0.005 to 0.06 wt % of Sol.Al, 0.015 wt % or less of P, and 0.020 wt % or less of S; additionally two or more elements selected from 0.002 to 0.025 wt % of Nb, 0.002 to 0.03 wt % of V, and 0.002 to 0.15 wt % of Co; and Fe and unavoidable impurities as the reminder, wherein a microstructure of a central portion of the steel plate is formed in a mixed structure of 20 area % or more of tempered martensite and the residue bainite.

Owner:POHANG IRON & STEEL CO LTD

Lingual tonsilitis treatment traditional Chinese medicine spray and preparation method thereof

InactiveCN104887863ARelieves sore throat symptomsRelieve painAerosol deliveryUnknown materialsSide effectLicorice roots

The invention discloses a lingual tonsilitis treatment traditional Chinese medicine spray. The raw materials of the prepared spray include ligusticum wallichii, snake gall, arctium lappa, radices trichosanthis, agilawood, dried rhizome of rehmannia, eucalyptus globulus, fructus forsythiae, radix angelicae, herba portulacae, rhizoma belamcandae, gomphostemma root, honeysuckle, Dichocarpum auriculatum, chamomile, honey-fried licorice root, jackfruit and pineberry. The spray has the advantages of dispelling pathogenic wind, eliminating stagnation, clearing heat, refreshing and enriching saliva, preventing bacterial and inflammatory and relieving pain and itching, pure traditional Chinese medicines are adopted, the medicine compatibility is appropriate, the spray is prepared by the modern advanced medicine pharmaceutical technology, both the symptoms and root causes can be addressed, action is fast, pain of patients can be relieved effectively, and the spray is safe and free of toxic and side effects; the problems of treatment resistance and toxicity caused by antibiotics for treatment are avoided, body injury caused by the risk of surgery is avoided, the fast curative effect is achieved, and the recrudescence is avoided after healing.

Owner:QINGDAO HAIZHIXING BIOLOGICAL SCI & TECH

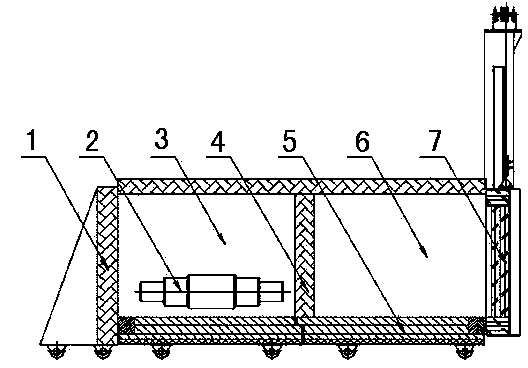

Segment type four-function heat treatment resistance furnace

A segment type four-function heat treatment resistance furnace comprises a furnace body (1), a rear furnace (3), a middle gate (4), a furnace vehicle (5), a front furnace (6) and a front gate (7). The furnace body (1) is arranged on the furnace vehicle (5), the furnace body (1) is divided into the rear furnace (3) and the front furnace (6) through the middle gate (4), the two sides of the furnace body (1) are provided with sealing doors, and workpieces (2) are placed into the furnace body (1) through the front gate (7). The segment type four-function heat treatment resistance furnace is characterized in that the middle gate (4) is vertically arranged in the movable furnace body (1). By means of the structure, the furnace body can be used as a whole or the rear furnace can also be used independently and the front furnace does not work, or the front furnace is used independently and the rear furnace does not work, and heat treatment workpieces of different temperatures can be processed at the same time.

Owner:JIANGSU BONENG FURNACE

A kind of dual-enzyme system probe and its application

Owner:PEKING UNIV FIRST HOSPITAL

Cancer treatment pharmaceutical composition containing cdk inhibitor

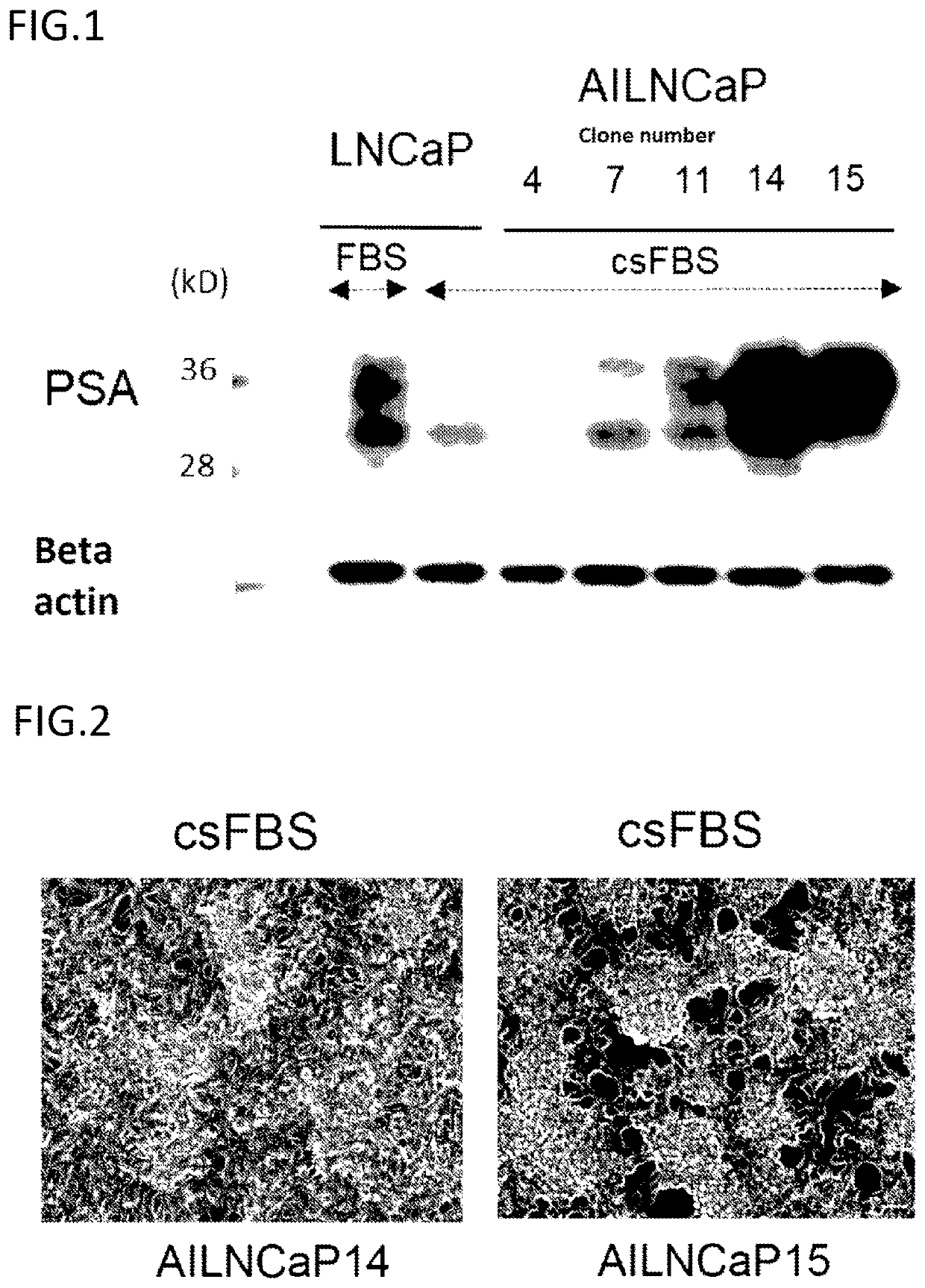

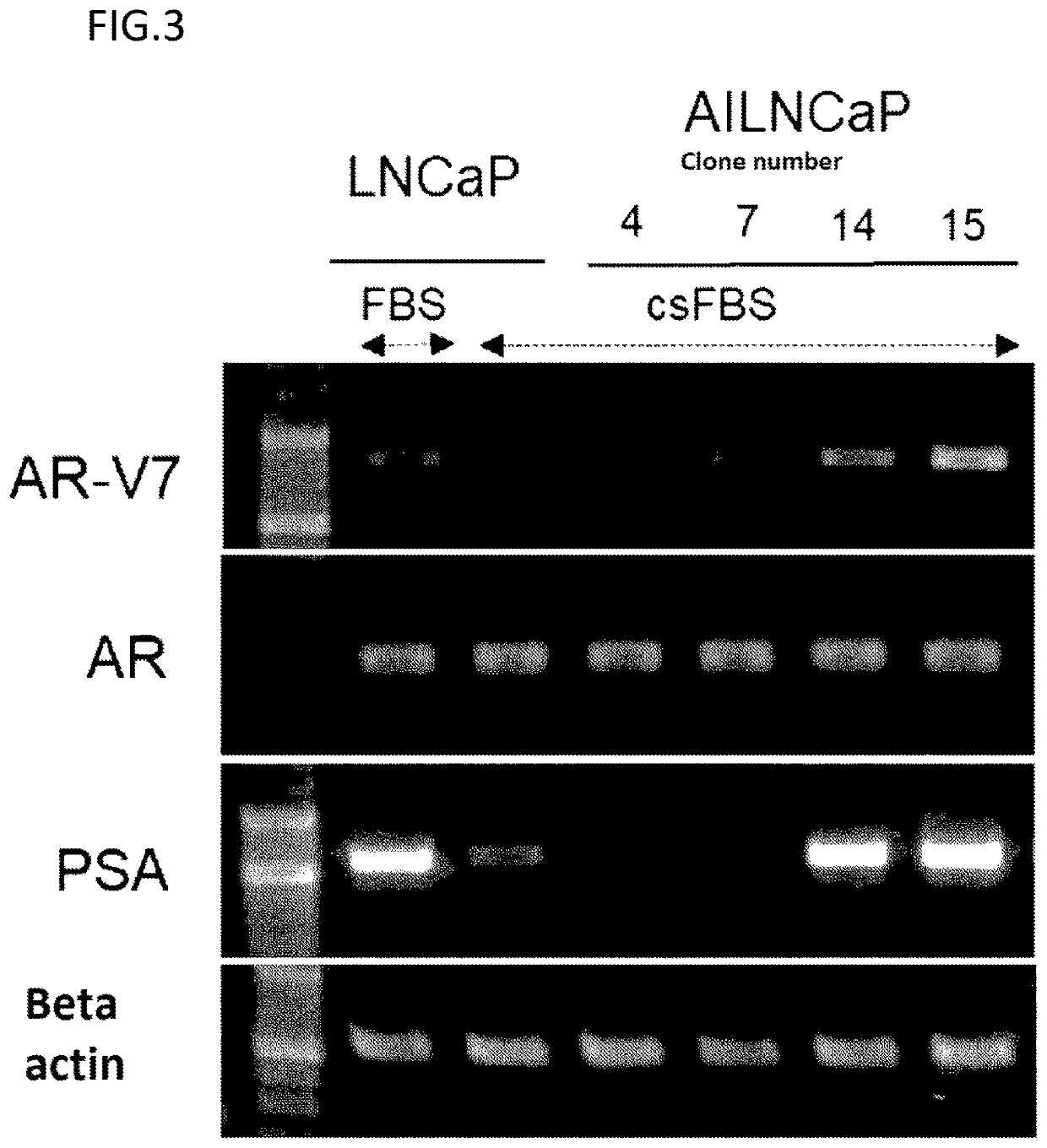

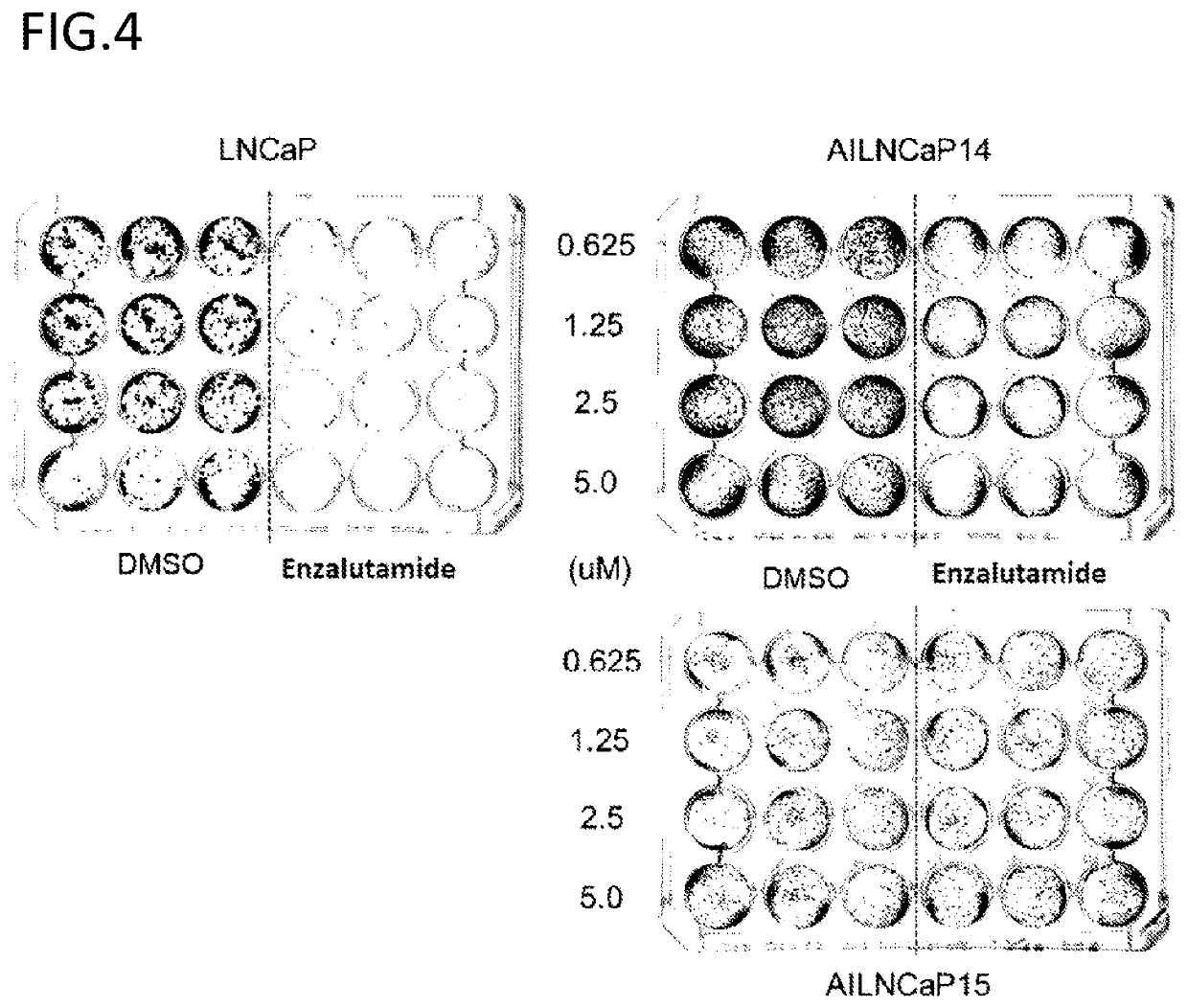

PendingUS20220071978A1Effective preventionEffective treatmentOrganic active ingredientsDisease diagnosisPhosphorylationPharmaceutical medicine

Provided is a cancer treatment pharmaceutical composition that contains a CDK inhibitor. A pharmaceutical composition that includes a CDK inhibitor and is for treating cancers that demonstrate resistance to androgen removal therapy. The CDK inhibitor includes alvocidib or a pharmaceutically acceptable salt thereof. The cancers are cancers that demonstrate treatment resistance to androgen receptor antagonists and / or androgen synthesis inhibitors. A cancer treatment composition that includes alvocidib or a pharmaceutically acceptable salt thereof as an active ingredient and is to be administered to subjects that have enhanced androgen receptor phosphorylation.

