Patents

Literature

43 results about "Magnetic annealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

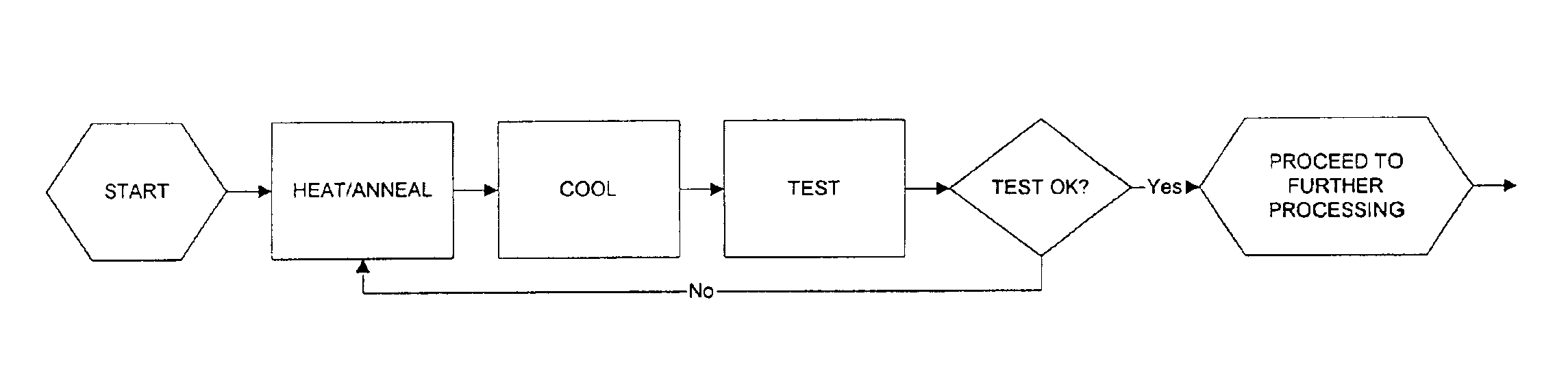

Magnetic annealing is applied to remove internal stresses and enforce recrystallization processes. This structural change in most cases increases permeability, reduces coercivity and defines a magnetically reliable state. Our stationary hydrogen furnaces are suitable for magnetic annealing procedures of most NiFe and CoFe alloys.

Method for manufacturing of insulated soft magnetic metal powder formed body

InactiveCN101213041AStable manufacturingReduce iron lossTransportation and packagingMetal-working apparatusMetal powderHeat treated

A method of manufacturing an insulating soft magnetic metal powder compact, by forming an inorganic insulating film on the surface of soft magnetic metal powder particles, compacting and molding the powder, and then performing heat treatment to provide an insulating soft magnetic metal powder compact, The method includes: compacting and forming the powder; then, at a high temperature higher than the Curie temperature of the soft magnetic metal powder and lower than the critical temperature for destroying the insulating film, in a non-oxidizing atmosphere such as vacuum, inert gas, etc., making the powder The powder is magnetically annealed; then further heat-treated in an oxidizing atmosphere such as air at a temperature of 400°C to 700°C.

Owner:MITSUBISHI STEEL MFG CO LTD

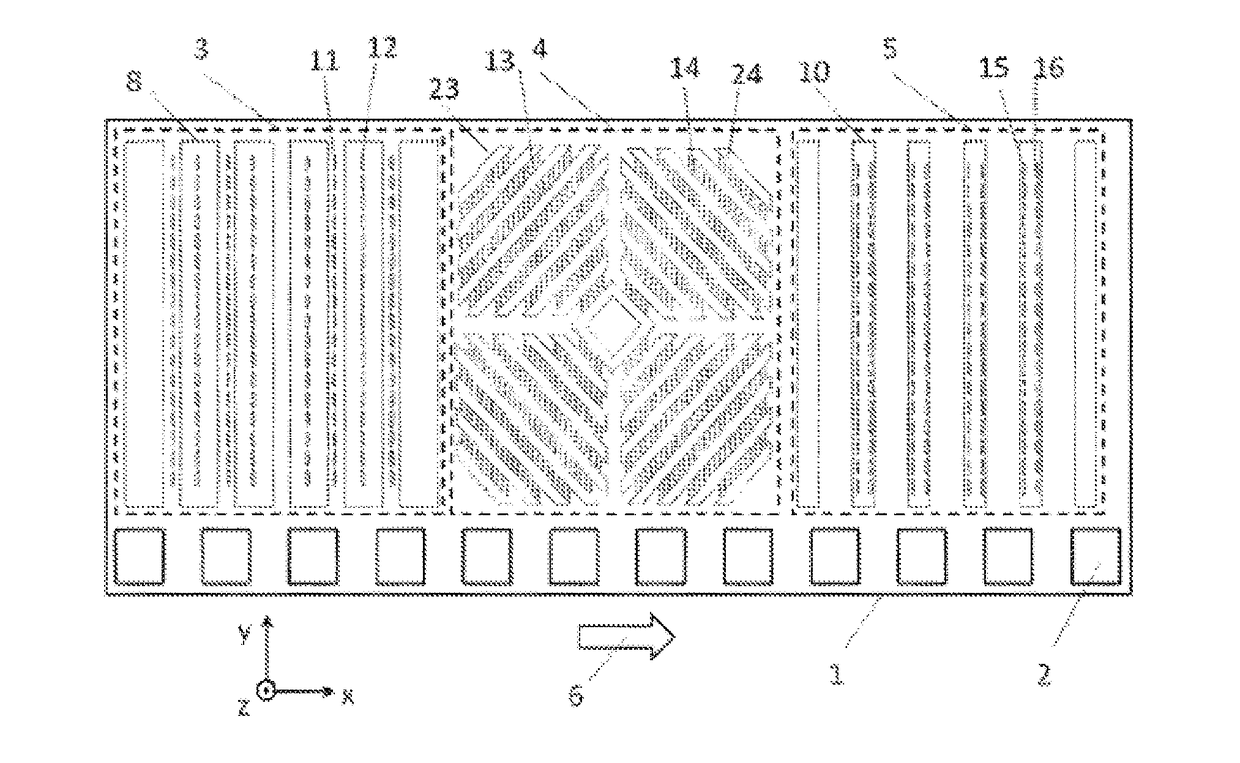

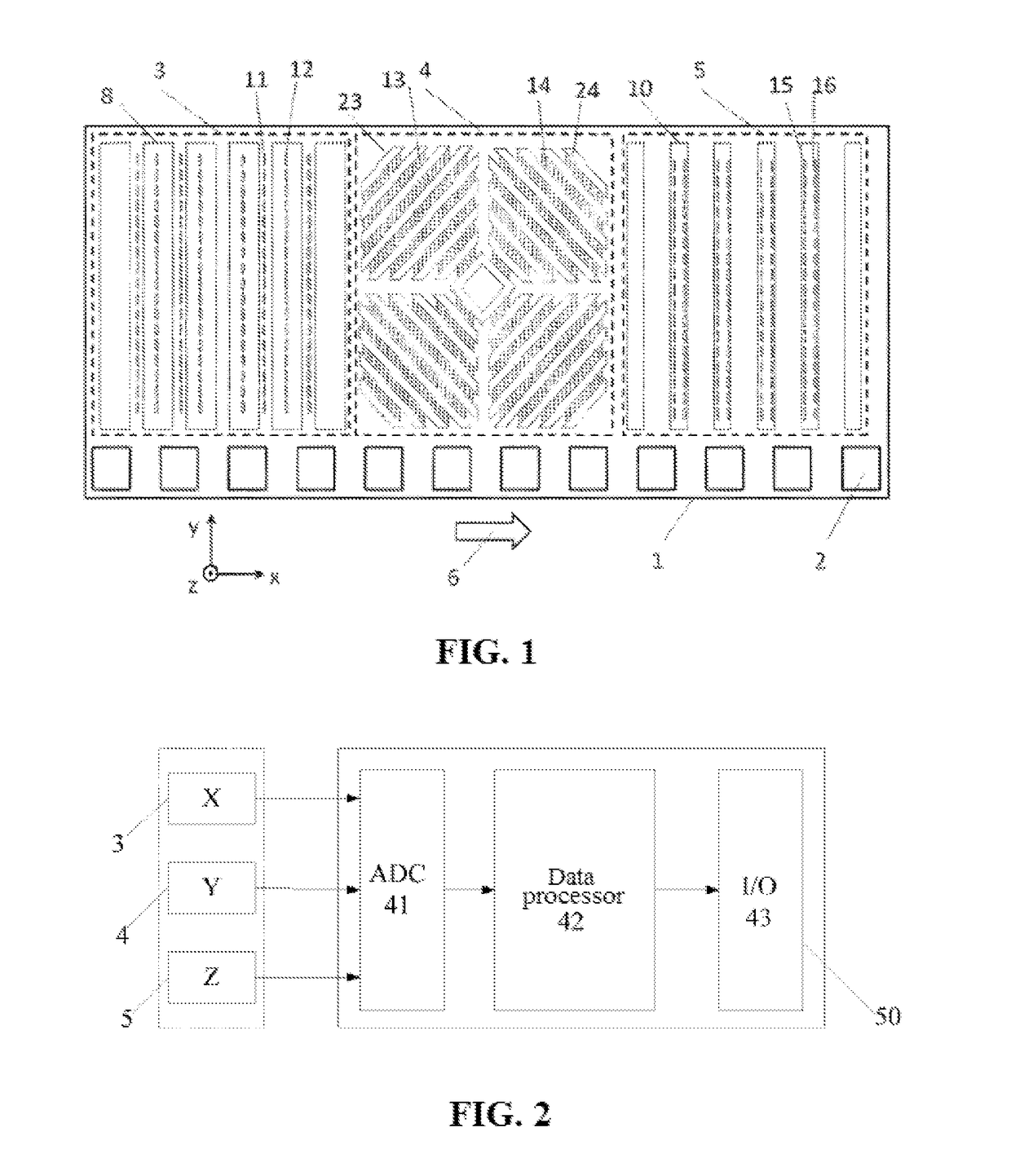

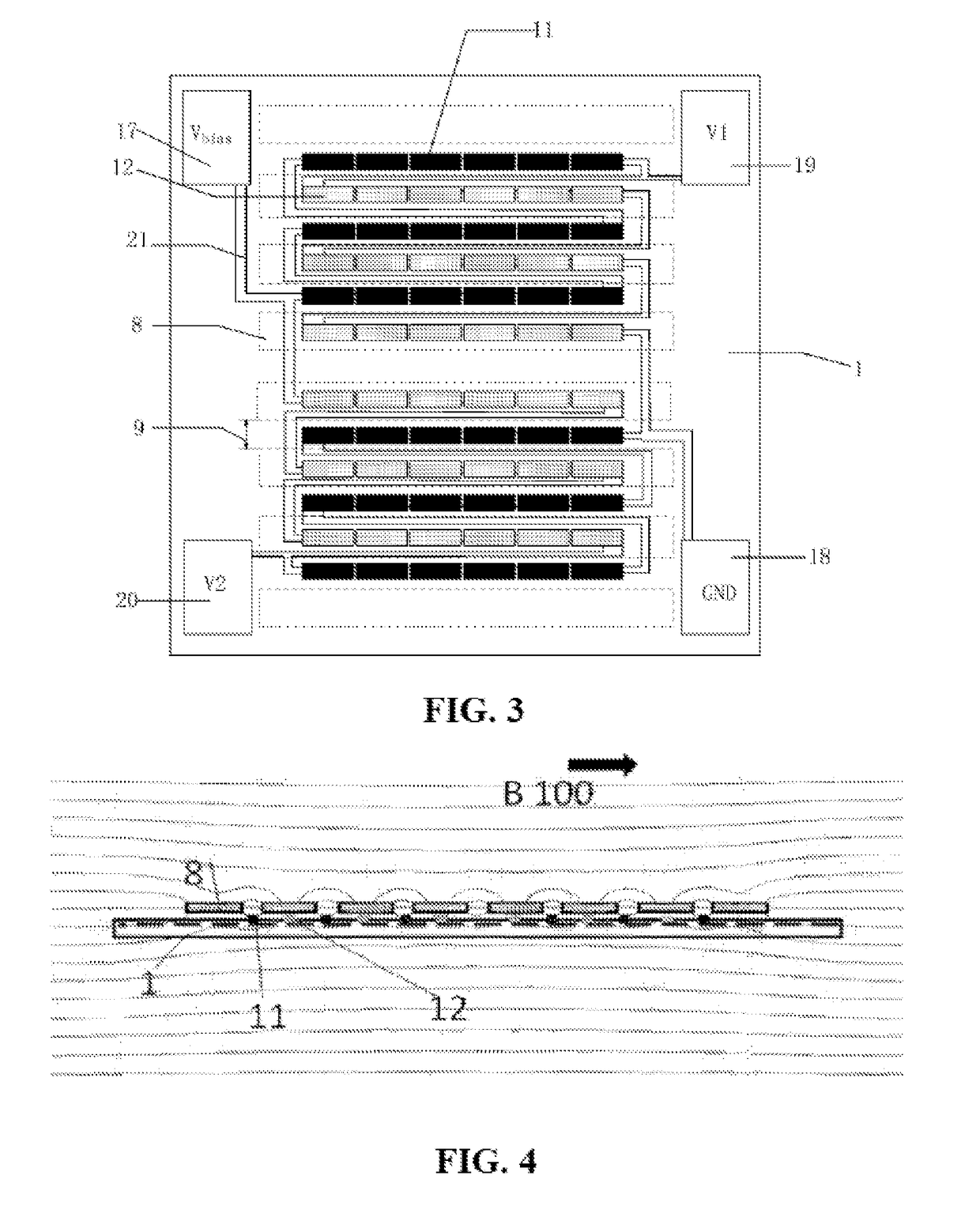

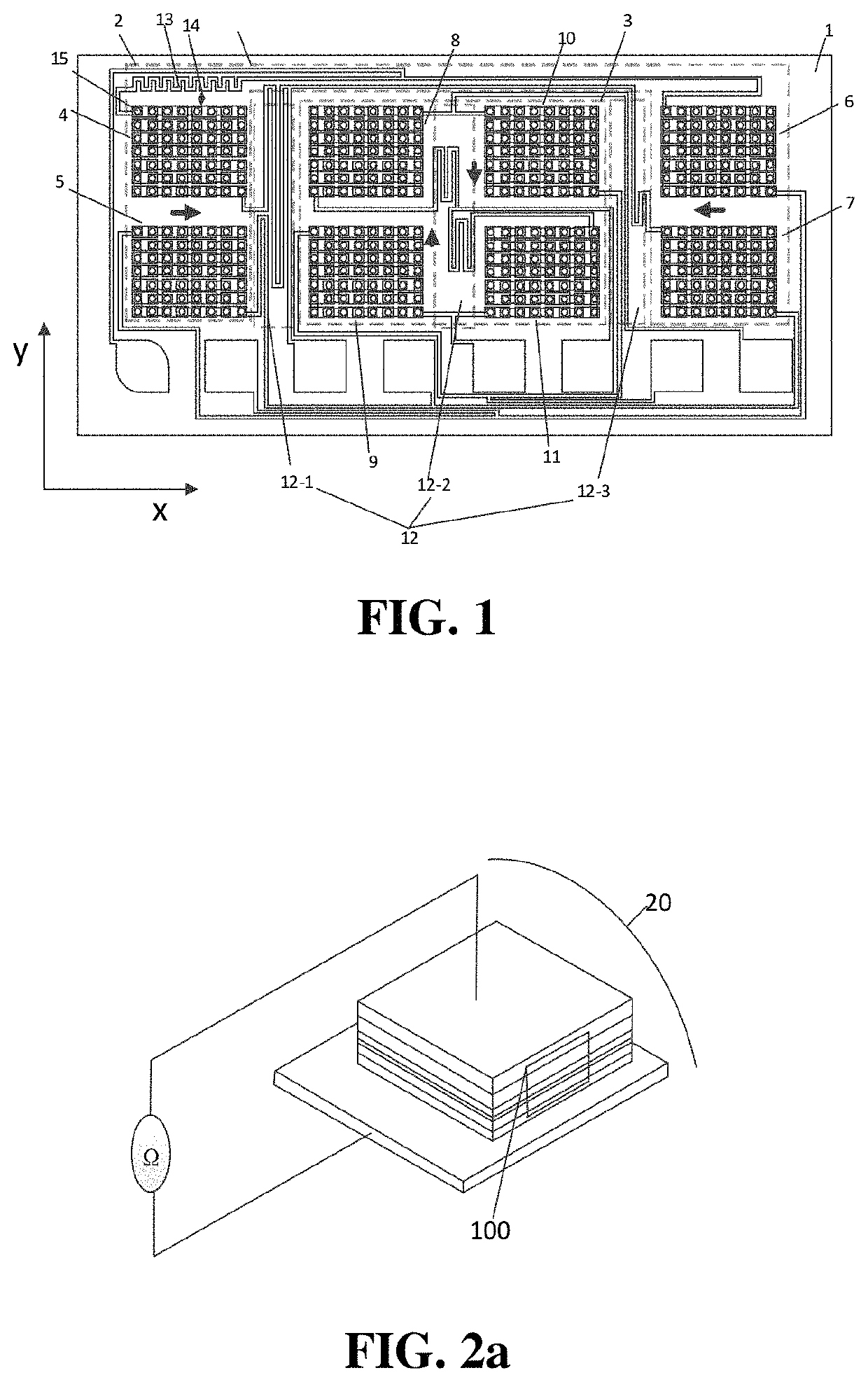

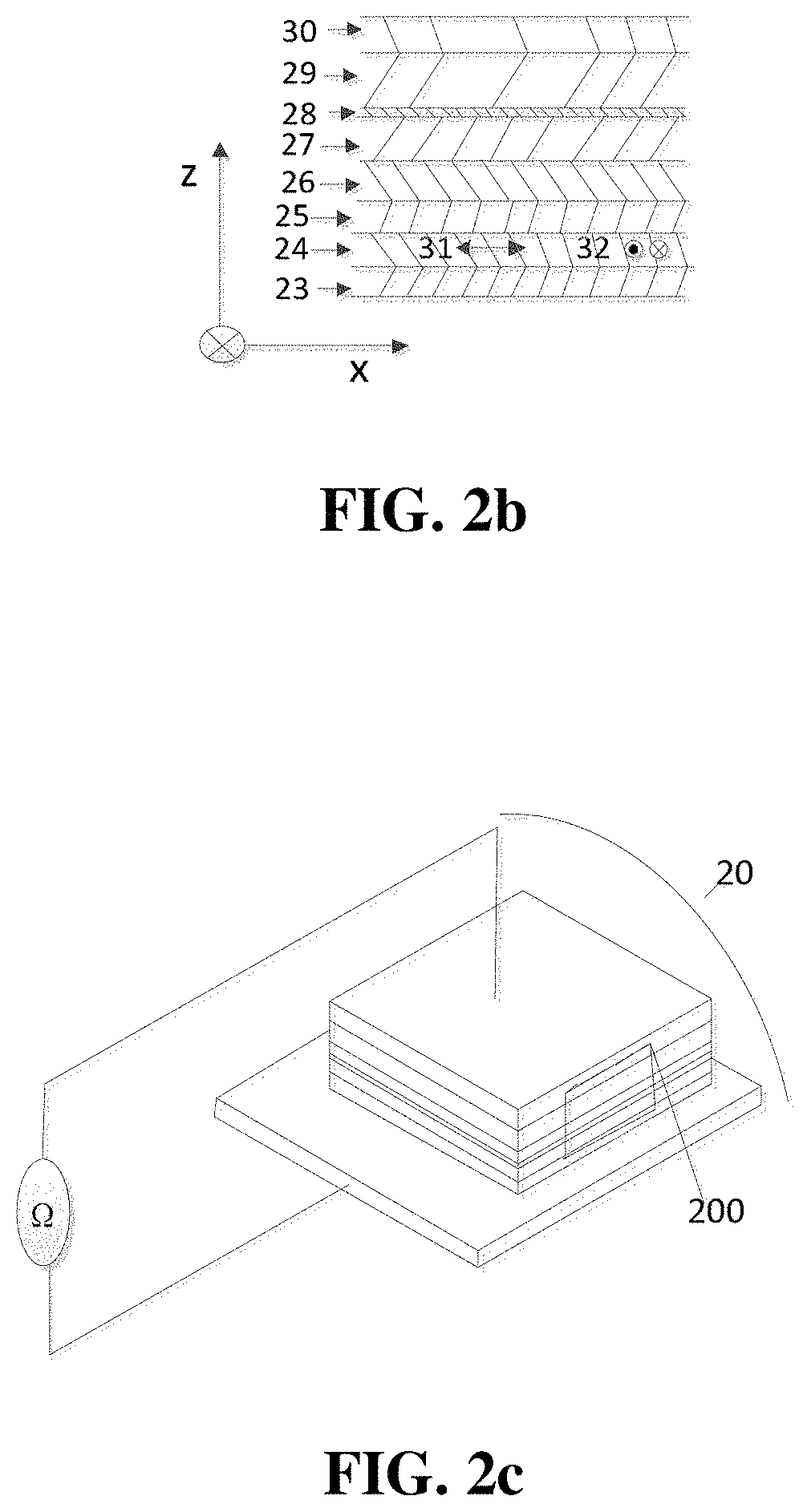

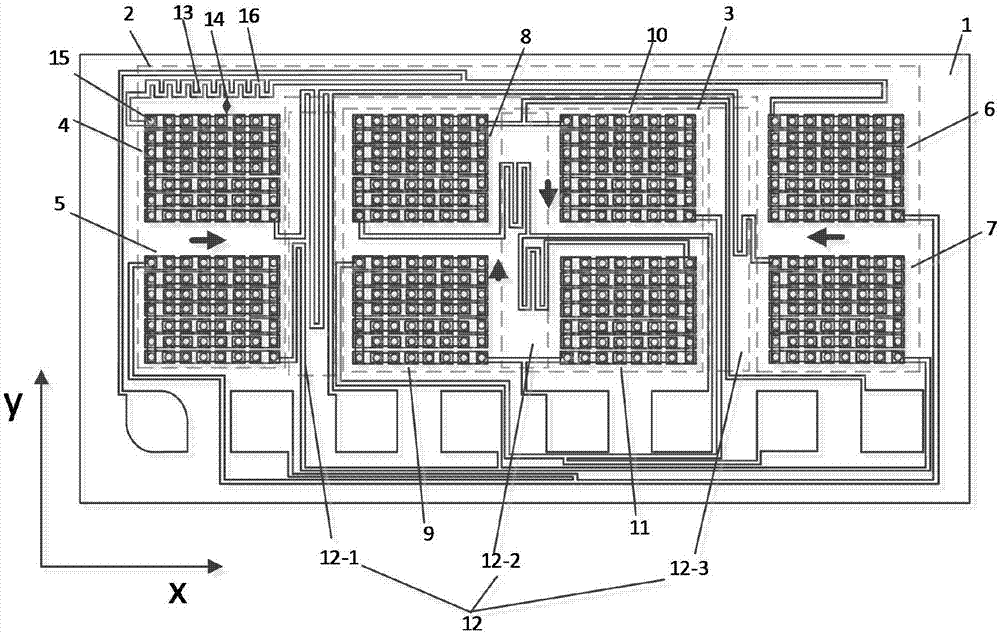

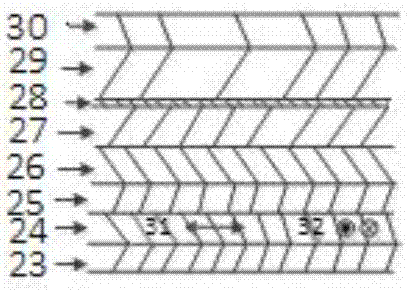

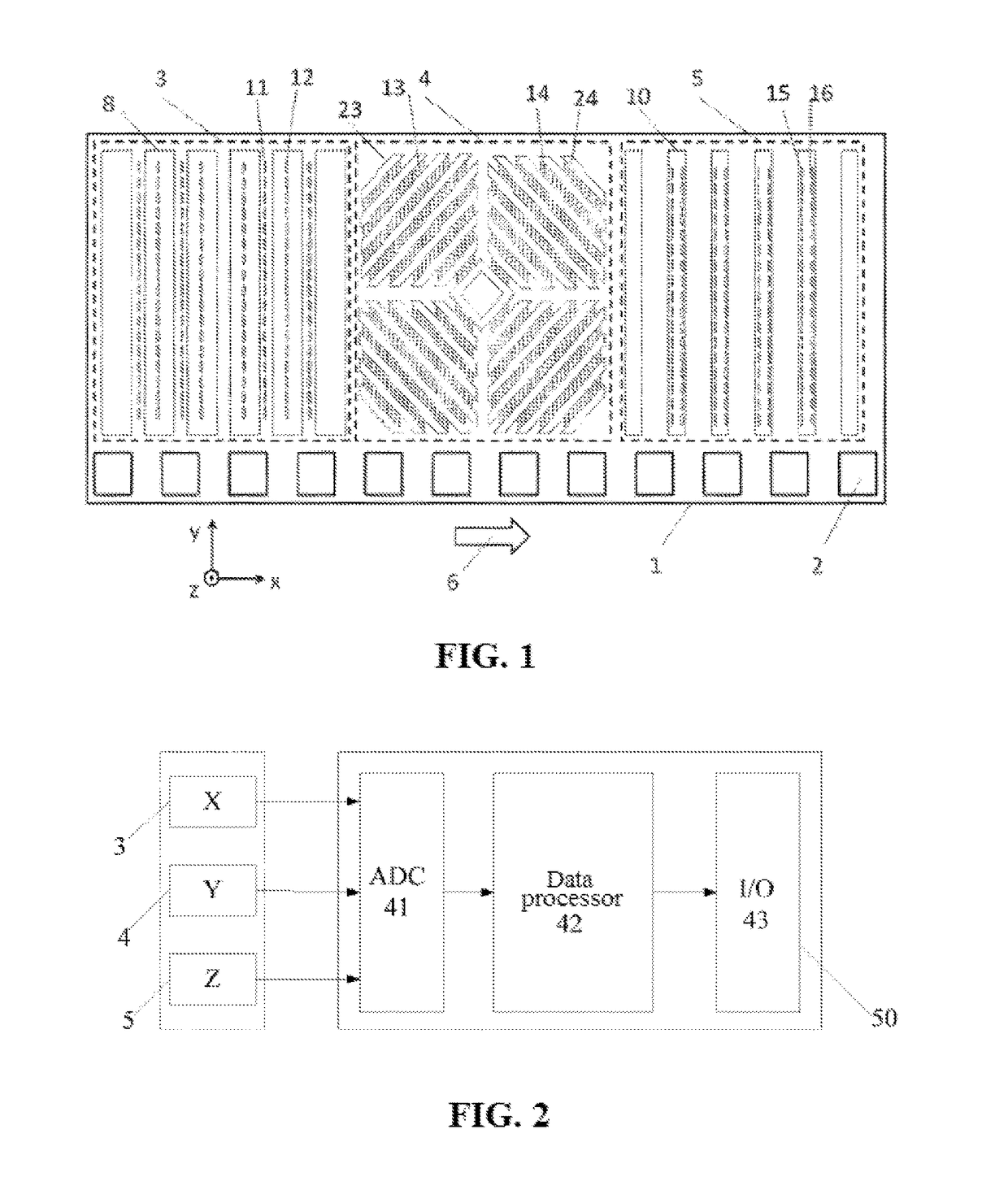

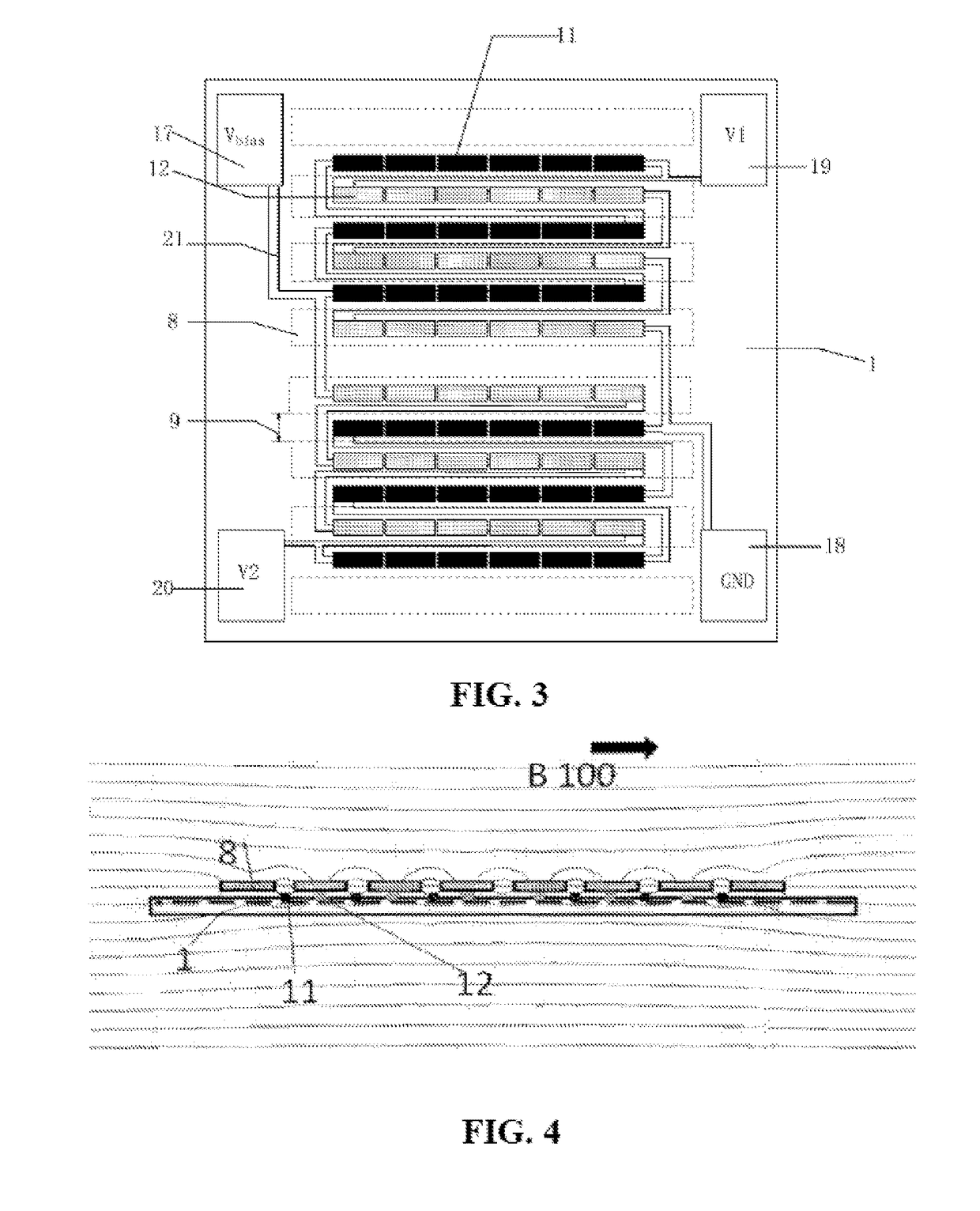

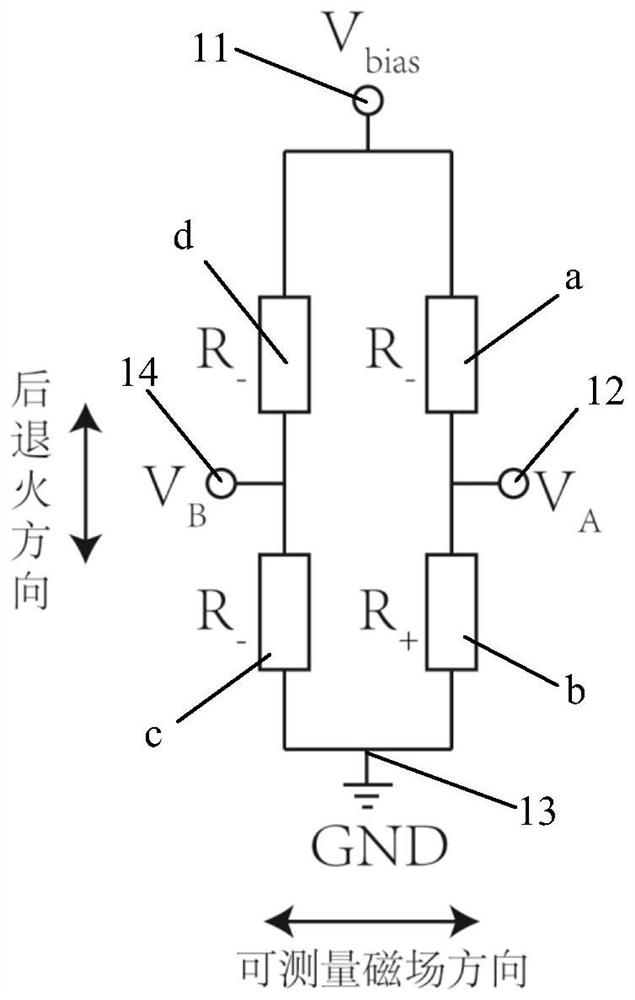

Monolithic three-axis linear magnetic sensor and manufacturing method thereof

ActiveUS20170123016A1Increasing thickness LzHigh sensitivityMagnetic field measurement using flux-gate principleResistorsMagnetizationMagnetic reluctance

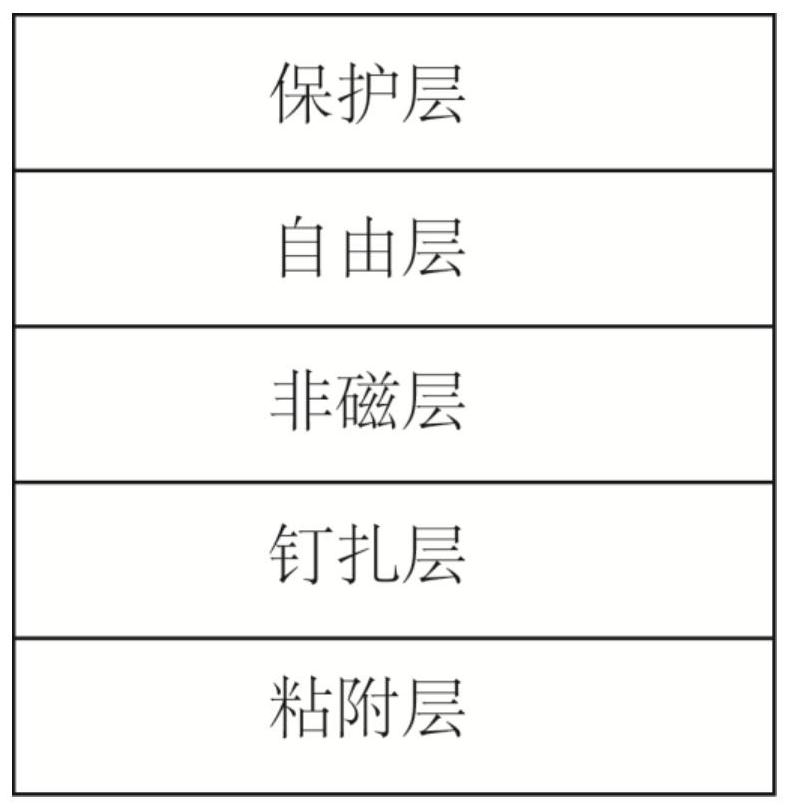

A monolithic three-axis linear magnetic sensor and manufacturing method wherein the sensor comprises an X-axis sensor, a Y-axis sensor and a Z-axis sensor. The X-axis sensor comprises a referenced bridge and at least two X ferromagnetic flux guides. The Y-axis sensor comprises a push-pull bridge and at least two Y ferromagnetic flux guides. The Z-axis sensor comprises a push-pull bridge and at least one Z ferromagnetic flux guide. The bridge arms of the referenced bridge and push-pull bridge are each formed by one or more magnetoresistive elements that are electrically interconnected. The directions of the sensing axes and the directions of magnetization of the pinned layers of the magnetoresistive elements are all oriented along the X-axis. This manufacturing method comprises first depositing a magnetoresistive thin film on a wafer, and then performing several processes such as magnetic annealing, photolithography, etching, coating, and the like in order to realize a sensor. This monolithic three-axis linear magnetic sensor has the advantages of low cost, easy manufacturability, good linearity, and high sensitivity.

