Heat pump type tableware washer and control method thereof

A dishwashing machine and heat pump technology, applied in dishwashing machine/rinsing machine parts, refrigerators, refrigeration components, etc., can solve problems such as low energy utilization efficiency, achieve improved energy utilization, smooth air circulation, avoid The effect of poor air circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0045] The present invention will be described in detail below with reference to the accompanying drawings and examples.

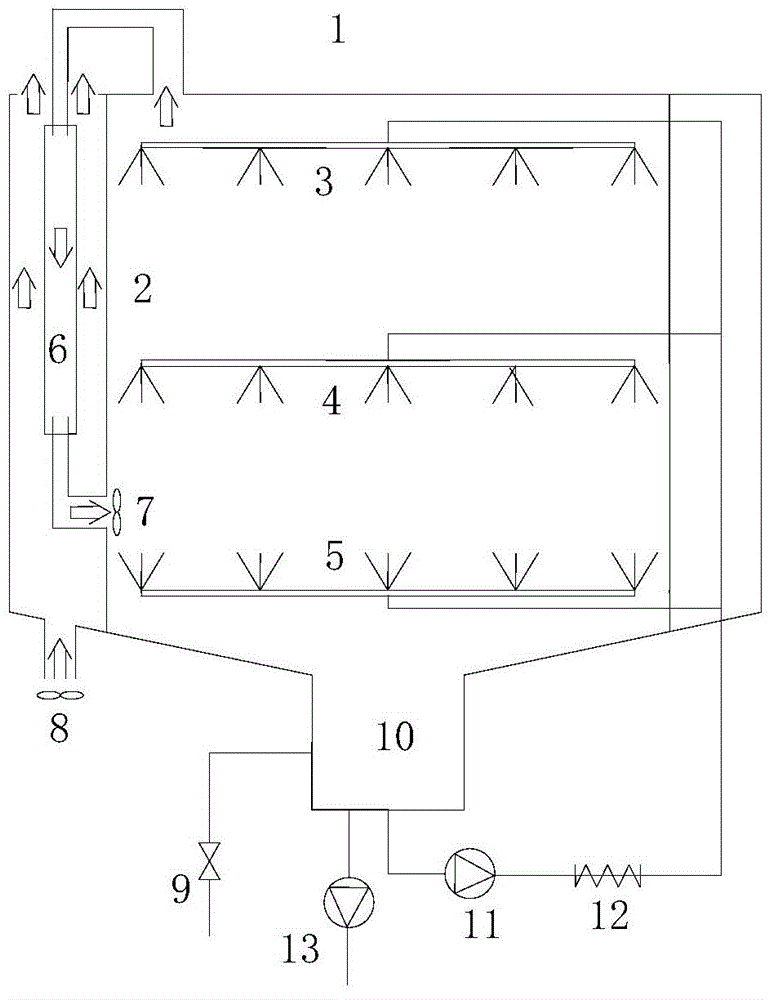

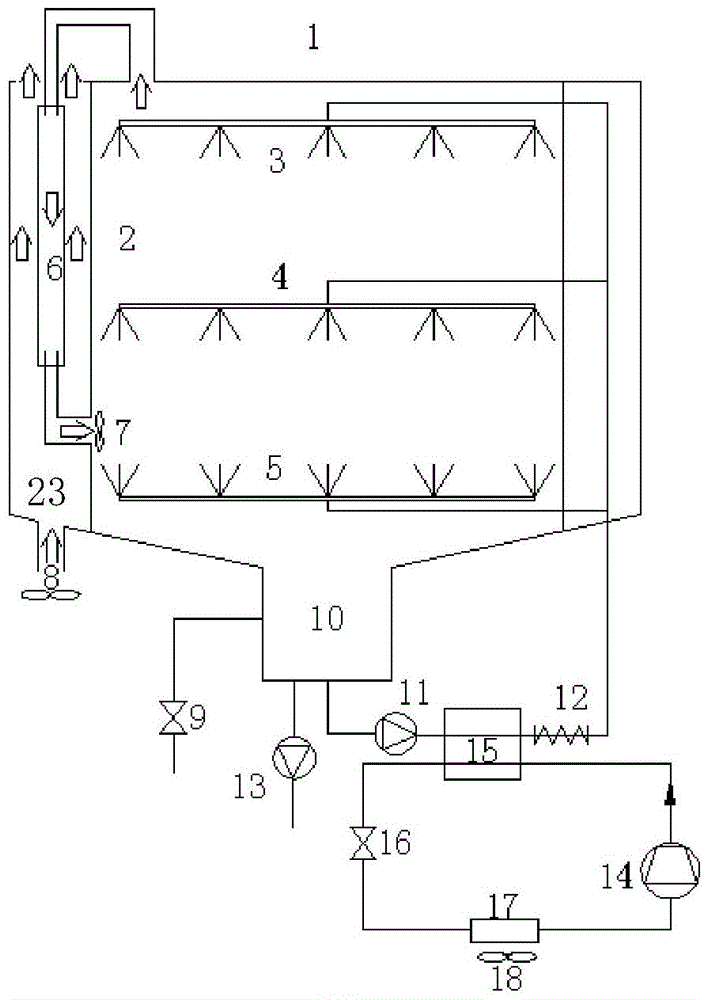

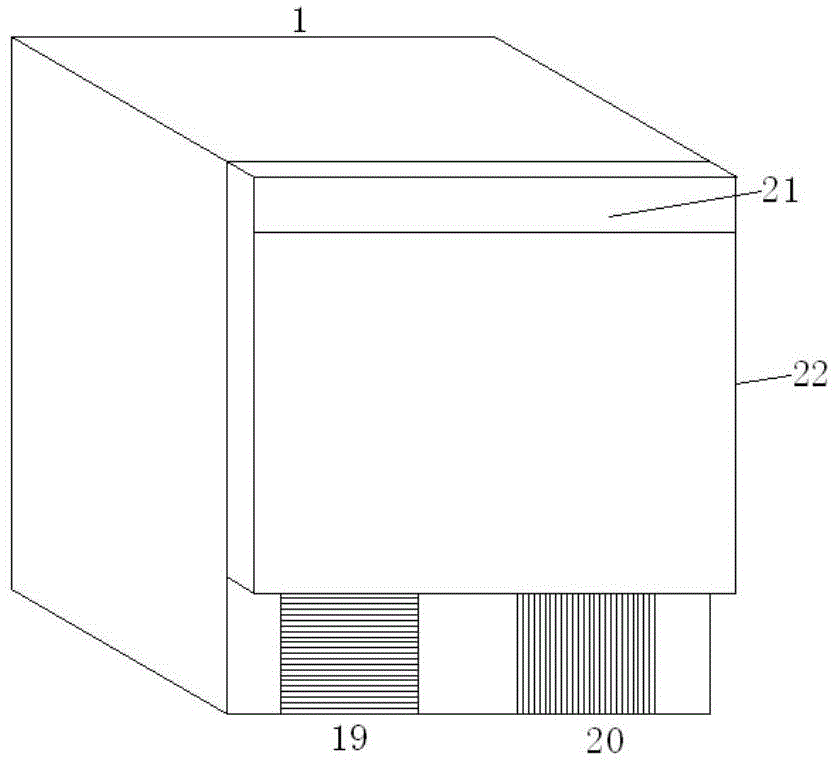

[0046] The present invention proposes a heat pump dishwasher, such as figure 2 As shown, the main components are: 1-cleaning machine; 2-processing chamber; 3-upper spray arm; 4-middle spray arm; 5-bottom spray arm; 6-condenser for drying; 7-inner fan ;8-outside fan; 9-inlet valve; 10-water collection tank; 11-circulating water pump; 12-electric heater; 13-drainage pump; 14-compressor; 15-condenser; 16-throttling device; 17 -evaporator; 18-evaporator fan; 19-inlet; 20-outlet; 21-control panel; 22-load switch door.

[0047] The cutlery is located in a fixed basket in the treatment chamber 2 .

[0048] The condenser 6 for drying is located in the gap between the side of the processing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com