Patents

Literature

256 results about "Decreased energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

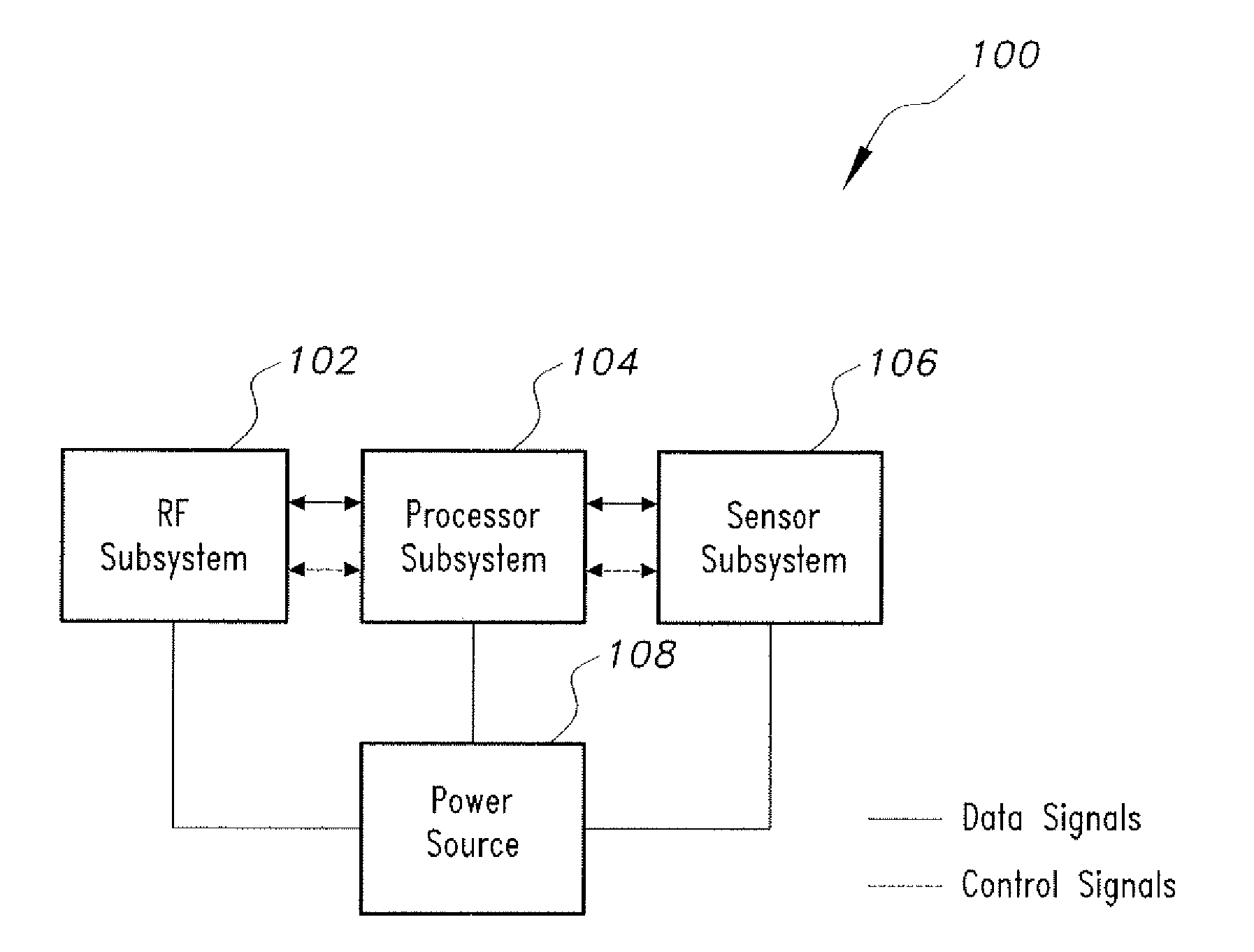

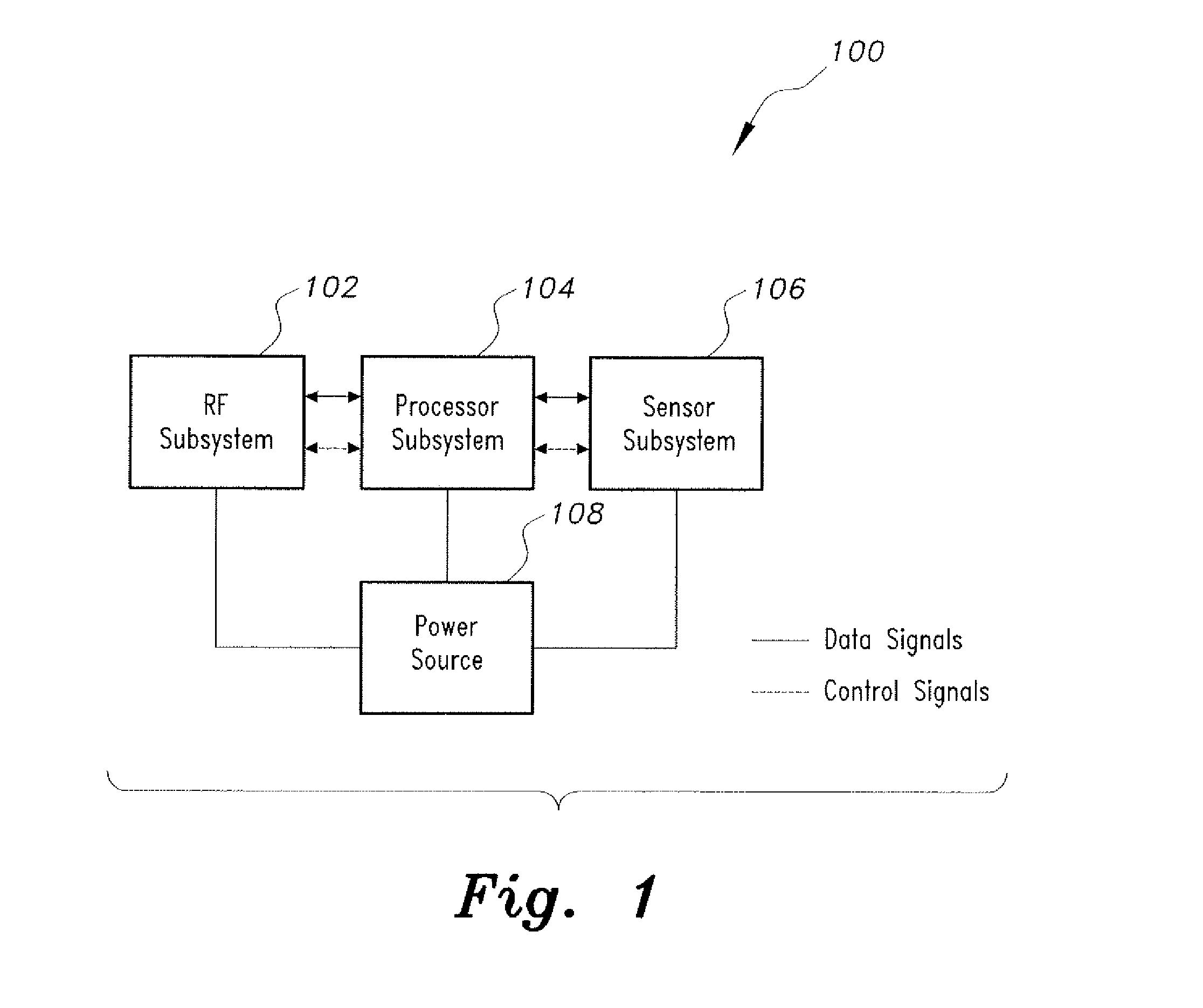

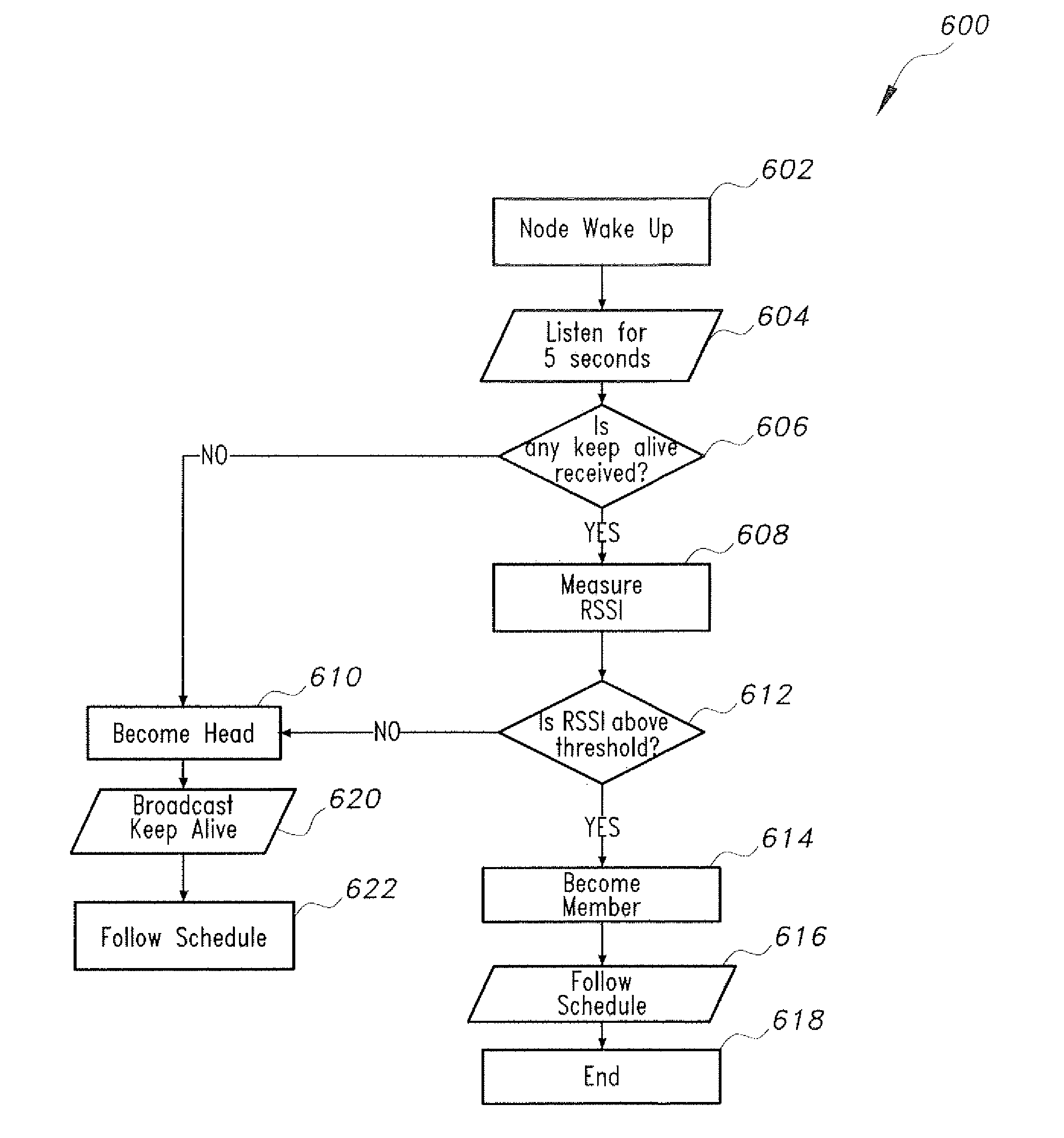

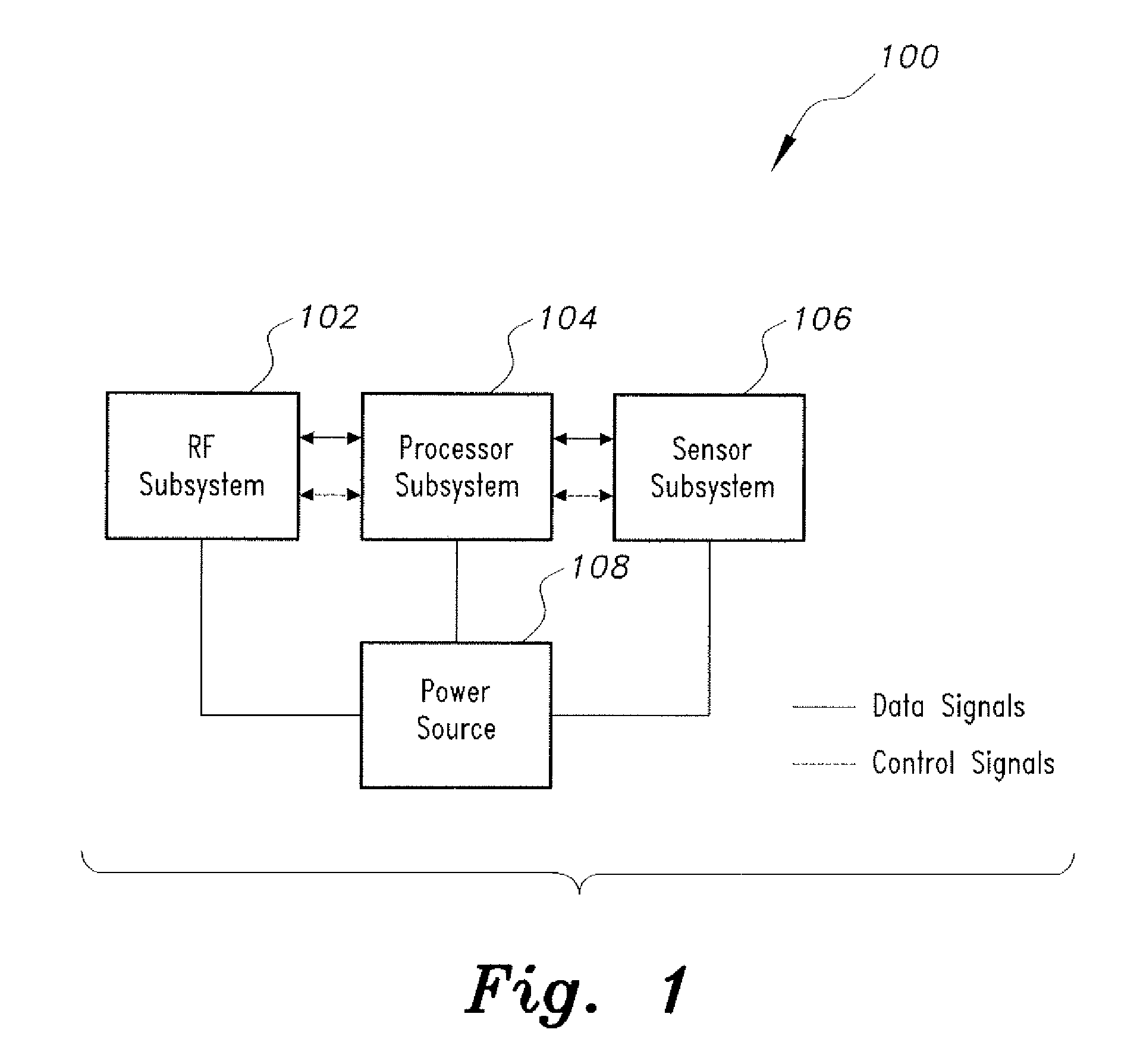

Wireless sensor network with energy efficient protocols

InactiveUS20130128786A1Small sizeReduce the overall heightPower managementEnergy efficient ICTWireless mesh networkWireless sensor network

The wireless sensor network with energy efficient protocols includes a network of external sensors in communication with a data sink. The network utilizes an algorithm integrating a modified S-MAC (an algorithm for medium access control) protocol for decreasing energy usage in operating the node and associated sensors. A routing protocol is further integrated into the algorithm, the routing protocol being based upon cluster head rotation.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS +1

