Styrene separation process

A process method, styrene technology, applied in chemical instruments and methods, distillation purification/separation, hydrocarbon purification/separation, etc., can solve problems such as increased equipment investment, longer residence time, and larger tar amount, and achieve reduction Small area and investment, reduced residence time, and reduced material loss

Inactive Publication Date: 2006-02-22

蓝仁水

View PDF1 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This part of light components will reduce the equilibrium condensation temperature of the gas phase at the top of the high-pressure distillation tower, and reduce the effective heat transfer temperature difference of the series reboiler, so the series reboiler needs to discharge more non-condensable gas (which will cause the series reboiler heat integration and energy saving effect), or the heat transfer area of the series reboiler is significantly increased (which will cause an increase in equipment investment), resulting in uneconomical implementation and application

[0012] (2) For the ethylbenzene/styrene separation tower, whether it is the heat-integrated serial reboiler or the ordinary single-tower separation reboiler, a self-circulating thermosiphon reboiler is generally used. When it is more, it will significantly increase the operating pressure drop of the series reboiler, signif

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

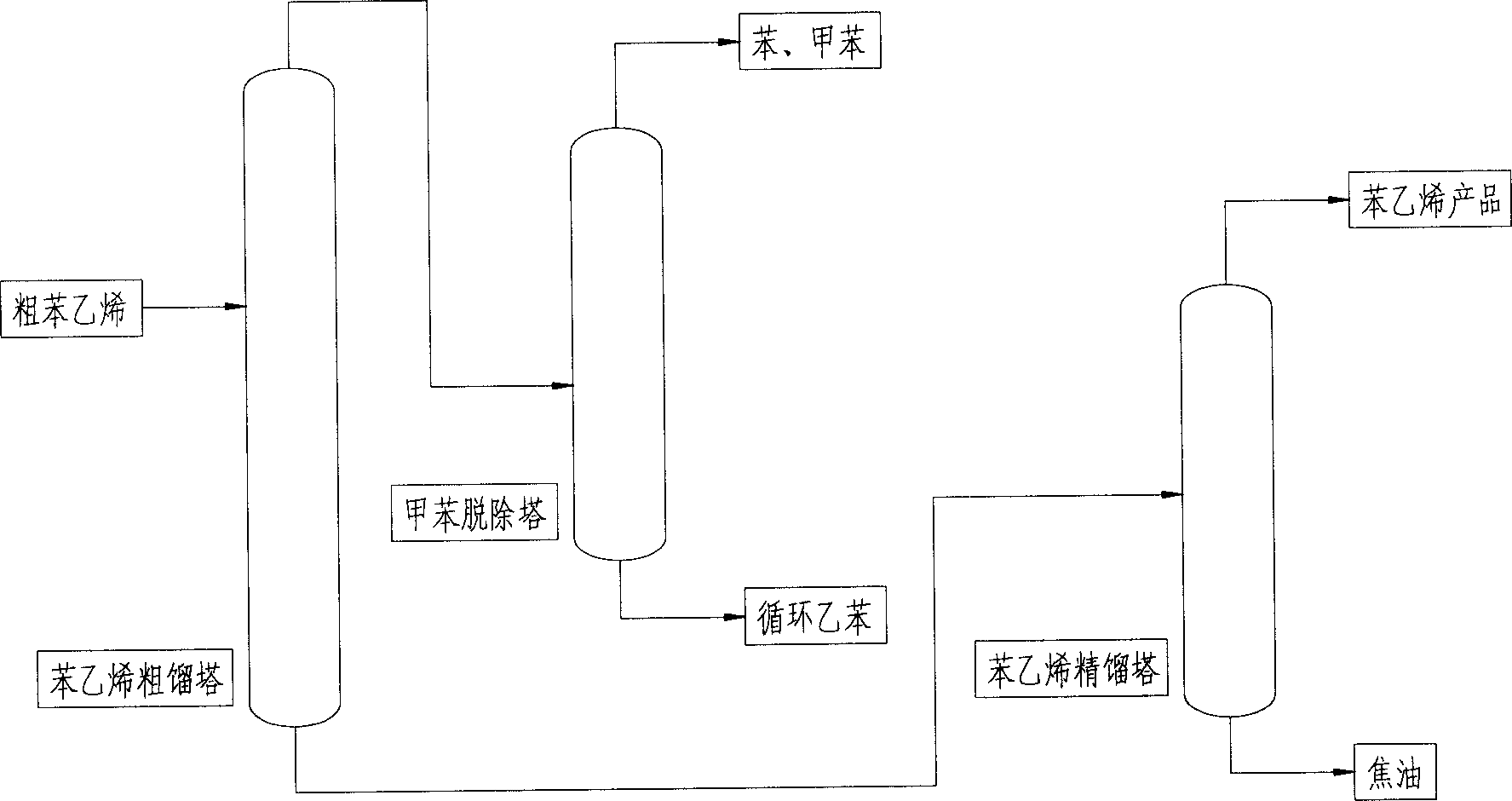

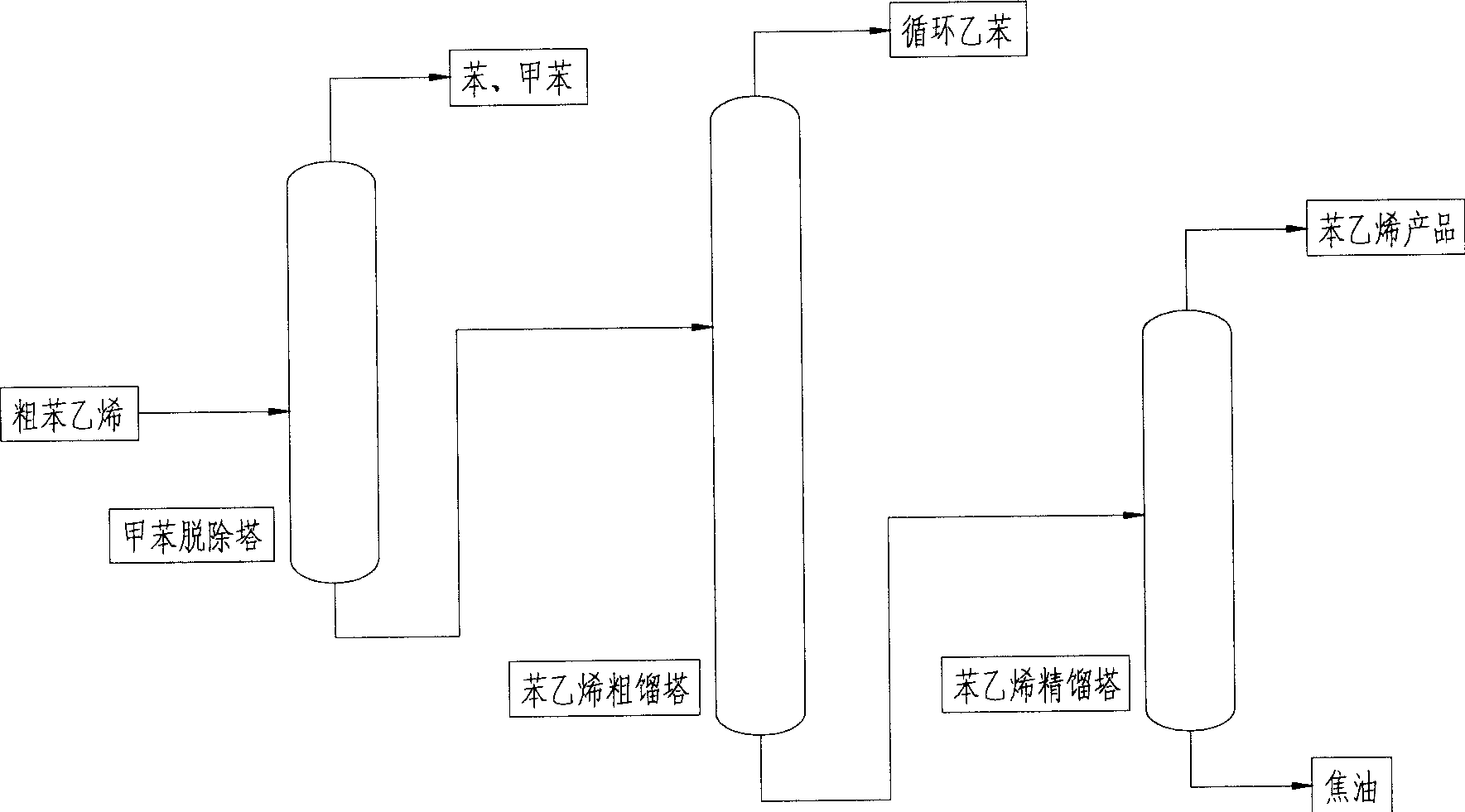

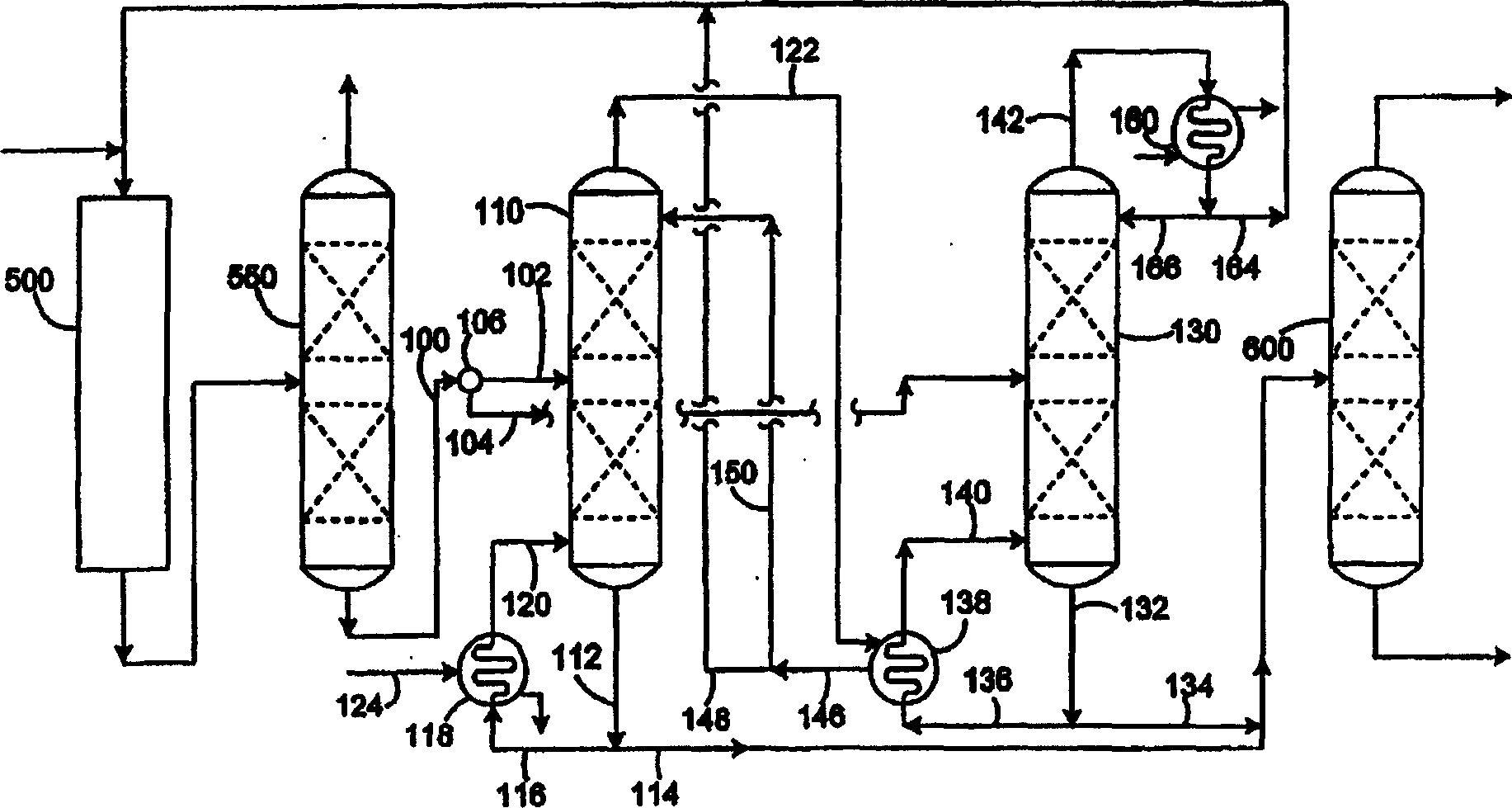

The invention relates to technique for styrene separation. Wherein, using transform heat integration technique to separate ethylbenzene/styrene, dividing common single tower into two towers of C101A with higher pressure and C101B with lower pressure; putting coarse raw material into C101B tower, drawing material from side line of C101B tower as feed to C101A; using gas phase on C101A top to heat directly liquid on bottom of C101B; heating just to C101A bottom; the ethylbenzene on top of C101A can de recycled without detoluening operation, but the material on top of C101B needs for detoluening operation on C102 tower. Compared with traditional technique, this invention can decrease energy consumption 40-50%.

Description

technical field [0001] The invention relates to a process for separating styrene, which uses a pressure-swing heat integration process to separate ethylbenzene / styrene, and divides an ordinary ethylbenzene / styrene separation tower (single tower) into two towers (C101A, B) for operation, and C101A The operating pressure of the tower is relatively high, and the operating pressure of the C101B tower is low. The gas phase at the top of the C101A tower is directly used to heat the liquid at the bottom of the C101B tower. Of the two towers C101A and B, only the bottom of the C101A tower needs steam (or other heat sources) for heating. Only the C101B tower is fed, and the C101A tower is fed from the side line of the C101B tower. Benzene and toluene are all removed from the top of the C101B tower. The technological process is simple, and compared with the traditional single-tower ethylbenzene / styrene separation tower, this technological method can significantly reduce the energy consu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C15/16C07C7/00C07C7/04

Inventor 蓝仁水黄贵明

Owner 蓝仁水

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com