Owner:SUMITOMO DAINIPPON PHARMA CO LTD

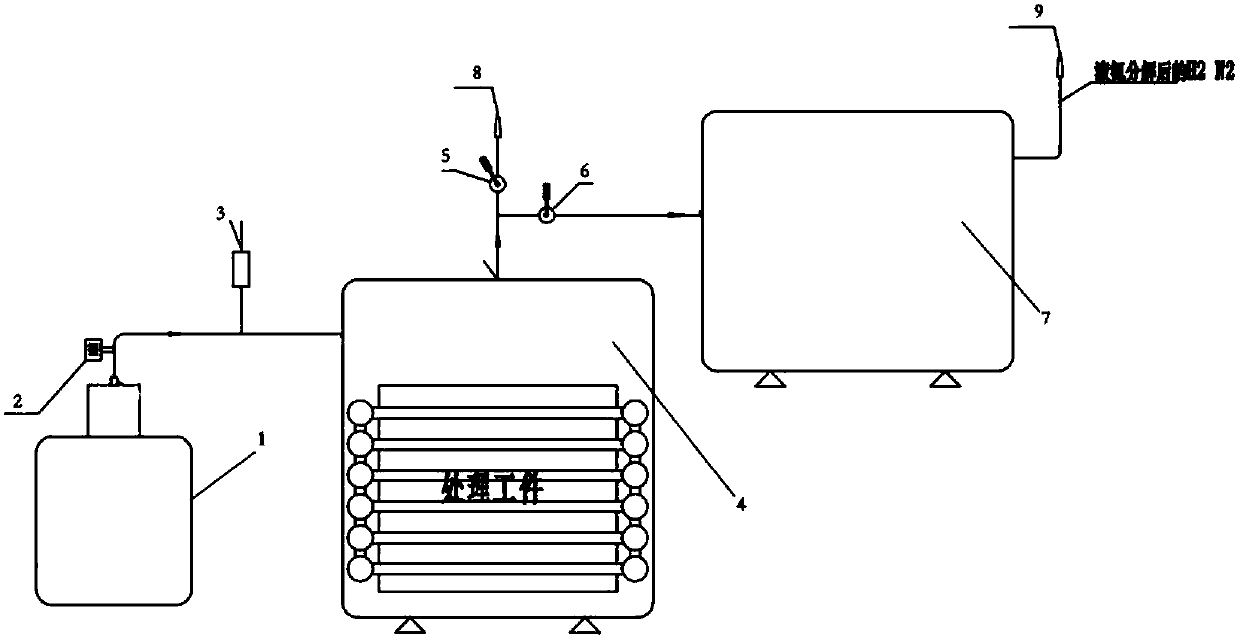

Thrust bearing nitriding system and process for iron-based powder metallurgy

InactiveCN107916390AReduce energy consumptionGuaranteed nitriding effectSolid state diffusion coatingDecompositionThrust bearing

The invention relates to a nitriding process for iron-based powder metallurgy, in particular to a thrust bearing nitriding system and process for iron-based powder metallurgy. By the thrust bearing nitriding system and process for iron-based powder metallurgy, safe discharge is implemented, energy consumption is low, and the nitriding efficiency is high. The thrust bearing nitriding system comprises a liquid ammonia tank (1), a pressure reducing valve (2), a glass rotor flowmeter (3), a heat treatment resistance furnace (4), a first valve (5), a second valve (6), an ammonia decomposition furnace (7), a first ignition opening (8) and a second ignition opening (9), wherein the liquid ammonia tank (1) communicates with the heat treatment resistance furnace (4) through the pressure reducing valve (2); the glass rotor flowmeter (3) is serially connected between the pressure reducing valve (2) and the heat treatment resistance furnace (4); the first valve (5) and the second valve (6) are arranged on the heat treatment resistance furnace (4); the first ignition opening (8) is formed in the first valve (5); the second valve (6) communicates with the ammonia decomposition furnace (7); and the second ignition opening (9) is formed in the ammonia decomposition furnace (7).

Owner:无锡佳力欣精密机械有限公司

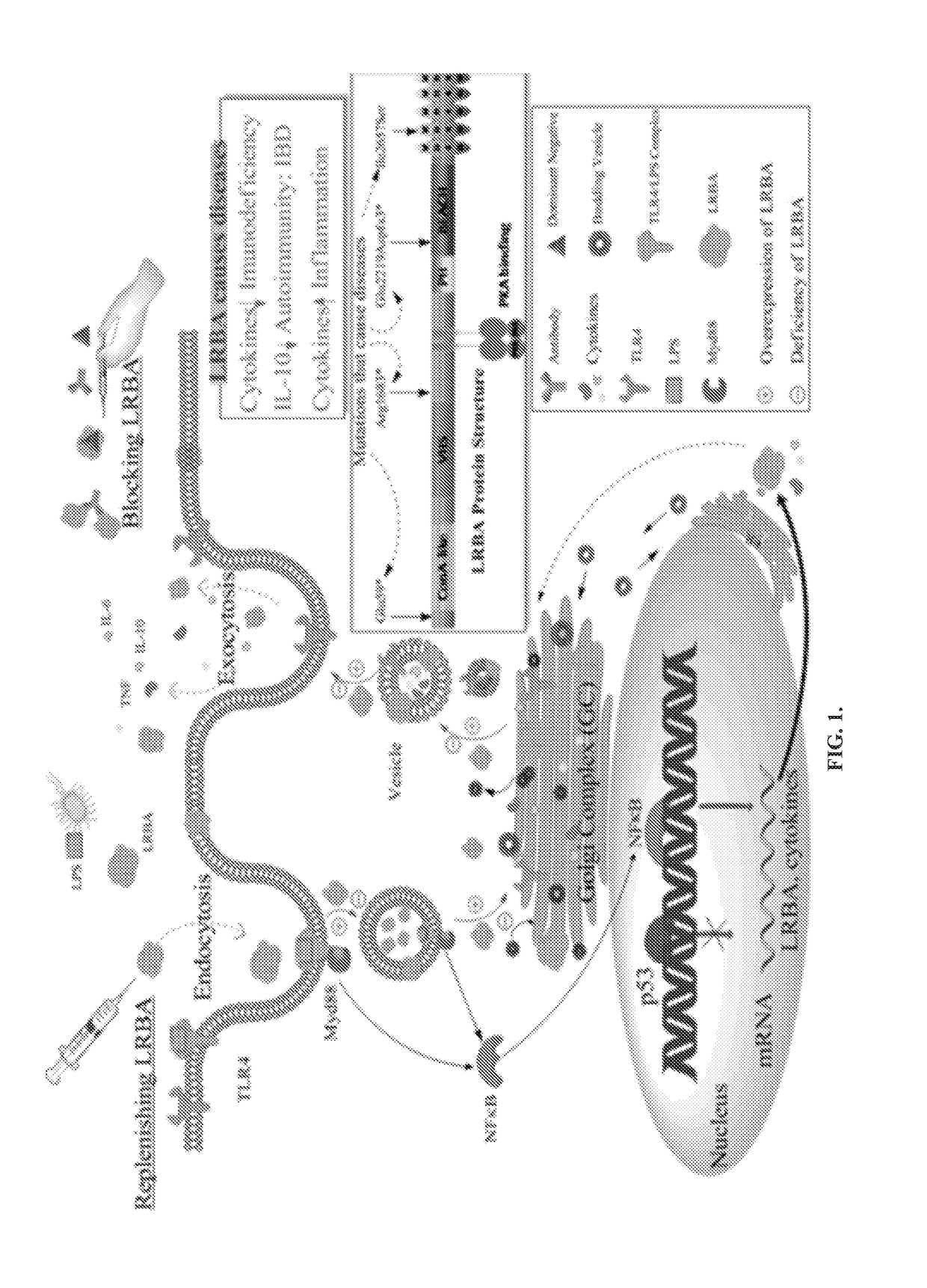

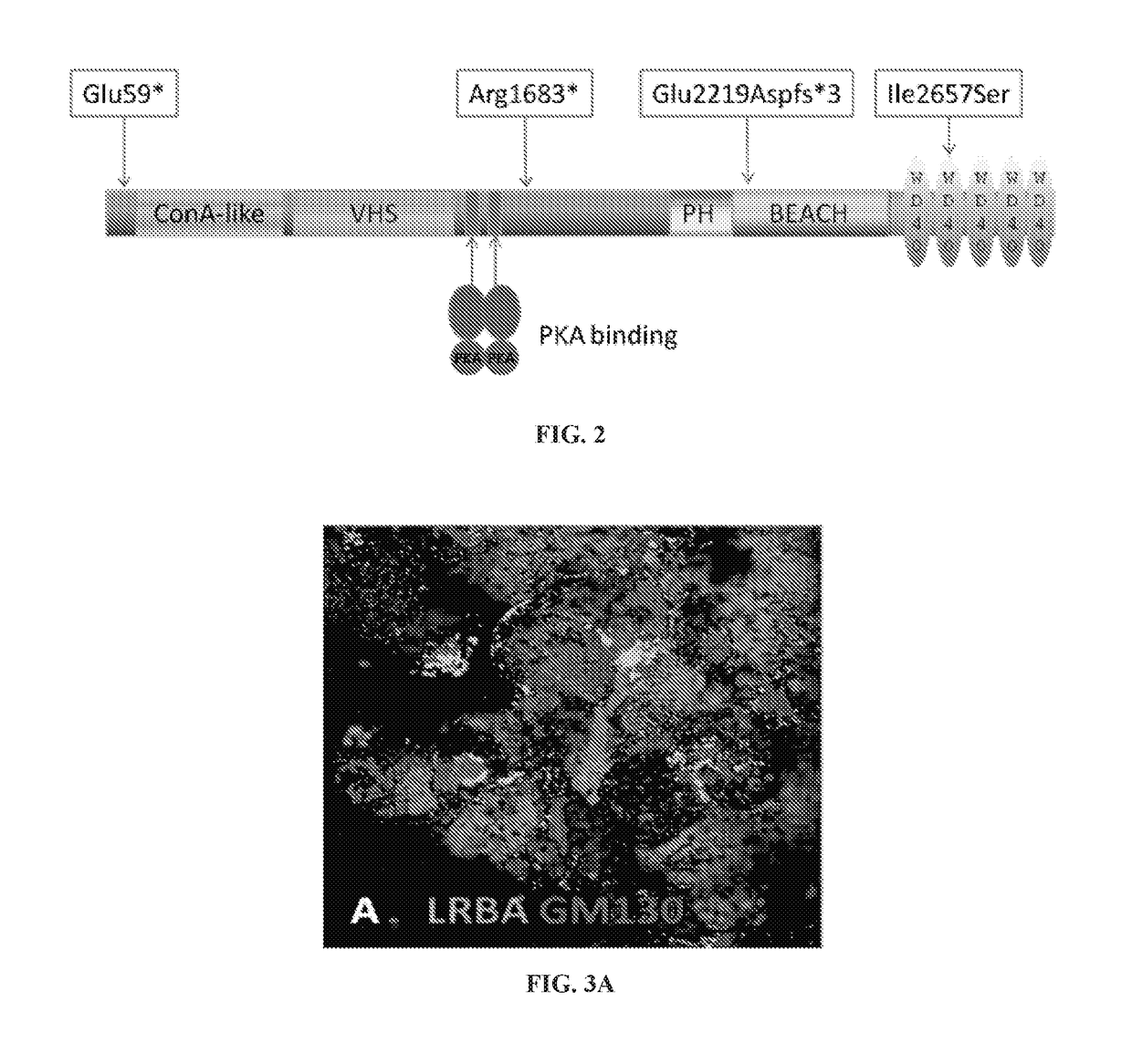

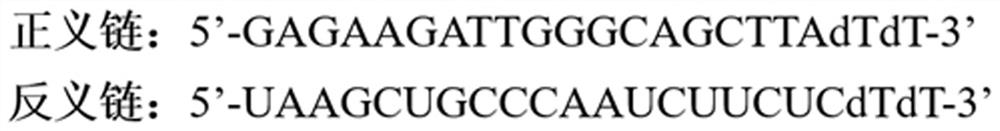

Inflammatory disease diagnosis and methods of treatment using lipopolysaccharide-responsive beige-like anchor

ActiveUS20180002413A1Risk of hospitalization for infectionPeptide/protein ingredientsImmunoglobulins against animals/humansLRBAAutoimmune responses

Anti-cytokine therapy has revolutionized immunological disease treatment, but is not always effective and subject to treatment resistance as the cytokine cascade is highly redundant and multiple cytokines are involved in inflammation. Targeting a critical common regulator of inflammatory effectors is desirable. Lipopolysaccharide (LPS)-responsive beige-like anchor (LRBA) is a master regulator of multiple genes important for inflammation. Subcellular localization shows that LRBA translocated to the nucleus upon LPS stimulation and colocalized with multiple proteins associated with the endosome membrane system, indicating a critical role in membrane / vesicle trafficking essential for deposition, secretion and signal transduction of immune effectors. Deregulation, deficiency, down-regulation and overexpression of LRBA causes defective trafficking and signaling of immune effector molecules, resulting in immunodeficiency and autoimmunity diseases associated with a broader spectrum of severe symptoms when compared to other CVID genes. Modulating LRBA through antibodies, dominant negative mutants, or small interference RNA can be used to treat inflammatory diseases.