Owner:MULTIDIMENSION TECH CO LTD

Method for manufacturing miniaturized fluxgate sensor

InactiveCN101481080AEase of mass productionGood repeatabilityTelevision system detailsSemi-permeable membranesResistElectrical conductor

The invention provides a method for producing a minimized fluxgate sensor in the micro electromechanical technical field, which comprises the following steps: producing a double-sized alignment symbol; sputtering a bottom layer; flinging positive photoresists, exposing and developing; plating a drive coil and a bottom layer coil of a receiving coil, connecting a conductor with a pin of the coil; removing photosensitive resist and a bottom layer; flinging polyimide, solidifying and polishing; sputtering the bottom layer; flinging positive photoresists, exposing and developing; plating a magnetic core, connecting the conductor with a pin; removing positive photoresists and the bottom layer; flinging polyimide, solidifying and polishing; sputtering the bottom layer; flinging the positive photoresists, exposing and developing; plating the drive coil and a top layer coil of the receiving coil and a pin; removing the photosensitive resist and the bottom layer; and magnetic annealing. The invention solves the problems of the traditional fluxgate sensor of poor stability, poor repetitiveness and poor mass production, ensures that the production technique is compatible with the large-scale integrated circuit technique, can be manufactured by integrating the interface circuit, and is widely applied in a plurality of new fields.

Owner:SHANGHAI JIAO TONG UNIV

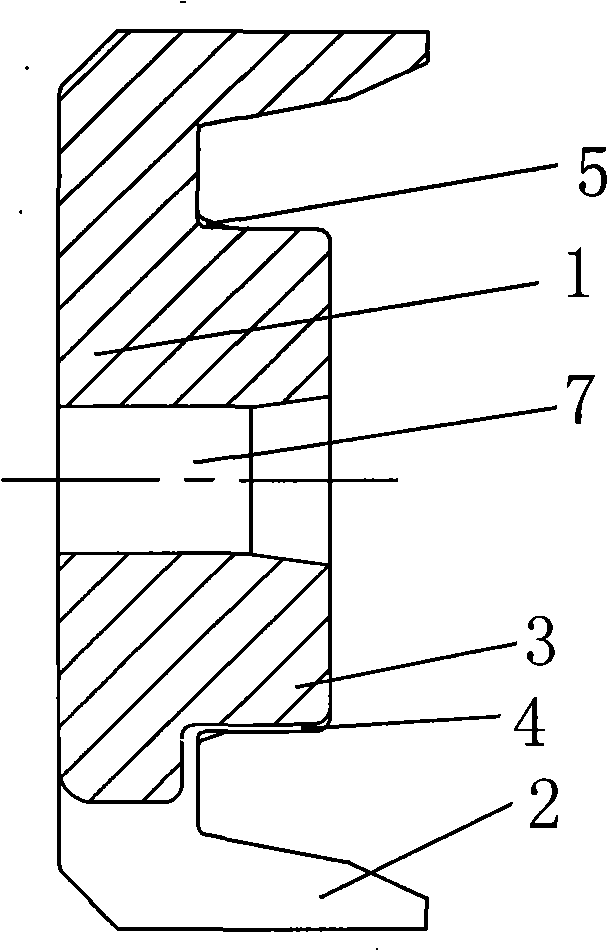

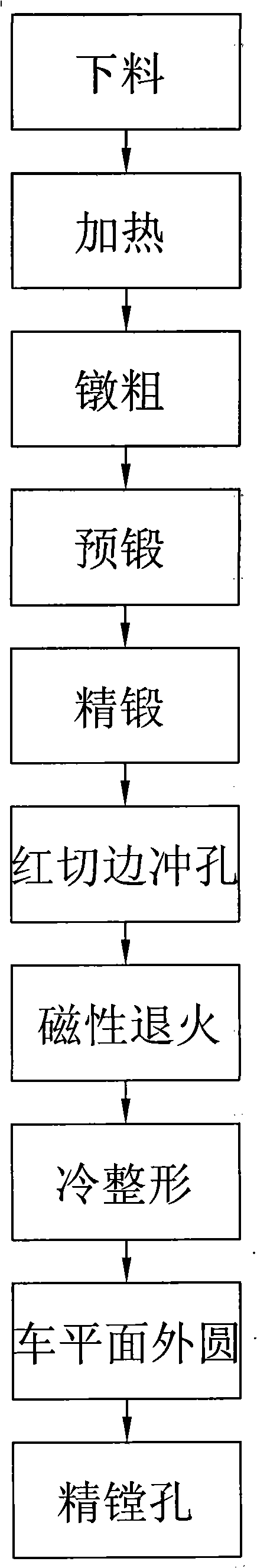

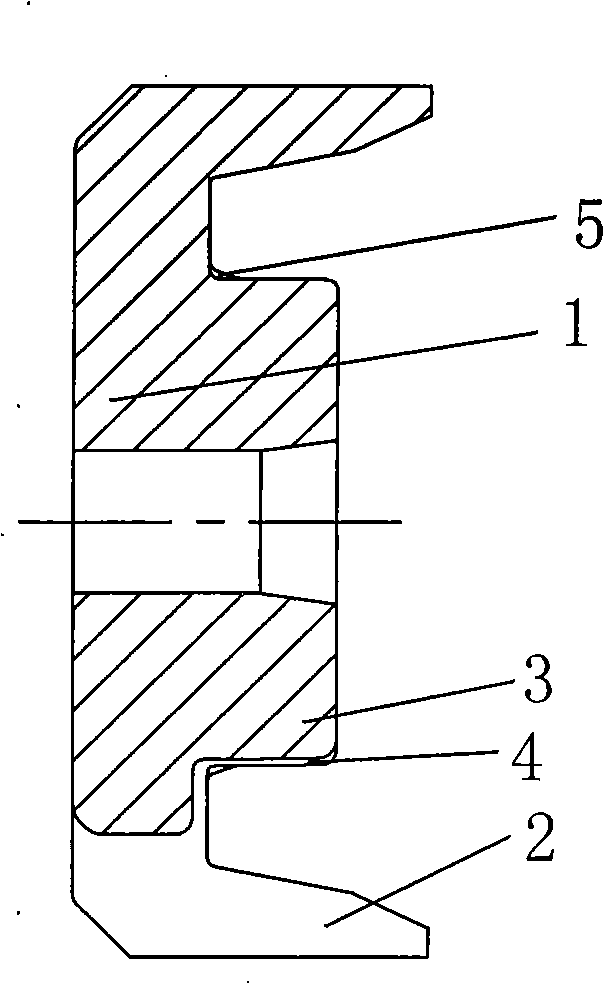

Red edge-cutting and hole-punching manufacture technology of automobile generator finish forging claw pole

InactiveCN101323080AIncrease power generationLow shear strengthRailway componentsVehicle componentsProduction lineManufacturing technology

The invention relates to a red trimming and punching manufacturing technique for finish forging claw poles of automobile generators, which comprises the following steps: a. blanking; b. heating; c. upsetting; d. dummying; e. finish forging; f. red trimming and punching; g. magnetic annealing; h. cold finishing; i. lathing the surface of excircle; j. finish boring holes. The red trimming and punching manufacturing technique is used for leading the five processes of heating, upsetting, dummying, finish forging and punching with red trimmings to form the flow line production, which reduces the logistic cost, and the temperature of products can reach 950 DEG C to 1050 DEG C when being punched, and the cutting strength of materials is low now. The invention reduces the tonnage of the equipment greatly, prolongs the service life of the equipment and reduces the noise. As the finish forging process and the process of red trimming and punching form the production line, the appearance quality of the finish forged products can be controlled effectively, thus improving the product quality. The punching can be finished when the red trimming is carried out, and the equipment and operators can be reduced; compared with the original art, the red trimming and punching manufacturing technique for the finish forging claw poles of the automobile generators can reduce the drilling processes, can reduce the production cost, enhance the safety and can improve the environment of production fields.

Owner:庄龙兴

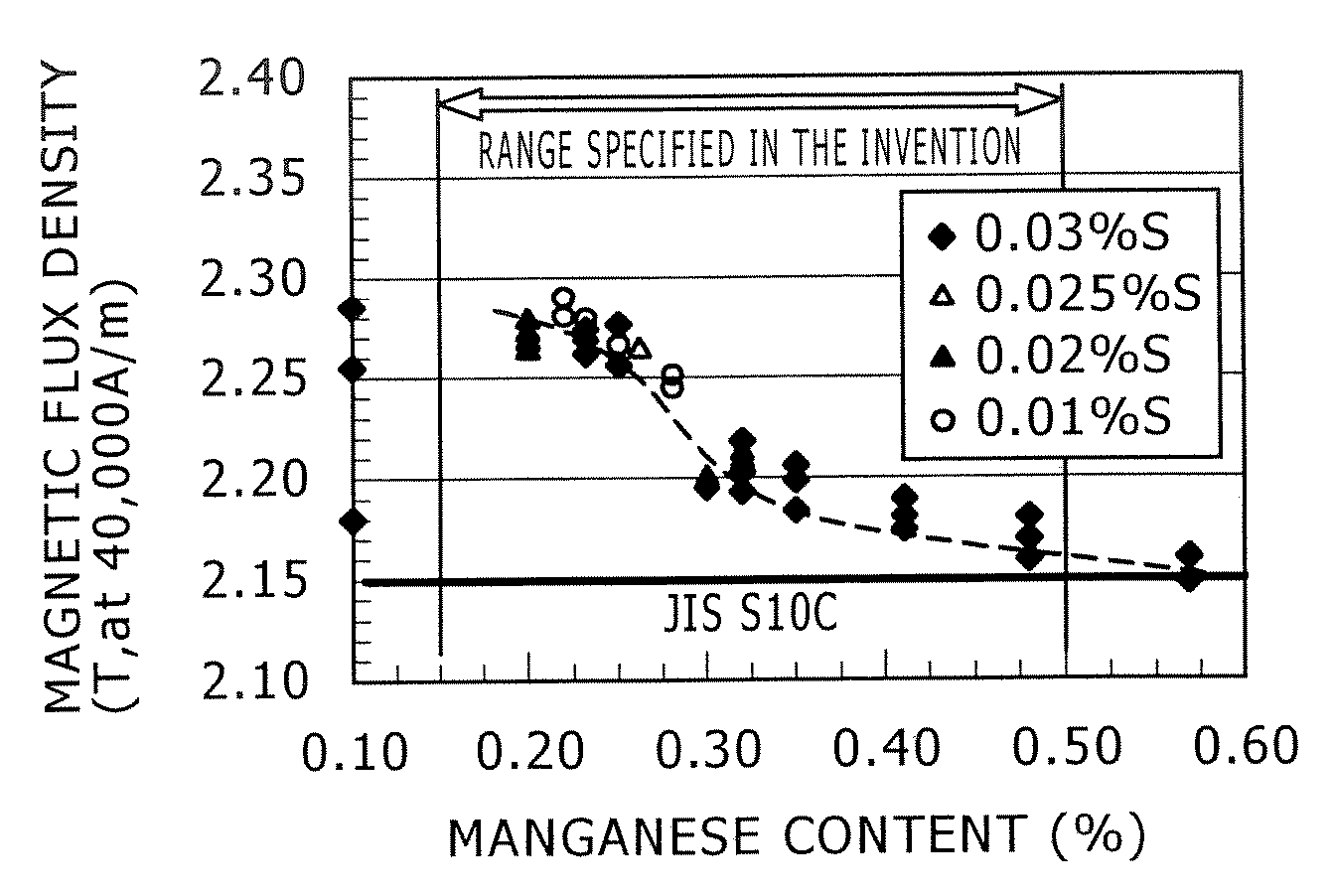

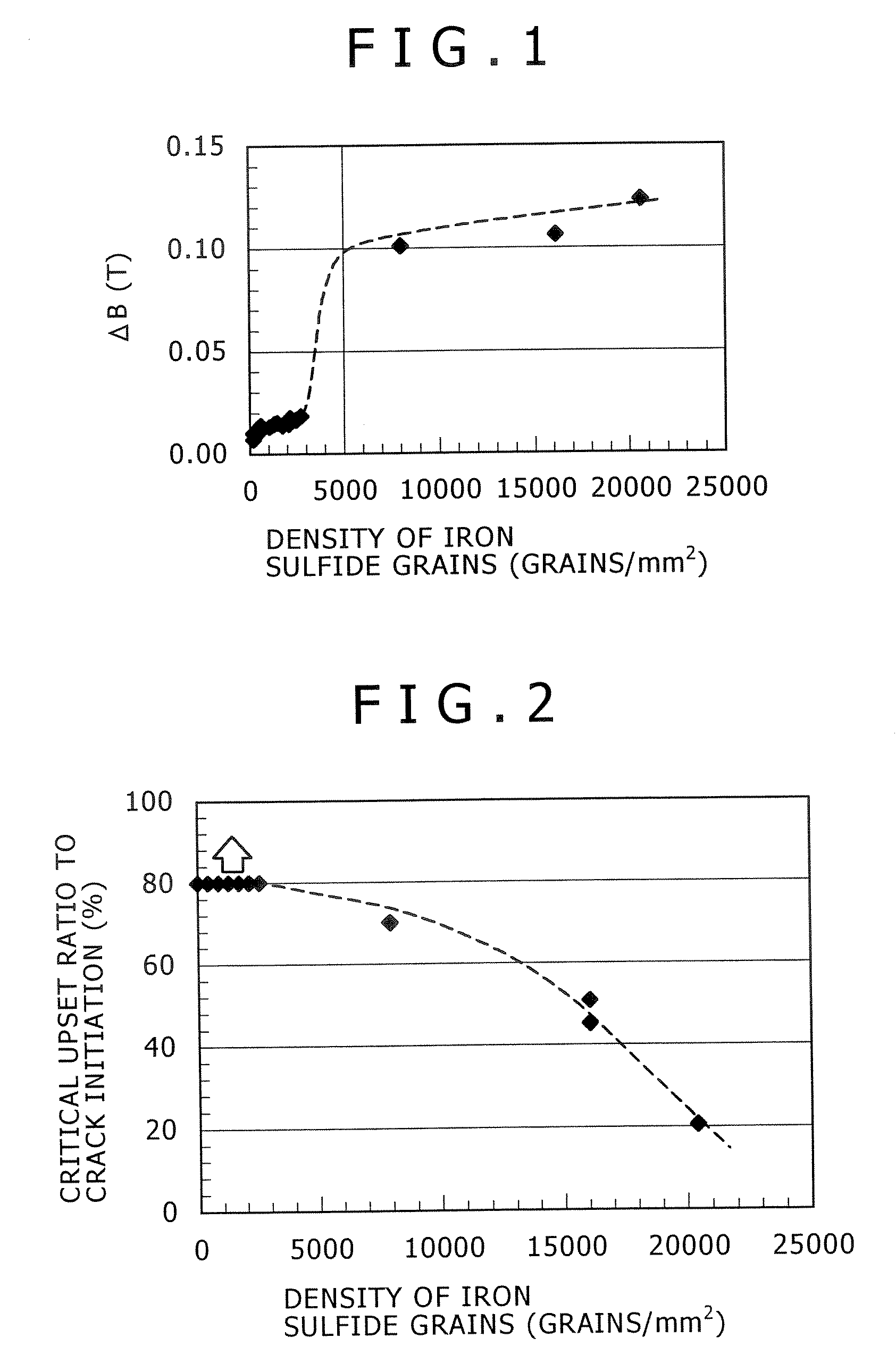

Soft magnetic steels excellent in cold forgeability, machinability and magnetic properties, and soft magnetic steel parts excellent in magnetic properties

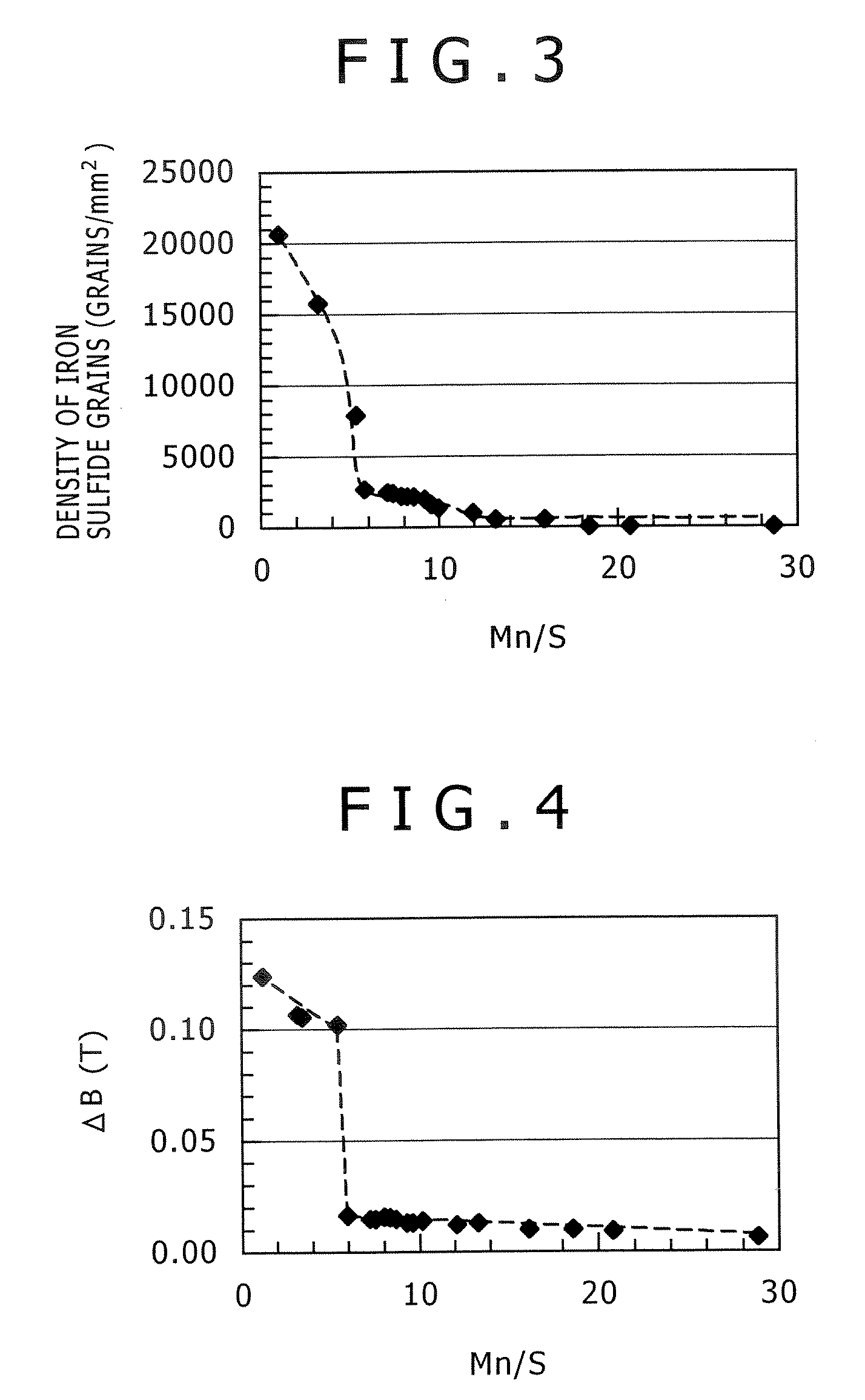

A soft magnetic steel has, on the mass basis, a carbon content of 0.0015% to 0.02%, a manganese content of 0.15% to 0.5%, and a sulfur content of 0.015% to 0.1%, has a ratio Mn / S of 5.7 or more, and contains a single-phase ferrite microstructure as its metallographic structure, in which the density of precipitated FeS grains having a major axis of 0.1 pm or more is 5000 grains / mm2 or less. This steel ensures excellent magnetic properties with less variation after magnetic annealing, exhibits excellent machinability and cold forgeability during production processes, and can thereby yield a steel part even having a complicated shape and a large size in a high yield.

