Plasma processing system, plasma processing method, plasma film deposition system, and plasma film deposition method

a plasma processing system and plasma technology, applied in the field of plasma processing system, plasma processing method, plasma film deposition system, plasma film deposition method, can solve the problems of difficult to generate uniform plasma, lowering efficiency, overheating or causing particles by etching action, etc., to suppress the effect of device destruction of the substrate due to the charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0079] A second embodiment will be described based on FIG. 3.

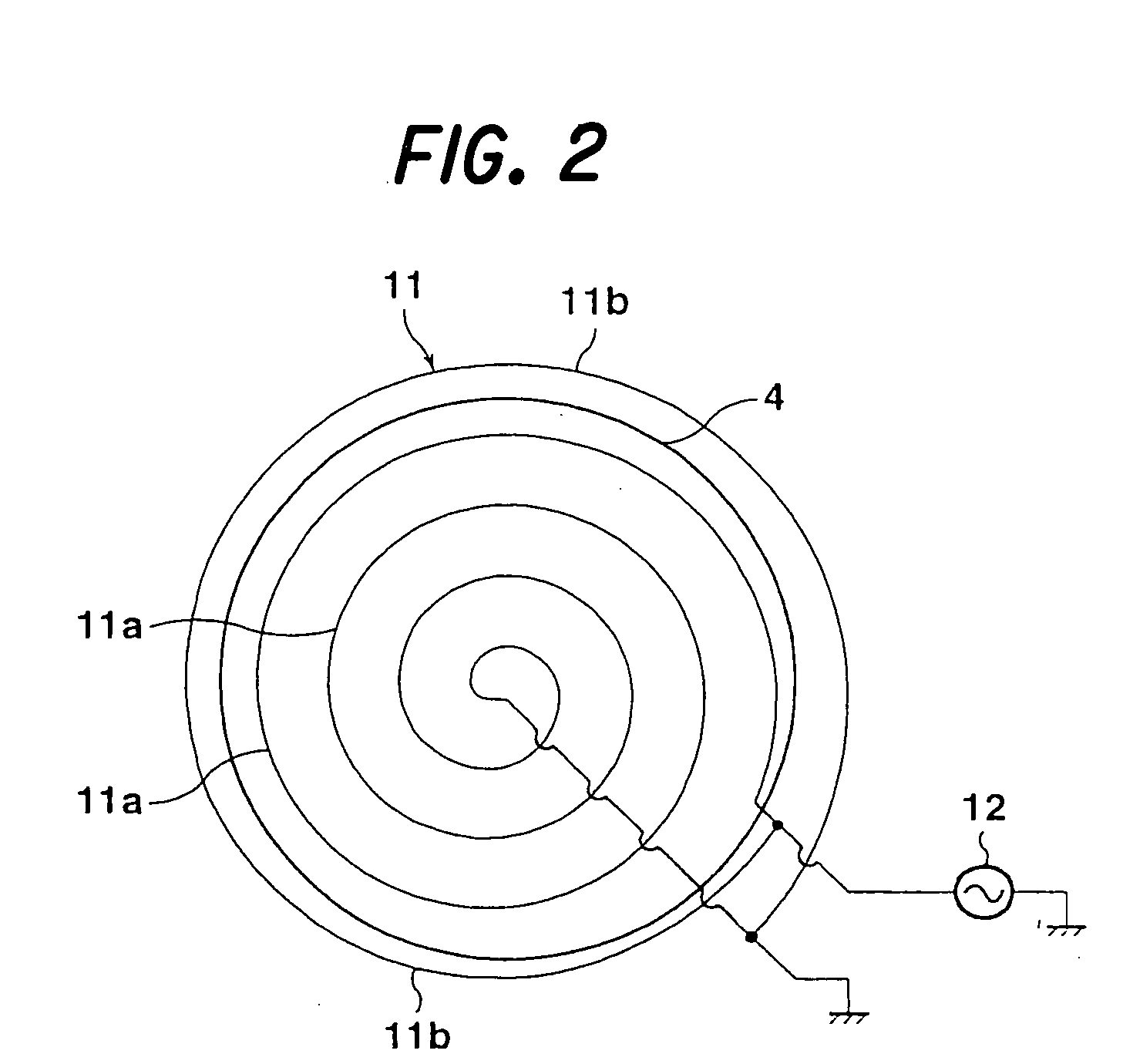

[0080] In the embodiment shown in FIG. 3, a high frequency antenna 11, as an antenna, is the same as that in FIGS. 1 and 2 in terms of its feature, and is in the form of a flat coil. A high frequency power source 12 is connected to the site of the antenna 11a, while a second high frequency power source 21 as second power supply means is connected to the site of a second antenna 11b. An electric current is supplied from the second high frequency power source 21 to the site of the second antenna 11b in a state of connection opposite to that for the site of the antenna 11a. In detail, at the site of the second antenna 11b, the high frequency power source 12 is connected to the coil on the grounded side at the site of the antenna 11a, so that the coil at the site of the antenna 11a on a side, where the high frequency power source 12 is connected, is brought into a grounded state.

[0081] Because of the above-described feature, ...

third embodiment

[0083] A third embodiment will be described based on FIG. 4.

[0084] In the embodiment shown in FIG. 4, a flat coil-shaped high frequency antenna 22, as an antenna having nearly the same diameter as the diameter of a ceiling plate 4, is disposed. A second antenna 23, having a different feature from that of the high frequency antenna 22, is disposed outside of the high frequency antenna 22, namely, outwardly of the ceiling surface. A high frequency power source 12 is connected to the high frequency antenna 22, while a second high frequency power source 24 as second power supply means is connected to the second antenna 23. The high frequency antenna 22 and the second high frequency power source 24 are connected to the high frequency power source 12 and the second high frequency power source 24 in the same direction. The second high frequency power source 24 is connected to the second antenna 23 via a phase shifter 25 as phase changing means.

[0085] An electric current of a phase opposit...

fourth embodiment

[0087] A fourth embodiment will be described based on FIG. 5.

[0088] In the embodiment shown in FIG. 5, a high frequency antenna 31, which has nearly the same diameter as the diameter of a ceiling plate 4, is composed of antennas 31a, 31b, 31c and 31d each in the form of a concentric ring. A ring-shaped second antenna 32 is disposed outside of the high frequency antenna 31, namely, outwardly of the ceiling surface. A high frequency power source 12 is connected in parallel to the antennas 31a, 31b, 31c, 31d, and the second antenna 32 is connected to the high frequency power source 12 in a state of connection opposite to that for the ring antenna 31. That is, the second antenna 32 is connected to the high frequency power source 12 in a state opposite to the state of connection of the antenna 31 to the high frequency power source 12, namely, such that the connected side and the grounded side for the second antenna 32 are opposite to those for the antenna 31.

[0089] Because of this featu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com