Owner:UNIV OF SOUTH FLORIDA

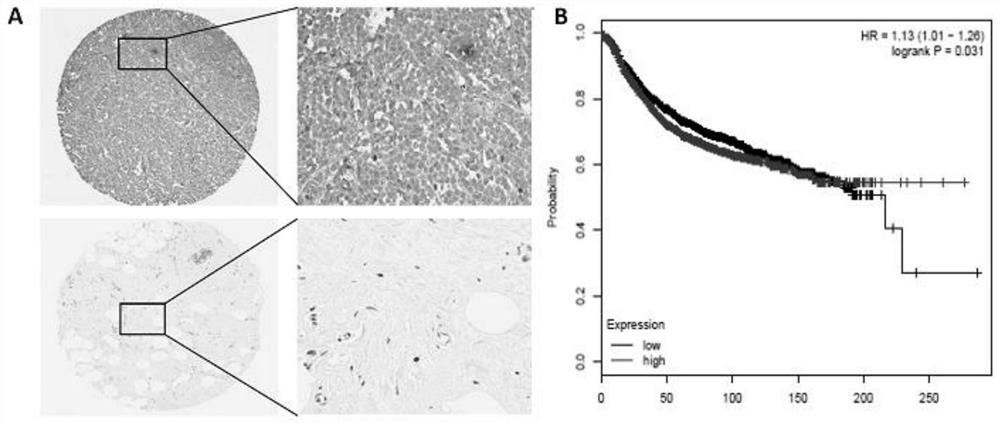

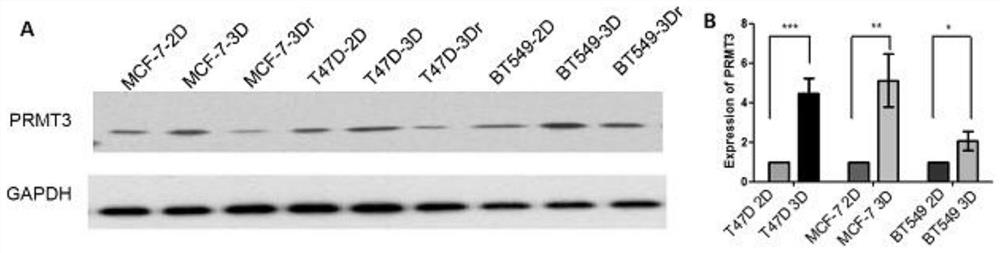

Application of arginine methyltransferase 3 in breast cancer diagnosis and treatment

PendingCN113533727AEnhanced clonogenicityIncreased drug resistanceMicrobiological testing/measurementBiological material analysisCancer cellArginine

The invention relates to an application of arginine methyltransferase 3 (PRMT3) in breast cancer diagnosis and treatment. It is proved that the PRMT3 expression in breast cancer tumor tissues is higher than that in normal tissues, and the high PRMT3 expression and the poor prognosis of breast cancer patients show significant positive correlation; overexpression or inhibition of the PRMT3 can change breast cancer cell stemness phenotype, microsphere formation, tumor forming ability and resistance to traditional chemotherapeutic drugs, the PRMT3 promotes recurrence, metastasis and generation of treatment resistance by promoting interstitial transformation and enhancement of breast cancer cell stemness, and the regulation effect of the PRMT3 on breast cancer stemness is mediated by activating a Wnt pathway. The invention provides a new means for diagnosis, prognosis and treatment of breast cancer.

Owner:SHANGHAI FIRST PEOPLES HOSPITAL

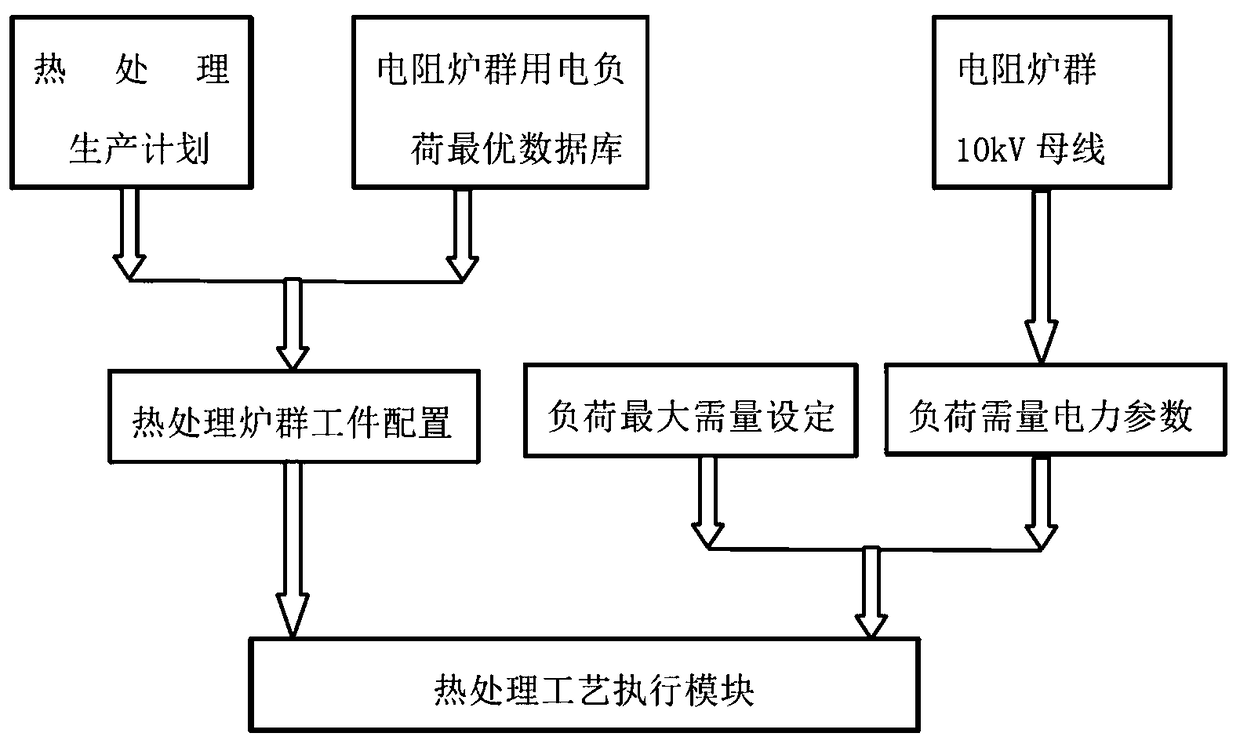

Electric load demand control system and control method for heat treatment resistance furnace group

ActiveCN109217312AControl the maximum demand of electric loadControl maximum demandLoad forecast in ac networkElectrical resistance and conductanceControl system

The invention relates to a control system and a control method for electric load demand of a heat treatment resistance furnace group, which establishes an optimal database for electric load of a heattreatment furnace group of a temperature-raising, insulation and temperature-lowering resistance furnace. According to the heat treatment process of the furnace group, the corresponding electric furnace load scheme is called and compared with the feedback electric load of the electric power parameter acquisition module. The green area is 96% of the maximum demand of the collecting power supply busbar below that of the electric load. Maximum demand for power supply busbar is 96%- 98% state is yellow zone, and the refresh frequency of the instantaneous power and electric quantity value of eachfurnace demand quantity is increased to generate the maximum demand curve of the bus bar and the load curve of each electric furnace, and the load change is prejudged; When the maximum power supply busbar demand exceeds 98% of the maximum power load, the system prompts alarm and the state is red zone. According to 1- 5 heat treatment furnaces are divide into heating section and graded to reduce power for sequential selection, and that heat treatment process execution module is used to set the sequence and divide the heating section and graded to reduce power for short time, so as to ensure theheat treatment process to be executed and to adjust the working conditions of the heat treatment furnace in real time.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