Owner:KOBE STEEL LTD

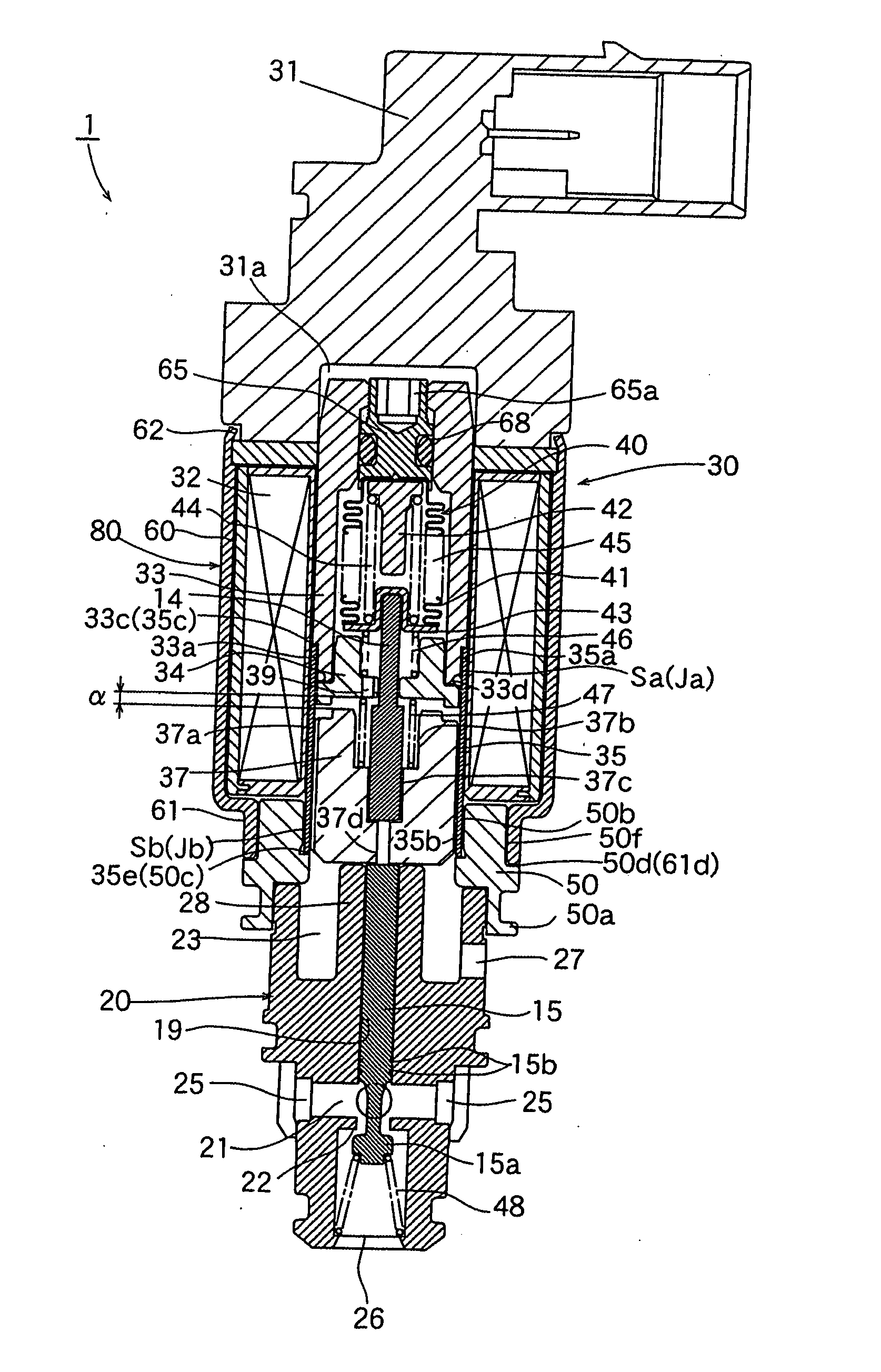

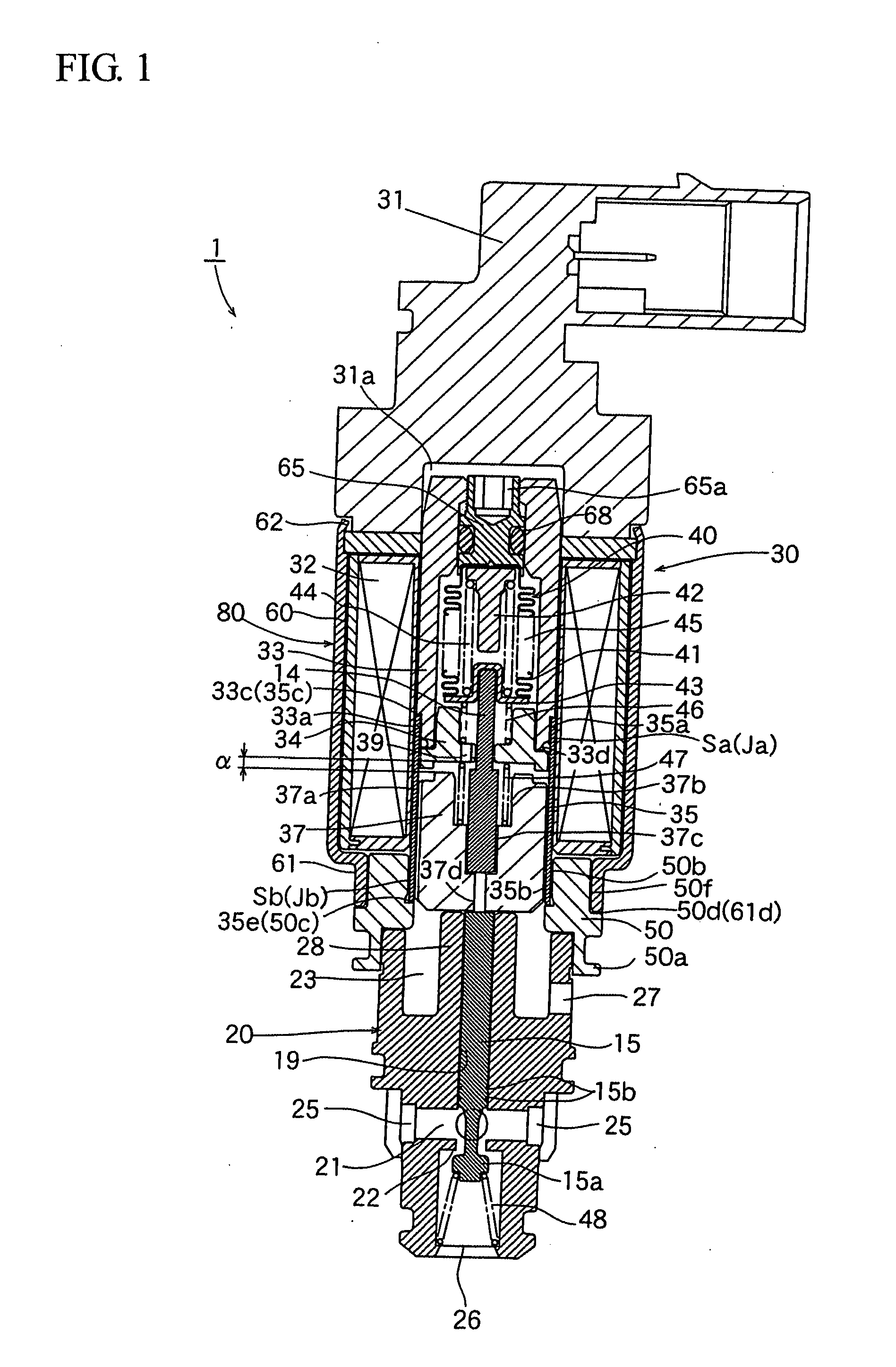

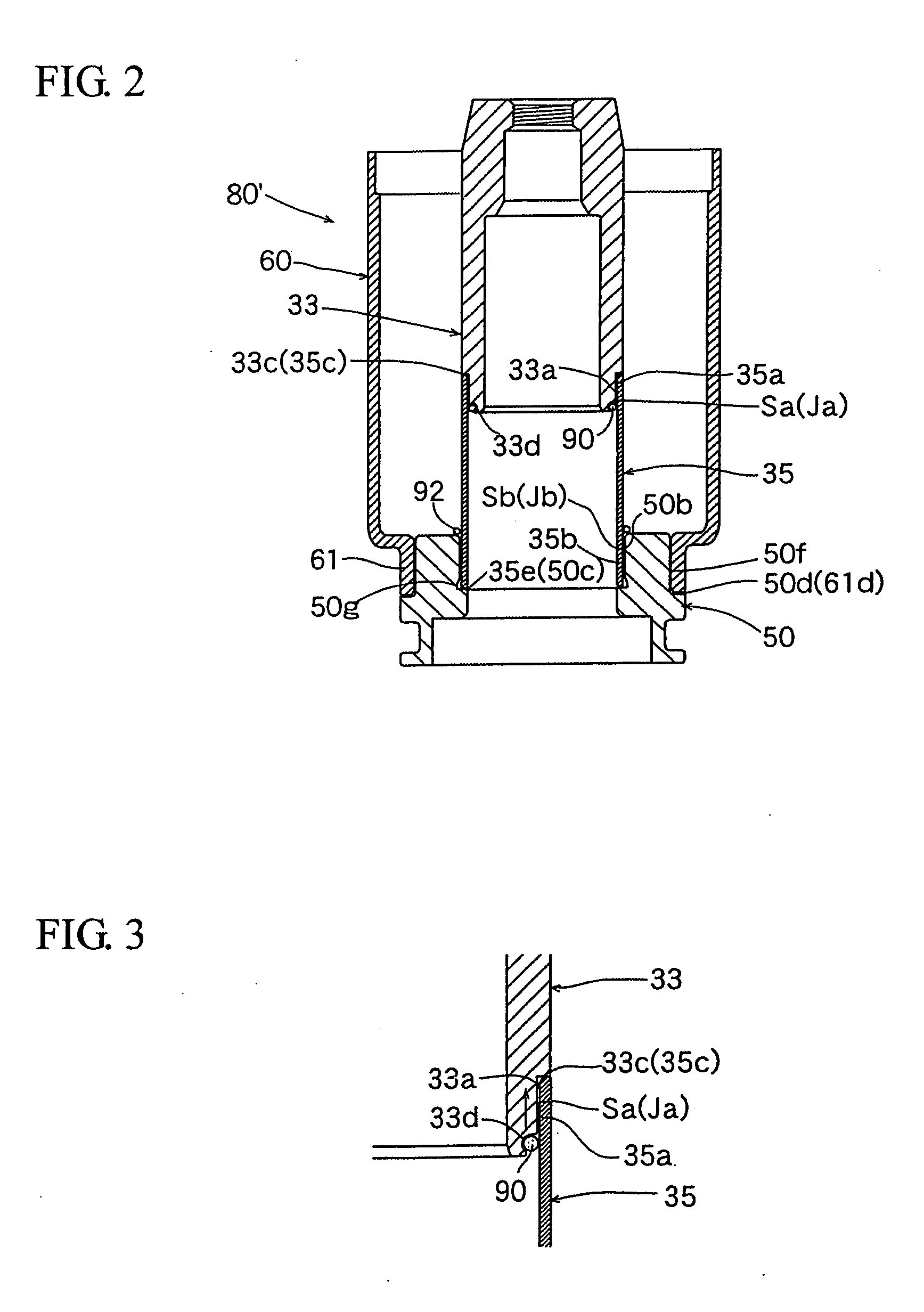

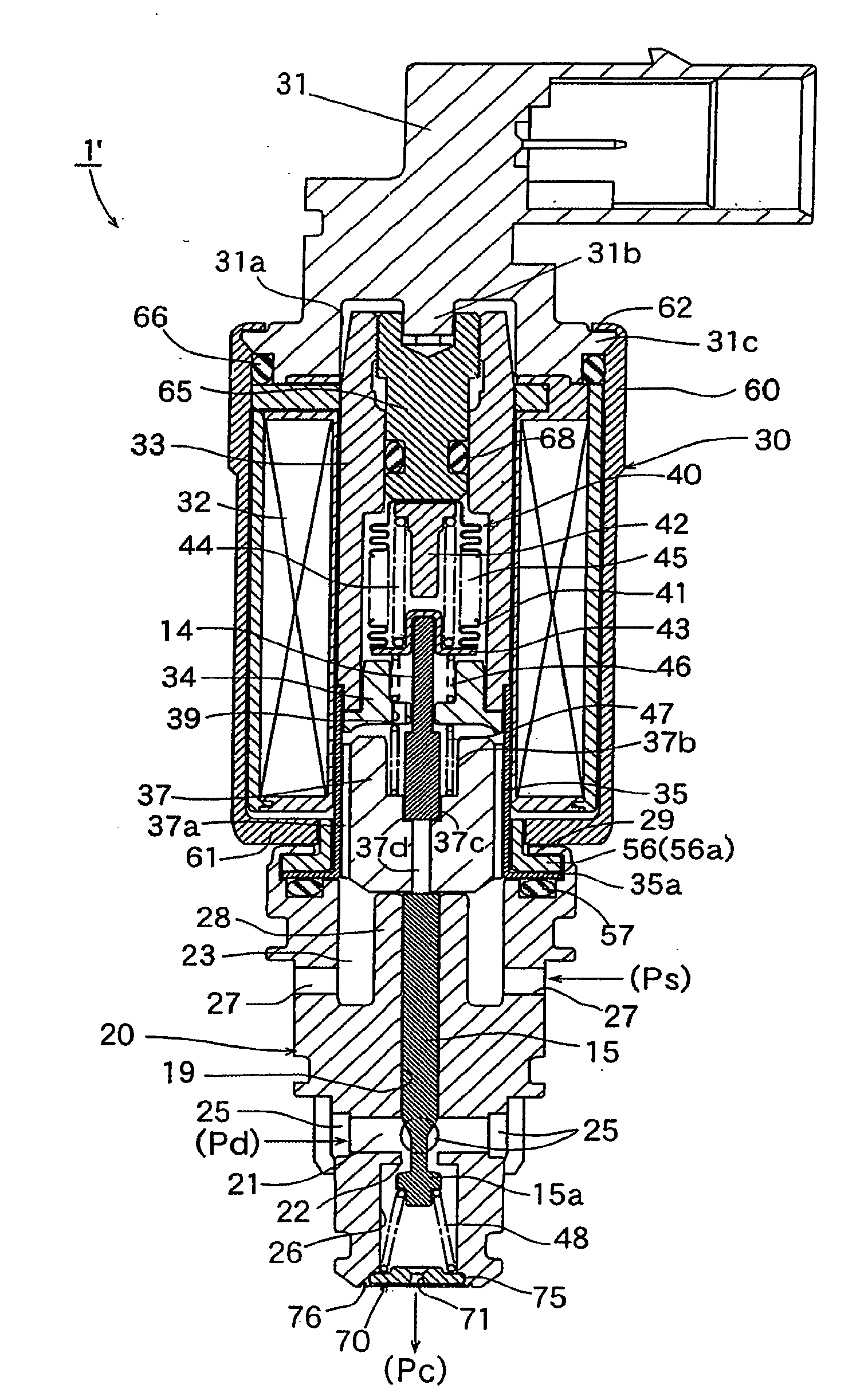

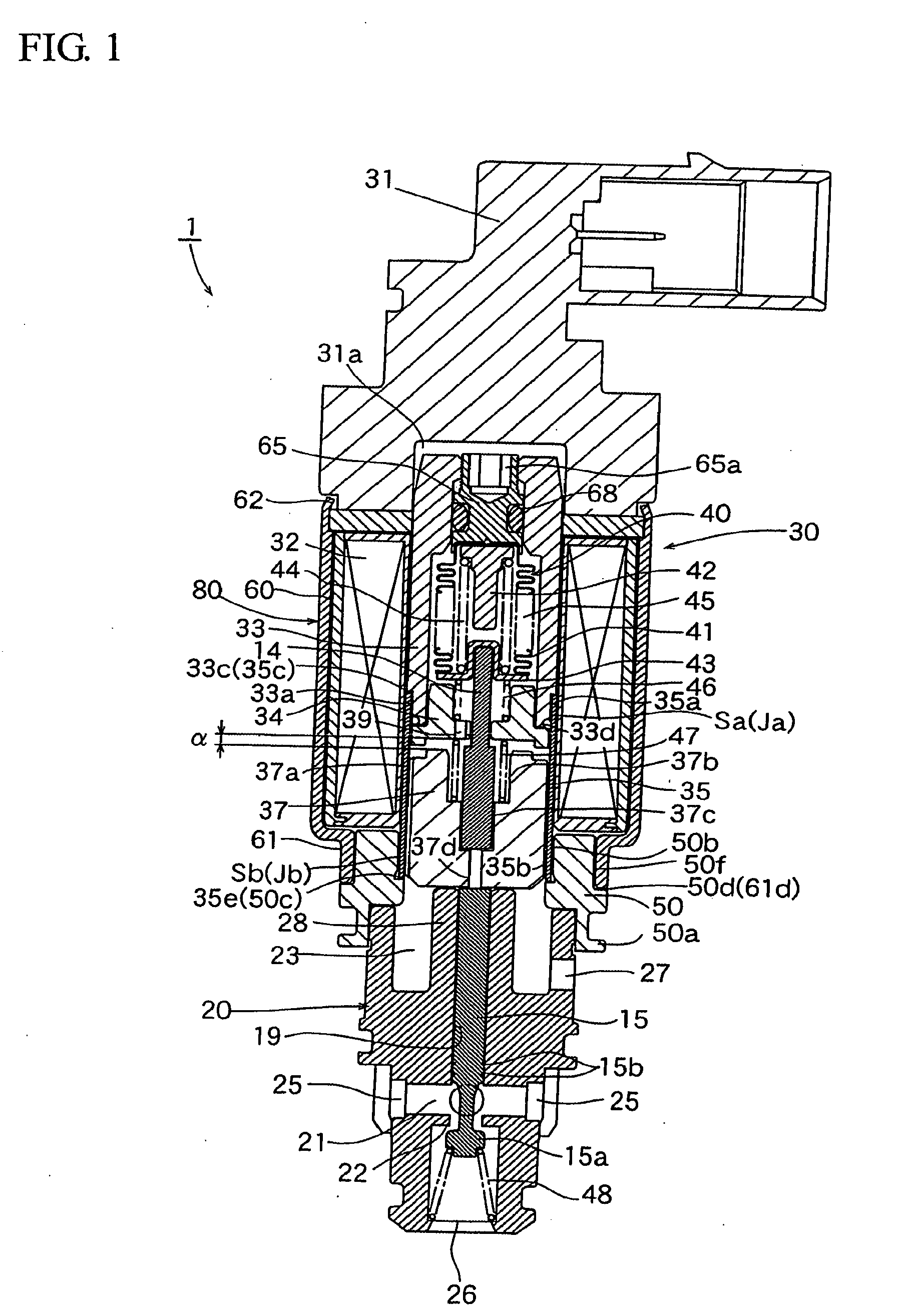

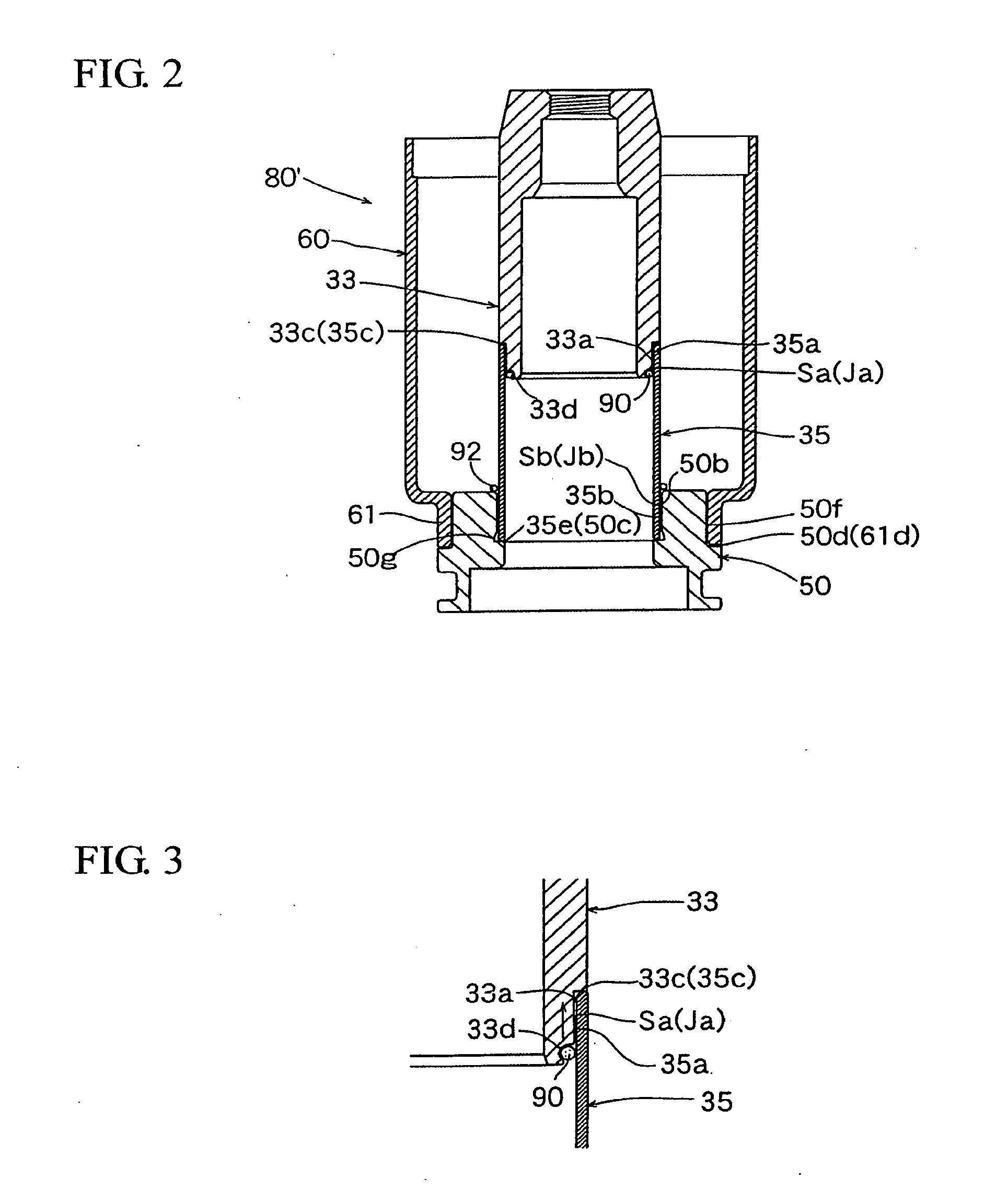

Method of manufacturing an assembled body composed of a plurality of members, manufacturing method of electromagnetic control valve, and control valve for variable capacity compressors

InactiveUS20060193733A1Low costWelding/cutting media/materialsMulti-stage pumpsMetallurgyControl valves

There is provided a brazing method which makes it possible to rationally perform not only the brazing between a metal member such as a stator made of a magnetic material and a metal member such as a guide pipe made of a non-magnetic material but also the magnetic annealing of these metal members. By making use of a brazing material (90) which can be fused at a lower temperature than a magnetic annealing temperature of metal member (33), the metal member such as a stator made of a magnetic material and the metal member (35) such as a guide pipe made of a non-magnetic material are heated to a predetermined temperature in a furnace to perform the magnetic annealing of the metal member (33) concurrent with the brazing of these metal members.