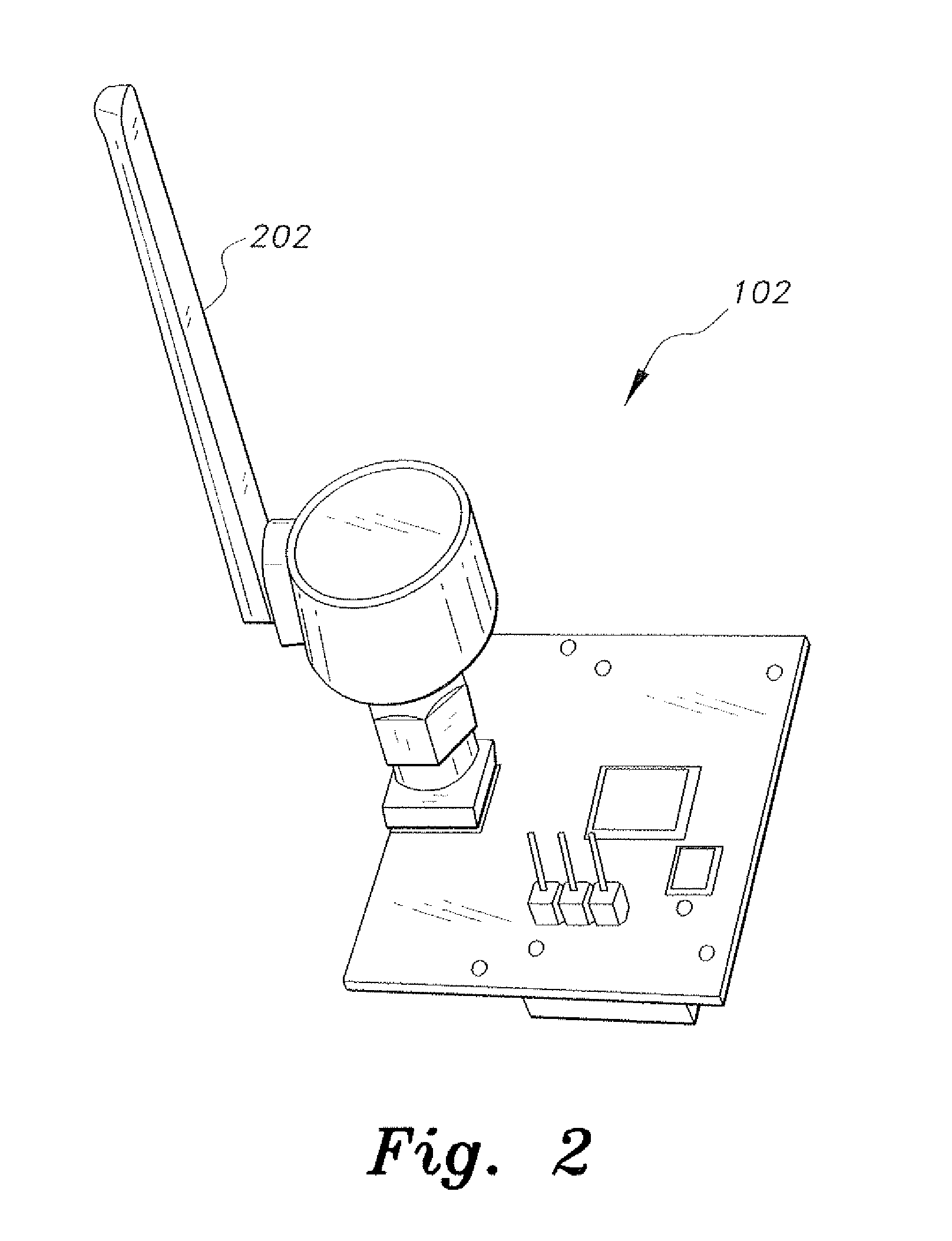

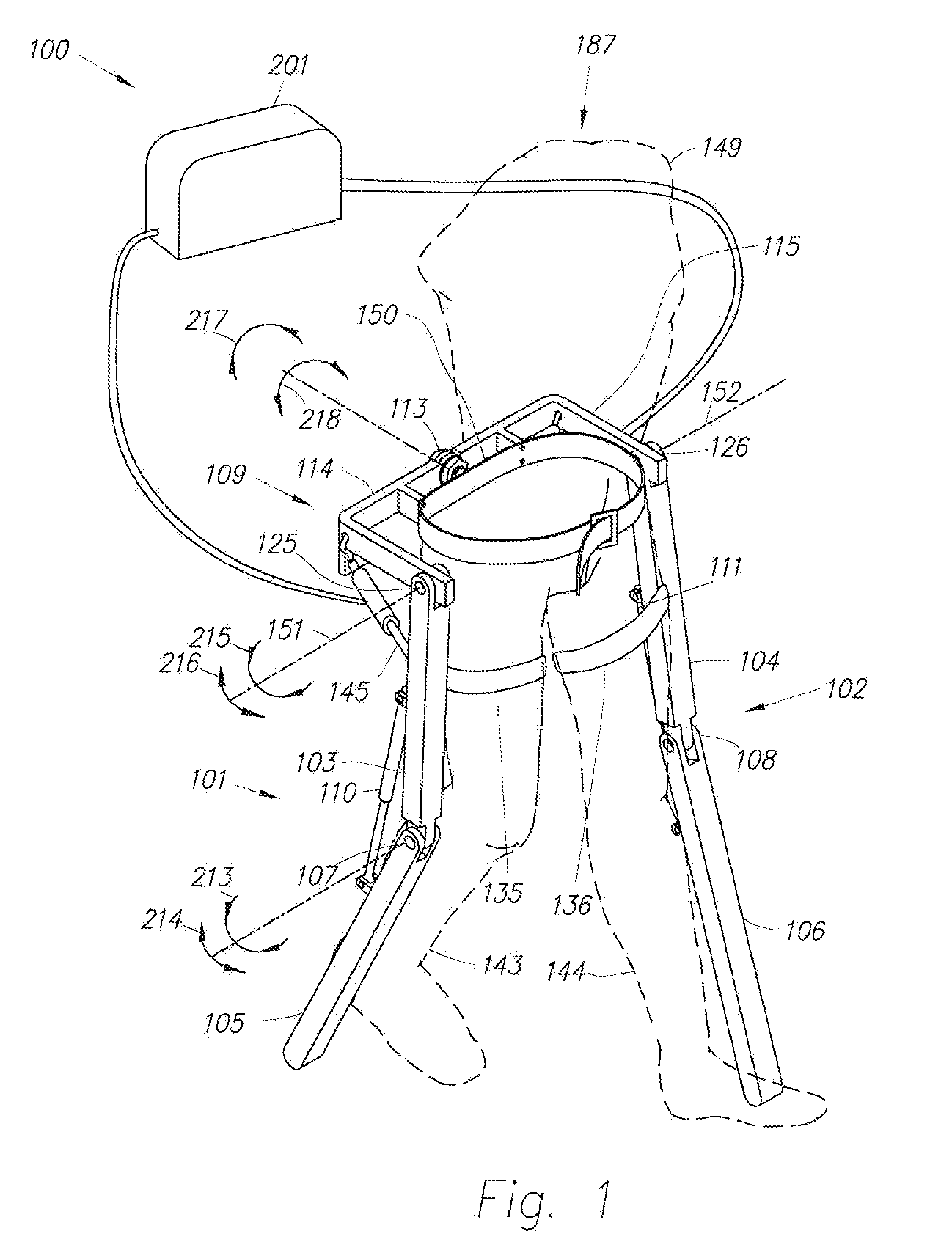

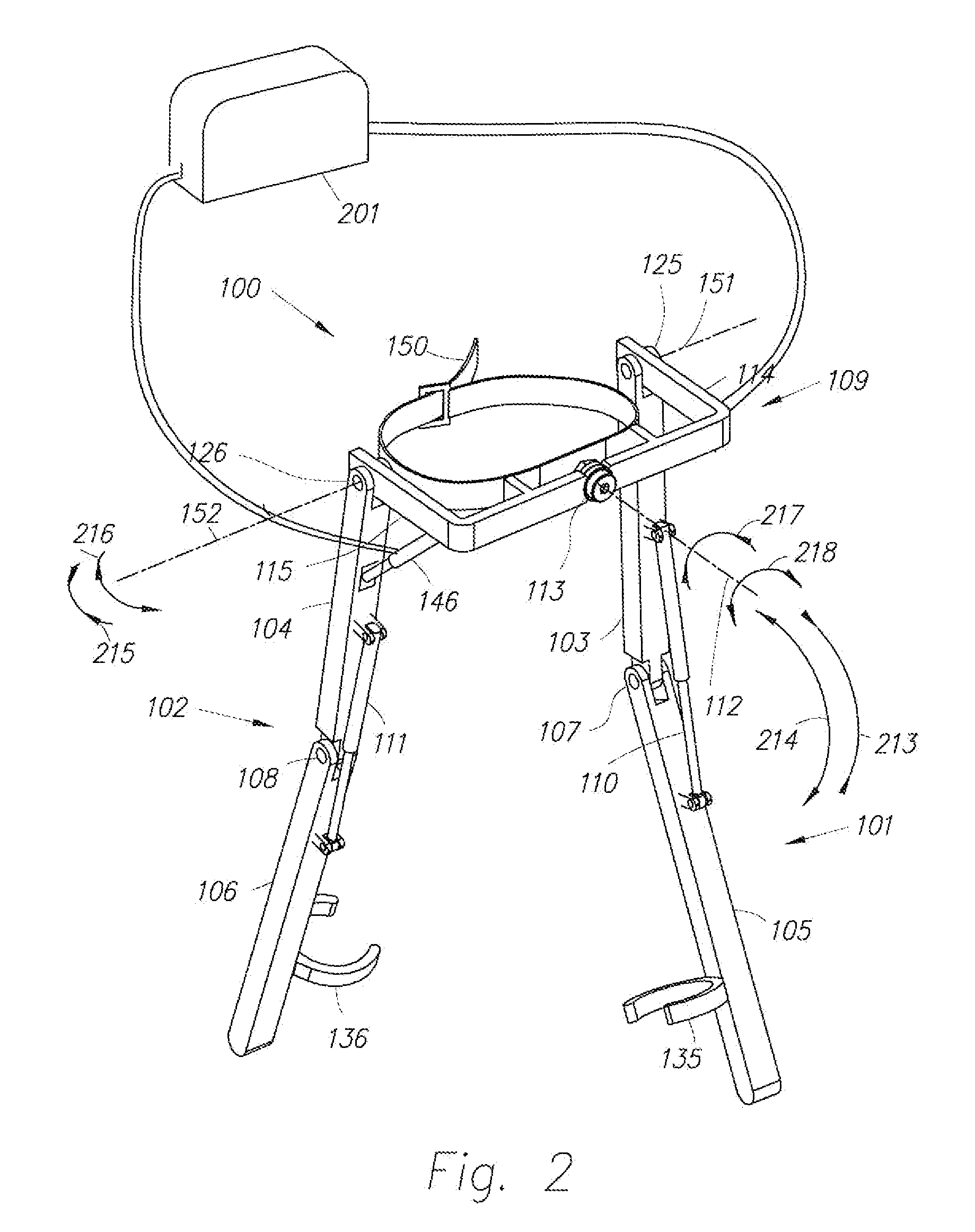

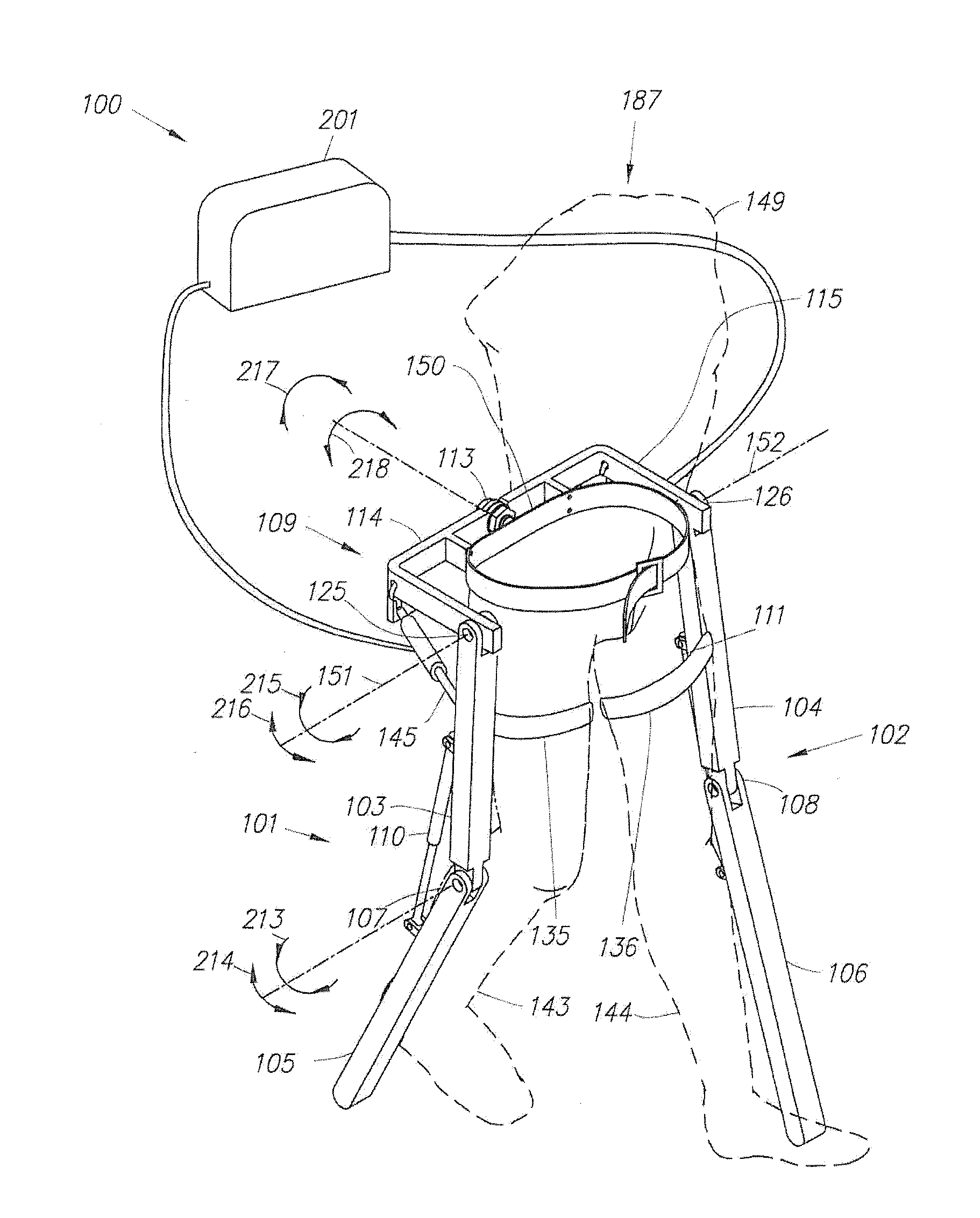

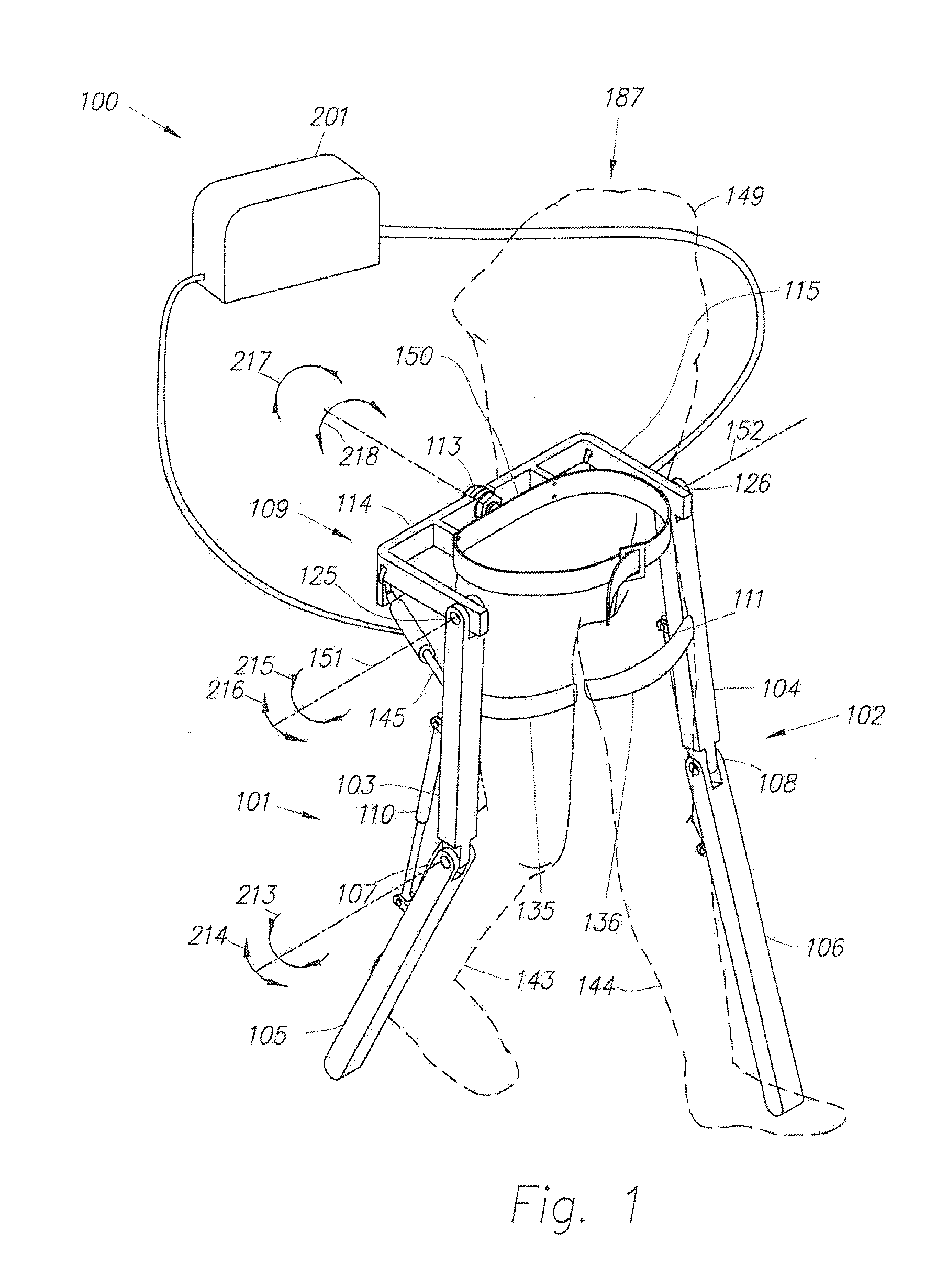

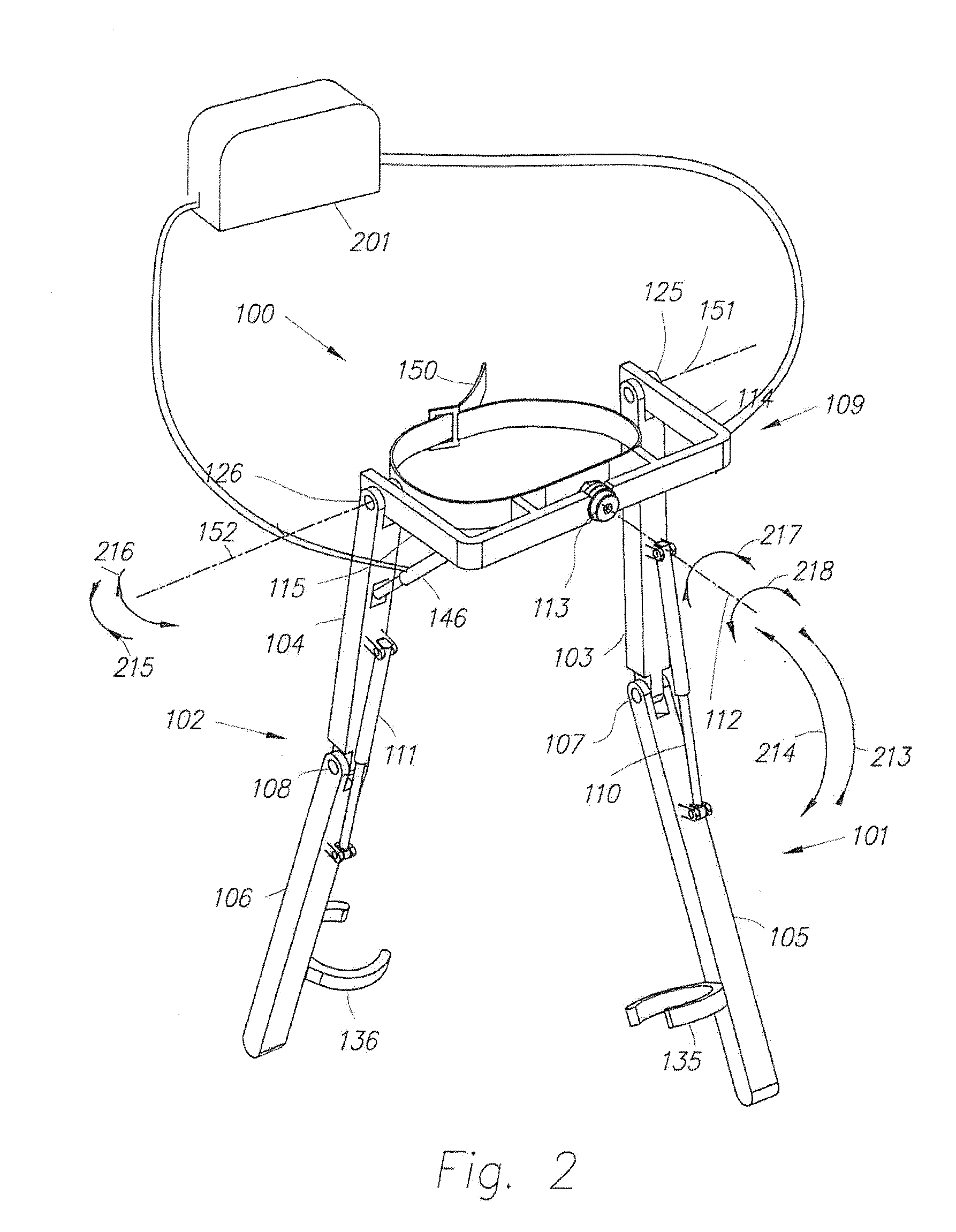

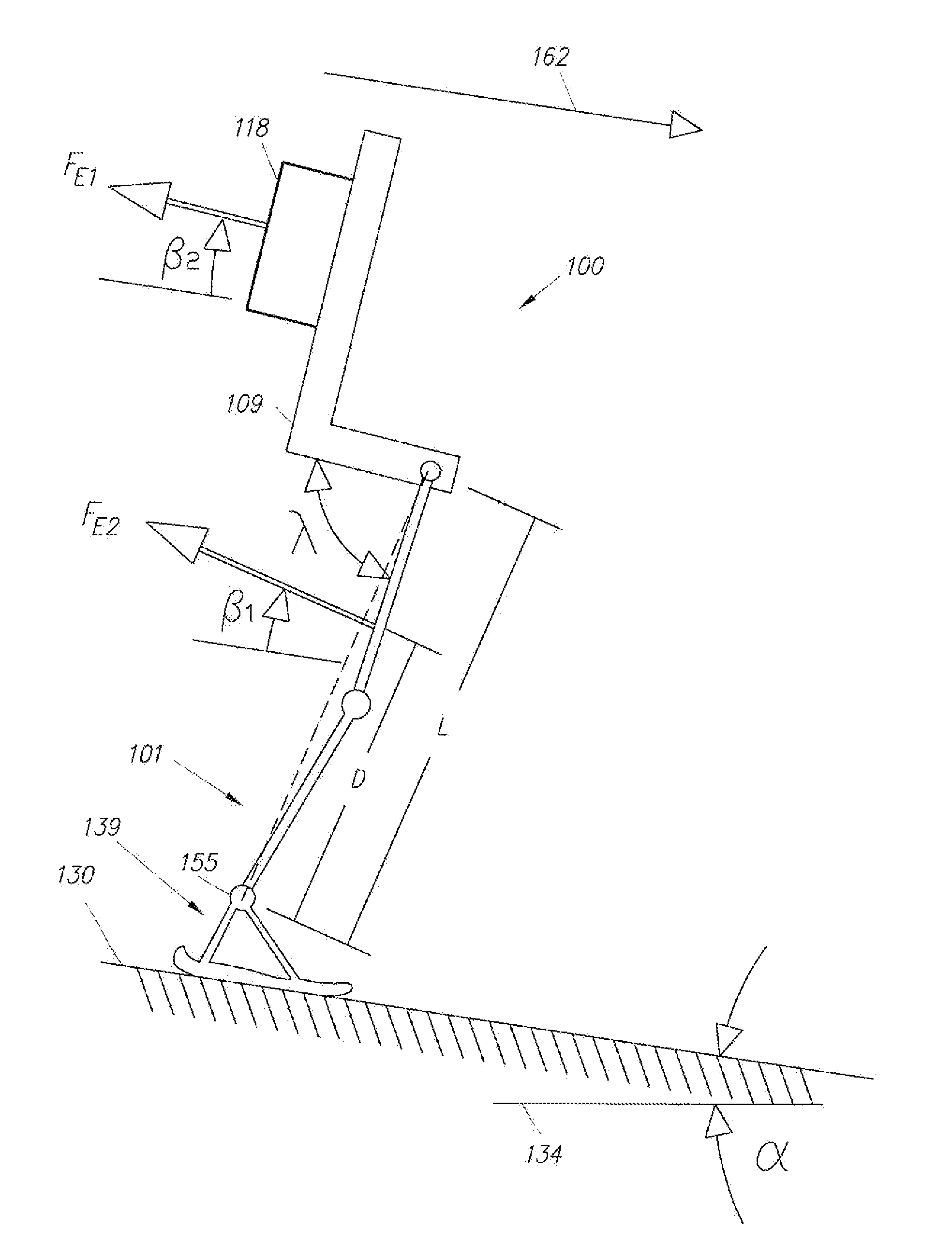

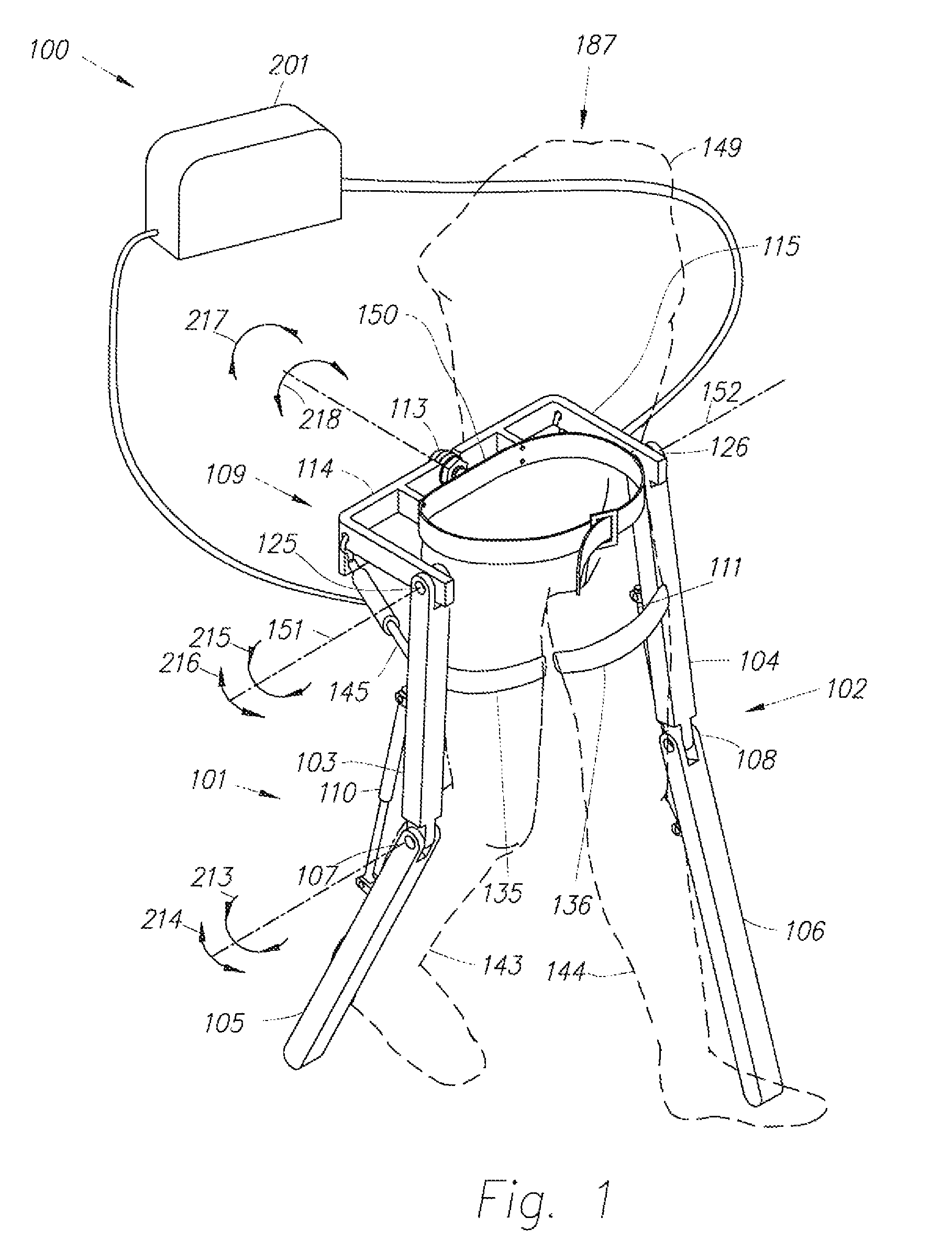

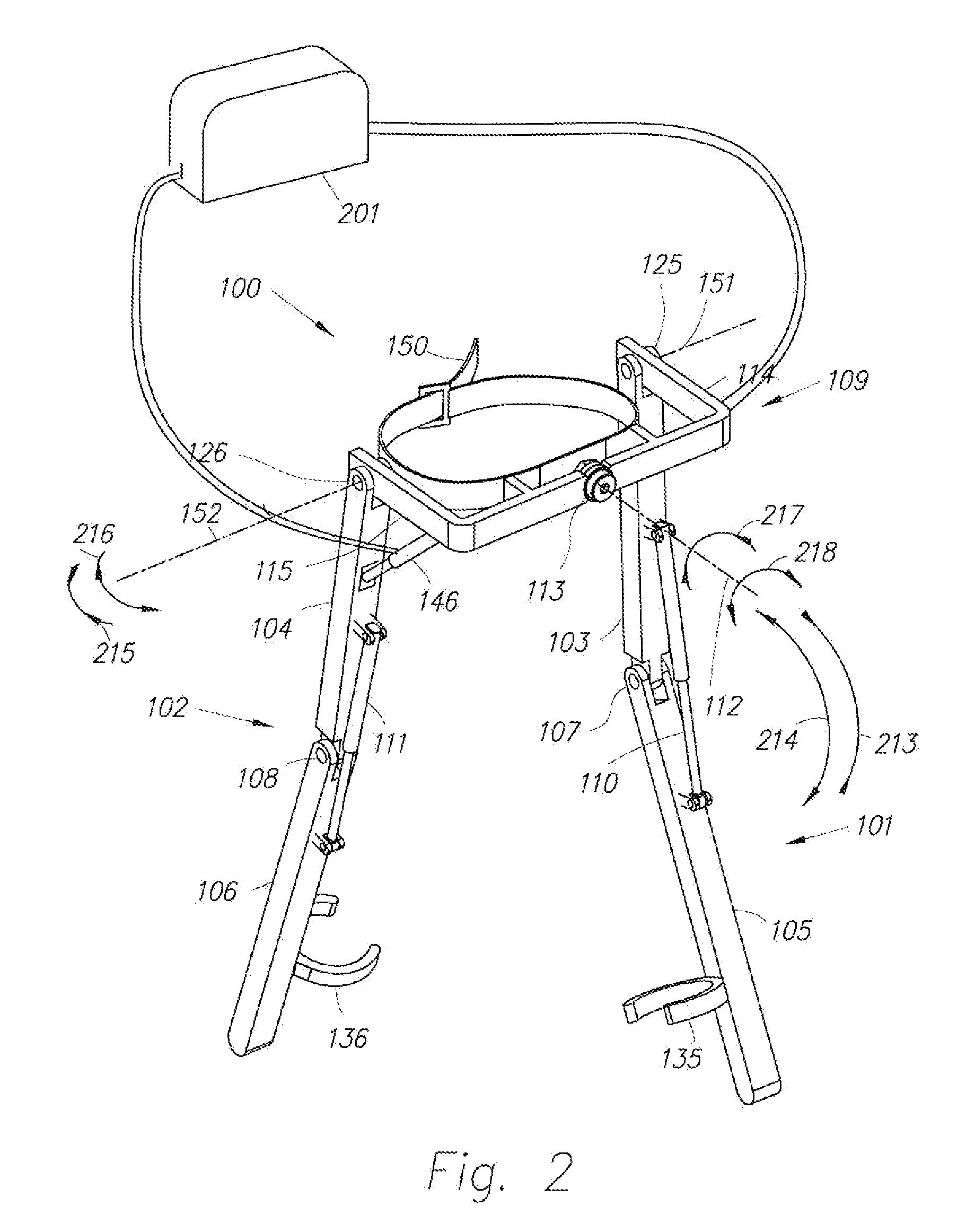

Device and Method for Decreasing Energy Consumption of a Person by Use of a Lower Extremity Exoskeleton

A lower extremity exoskeleton, configurable to be coupled to a person, includes: leg supports configurable to be coupled to the person's lower limbs and designed to rest on the ground during stance phases, with each leg support having a thigh link and a shank link; two knee joints, each configured to allow flexion and extension between respective shank and thigh links; an exoskeleton trunk configurable to be coupled to the person's upper body, rotatably connectable to the thigh links of the leg supports, allowing for the flexion and extension between the leg supports and the exoskeleton trunk; two hip actuators configured to create torques between the exoskeleton trunk and the leg supports; and at least one power unit capable of providing power to the hip actuators. In use, power is supplied to the hip actuators in an amount to reduce the energy consumed by a user during a walking cycle.

Owner:EKSO BIONICS

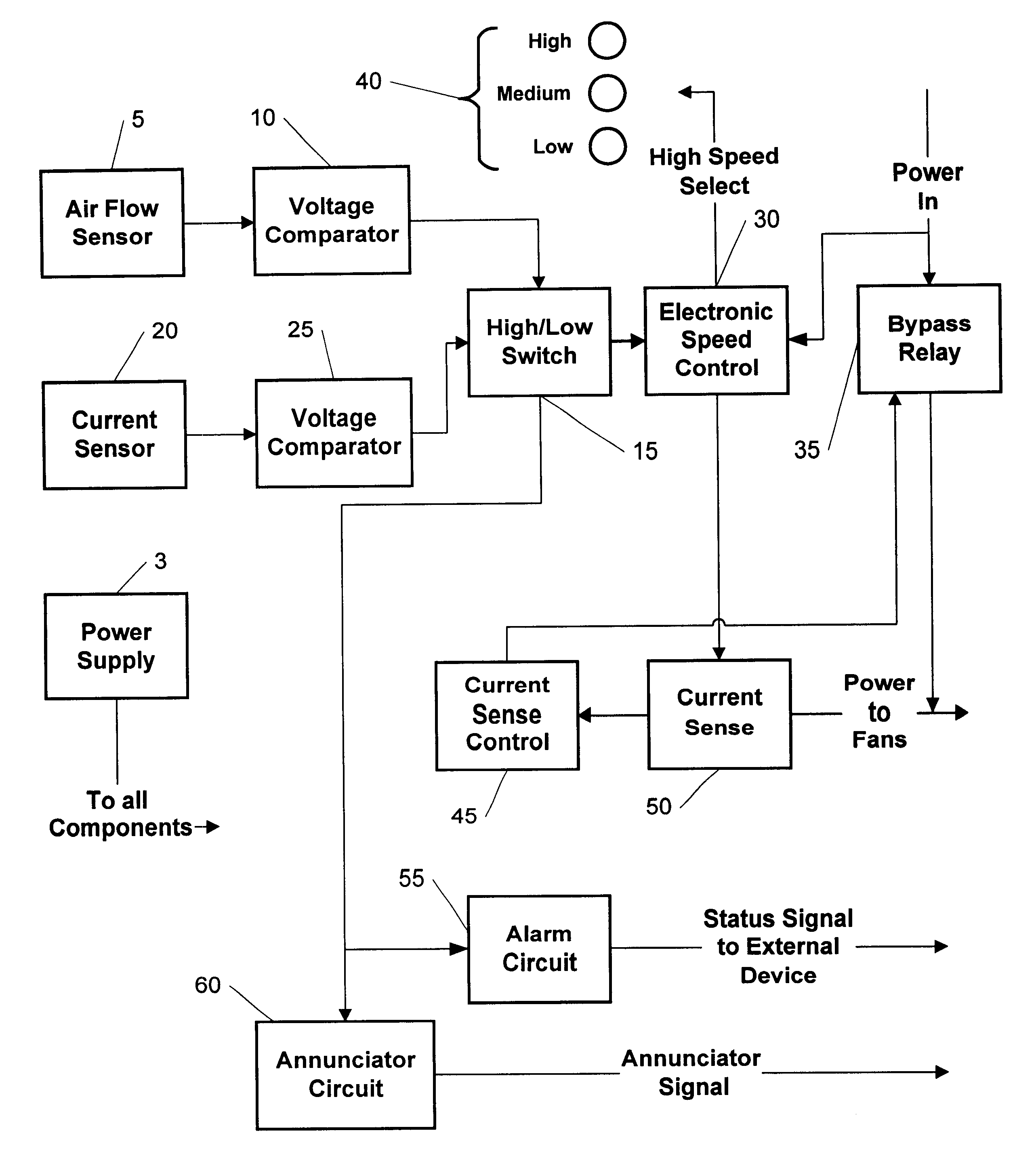

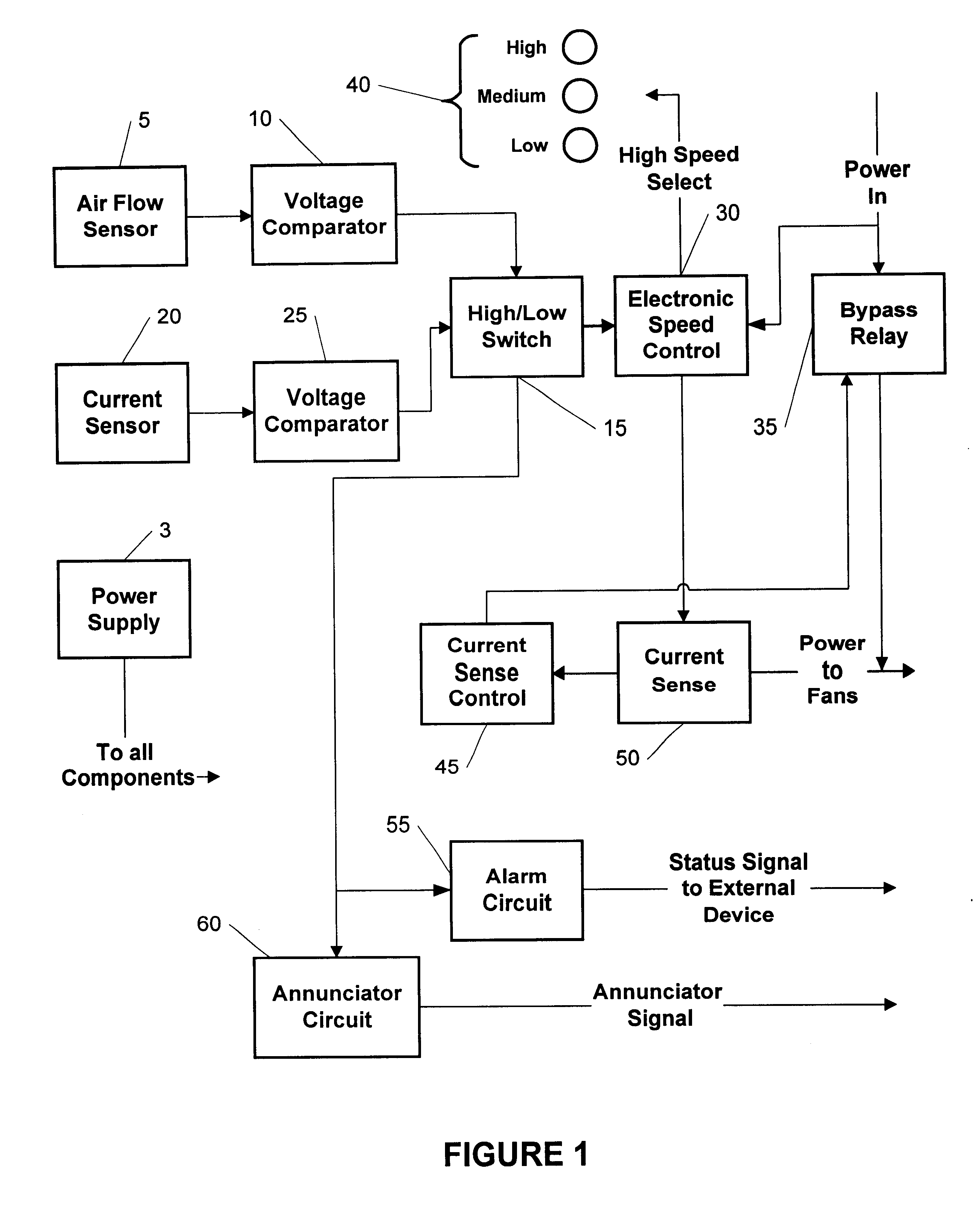

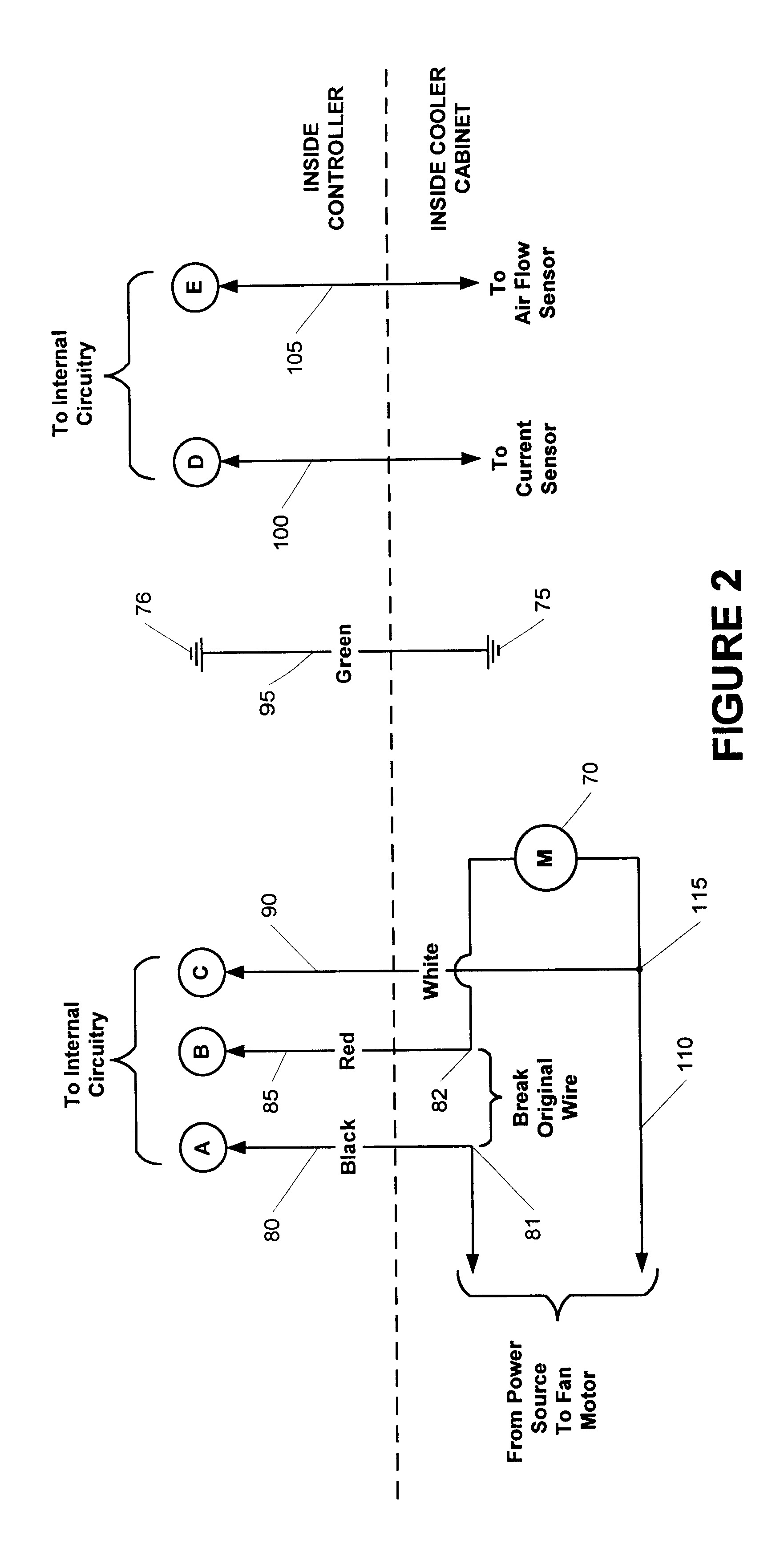

Energy saving device for walk-in refrigerators and freezers

InactiveUS6397612B1Weaken energyReduce speedMechanical apparatusSpace heating and ventilation safety systemsDecreased energyLow speed

An energy saving apparatus for use with a heat exchange system having a cooled chamber, a compressor, a condenser, an evaporator, an evaporator fan, and refrigerant within refrigerant carrying lines has an evaporator fan controller for monitoring operational status of the system (cooling or non-cooling) and setting an energy saving operational speed for the evaporator fan based on the operational status of the system (cooling or non-cooling) and a current sensor coupled to the evaporator fan controller for detecting the operational status of the system (cooling or non-cooling). If the system is detected as cooling, the evaporator fan controller directs the evaporator fan to operate at a high speed and if the system is detected as not cooling (non-cooling), the evaporator fan controller decreases the operational speed of the evaporator fan to a low speed, thereby decreasing evaporator fan produced heat, resulting in an overall decreased energy requirement for the heat exchange system.

