Patents

Literature

153results about How to "Reduce heating times" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inner step profile section ring parts rolling forming method

InactiveCN101053887AImprove metal structureImprove performanceFurnace typesHeat treatment process controlHeat deflection temperatureThermal state

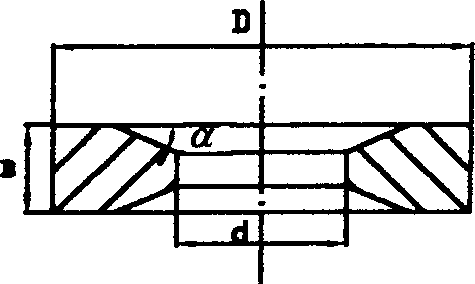

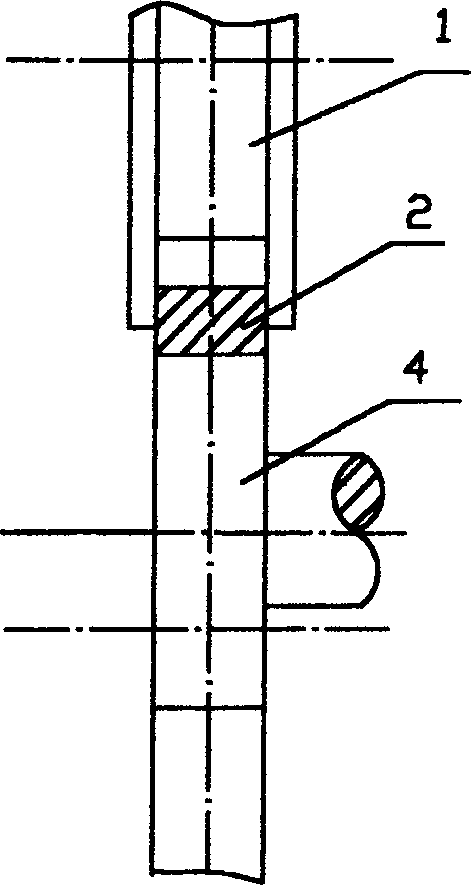

The invention relates to a rolling forming method of a ring with inner step section. The rolling forming method of a ring with inner step section is characterized in that it comprises the following steps: 1) blanking; 2) preforming: uniformly heating the material section from room temperature to a heat distortion temperature with high plasticity and low resistance, then upsetting, piercing and stamping the material section in thermal state to fabricate ring blank for rolling; 3) rolling by a ring rolling mill: heating the ring blank in a heating furnace, taking out when the temperature reaches the heat distortion temperature and putting the ring blank into the ring rolling mill to carry out rolling, during the rolling process, excellent lubrication is maintained between the ring blank and the rollers, and the ring forging is formed by multiple rolling the ring blank; 4) mechanical cutting processing the ring forging to form the ring with inner step section. Accordingly, the invention has advantages of low cost and high production efficiency.

Owner:WUHAN UNIV OF TECH

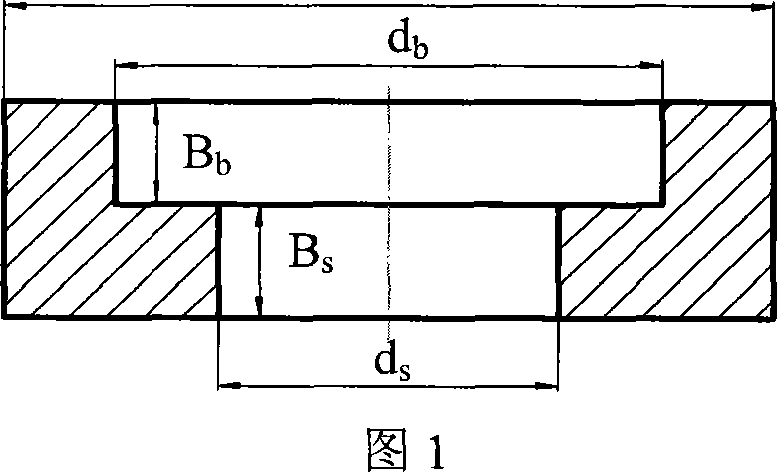

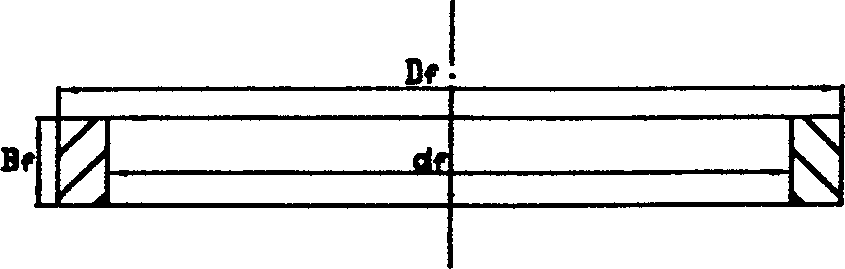

Method for rolling and forming rectangular section aluminium alloy ring piece

InactiveCN1586753AImprove metal structureImprove performanceMetal rolling arrangementsPunchingRoom temperature

The process of rolling to form aluminum alloy ring with rectangular cross section includes the following steps: sawing aluminum alloy rod into section; making ring blank via homogeneous heating from room temperature to the heat deforming temperature of 350-550 deg.c, upsetting, punching hole and punching coating; rolling the blank heated in a heating furnace to 350-550 deg.c via radial or radial-axial rolling inside groove; and cutting mechanically into the product. The present invention has the features of low cost and high production efficiency.

