Segment type four-function heat treatment resistance furnace

A segmented, resistance furnace technology used in furnaces, furnace types, furnace components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

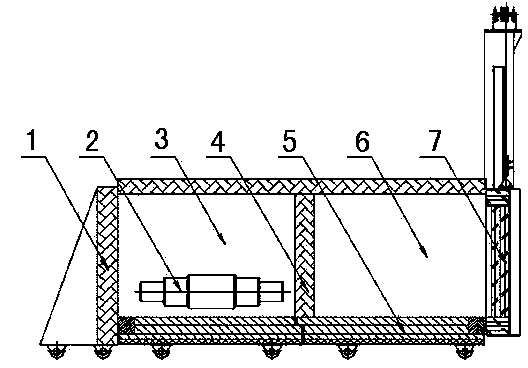

[0008] Depend on figure 1 As we know, the segmented four-function heat treatment resistance furnace consists of a furnace body 1, a rear furnace 3, an intermediate gate 4, a furnace car 5, a front furnace 6 and a front gate 7. The furnace body 1 is arranged on the furnace car 5, and the movable furnace The body 1 is divided into a back furnace 3 and a front furnace 6 by an intermediate gate 4. The two sides of the furnace body 1 are equipped with sealed doors, and the workpiece 2 is placed in the furnace body 1. The intermediate gate 4 is vertically arranged on the movable furnace body 1 Inside. An air outlet is provided at the outlet of the front gate 7 of the furnace body 1, and an air inlet is provided at the entrance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com