Owner:ADRIEL ENERGY

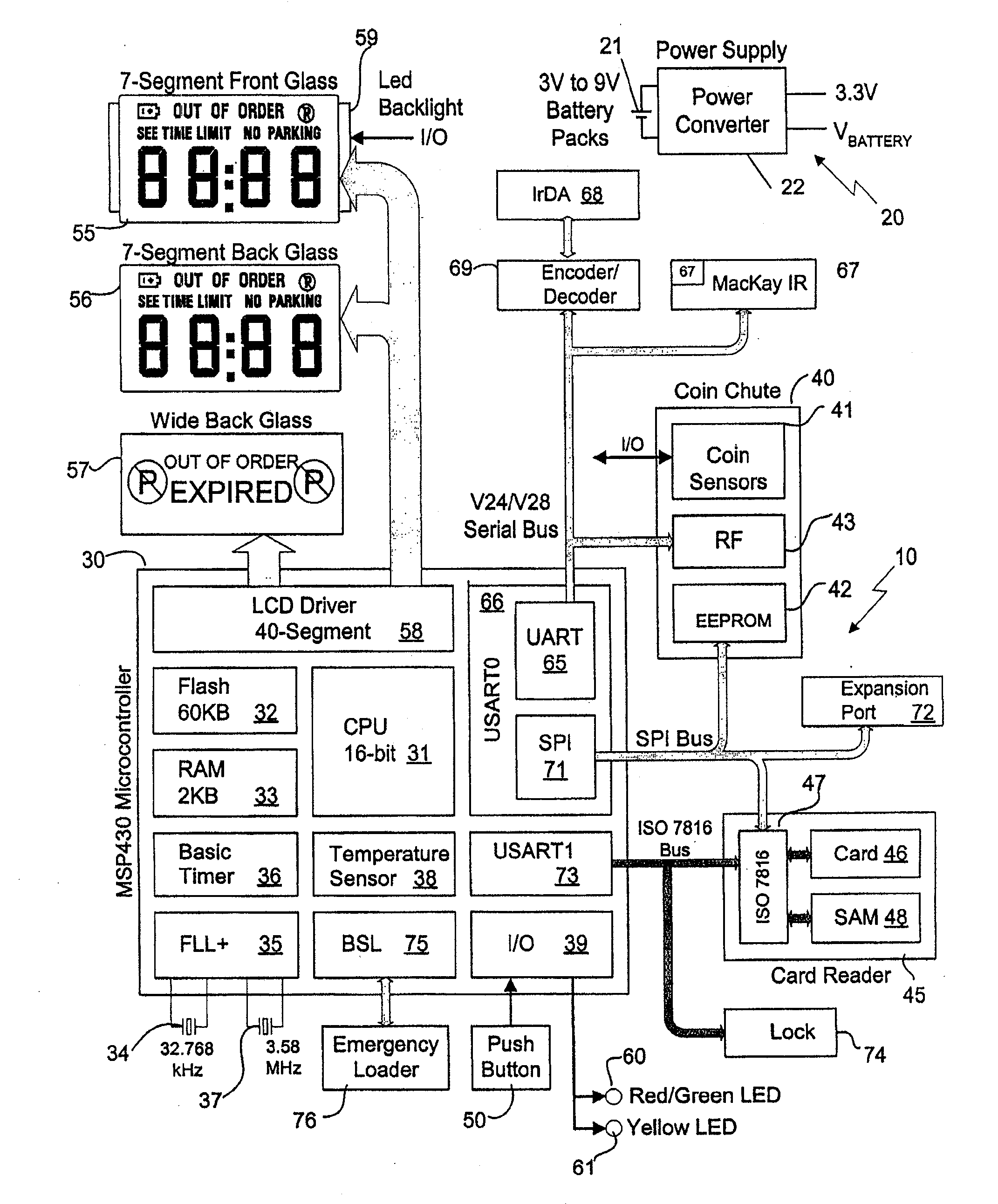

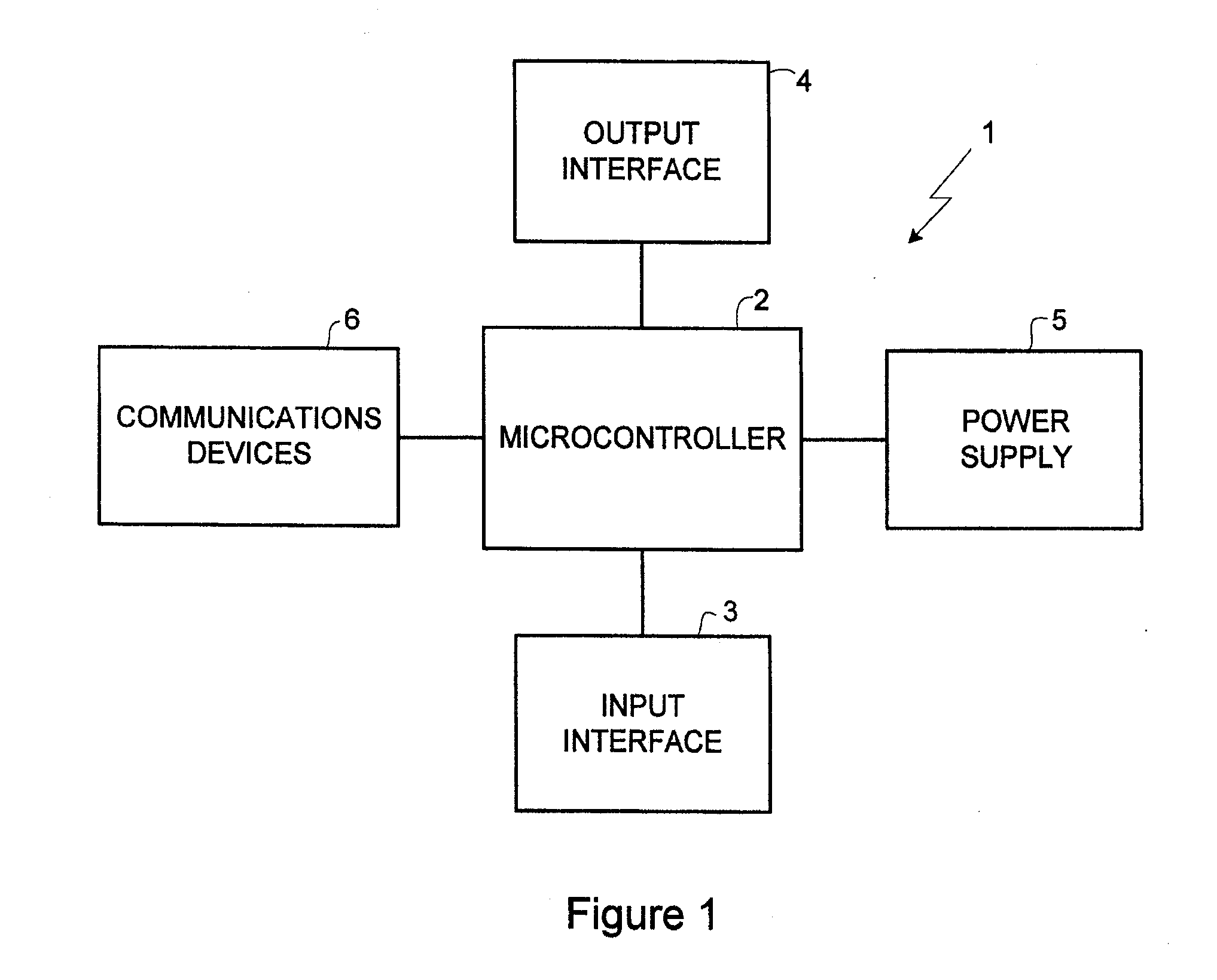

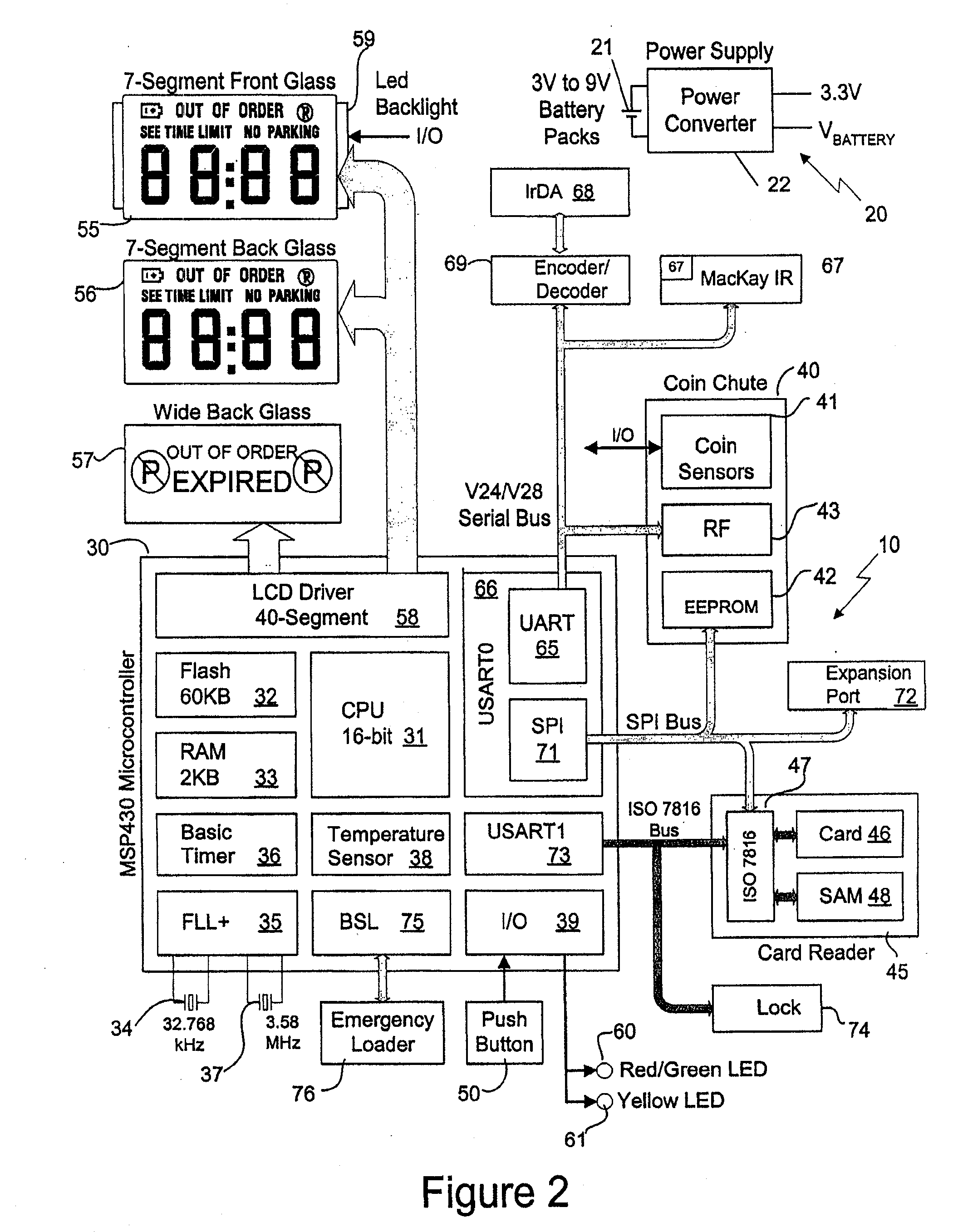

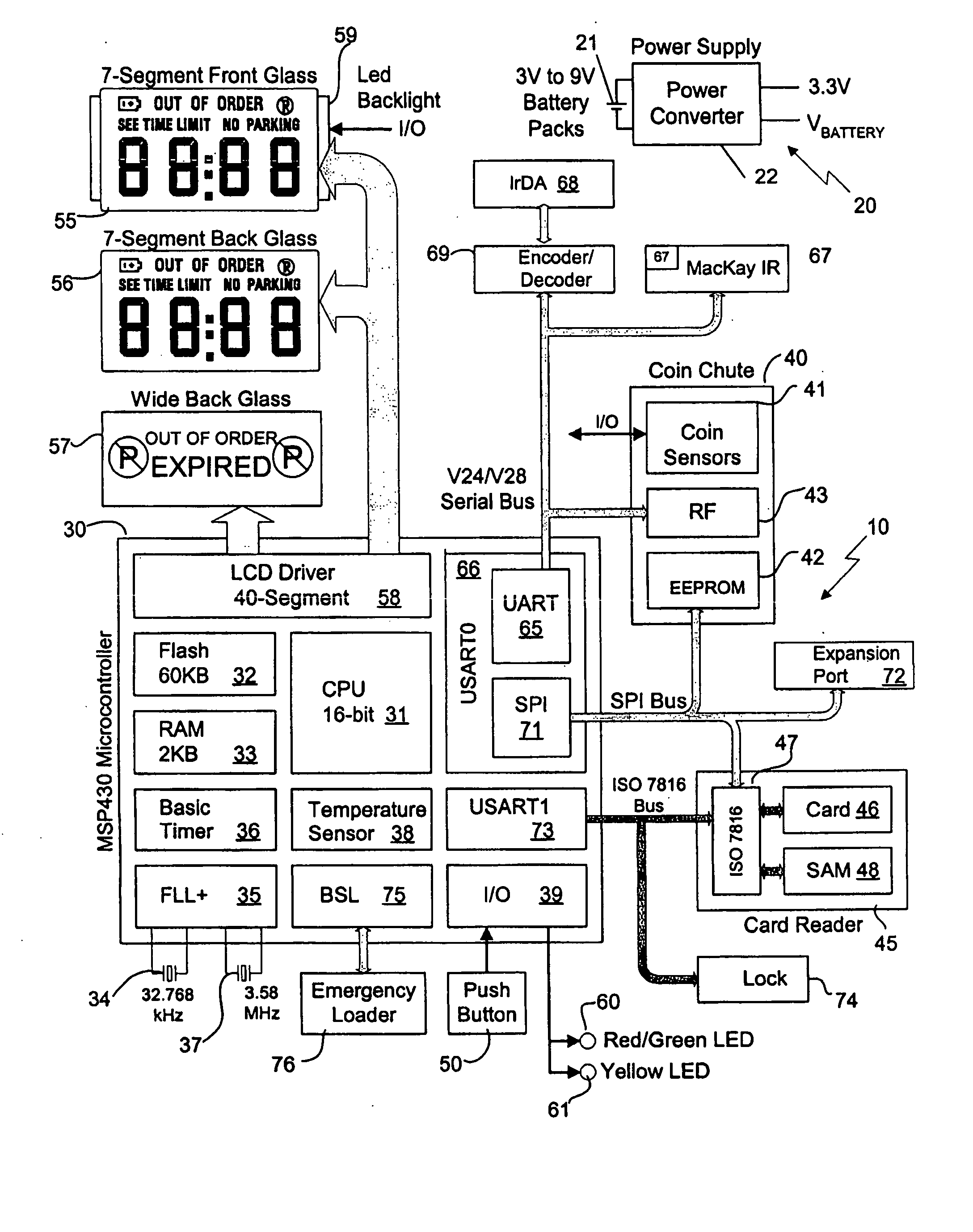

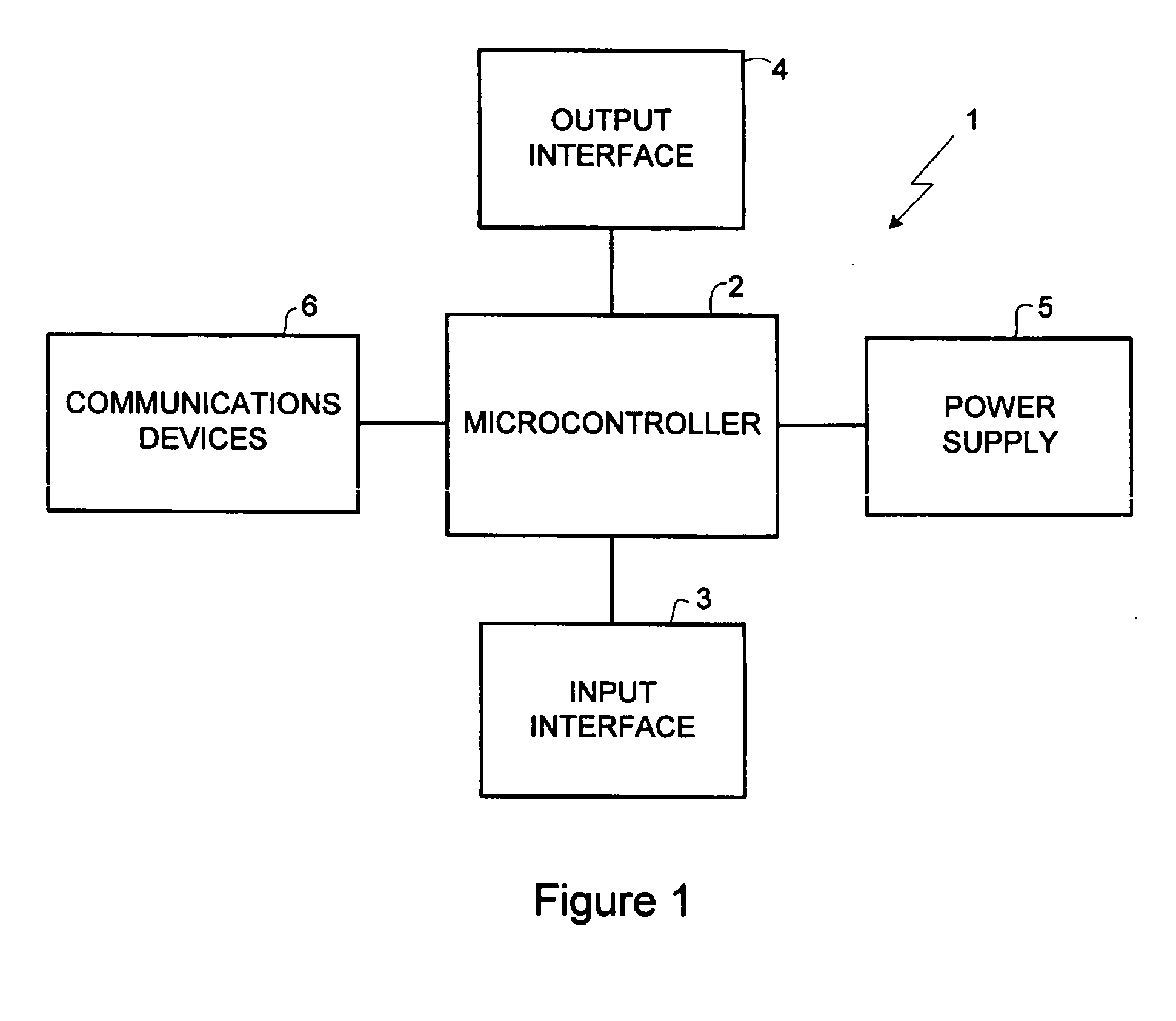

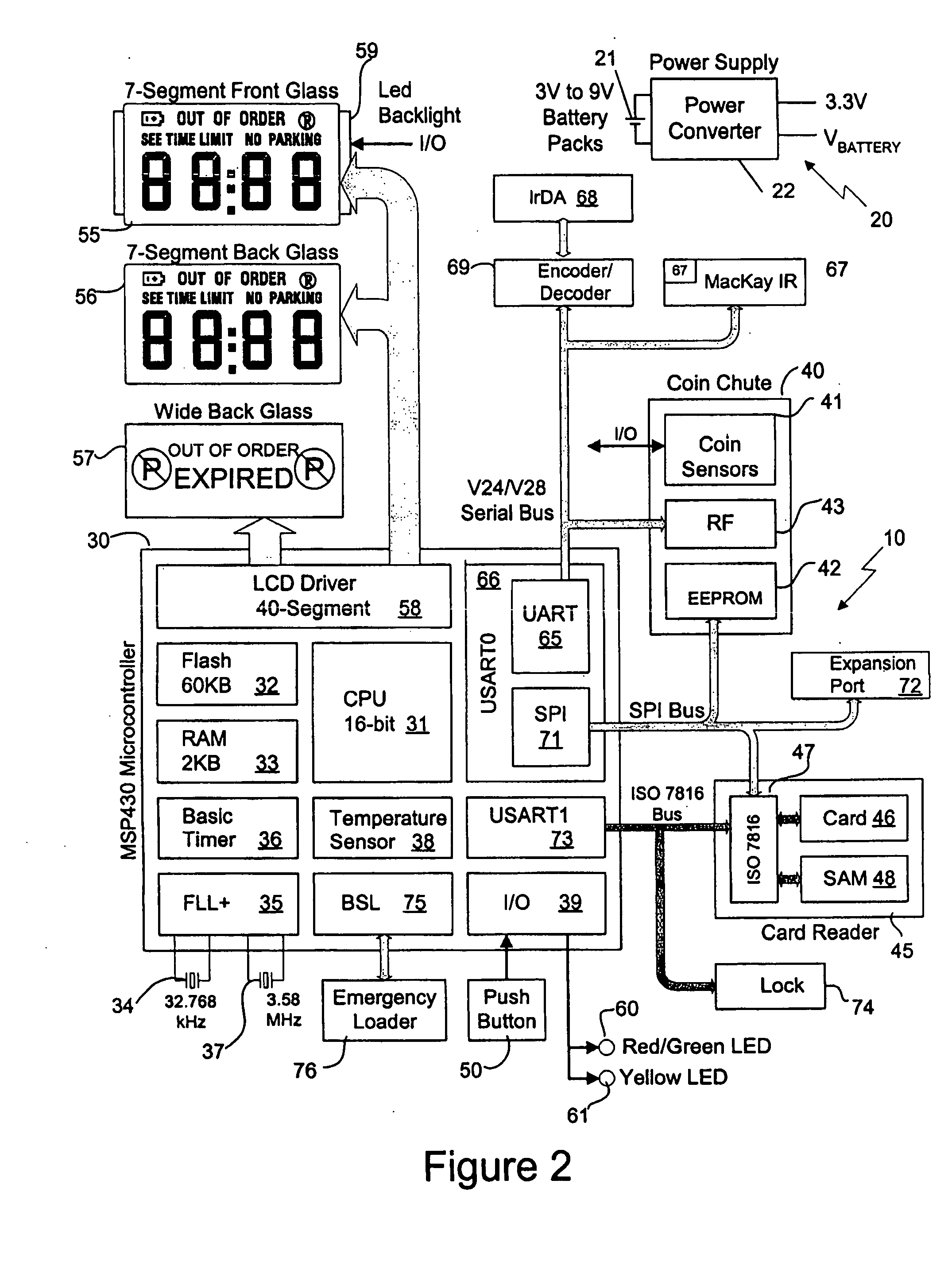

Efficient battery powered electronic parking meter

InactiveUS20070119682A1Increase awarenessTicket-issuing apparatusPaper-money testing devicesMicrocontrollerDecreased energy

The electronic parking meter includes a microcontroller, an input interface, an output interface, communications devices and a power supply. The microcontroller receives instructions through the input interface from a user wishing to purchase parking time, controls the output interface to provide parking related messages or indications, and controls the electronic parking meter's communications with other devices through the communications devices for transmitting and receiving information and data. The power supply, which converts a battery pack voltage up to the operating voltage, may include an isolation transformer and a flyback switcher. The parking meter is maintained in a sleep mode as a default state, is placed in a schedule wake-up mode at a predetermined frequency for a predetermined short period of time to carry-out maintenance functions, and is only placed in an event wake-up mode for the time required to process major events, such as coin chute, card reader or communications port interrupts. The maintenance-free life of the parking meter is extended by using more of the energy that is available in standard battery packs and by decreasing energy consumed in the parking meter to carry out its functions through the three operating modes including the periodic schedule wake-up mode.

Owner:BANKS KEN +3

Efficient battery powered electronic parking meter

InactiveUS20050155839A1Increase awarenessTicket-issuing apparatusPaper-money testing devicesMicrocontrollerDecreased energy

The electronic parking meter includes a microcontroller, an input interface, an output interface, communications devices and a power supply. The microcontroller receives instructions through the input interface from a user wishing to purchase parking time, controls the output interface to provide parking related messages or indications, and controls the electronic parking meter's communications with other devices through the communications devices for transmitting and receiving information and data. The power supply, which converts a battery pack voltage up to the operating voltage, may include an isolation transformer and a flyback switcher. The parking meter is maintained in a sleep mode as a default state, is placed in a schedule wake-up mode at a predetermined frequency for a predetermined short period of time to carry-out maintenance functions, and is only placed in an event wake-up mode for the time required to process major events, such as coin chute, card reader or communications port interrupts. The maintenance-free life of the parking meter is extended by using more of the energy that is available in standard battery packs and by decreasing energy consumed in the parking meter to carry out its functions through the three operating modes including the periodic schedule wake-up mode.

Owner:J J MACKAY CANDADA

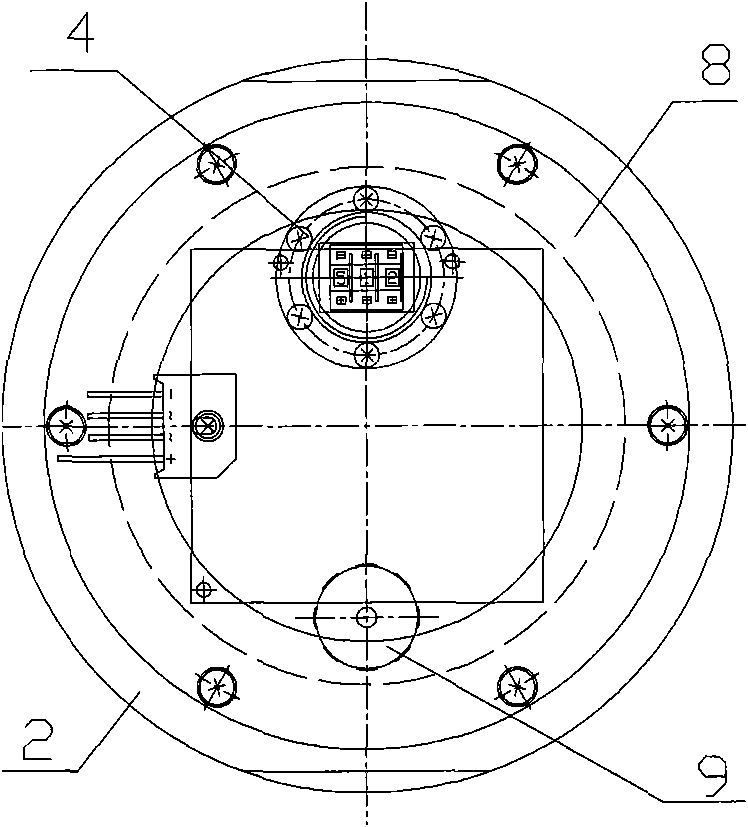

High-brightness LED underwater energy saving lamp

InactiveCN101608781ARealize direct coolingReduce adverse effectsPoint-like light sourceElectric circuit arrangementsDecreased energyEngineering

The invention relates to a high-brightness LED underwater lamp with low energy consumption and numerically controlled light color. A groove surface of a double-sided groove type lamp housing is provided with one or more LED chips. A transparent cover is arranged on and matched with one side, where an LED is arranged, of the double-sided groove type lamp housing by a rubber sealing ring in a waterproof sealed manner. Another groove cavity of the double-sided groove type lamp housing is internally provided with a control circuit board, a signal end of which is respectively connected with signal ends of one or more LED chips. A wiring terminal is sealed and connected on a sealing cover plate and a lead of the wiring terminal is connected with the signal end of the control circuit board. The sealing cover plate is sealed and matched with the other side of the double-sided groove type lamp housing. The energy saving lamp has the advantages of firstly, not only avoiding unfavorable effect of the control circuit board on the LED chip, but also considerably improving the optical conversion efficiency of the LED chip; secondly, realizing the direct temperature reduction to the LED chip, decreasing energy consumption, improving the optical conversion efficiency of the LED chip and considerably prolonging the service life of the LED chip; and thirdly, realizing the purpose of direct water-cooled temperature reduction.