Owner:WUHAN UNIV OF TECH

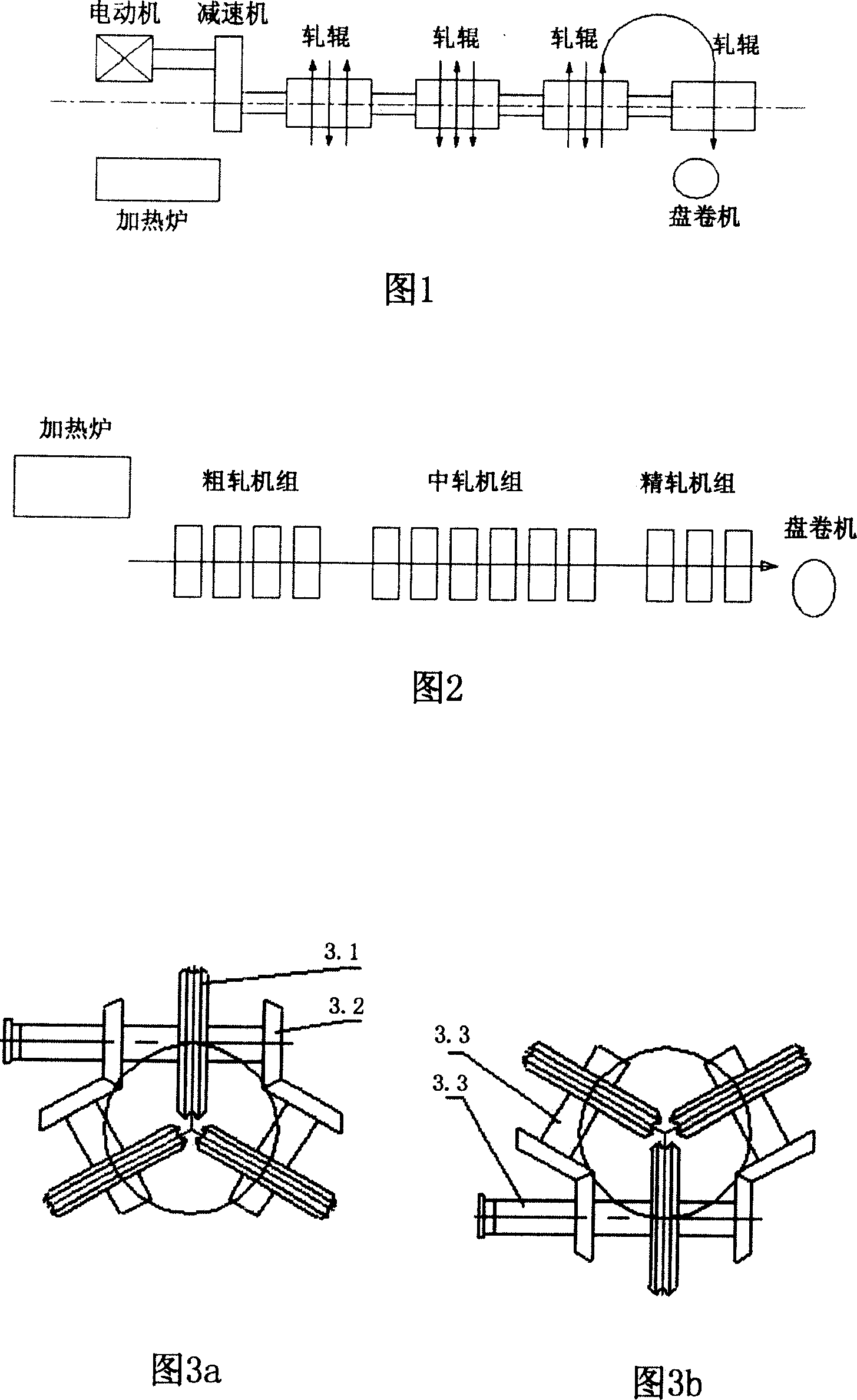

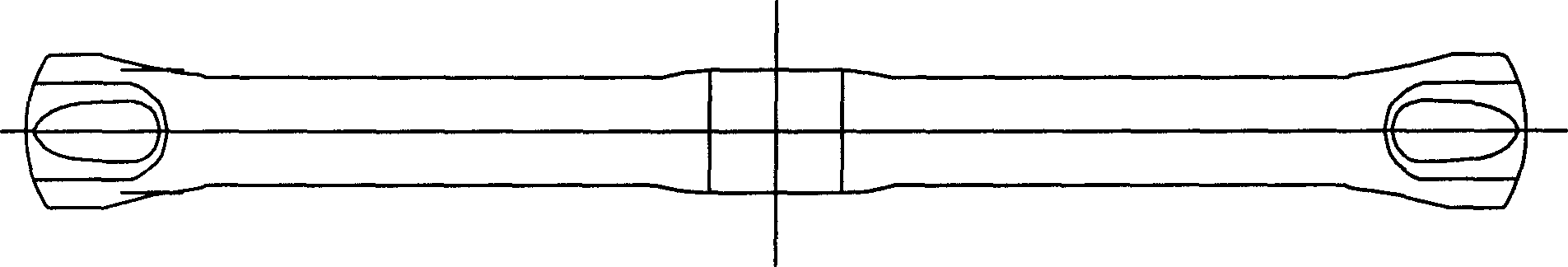

Method for rolling titanium and titanium alloy bar wire bar with three-roller type Y continuous rolling mill

InactiveCN101152653AImprove surface qualityFew beginningsTemperature control deviceMetal rolling stand detailsLow noiseWire rod

The invention provides a method for rolling of titanium and titanium alloy bar and wire rod with three-roller Y continuous rolling mill. The technical proposal of the invention is as follows that the three-roller Y continuous rolling mill group is used for 6 to 18 pass continuous rolling of heated titanium and titanium alloy bar billet of phi50mm to form bar billet of 30 to 8mm (or hexagonal and triangular structure of 24 to 8mm) or rolling wire billet of phi20 to 8mm. by adopting the method, bar billet of phi50mm can be rolled into bar billet of phi30 to 8mm (or triangular and hexagonal structure) or rolling wire billet of phi20 to 8mm after heated for one time. Compared with the prior methods of multiple fire time casting, swaging, two-roller transverse-arrangement non-continuous rolling and two-roller longitudinal-arrangement continuous rolling, all of which are used for production of titanium and titanium alloy bar or rolling wire billet, the invention not only has the advantages of high efficiency, energy saving, low noise, small occupying and high precision of the size as well as good organization perforation of titanium and titanium alloy bar and wire rod, but also can produce triangular or hexagonal section and other allotype section.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

