Device for producing alumina clinker by semi-dry process

A kind of technology of alumina and semi-dry method, which is applied in the direction of alumina/hydroxide, etc., can solve the problems of high cost of alumina clinker, and achieve the effects of reducing pollution, shortening length and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

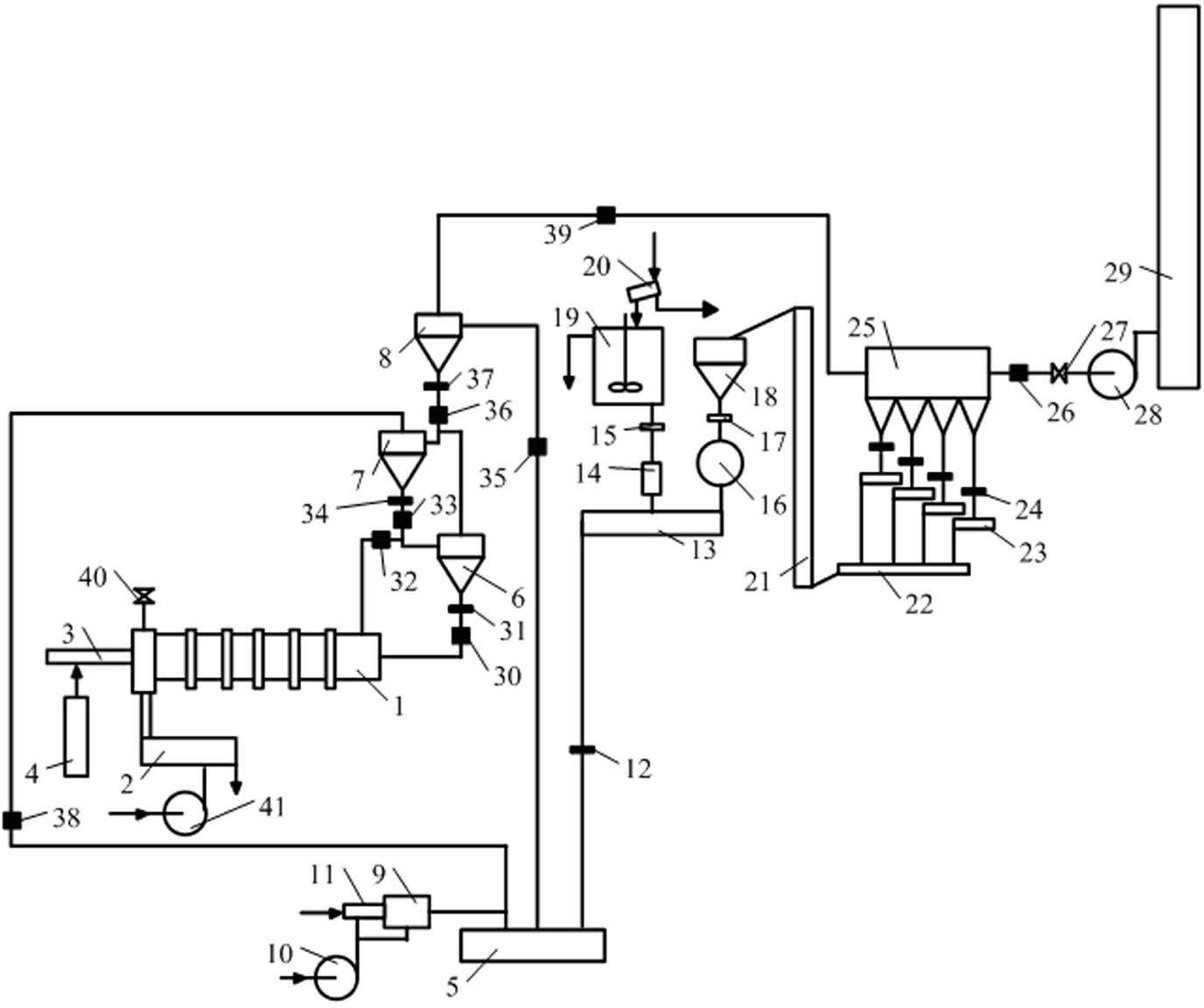

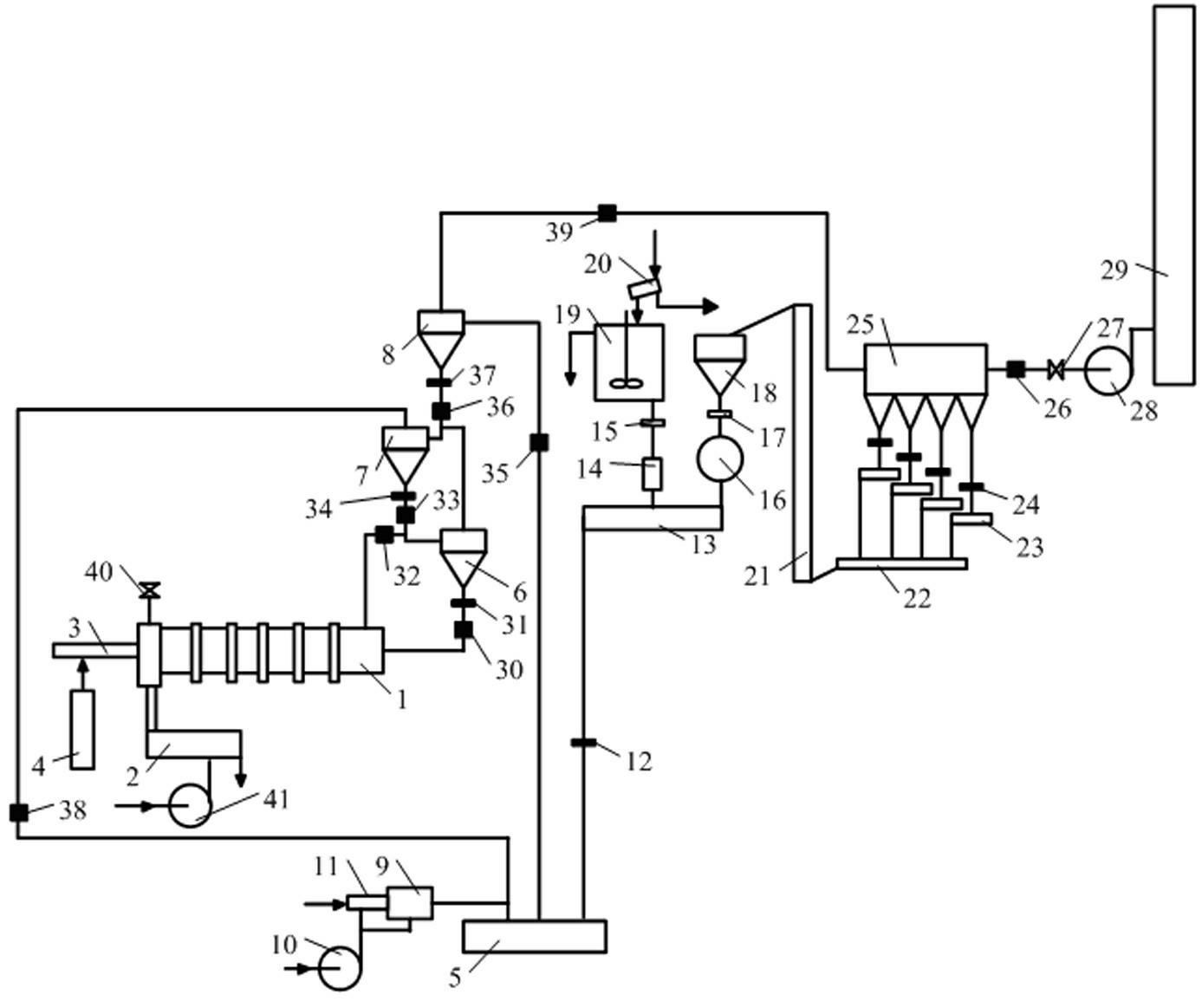

[0047] The structure of the device for producing alumina clinker by semi-dry method is as follows: figure 1 As shown, it includes rotary kiln 1, cooler 2, rotary kiln burner 3, cyclone separator, electric dust collector 25, drying crusher 5, screw conveyor 13, primary conveyor 22, hoist 21, powder Stock bin 18, secondary conveyor 23, slurry mixing tank 19 and hot blast stove 9; among them, three cyclone separators are arranged between the rotary kiln 1, the electric dust collector 25 and the drying crusher 5, and one cyclone separator serves as The dust collector 8 and the other two cyclone separators are respectively used as the first-level suspension preheater 7 and the second-level suspension preheater 6. The gas outlet of the rotary kiln 1 is connected with the outlet of the first-level suspension preheater 7 and The air inlet of the secondary suspension preheater 6 is connected, the feed port of the rotary kiln 1 is communicated with the discharge port of the secondary su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com