Owner:杭州亿奥光电有限公司

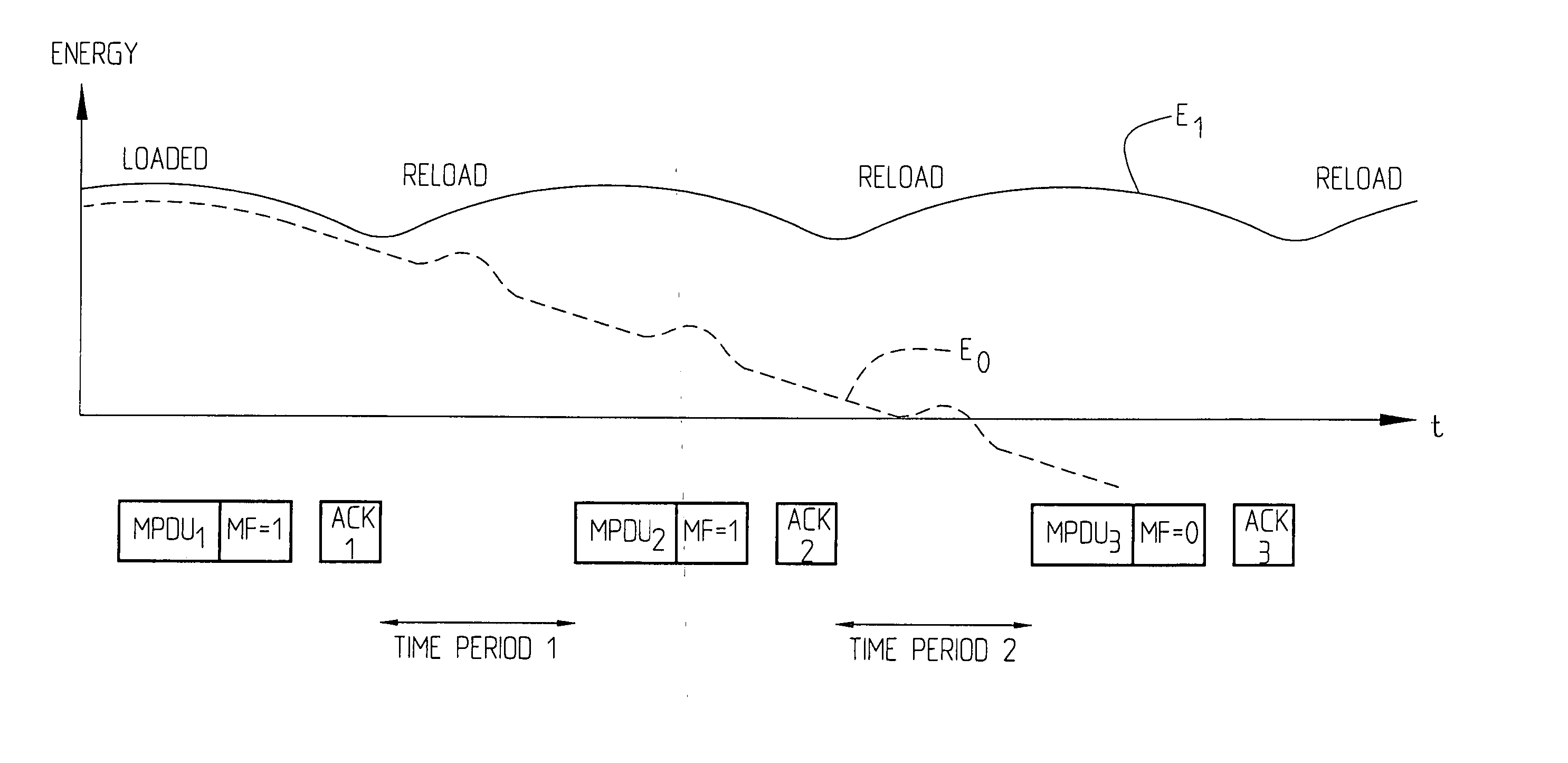

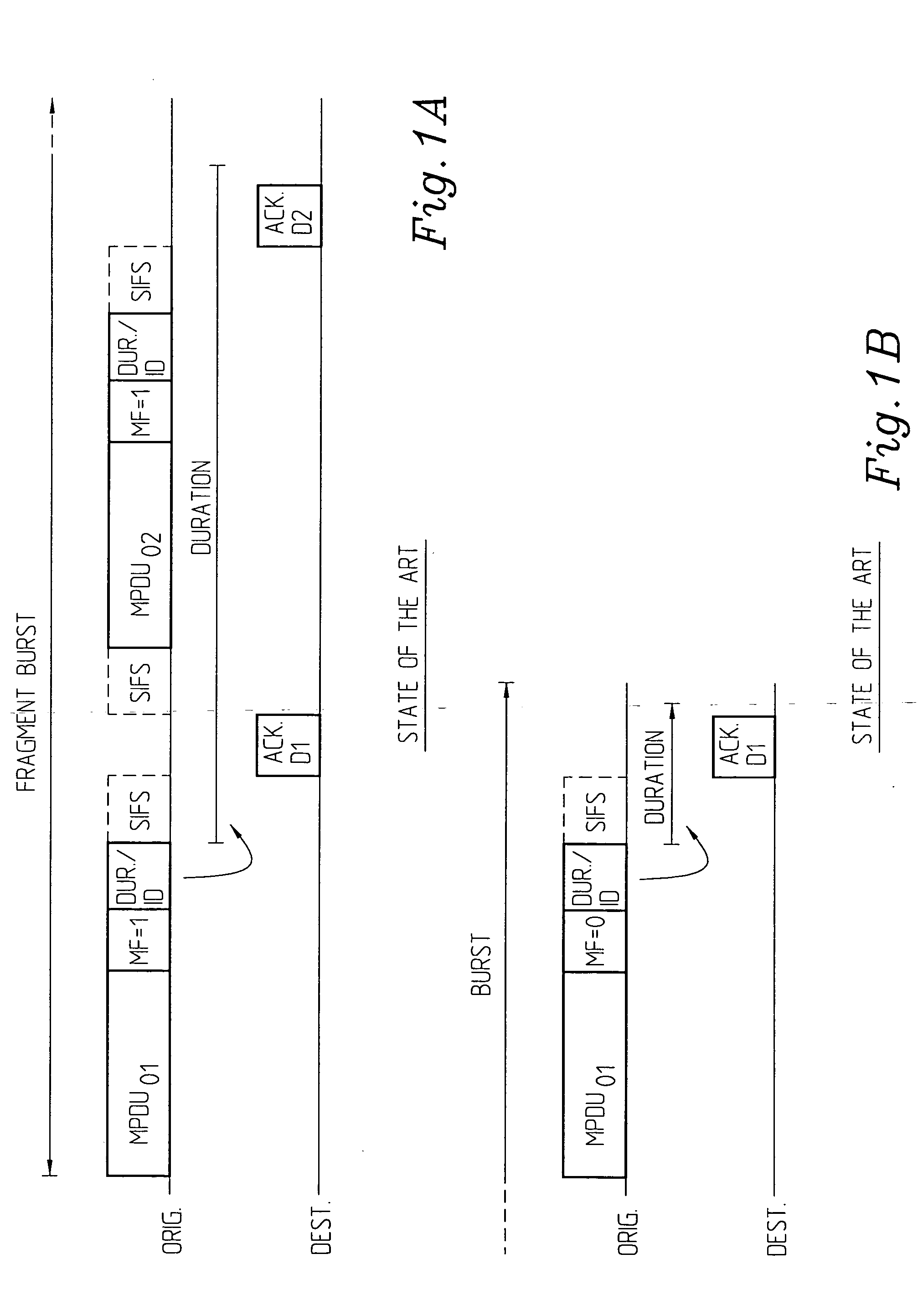

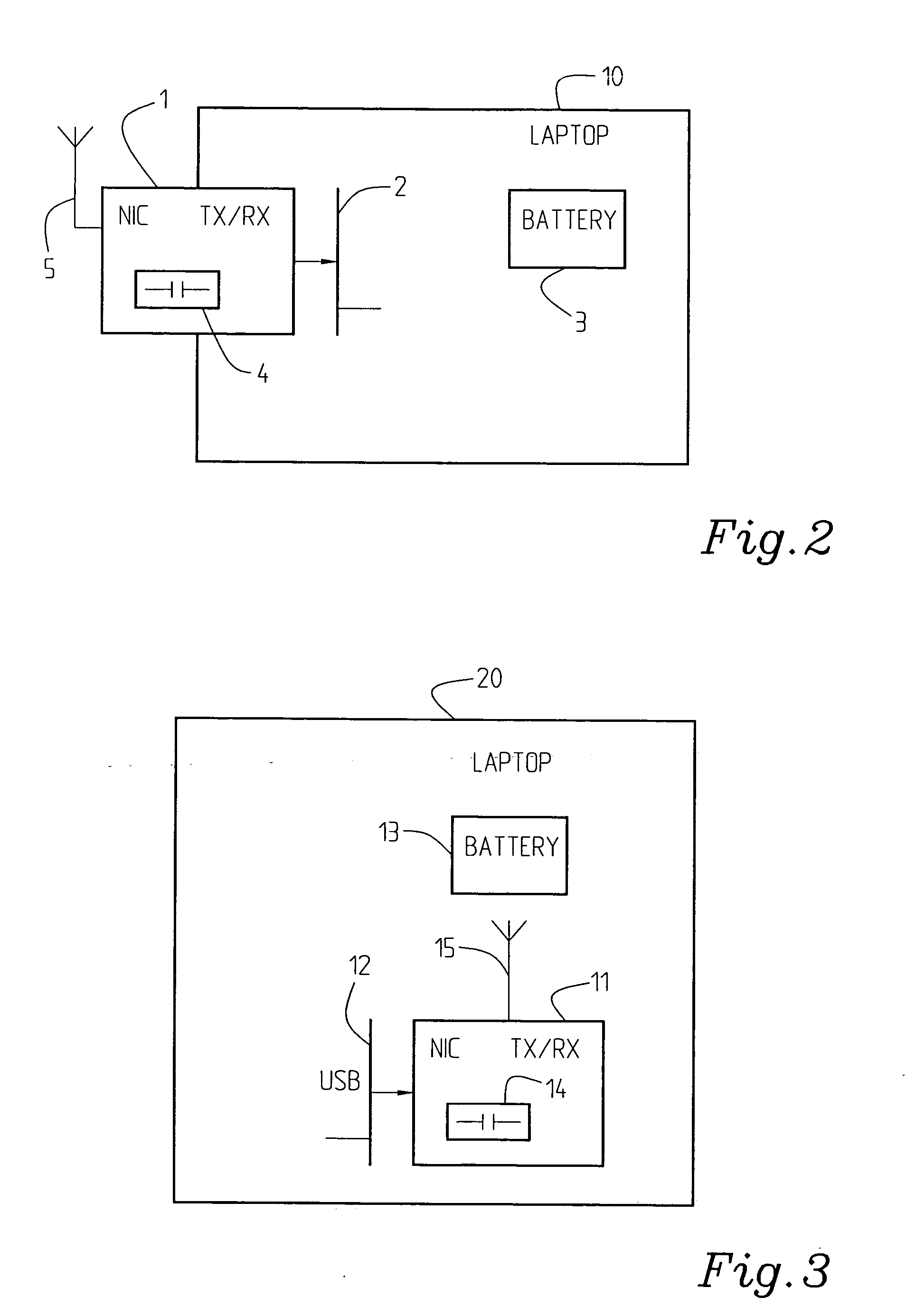

Wireless station and a transmission method in a wireless local area network

ActiveUS20050018638A1Reduced Power RequirementsEven consumptionPower managementEnergy efficient ICTDecreased energyTime segment

The present invention relates to a wireless station, in a wireless LAN, comprising a network interface to network interface means comprising receiving / transmitting means, antenna means, at least first power supply means or energy holding means, said wireless station further supporting transmission of data in frames of variable length. Frame fragmentation is implemented by dividing a (long) frame into a number of frame fragments. Each fragment is sent as a non-fragmented frame and means are provided for controlling the length of the time periods before / between transmission of (consecutive) frame fragments in order to decrease energy consumption during a predetermined time interval.

Owner:TELEFON AB LM ERICSSON (PUBL)

Device and Method for Decreasing Energy Consumption of a Person by Use of a Lower Extremity Exoskeleton

A lower extremity exoskeleton, configurable to be coupled to a person, includes: leg supports configurable to be coupled to the person's lower limbs and designed to rest on the ground during stance phases, with each leg support having a thigh link and a shank link; two knee joints, each configured to allow flexion and extension between respective shank and thigh links; an exoskeleton trunk configurable to be coupled to the person's upper body, rotatably connectable to the thigh links of the leg supports, allowing for the flexion and extension between the leg supports and the exoskeleton trunk; two hip actuators configured to create torques between the exoskeleton trunk and the leg supports; and at least one power unit capable of providing power to the hip actuators. In use, power is supplied to the hip actuators in an amount to reduce the energy consumed by a user during a walking cycle.

Owner:EKSO BIONICS

Device and method for decreasing energy consumption of a person by use of a lower extremity exoskeleton

A lower extremity exoskeleton, configurable to be coupled to a person, includes: leg supports configurable to be coupled to the person's lower limbs and designed to rest on the ground during stance phases, with each leg support having a thigh link and a shank link; two knee joints, each configured to allow flexion and extension between respective shank and thigh links; an exoskeleton trunk configurable to be coupled to the person's upper body, rotatably connectable to the thigh links of the leg supports, allowing for the flexion and extension between the leg supports and the exoskeleton trunk; two hip actuators configured to create torques between the exoskeleton trunk and the leg supports; and at least one power unit capable of providing power to the hip actuators. In use, power is supplied to the hip actuators in an amount to reduce the energy consumed by a user during a walking cycle.

Owner:EKSO BIONICS

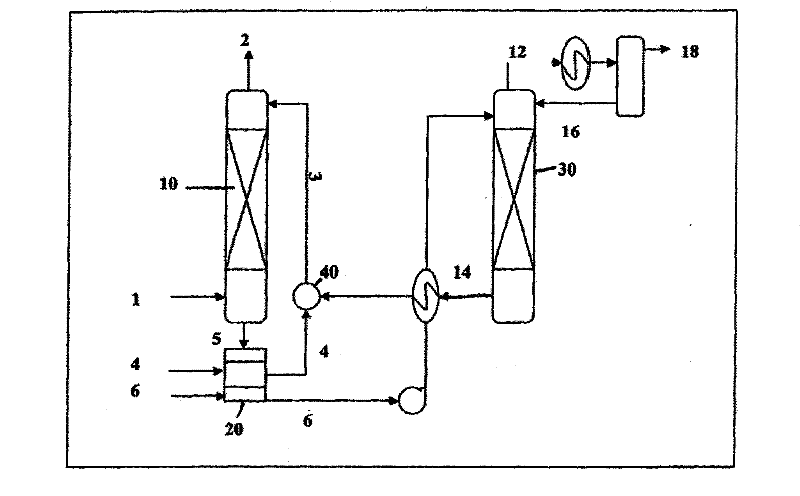

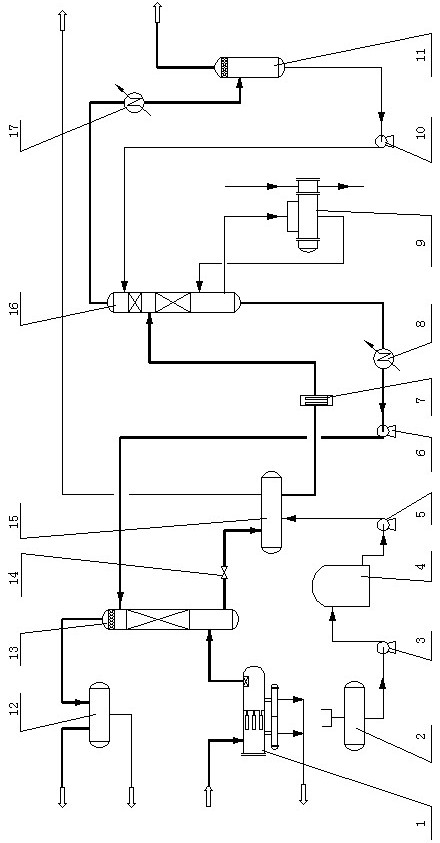

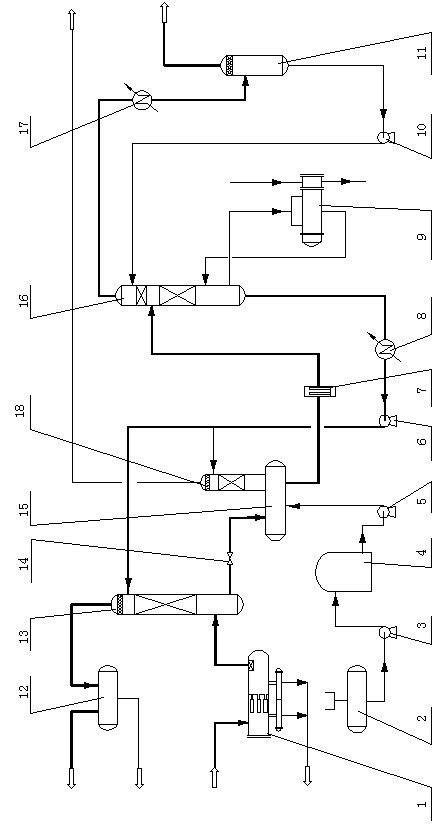

Methods and systems for deacidizing gaseous mixtures

InactiveCN102186559AReduce energy consumptionIncrease absorption rateGas treatmentCarbon compoundsDecreased energyGas phase

The invention provides a process for deacidizing a gaseous mixture. The method comprises absorbent is used to contact with the gaseous mixture in an absorbing unit, and the absorbent contains organic phase and load phase which do not mix with each other; the organic phase absorbs acid gas and transforms the acid gas into the absorptive acid gas so as to transform the absorbent into rich acid gas absorbent and transform the gaseous mixture into purified gaseous mixture; the absorbed acid gas is delivered to the load phase so that first poor acid gas phase and rich acid gas phase are formed in the rich acid gas absorbent to provide the rich acid gas phase to a separating unit to separate the first poor acid gas phase and rich acid gas phase; the separated first poor acid gas phase is recycled into the absorbing unit; the separated rich acid gas phase is provided to a regenerating unit to gain acid gas and second poor acid gas phase; and the second poor acid gas phase is recycled into the absorbing unit. The deacidizing process, compared with the prior art, decreases energy consumption to the minimum and increases the absorbing efficiency to the maximum.

Owner:胡亮

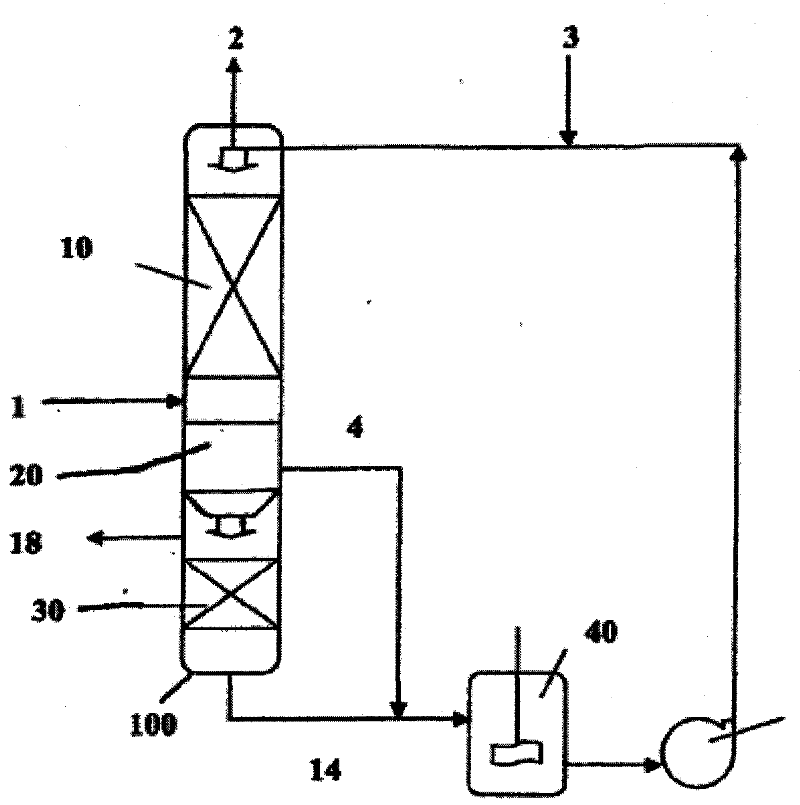

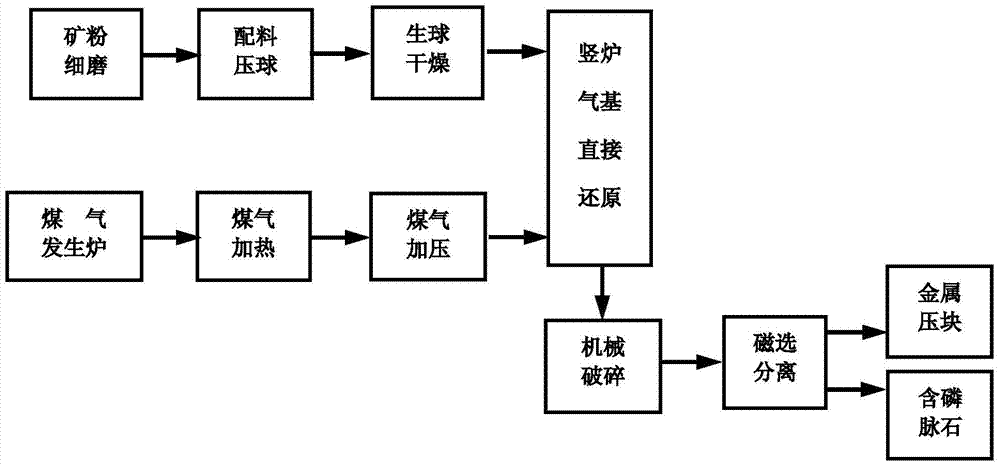

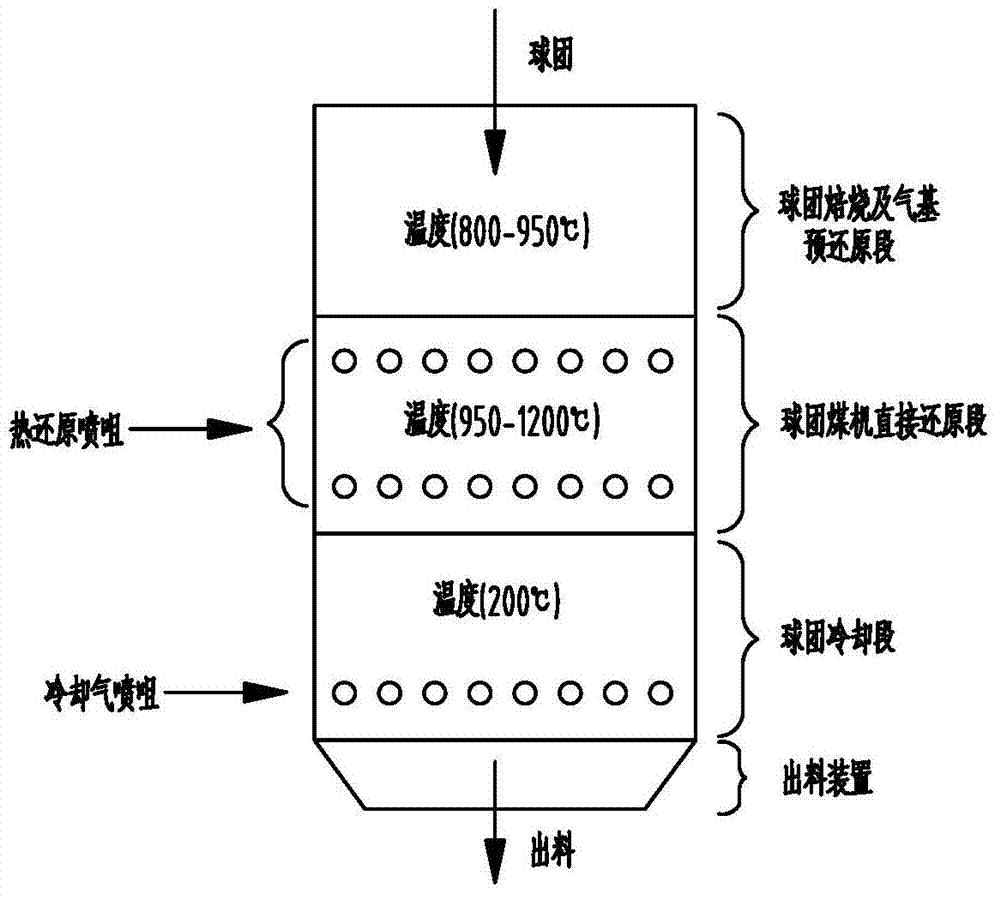

Method for preventing pellets from high temperature reduction bonding in high phosphorus oolitic hematite treatment shaft furnace

ActiveCN103667687ARelieve stickingGood for magnetic separationShaft furnaceDecreased energyShaft furnace

The invention discloses a method for preventing pellets from high temperature reduction bonding in a high phosphorus oolitic hematite treatment shaft furnace, belonging to the technical field of direct-reduction ironmaking. High phosphorus oolitic hematite powder, pulverized coal, a dephosphorization agent and a bonding agent are mixed together according to a proper ratio, the mixture is milled and pressed into balls so as to prepare cold bound pellets, and the bound pellets are dried or maintained and are further conveyed into a direct-reduction shaft furnace; in the direct-reduction shaft furnace, the pellets are subjected to hot coal gas roasting, gas-based prereduction, coal-based direct reduction and cooling process from top to bottom, temperature range of gas-based prereduction and coal-based direct reduction for the bound pellets is 850-1200 DEG C, and standing time in the shaft furnace is 1-5 hours; the reduction gas comprises H2 and CO in a ratio of 1.2-4; the reduced pellets are sealed and cooled, at the outlet of a cooling section, temperature of the bound pellets is controlled to be 100-200 DEG C, and the bound pellets are further smashed, magnetically separated and briquetted, wherein TFe in the obtained iron product is not less than 88%, and phosphorus content is less than 0.3%. The method has the advantages of decreasing energy consumption of reduction process of the shaft furnace.

Owner:韩其平

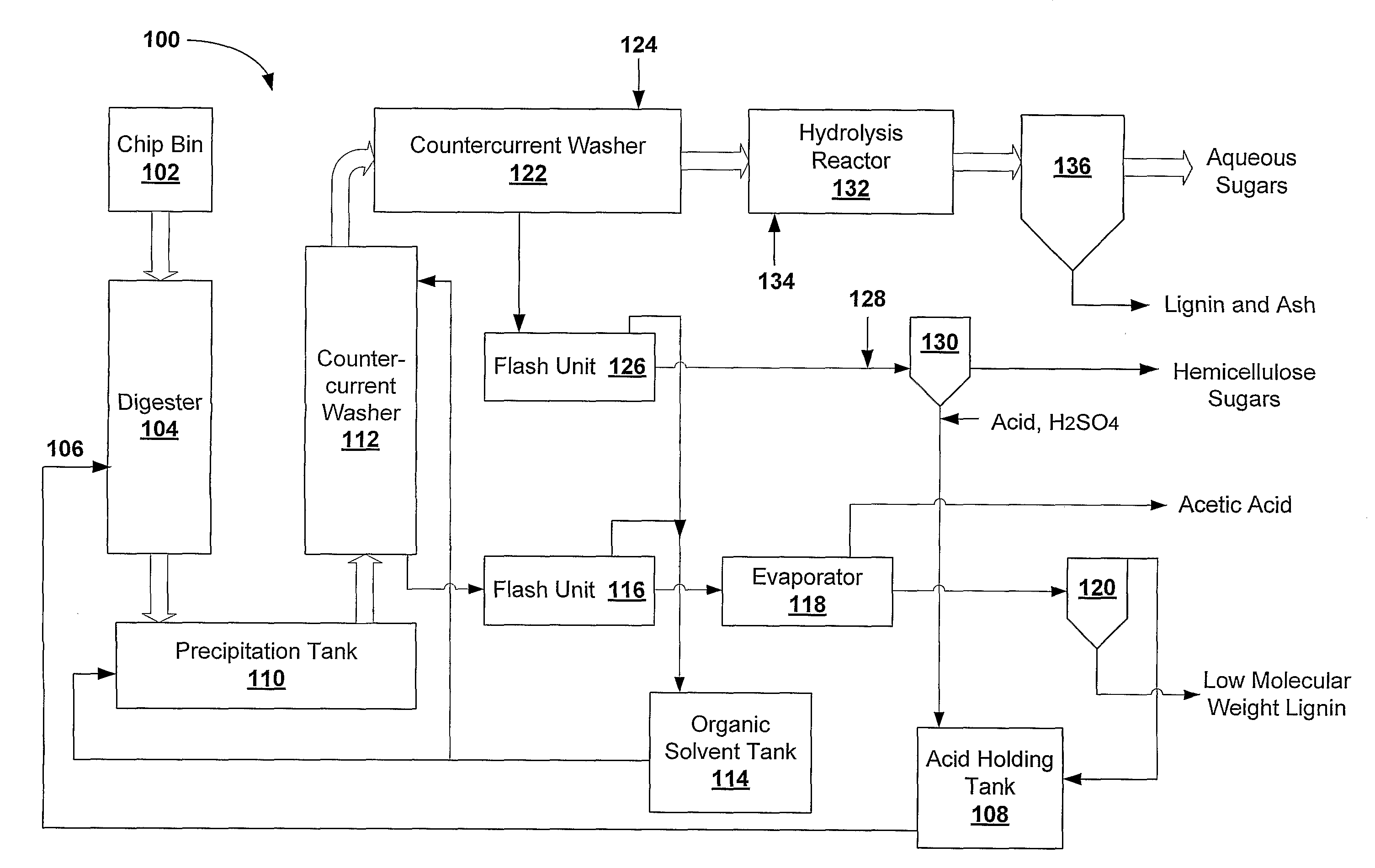

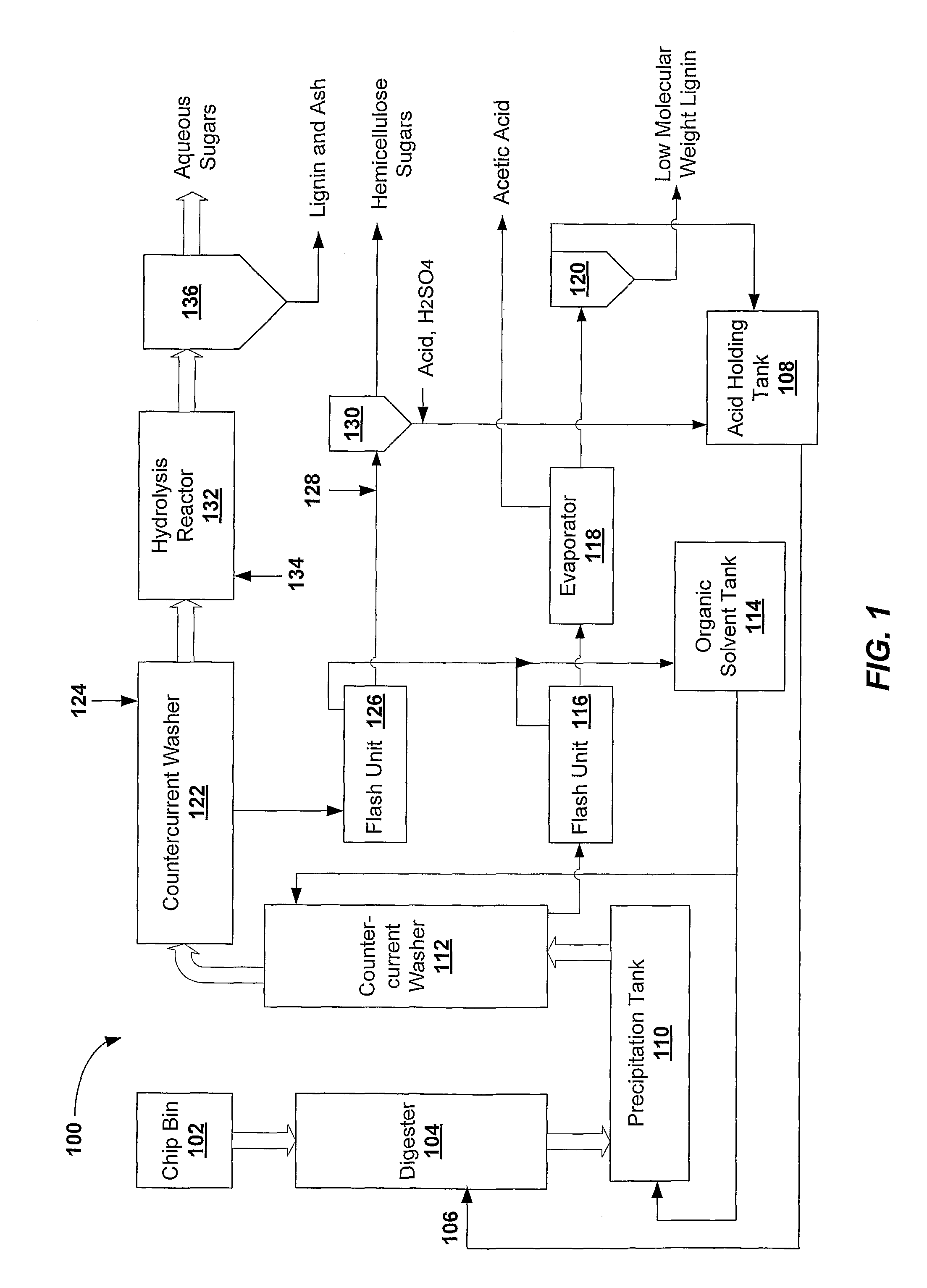

Method and Apparatus for Saccharide Precipitation From Pretreated Lignocellulosic Materials

InactiveUS20090017503A1High saccharide yieldFast hydrolysisSugar derivativesBiofuelsAcetic acidOrganic solvent

A method for separating saccharide components and lignin fractions from a concentrated acid treated lignocellulosic biomass is disclosed. The method involves precipitating the saccharide components by adding an organic solvent to the biomass slurry. The acid may then be recovered, for example, by filtration or by countercurrent washing and the organic solvent may be flashed and recycled. During acid recovery and organic recovery steps, two main lignocellulose components (hemicellulose and lignin) as well as minor components such as acetic acid are separated as well. The method decreases the amount of cellulase required for hydrolysis, increases hydrolysis rates, reduces formation of inhibitor molecules, increase sugar yields, produces high value by-products such as high quality lignin and hemicellulose, and decreases energy and equipment costs.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

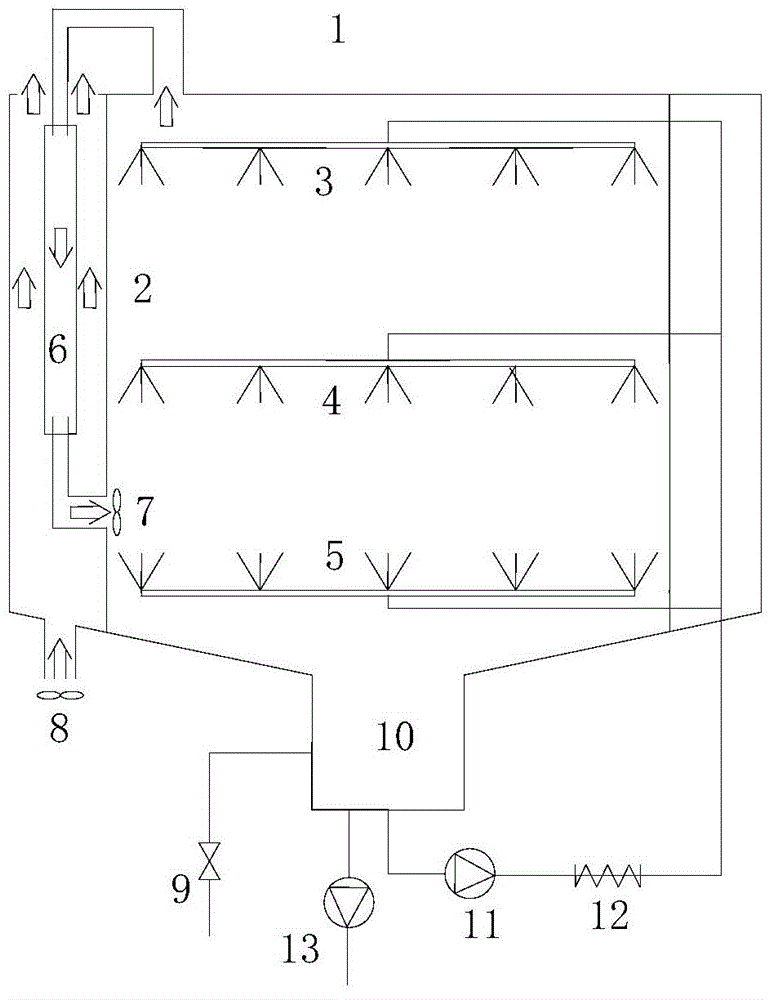

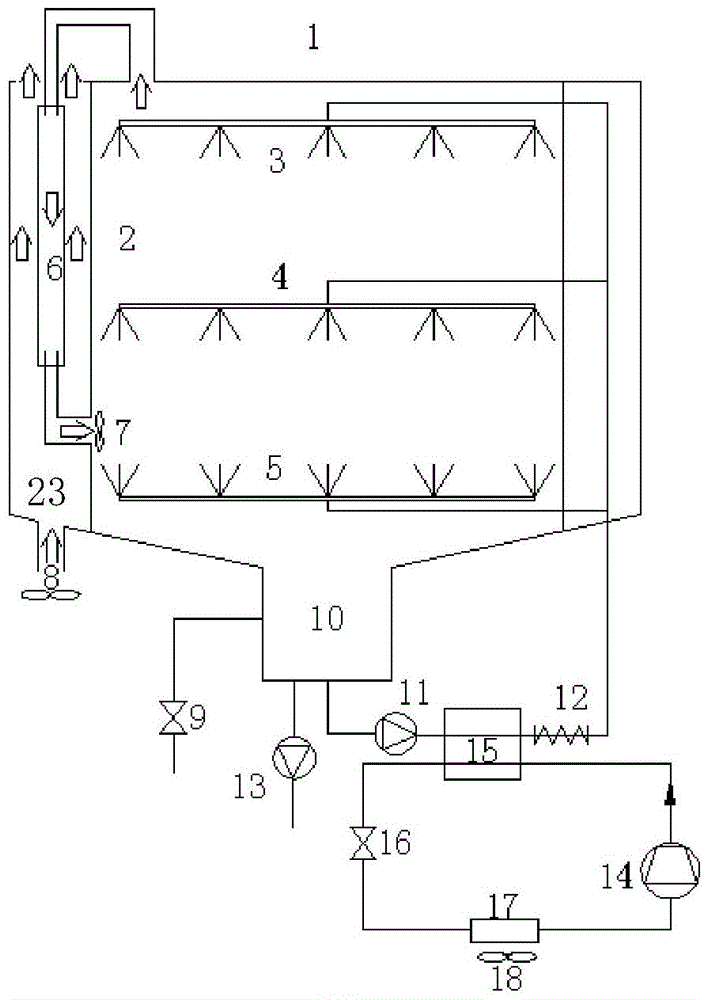

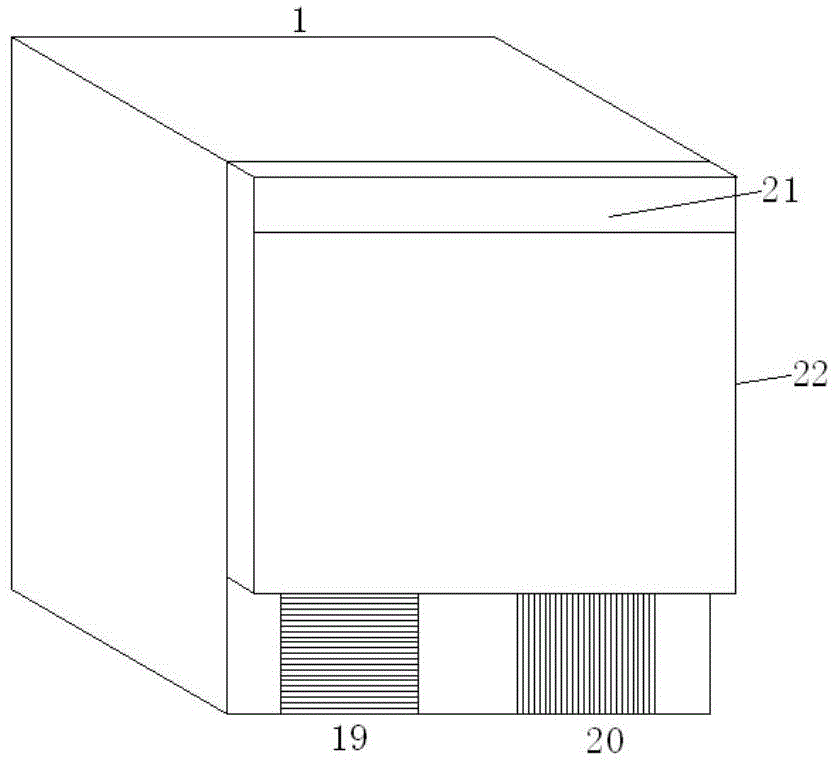

Heat pump type tableware washer and control method thereof

ActiveCN105476584AImprove energy efficiencyFast heatingTableware washing/rinsing machine detailsFluid circulation arrangementDecreased energyEngineering

The invention provides a heat pump type tableware washer and a control method thereof. The washer is added with a heat pump device comprising a compressor, a condenser, a throttle device, an evaporator and an evaporator fan. The condenser is disposed on a line where a circulating water pump is located; a heating heat-exchange passage is also disposed between a housing and a treatment chamber, the evaporator and the evaporator fan of the heat pump device are received in the heating heat-exchange passage, and both an air inlet and an air outlet of the heating heat-exchange passage are arranged in the front of the housing. The heat pump device provides hot water in a washing stage, decreasing energy consumption; both the air inlet and the air outlet are arranged in the front of a body, enabling air to circulate more smoothly, avoiding the problem that unsmooth air circulation in a cupboard where the washer is mounted may cause poor heat dissipation of a chamber of the compressor; a guarantee is given to both timely discharge of heat of the chamber of the compressor and reduction of exhaust temperature, thus prolonging life of the compressor.

