Microwave counter current continuous extraction apparatus

An extraction device and microwave countercurrent technology are applied in the structural field of microwave countercurrent extraction devices, which can solve the problems of increased cost, low concentration, no observation window, etc., and achieve the effects of reasonable design, reduced equipment cost, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

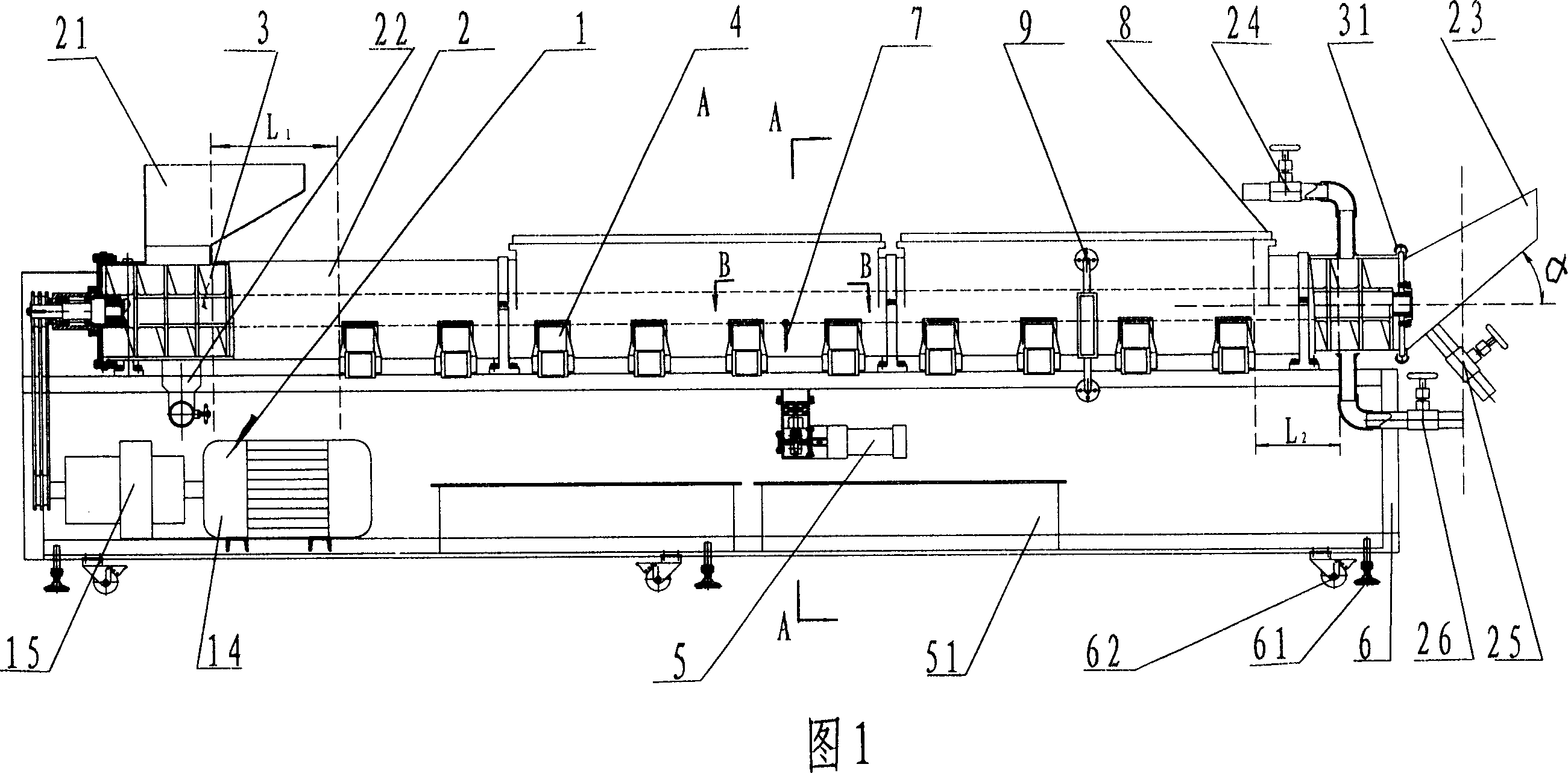

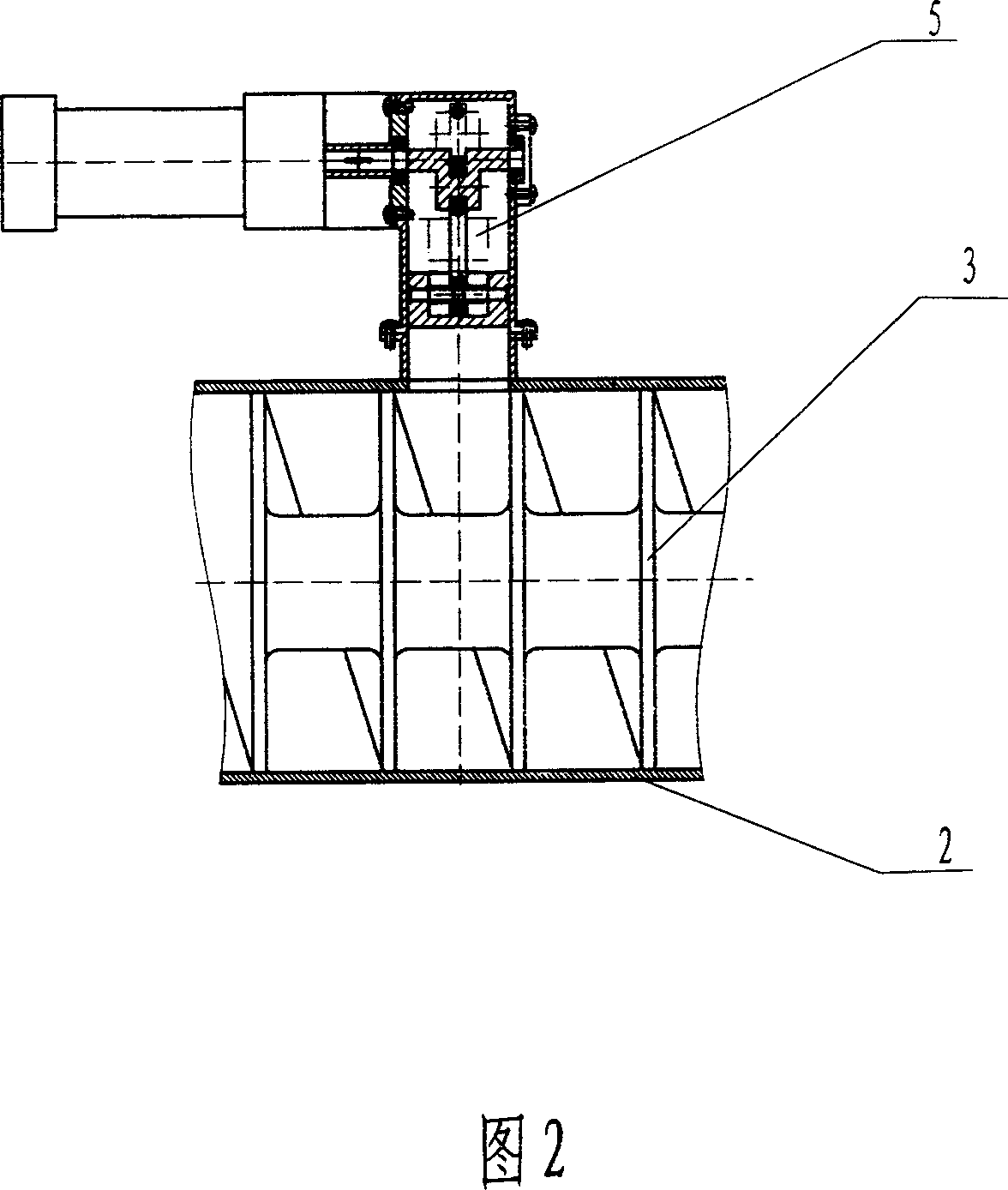

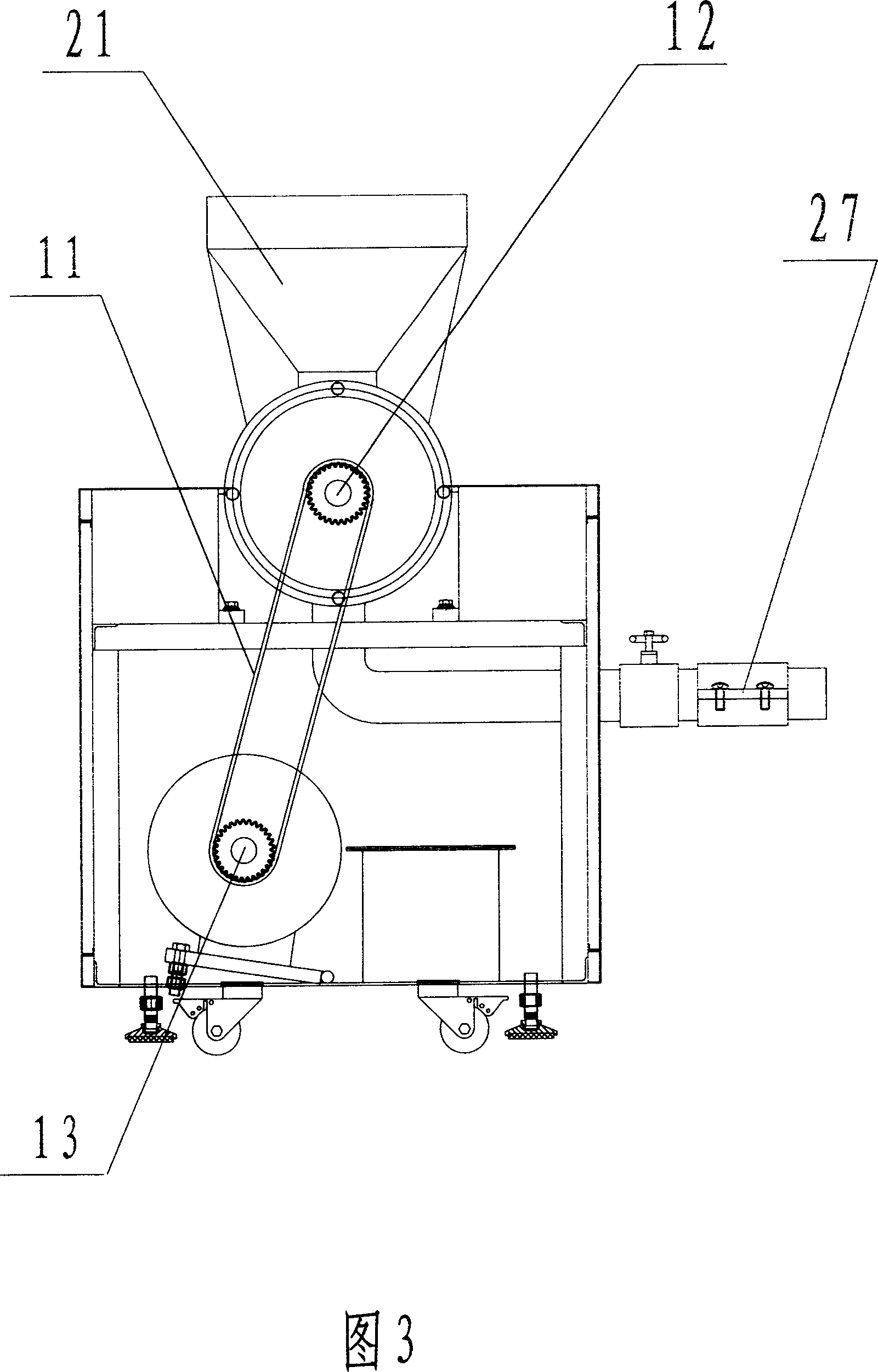

[0029] Embodiment 1: see Fig. 1, Fig. 2, Fig. 3, Fig. 9, microwave countercurrent continuous extraction device, extraction drum 2, its one end is provided with feeding hopper 21 and extraction solution outlet 22, and the other end is provided with slag