Energy saving device for walk-in refrigerators and freezers

a technology for walk-in refrigerators and freezers, which is applied in the direction of lighting and heating apparatus, heating types, domestic cooling apparatus, etc., can solve the problems of inherent delay in the change of temperature associated with the expansion valv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

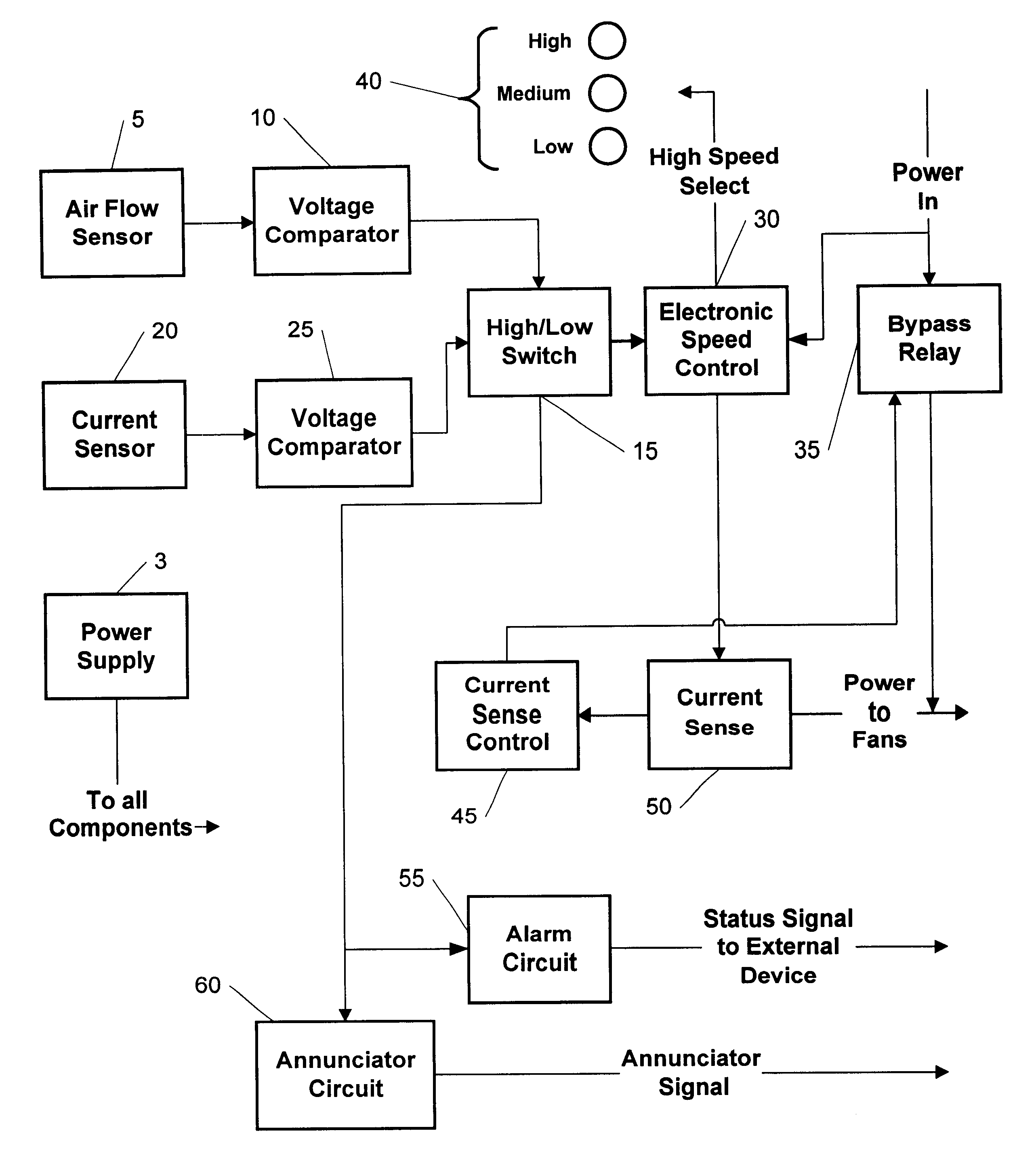

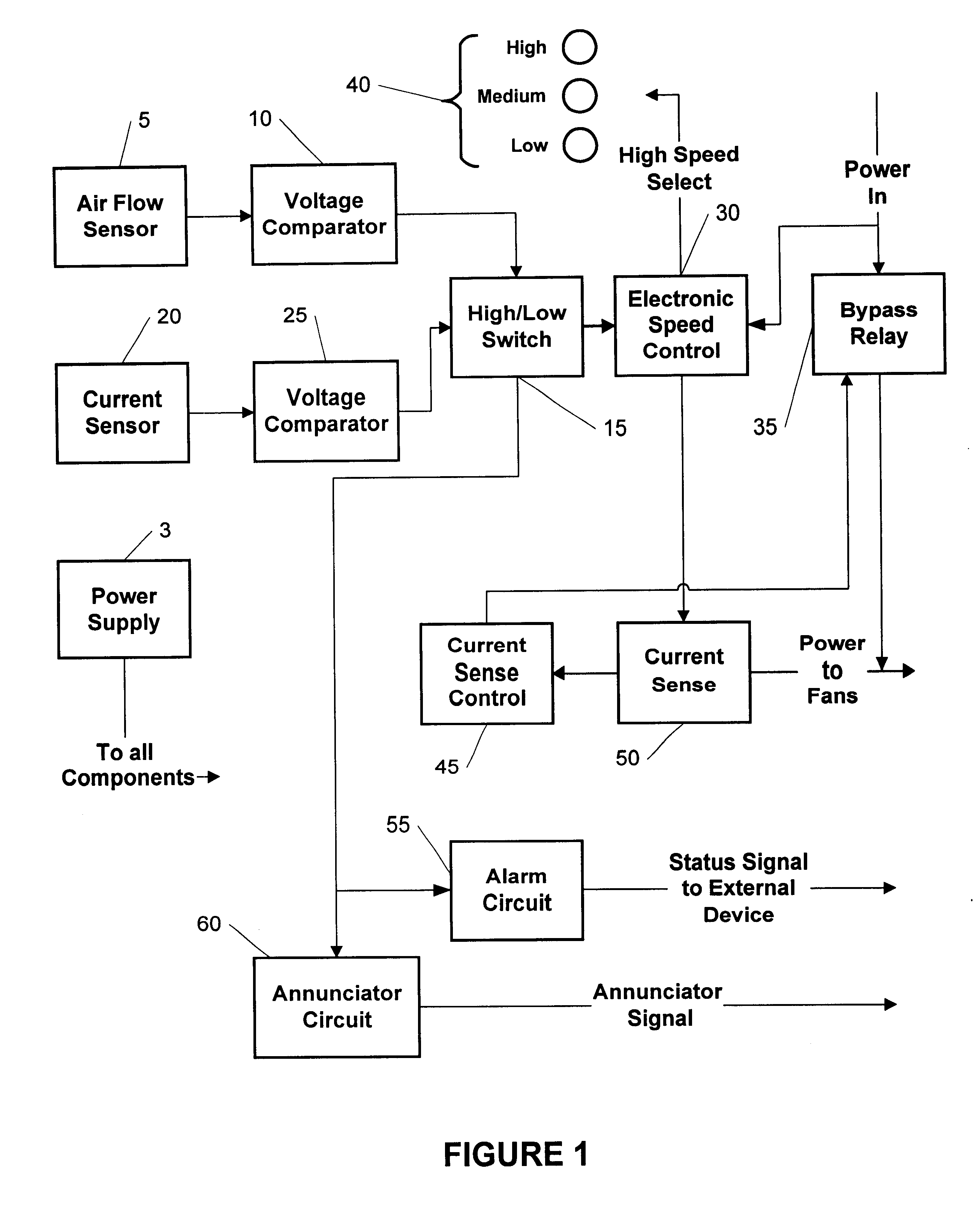

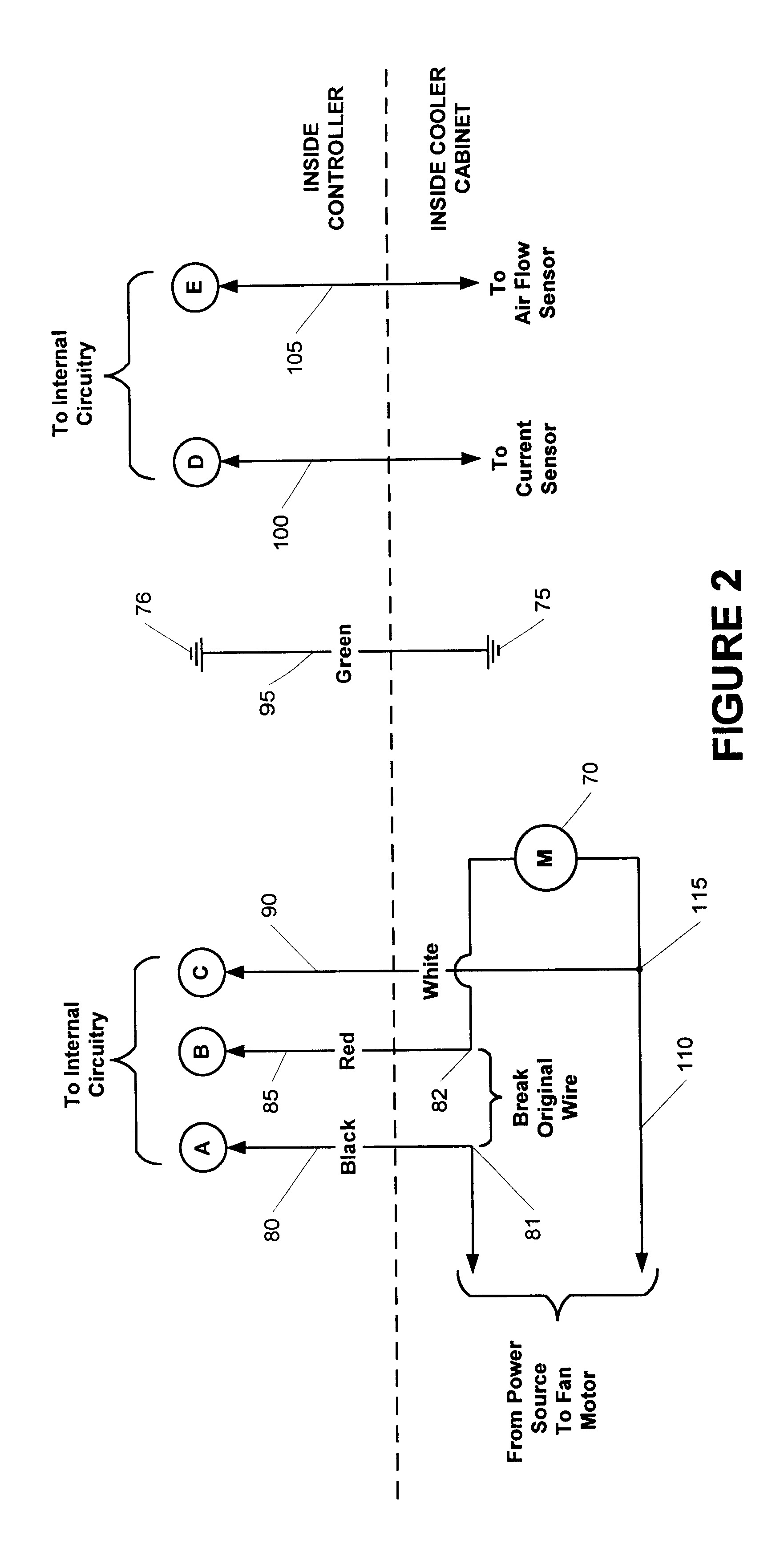

By way of example and not by way of limitation, a working example of the subject invention is now related in FIGS. 2-7. The various exemplary components and values, if applicable to a component, are all listed in the included tables (TABLES 1-3) with each functioning in its own customary manner. Shown in FIG. 2 (and associated TABLE 1) are the typical connections between the subject controller and the refrigeration system (it must be remembered that equivalent connections are also considered to be within the realm of this disclosure). The top portion of FIG. 2 illustrates connections inside the controller, while the lower portion of FIG. 2 depicts connections inside the chamber / cabinet which contains the evaporator coils and fans. The evaporator fan motor 70 is adapted to have the controller coupled into its power supply by breaking an original wire between points 81 and 82 and adding wires 80, 85, and 90 that run to the internal controller circuitry at locations A, B, and C. A comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com