Owner:HANGZHOU SANHUA RES INST CO LTD

Composite decarbonization solvent for eliminating carbon dioxide in natural gases

ActiveCN101822932AIncrease reaction rateReduce concentrationGaseous fuelsDispersed particle separationDecreased energyAntioxidant

The invention discloses a composite decarbonization solvent for eliminating carbon dioxide in natural gases, consisting of the following components in percentage by weight: 91.00%-96.45% of N-methyldiethanolamine solvent, 3.4%-8% of activator, 0.05%-0.4% of foam inhibiting agent, 0.05%-0.3% of corrosion inhibitor and 0.05%-0.3% of antioxidant. The invention has the advantages that the composite decarbonization solvent improves reaction rate of the composite decarbonization solvent and the carbon dioxide, increasing adsorption amounts; reduces circulation quantity of a decarbonization solution, decreasing energy consumption of solution circulation; reduces the degradation of the decarbonization solvent, lowering consumption of the decarbonization solvent; and at the same time, the composite decarbonization solvent improves corrosion resistance, oxidation resistance and foaming resistance of the decarbonization solution.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Energy-saving reverse osmosis treatment system

InactiveCN1721047ALess investmentSave energyWater/sewage treatment bu osmosis/dialysisReverse osmosisDecreased energyEnergy recovery

The invention discloses energy-saving reverse osmosis treatment system. It uses high pressure operation condition of itself, recoveries and uses the residual pressure energy to achieve purpose. According to fluid pressure principle, connect two hydraulic equipments to form energy recovery device; uses reverse osmosis dense water pressure as drive force to complete conveying process and recovery. The advantage of this invention is that decreases energy consumption, convenient to operate and simple, and fits to all kinds situations for reverse osmosis system.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

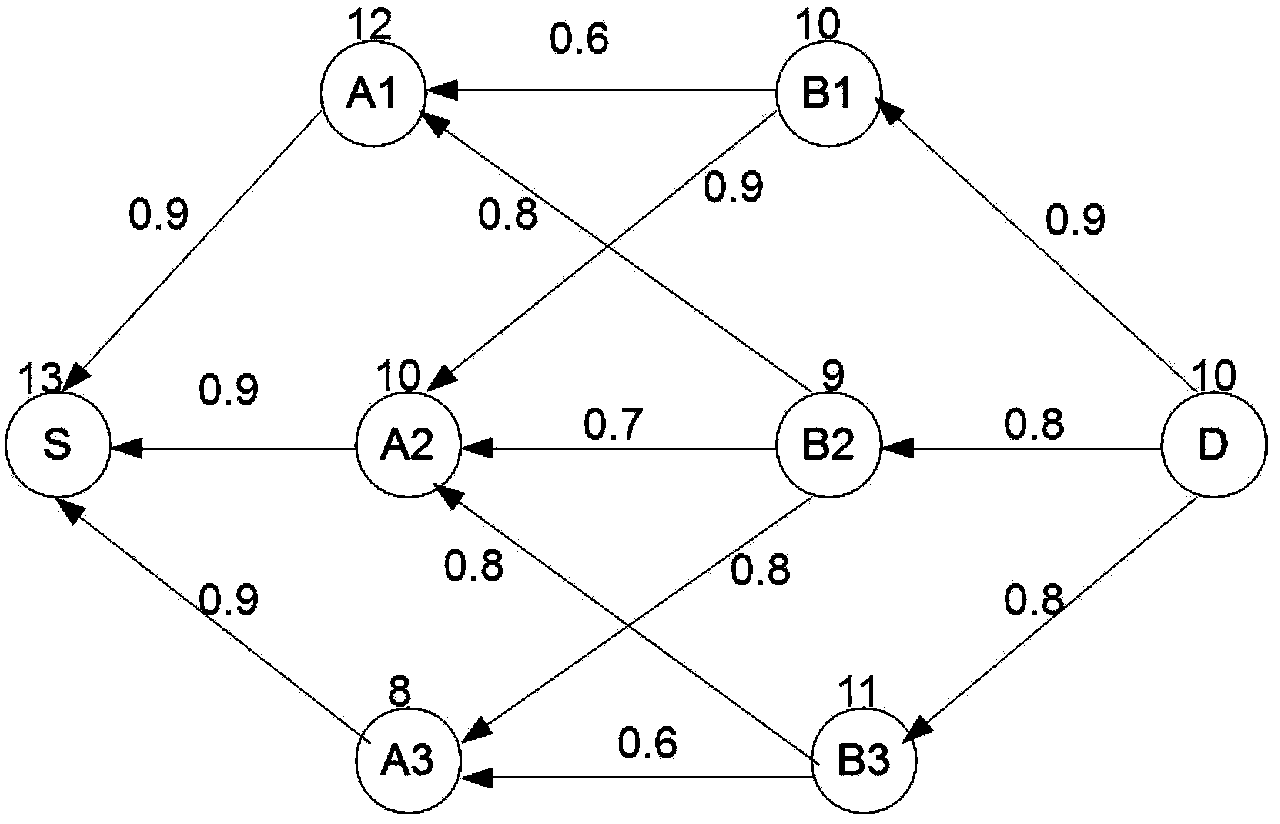

Method for designing multi-channel opportunistic routing protocol (MCORP) in cognitive radio sensing network (CRSN)

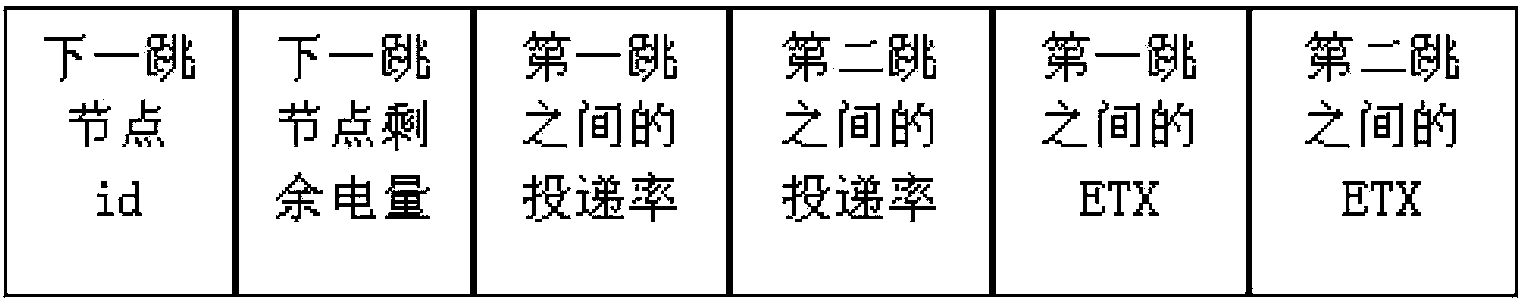

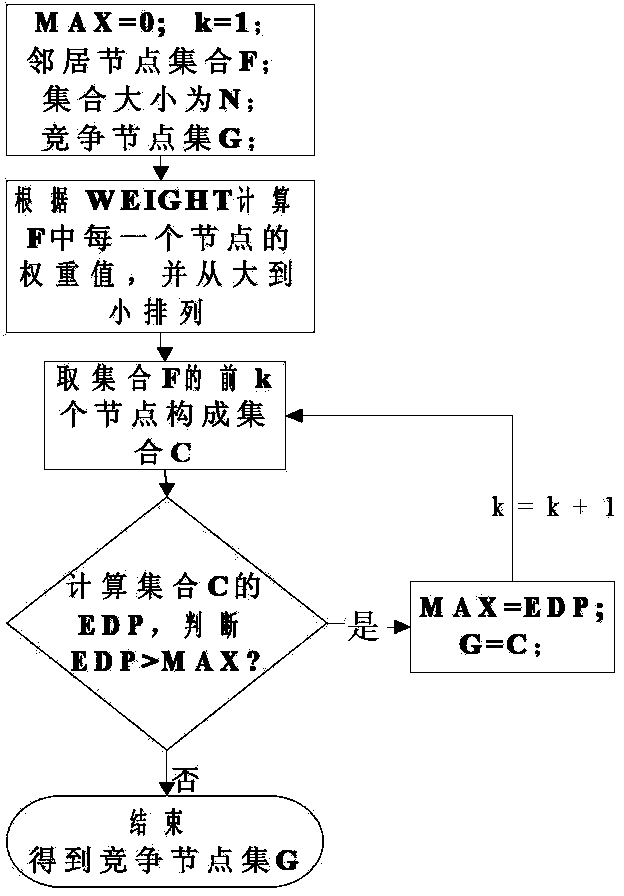

InactiveCN103781145AOvercoming the Unstable FeaturesHigh reliability of data transmissionNetwork topologiesHigh level techniquesNODALJoule

The invention provides a method for designing a multi-channel opportunistic routing protocol (MCORP) in a cognitive radio sensing network (CRSN). In the method, the priority orders of competitive nodes of each node are determined by weighing the residual electricity amount of the competitive nodes, and delivery ratio and ETX between the node and the competitive nodes thereof. The delivery ratio and the ETX of each link are obtained by calculating the average value of all channels in the network. Energy consumption is increased while a competitive node set is enlarged. In view of the finiteness of the energy of nodes, weighing is required to be considered between the delivery ratio and the energy when the value of the competitive node set is selected in order to decrease energy expenditure. For this purpose, the invention provides an evaluation index EDP (expected energy delivery ratio per joule) in order to weigh the relation of the delivery ratio and the energy. A simulation result further proves that the routing protocol provided in the invention has better performance than a multi-channel routing protocol (MCR) in aspects of throughput and data packet loss rate.

Owner:SHANGHAI JIAO TONG UNIV +1

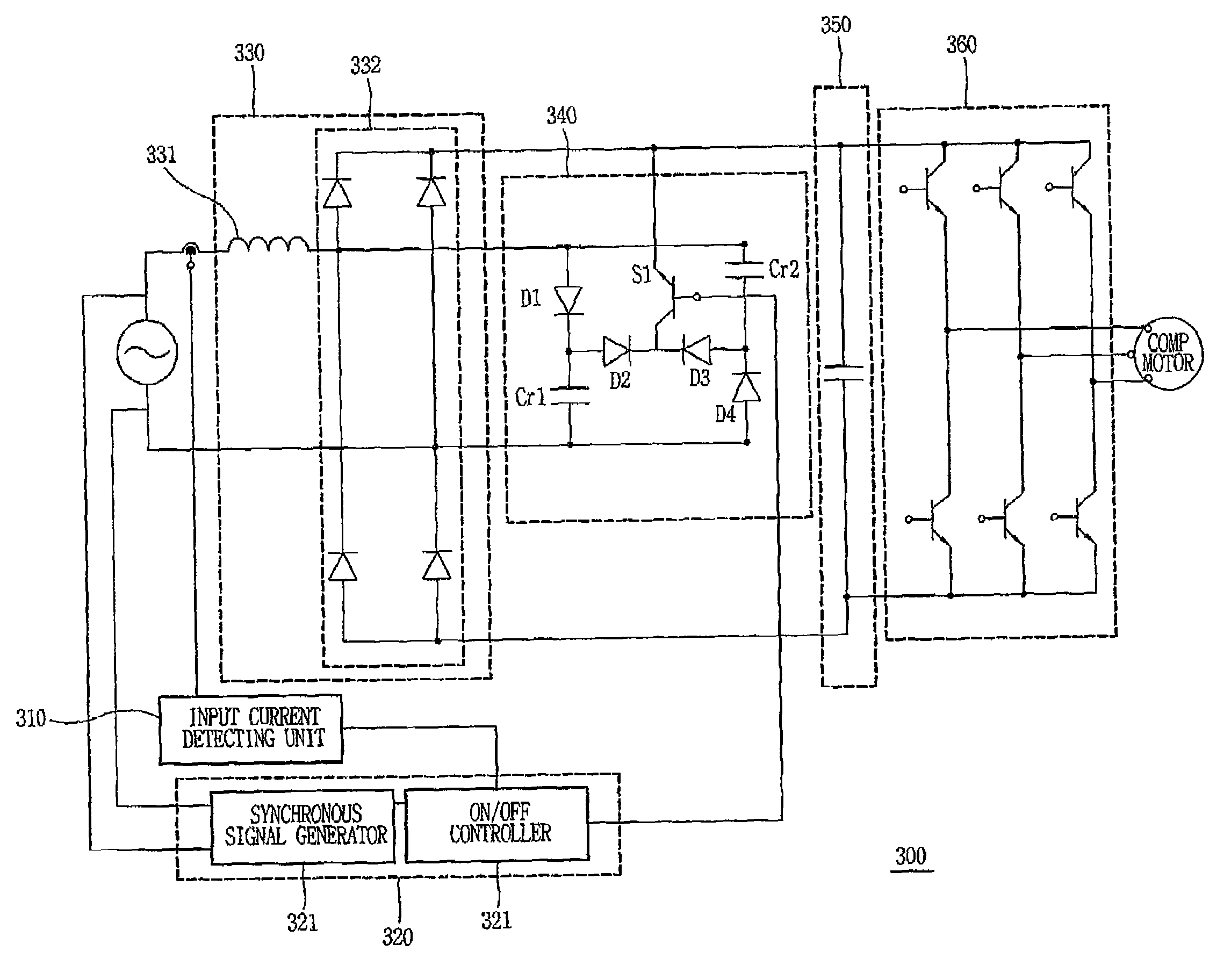

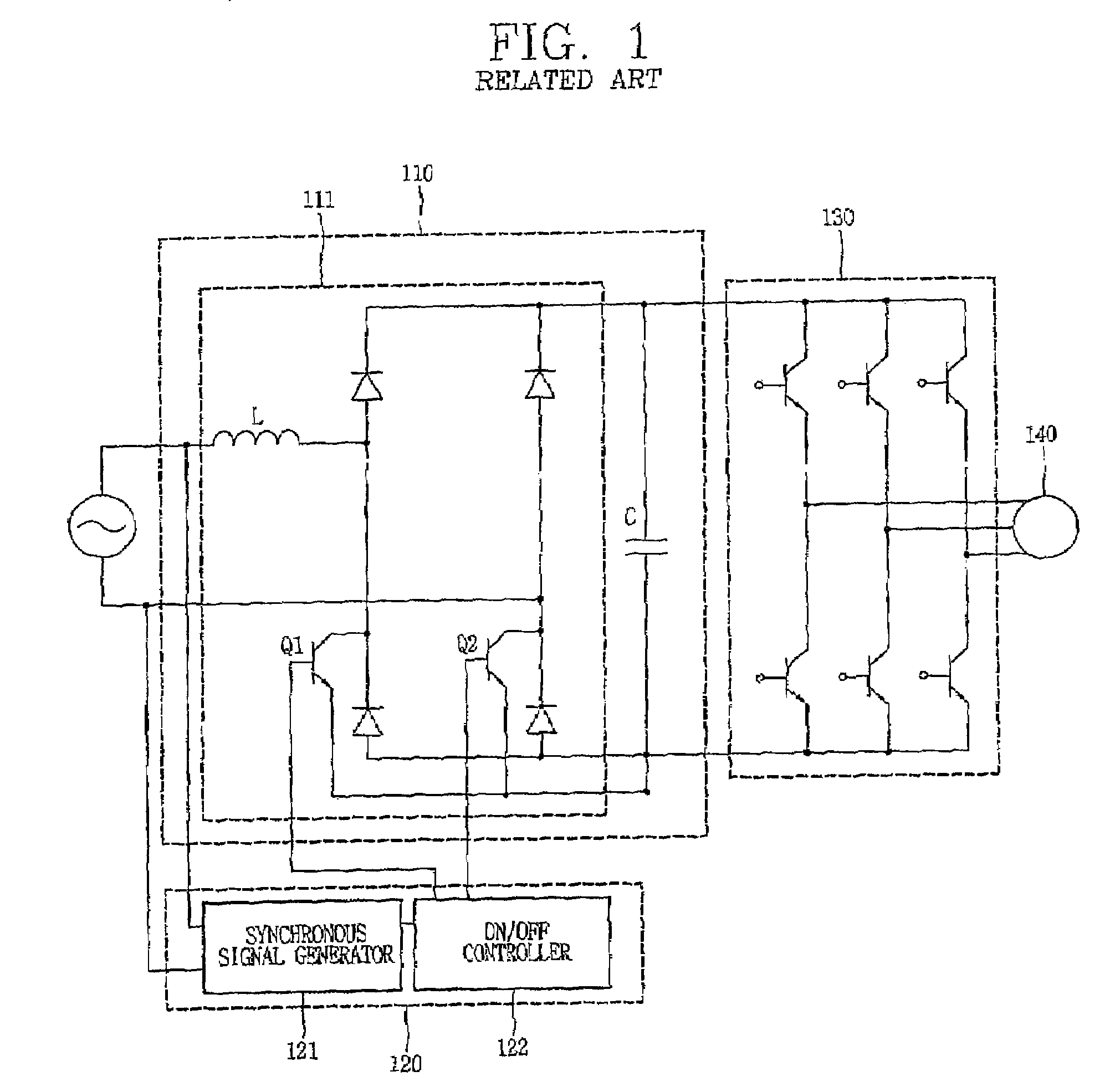

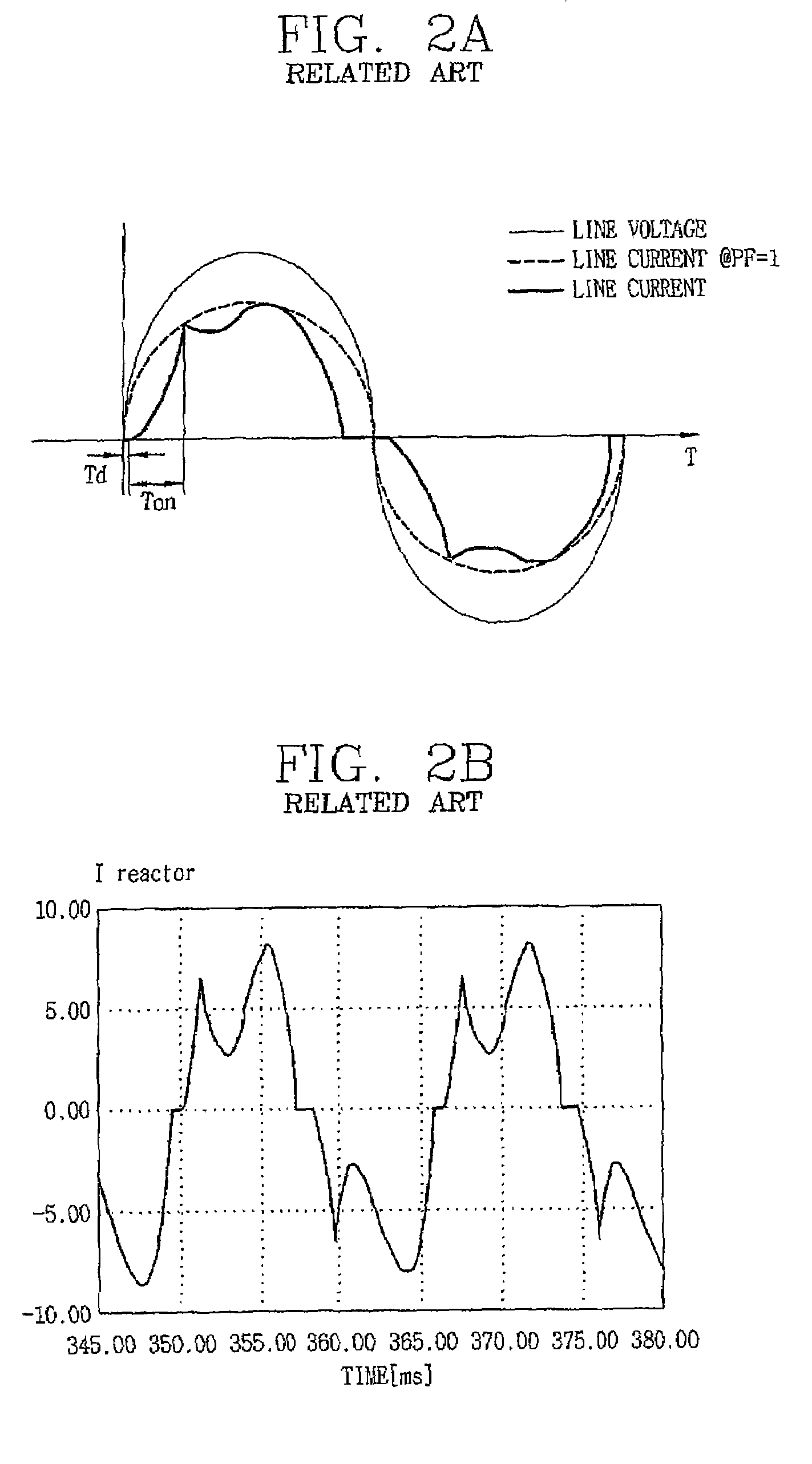

Apparatus and method for supplying DC power source

InactiveUS7532491B2Reduce manufacturing costScaffold connectionsAc-dc conversion without reversalDecreased energyPower factor

An apparatus and method for supplying a direct current power source capable of compensating a power factor of an input power source by increasing and decreasing energy required by load changes, the apparatus comprising: an input current detecting unit for detecting an input current amount to determine a load size, a switching control unit for outputting a switching control signal to compensate a power factor of an input power source based upon the determined load size, a filtering / rectifying unit for reducing a harmonic of the input current and rectifying an input AC voltage, a power factor compensating unit for supplying charged energy to the load based upon the switching control signal, a smoothing unit for smoothing the rectified input AC voltage into a DC voltage, and an inverter for converting the smoothed DC voltage into an AC voltage and outputting the converted AC voltage to drive the load, whereby the power factor compensation (PFC) standard can be satisfied although the load is increased, and a fabricating cost can be reduced by using a reactor with a low capacity.