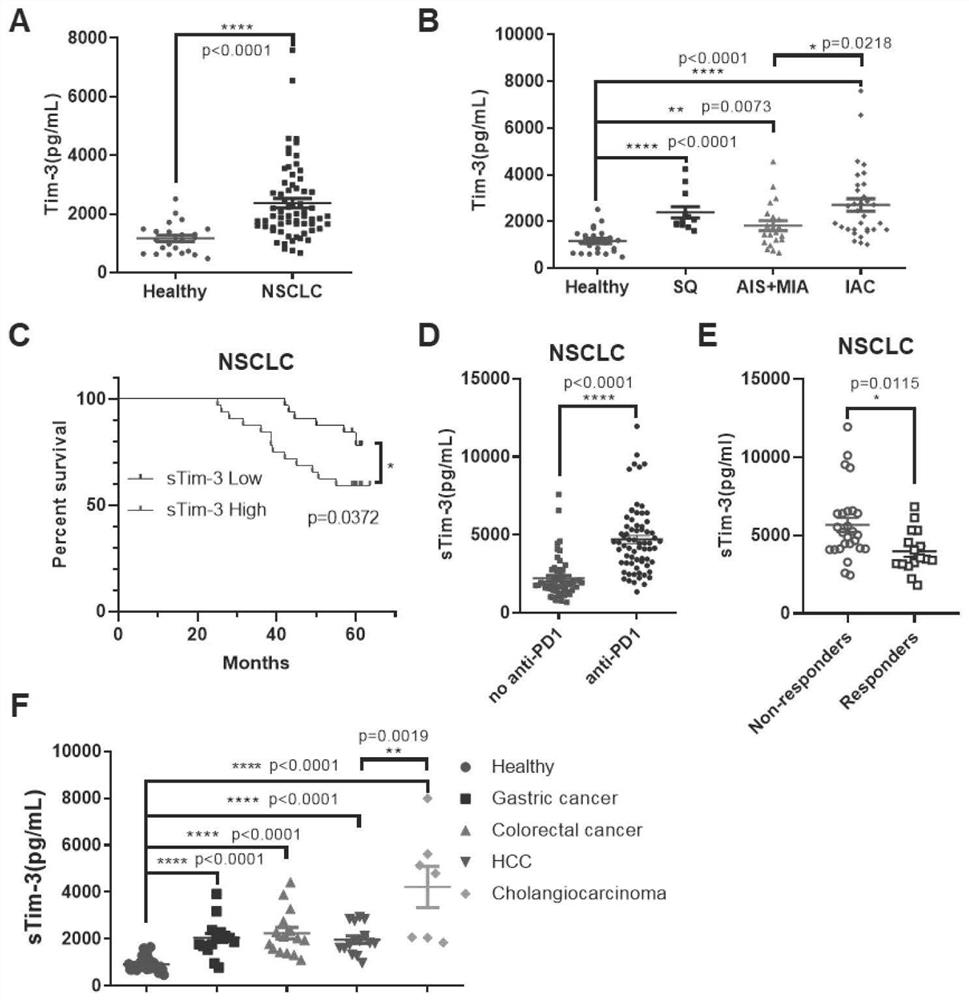

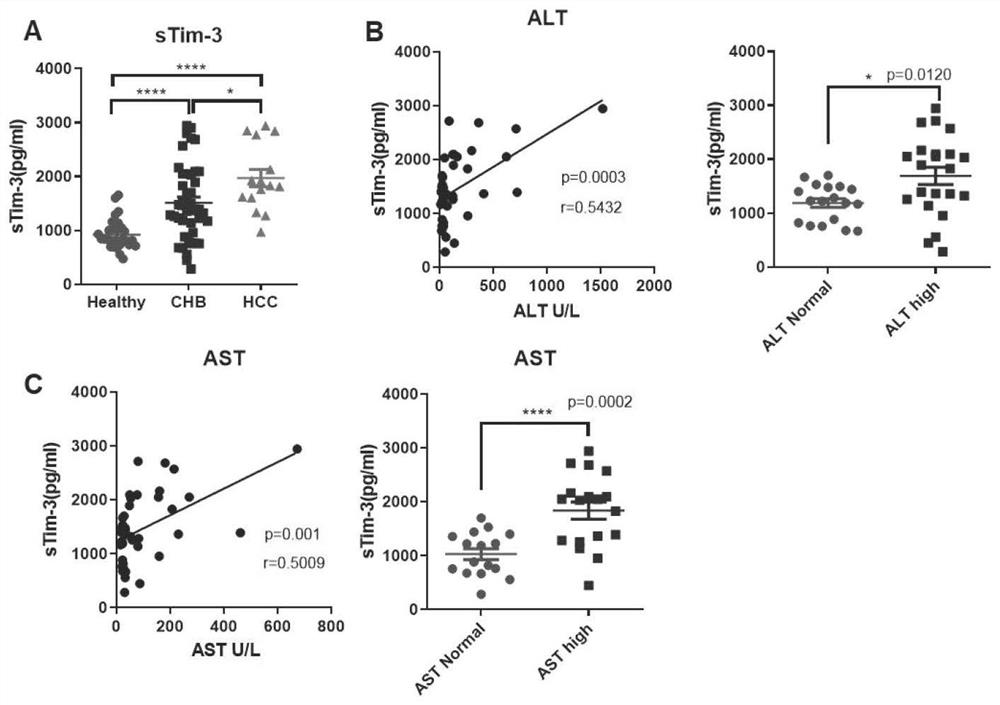

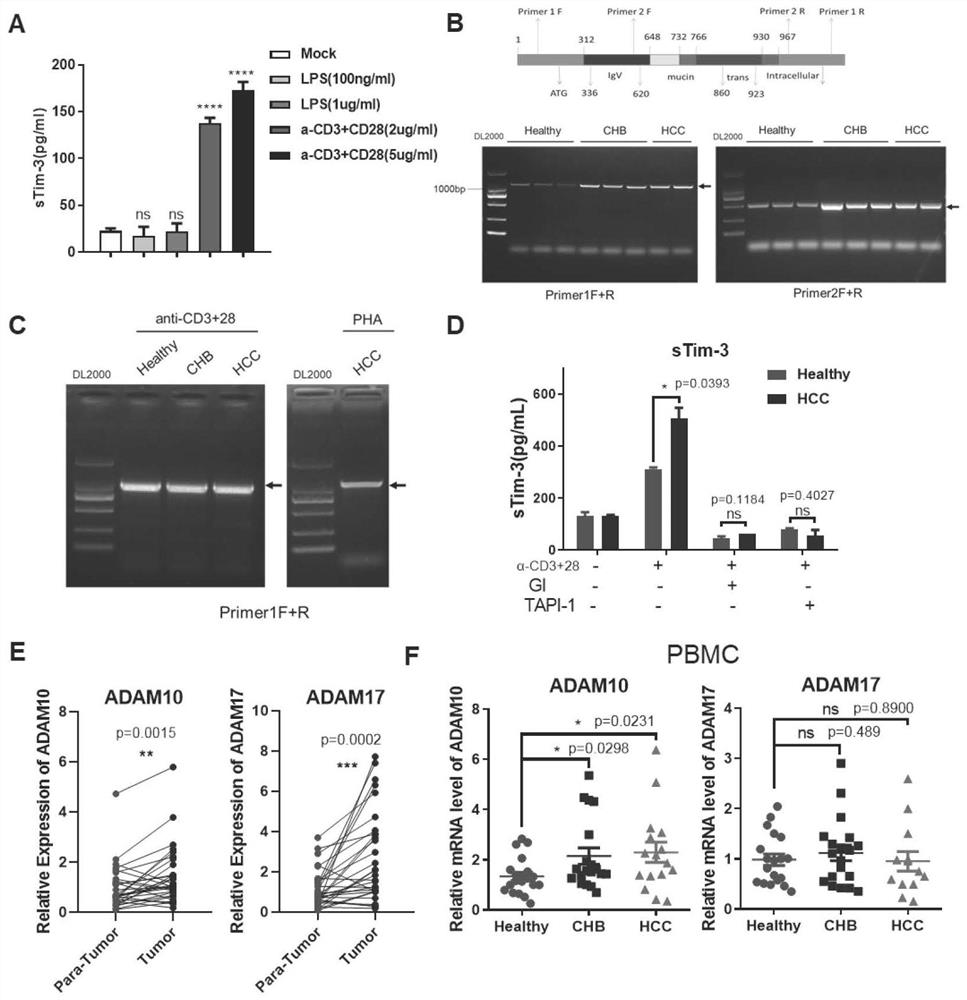

Soluble form of tim3 in immune checkpoint blockade therapy resistance

ActiveCN113866416BSpeed up progressInhibitory functionCompound screeningApoptosis detectionBiomarker (medicine)T cell

The invention provides the application of a soluble form of Tim3 in immune checkpoint blockade treatment resistance, and belongs to the technical fields of biomedicine and molecular biology. The present invention has found through research that the soluble form of Tim3 is not only significantly up-regulated in NSCLC that does not respond to PD-1 blockade therapy, but also shows a higher serum level in cholangiocarcinoma, which has been reported to be resistant to PD-1 Blocking therapy has strong resistance. Importantly, the present invention found that sTim-3 induced resistance to PD-1 antibody blockade therapy in a mouse model of ICC and promoted tumor progression by suppressing T cell function in a CEACAM1-dependent manner. Therefore, human sTim‑3 can be used as a candidate biomarker for tumor progression and resistance to PD‑1 blockade therapy, and a new mechanism for Tim‑3-mediated immunosuppression and resistance to PD‑1 blockade therapy in the tumor environment was proposed , has good practical application value.

Owner:SHANDONG UNIV

Efficient treatment resistance sheet type silencer

InactiveCN105719635AEasy maintenanceEfficient governance and good effectSound producing devicesArchitectural engineeringTreatment resistance

The present invention relates to the technical field of muffler devices, in particular to a resistive chip muffler with high efficiency treatment. The resistive chip muffler of the present invention is easy to disassemble and assemble, and reduces maintenance costs; and it can be efficiently treated; it includes a shell And the muffler, the shell includes the left split body, the right split body and the adjustment pipe, the right end of the left split body and the left end of the right split body are provided with external thread structure, the inner wall of the adjustment pipe is provided with internal thread structure, the left split body The right end of the right split body and the left end of the right split body are inserted and screwed into the inside of the regulating tube; both the left split body and the right split body are provided with placement cavities, and are respectively set on the front side wall and the rear side wall of the placement cavity. A front spring and a rear spring are arranged, and the rear end of the front spring and the front end of the rear spring are respectively provided with a front clamp and a rear clamp, and the sound-absorbing sheet is clamped between the front clamp and the rear clamp.

Owner:FUJIAN SANYI ENVIRONMENTAL TECH CO LTD

A kind of resistance wire alloy and its pre-oxidation treatment method

InactiveCN104513929BEliminate "wrinkled skin" phenomenonUniform and dense oxidation moldSolid state diffusion coatingMetal/alloy conductorsPickling AgentsAlloy