Owner:FUJIKOKI CORP

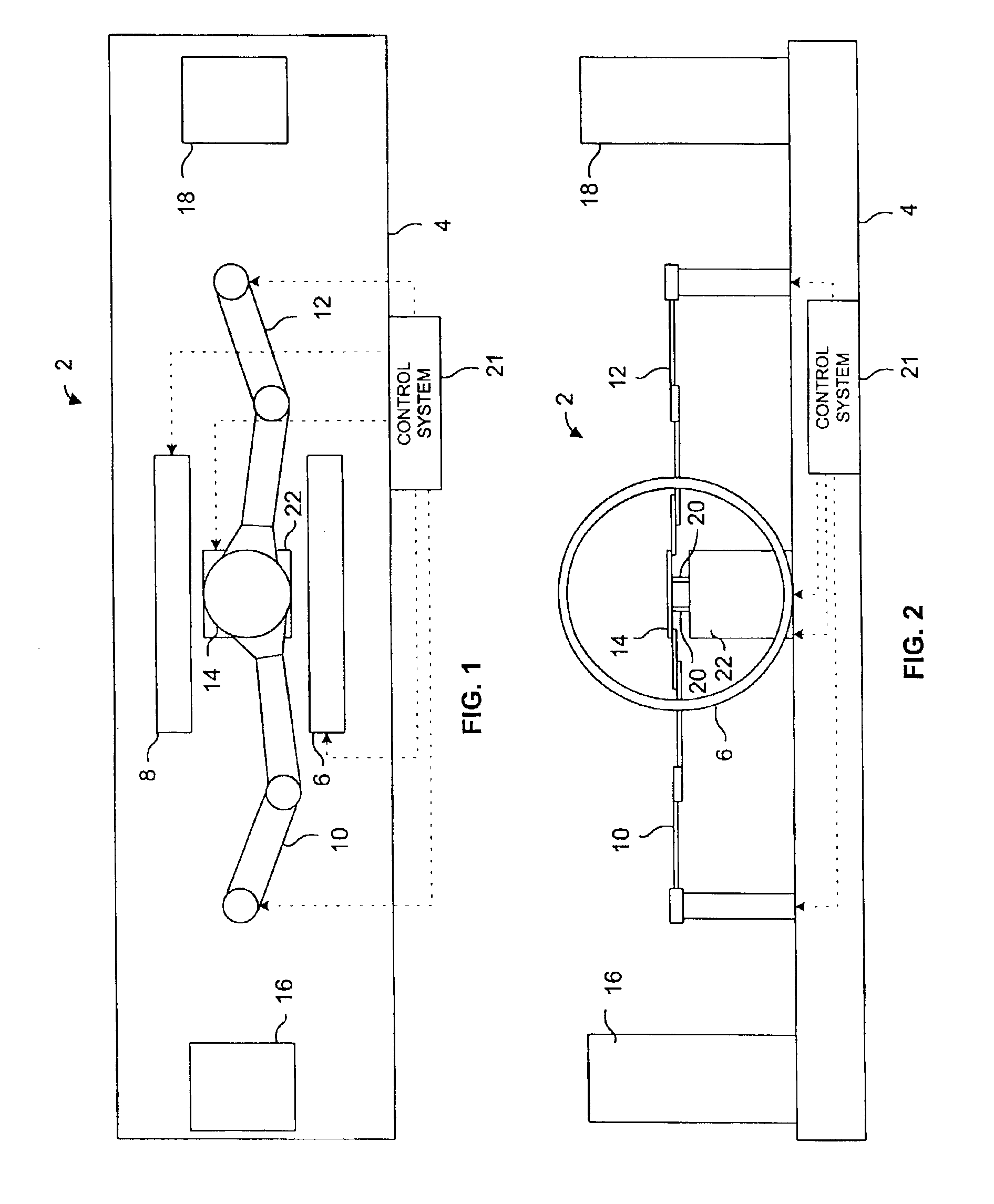

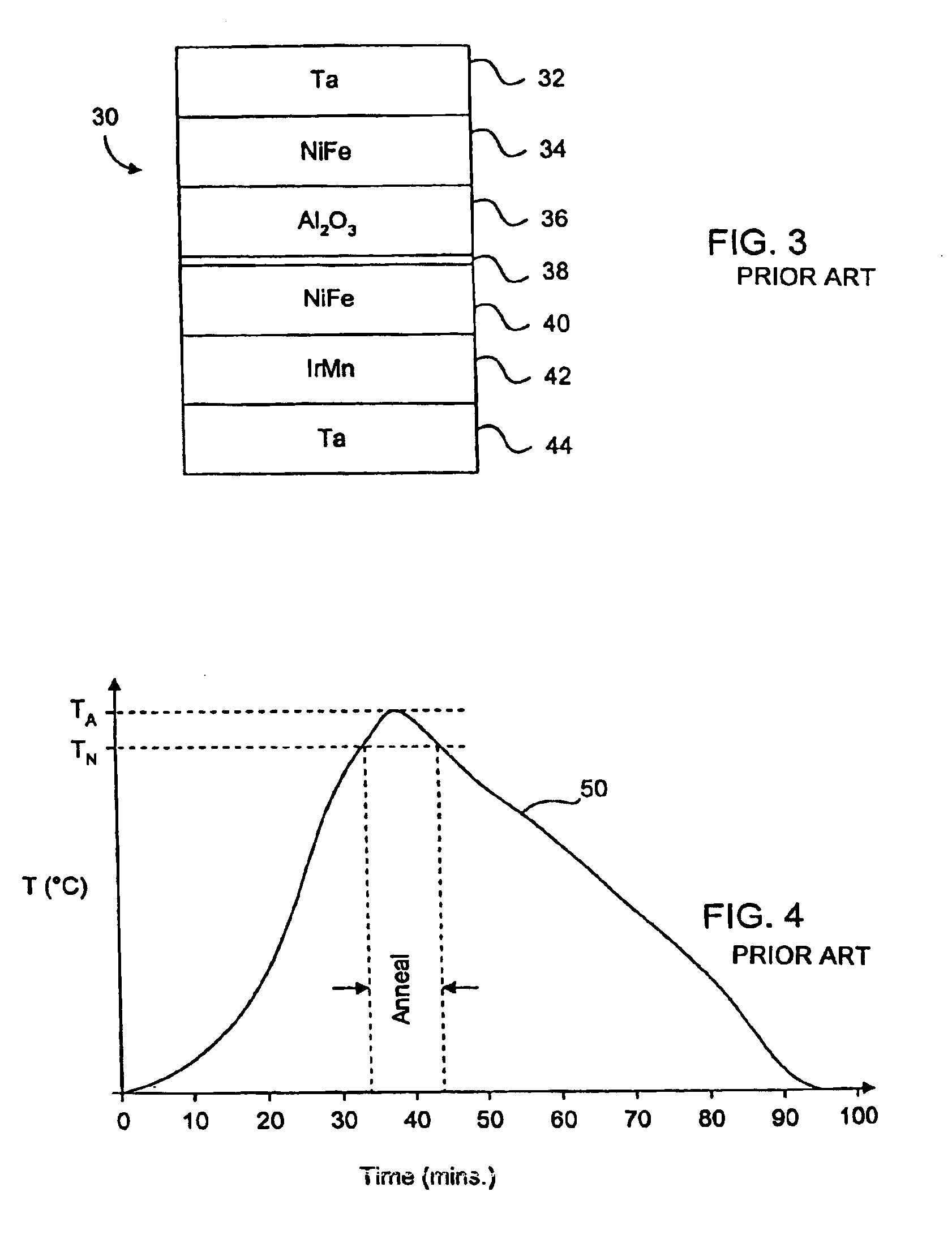

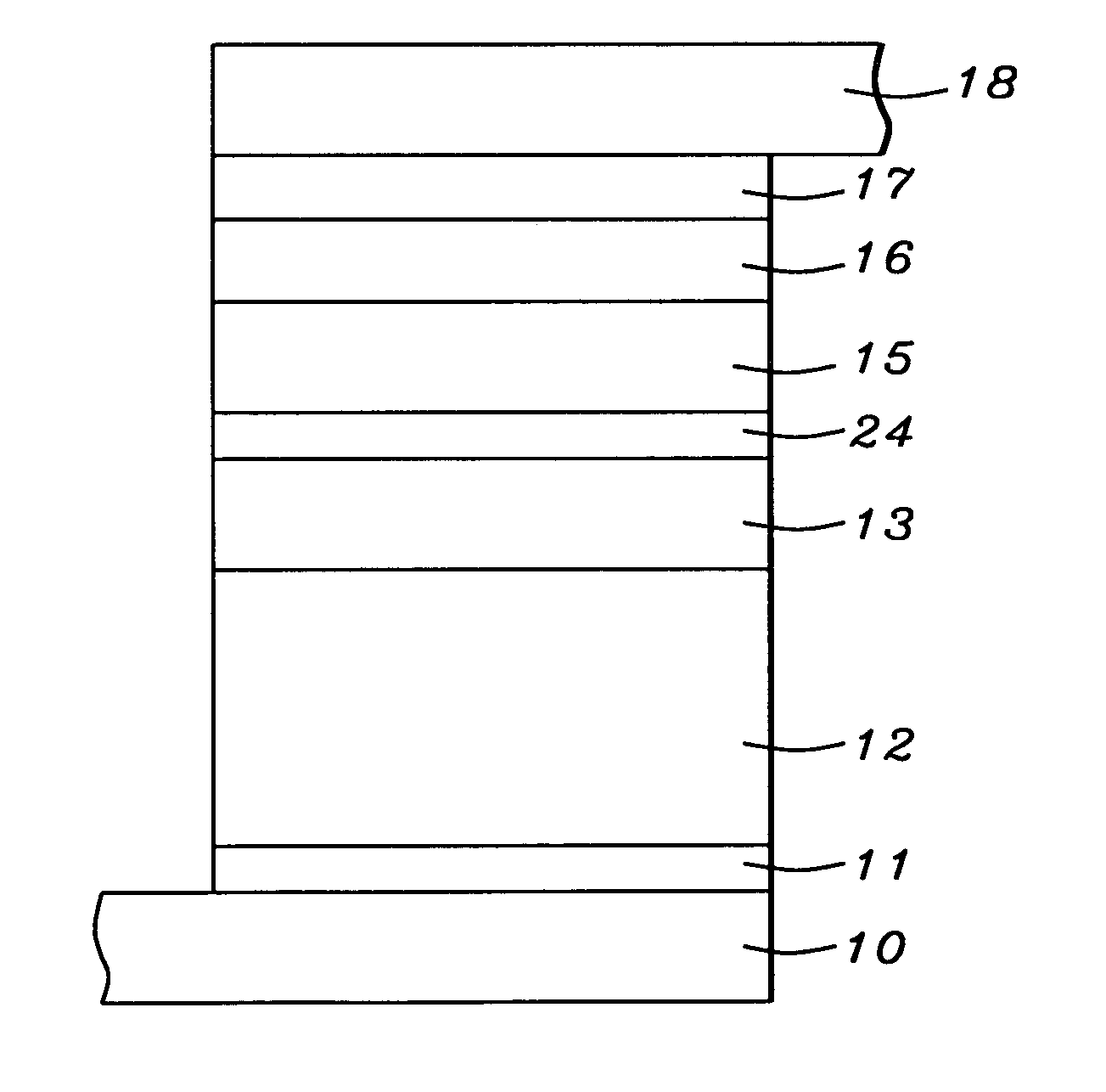

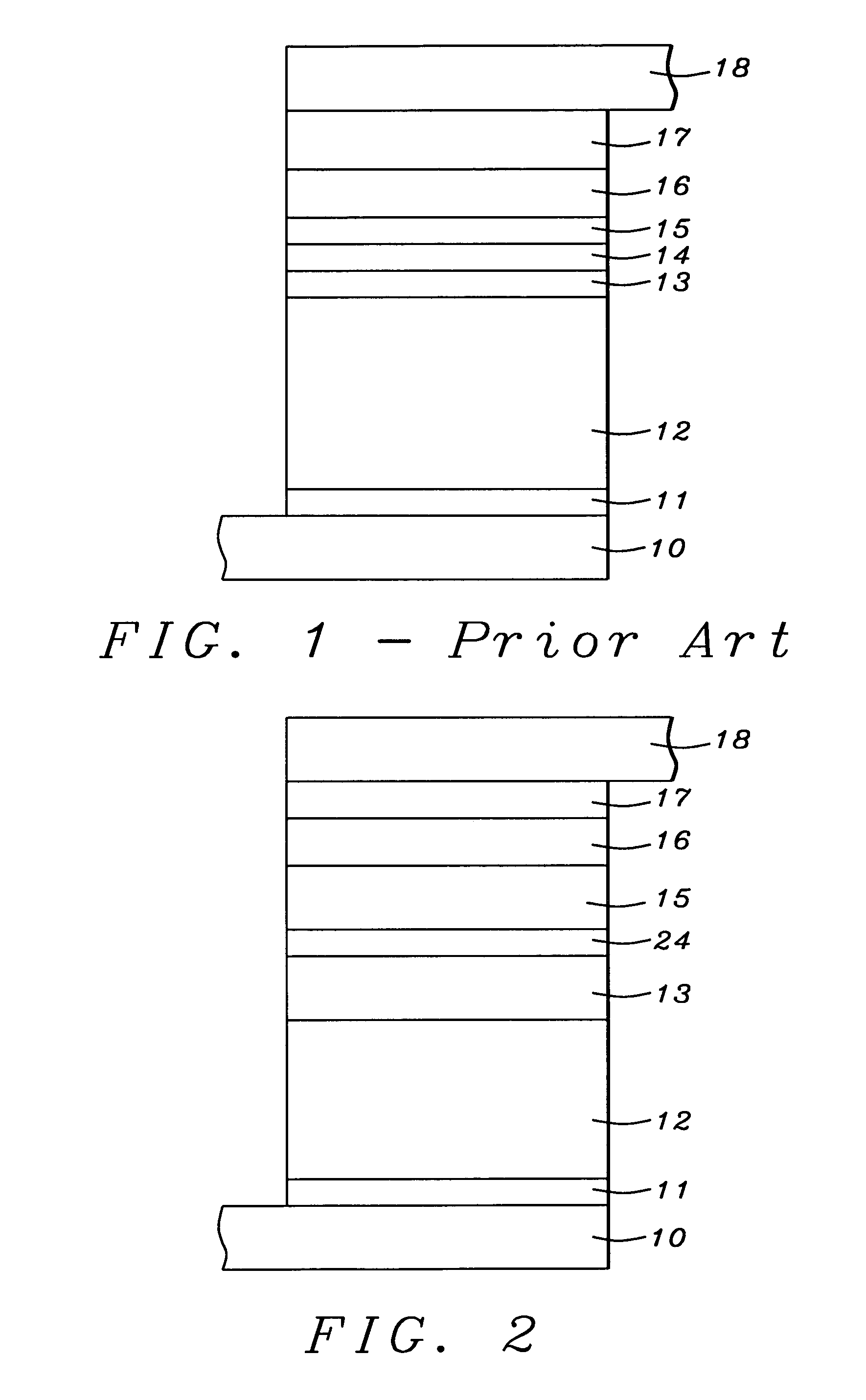

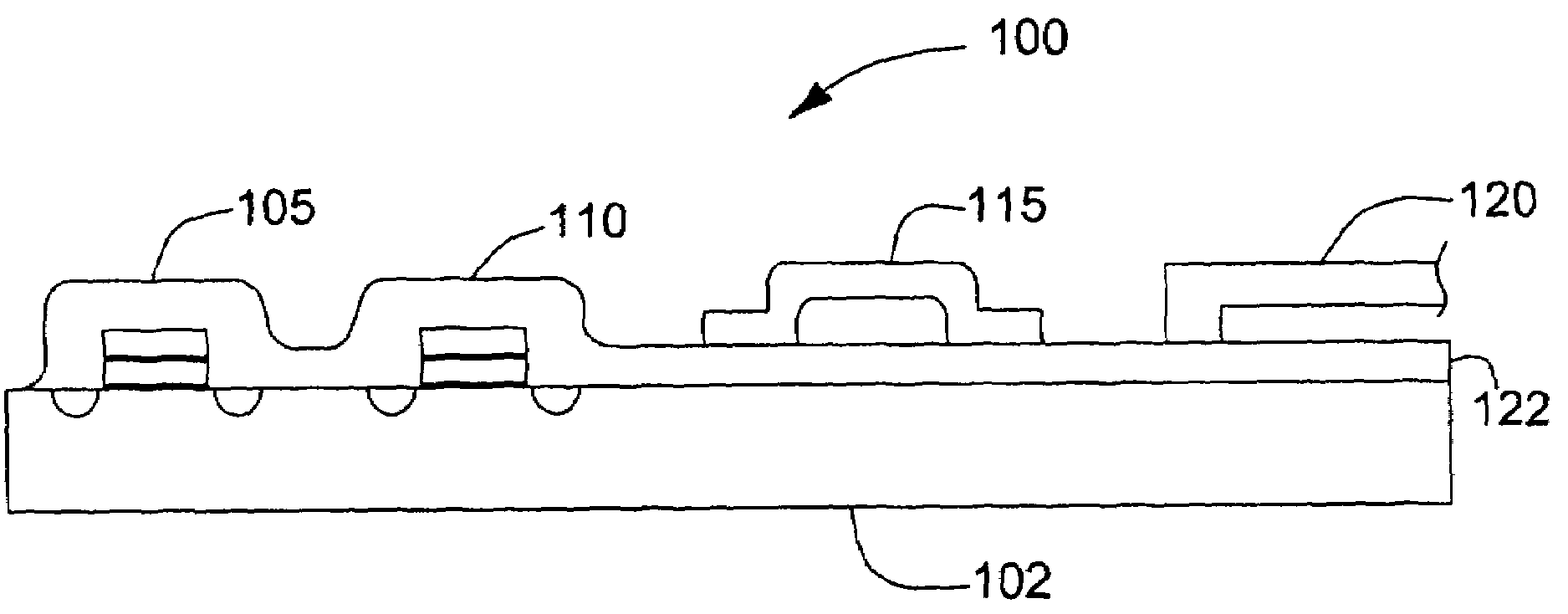

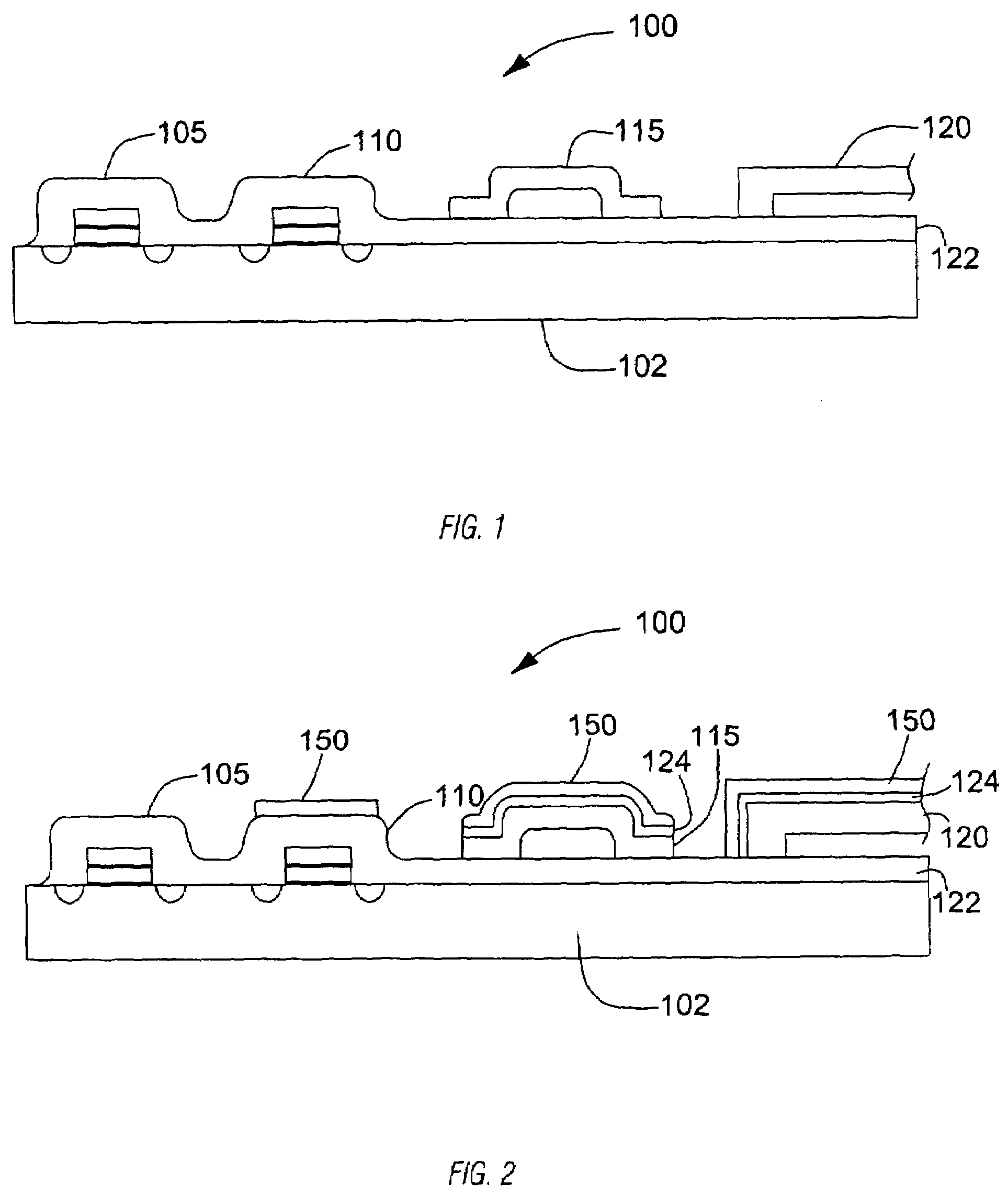

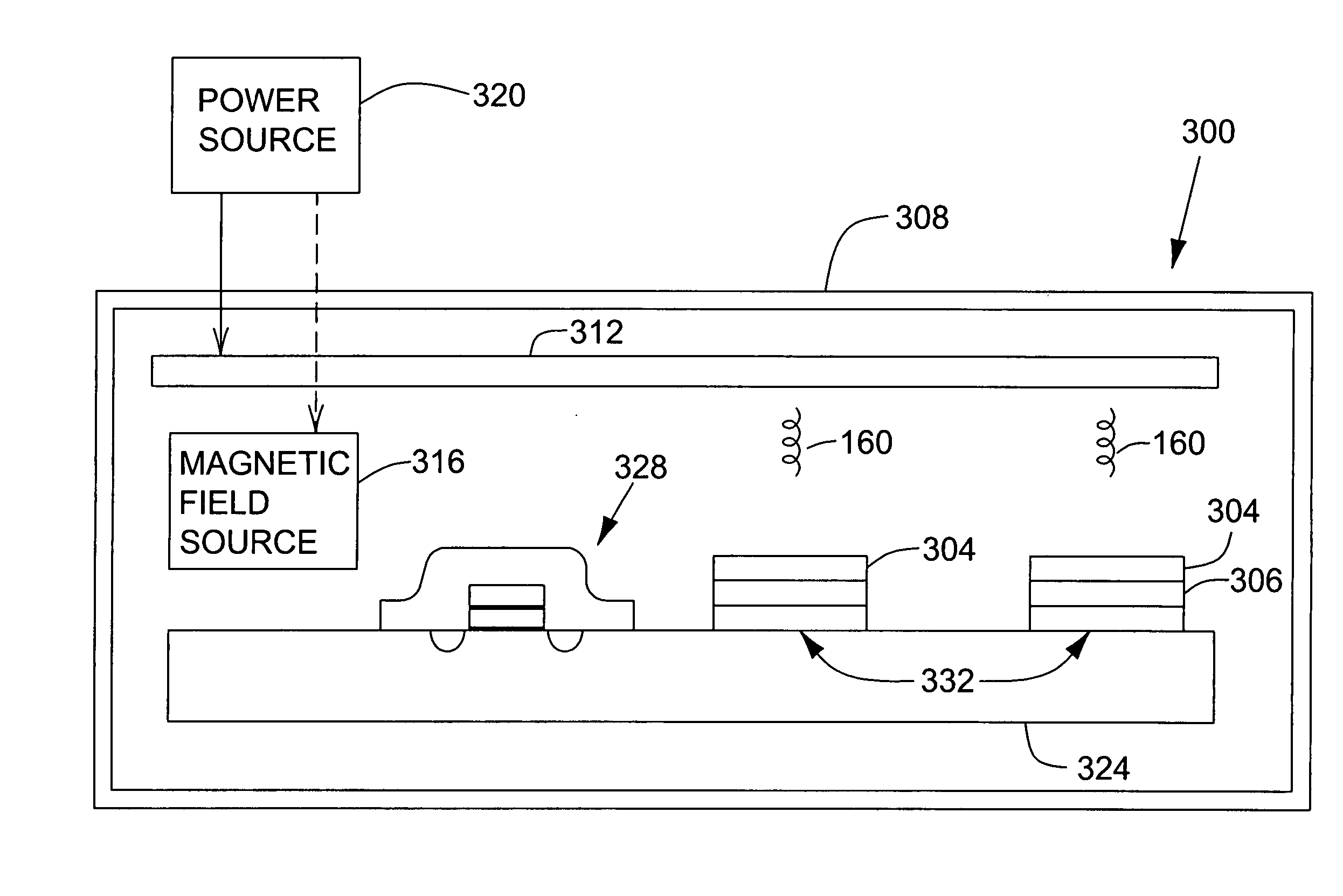

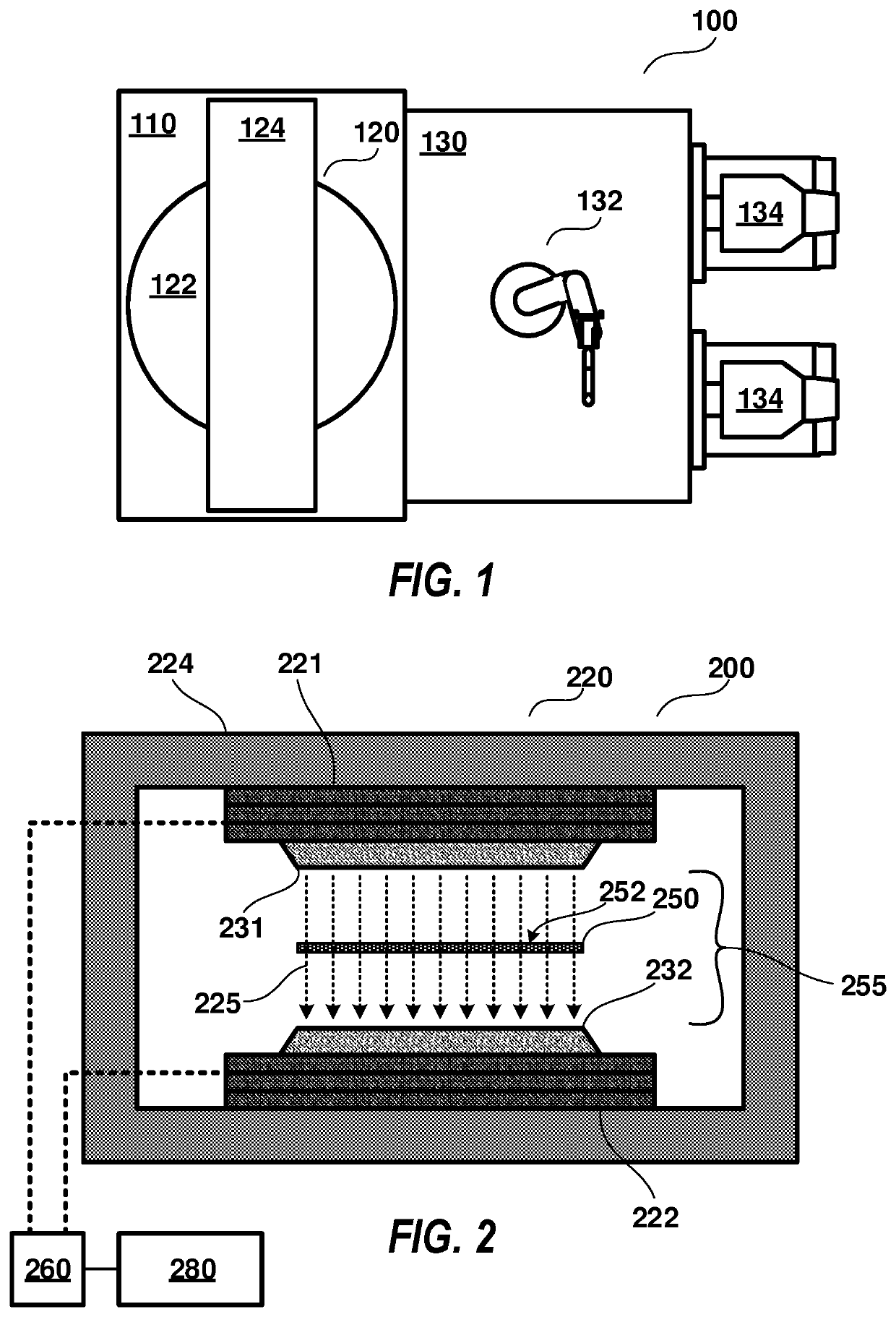

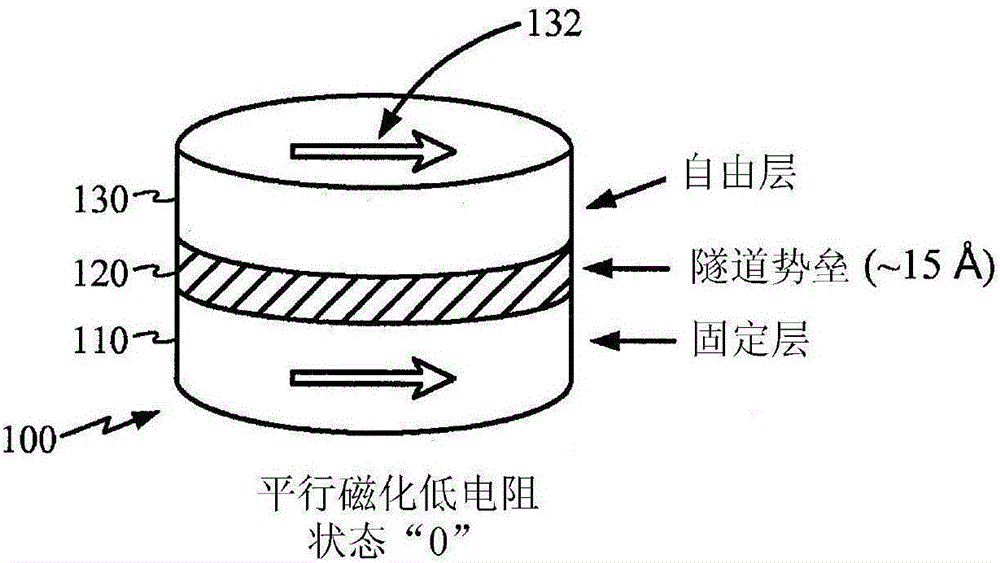

Single substrate annealing of magnetoresistive structure

InactiveUS6918965B2Rapid heating and coolingAccurate and uniform temperature controlNanostructure applicationNanomagnetismControl systemMagnetic reluctance

A device for magnetically annealing magnetoresistive elements formed on wafers includes a heated chuck and a delivery mechanism for individually placing the wafers individually on the chuck one at a time. A coil is adjacent to the chuck and generates a magnetic field after the wafer is heated to a Néel temperature of an anti-ferromagnetic layer. A control system regulates the temperature of the heated chuck, the strength of the magnetic field, and a time period during which each chuck is heated to control the annealing process. The annealed elements are incorporated in the fabrication of magnetic memory devices.

Owner:MICRON TECH INC

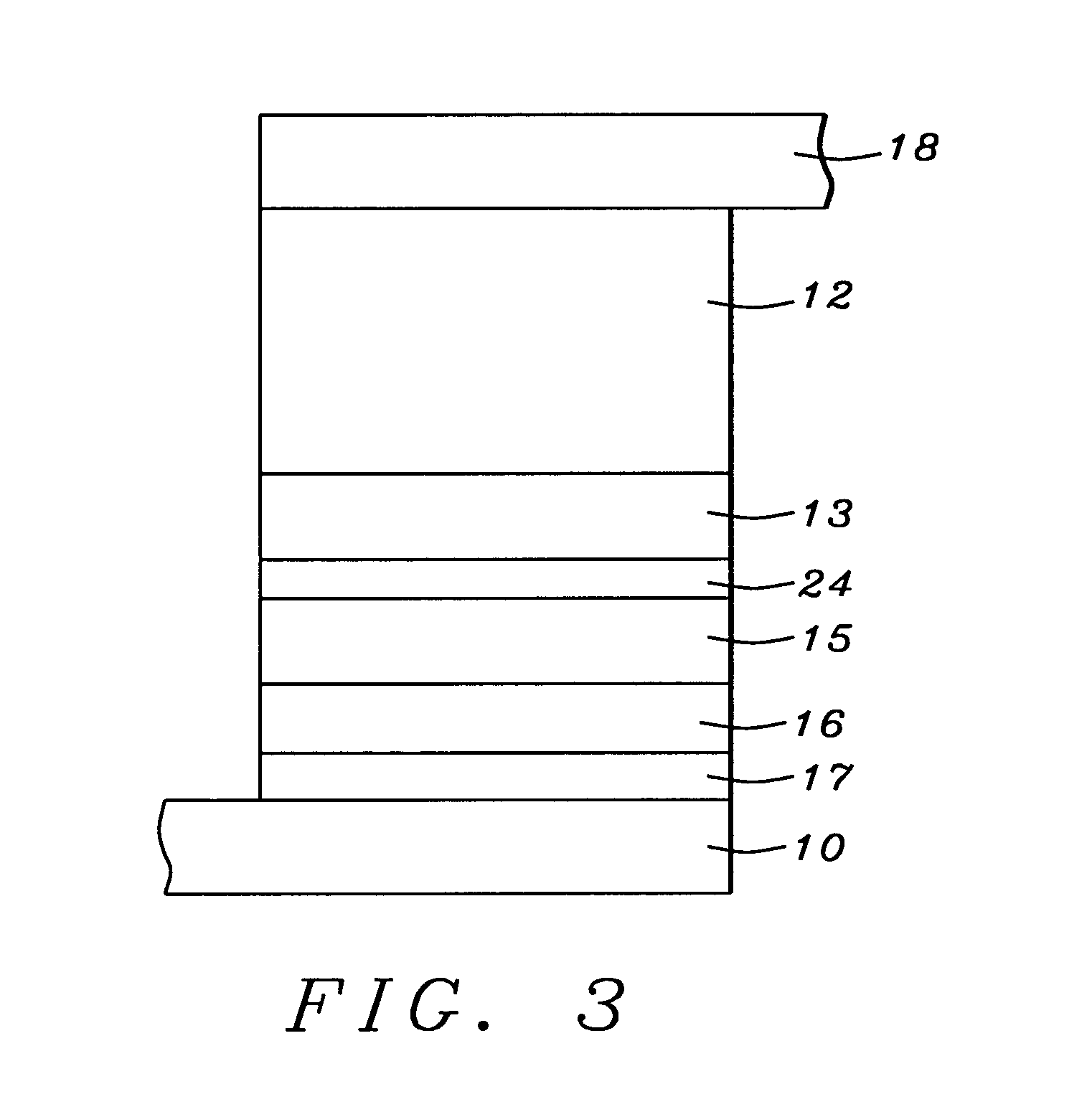

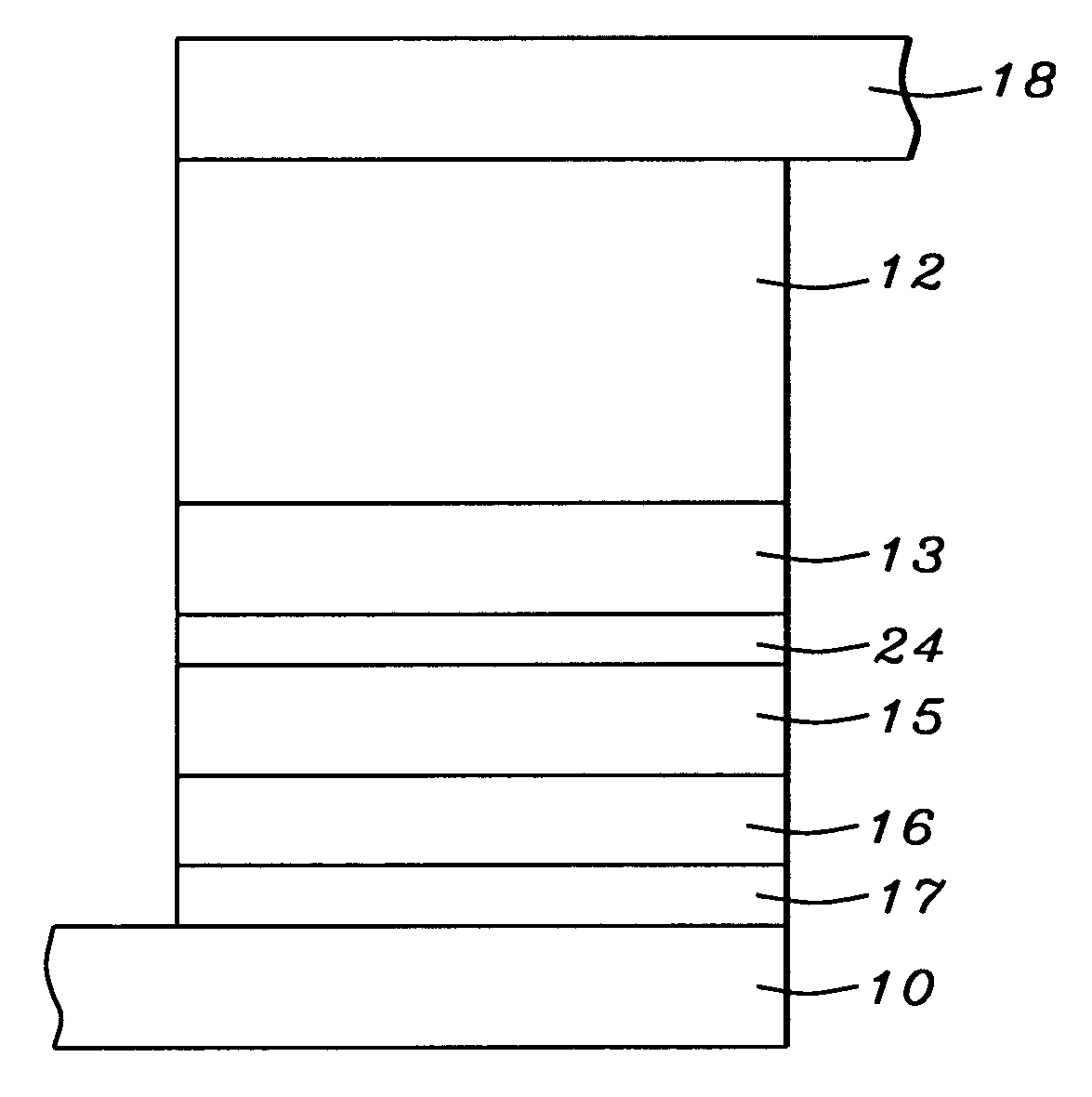

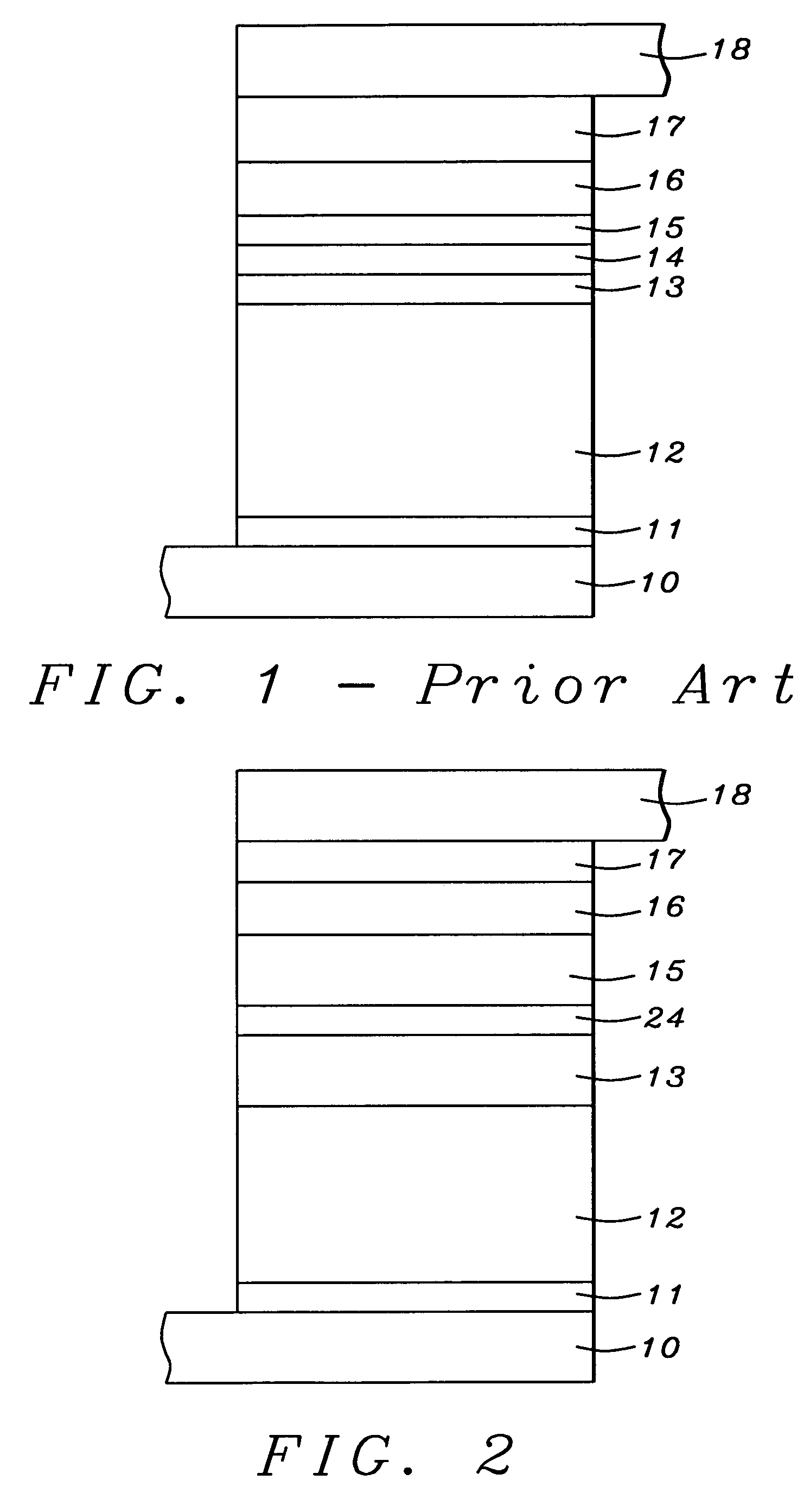

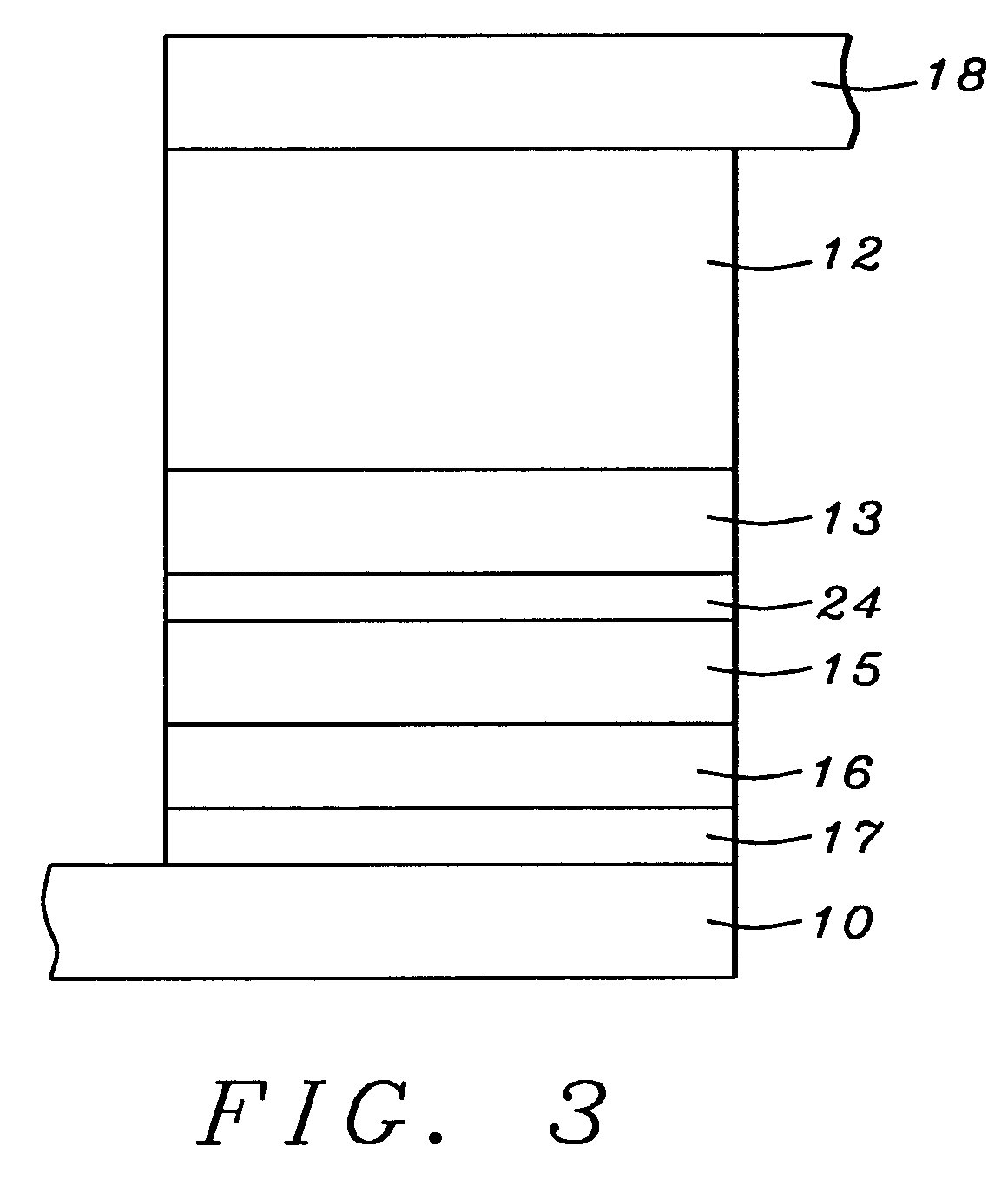

CPP GMR read head

InactiveUS20050024792A1Improve stabilityImprove device performanceNanostructure applicationNanomagnetismRutheniumLayer thickness

Replacing ruthenium with rhodium as the AFM coupling layer in a synthetically pinned CPP GMR structure enables the AP1 / AP2 thicknesses to be increased. This results in improved stability and allows the free layer and AFM layer thicknesses to be decreased, leading to an overall improvement in the device performance. Another key advantage of this structure is that the magnetic annealing requirements (to establish antiparallelism between AP1 and AP2) can be significantly relaxed.