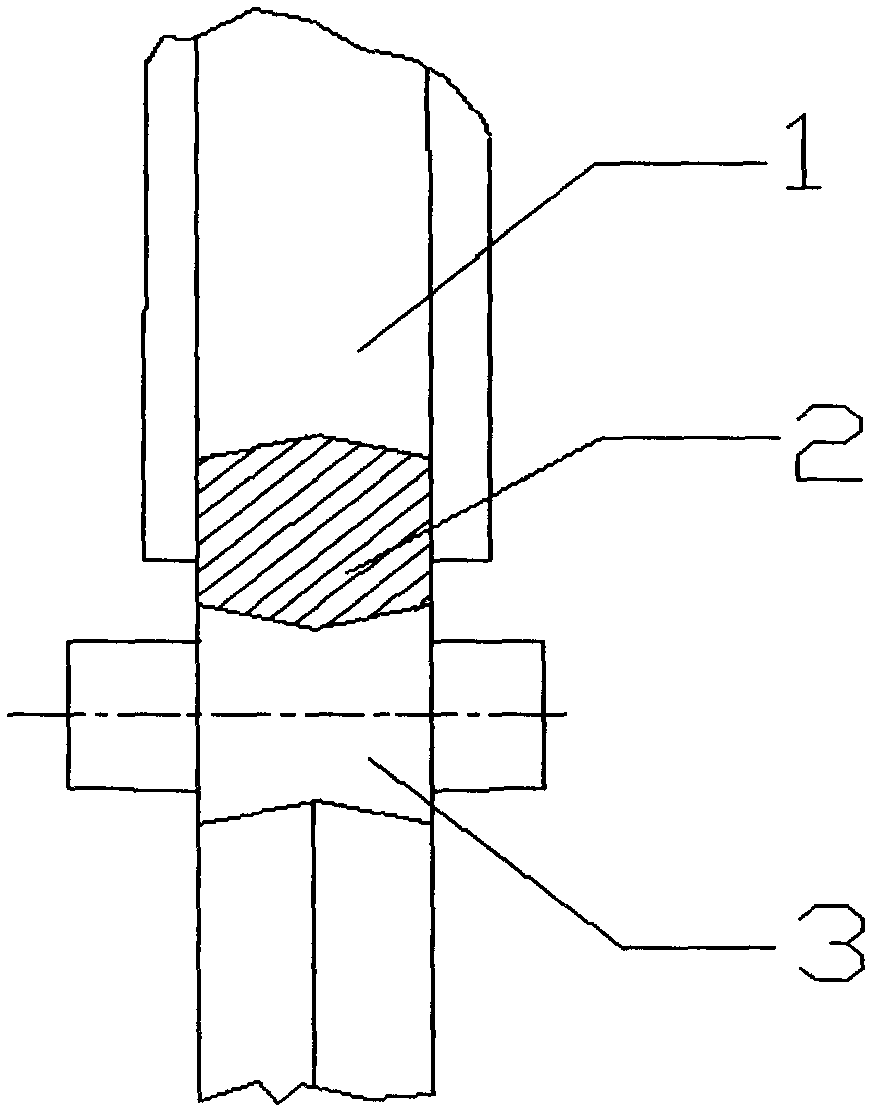

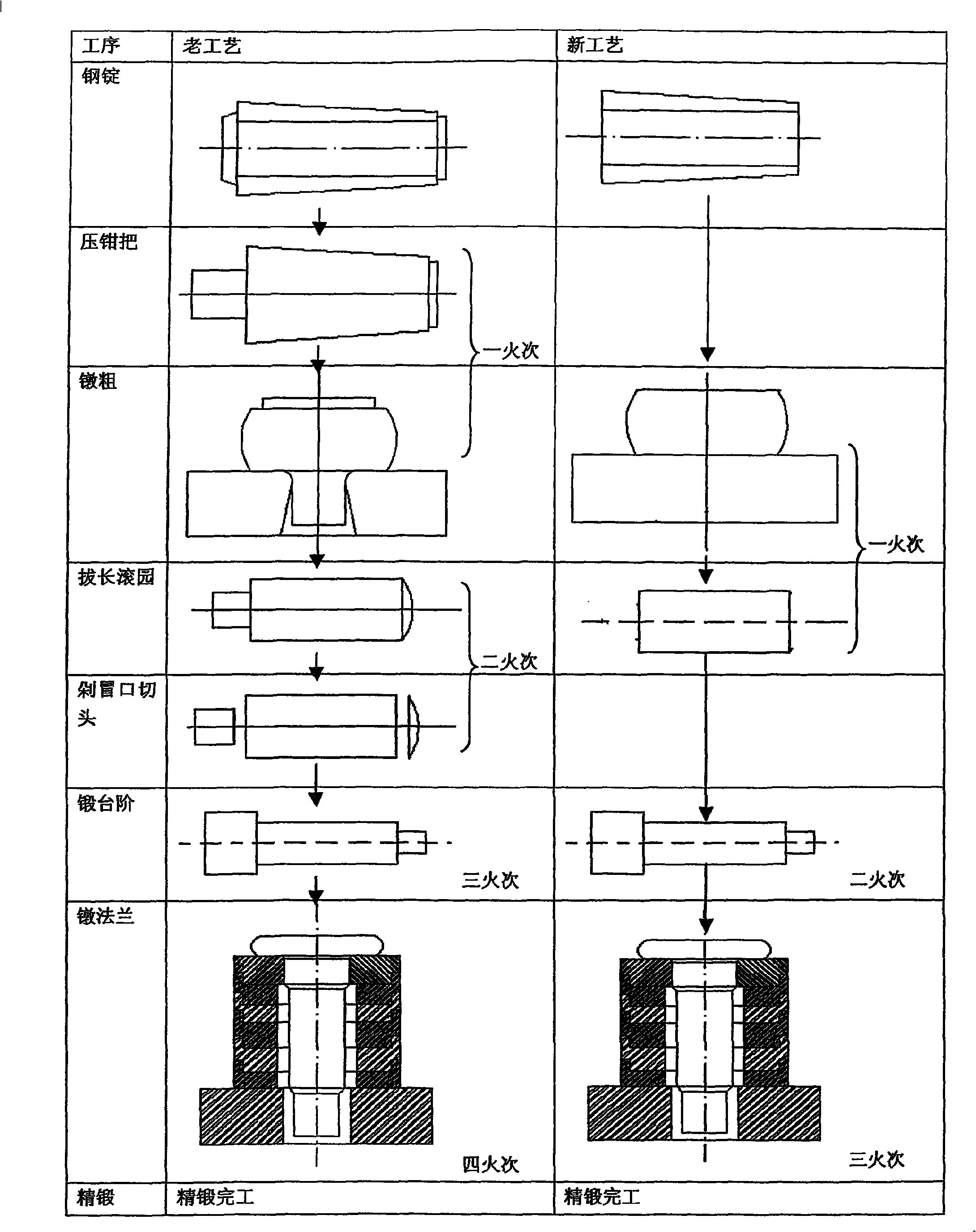

Ring forging and rolling processing method of bearing ring parts used for large-scale wind turbine unit

The invention discloses a ring forging and rolling processing method of bearing ring parts used for a large-scale wind turbine unit. The technical scheme of the invention is that the processing method comprises the following steps: (1) blanking; (2) heating by a first heating number; (3) forging and making a blank forming; (4) heating by a second heating number; (5) chambering and reforming; (6) heating by a third heating number; (7) carrying out diameter expansion and ring rolling; (8) cutting two connected bearing ring part workblanks which are obtained in the step (7) to obtain a single workblank; and (9) thermally treating: normalizing, quenching and tempering. The processing method disclosed by the invention has the following beneficial effects: compared with the prior art, four heating numbers are decreased to three heating numbers; two ring parts can be obtained by one-time rolling and expanding processing through the improvement of a mold, so that the production efficiency is improved, the cost is lowered, and good combination property of a flange is ensured; and the bearing ring parts processed by the processing method of the invention have high strength, good hardenability, strong toughness, small deformation in the quenching, and stronger creep strength and persistent strength at the high temperature, and are applied to a large-scale wind turbine unit in a severe environment.