Owner:上海埃鲁秘工业炉制造有限公司

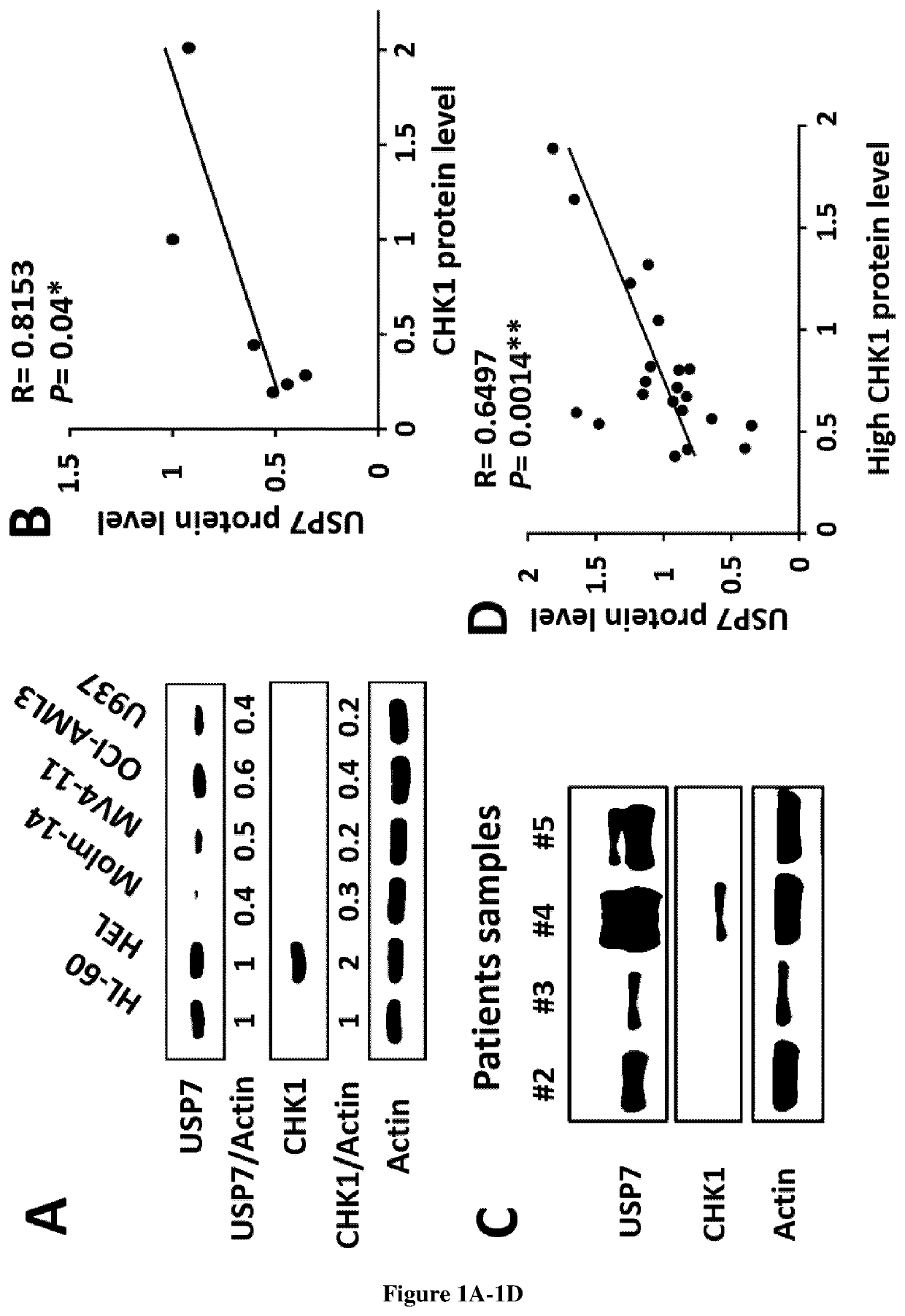

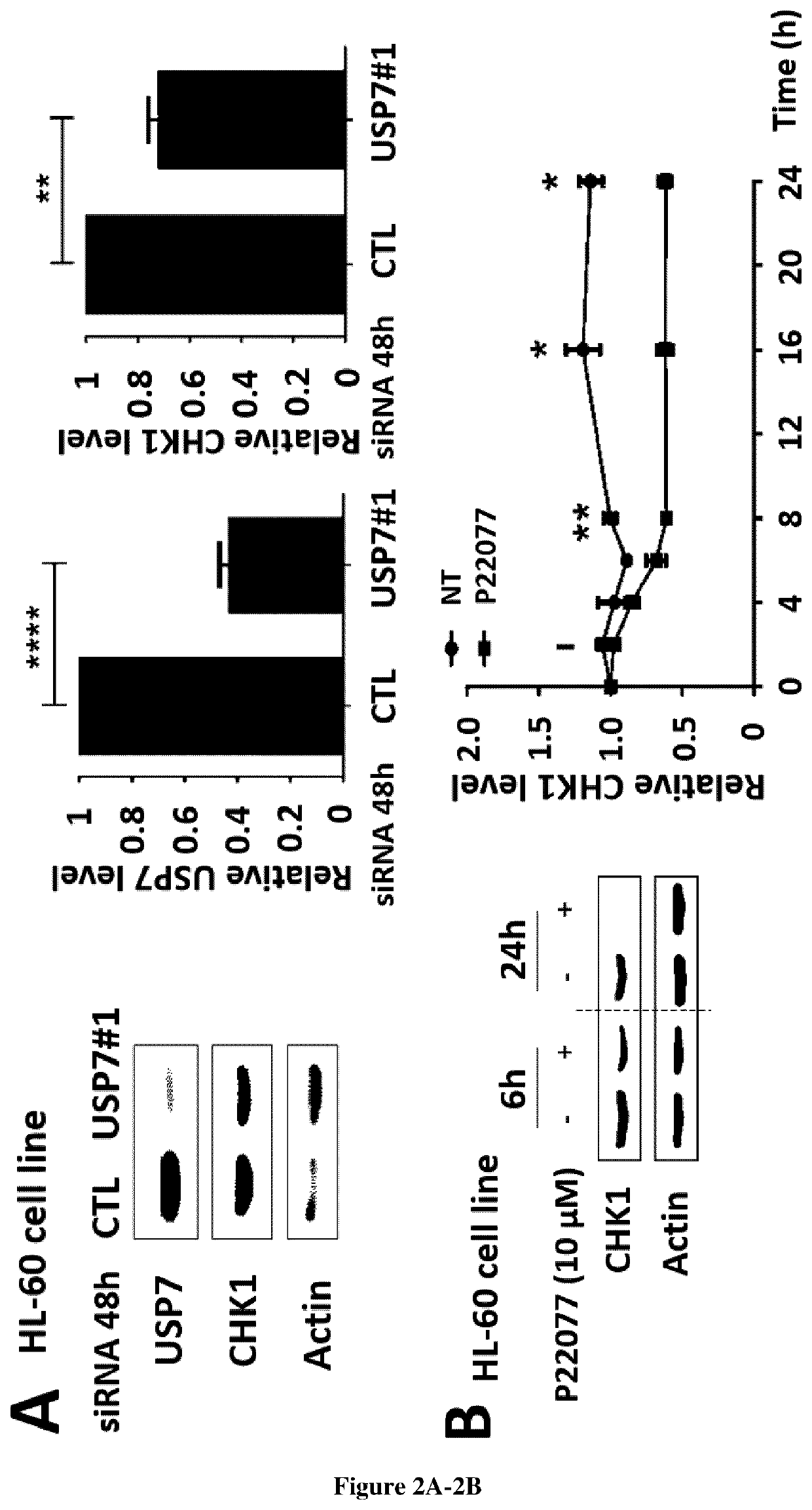

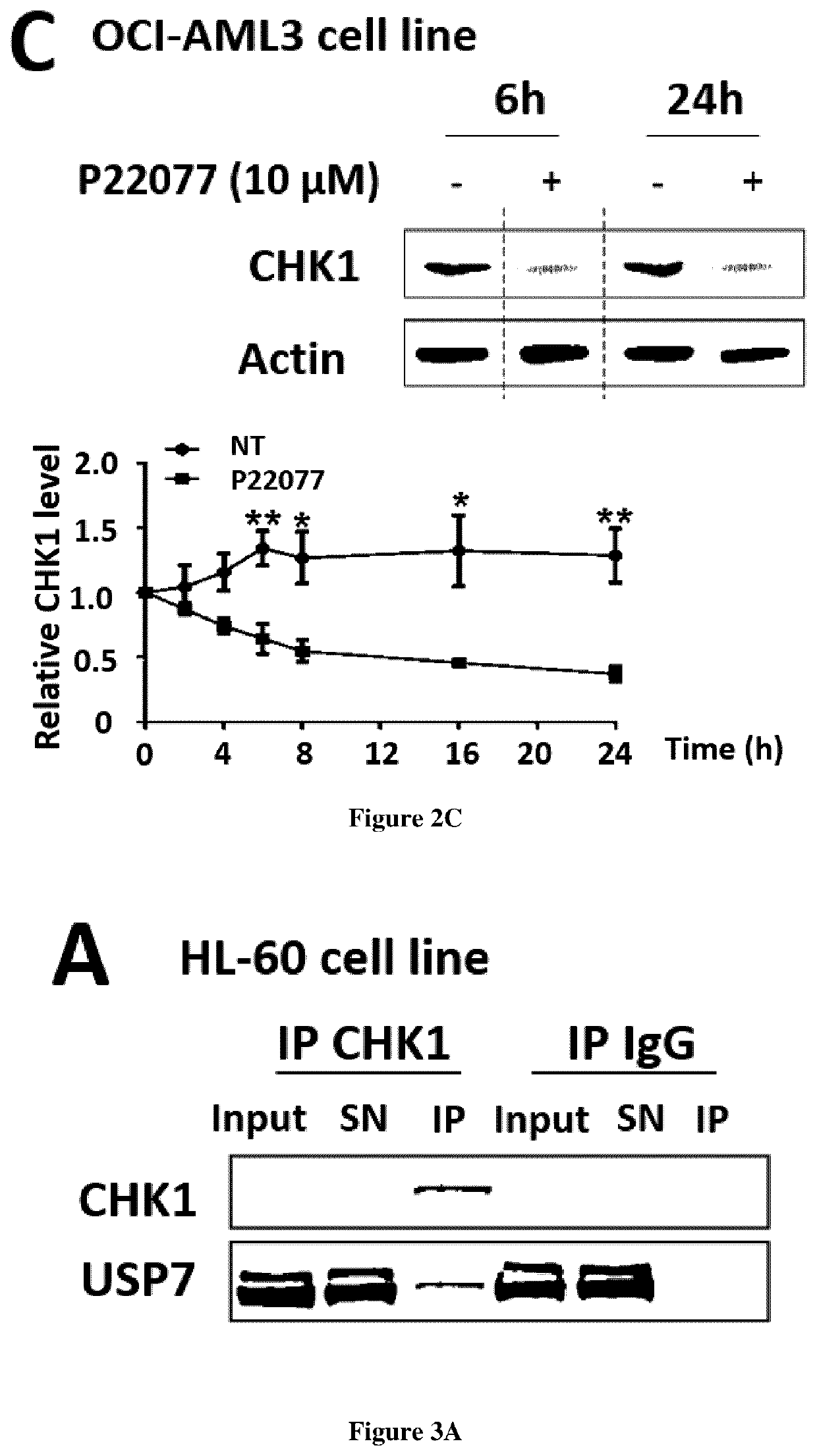

Use of usp7 inhibitors for the treatment of acute myeloid leukemia (AML)

PendingUS20220125760A1Positively correlatedHigh levelOrganic active ingredientsAntineoplastic agentsCytarabinePharmacometrics

Resistance of acute myeloid leukemia (AML) cells to DNA damaging therapeutic agents is dependent on CHK1 protein levels. Here, the inventors demonstrate that in AML, CHK1 protein stability relies on the expression and activity of Ubiquitin Specific Protease 7 (USP7). CHK1 and USP7 levels are positively correlated in AML cell lines and primary patient specimens with high CHK1 protein levels. USP7 associates with CHK1, leading to its stabilization by deubiquitinylation, and this association is enhanced in response to cytarabine treatment. Pharmacological or RNA interference-mediated inhibition of USP7 significantly reduced AML proliferation in vitro and in vivo, and increased AML cell death. It is important to note that USP7 inhibition synergized with cytarabine to kill AML cell lines. This is also the case in primary patient specimens with high CHK1 levels. Transcriptomic dataset analyses revealed that a USP7 gene signature is highly enriched in cells from AML patients at relapse, as well as in residual blasts from Patient Derived Xenograft (PDX) models treated with clinically relevant doses of cytarabine, strongly suggesting a relationship between USP7 expression and resistance to therapy. Finally, single cell analysis from AML patient at relapse versus diagnosis showed that a gene signature of the pre-existing subpopulation responsible for relapse is enriched in transcriptomes of patients with high USP7 level. Altogether, these data demonstrate that USP7 is a master regulator of CHK1 protein kinase in AML cells, and represents both a marker of resistance to chemotherapeutic treatments, as well as a potential therapeutic target to overcome treatment resistance.

