An ultramicrocrystalline iron core strong magnetic annealing process and its special equipment

An annealing process and ultra-microcrystalline technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of complex process, increased excitation power, unsuitable use, etc., to achieve simple overall process and reduce magnetic flux Density, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Common mode inductor core on frequency conversion air conditioner

[0042] Such as 32 / 20*10, weight 27g, technical requirements: 1kHz / 0.3V, L>60uH; 100KHz / 0.3V, L>6uH.

[0043] The comparison of the two heat treatment processes is as follows:

[0044]

Embodiment 2

[0046] Inverter welding machine transformer core

[0047] For the inverter welding machine transformer core, we hope that its primary no-load single-turn saturation voltage is as high as possible, so that the number of primary winding turns can be reduced. Taking 100 / 50*25 as an example, N1=6 turns. Comparison of two annealing processes:

[0048]

[0049]

[0050] It can be seen from the above that the annealing process under a strong magnetic field has its unique advantages, which makes the performance of the iron core and the design of components more optimized, and is more in line with the development direction of miniaturization, light weight and energy saving of electronic components.

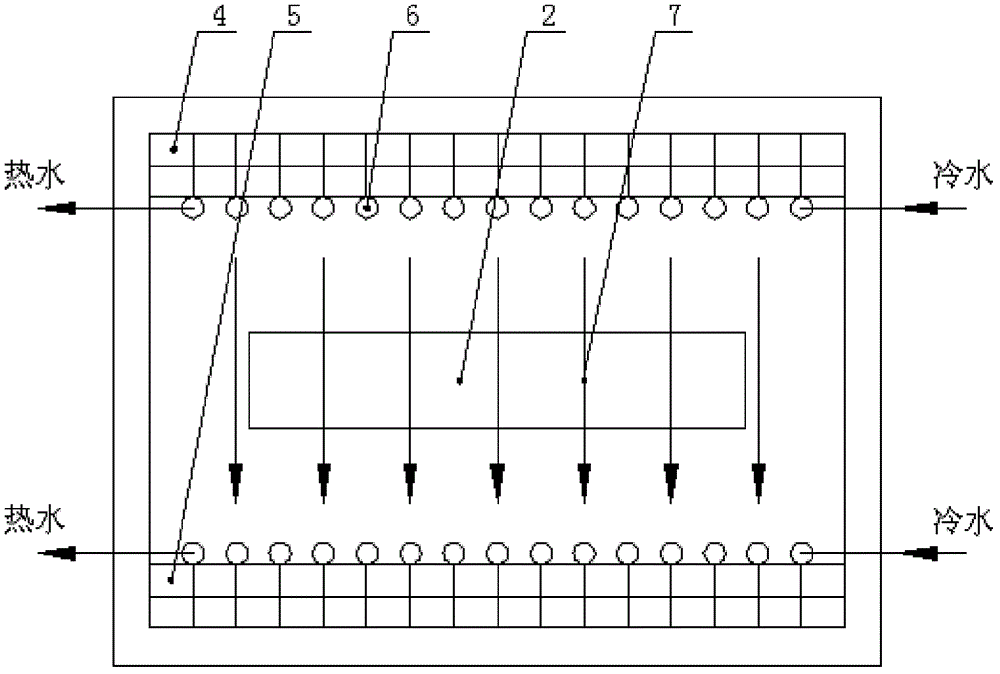

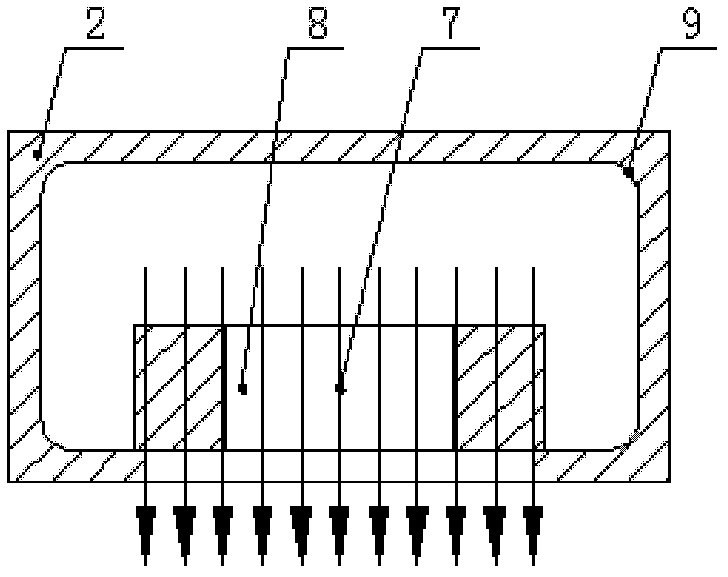

[0051] In the present invention, a uniformly covered strong magnetic field is formed by a magnetically conductive frame and a permanent magnet, and the ultramicrocrystalline iron core is subjected to a strong magnetic field treatment after the temperature of the ultramicrocrystallin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com