The method of removing dummy gate

A dummy gate and wet etching technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems affecting transistor performance, substrate damage, etc., achieve low electron temperature, not easy to damage, and reduce accumulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

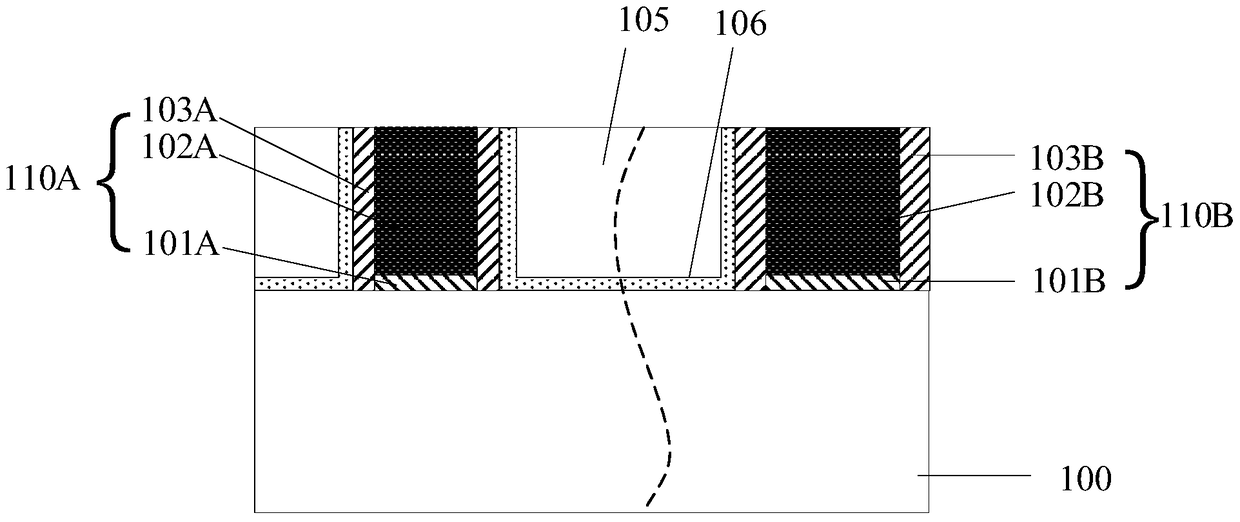

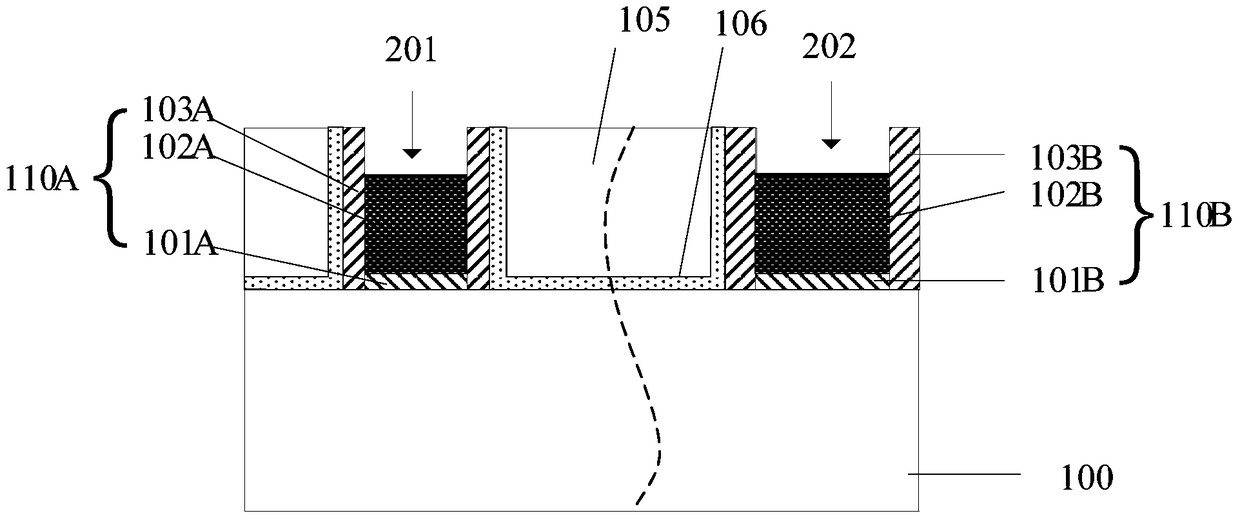

[0027] In the prior art, plasma etching and wet etching are generally performed in sequence to remove the dummy gates, wherein the plasma etching causes relatively large damage to the substrate.

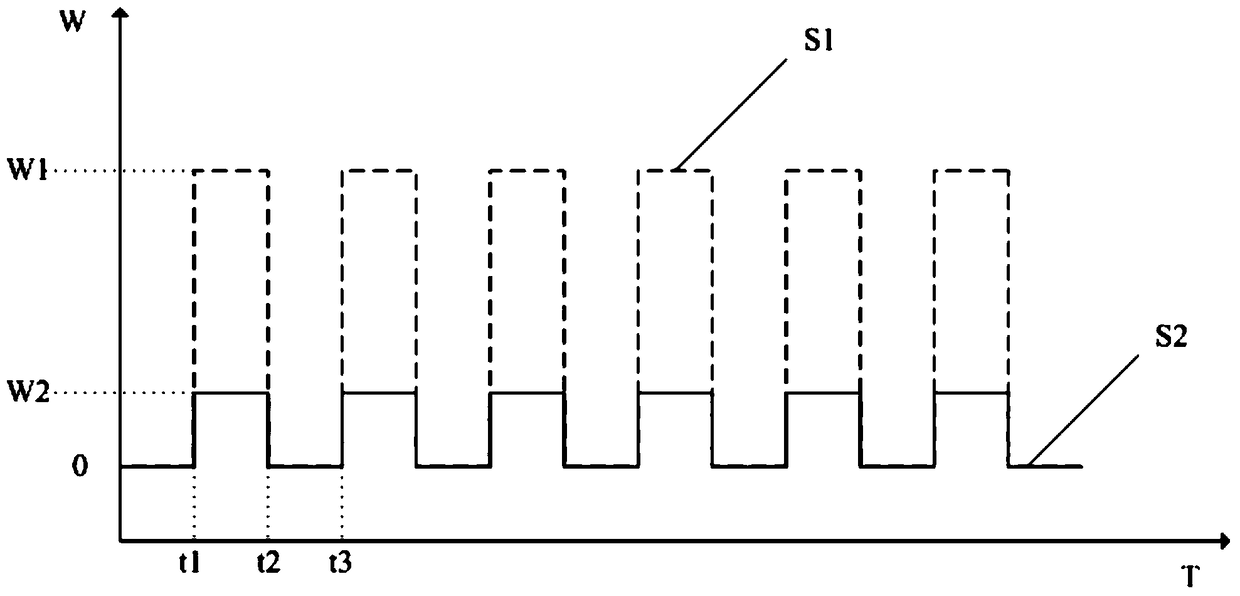

[0028] The damage to the substrate can be roughly divided into two types: the damage to the substrate performance and the damage to the substrate morphology, and the damage to the substrate morphology will also affect the performance of the substrate. In the process of plasma etching, the plasma with high electron temperature easily enters the substrate under the dummy gate, which affects the performance of the carrier distribution in the substrate such as holes, thereby affecting the performance of the transistor; The vacuum ultraviolet (Vacuum Ultraviolet, VUV) generated by the plasma etching process irradiates the semiconductor substrate, which will also cause damage to the substrate performance; in addition, plasma etching has different etching rates for dummy gates of different s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com