Owner:INST NAT DE LA SANTE & DE LA RECHERCHE MEDICALE (INSERM) +2

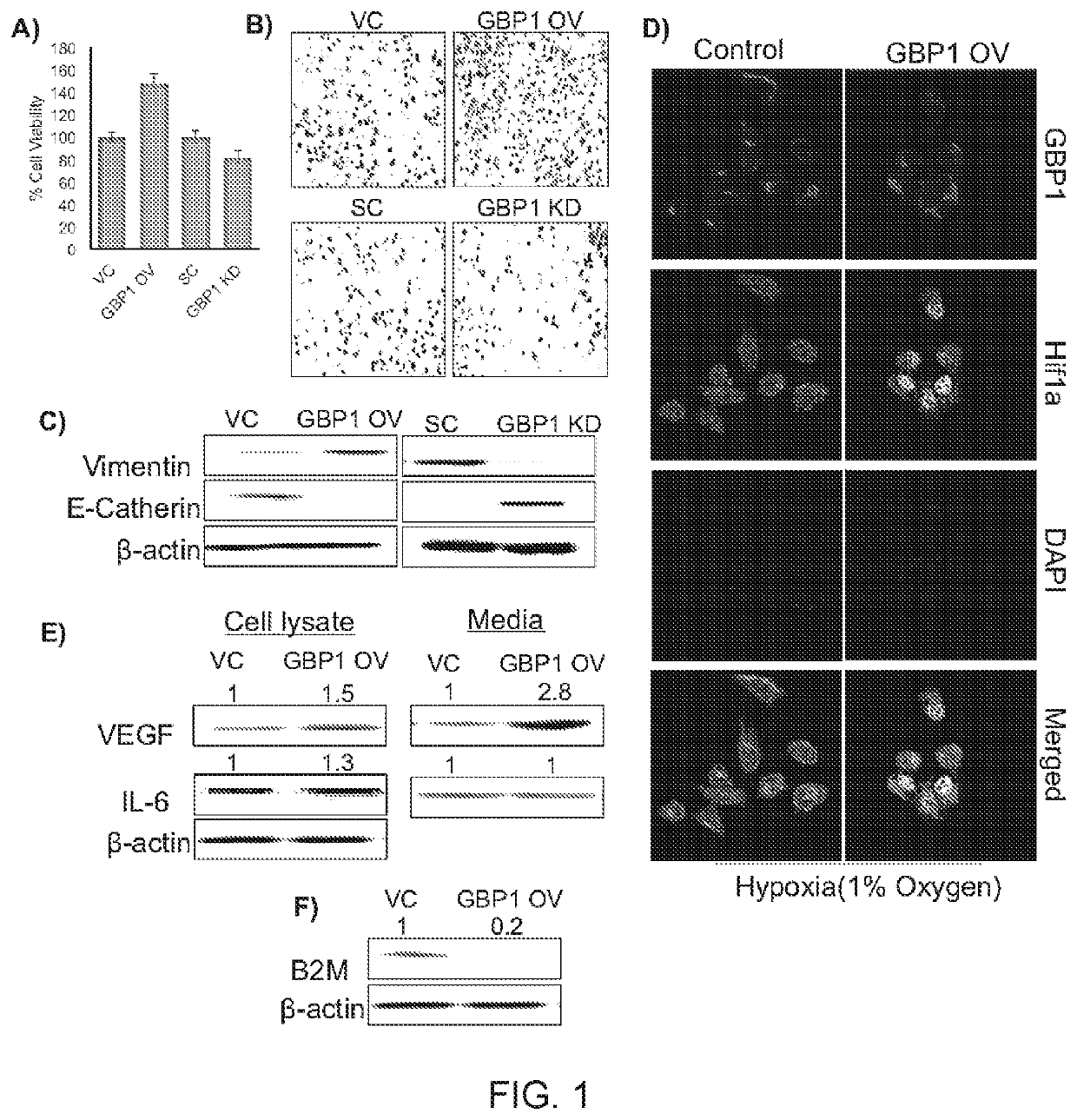

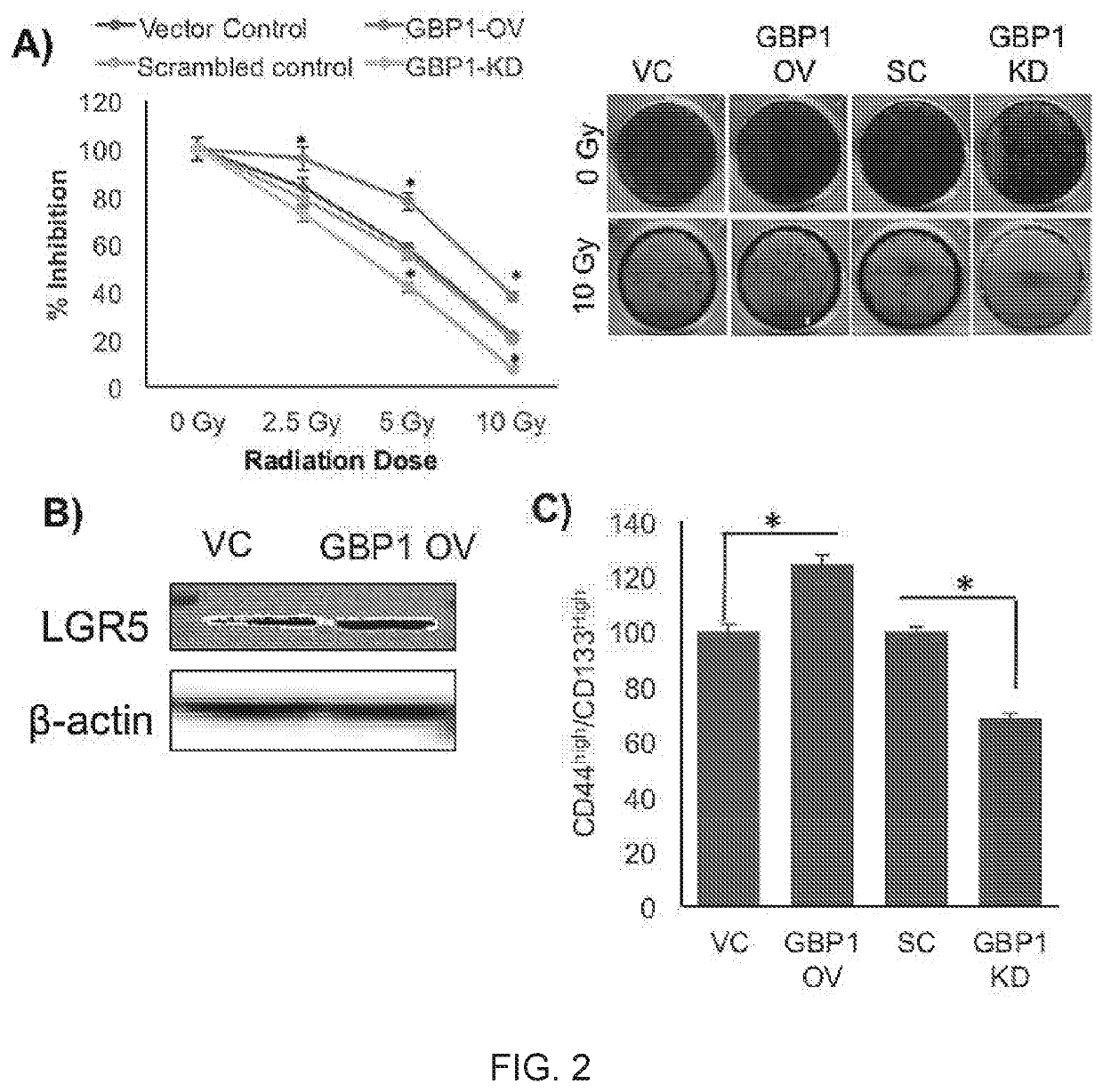

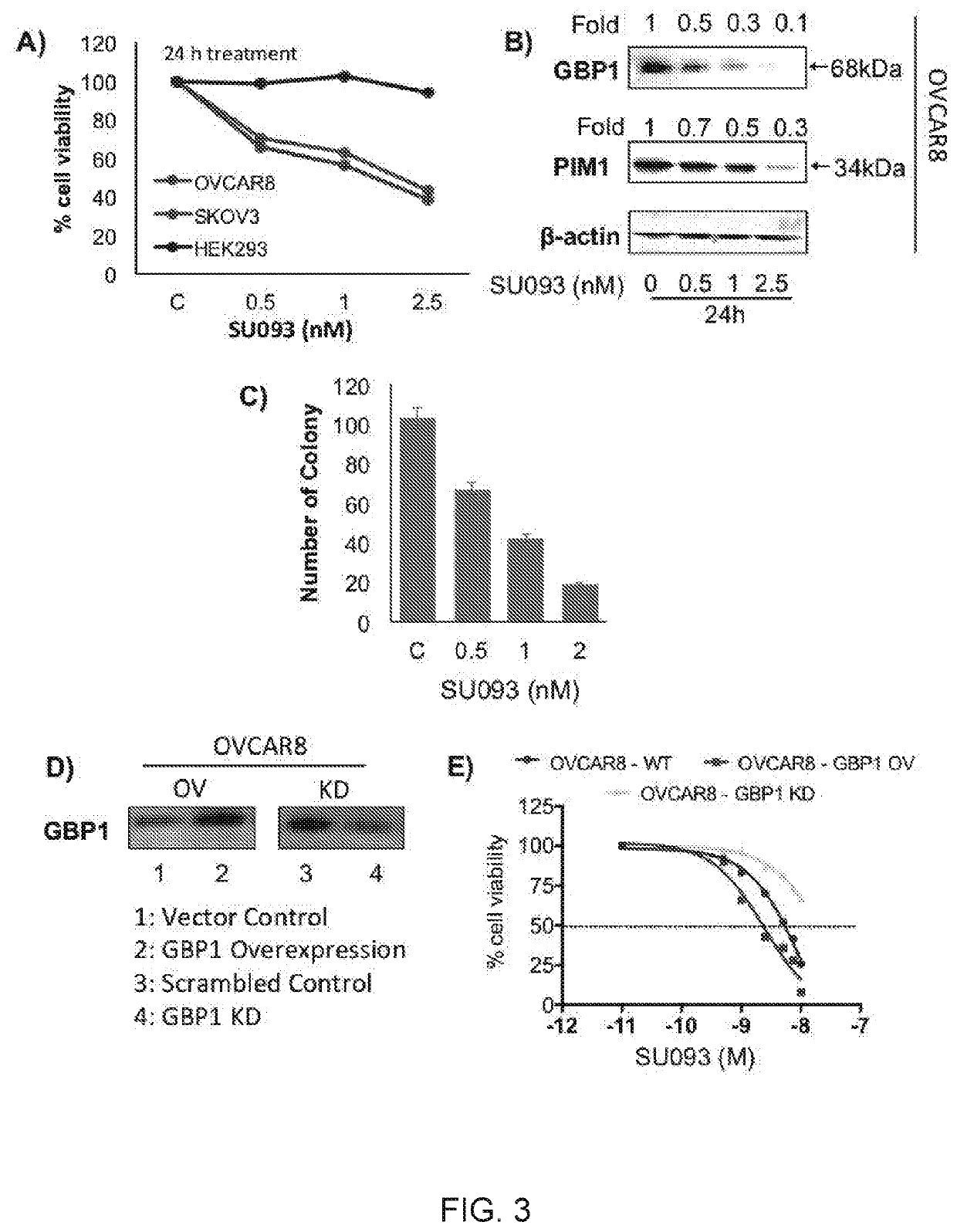

Novel n-hydroxyethyl didehydroazapodophyllotoxins as gbp1 inhibitors and methods of overcoming treatment resistance in cancer

PendingUS20200375977A1Avoid interactionTreat cancerOrganic active ingredientsOrganic chemistryPIM1Threonine

Compounds, compositions and methods are provided for the inhibition of GBP1. The subject inhibitor compounds can act by inhibiting GBP1 alone and / or GBP1: pro-survival kinase (e.g. serine / threonine-protein kinase pim-1 (PIM1)) interactions. Aspects of the subject methods include contacting a cellular sample with a GBP 1 inhibitor to inhibit the GBP 1 alone and / or GBP 1: PIM 1 interactions. Also provided are compositions and methods for treating cancer. In certain cases the cancer is resistant towards chemotherapy and radiation therapy.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

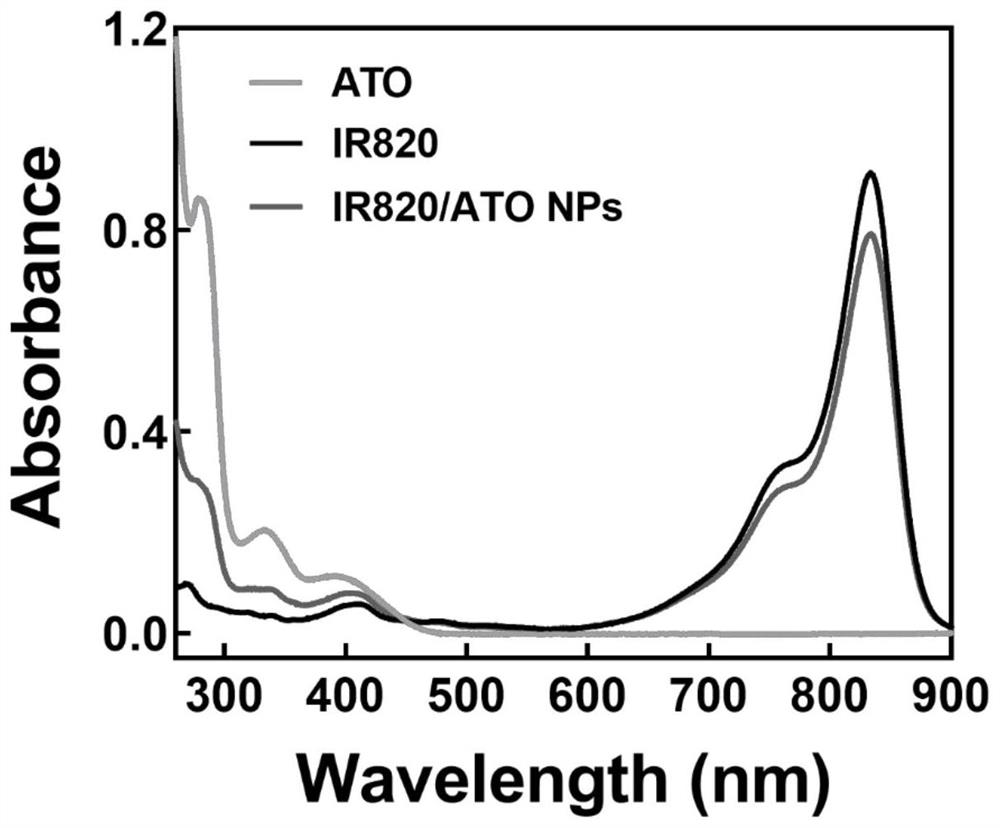

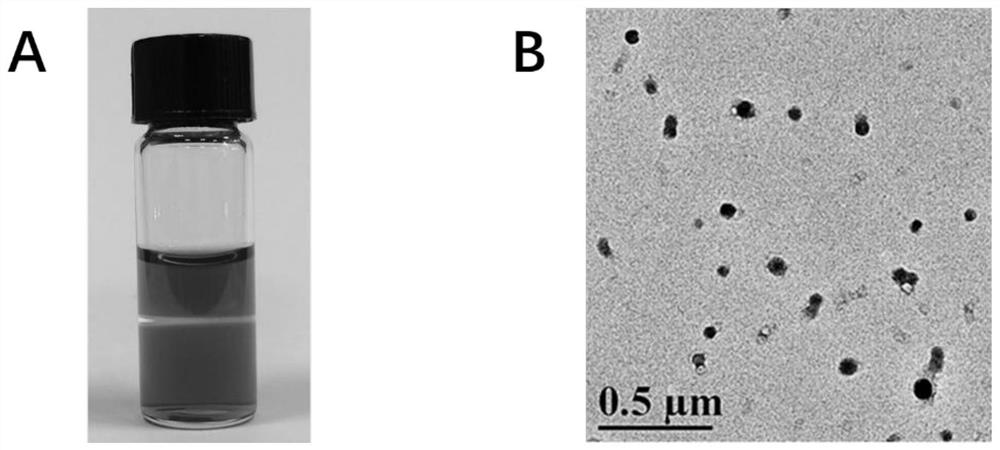

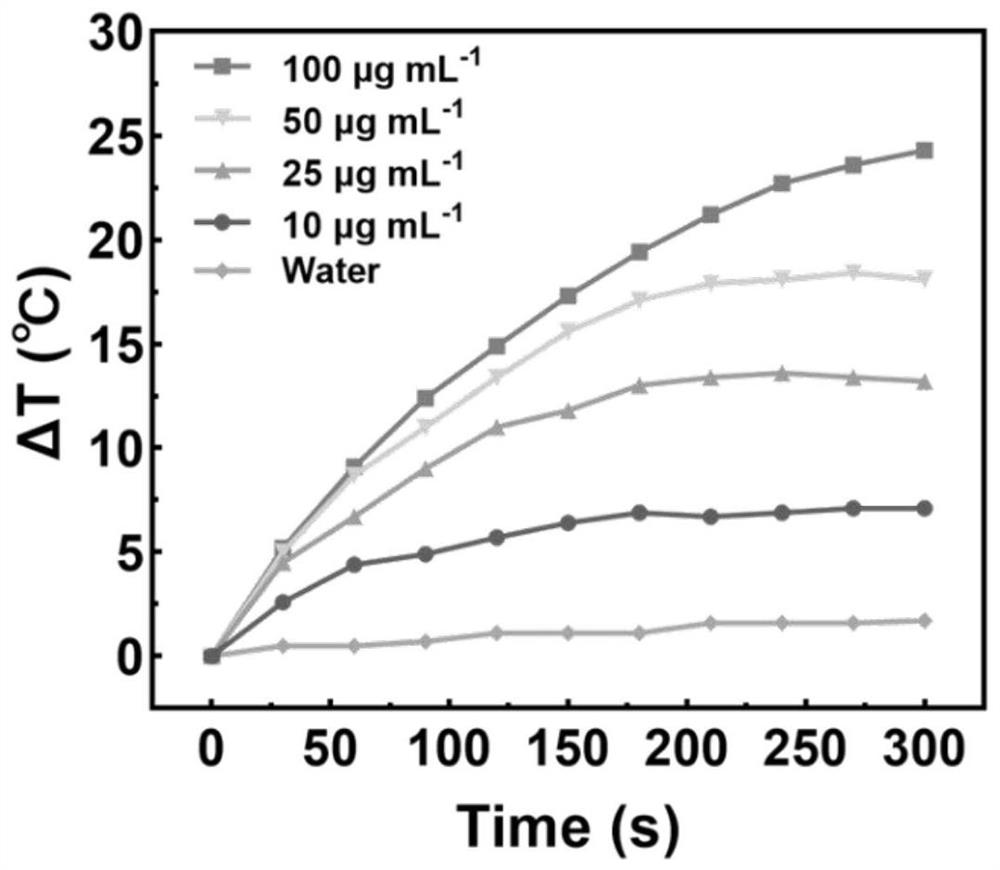

IR820 and atorvaquone carrier-free self-assembled nanoparticles and preparation method and application thereof

ActiveCN112933229ASolve problems such as poor stability and easy eliminationSolve the problems of poor water solubility and low bioavailabilityPowder deliveryOrganic active ingredientsBenign tumoursAtovaquone

The invention provides IR820 and atorvaquone carrier-free self-assembled nanoparticles and a preparation method and application thereof, and belongs to the technical field of medicines. According to the nanoparticle, IR820 and atorvaquone are taken as active ingredients, the nanoparticle not only solves the problems that IR820 is extremely easy to remove and poor in stability, but also solves the problems that atorvaquone is extremely poor in water solubility and low in bioavailability, and treatment resistance of IR820 is caused by rising of heat shock protein in photo-thermal therapy. The nanoparticle is high in drug loading capacity, uniform in particle size, high in stability and good in biocompatibility, provides more efficient photothermal therapy, can be used for treating or relieving benign tumors or malignant tumors, and therefore has good practical application value.

Owner:SHANDONG UNIV

Cell-specific signaling biomarker analysis by high parameter cytometry; sample processing, assay set-up, method, analysis

ActiveUS10845363B2Fine surfaceHigh activityDisease diagnosisIndividual particle analysisDiagnosis laboratoryMarker selection

The present invention recognizes that current clinical laboratory testing methods for multiparametric single cell analysis are limited to analysis of intact live cells, and are insufficient for identification of signaling activation profile defining certain cell types, including but not limited to neoplastic and immunologically activated cell subsets. One aspect of the present invention generally relates to marker selection in panels to include proteins routinely assessed in standard FCM, while preferably also incorporating markers for surface receptor proteins within activated signaling cascades. A further aspect of the present invention generally relates to panel design for the following indications in neoplastic and non-neoplastic clinical applications as examples of the technology: (a) identification of CML progenitor cell subsets in the setting of disease recurrence after treatment discontinuation or relapse due to treatment resistance, and (b) characterization of activated basophils to predict the severity of an allergic response. Another aspect of the present invention generally relates to methods to measure levels of surface and IC biomarkers in separate or combined assays for robust characterization of each or select cell compartment, and data analysis based on results from each or all method(s) used for optimal detection of the markers. A further aspect of the present invention generally relates to the identification and profiling of cell subpopulations based on analysis of surface markers including those associated with lineage and maturation of cell types and receptor proteins, and the corresponding IC phosphoproteins including those in activated signaling cascades to predict certain disease states or response to treatment.