outlet 23 and The extraction liquid inlet 24; the microwave system 4 is provided on the extraction drum 2, and the inner cavity of the extraction drum 2 is provided with a screw propeller 3. The main sprocket 13 is driven by the motor 14 through the speed reducer 15, and the main sprocket 13 drives the screw propeller 3 through the chain 11 and the sprocket 12. The microwave system 4 is located in the middle of the extraction drum 2 . The extraction drum 2 is arranged horizontally and is horizontal; the screw propeller 3 and the extraction drum 2 are both arranged horizontally and is horizontal, and the two axes coincide. The extraction drum 2 is provided with a pressurizing device 5 , and its pressure output port communicates ...

Embodiment 2

[0034]Embodiment 2: see Fig. 4, the screw propeller 3 that is provided with in the inner cavity of the extraction drum 2, the material used for the screw propeller 3 is polypropylene. Axial through-holes 31 are provided on its spiral blade surface. The diameter of the through hole 31 is φ1.5mm. The distance L between the axis of the feed hopper 21 and the start end of the microwave system 4 1 is 2500mm; the distance L between the end of the microwave system 4 and the end of the extraction drum 2 2 It is 2500mm. The diameter of screw propeller 3 is φ 3500mm. The rest of the structure is the same as the previous example.

Embodiment 3

[0035] Embodiment 3: See FIG. 1 , on the basis of the above two embodiments, the material used for the screw propeller 3 is ceramics. The rest of the structure is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com