Owner:LG ELECTRONICS INC

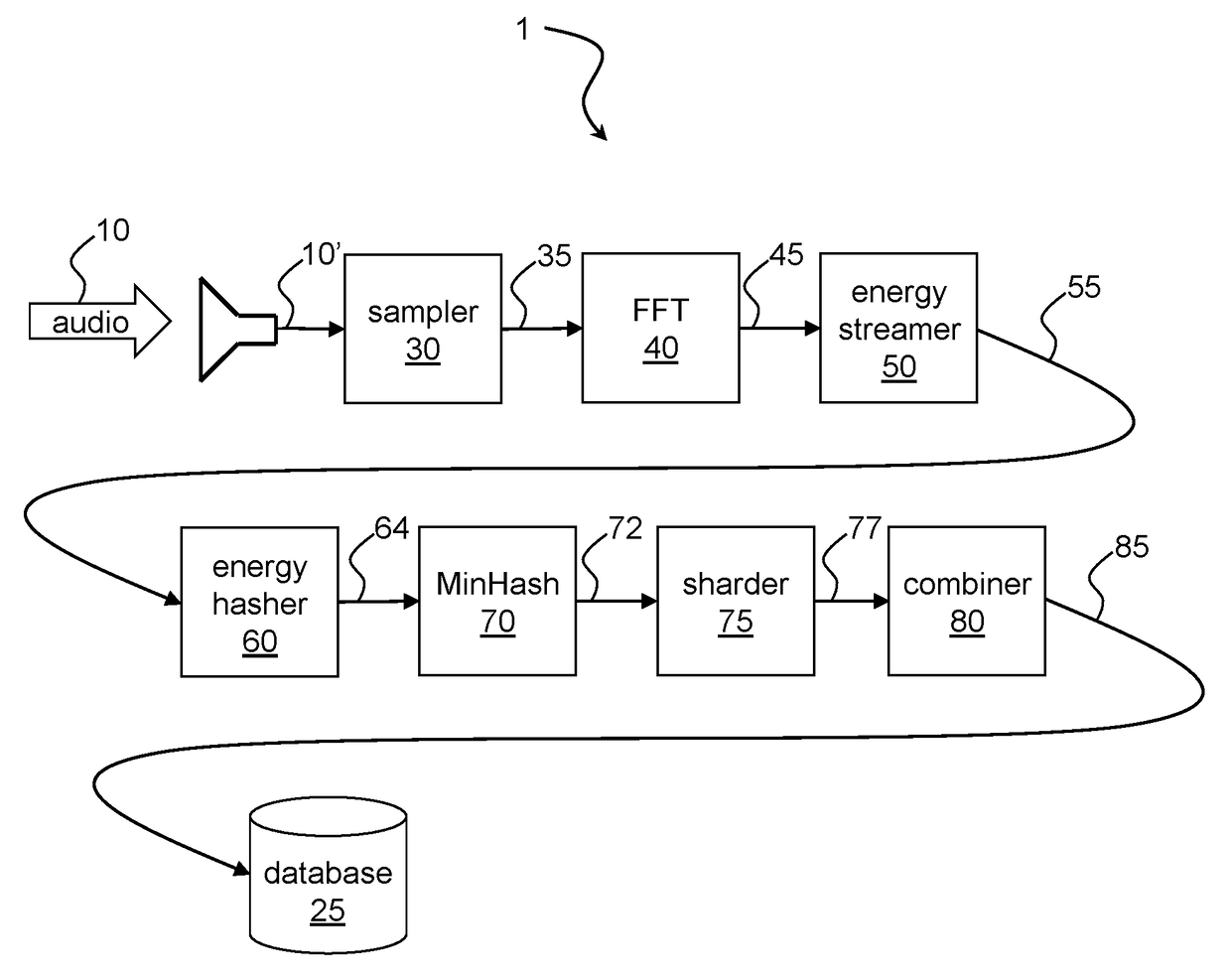

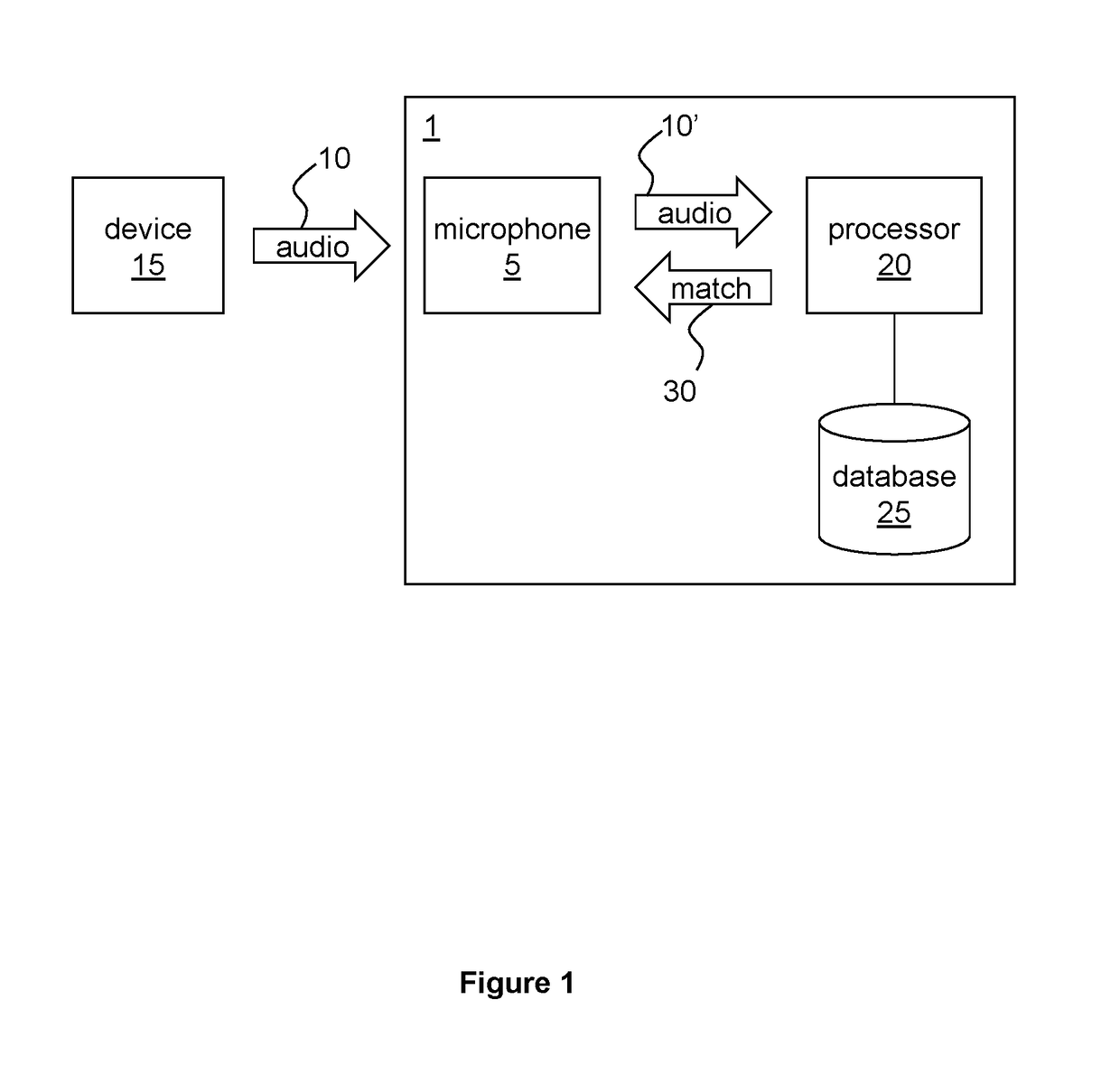

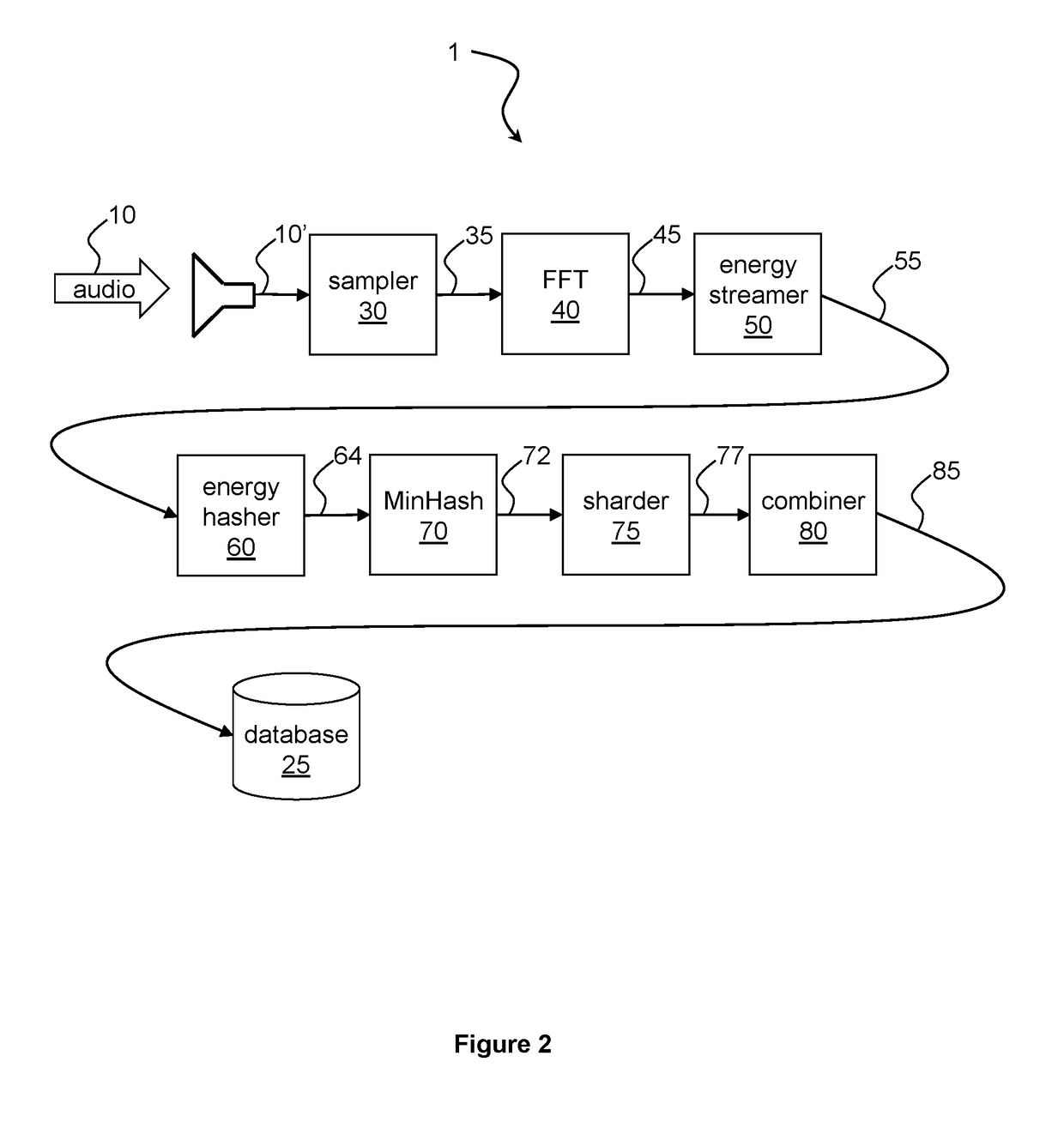

Audio fingerprinting based on audio energy characteristics

ActiveUS9786298B1Reduce delaysSmall sizeElectrophonic musical instrumentsDigital data information retrievalDecreased energyComputer science

Audio fingerprinting includes obtaining audio samples of a piece of audio, generating frequency representations of the audio samples, identifying increasing and decreasing energy regions in frequency bands of the frequency representations, and generating hashes of features of the piece of audio. Each hash of features corresponds to portions of the identified energy regions appearing in a respective time window. Each feature is defined as a numeric value that encodes information representing: a frequency band of an energy region appearing in the respective time window, whether the energy region appearing in the respective time window is an increasing energy region or whether the energy region appearing in the respective time window is a decreasing energy region, and a placement of the energy region appearing in the respective time window.

Owner:SOURCE DIGITAL INC

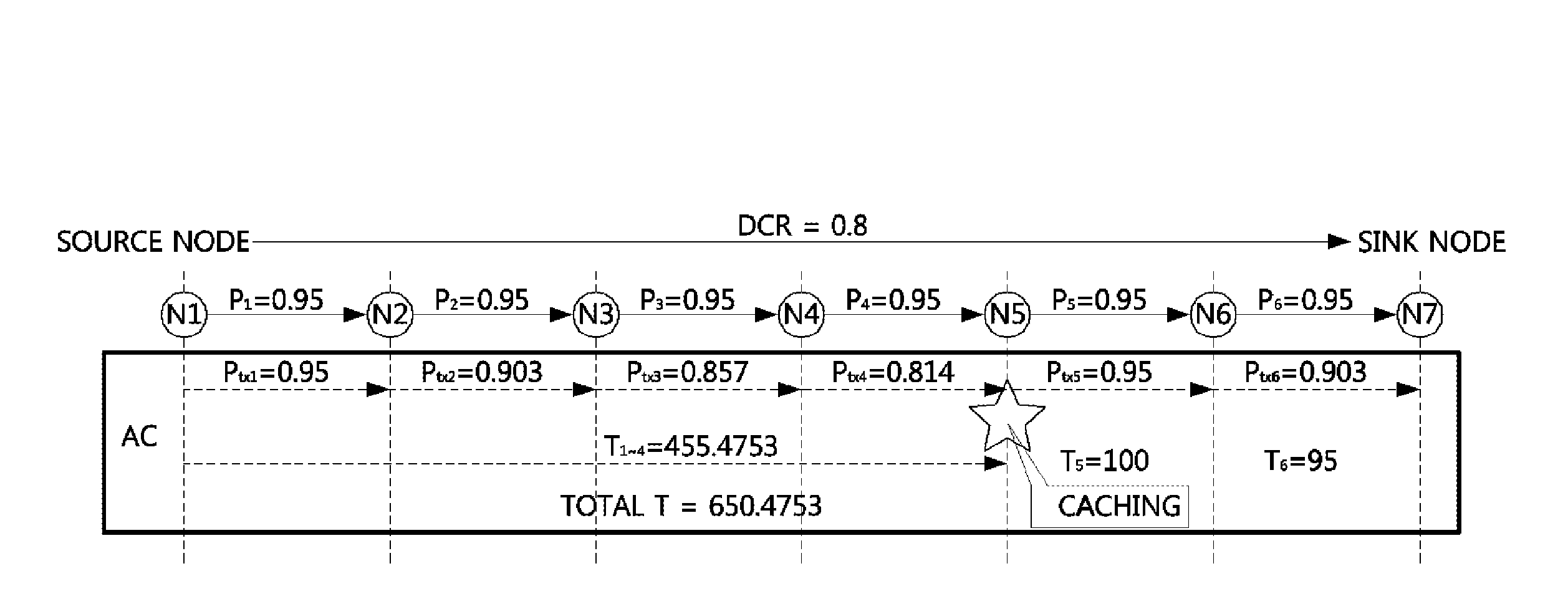

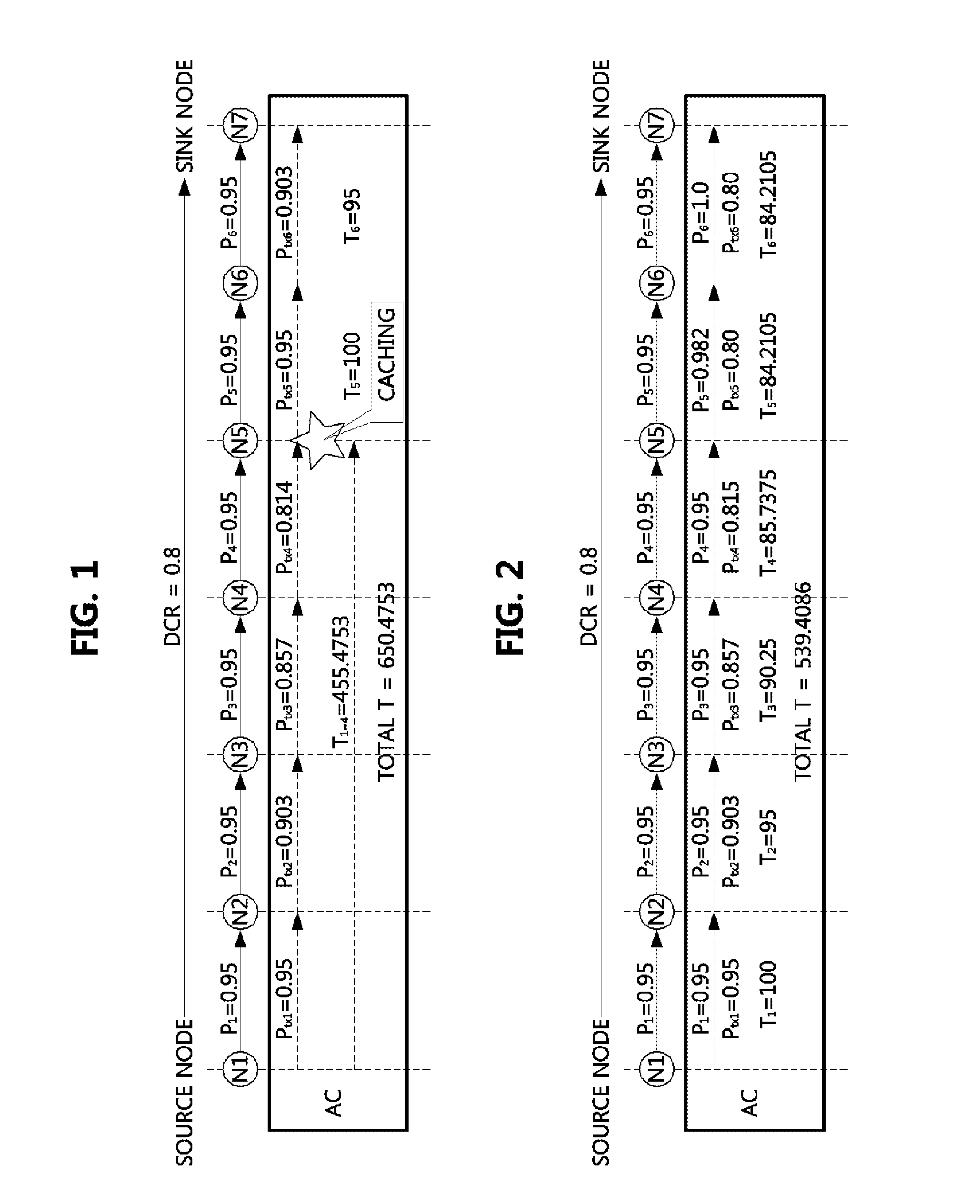

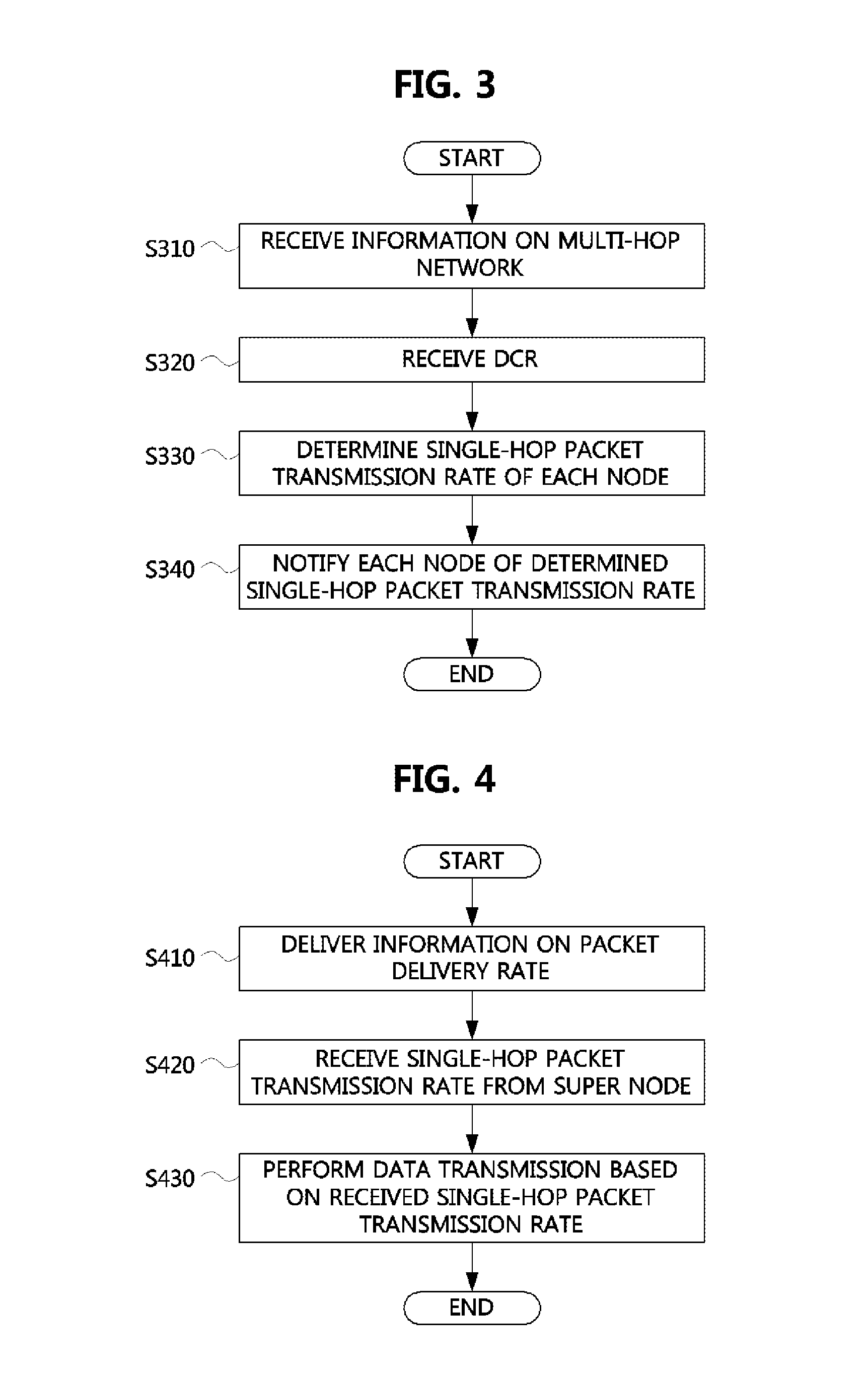

Data transmission method of multi-hop network and device using the same

InactiveUS20140307605A1Easy to useReduce overheadPower managementTransmission systemsDecreased energyData transmission

Owner:ELECTRONICS & TELECOMM RES INST

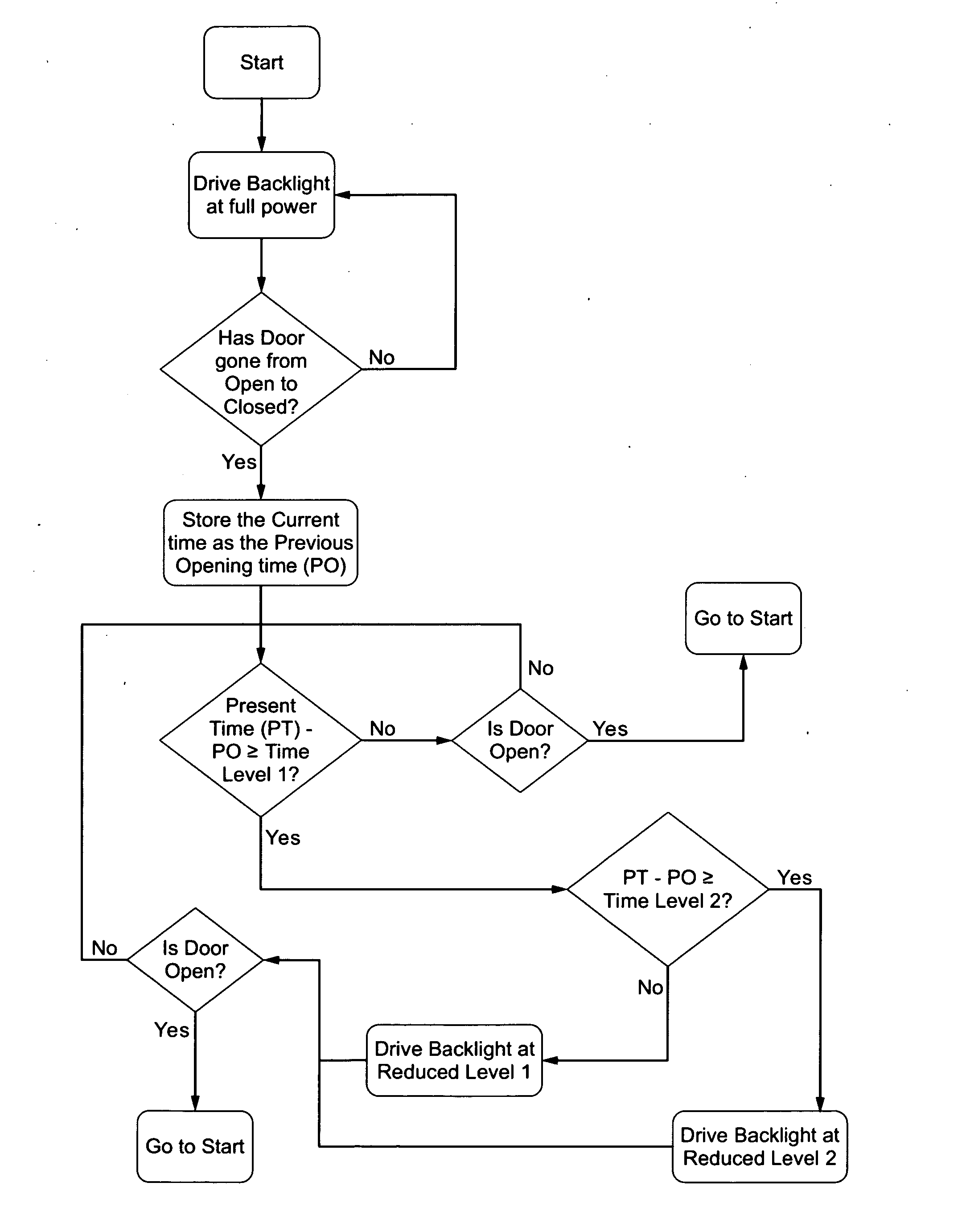

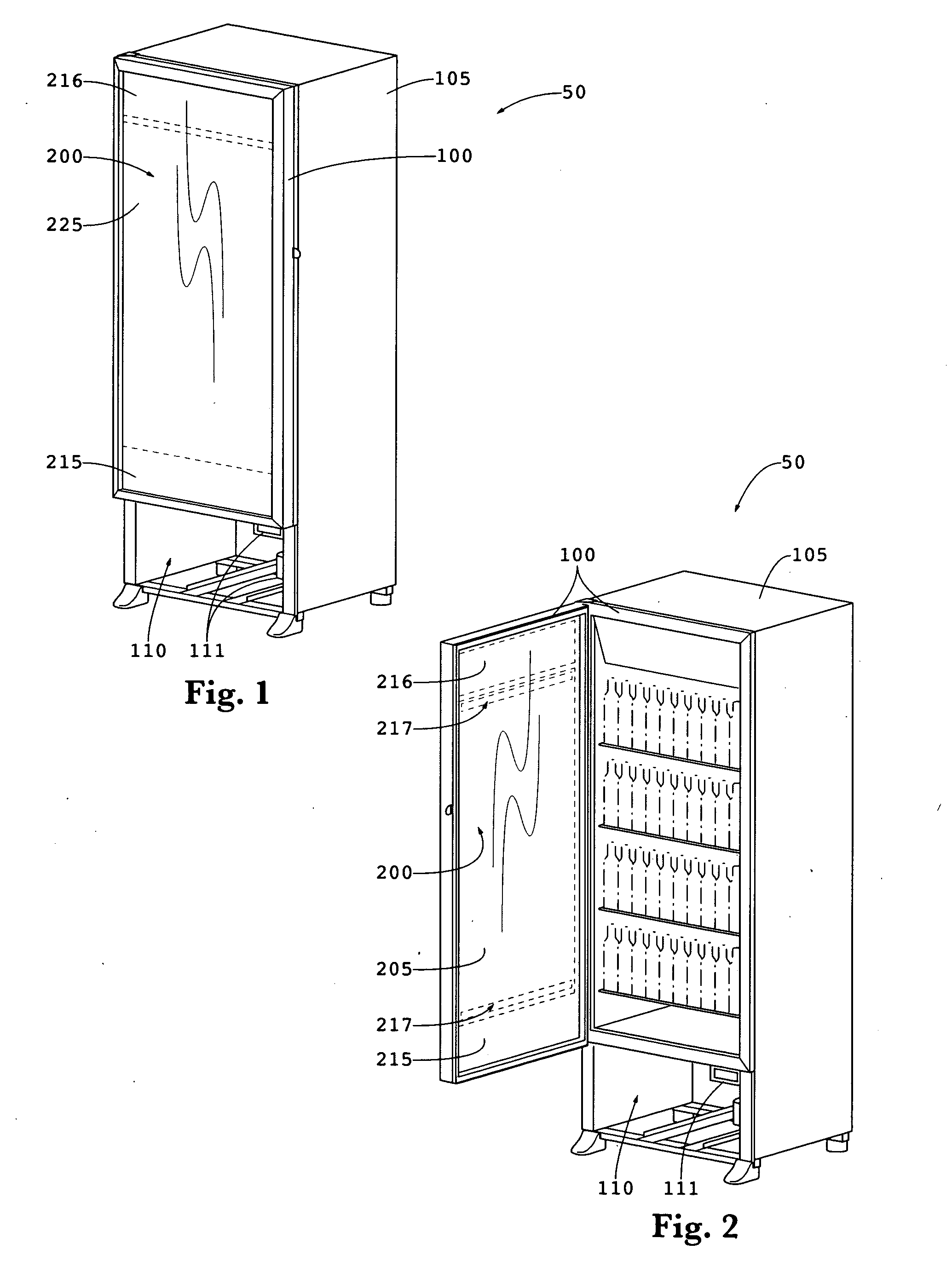

System for Decreasing Energy Usage of a Transparent LCD Display Case

ActiveUS20160192451A1Reduce energy useElectrical apparatusElectroluminescent light sourcesDecreased energyLiquid-crystal display

An apparatus for controlling a backlight is disclosed. The apparatus includes a housing and door. A transparent liquid crystal display and associated backlight is positioned between front and rear glass panels of said door. A door sensor is positioned to detect if the door is open or shut, and a controller connected to the backlight and door sensor measures the amount of time that has passed between door openings and drives the backlight at various levels based upon the elapsed time.

Owner:MFG RESOURCES INT INC

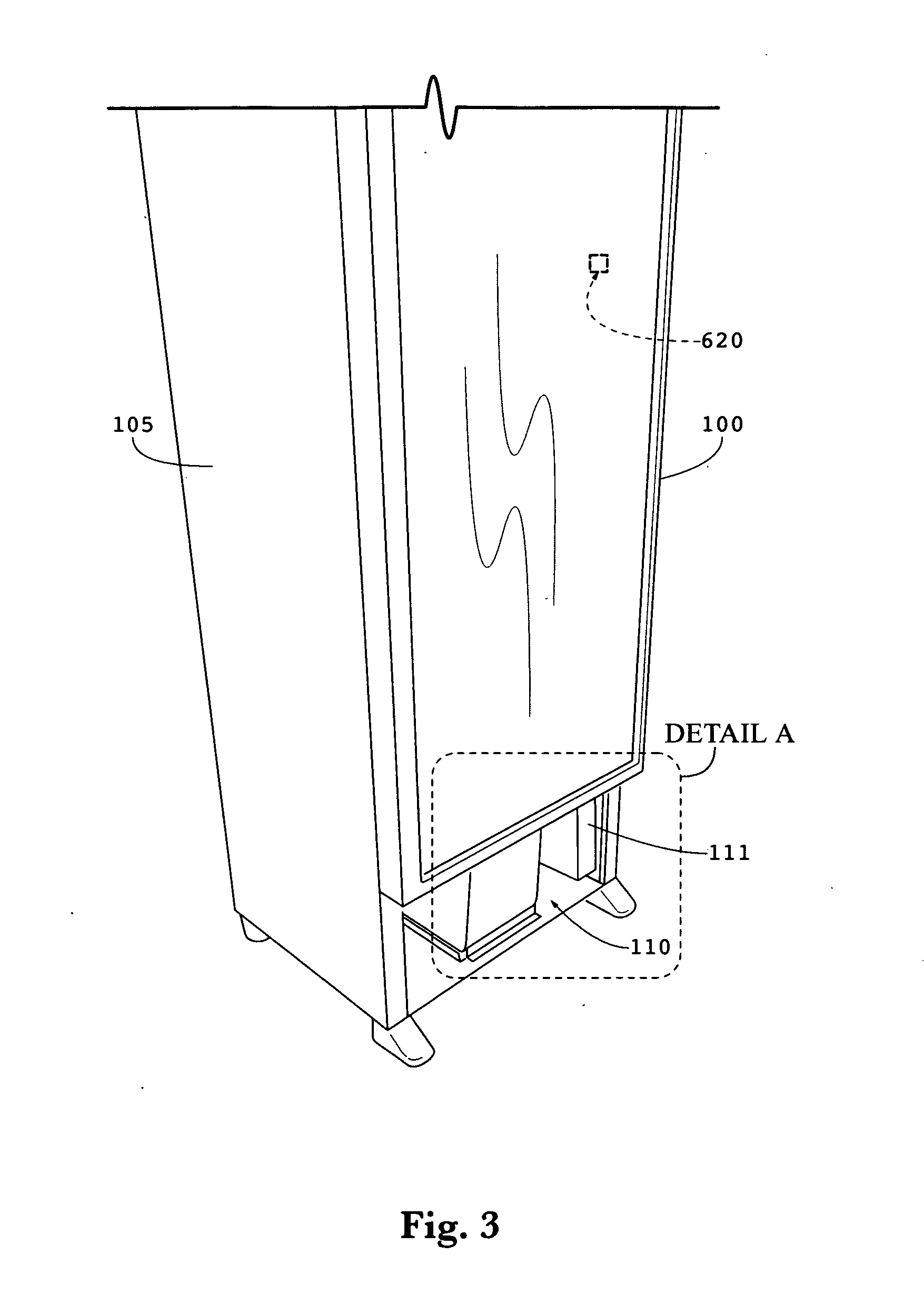

Air conditioning water heater using air source heat pump

InactiveCN1995855AAchieve recyclingRealize the cooling functionEnergy recovery in ventilation and heatingFluid heatersDecreased energyEngineering

The invention relates to an air-source heat pump air-conditioner heater, comprising in-out heating water system and air-conditioner system. The in-out heating water system is connected with the air-conditioner system. Said in-out heating water system comprises water tank, heat exchanger of water tank, water inlet port and water outlet port. The water inlet port of heat exchanger of water tank is connected with water inlet port by pipe and the water outlet port of heat exchanger of water tank is connected with water inlet port of water tank. The water outlet port of water tank is connected with the water outlet port. In the invention, because the structure that in-out heating water system is combined with the air-conditioner system is adopted; little electric power can be needed to drive the compressor run. Not only refrigerating and heating performance can be realized but also hot water is generated in cycle so as to realize energy recovery. It is provided with compact structure, low cost, convenience installment and maintenance. It can decrease energy consumption greatly and the thermal efficiency is improved greatly.