Owner:HEADWAY TECH INC

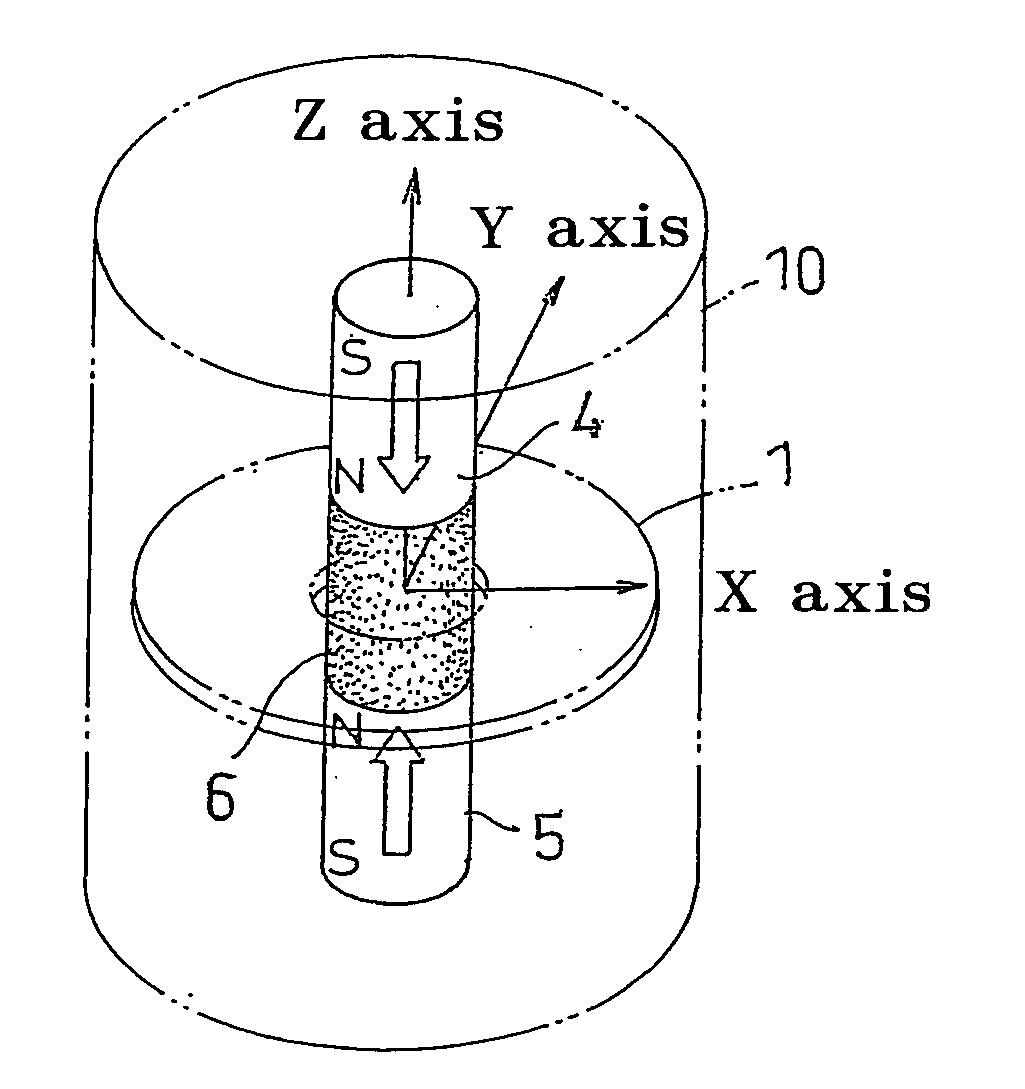

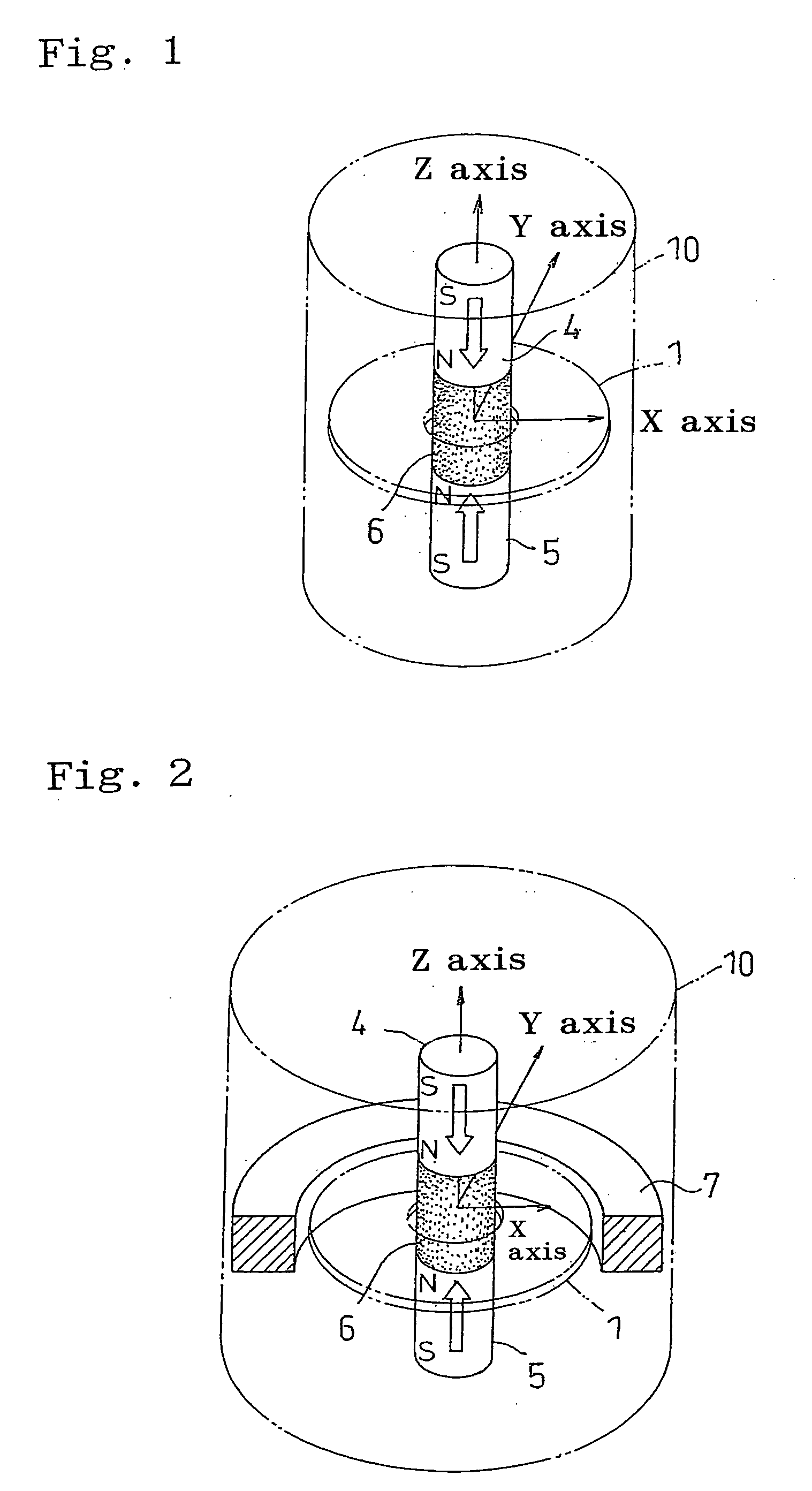

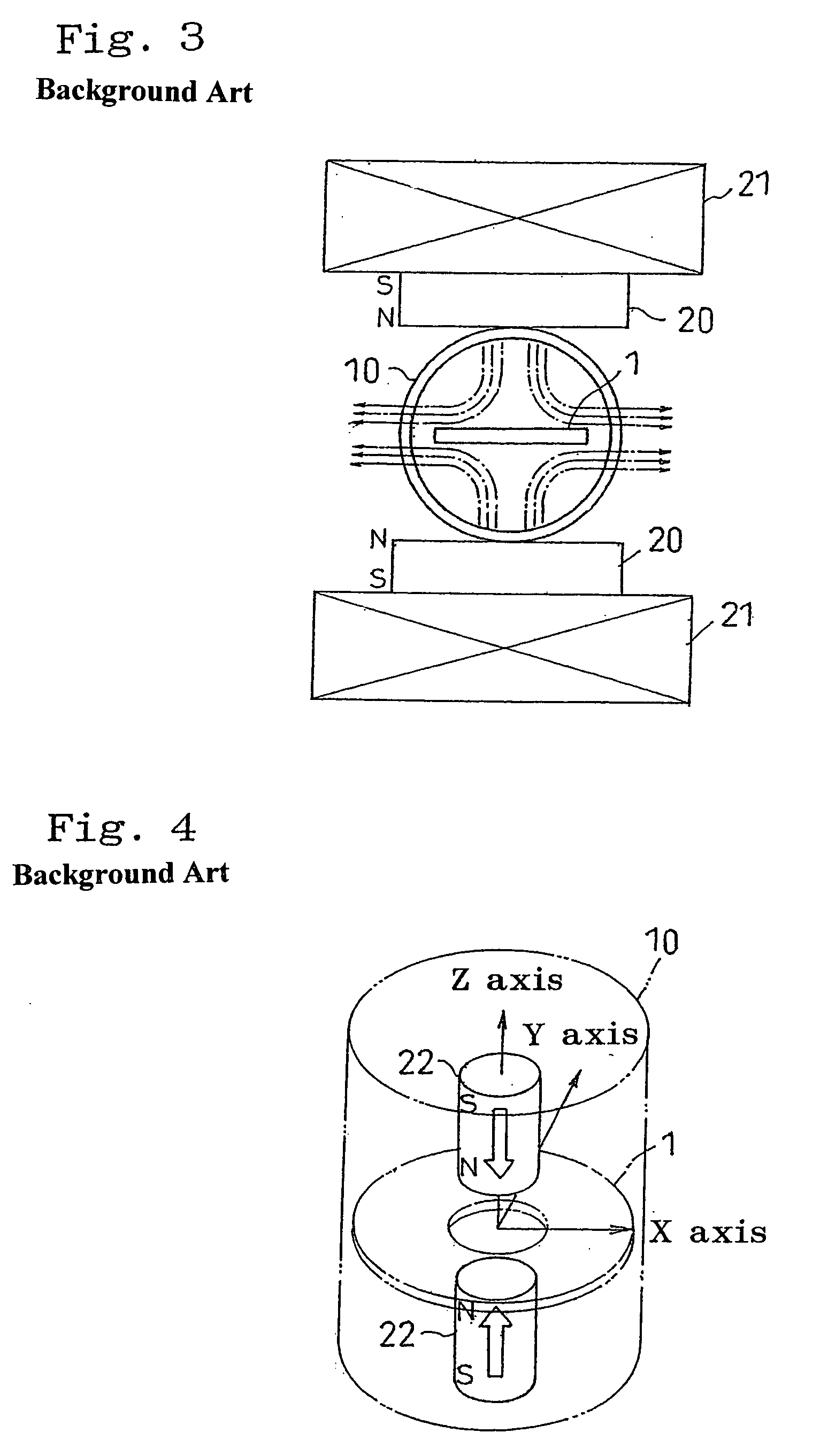

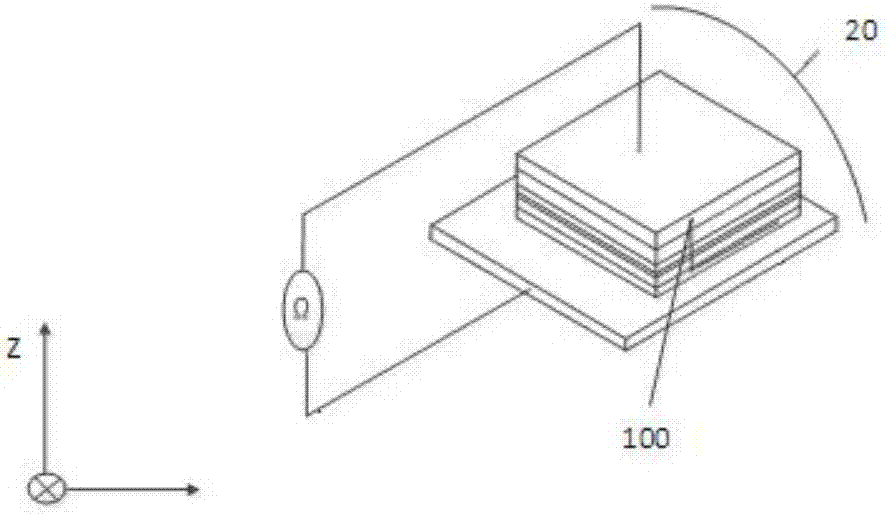

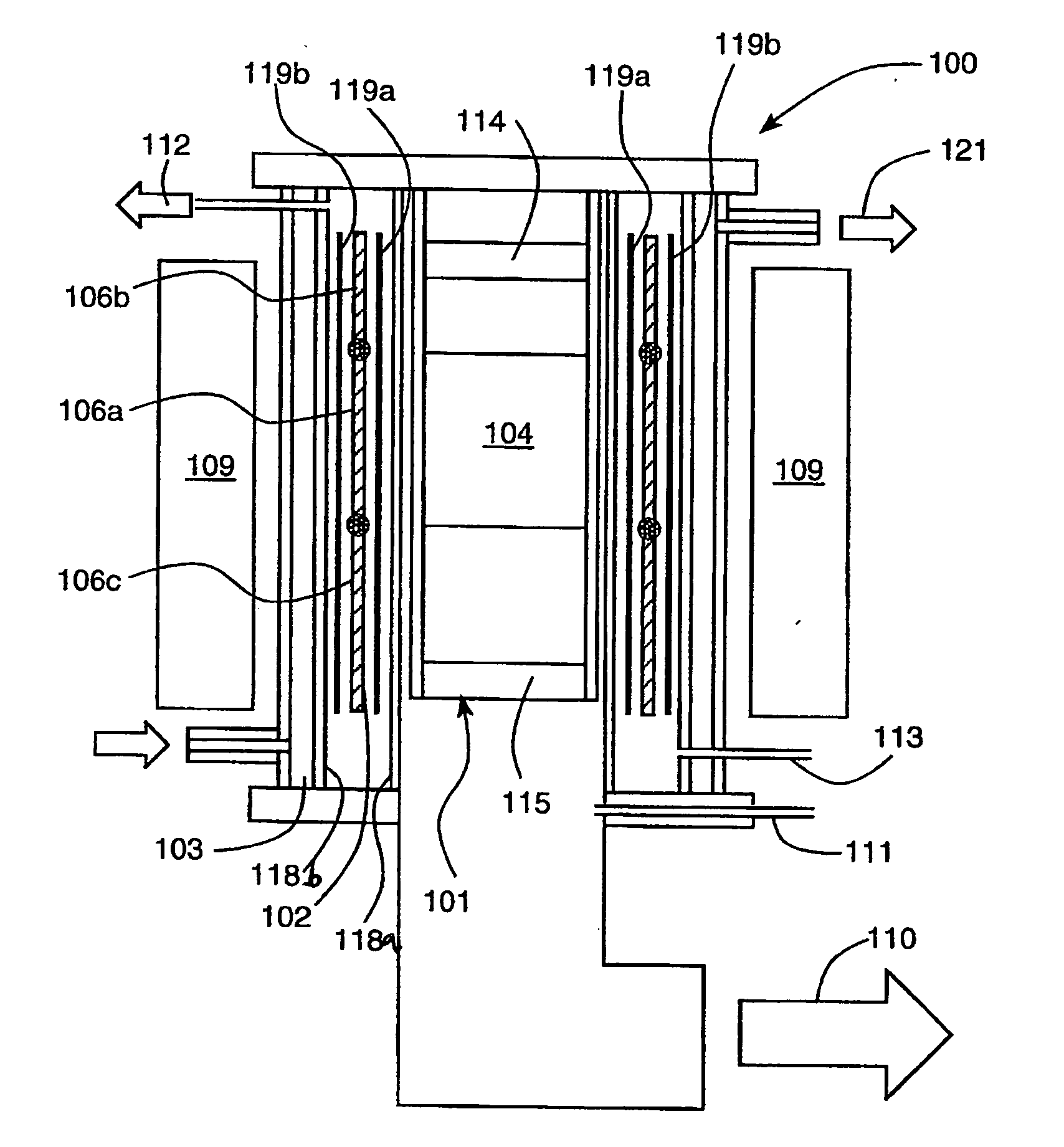

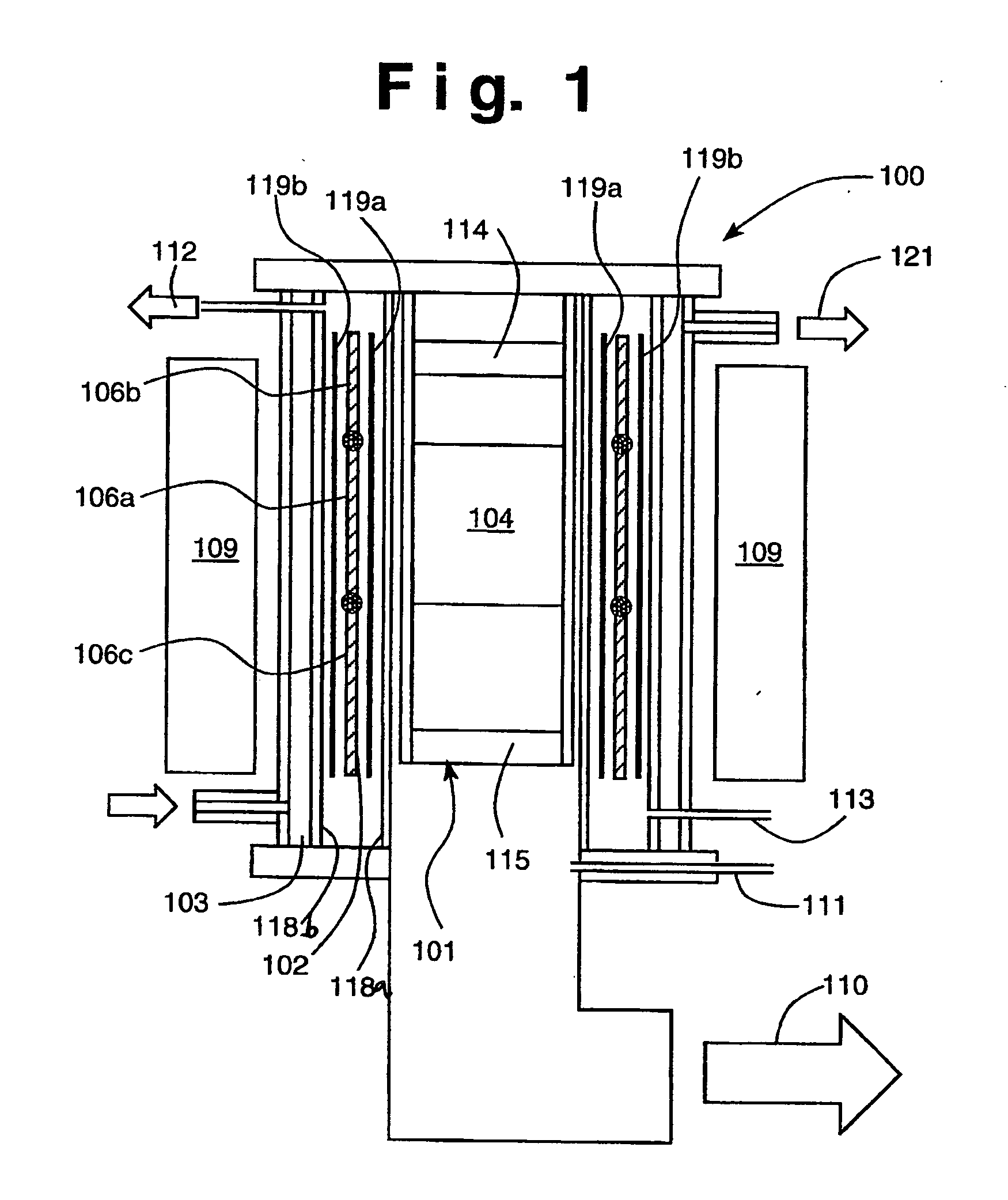

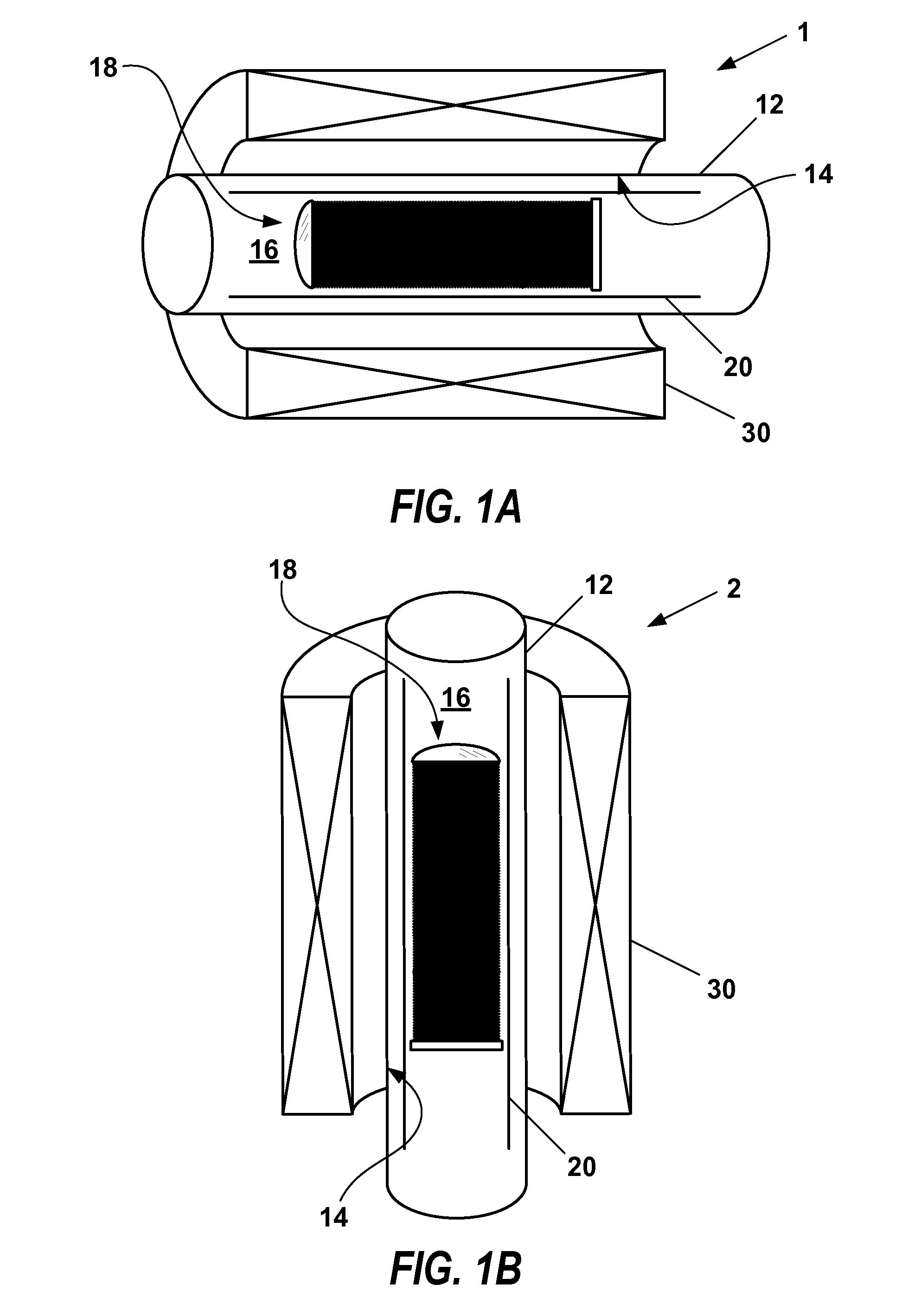

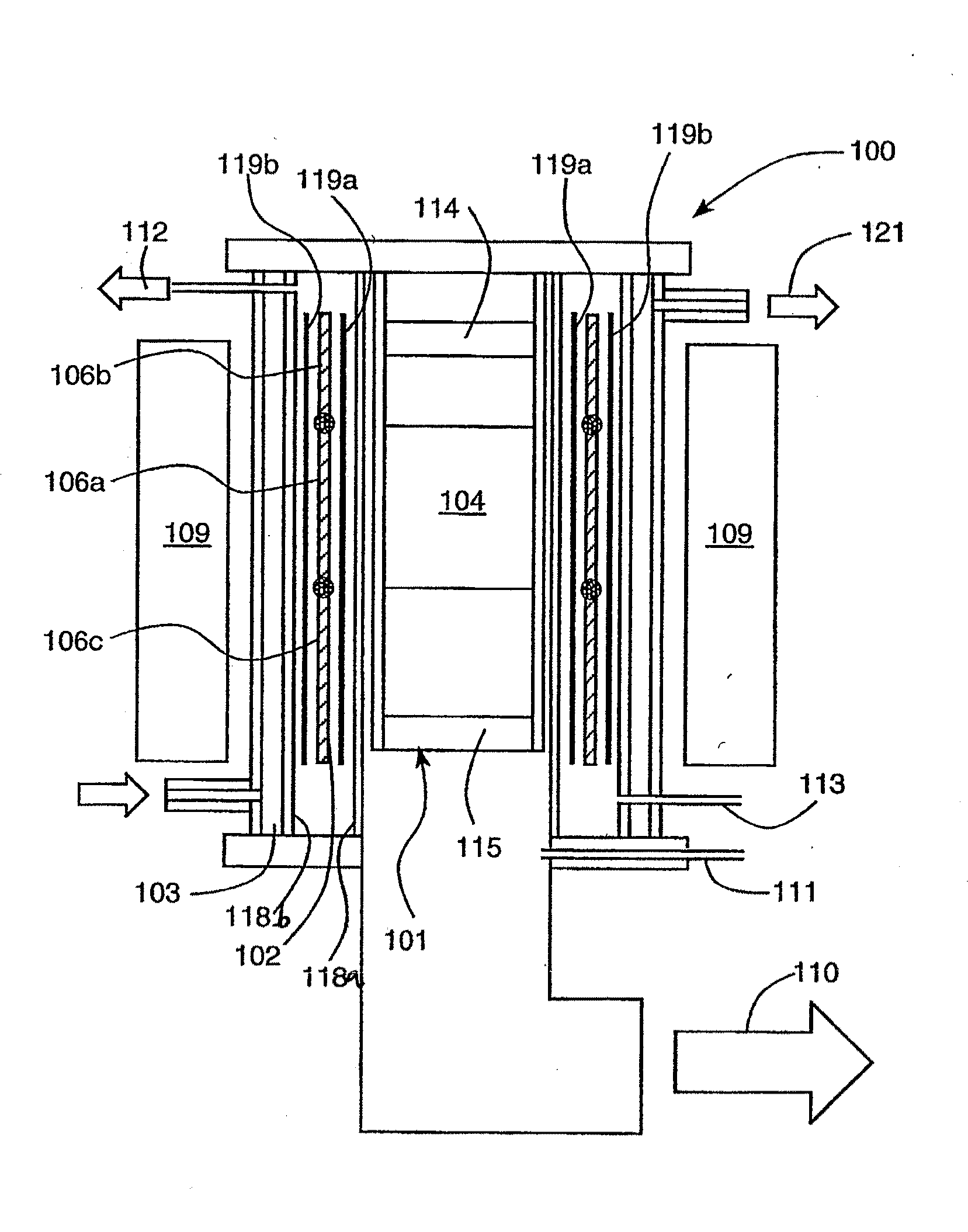

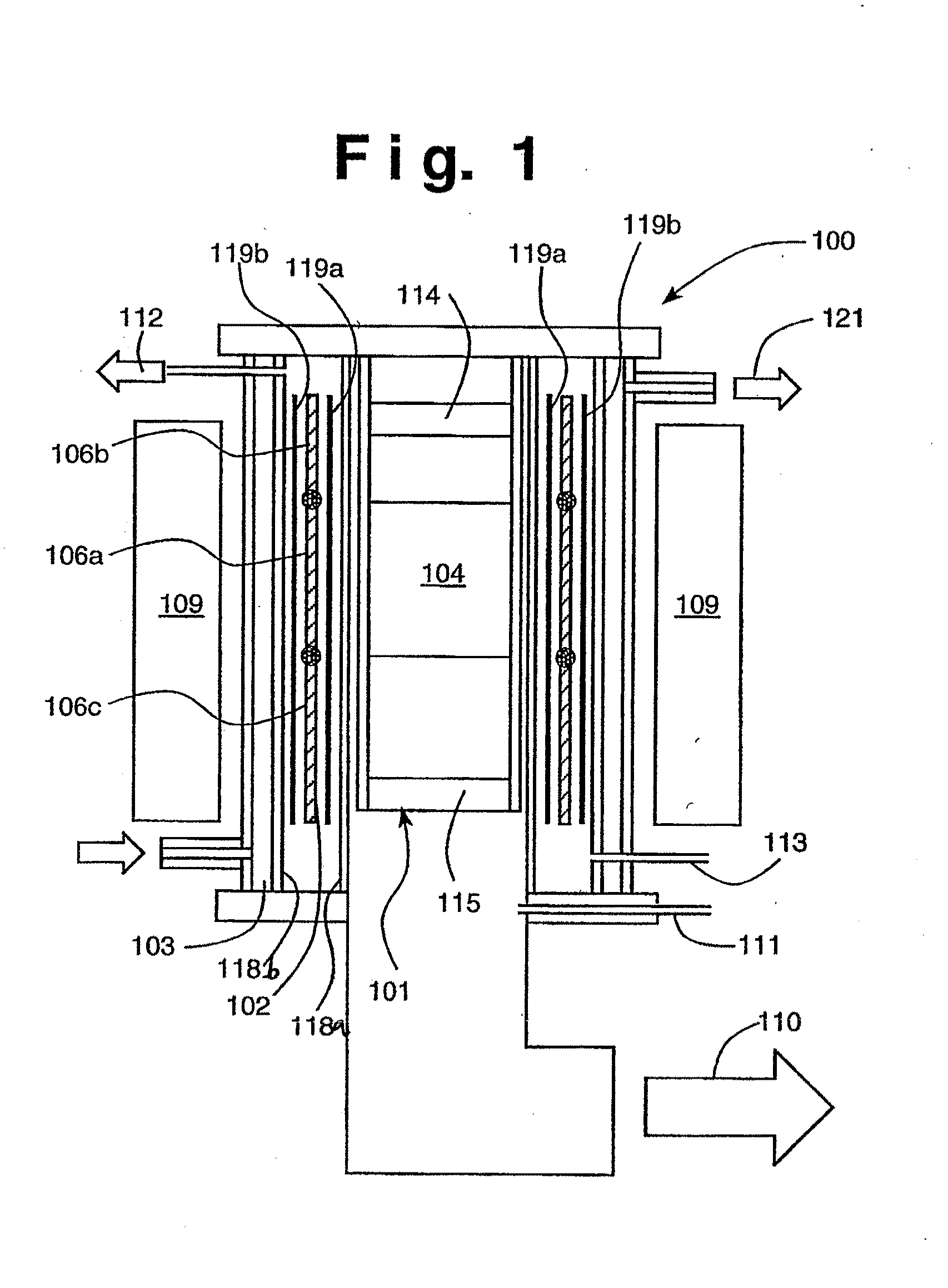

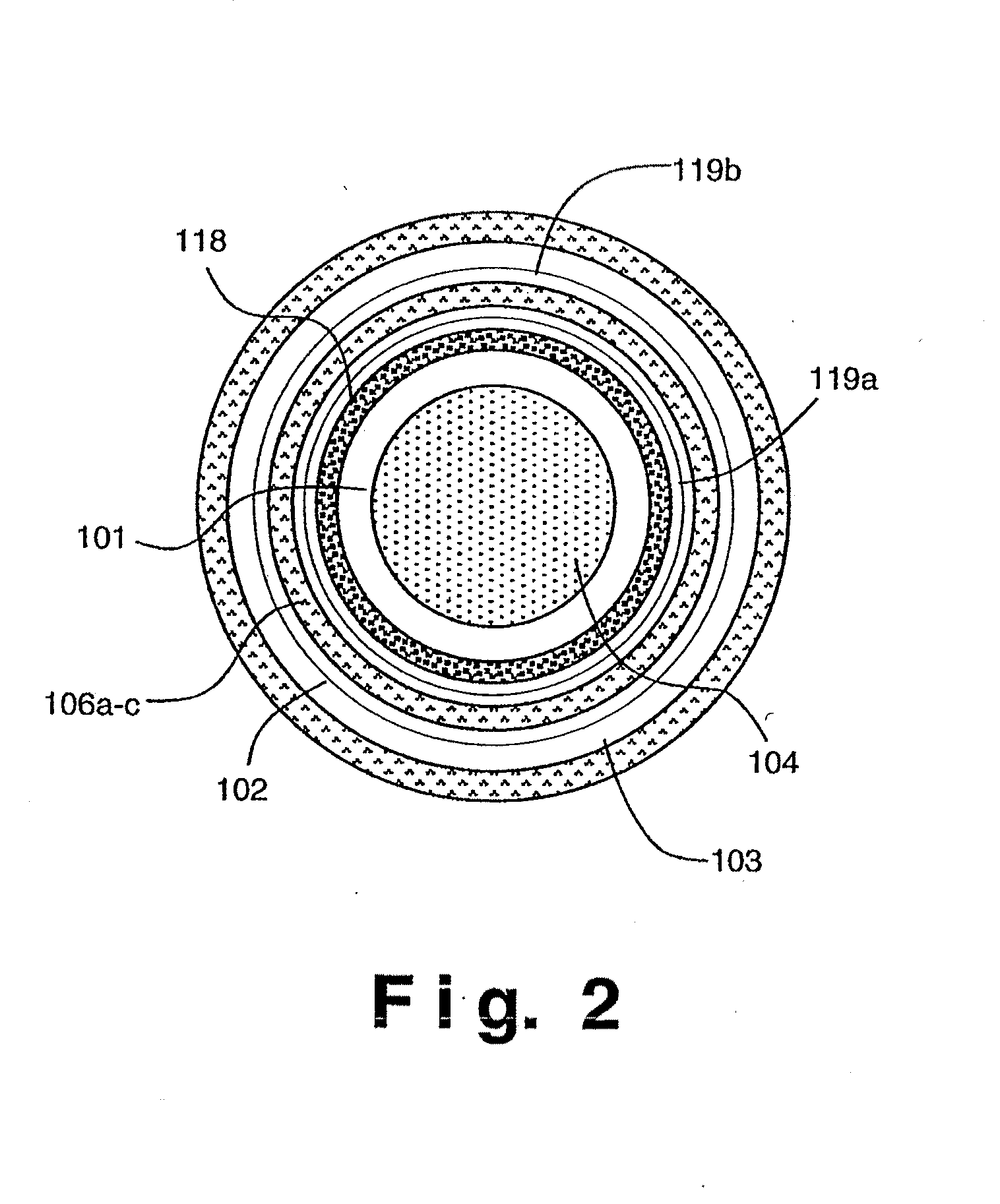

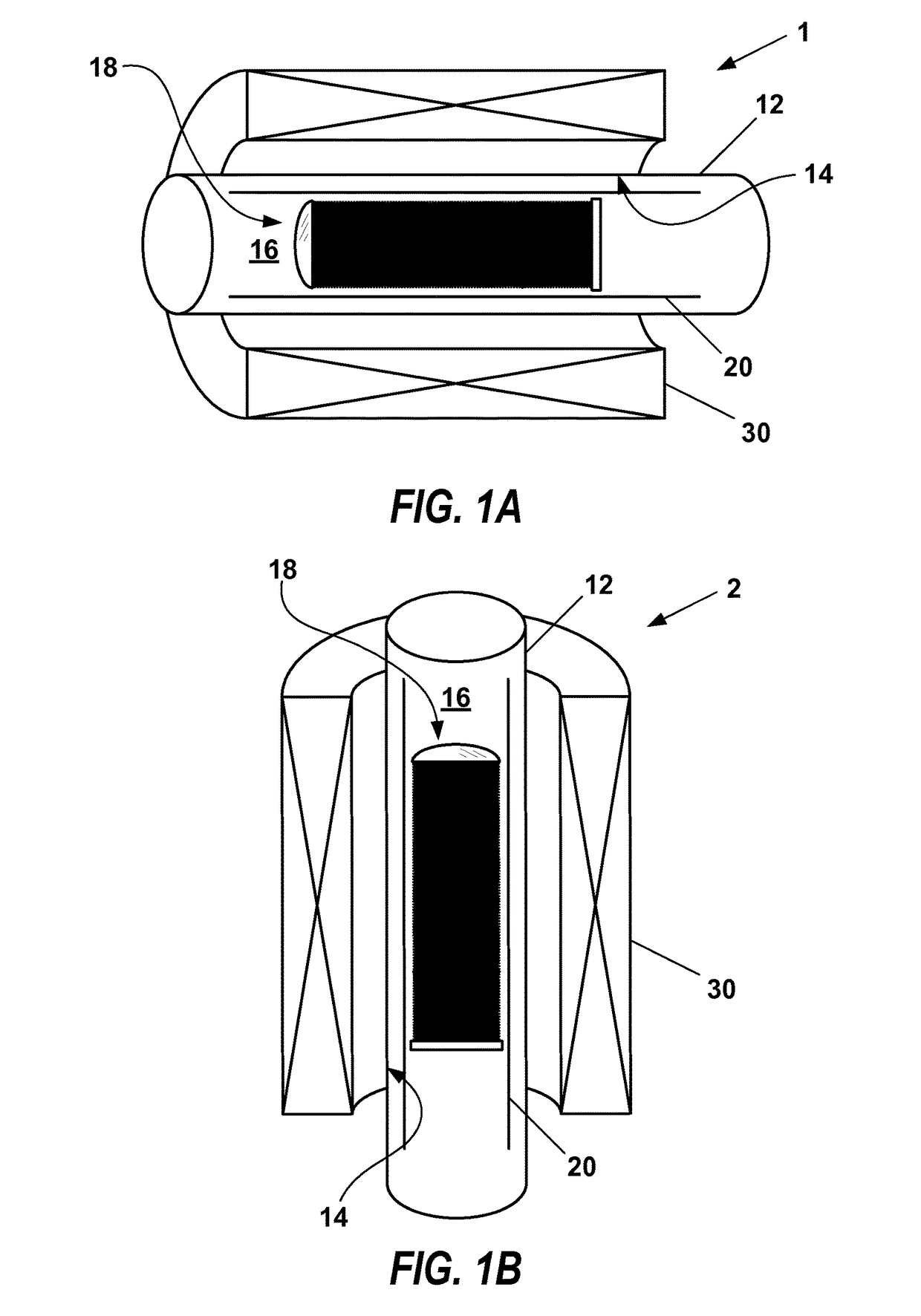

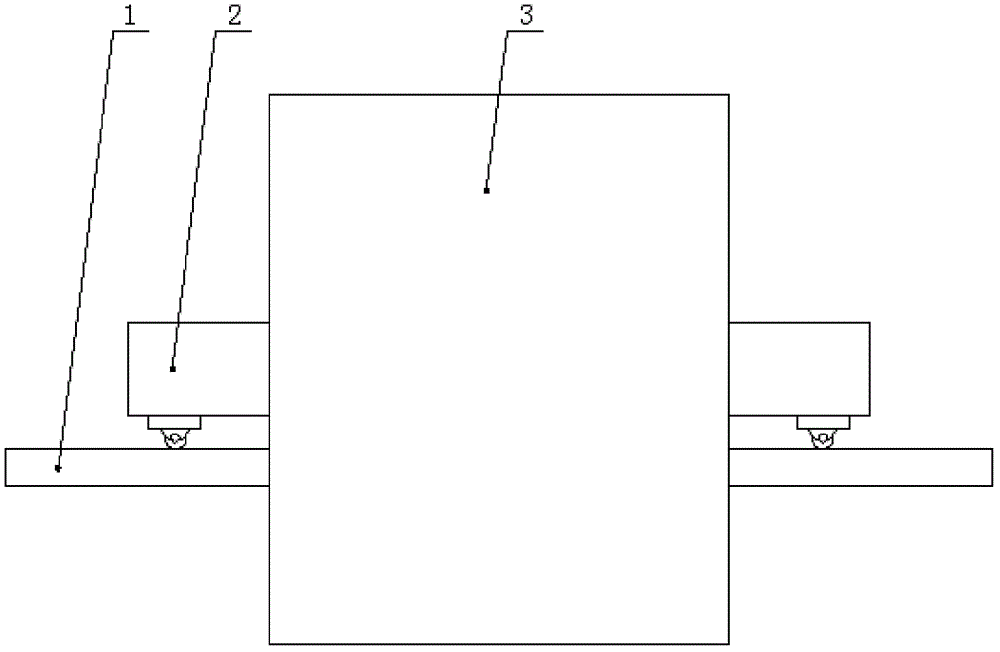

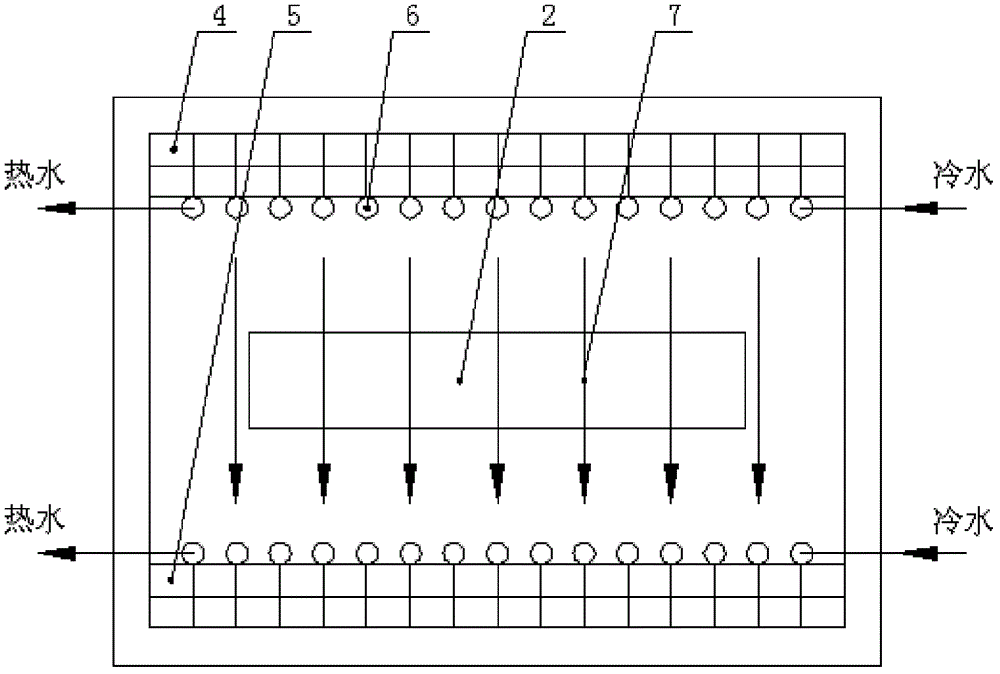

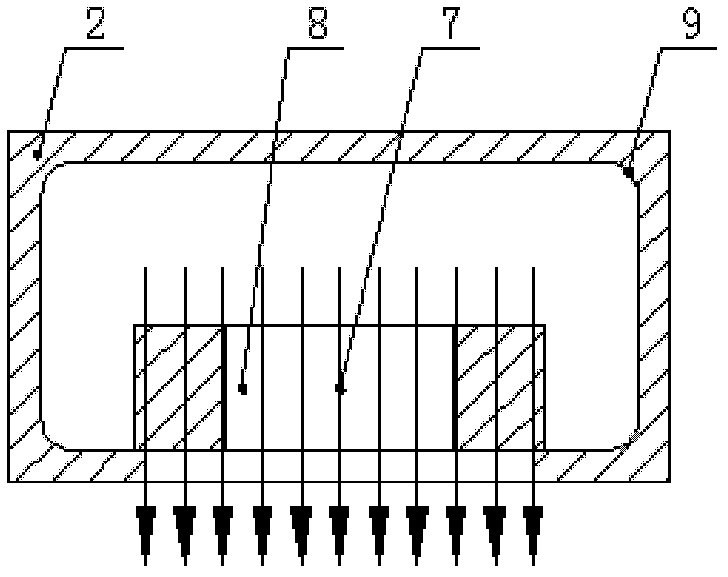

In-magnetic-field heat-treating device

InactiveUS20060082035A1Improve propertiesImprove horizontal accuracyMagnetic field orientationFurnace typesHeat treatedRecording media

A magnetic annealing device for inserting a recording medium 1 provided with an axial hole formed at a center thereof and having a disk shape into a chamber 10 and applying a heat treatment to the recording medium 1 in a magnetic field is provided with a magnetic circuit for forming a magnetic field in the chamber 10, the magnetic circuit comprises a pair of magnets 4 and 5 disposed with a distance therebetween along an axial direction of the axial hole and having magnetic fields directionally opposed to each other and a first ferromagnetic substance 6 disposed between the pair of magnets 4 and 5, wherein the recording medium 1 to be heat-treated is disposed at an intermediate position between the pair of magnets 4 and 5 facing each other in the state in which the first ferromagnetic substance 6 is inserted into the axial hole. A second ferromagnetic substance 7 having a ring shape is preferably disposed in a periphery of the recording medium 1.

Owner:HITACHI METALS LTD +1

Magnetic annealing of ferromagnetic thin films using induction heating

InactiveUS7193193B2Furnaces without endless coreLiquid surface applicatorsMagnetic characteristicOscillating magnetic field

Owner:MICHIGAN TECHNOLOGICAL UNIVERSITY

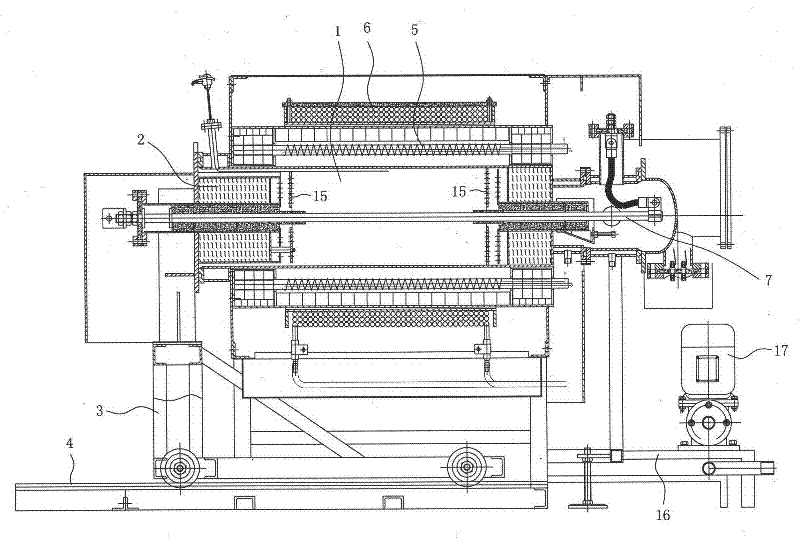

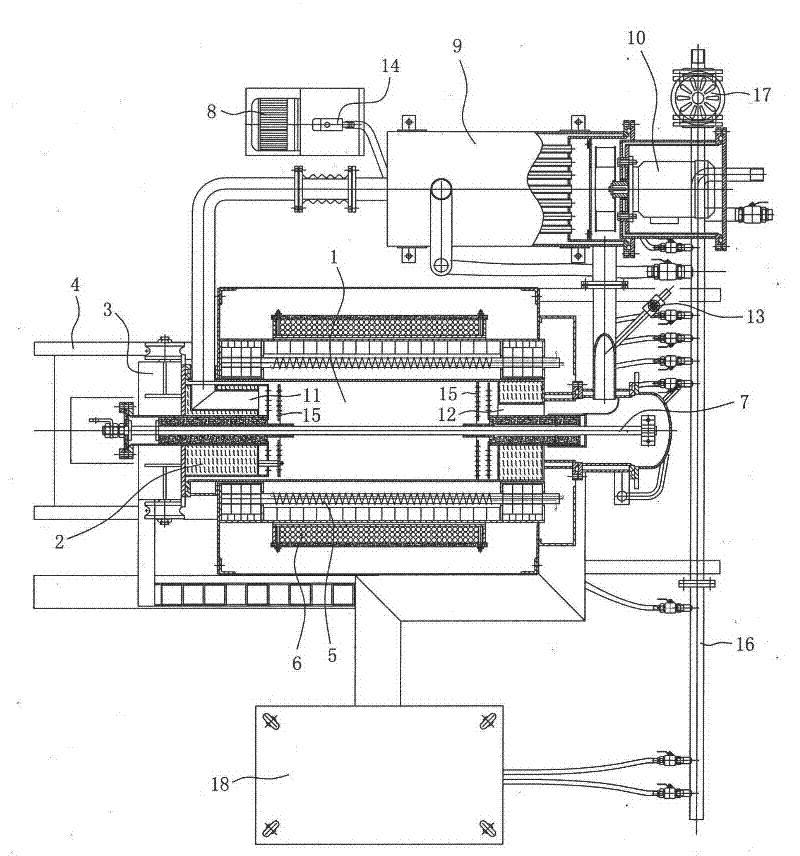

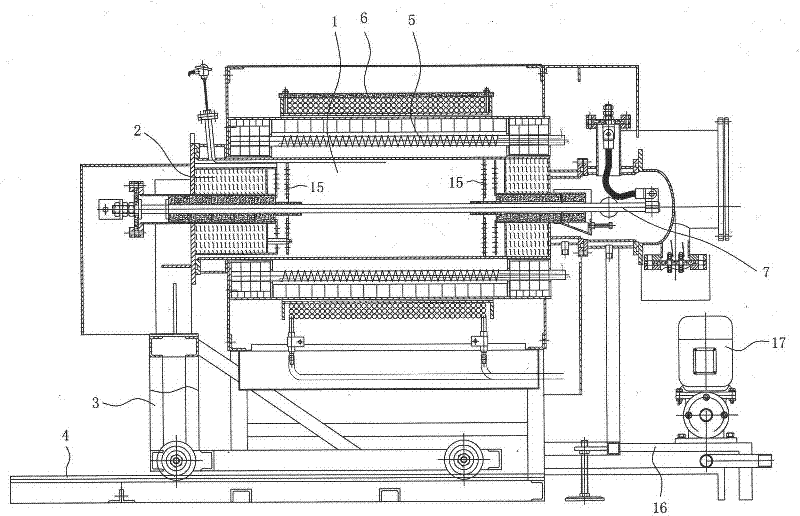

Magnetic annealing furnace for magnetic conductive iron core

InactiveCN102392108AImprove magnetic permeabilityImprove magnetic propertiesFurnace typesInductances/transformers/magnets manufactureMetallurgyDevice form

The invention discloses a multifunctional magnetic annealing furnace for magnetizing and annealing. The magnetic annealing furnace comprises a furnace body, a furnace lid, a dolly for driving the furnace lid to open and close and an electrical box with a control circuit. The furnace body is provided with a heating device. A transverse magnetic generator and a longitudinal magnetic generator are arranged inside the furnace body. A cooling device is disposed outside the furnace body. The core space of the furnace body and the cooling device form a circulation loop. A vacuum pump and nitrogen filling equipment are connected on the circulation loop.

Owner:朱巧明

Method for manufacturing of insulated soft magnetic metal powder formed body

ActiveUS20090116990A1Low iron-lossHigh mechanical strengthTransportation and packagingMetal-working apparatusCurie temperatureMetal powder

A method for manufacturing bodies formed from insulated soft magnetic metal powder by forming an insulating film of an inorganic substance on the surface of particles of a soft magnetic metal powder, compacting and molding the powder, then carrying out a heat treatment to provide a body formed from insulated soft magnetic metal powder the method comprising: compacting and molding the powder; then magnetically annealing the powder at a high temperature above the Curie temperature for the soft magnetic metal powder and below the threshold temperature at which the insulating film is destroyed in a non-oxidizing atmosphere, such as a vacuum, inert gas, or the like; and then carrying out a further heat treatment at a temperature of from 400° C. to 700° C. in an oxidizing atmosphere, such as air, or the like.

Owner:MITSUBISHI STEEL MFG CO LTD

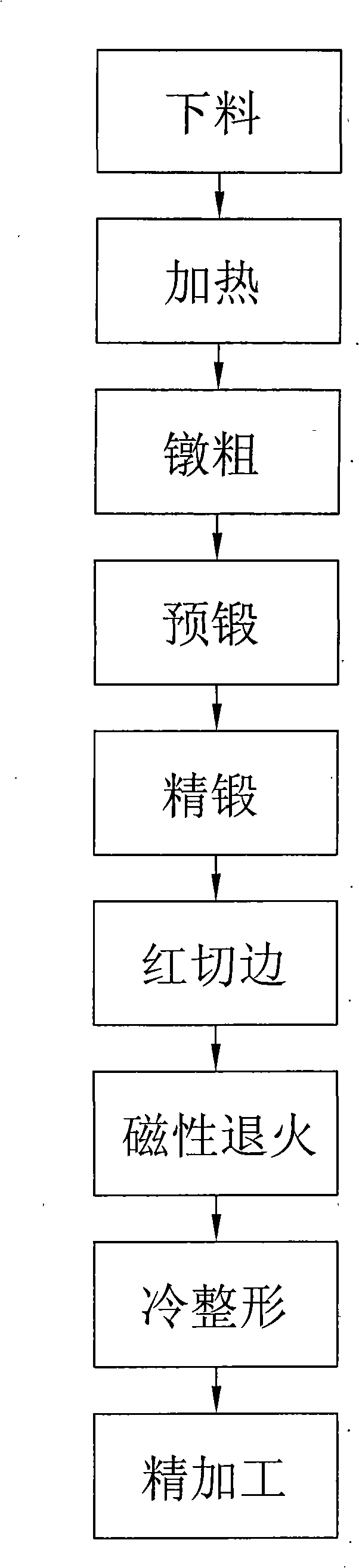

Hot edge-cutting manufacture technology for automobile generator finish forging claw pole