Owner:SHANDONG IRAETA HEAVY IND

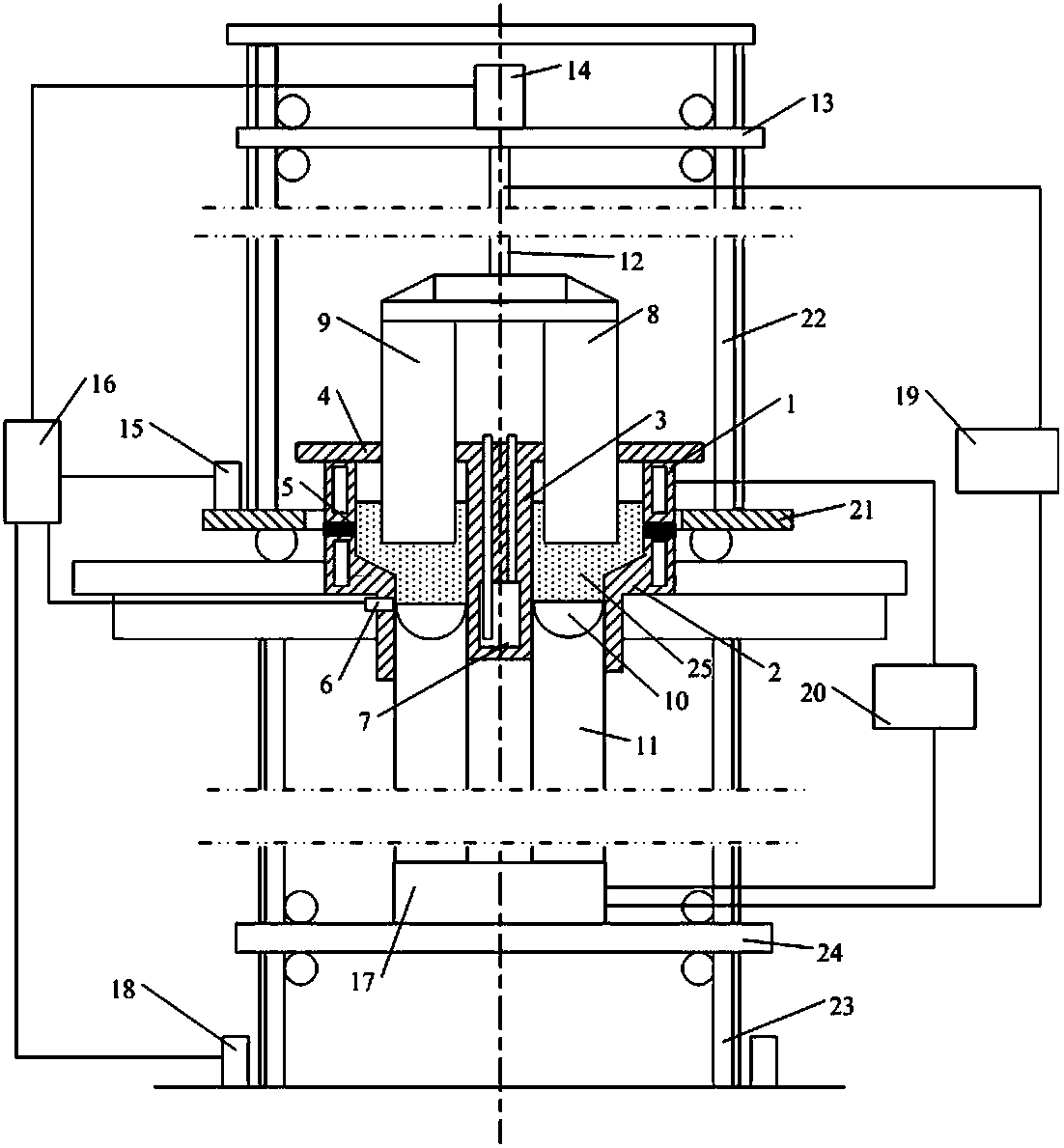

Method for preparing hollow steel ingot for protection ring of large power generator by adopting electroslag remelting

ActiveCN104164574AIncrease profitReduce heating timesCasting parameters measurement/indication devicesTransformerProtection ring

The invention discloses a method for preparing a hollow steel ingot for a protection ring of a large power generator by adopting electroslag remelting. The method comprises the following steps: (1) preparing consumable electrode groups; (2) melting slag into liquid molten slag; (3) inserting the consumable electrode groups into an electroslag remelting hollow ingot crystallizer; (4) starting two transformers; (5) injecting the liquid molten slag into the electroslag remelting hollow ingot crystallizer; (6) when the consumable electrode groups are in contact with the liquid molten slag, forming an electrifying loop among fake electrodes, the consumable electrode groups and a bottom water tank; (7) when the liquid molten slag is in contact with an upper section, forming a loop among the upper section, the bottom water tank and the transformers connected with the bottom water tank; (8) adjusting the output currents and voltages of the two transformers; (9) when a metal melt is in contact with a molten steel liquid level detection device, starting an ingot stripping device for ingot stripping; (10) exchanging the consumable electrode groups; and (11) inserting subsequent consumable electrode groups into the liquid molten slag, and repeating the steps (8 to 10) until the ingot stripping is finished.

