Heat treatment process of thread rolling plate

A kind of thread rolling and process technology, which is used in heat treatment furnaces, heat treatment equipment, metal material coating processes, etc., can solve problems such as short service life, improve wear resistance, improve wear resistance and toughness, and improve wear resistance. performance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

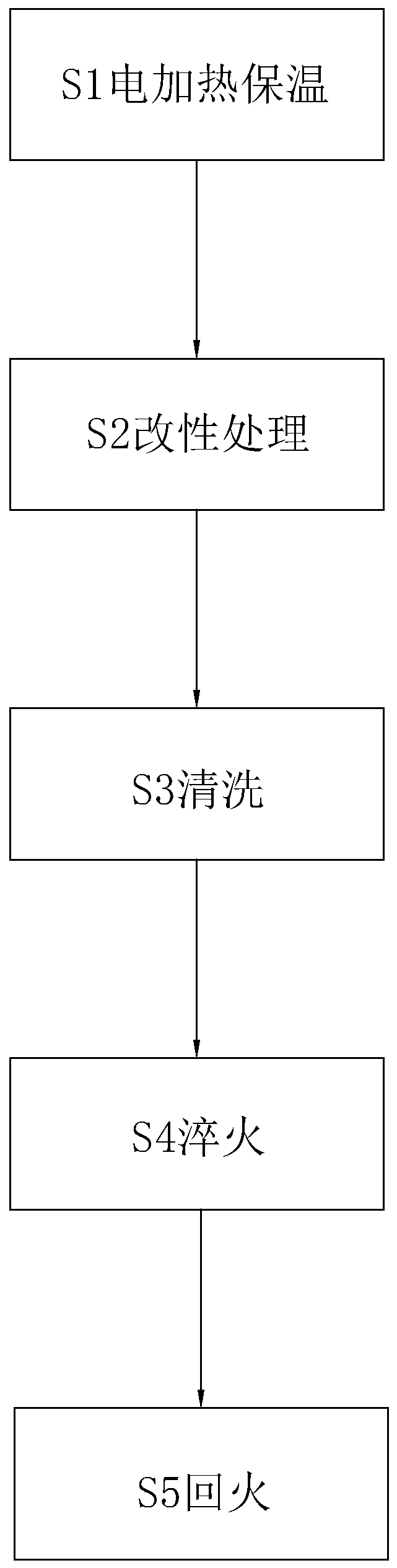

[0042] A heat treatment process for a thread rolling board, comprising the steps of:

[0043] S1. Electric heating and heat preservation; place the thread rolling board in a heat treatment resistance furnace, evacuate to below 1.0Pa, and keep heat at 200°C for 55min;

[0044] S2. Modification treatment; immerse the thread rolling board in the co-infiltration agent, take it out after keeping it warm at 950°C for 6 hours; the preparation method of the co-infiltration agent is: first put 80 parts of borax into a muffle tank and heat and melt to 900°C , then add 12 parts of aluminum powder and 5 parts of nano-SiO 2 , stir evenly, after staying for 10min, then add 3 parts of silane coupling agent KH570 and 4 parts of stearic acid in turn, stir evenly, then add 3 parts of carbon nanotubes, stir evenly and then stay for 15min;

[0045] S3, cleaning; the thread rolling board in the step S2 is placed in a cleaning agent at 840° C., and cleaned for 6 minutes; the cleaning agent is prep...

Embodiment 2

[0049] The difference with embodiment 1 is that a kind of heat treatment process of thread rolling board comprises the following steps:

[0050] S1. Electric heating and heat preservation; place the thread rolling board in a heat treatment resistance furnace, evacuate to below 1.0Pa, and keep heat at 110°C for 35 minutes;

[0051] S2. Modification treatment: immerse the thread rolling board in the co-penetration agent, and take it out after keeping it warm at 850°C for 2 hours;

[0052] The preparation method of co-penetration agent is: first put 60 parts of borax into the muffle tank and heat and melt to 900 degrees Celsius, then add 8 parts of aluminum powder and 3 parts of nano-SiO 2 , stir evenly, after staying for 10 minutes, then add 6 parts of silane coupling agent KH570 and 3 parts of stearic acid in turn, stir evenly, then add 2 parts of carbon nanotubes, stir evenly and then stay for 15 minutes;

[0053] S3, cleaning; the thread rolling board in the step S2 is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com