Owner:DEEPATH MEDICAL

Extruding and collecting system for machine production coiled materials

InactiveCN106626472AEffective squeezeExtrusion process is simpleHeating arrangementRotary pressSupporting systemEngineering

The invention relates to an extruding and collecting system for machine production coiled materials. The extruding and collecting system comprises a first strut, a second strut and a third strut which are sequentially installed from left to right. Supporting cross bars are arranged at the upper ends of the first strut, the second strut and the third strut. An upper rotating mechanism and a lower rotating mechanism which are opposite are installed at the middle portion of each of the first strut, the second strut and the third strut. A first supporting system is arranged between the first strut and the second strut, and a second supporting system is arranged between the second strut and the third strut. A bottom supporting system is installed at the upper portion of the first supporting system. A drying treatment wire pipe is installed in the bottom supporting system. A drying treatment resistance wire is installed on the drying treatment wire pipe. An extrusion rotating mechanism is installed at the upper portion of the bottom supporting system. The extruding and collecting mechanism can be used for effectively extruding the machine production coiled materials, and therefore the raw materials can be easily extruded to be flat and then are collected.

Owner:巴南区天虹仪表厂

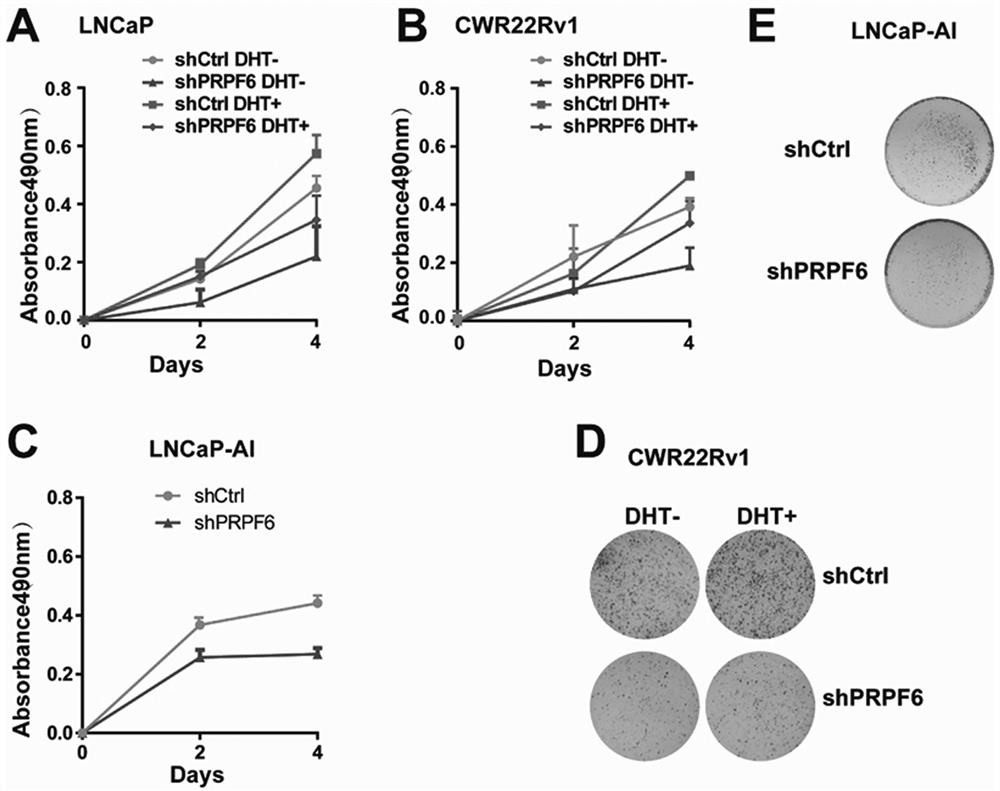

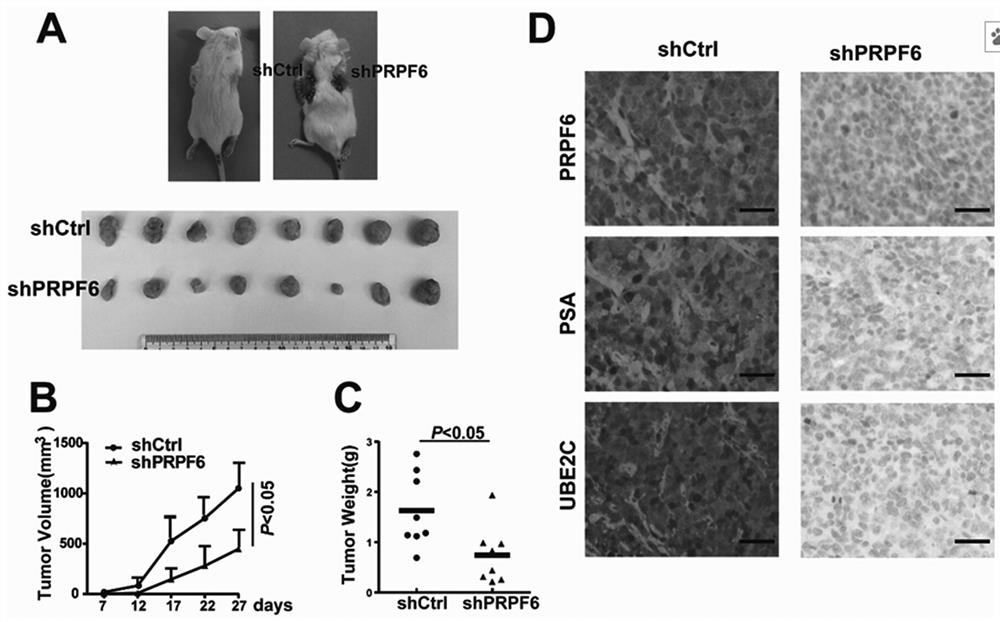

Application of prpf6 in the treatment of prostate cancer and castration-resistant prostate cancer

ActiveCN112043722BSpeed up the processOrganic active ingredientsAntineoplastic agentsProstate cancerPharmaceutical drug

The invention belongs to the technical field of biomedicine, and relates to the application of PRPF6 in the treatment of prostate cancer and castration-resistant prostate cancer. Application of the PRPF6 targeting inhibitor in the preparation of drugs and pharmaceutical compositions for preventing or treating prostate cancer and castration-resistant prostate cancer. The present invention finds for the first time that PRPF6 can promote the progression of prostate cancer and castration-resistant prostate cancer, that PRPF6 is more highly expressed in prostate cancer tissues with higher malignancy, and inhibiting PRPF6 can significantly inhibit the occurrence and development of prostate cancer and castration-resistant prostate cancer. Role of PRPF6 in resistance to treatment in prostate cancer and castration-resistant prostate cancer. It is found that PRPF6 has a potential function of drug resistance in prostate cancer and castration-resistant prostate cancer endocrine drugs, and the preparation of small molecule inhibitors of PRPF6, siRNA or the discovery of inhibition of PRPF6 transcription to generate miRNA can be used to treat clinical prostate cancer and castration-resistant prostate cancer. The invention provides a new idea and a new target for treating prostate cancer and castration-resistant prostate cancer.

Owner:中国医科大学

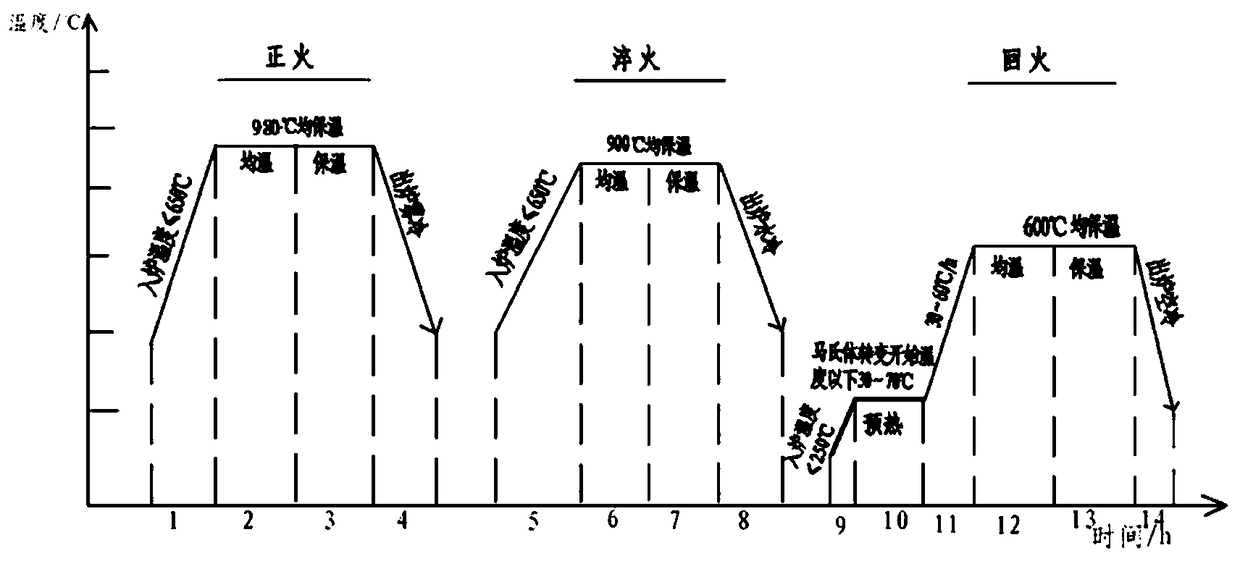

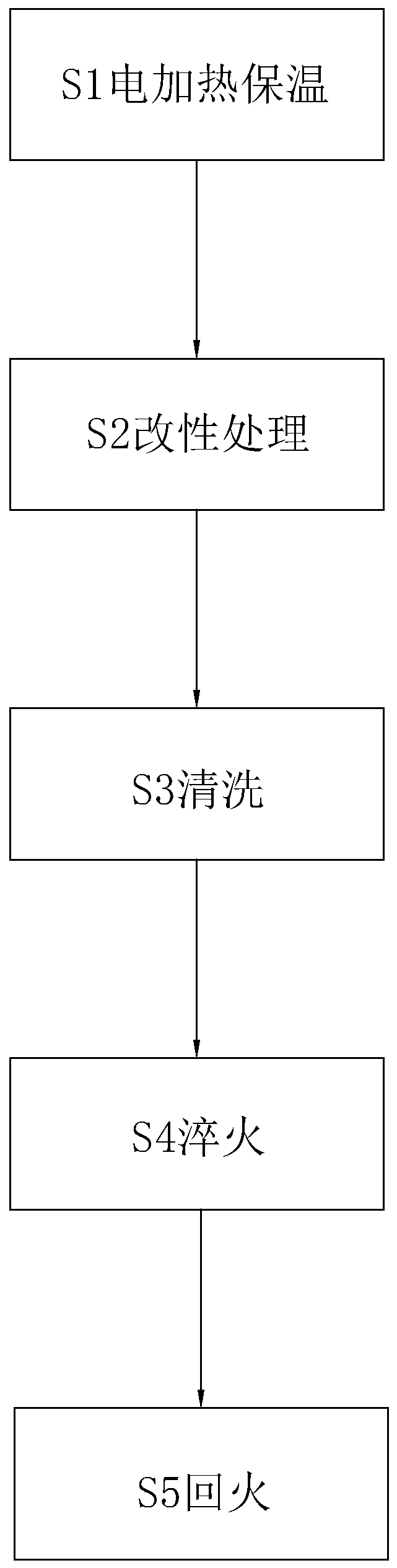

Heat treatment process of thread rolling plate

InactiveCN110343826AImprove wear resistanceImprove hardenabilitySolid state diffusion coatingFurnace typesHardnessCleansing Agents

The invention relates to the technical field of metal heat treatment, and discloses a heat treatment process of a thread rolling plate. The heat treatment process comprises the steps that S1, electricheating and heat preservation are carried out, particularly, the thread rolling plate is placed in a heat treatment resistance furnace, the vacuum is pumped to 1.0Pa or below, and heat preservation is carried out for 35-55min at the temperature of 110-200 DEG C; S2, modifying treatment is carried out, and particularly, the thread rolling plate is immersed in co-infiltrant, and taken out after being subjected to heat preservation for 2-6h at the temperature of 850-950 DEG C; S3, cleaning is carried out, and particularly the thread rolling plate in the step 2 is placed in a cleaning agent at the temperature of 820-840 DEG C to be cleaned for 4-6min; S4, quenching is carried out, and particularly liquid ammonia is introduced into a resistance furnace in a gas form, and heating and heat preservation are carried out at the temperature of 60-70 DEG C; S5, tempering is carried out, and particularly the quenched thread rolling plate is heated to 80-90 DEG C, subjected to heat preservation for2-3h, and cooled. The heat treatment process of the thread rolling plate has the advantages and benefits that boron and aluminum elements penetrate into the thread rolling plate to form a high-hardness diffusion layer, and a boron-aluminum co-cementation layer and a base body of the thread rolling plate are combined in a zigzag manner; and nano SiO2 and the boron-aluminum co-cementation layer canhave a synergistic effect, so that the wear resistance of the thread rolling plate is improved.