Owner:NORTHEASTERN UNIV LIAONING

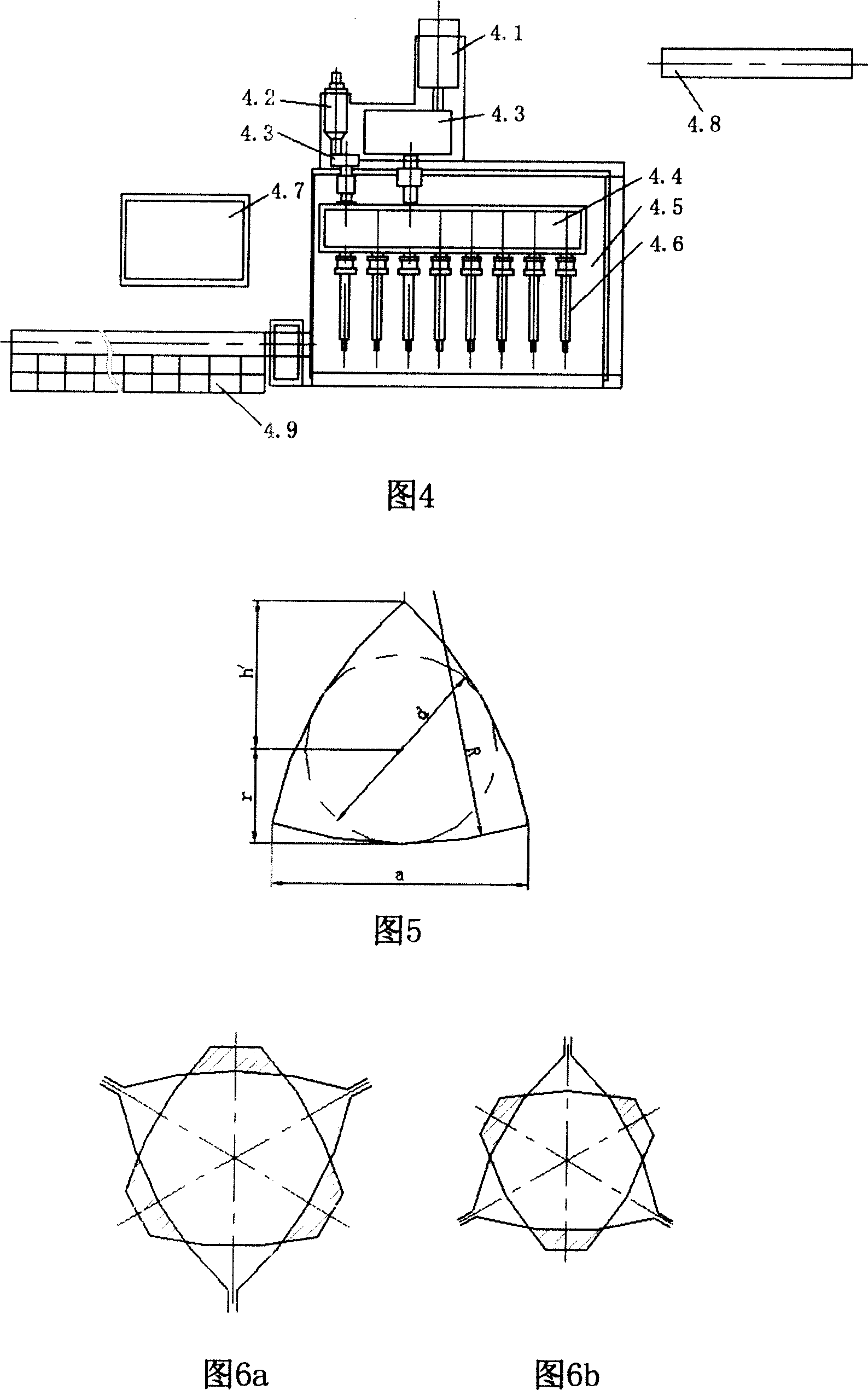

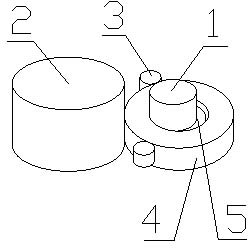

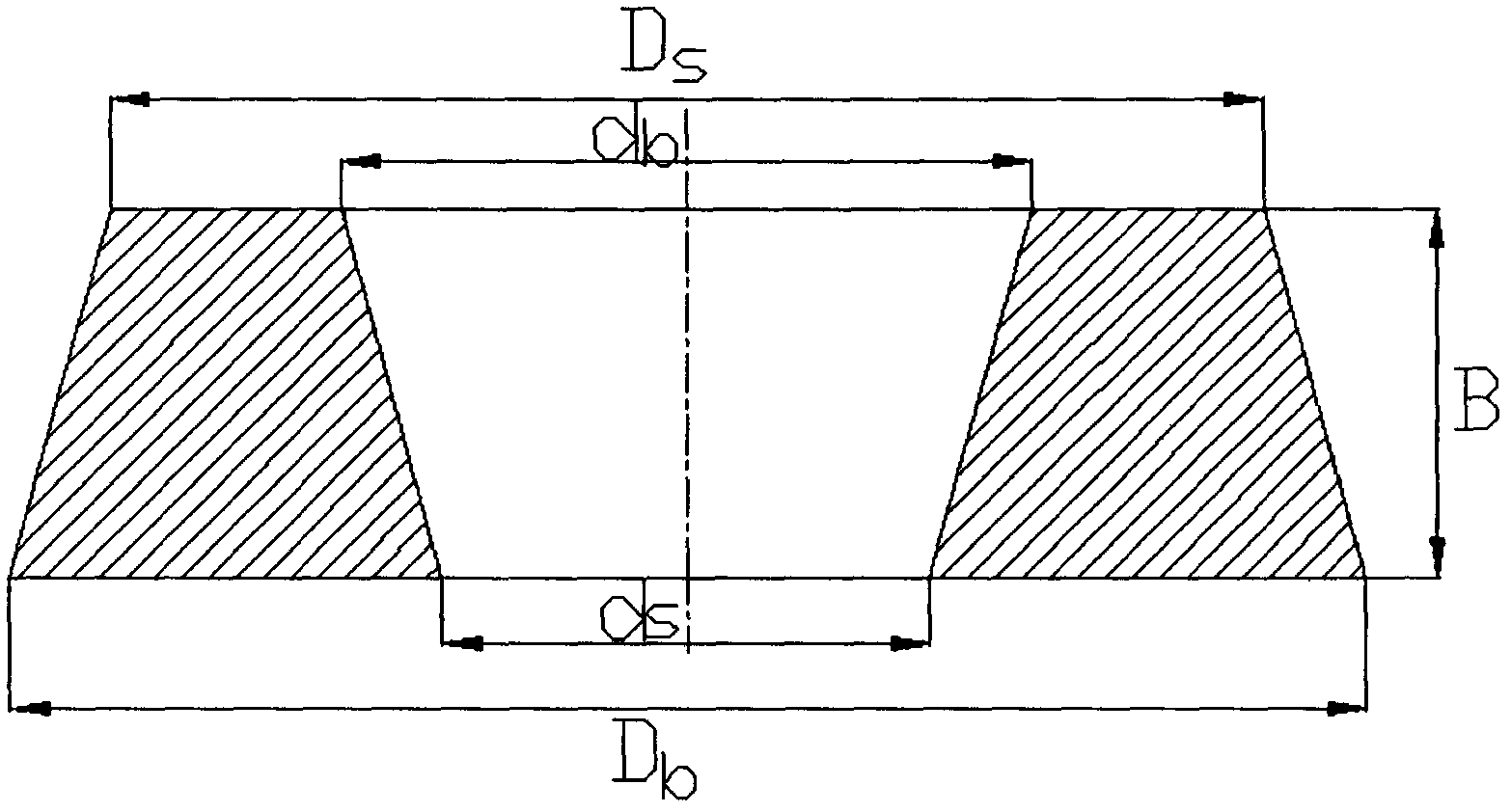

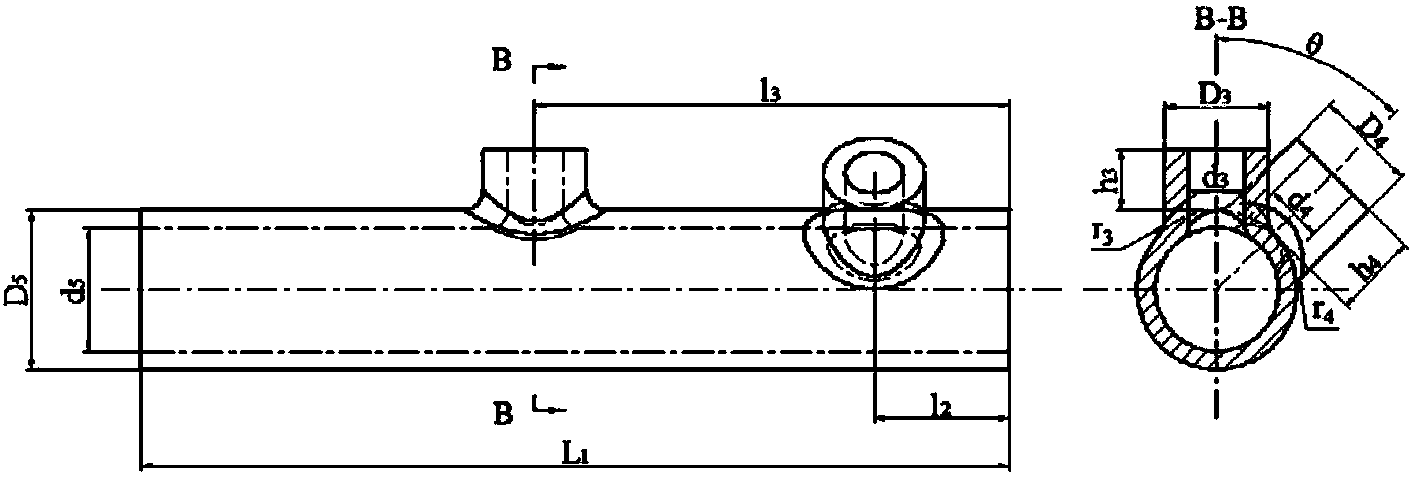

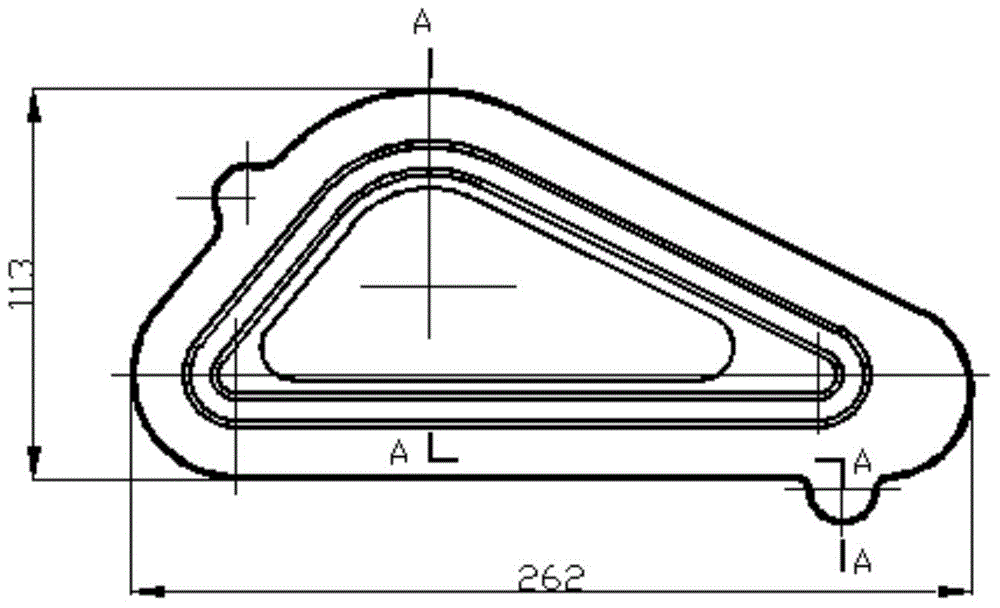

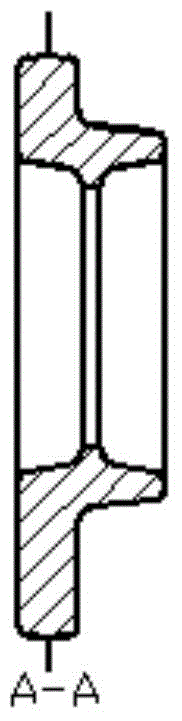

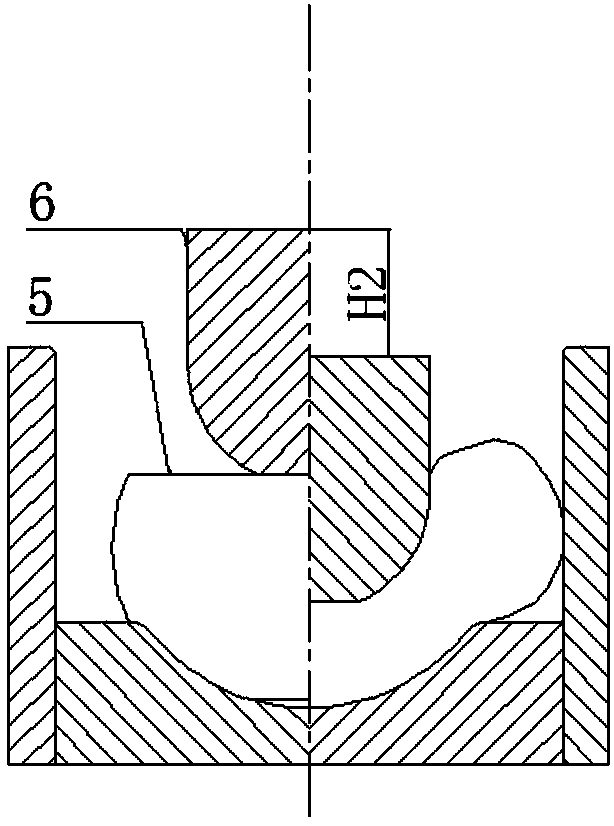

Method for simultaneously rolling and expanding two trapezoid-cross-section flange ring forge pieces

ActiveCN102615223AReduce heating timesImprove organizationGas flame welding apparatusMetal rollingRoom temperatureEngineering

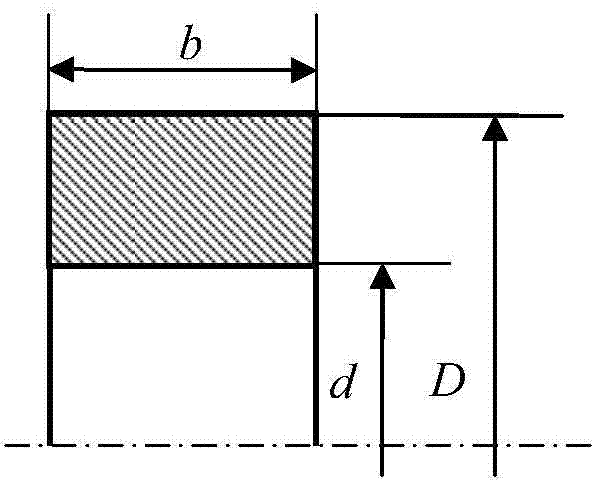

The invention relates to a method for simultaneously rolling and expanding two trapezoid-cross-section flange ring forge pieces. The method comprises cutting a cylindrical billet into material sections; heating the material sections from room temperature to austenitizing temperature evenly and keeping warm; then heading, punching and chambering the material sections to be manufactured into ring piece blanks to be rolled and expanded; baking again and heating the obtained blanks to reach target temperature and keep warm; placing the obtained blanks into a hole mould of a ring rolling machine formed by an irregular-shaped driving roller and an irregular-shaped core roller to be rolled, expanded and formed; achieving the ring forge pieces which is narrow at two ends and wide in middle and with the axial height as twice as the height of a target trapezoid flange; cutting the ring forge pieces from the middle of the axial height, symmetrically dividing a work piece into two parts to obtain two trapezoid-cross-section flange ring forge pieces; and finally turning the forge pieces into end product flanges. The method for simultaneously rolling and expanding two trapezoid-cross-section flange ring forge pieces is high in production efficiency, energy-saving, environmental-friendly and capable of improving utilization rate of raw materials and quality of products.

Owner:SHANDONG JIANZHU UNIV

Method for correcting tubular structure diameter distortion by flame

The invention discloses a method for correcting tubular structure diameter distortion by flame. The method includes that before heating, radial outward pushing force is applied on the inner wall of a tubular structure area with a negative roundness error value to enable an additional stress to radially outwardly act on the area with the negative roundness error value in advance, and simultaneously stress radially inwardly acting on a tubular structure area with roundness error larger than tolerance is generated in the tubular structure area, so that when an area is heated, deformation of the heated area can be accelerated, roundness of a tubular structure can be corrected, correction amount can be well controlled, number of heating time is decreased, period for integral correcting work is shortened, and the situation about tubular structure scrapping caused by over times of heating is avoided.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