InactiveCN101327561AIncrease power generationLow shear strengthRailway componentsMetal-working apparatusProduction lineManufacturing technology

The present invention relates to a hot-trimming fabrication technique of the finish-forged claw poles of an automobile generator. The hot-trimming fabrication technique includes the following steps: (a) blanking; (b) heating; (c) continuous upsetting; (d) preforging; (e) finish forging; (f) hot trimming; (g) magnetic annealing; (h) cold shaping; (i) finish machining. Since the hot trimming technique is adopted, the five processes, heating, continuous upsetting, preforging, finish forging and hot trimming, form flow line production, thus reducing the cost of logistics, moreover, the temperature of the product reaches 950 DEG C to 1050 DEG C during hot trimming, at the moment, the shearing strength of the material is low, as a result, the tonnage of equipment can be greatly reduced, the service life of equipment is increased, consequently, the production cost is reduced, and noise is decreased. Since the finish forging and hot trimming processes form a production line, the appearance quality of the finish-forged product is effectively controlled, and therefore the quality of the product is increased.

Owner:庄龙兴

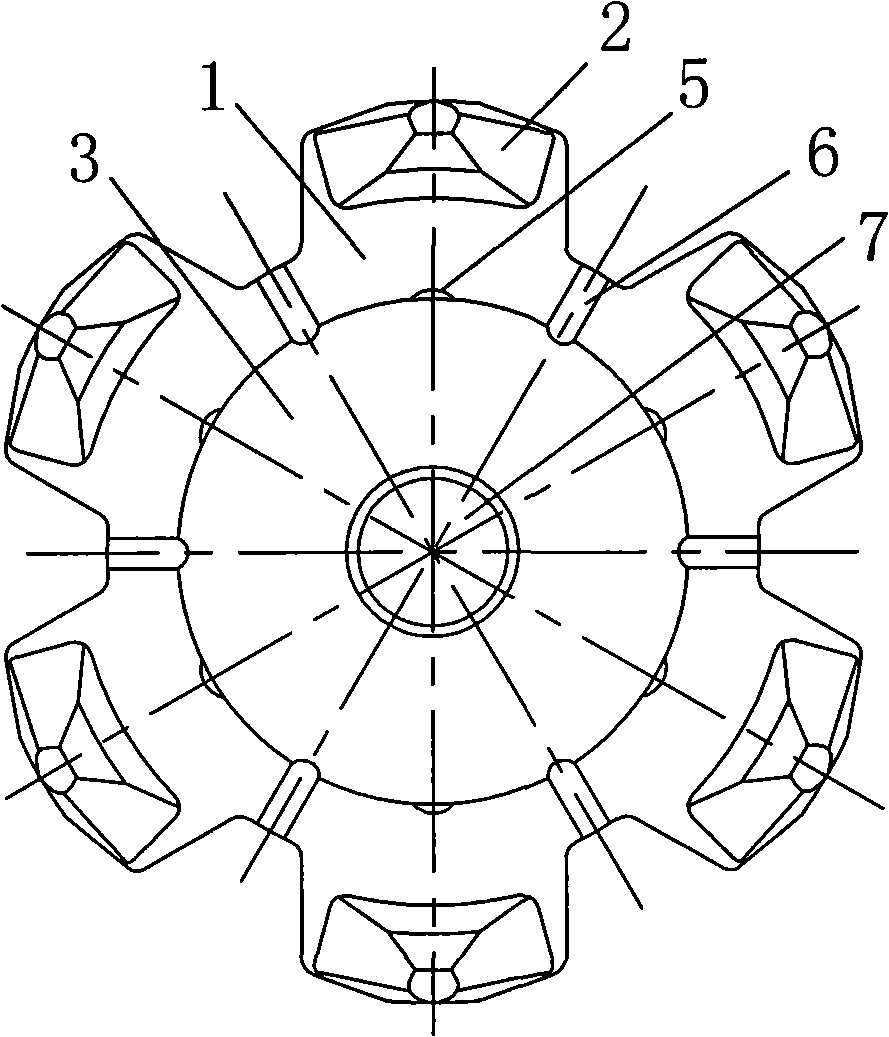

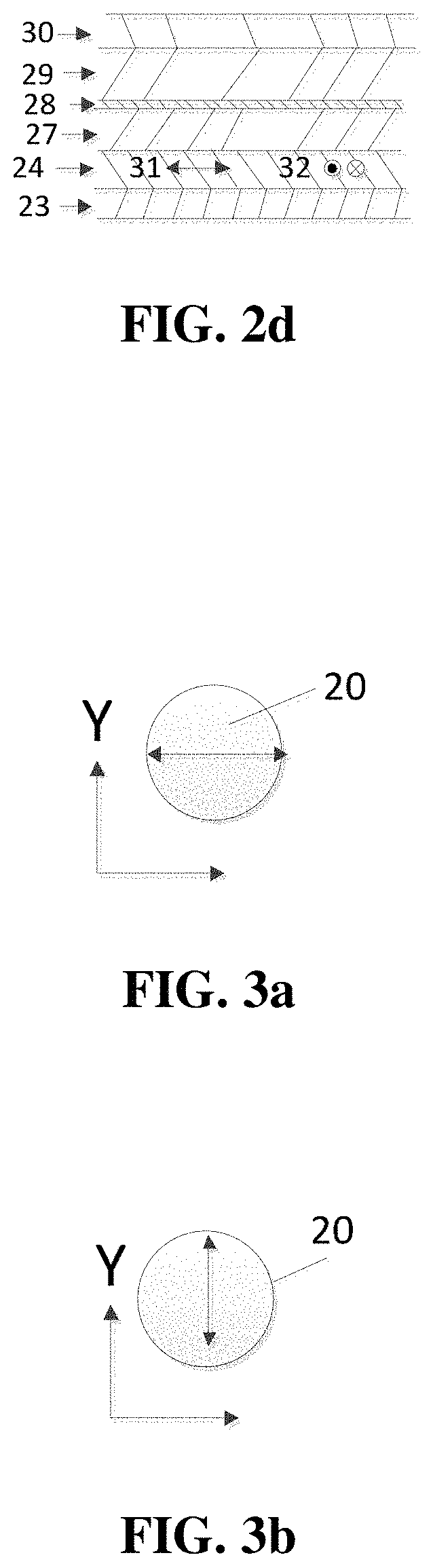

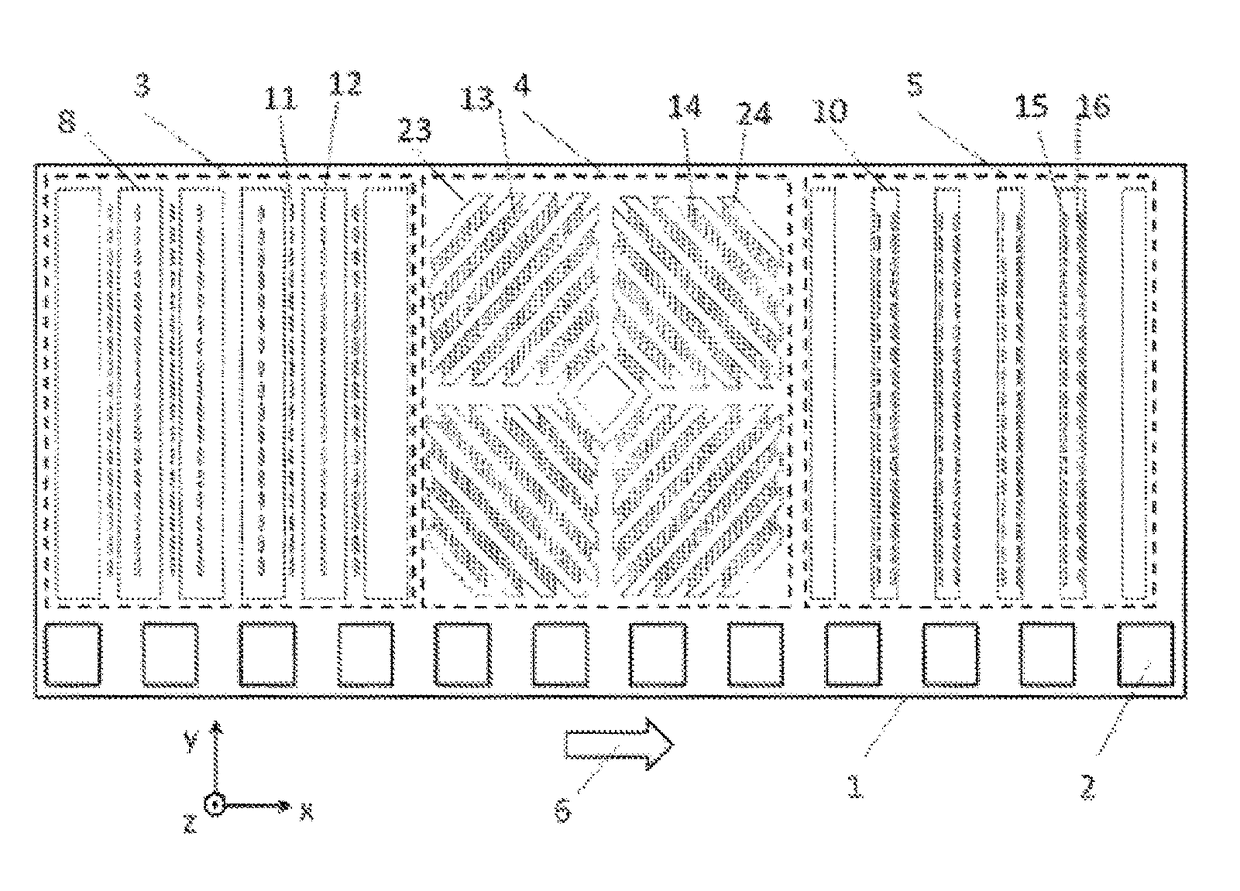

Single-chip double-axis magnetoresistive angle sensor

ActiveUS20190368858A1Compact structureImprove accuracyUsing electrical meansSingle device manufacturingUltrasound attenuationMagnetic reluctance

A single-chip two-axis magnetoresistive angle sensor comprises a substrate located in an X-Y plane, a push-pull X-axis magnetoresistive angle sensor and a push-pull Y-axis magnetoresistive angle sensor located on the substrate. The push-pull X-axis magnetoresistive angle sensor comprises an X push arm and an X pull arm. The push-pull Y-axis magnetoresistive angle sensor comprises a Y push arm and a Y pull arm. Each of the X push, X pull, Y push arm, and Y pull arms comprises at least one magnetoresistive angle sensing array unit. The magnetic field sensing directions of the magnetoresistive angle sensing array units of the X push, X pull, Y push, and Y pull arms are along +X, −X, +Y and −Y directions respectively. Each magnetoresistive sensing unit comprises a TMR or GMR spin-valve having the same magnetic multi-layer film structure. A magnetization direction of an anti-ferromagnetic layer is set into a desired orientation through the use of a laser controlled magnetic annealing, and a magnetic field attenuation layer can be deposited in the surface of the magnetoresistance angle sensing unit.

Owner:MULTIDIMENSION TECH CO LTD

Single-chip double-axis magneto-resistance angle sensor

ActiveCN106871778ACompact structureHigh precisionUsing electrical meansSingle device manufacturingUltrasound attenuationPush pull

The invention discloses a single-chip double-axis magneto-resistance angle sensor. The sensor comprises a substrate in an X-Y plane and magneto-resistance angle sensors in the push-pull X and Y axes on the substrate, the magneto-resistance angle sensor in the push-pull X axis comprises an X push arm and an X pull arm, the magneto-resistance angle sensor in the push-pull Y axis comprises a Y push arm and a Y pull arm, each of the push arms comprises at least one magneto-resistance angle sensing unit array, magnetic field sensing directions of the magneto-resistance angle sensing unit arrays of the X push arm, the X pull arm, the Y push arm and the Y pull arm are along +X, -X, +Y and -Y directions respectively, each magneto-resistance angle sensing unit includes a TMR / GMR spin valve of the same magnetic multi-layer film structure, a magnetization direction of an anti-ferromagnetic layer is obtained by laser program-control heating magnetic annealing, and a magnetic field attenuation layer can be deposited in the surface of the magneto-resistance angle sensing unit to broaden the working magnetic-field range. The single-chip double-axis magneto-resistance angle sensor has the advantages of compact structure, high precision, small size and capable of realizing the wide working magnetic-field range.