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

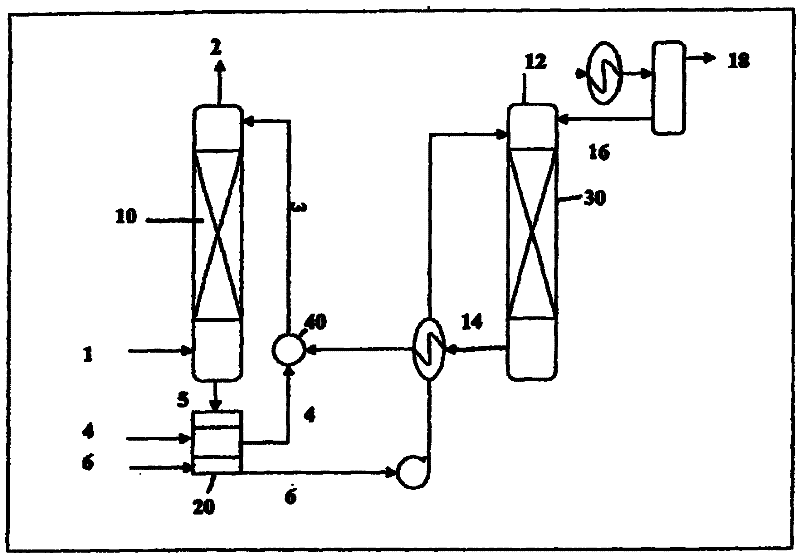

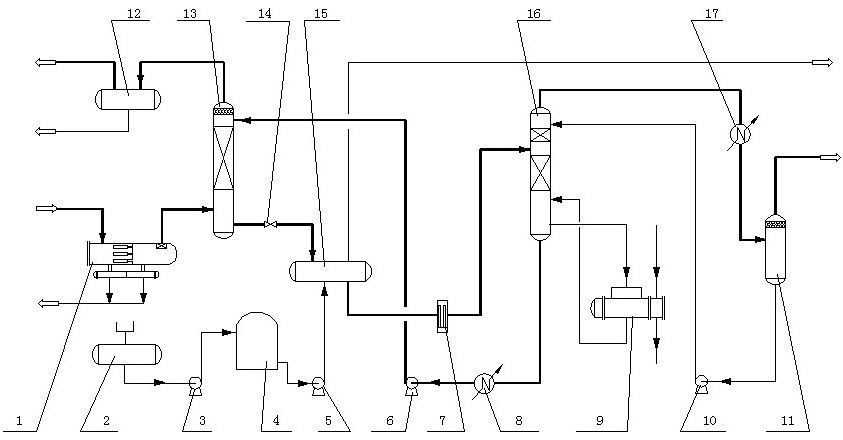

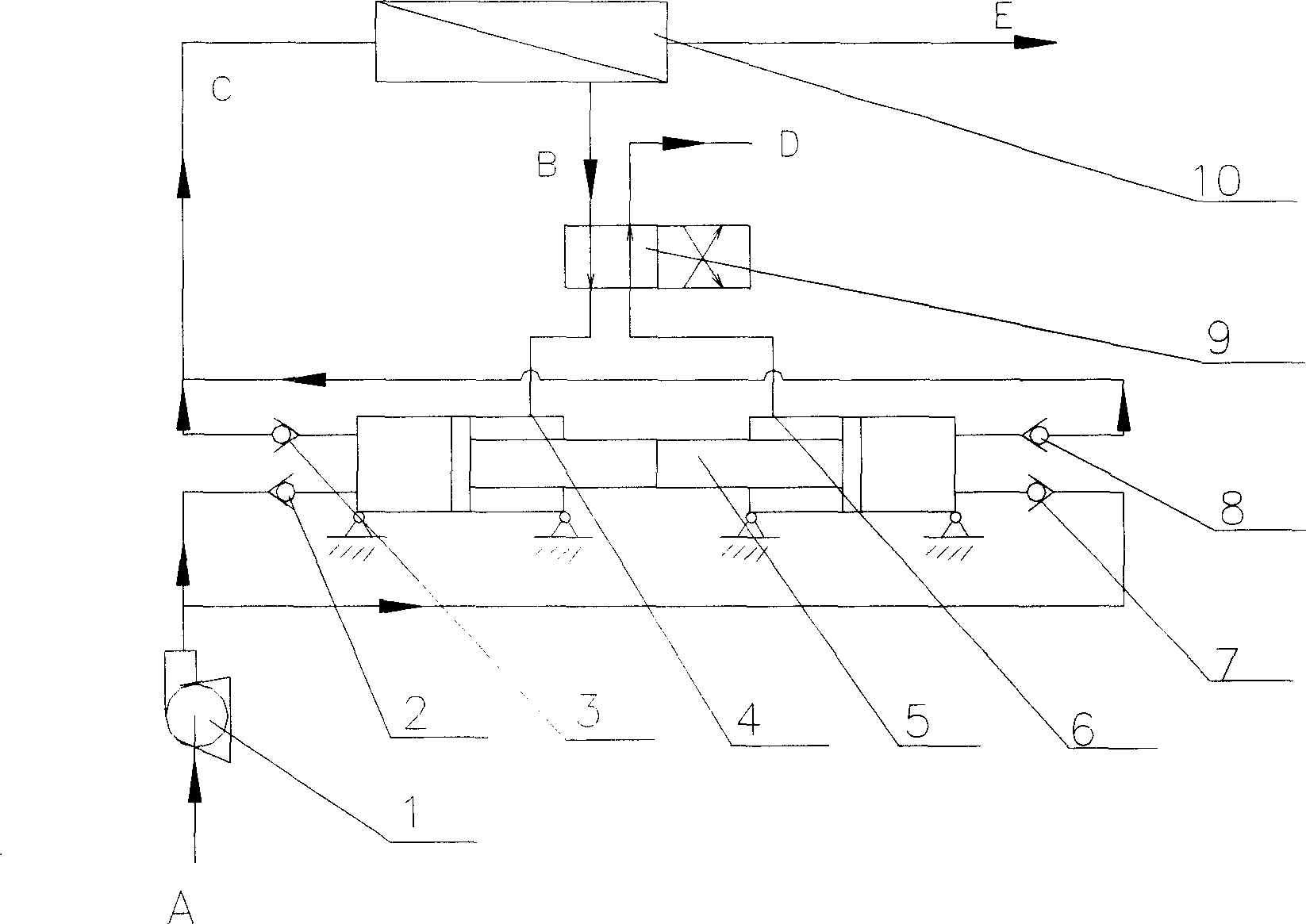

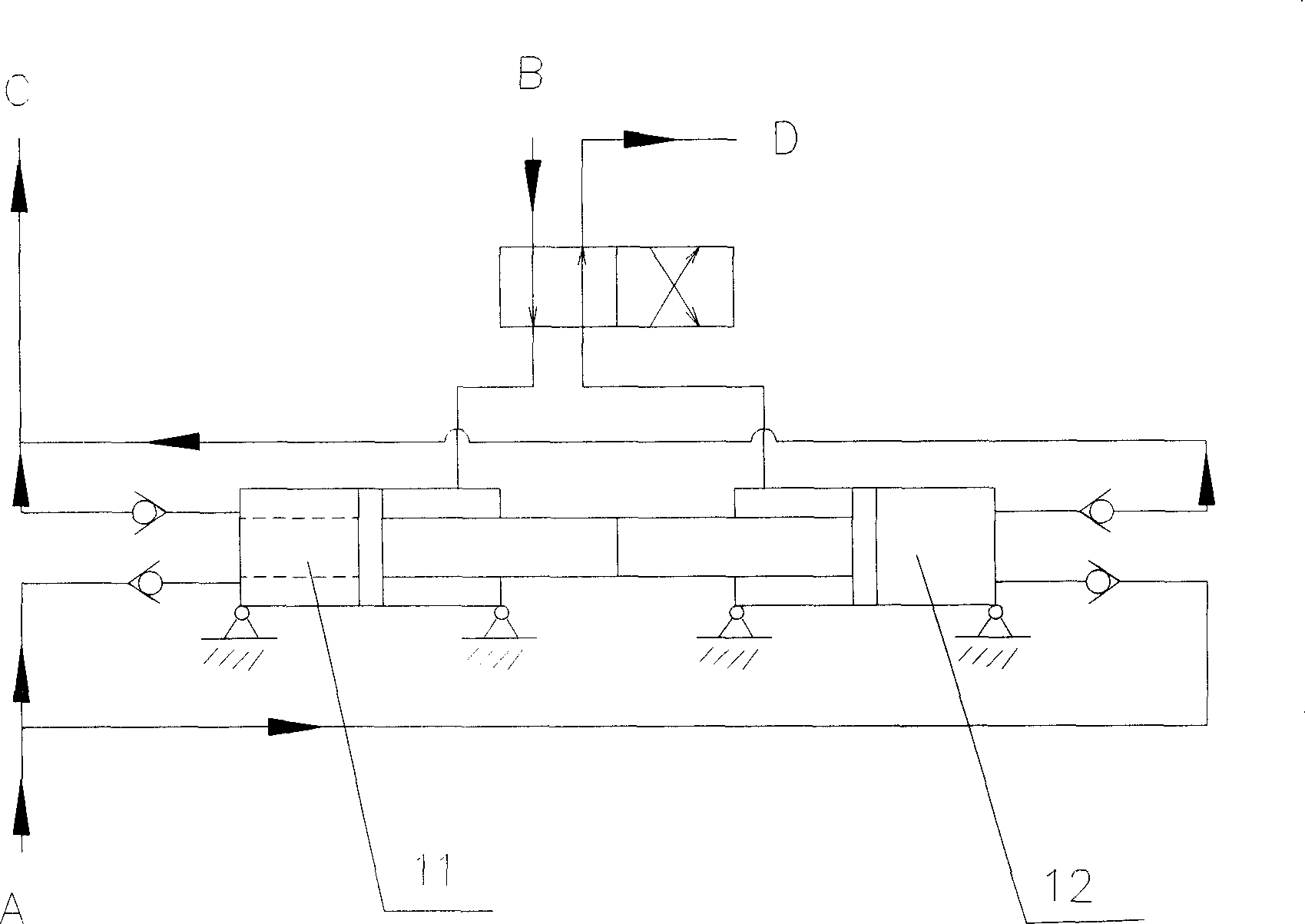

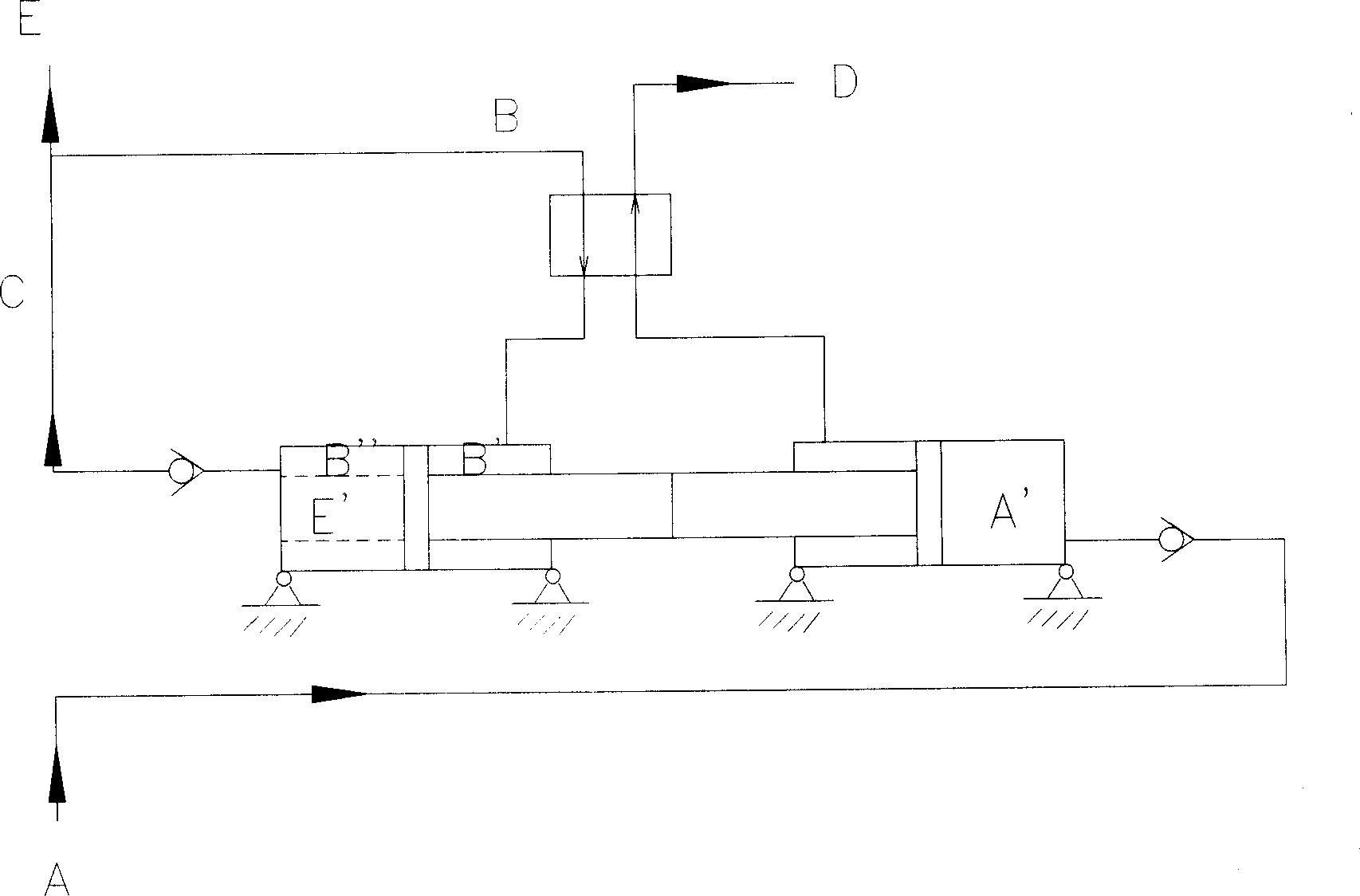

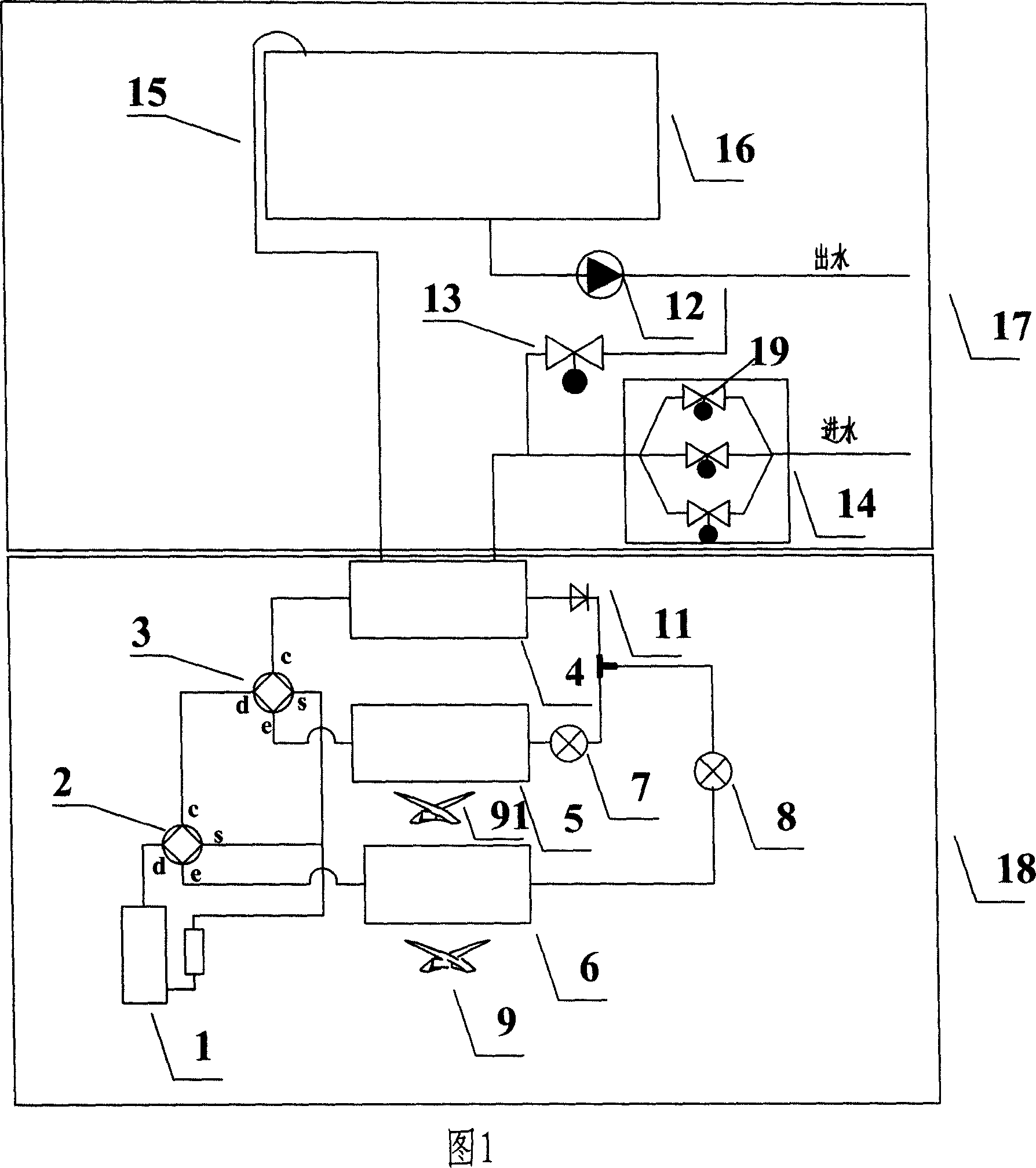

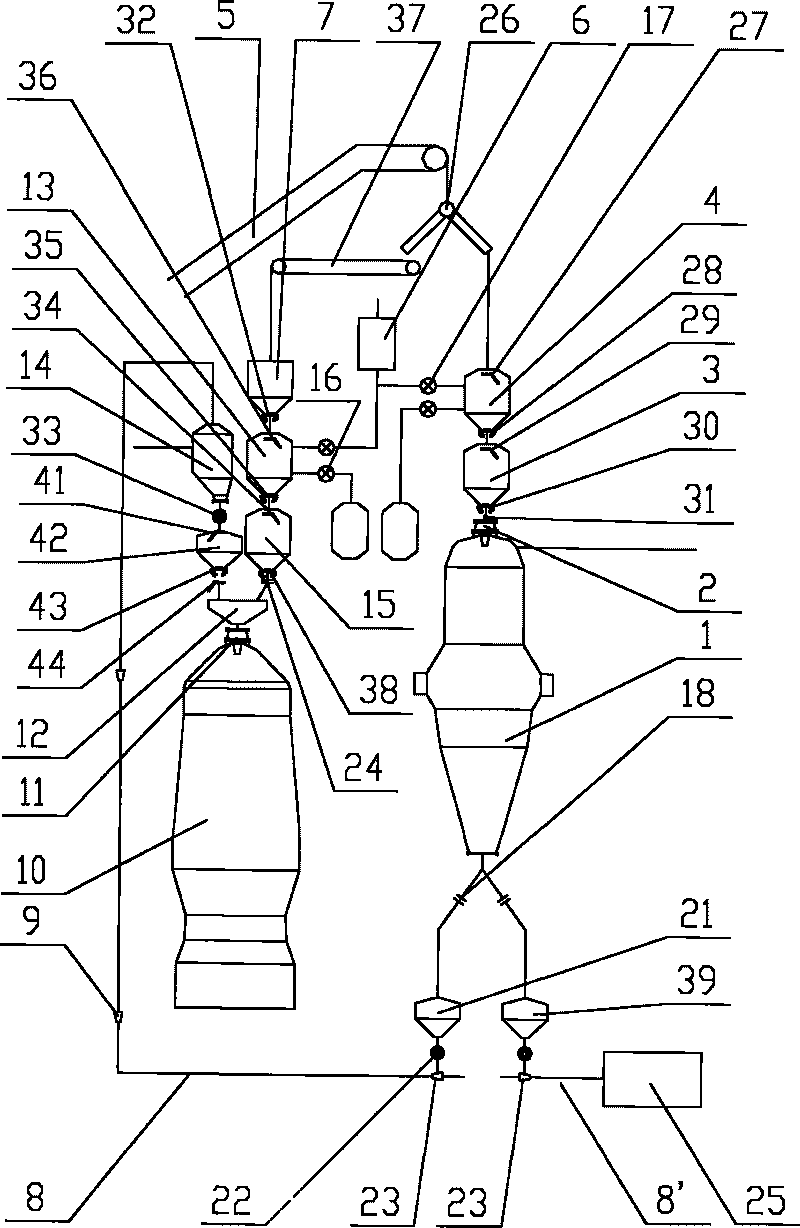

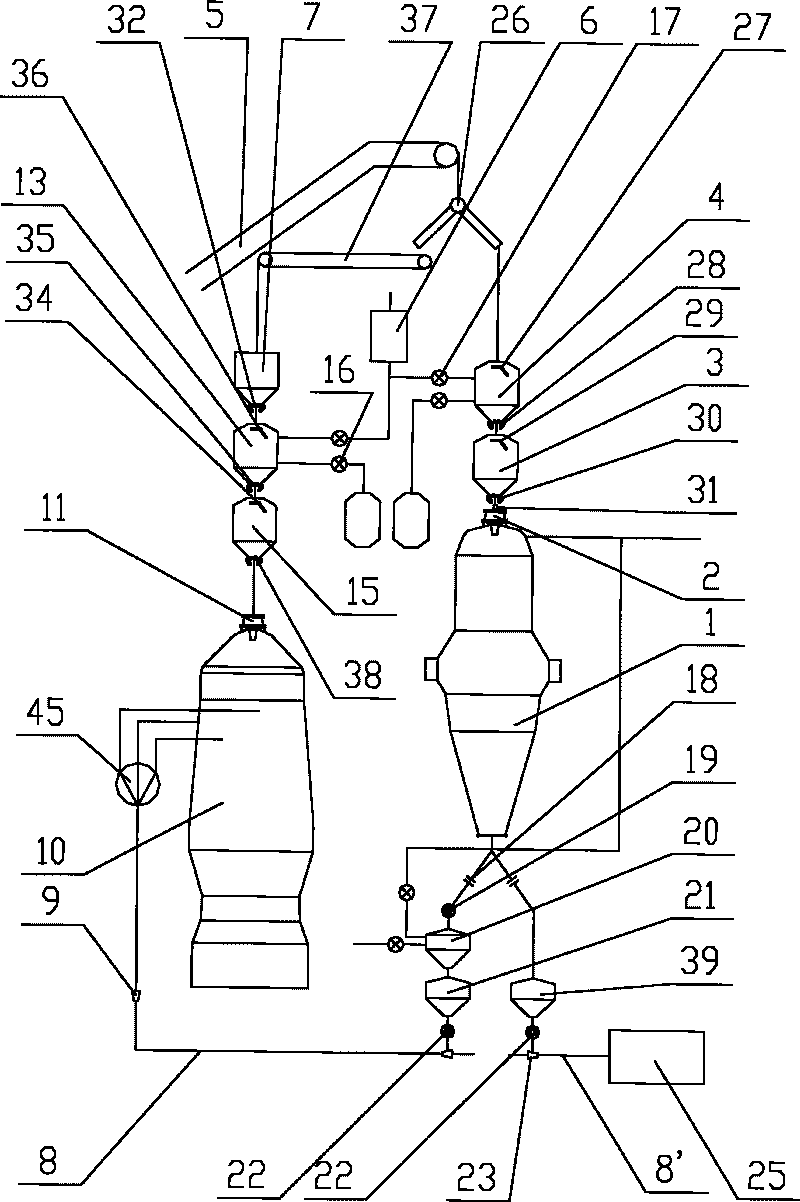

Ironmaking technical furnace top charging technology

ActiveCN101693933AReduce heat lossReduce the overall heightFluidised-bed furnacesProduction rateThermal state

The invention relates to an ironmaking technical furnace top charging technology. The technology includes a direct reduction furnace top charging system, a melting furnace top charging system and a sponge iron delivery system, wherein the direct reduction furnace top charging system and the melting furnace top charging system are arranged in parallel, the top of a direct reduction furnace is provided with a raw material delivery device that delivers ores, fuels and auxiliary materials to the top of a direct reduction furnace (1) and a melting furnace (10); and after passing through at least one distribution device, the ores pass through the direct reduction furnace top charging system and are added in the direct reduction furnace (1), and the fuels and the auxiliary materials pass through the melting furnace top charging system and are then added in the melting furnace (10). The technology lowers the whole height of charging systems and is convenient for construction. Simultaneously, the method combines the technology of producing sponge iron through direct reduction with the technology of producing molten iron through melting into a whole, thus reducing the heat loss of thermal-state sponge iron in delivery process, improving productivity and decreasing energy consumption.

Owner:CISDI ENG CO LTD

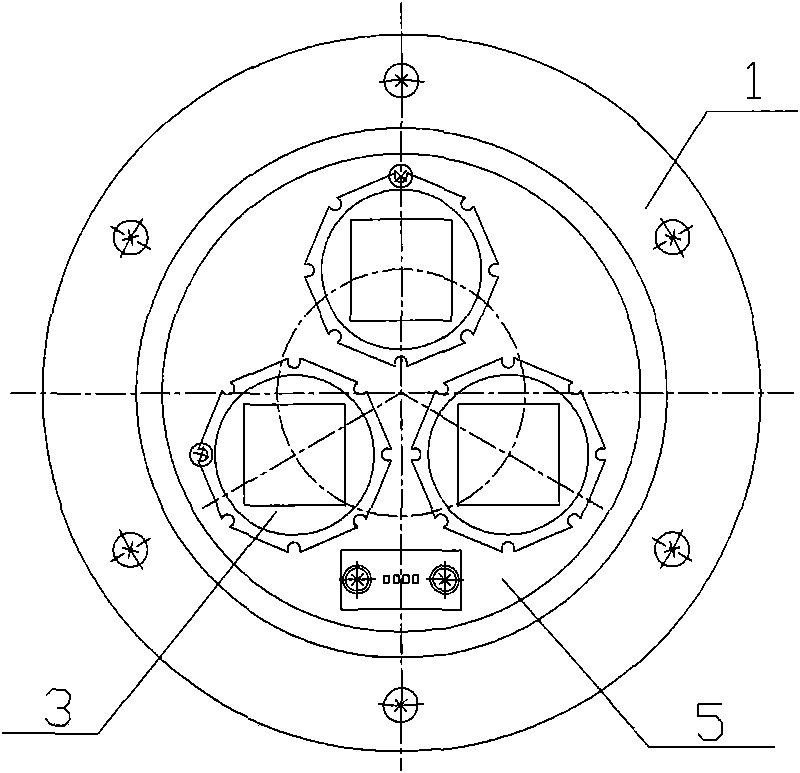

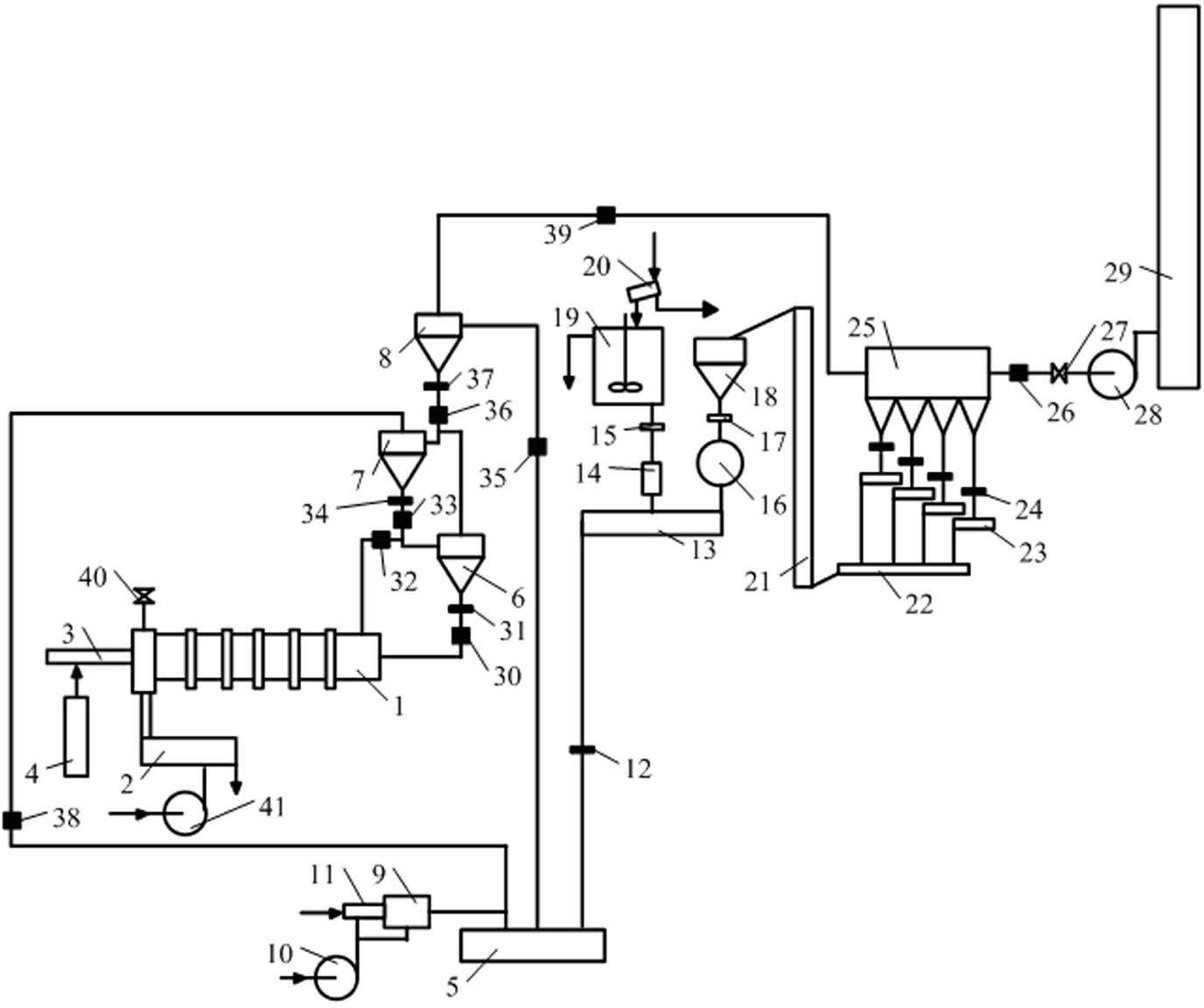

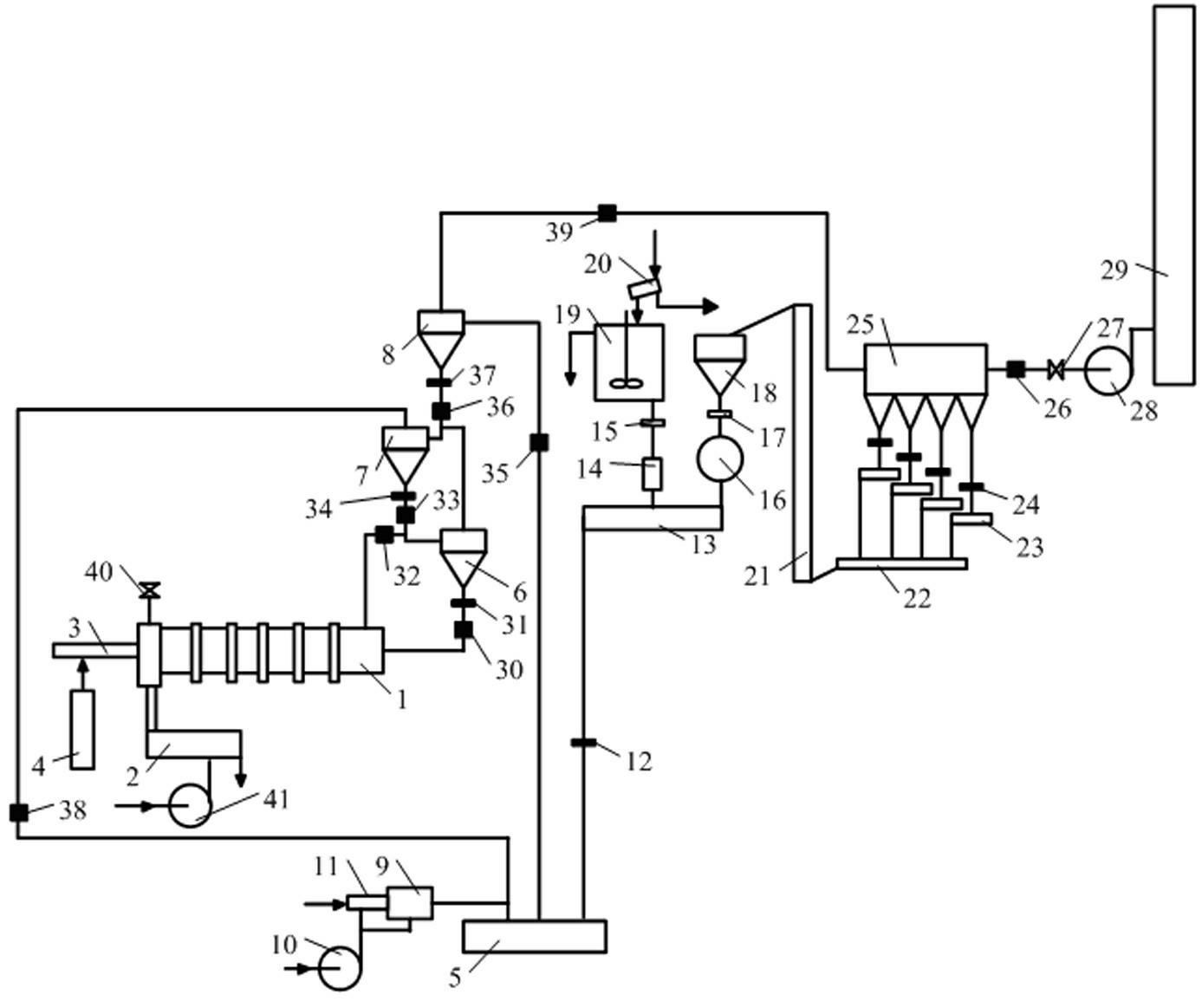

Device for producing alumina clinker by semi-dry process

ActiveCN102180496AIncrease production capacityReduce consumptionAluminium oxides/hydroxidesDecreased energyEngineering