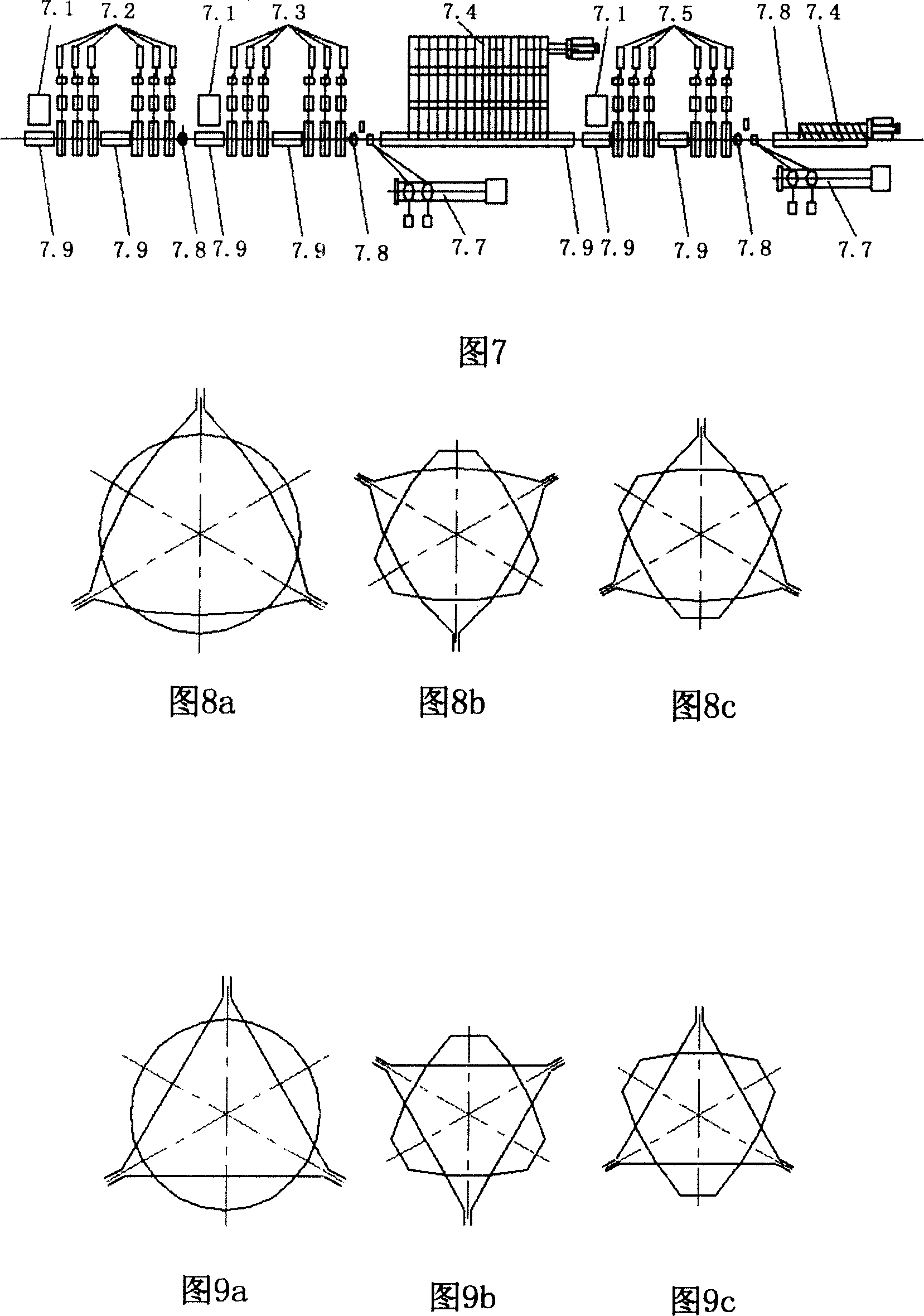

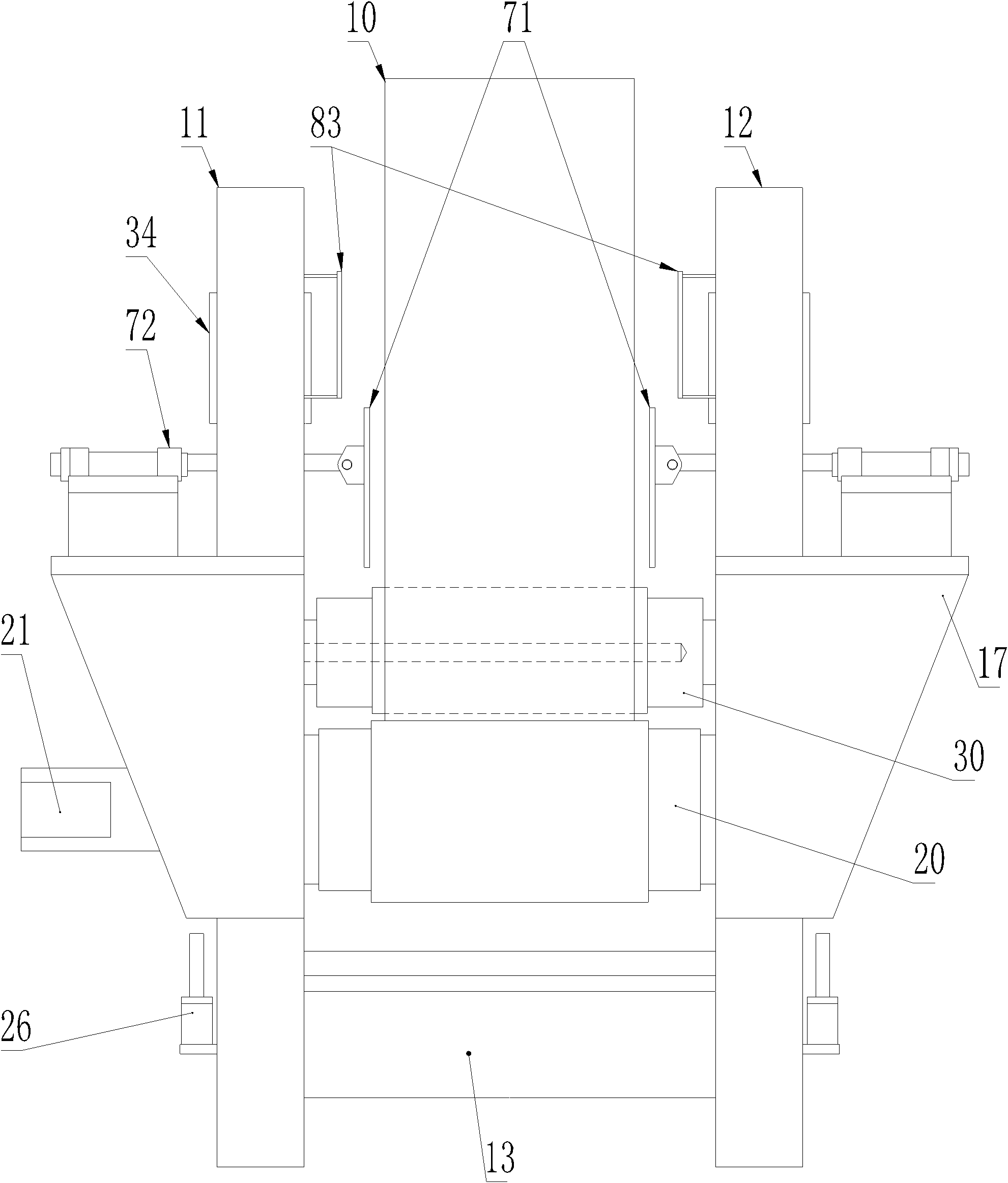