Owner:MULTIDIMENSION TECH CO LTD

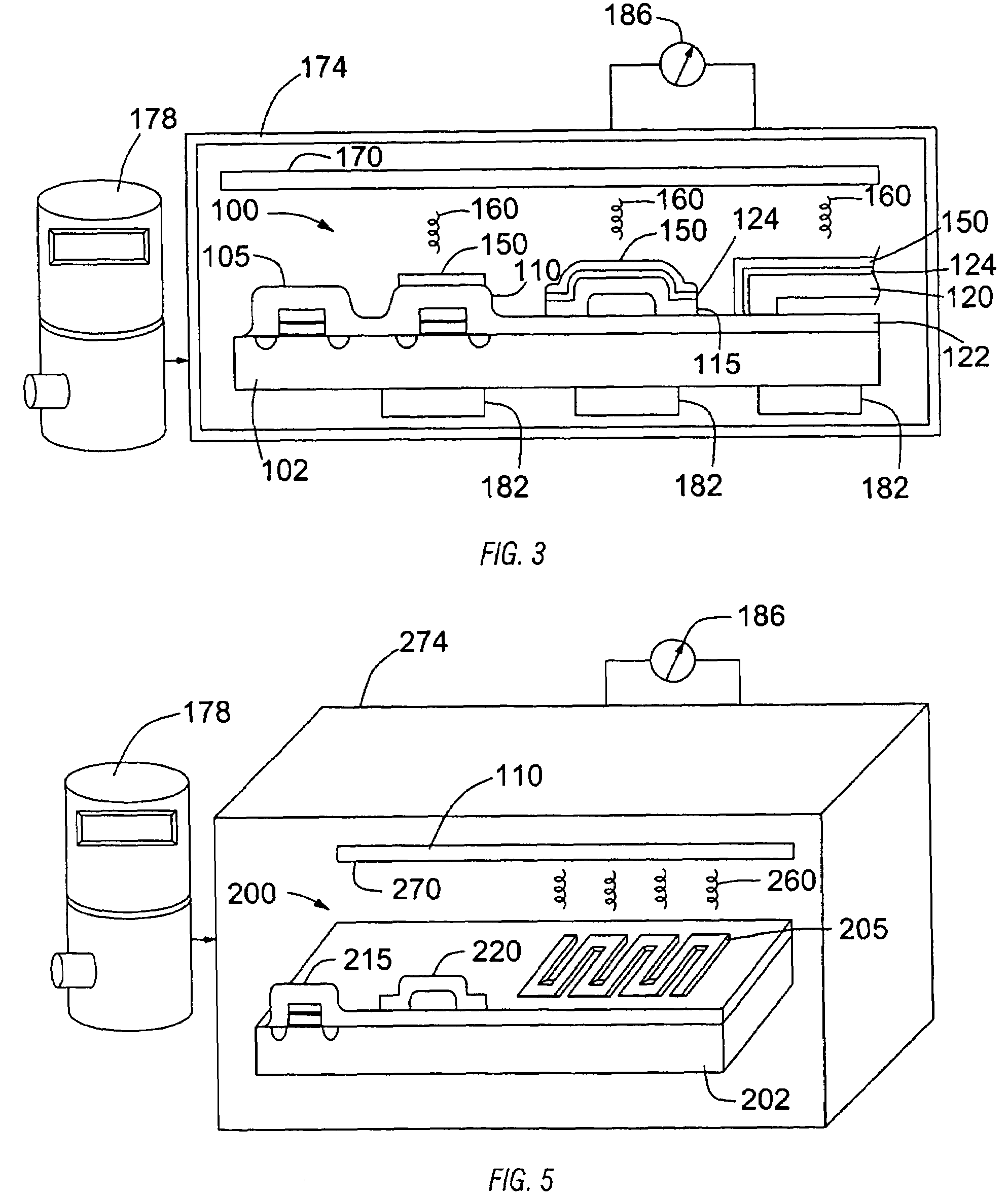

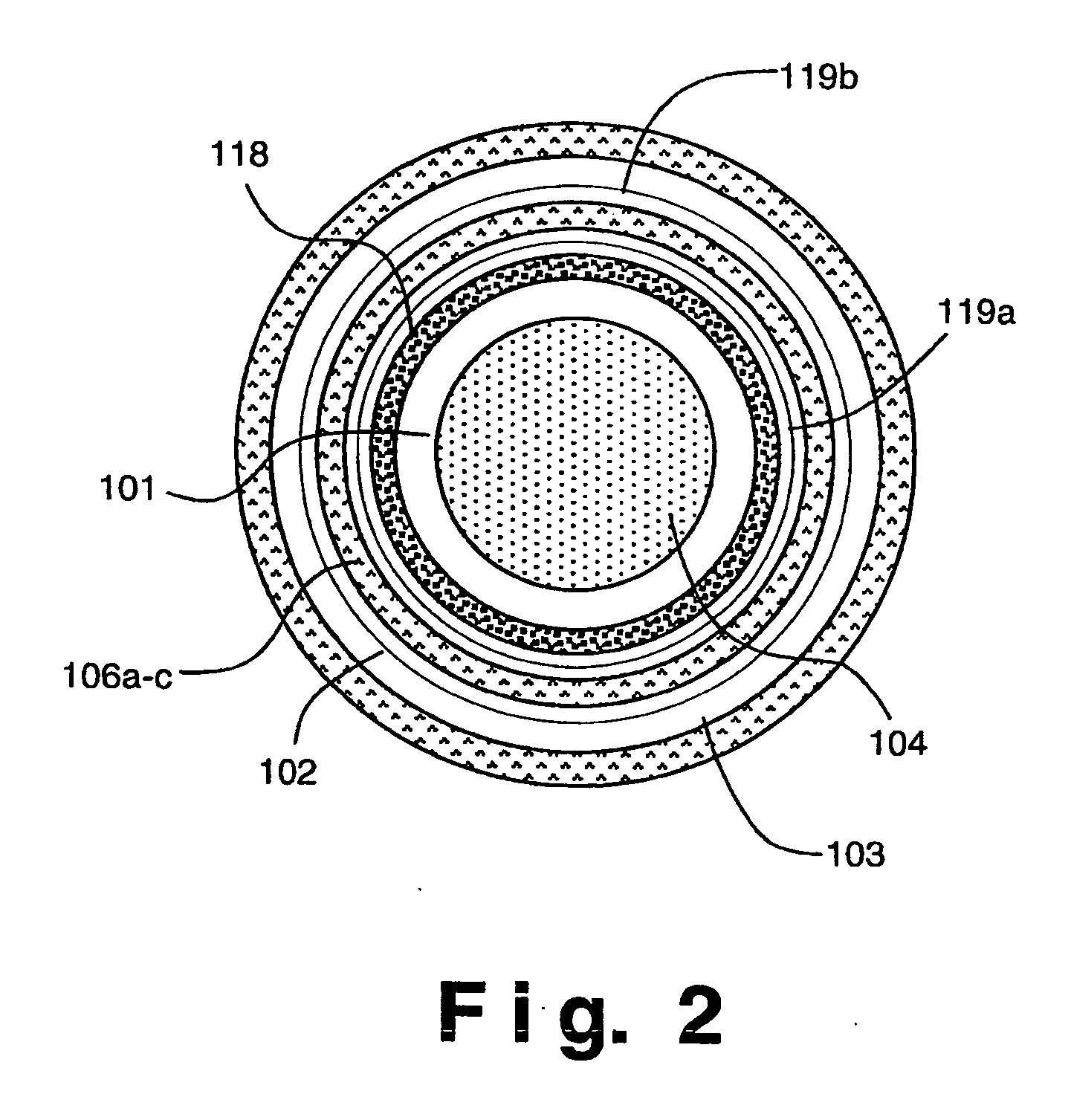

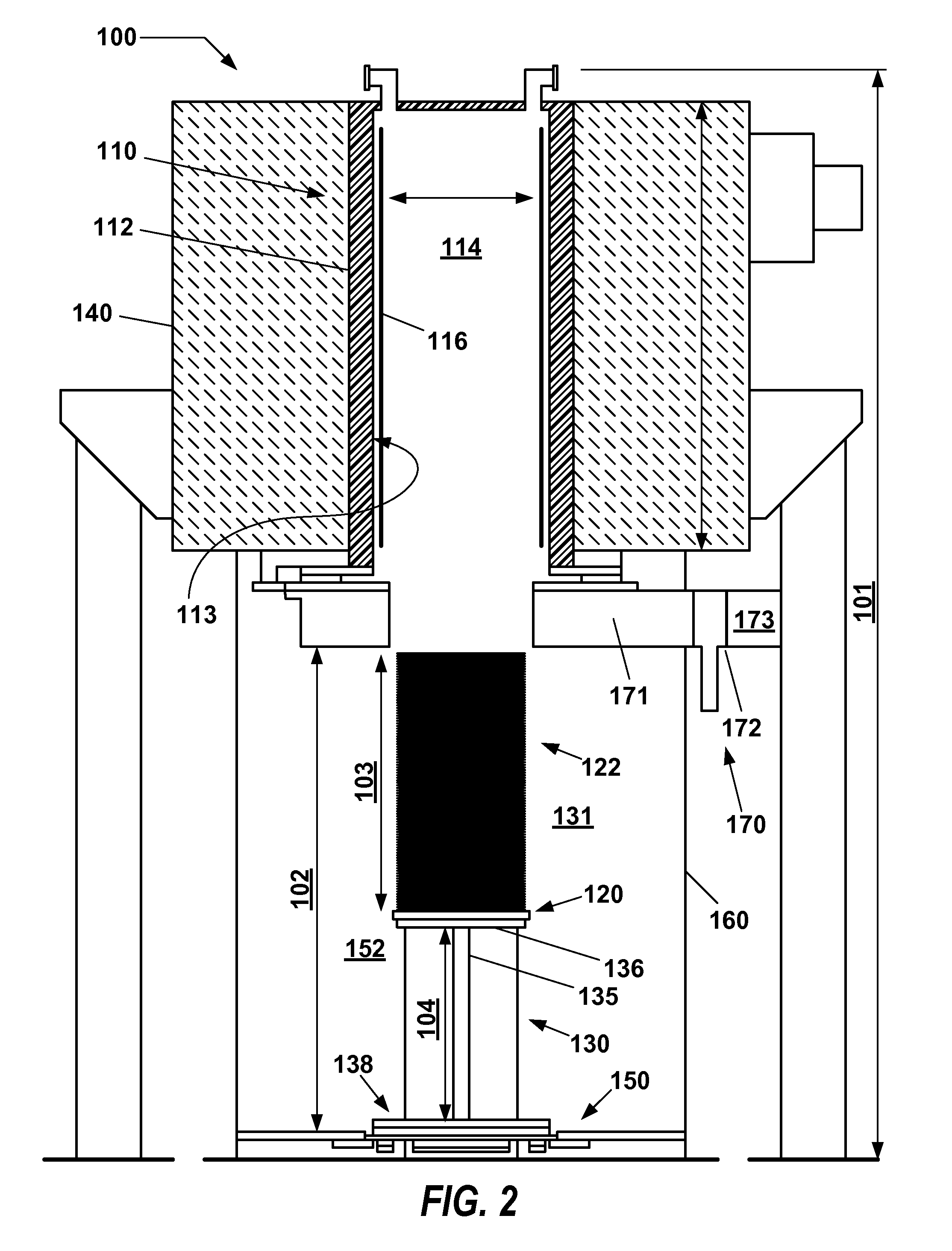

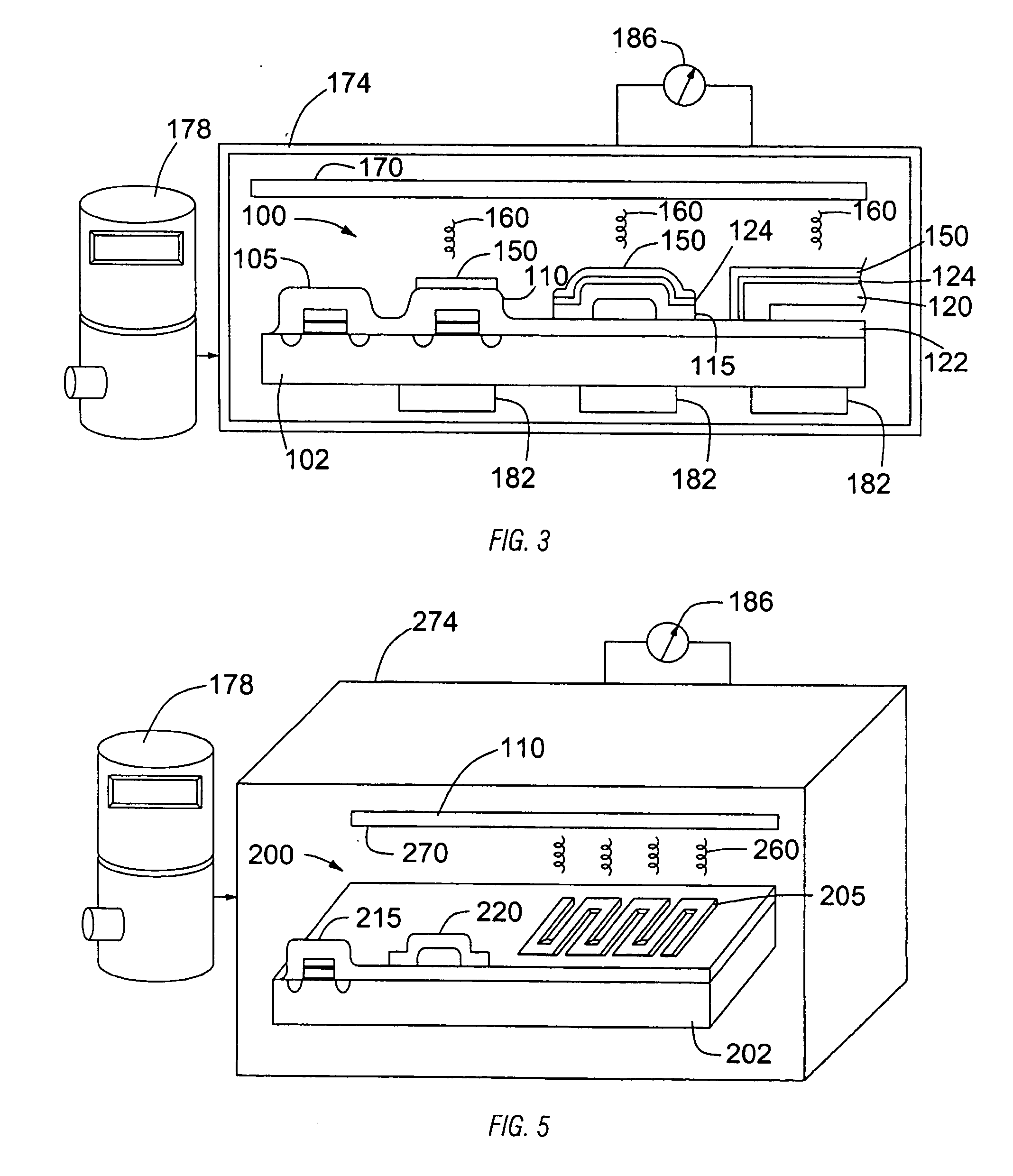

Magnetic annealing tool heat exchange system and processes

InactiveUS20070125767A1Heating fastImprove cooling effectSemiconductor/solid-state device manufacturingInorganic material magnetismCooling chamberEngineering

A heat exchange system and processes for a magnetic annealing tool is provided. The system includes a process chamber housing workpieces to be processed; an element chamber partly surrounding the periphery of the process chamber, at least one means for drawing a vacuum in fluid communication with the process chamber and separately with the element chamber in order to apply a vacuum to either or both of the process and element chamber so as to promote radiation heating of the workpieces; at least one supply of fluid in communication with the process chamber and separately with the element chamber to supply a cooling gas so as to promote conductive cooling of the workpieces; a cooling chamber disposed to surround the element chamber; and means for generating a magnetic field disposed on the outer periphery of the cooling chamber.

Owner:MAGNETIC SOLUTIONS HLDG

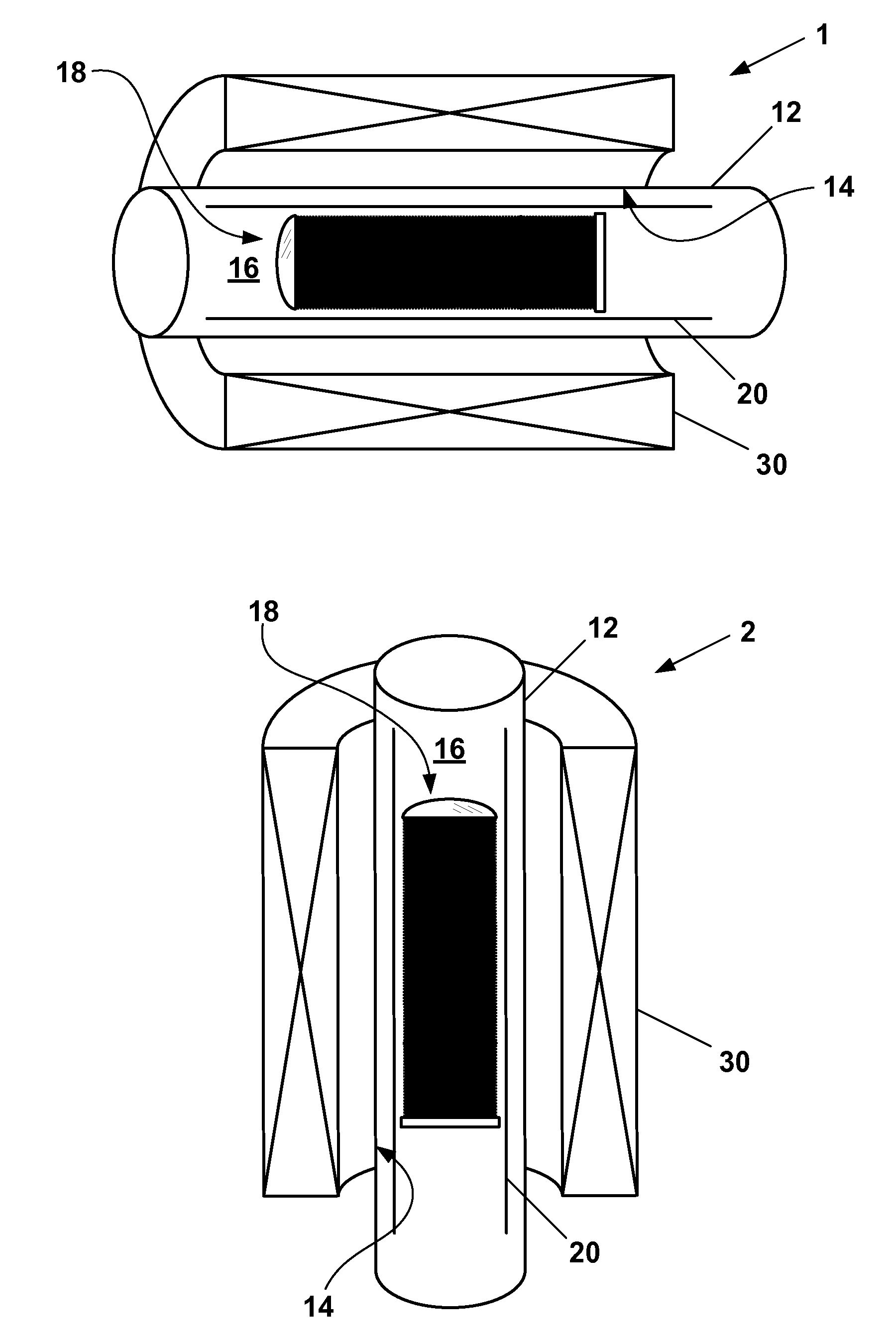

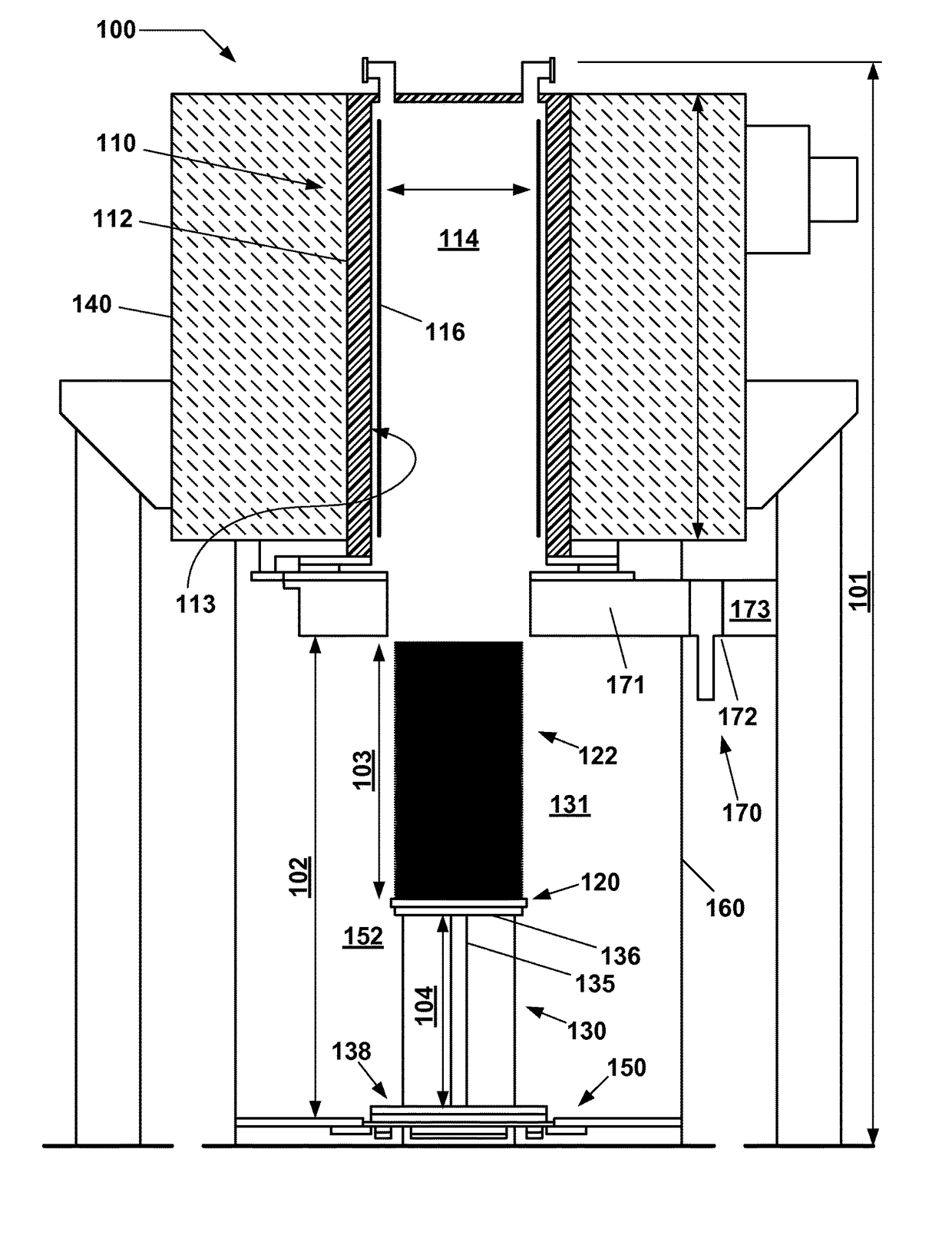

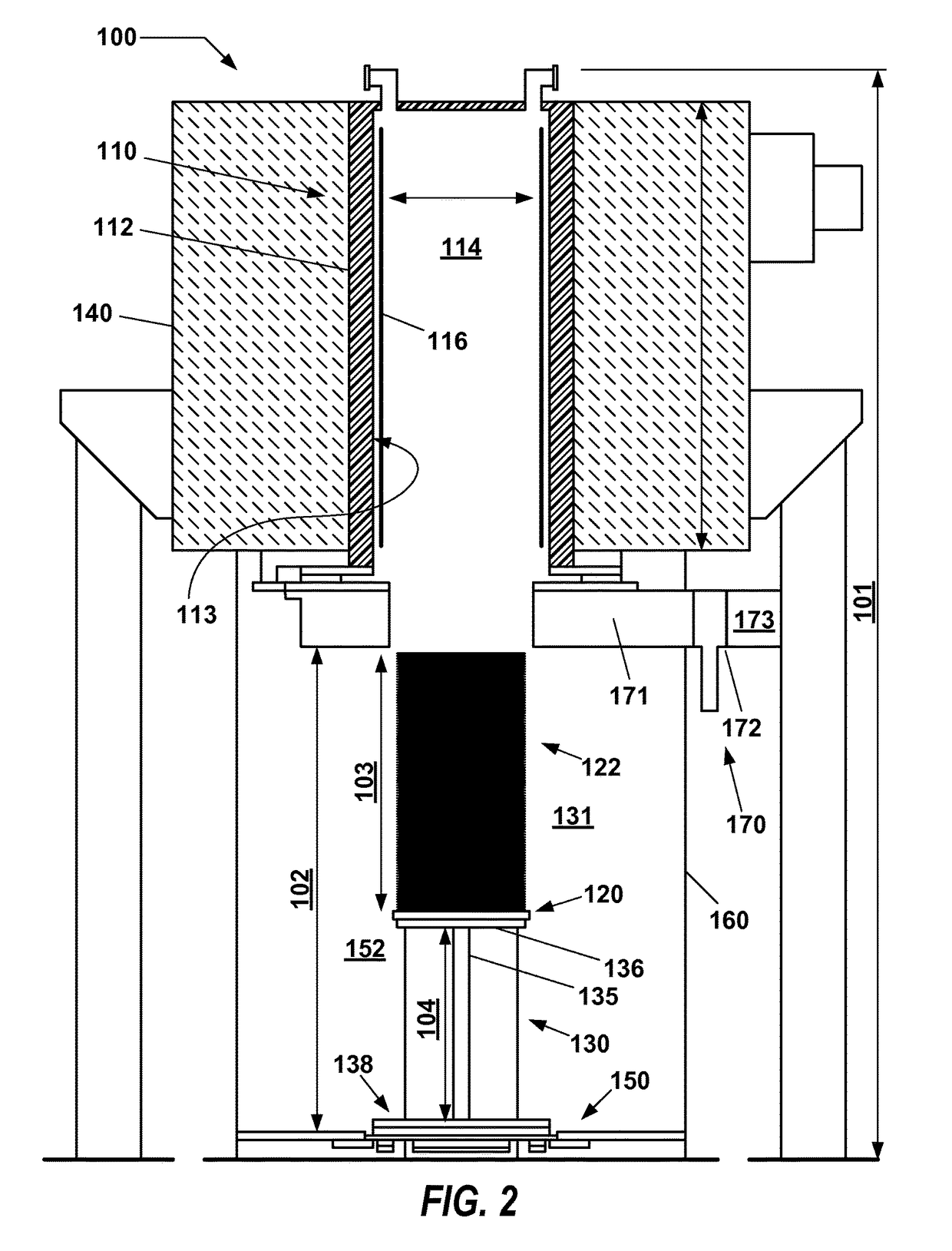

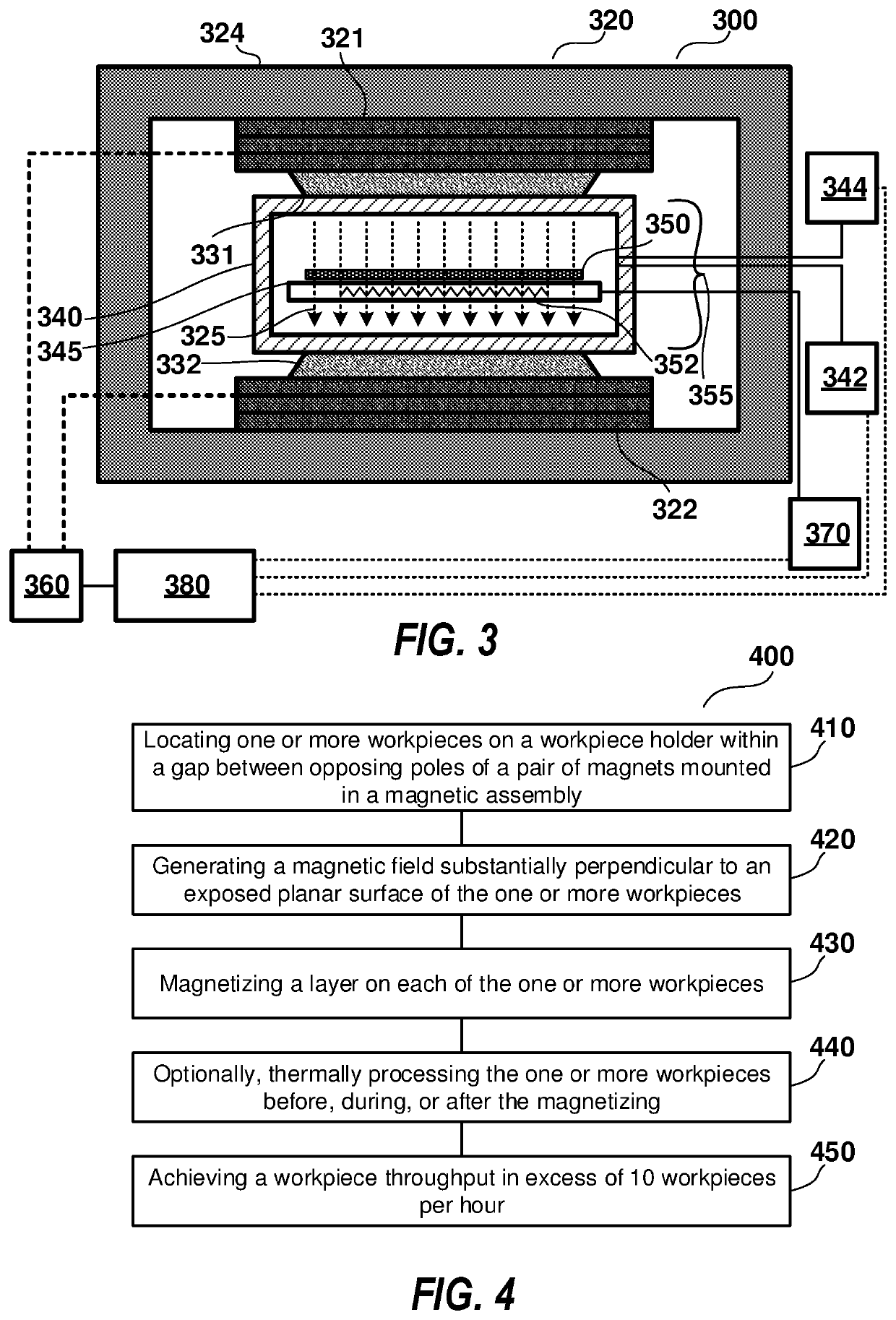

High rate magnetic annealing system and method of operating

ActiveUS20160177412A1Furnace typesInductances/transformers/magnets manufactureHigh rateVacuum chamber

An annealing system and method of operating is described. The annealing system includes a furnace having a vacuum chamber wall that defines a processing space into which a plurality of workpieces may be translated and subjected to thermal and magnetic processing, wherein the furnace further includes a heating element assembly having at least one heating element located radially inward from the vacuum chamber wall and immersed within an outer region of the processing space, and wherein the heating element is composed of a non-metallic, anti-magnetic material. The annealing system further includes a magnet system arranged outside the vacuum chamber wall of the furnace, and configured to generate a magnetic field within the processing space.

Owner:TOKYO ELECTRON LTD

Magnetic annealing of ferromagnetic thin films using induction heating

InactiveUS20050181126A1Furnaces without endless coreLiquid surface applicatorsMagnetic characteristicOscillating magnetic field

A method of performing magnetic annealing of a ferromagnetic thin film applied to a substrate includes applying an oscillating magnetic field to the ferromagnetic thin film to induce a current therein and heat the ferromagnetic thin film. A directional magnetic field is applied to the ferromagnetic thin film at the same time as the ferromagnetic thin film is heated, and the ferromagnetic thin film is allowed to acquire a desired magnetic characteristic, and then the oscillating magnetic field is removed and the ferromagnetic thin film is allowed to cool.

Owner:MICHIGAN TECHNOLOGICAL UNIVERSITY

Magnetic annealing tool heat exchange system and processes

InactiveUS20080121634A2Semiconductor/solid-state device manufacturingInorganic material magnetismCooling chamberEngineering

A heat exchange system and processes for a magnetic annealing tool is provided. The system includes a process chamber housing workpieces to be processed; an element chamber partly surrounding the periphery of the process chamber, at least one means for drawing a vacuum in fluid communication with the process chamber and separately with the element chamber in order to apply a vacuum to either or both of the process and element chamber so as to promote radiation heating of the workpieces; at least one supply of fluid in communication with the process chamber and separately with the element chamber to supply a cooling gas so as to promote conductive cooling of the workpieces; a cooling chamber disposed to surround the element chamber; and means for generating a magnetic field disposed on the outer periphery of the cooling chamber.

Owner:MAGNETIC SOLUTIONS HLDG

Continuous annealing method for low coercive force cold-rolled electromagnetic pure iron plate and strip

ActiveUS20180265945A1Good molding effectLow coercivityFurnace typesHeat treatment furnacesSlow coolingContinuous annealing

A continuous annealing method for low coercive force cold-rolled electromagnetic pure iron plate and strip. Control parameters of each stages in a continuous annealing process are as follows: 750-850° C. at a heating stage; 750-850° C. at a soaking stage, the soaking time is 100-150 s; an outlet temperature of 575-675° C. at a slow-cooling stage, the cooling speed in slow-cooling stage is 2.5-10° C. / s; an outlet temperature of 380-420° C. at a fast-cooling stage, the cooling speed of the fast-cooling stage is 15-25° C. / s; and 270-310° C. at an overaging stage. The annealing medium is a non-oxidizing atmosphere composed of H2 and N2. After annealing, the cold-rolled electromagnetic pure iron plate and strip is leveled and pressed such that the leveling elongation rate of the plate and strip is controlled within the range of 0.2±0.1%. The process of the continuous annealing method is simple, and the produced cold-rolled electromagnetic pure iron plate and strip can achieve an overall performance of low coercive force and good formability without further magnetic annealing.

Owner:BAOSHAN IRON & STEEL CO LTD

High rate magnetic annealing system and method of operating

An annealing system and method of operating is described. The annealing system includes a furnace having a vacuum chamber wall that defines a processing space into which a plurality of workpieces may be translated and subjected to thermal and magnetic processing, wherein the furnace further includes a heating element assembly having at least one heating element located radially inward from the vacuum chamber wall and immersed within an outer region of the processing space, and wherein the heating element is composed of a non-metallic, anti-magnetic material. The annealing system further includes a magnet system arranged outside the vacuum chamber wall of the furnace, and configured to generate a magnetic field within the processing space.

Owner:TOKYO ELECTRON LTD

Monolithic three-axis linear magnetic sensor and manufacturing method thereof

ActiveUS9891292B2Increasing thickness LzHigh sensitivityMagnetic field measurement using flux-gate principleSolid-state devicesElectricityMagnetization

A monolithic three-axis linear magnetic sensor and manufacturing method wherein the sensor comprises an X-axis sensor, a Y-axis sensor and a Z-axis sensor. The X-axis sensor comprises a referenced bridge and at least two X ferromagnetic flux guides. The Y-axis sensor comprises a push-pull bridge and at least two Y ferromagnetic flux guides. The Z-axis sensor comprises a push-pull bridge and at least one Z ferromagnetic flux guide. The bridge arms of the referenced bridge and push-pull bridge are each formed by one or more magnetoresistive elements that are electrically interconnected. The directions of the sensing axes and the directions of magnetization of the pinned layers of the magnetoresistive elements are all oriented along the X-axis. This manufacturing method comprises first depositing a magnetoresistive thin film on a wafer, and then performing several processes such as magnetic annealing, photolithography, etching, coating, and the like in order to realize a sensor. This monolithic three-axis linear magnetic sensor has the advantages of low cost, easy manufacturability, good linearity, and high sensitivity.

