Testing method for internal oxidization at differential pressure of Ag-Sn-In alloy

A test method and internal oxidation technology, which is applied in the direction of testing the hardness of materials, measuring devices, and using the measurement of secondary emissions for material analysis, etc. It can solve problems affecting material processing, temperature rise, and large contact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The test method provided by the present invention will be described in detail below.

[0018] Step 1) Use RG-8-8 industrial heat treatment resistance furnace to conduct high-temperature internal oxidation experiments on Ag-6.0Sn-2.8In alloy wire particles (φ1.8×6mm). The temperature in the furnace is set to 750 ° C, and the oxidation pressure is set to Atmospheric pressure, 0.3MPa, 1.5MPa.

[0019] Step 2) After oxidizing the Ag-6.0Sn-2.8In alloy wire particles in step 1) for 48 hours, cool to room temperature with the furnace;

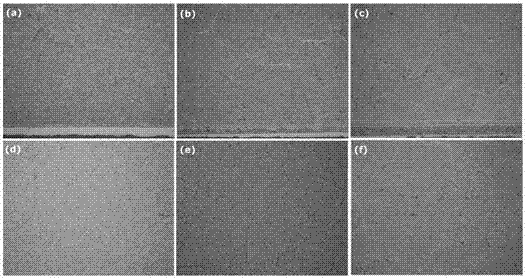

[0020] Step 3) Observing the internal structure of the sample with a metallographic microscope (OM, Olympus GX-FSL, Japan);

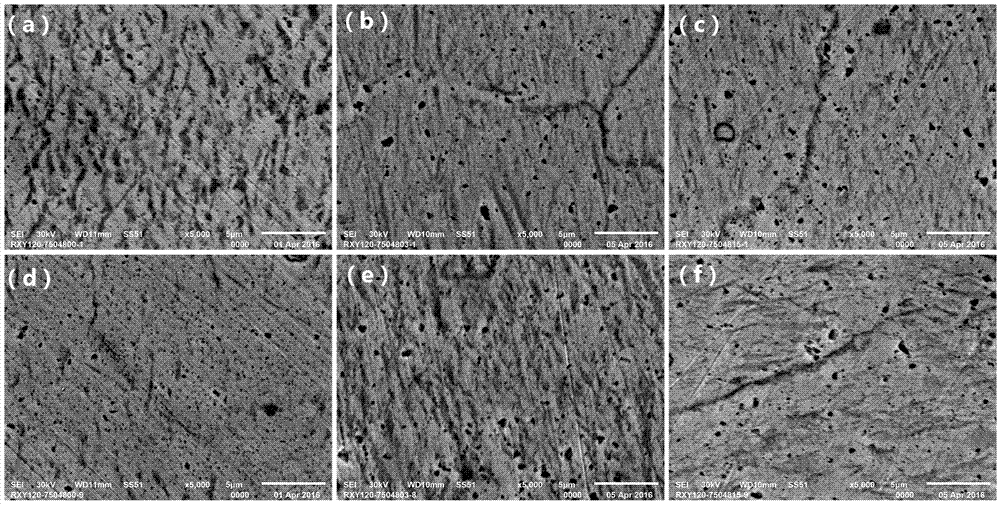

[0021] Step 4) Use a scanning electron microscope (SEM, JSM-6510A, Japan) to observe the cross-sectional morphology of the alloy after oxidation, and use the built-in EDS for energy spectrum analysis;

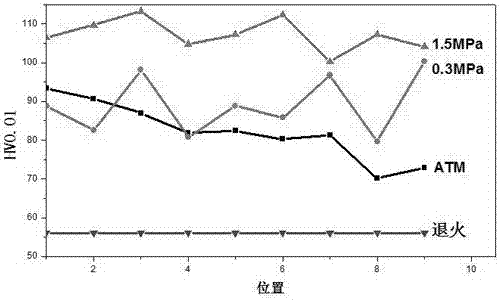

[0022] Step 5) Use HSX-100TAY microhardness tester for hardness test;

[0023] Step 6) Obtain the microstructure and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com