A device for producing alumina clinker by a semi-dry process is characterized in that: three cyclone separators are disposed among a rotary kiln, a dust collector and a dryer crusher; an air inlet of a deduster is communicated with an air outlet of the dryer crusher through a pipeline; an air outlet of the deduster is communicated with an air inlet of the dust collector through a pipeline; an airoutlet of a primary suspension preheater is communicated with an air inlet of the dryer crusher through a pipeline; and the pipeline connecting the primary suspension preheater with the dryer crusheris also communicated with an air outlet of a hot-blast stove. The device of the invention can greatly decrease energy consumption, reduce pollution, and save cost; the length of the rotary kiln required for producing the same amount of products is shortened by 20-25%; the productivity is increased by 30-50%; and the energy consumption of unit product is decreased by above 30%; compared with alumina clinker production by a dry process, the production with the device of the invention does not require a lot of reconstruction of traditional equipment, and is realized by simply adjusting present equipment, and the device has convenient operation, and simple and practical effects.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

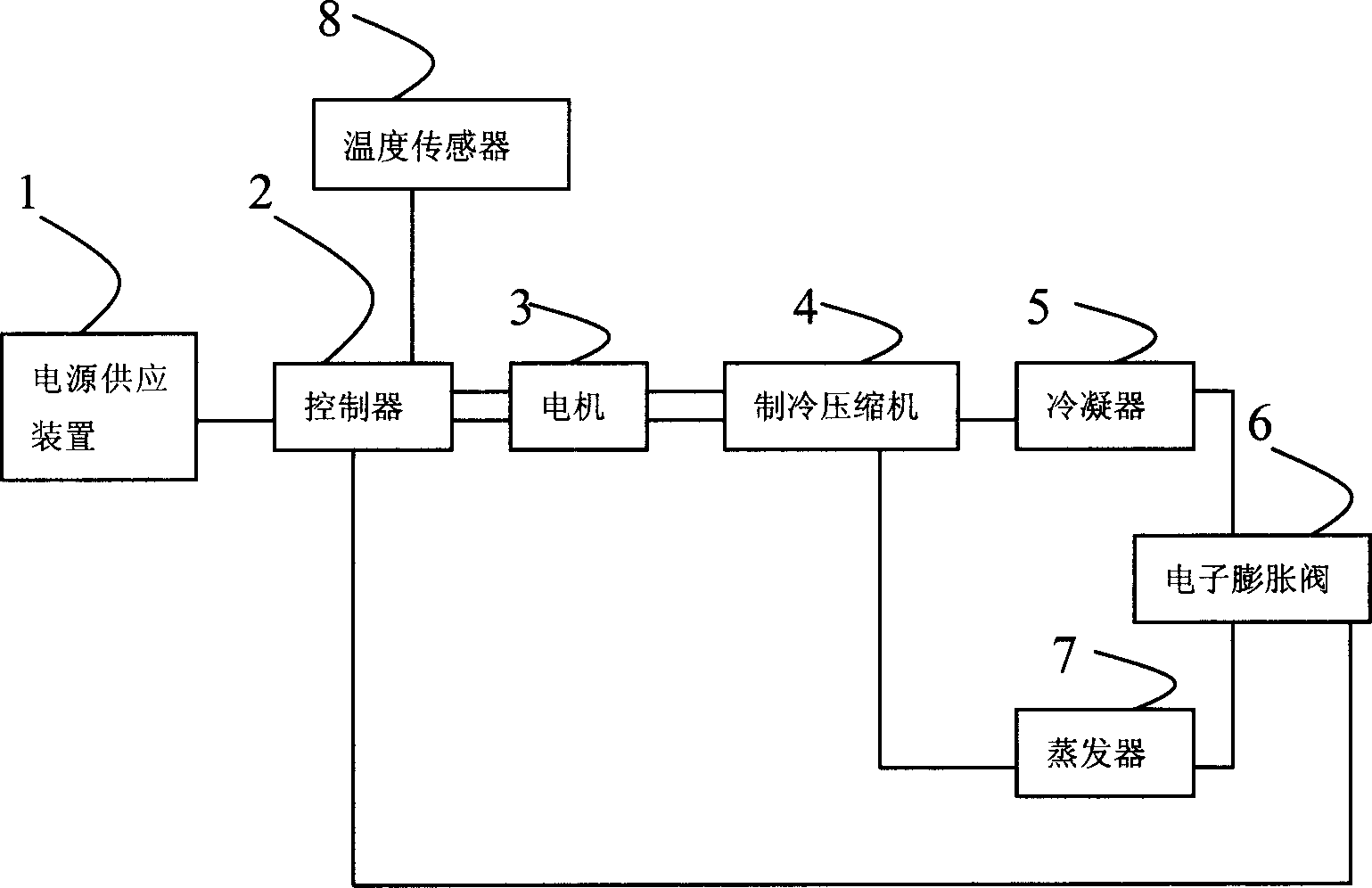

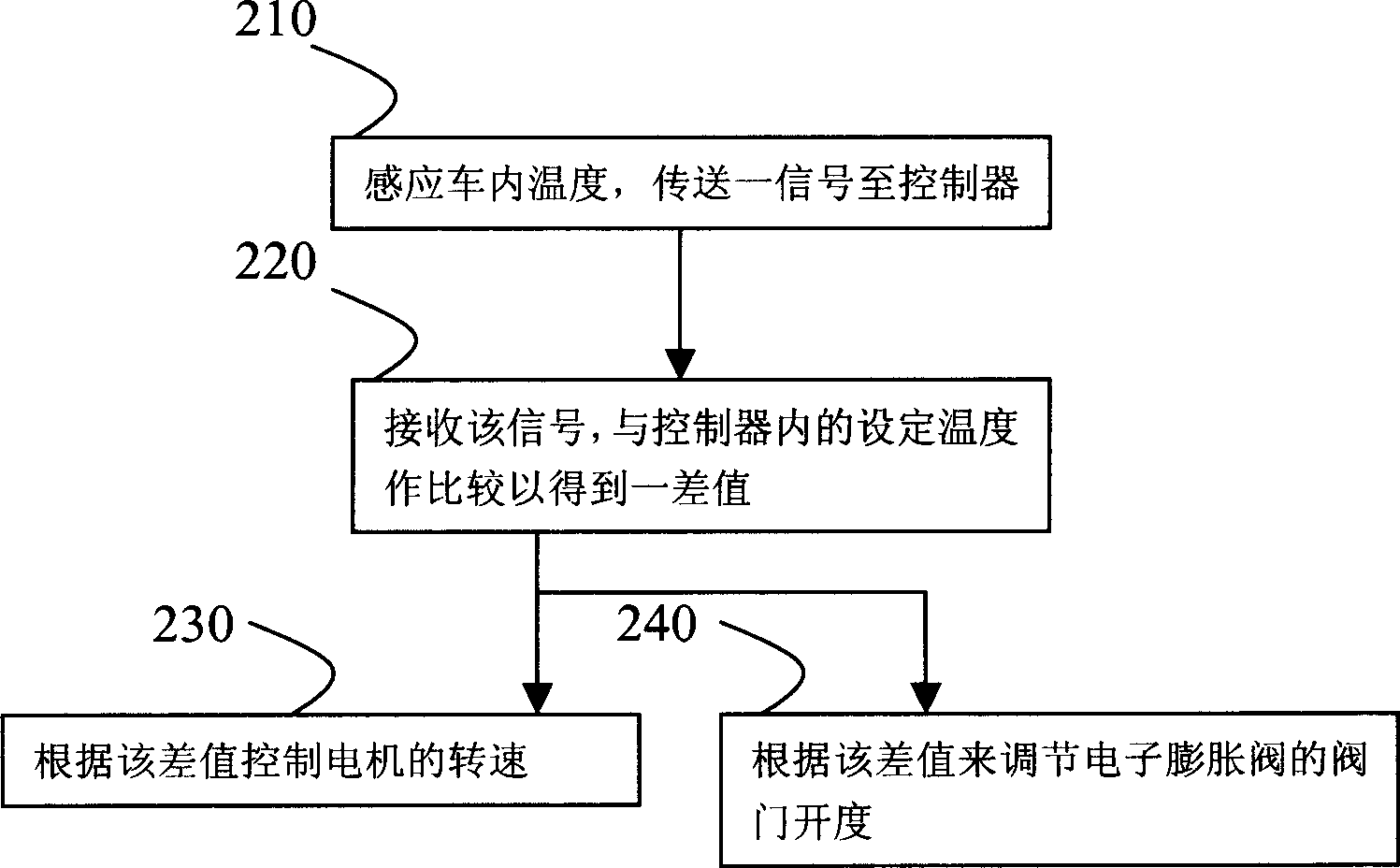

Air-conditioner system and controlling method for electric vehicle

InactiveCN1896630AGuaranteed mileageReasonable matchAir-treating devicesSpace heating and ventilation safety systemsRefrigeration compressorDecreased energy

This invention discloses a kind of motor vehicle air conditioner system. It includes power-supplying device, electric engine, refrigerating compressor, condenser, electronic expanding valve, evaporator, controller and temperature sensor. The said power-supplying device supplies power to electric engine, which drives the refrigerating compressor working. The said refrigerating compressor, condenser, electronic expanding valve and evaporator connect in turn to form refrigerating loop. The said controller positions between power supplying device and electric engine. The power-supplying device supplies power to electric engine through controller. The temperature sensor senses the temperature in the car and sends signal to the controller, which controls the rotating rate of electric engine. This invention can decrease energy consumption.

Owner:BYD CO LTD

Wireless sensor network with energy efficient protocols

InactiveUS8547982B2Reduce the overall heightExtended service lifeEnergy efficient ICTPower managementWireless mesh networkDecreased energy

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS +1

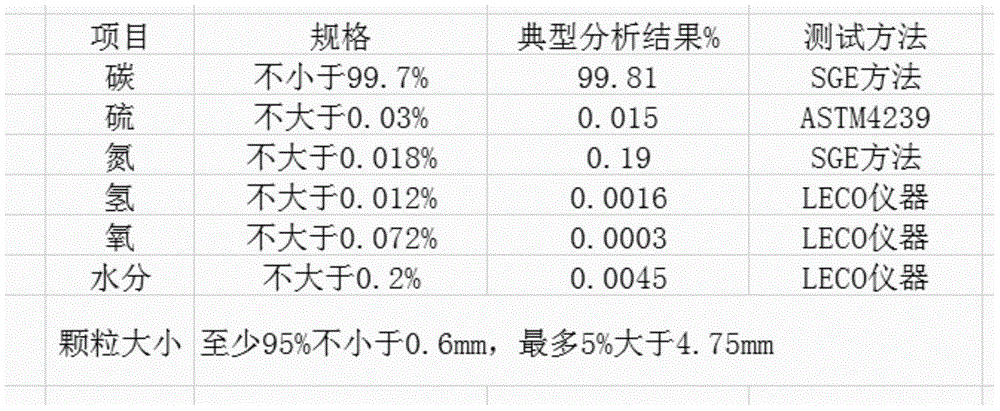

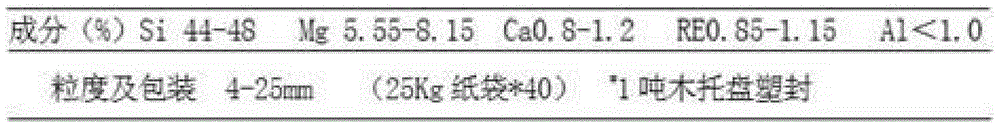

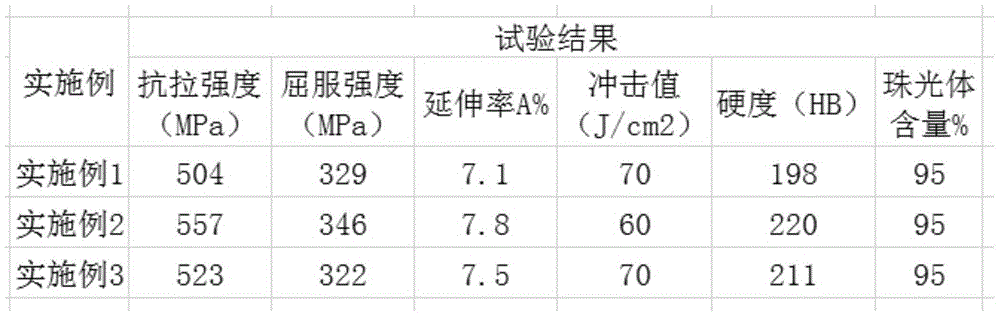

Ductile iron casting and manufacturing method thereof

InactiveCN105441782AReasonable ratioEasy to controlProcess efficiency improvementRare earthDuctile iron

The invention provides a ductile iron casting, which comprises the following chemical components: 3.5-3.9% of C, 2.4-3.2% of Si, 0.4-0.5% of Mn, less than or equal to 0.1% of P, less than or equal to 0.03% of S, less than 0.04% of Ti, 0.030-0.045% of Mg residual, 0.005-0.015% of Re residual, and the balance Fe. The manufacturing method consists of: conducting inspection and compounding in front of a furnace, then carrying out smelting, nodularization, and then performing aftertreatment, like heat treatment, shot blasting, polishing and machining, etc., thus obtaining an output product. Twice inoculation achieves a good effect. The production process is simple, and has obviously decreased energy consumption, thus being suitable for mass production. While ensuring good comprehensive mechanical properties of ductile iron, the method saves adding of copper, tin and other precious metals. In addition, the ratio of raw materials is simple, and magnesium and rare earth are both controlled within the required range, so that the graphitization level of the ductile iron body molded by casting is stabilized at 1-2.

Owner:TIANJIN ZHONGDA PRECISION MACHINERY

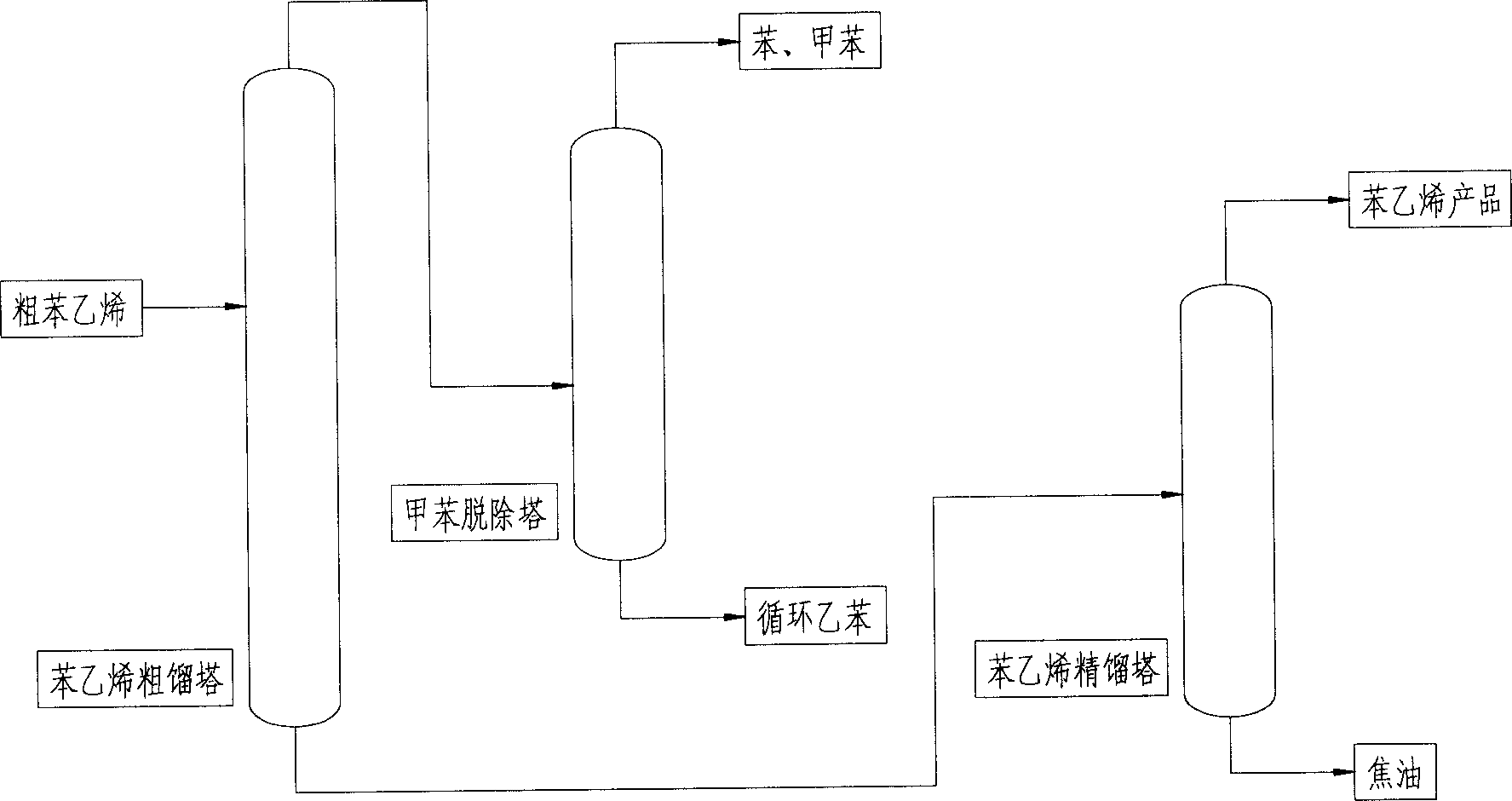

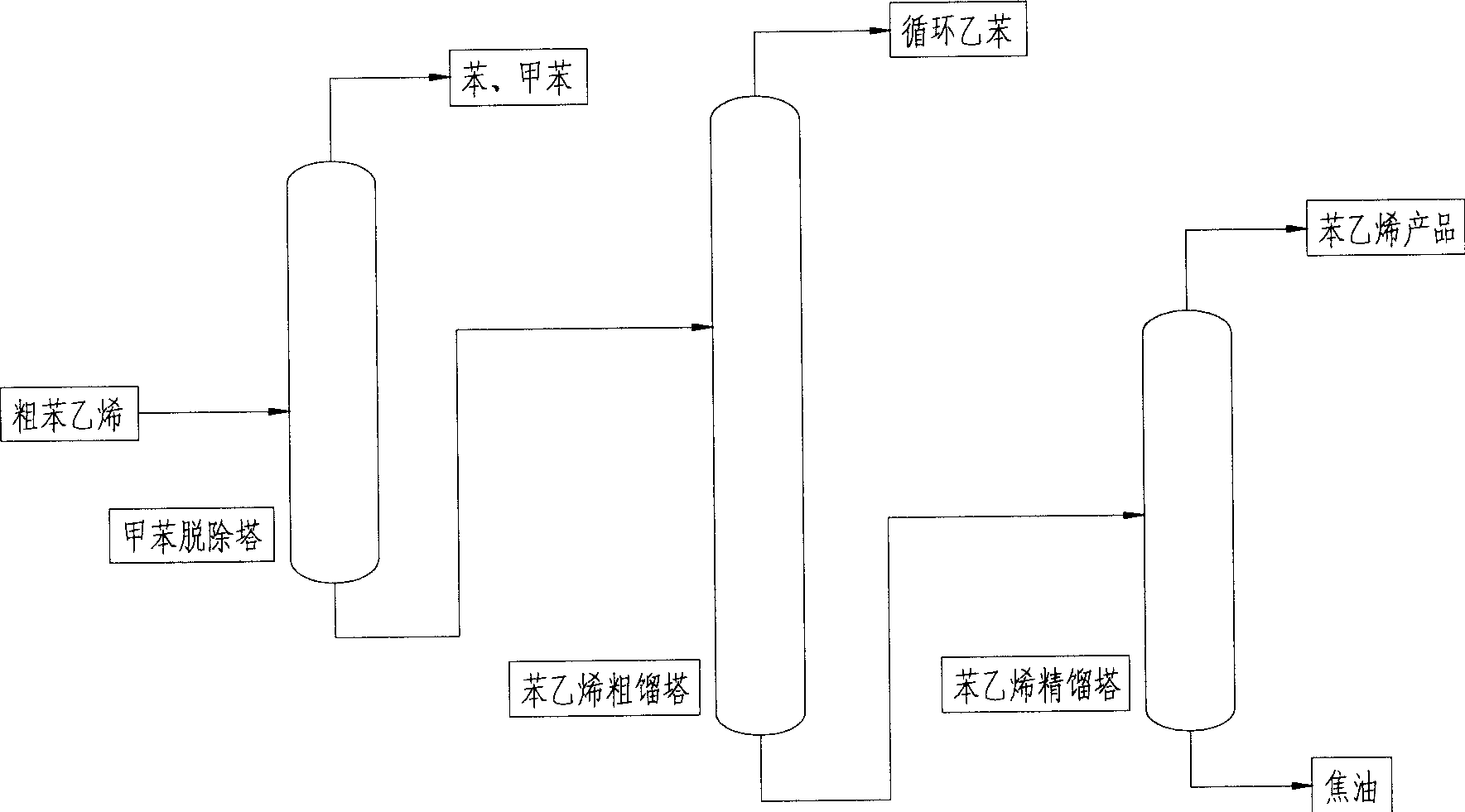

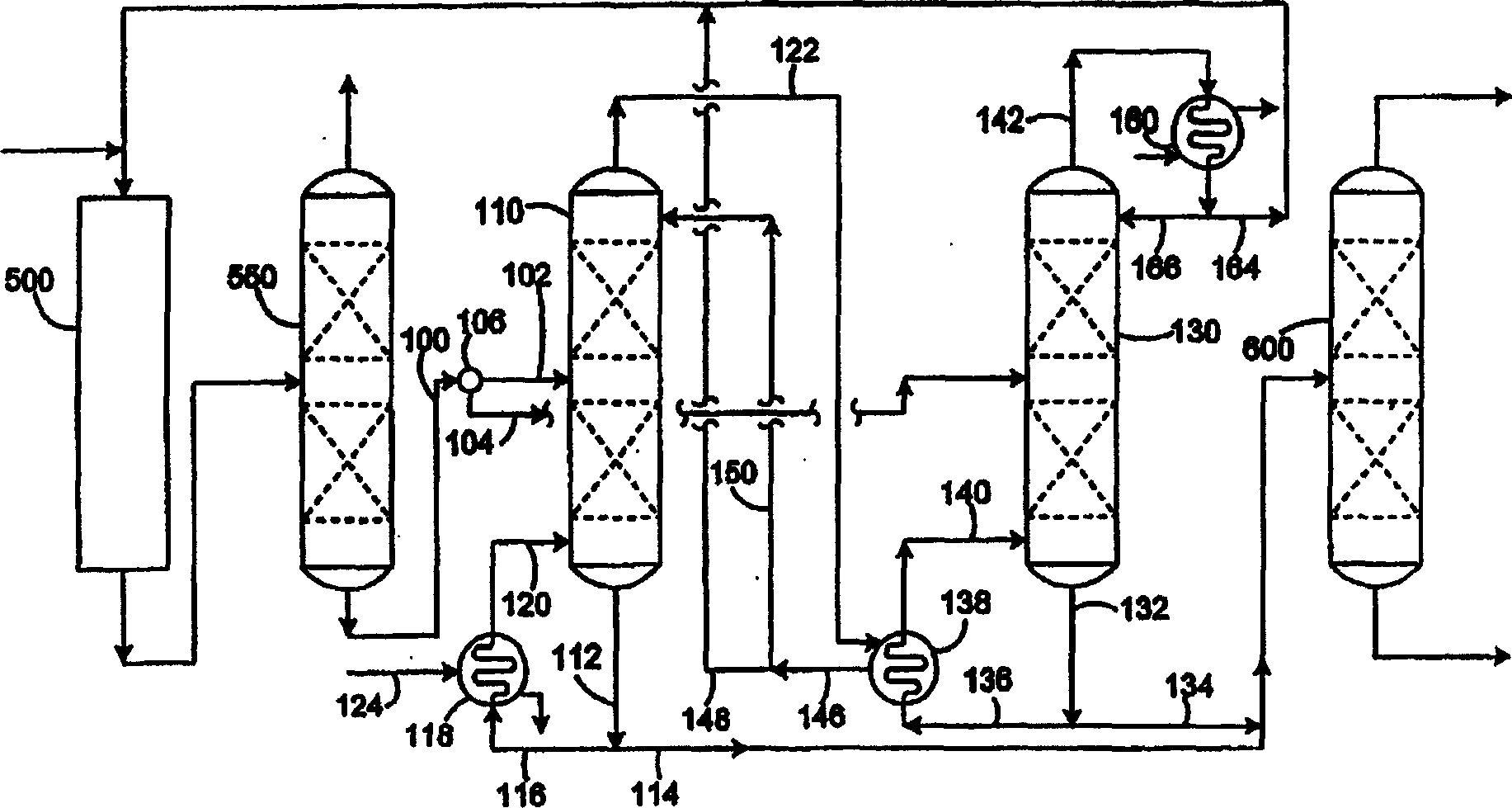

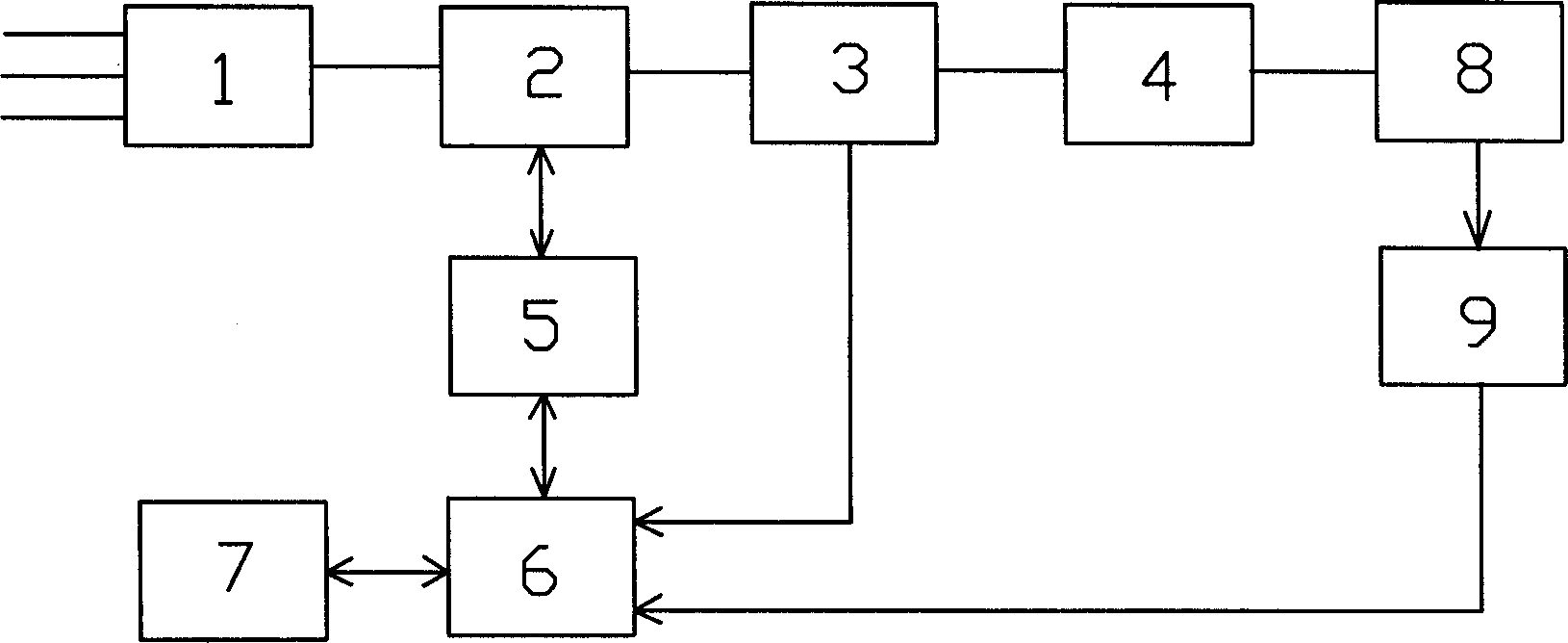

Styrene separation process

InactiveCN1736961AReduce areaReduce investmentDistillation purification/separationHydrocarbonsDecreased energyGas phase

Owner:蓝仁水

Nano-suspension for silybin-phospholipid complex and preparation method thereof

InactiveCN102228430AImprove long-term stabilityFor long-term storageOrganic active ingredientsPowder deliverySolubilityDecreased energy

The invention discloses a nano-suspension for a silybin-phospholipid complex and a preparation method thereof, wherein the nano-suspension for a silybin-phospholipid complex is prepared by combining a technology of promoting medicine absorption by a phospholipid complex with a solubilizing-targeting technology of nano-suspension; the ingredients of the nano-suspension for silybin-phospholipid complex comprise a silybin-phospholipid complex, a stabilizer and water; the nano-suspension exists in the form of suspension or freeze-dried powder and prepared by combining a microprecipitation method with a high-pressure homogenization method; the method of the invention prepares a nano-suspension hard to dissolve in a medicine, without a need to pre-micronize raw material medicines, which greatly decreases energy consumption; the grain diameter distribution range of the prepared nano-grains is narrow, and the medicine highly disperses in a granular state, which increases the wettability, solubility and solution velocity of the medicine, thereby improving the oral bioavailability thereof; the technique process of the preparation method is simple and easy to realize industrial production.

Owner:INST OF CHINESE MATERIA MEDICA CHINA ACAD OF CHINESE MEDICAL SCI

Method for improving efficiency, saving energy and lowering consumption of wetting intermitten ball mill

InactiveCN1745900AShorten milling timeIncrease productionGrain treatmentsDecreased energyEngineering

A method for increasing the efficiency of intermittent wet ball grinder and decreasing energy consumption features that the ball grinder is working at the optimal rotation speed for different materials and different grinding stages. As a result, a speed regulation controller is used to automatically optimize the rotation speed according to the environmental factors of grinding in drum.

Owner:唐慧光

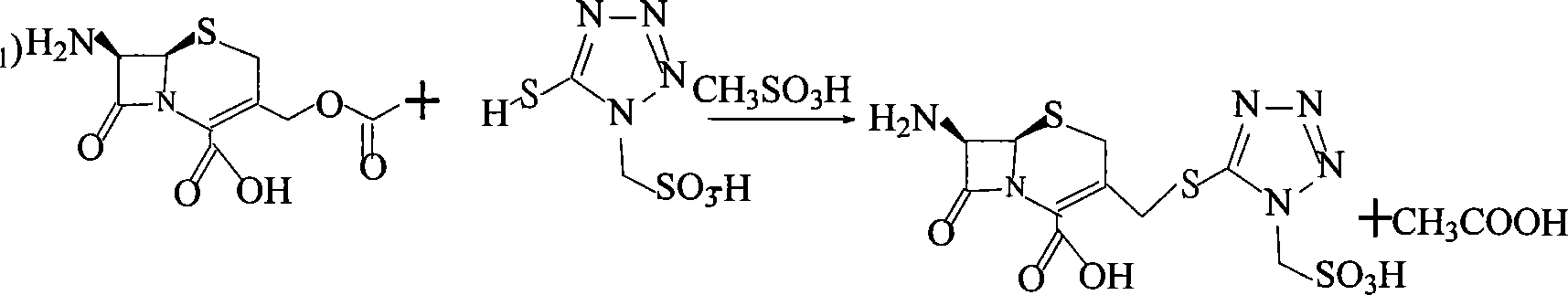

Method for preparing cefonicid or its medicinal salt and intermediate

ActiveCN101085781AProduced noHigh post-processing costOrganic chemistryDecreased energyEconomic benefits

The invention provides a method for preparing cephalosporin nixi or its salt and its intermediate. The invention employs alkyl sulfonic acid to replace BF3 used in curretn technique as catalyst for reaction of 1- methanesulfonic acid- 5- mercapto- 1, 2, 3, 4- tetrazole acid or its salt and 7-aminocephalosporanic acid or its salt. It is characterized by reduced cost, decreased energy consumption, less toxic waste gas discharge and apparent economic benefit.

Owner:SHANDONG SALUBRIS PHARMA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com