Owner:MULTIDIMENSION TECH CO LTD

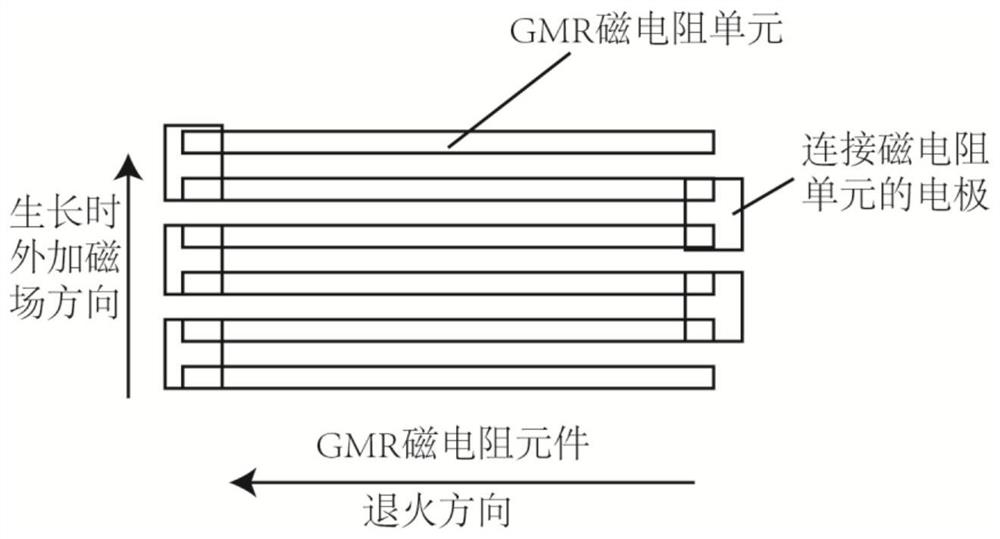

Preparation method of GMR magnetic field sensor

ActiveCN111965571AReduce hysteresisChange spontaneous orientationSingle device manufacturingTemperature controlFull bridge

The invention discloses a preparation method of a GMR magnetic field sensor. The preparation method comprises the steps of providing a substrate; depositing a GMR multilayer film structure on the substrate, wherein the GMR magnetoresistance unit at least comprises a pinning layer, a non-magnetic metal layer and a free layer; applying an external magnetic field to magnetize the pinning layer whiledepositing the GMR multilayer film structure; carrying out low-temperature magnetic annealing, wherein the annealing direction is perpendicular to the magnetization direction of the pinning layer, andthe annealing temperature is lower than the blocking temperature of an antiferromagnetic material in the pinning layer; forming mutually independent GMR magnetoresistance chips on the GMR multilayerfilm structure; and connecting the GMR magnetoresistance chips according to a full-bridge structure, and connecting the GMR magnetoresistance chips with the input electrode and the output electrode toobtain the GMR magnetic sensor with the full-bridge structure. By adopting a low-temperature low-field annealing mode, the difficulty of temperature control is reduced, interlayer diffusion is inhibited, and the sensor can have higher magnetoresistance value and sensitivity.

Owner:珠海多创科技有限公司

Control valve for a variable capacity compressor

InactiveUS20090205348A1Low costOperating means/releasing devices for valvesCompression machines with non-reversible cycleControl valvesNon magnetic

There is provided a brazing method which makes it possible to rationally perform not only the brazing between a metal member such as a stator made of a magnetic material and a metal member such as a guide pipe made of a non-magnetic material but also the magnetic annealing of these metal members. By making use of a brazing material (90) which can be fused at a lower temperature than a magnetic annealing temperature of metal member (33), the metal member such as a stator made of a magnetic material and the metal member (35) such as a guide pipe made of a non-magnetic material are heated to a predetermined temperature in a furnace to perform the magnetic annealing of the metal member (33) concurrent with the brazing of these metal members.

Owner:KUME YOSHIYUKI +3

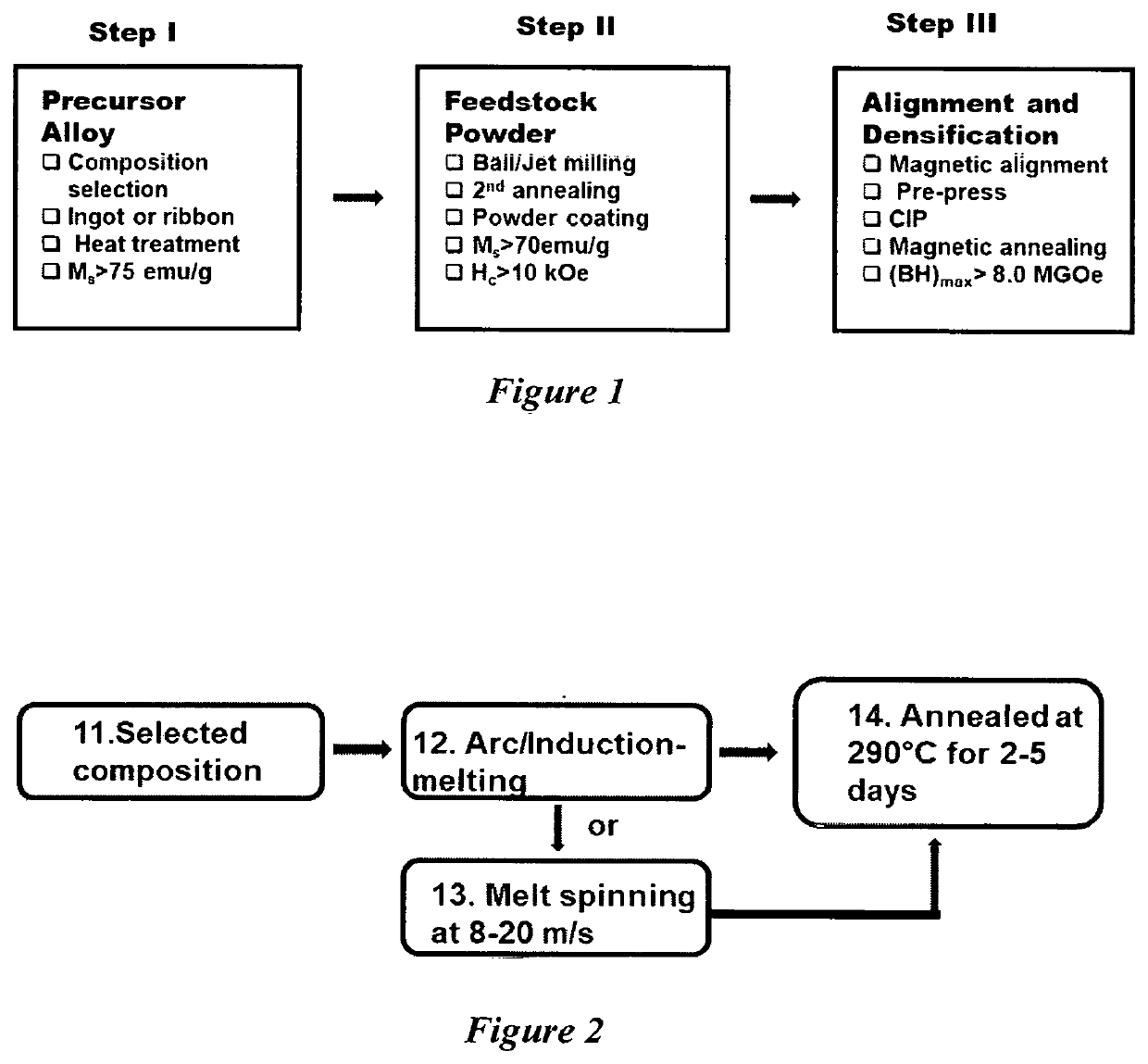

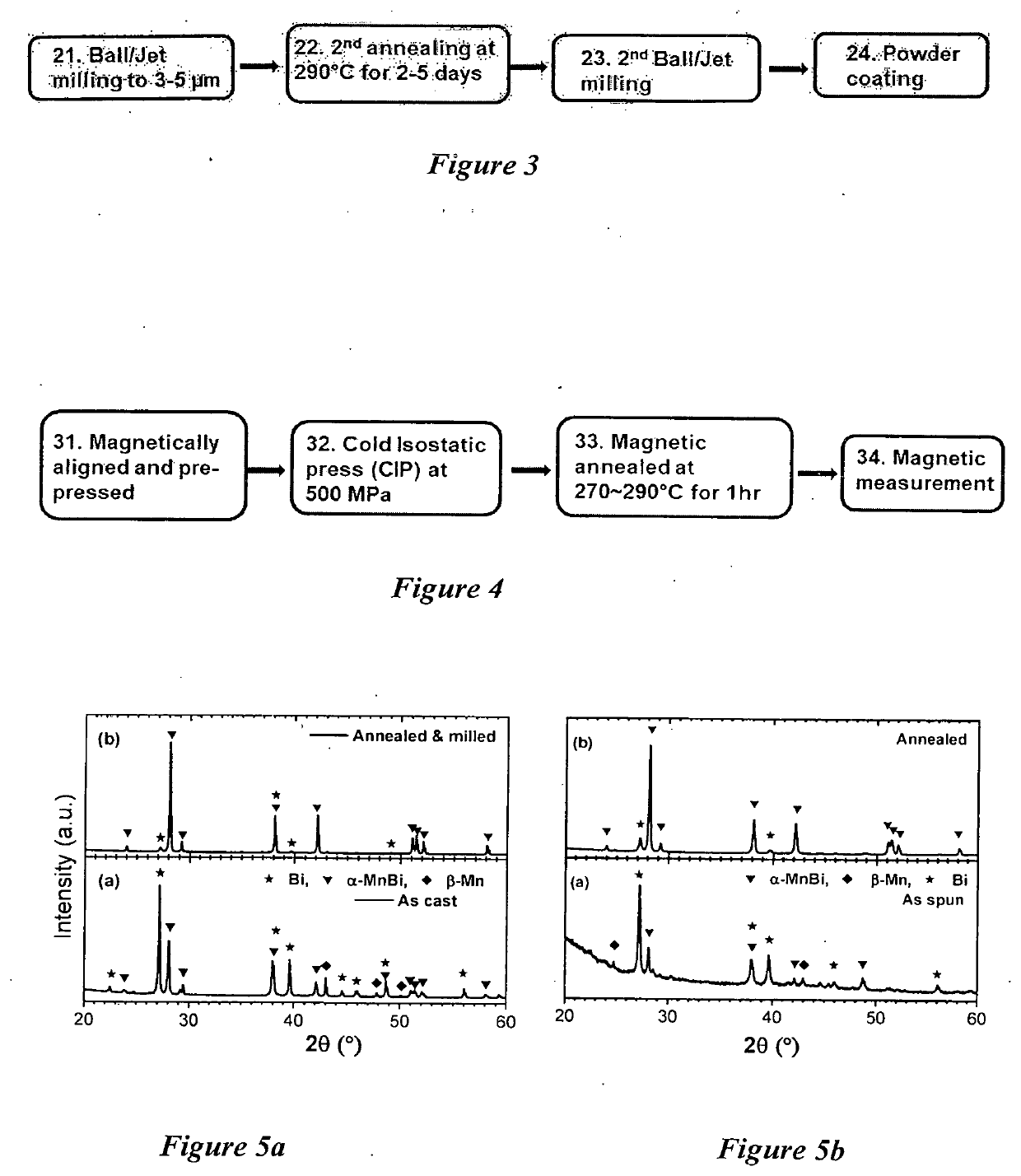

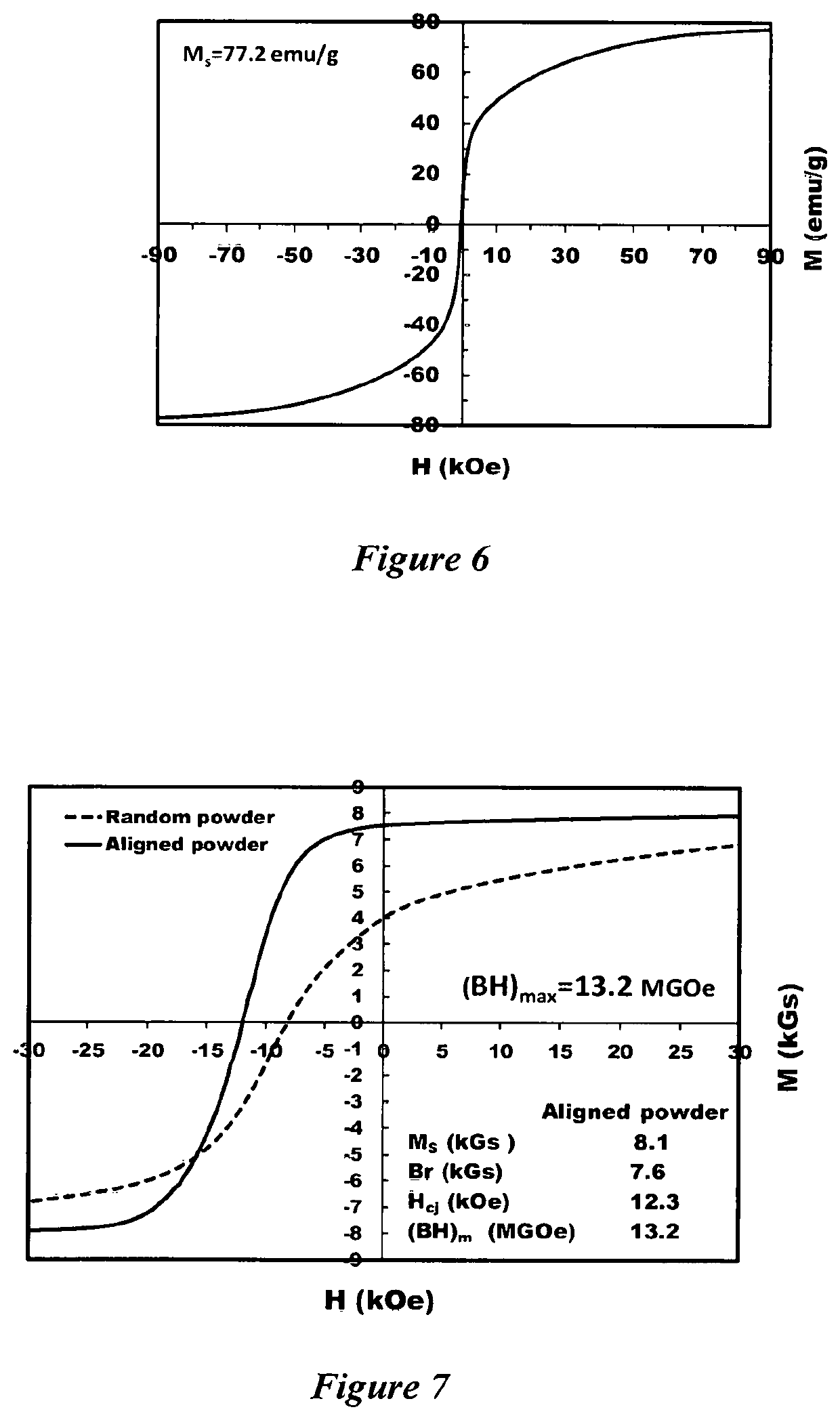

Synthesis of high purity manganese bismuth powder and fabrication of bulk permanent magnet

A synthesis process is disclosed for fabrication of mass quantities of high-purity α-MnBi magnetic powder and subsequent bulk permanent magnet. An illustrative process includes certain steps that include: multiple annealing, multiple comminuting such as multiple ball milling, forming a non-magnetic phase on and / or in the powder particles at particle grain boundaries before particle consolidation such as pressing, and magnetic annealing of a pressed compact. A reproducible and high productive synthesis process is created by combining these steps with other steps, which makes possible production of mass quantities of MnBi powder and bulk magnets with high performance.

Owner:IOWA STATE UNIV RES FOUND

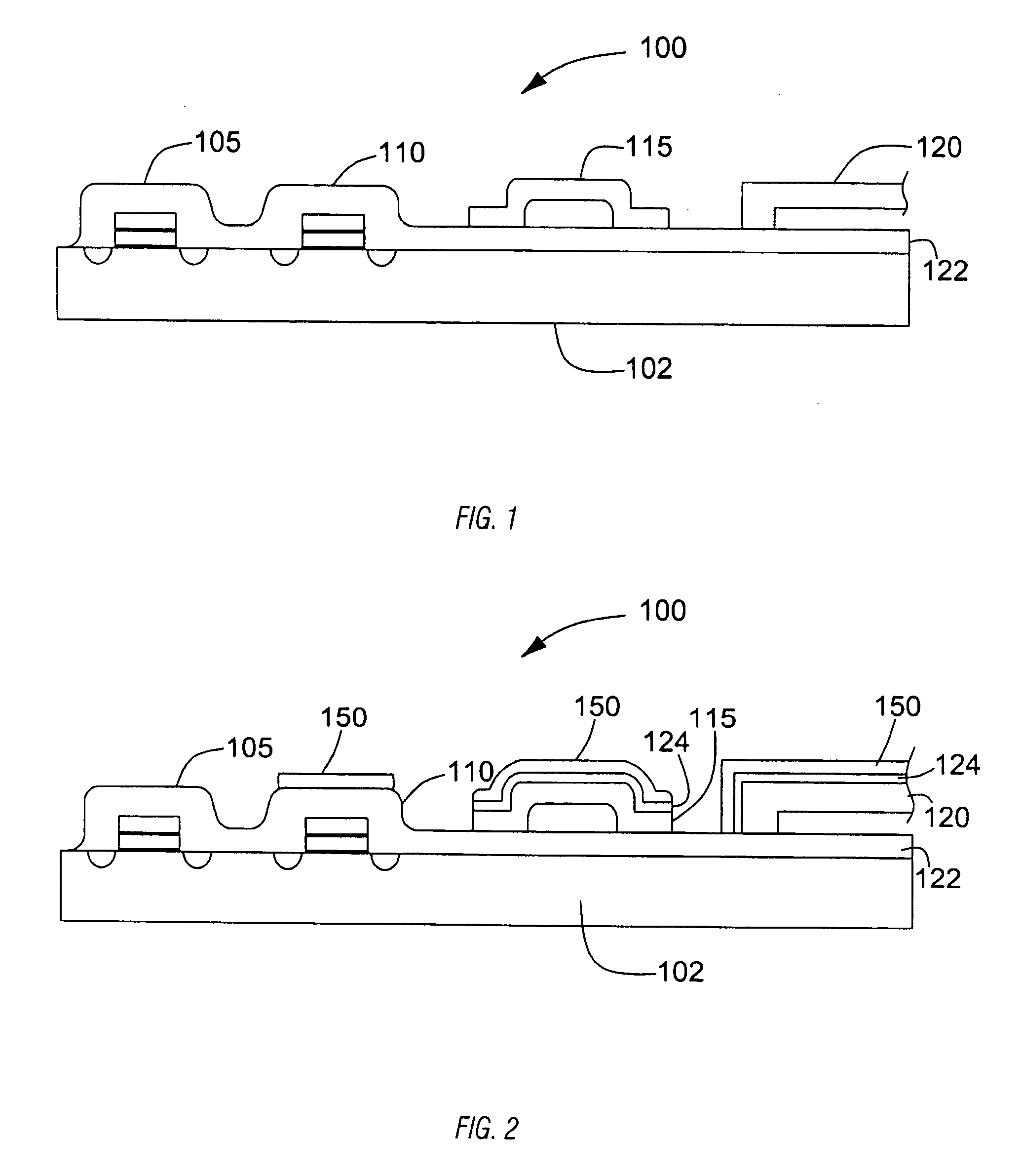

Workpiece magnetizing system and method of operating

An apparatus for magnetic annealing one or more workpieces, and a method of operating the apparatus, are described. The apparatus includes: a workpiece holder configured to support one or more workpieces, wherein the one or more workpieces having at least one substantially planar surface; an optional workpiece heating system configured to elevate the one or more workpieces to an anneal temperature; and a magnet assembly having a first magnet and a second magnet, the first and second magnets defining a gap between opposing poles of each magnet, wherein the magnet assembly is arranged to generate a magnetic field substantially perpendicular to the planar surface of the one or more workpieces.

Owner:TOKYO ELECTRON LTD

CPP GMR read head

InactiveUS7068478B2Improved stability and performanceImprove stabilityNanostructure applicationElectrical transducersLayer thicknessPhysics

Replacing ruthenium with rhodium as the AFM coupling layer in a synthetically pinned CPP GMR structure enables the AP1 / AP2 thicknesses to be increased. This results in improved stability and allows the free layer and AFM layer thicknesses to be decreased, leading to an overall improvement in the device performance. Another key advantage of this structure is that the magnetic annealing requirements (to establish antiparallelism between AP1 and AP2) can be significantly relaxed.

Owner:HEADWAY TECH INC

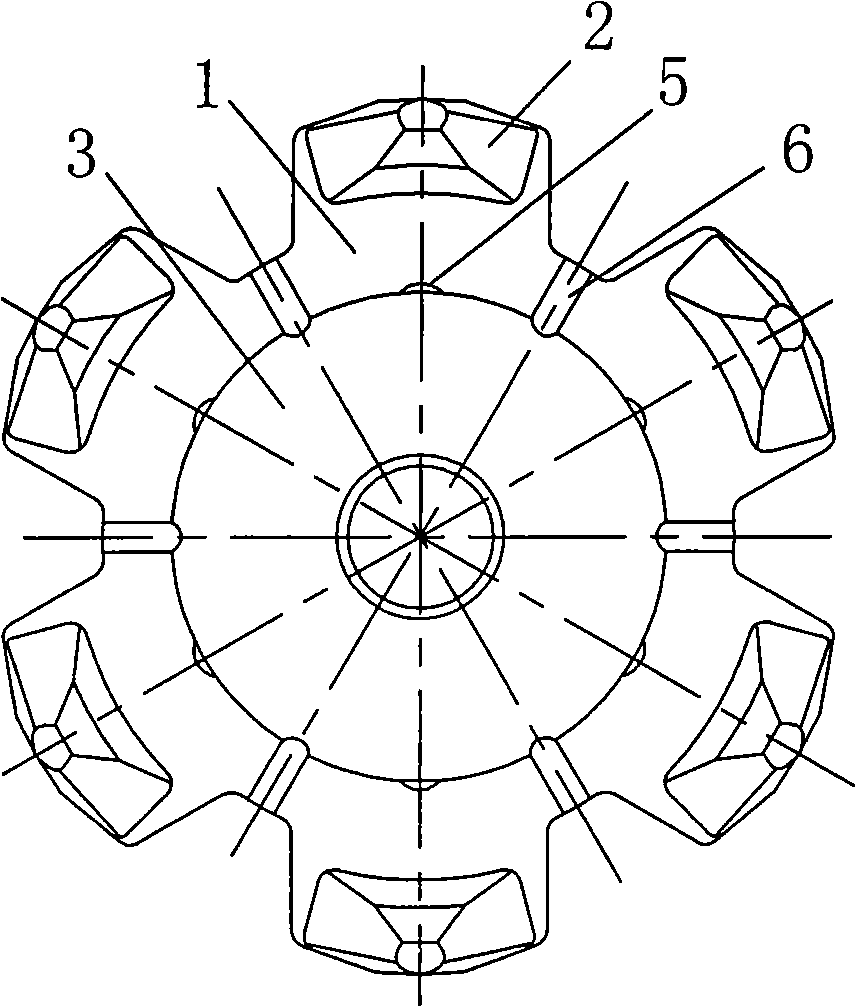

An ultramicrocrystalline iron core strong magnetic annealing process and its special equipment

ActiveCN102496450BReduce flux densityReduce manufacturing costInductances/transformers/magnets manufactureRoom temperatureLinearity

The invention relates to a strong magnetic annealing process for an ultracrystalline iron core. The process comprises the following steps of: (1) placing the ultracrystalline iron core in a heat treatment area of a square furnace to make the axial direction of the ultracrystalline iron core upward, gradually raising the internal temperature of the square furnace to 475 DEG C, and uniformly heating the ultracrystalline iron core; (2) pushing the square furnace into a strong magnetic field to make the square furnace in the center of the strong magnetic field; (3) keeping the internal temperature of the square furnace at 475 to 495 DEG C, and taking the square furnace out of the strong magnetic field after 3 to 4 hours; (4) raising the internal temperature of the square furnace which is taken out of the strong magnetic field to 565 DEG C, and keeping the temperature for 2 to 3 hours; and (5) after the step (4) is finished, naturally reducing the internal temperature of the square furnace to room temperature to finish the strong magnetic annealing process for the ultracrystalline iron core. By adoption of the strong magnetic annealing process for the ultracrystalline iron core, residual magnetism and magnetic conductivity are effectively controlled, linearity is improved, the whole process is simple and convenient, cutting of the ultracrystalline iron core is not required, production cost is reduced, and product yield is improved.

Owner:TIANJIN AONA TECH

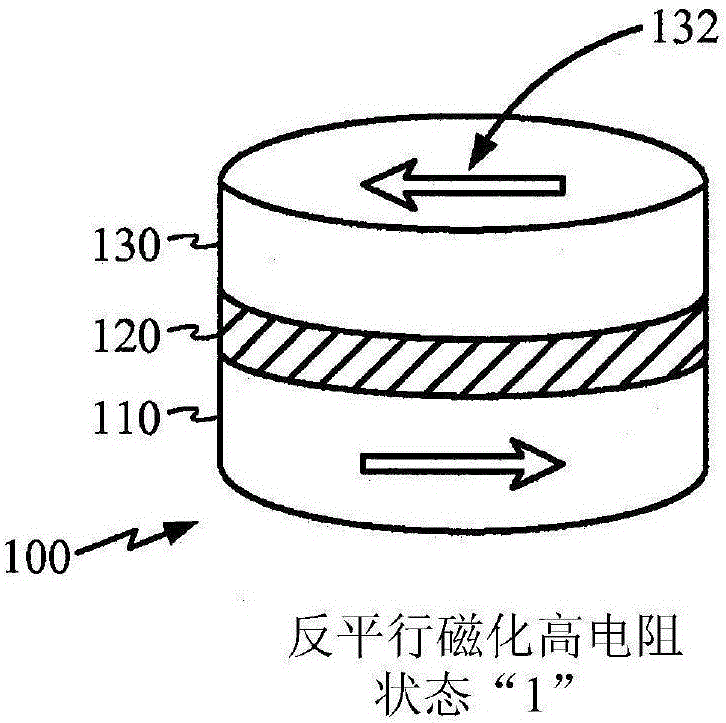

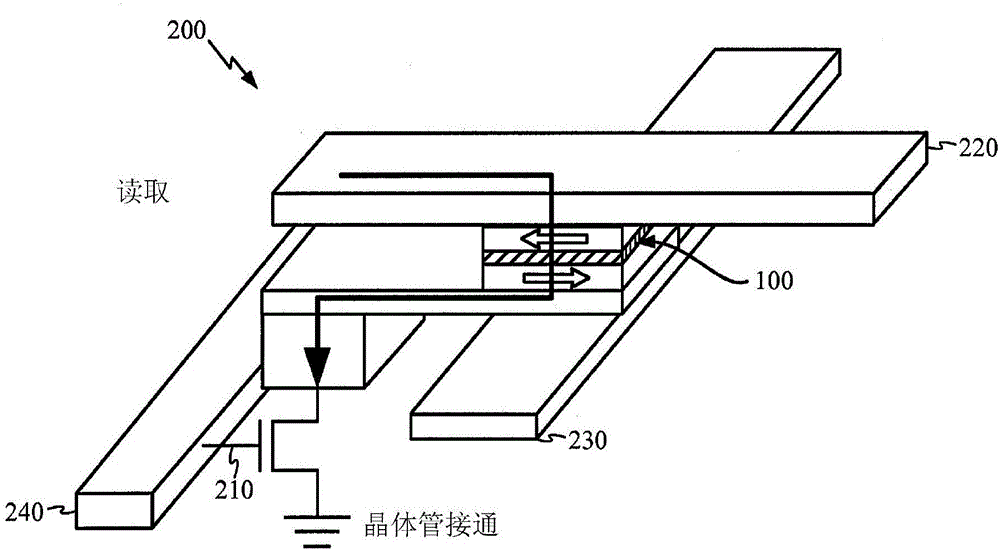

mram sensing using magnetically annealed reference cells

Systems and methods for reading / sensing data stored in magnetoresistive random access memory (MRAM) cells using magnetically annealed reference cells are disclosed. The MRAM includes a reference circuit (570) that includes at least one magnetic storage cell (506), wherein each magnetic storage cell in the MRAM is programmed to the same state. The reference circuit includes a load element coupled to the magnetic memory cell, wherein the load element (512) is configured to establish a reference voltage during a read operation.

Owner:QUALCOMM INC

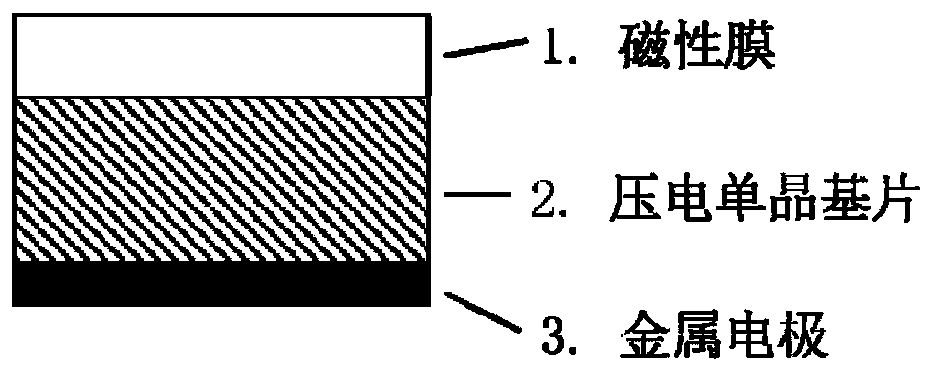

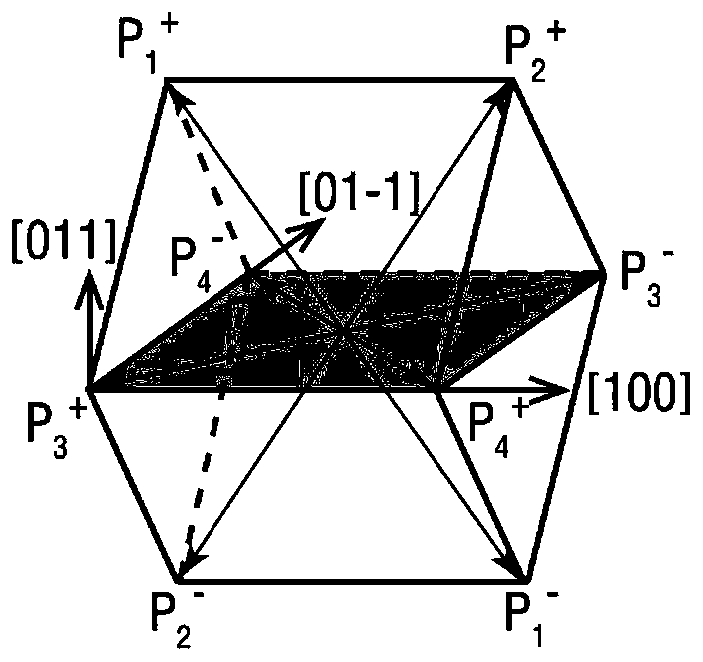

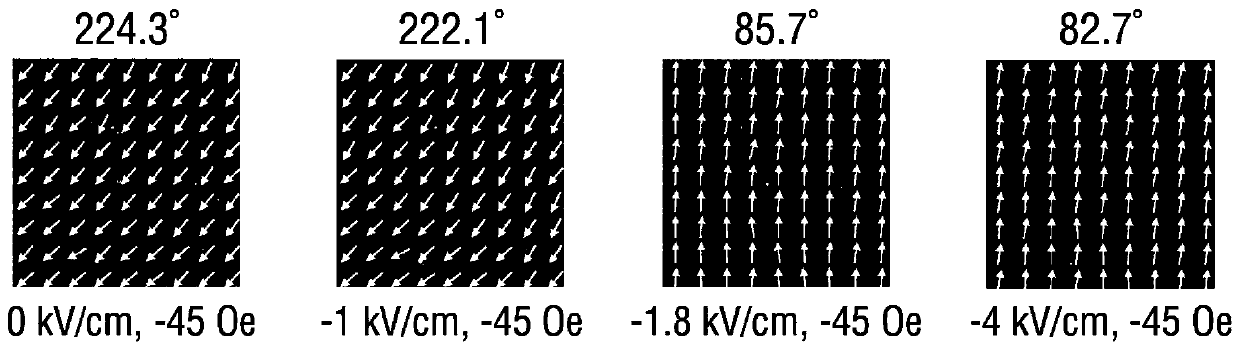

Method for realizing magnetic domain overturning by adopting piezoelectric shearing mode

ActiveCN111312890ASimple structureSimple processMagnetic-field-controlled resistorsVacuum evaporation coatingHeterojunctionMagnetic storage

The invention discloses a method for realizing magnetic domain overturning by adopting a piezoelectric shearing mode. The method comprises the steps of 1 preparing a magnetoelectric heterojunction; and 2 enabling shear strain generated by electric field induction and a direct-current bias magnetic field to jointly act on the magnetoelectric heterojunction. The magneto-electric heterojunction required by the invention is composed of a common commercial rhombohedral phase piezoelectric single crystal substrate and an industrially common magnetic single-layer film, and the structure is simple. Strong shape anisotropy does not need to be introduced through micromachining process, and bias magnetic field does not need to be applied in the preparation process or exchange bias does not need to beintroduced through subsequent magnetic annealing. Magnetization overturning with electric field regulation and control local magnetic domain larger than 90 degrees can be achieved through magnetoelectric effect of shear strain modulation. The process is simple, and energy consumption is low. The method has important significance in developing low-power-consumption magnetic storage and logic devices.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com