Owner:温州中牙模具有限公司

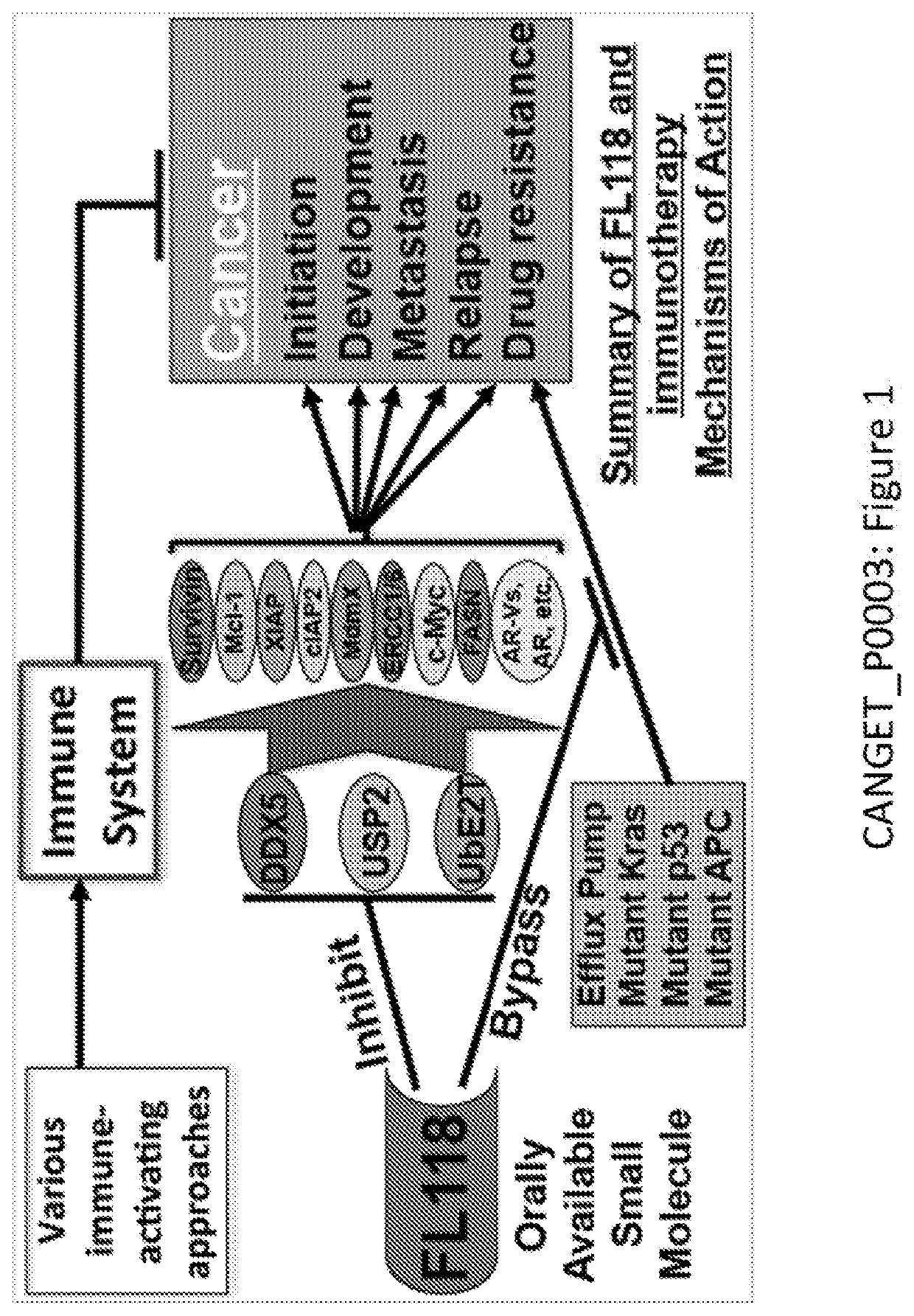

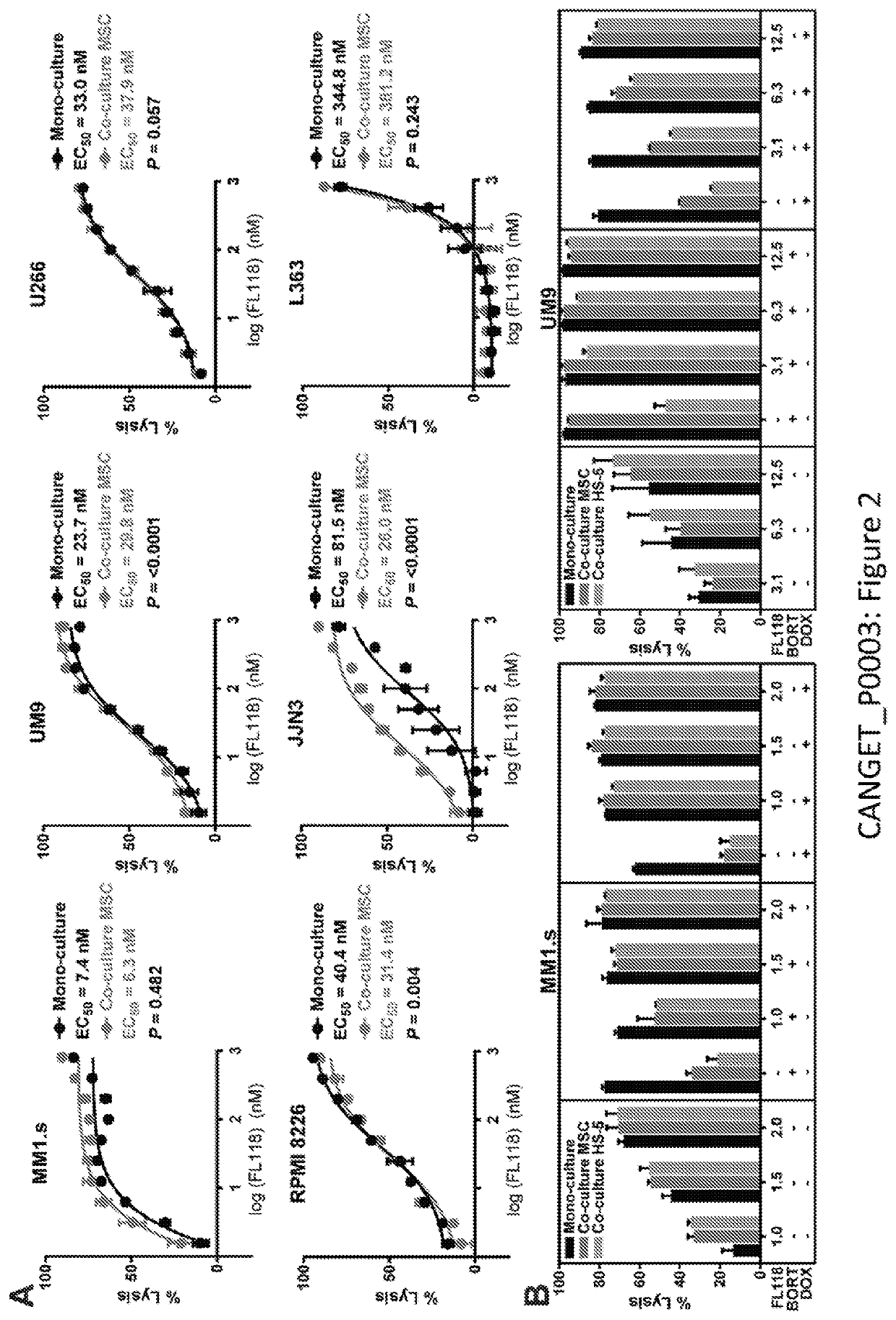

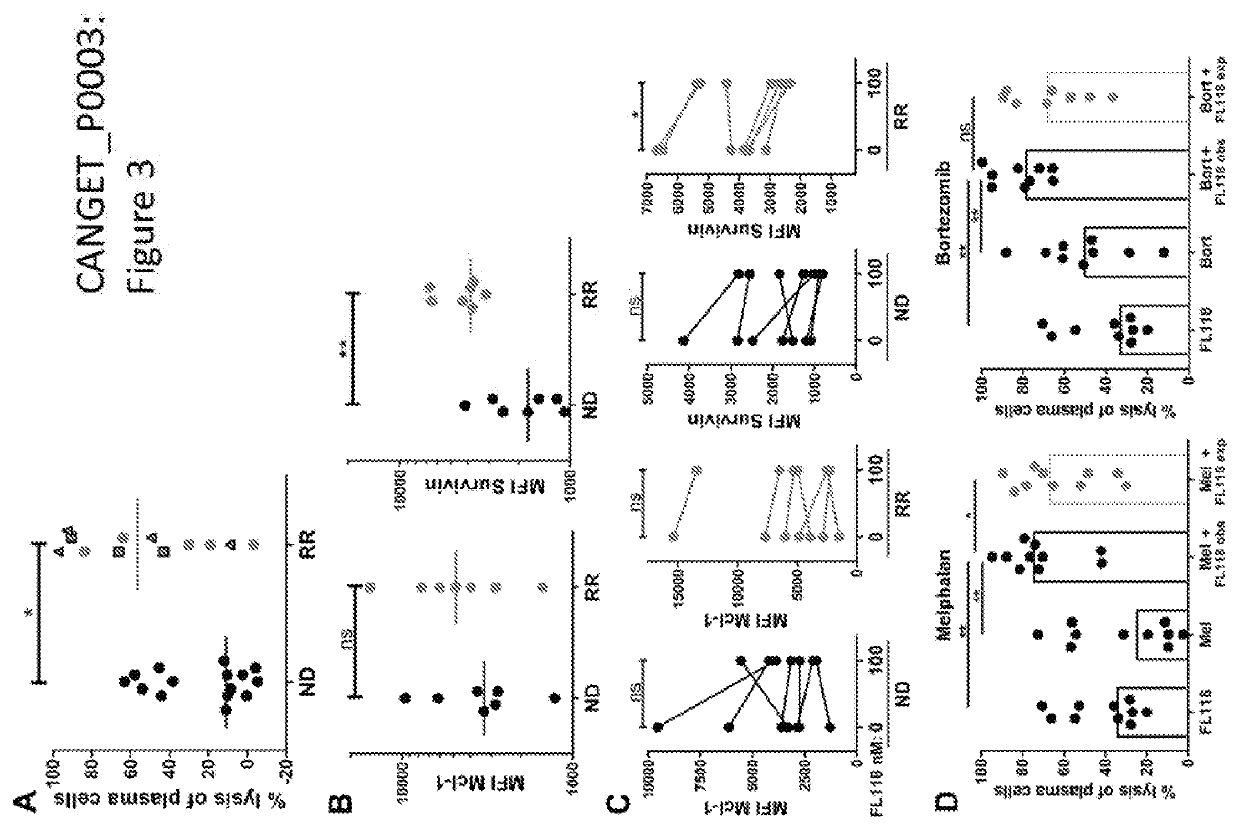

Novel anticancer drug fl118 formulation in combination with immunotherapy for treatment of human cancer

PendingUS20220249464A1Good curative effectConvenience to workOrganic active ingredientsDispersion deliveryAntigenHuman cancer

Described herein, are the extended and newly discovered novel formulations of FL118 used alone or in combination with a type of cancer immunotherapy including but not be limited to, cell-based immunotherapy, antigen-based immunotherapy, cytokine-based immunotherapy, immunomodulatory therapy and other agents-based immunotherapy or their combinations in a certain way, ant sequential regimens or schedules, for cancer treatment to preclude, eliminate or reverse cancer phenotypes and treatment resistance.

Owner:CANGET BIO TEKPHARMA LLC

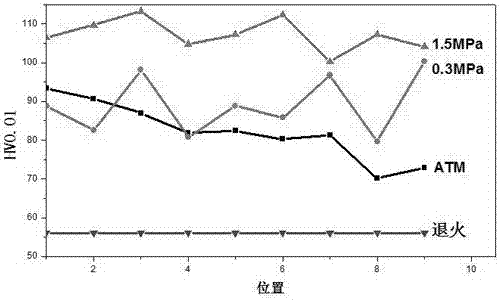

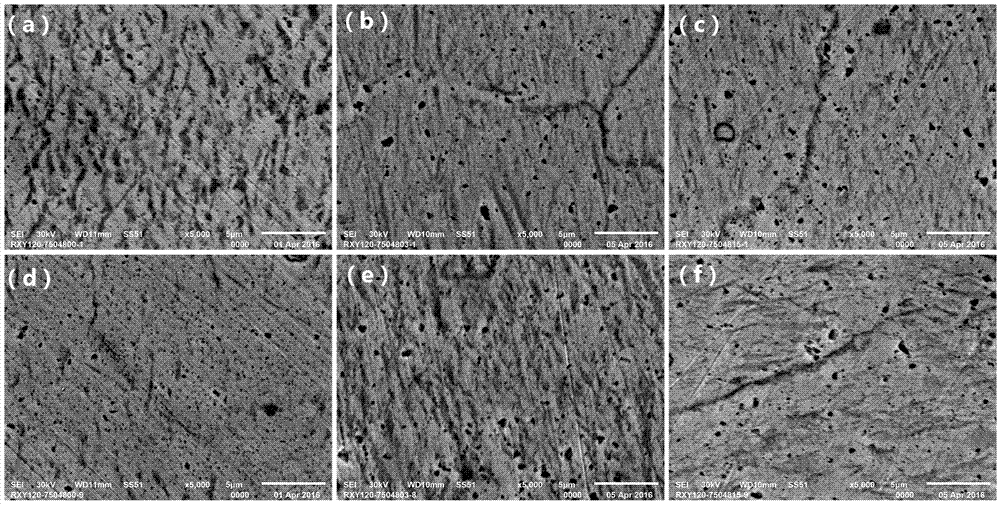

Testing method for internal oxidization at differential pressure of Ag-Sn-In alloy

InactiveCN107064140AImprove performanceImprove electrical contact performanceMaterial analysis by optical meansInvestigating material hardnessDifferential pressureMicroscopic observation

The invention discloses a testing method for internal oxidization at differential pressure of an Ag-Sn-In alloy. The method comprises the following steps of: performing a high-temperature internal oxidation experiment on Ag-6.0Sn-2.8In alloy wire particles by using an industrial heat treatment resistance furnace, wherein the diameter of the alloy wire particles is 1.8mm and the length is 6mm, the temperature in the furnace is set at 750 DEG C, and the oxidizing pressures are separately set at a constant pressure, 0.3MPa and 1.5MPa; after oxidization in 48 hours, performing furnace cooling to room temperature; observing internal tissues of a sample by means of a metalloscope; observing the section morphology of the alloy after internal oxidization by means of a scanning electron microscope, and performing energy spectrum analysis by means of an EDS; testing hardness by means of a microhardness tester; and acquiring silver stannic oxide prepared under different differential pressure conditions, wherein the silver stannic oxide has microstructures and mechanical properties. Ag-SnO2-In2O3 is prepared by means of a high-temperature internal oxidization process, and the silver stannic oxide prepared under different differential pressure conditions has different microstructures and mechanical properties.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com