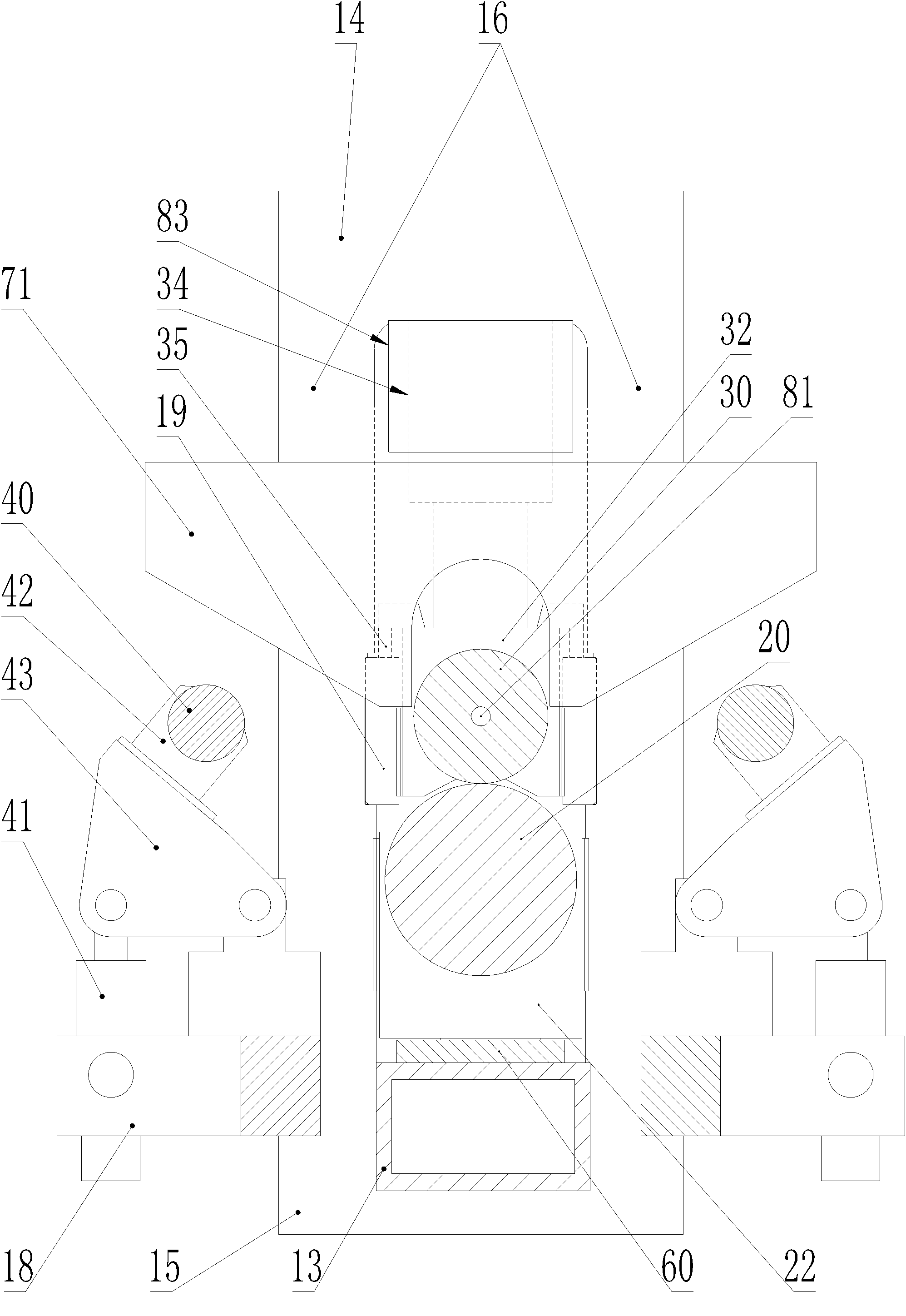

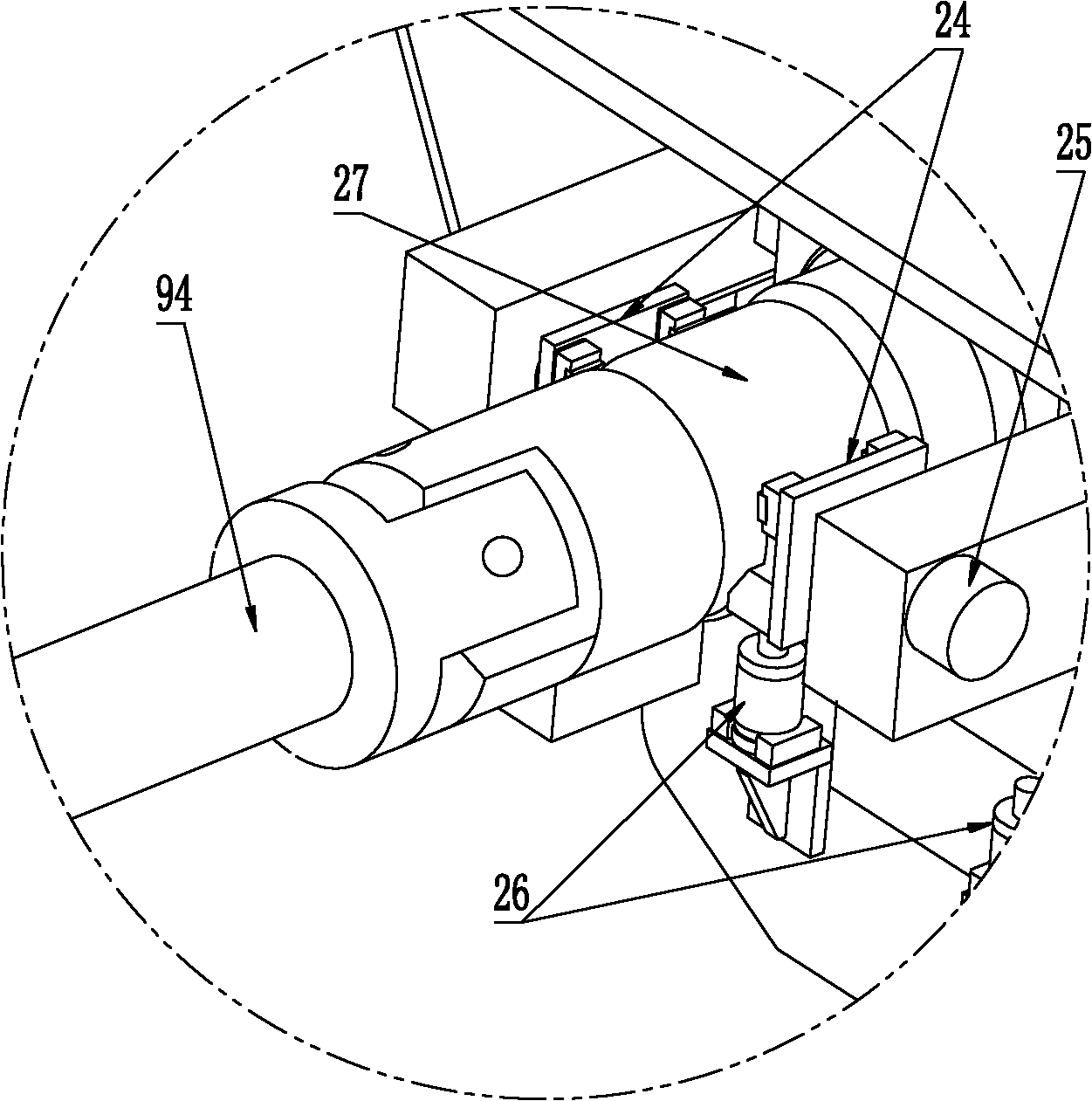

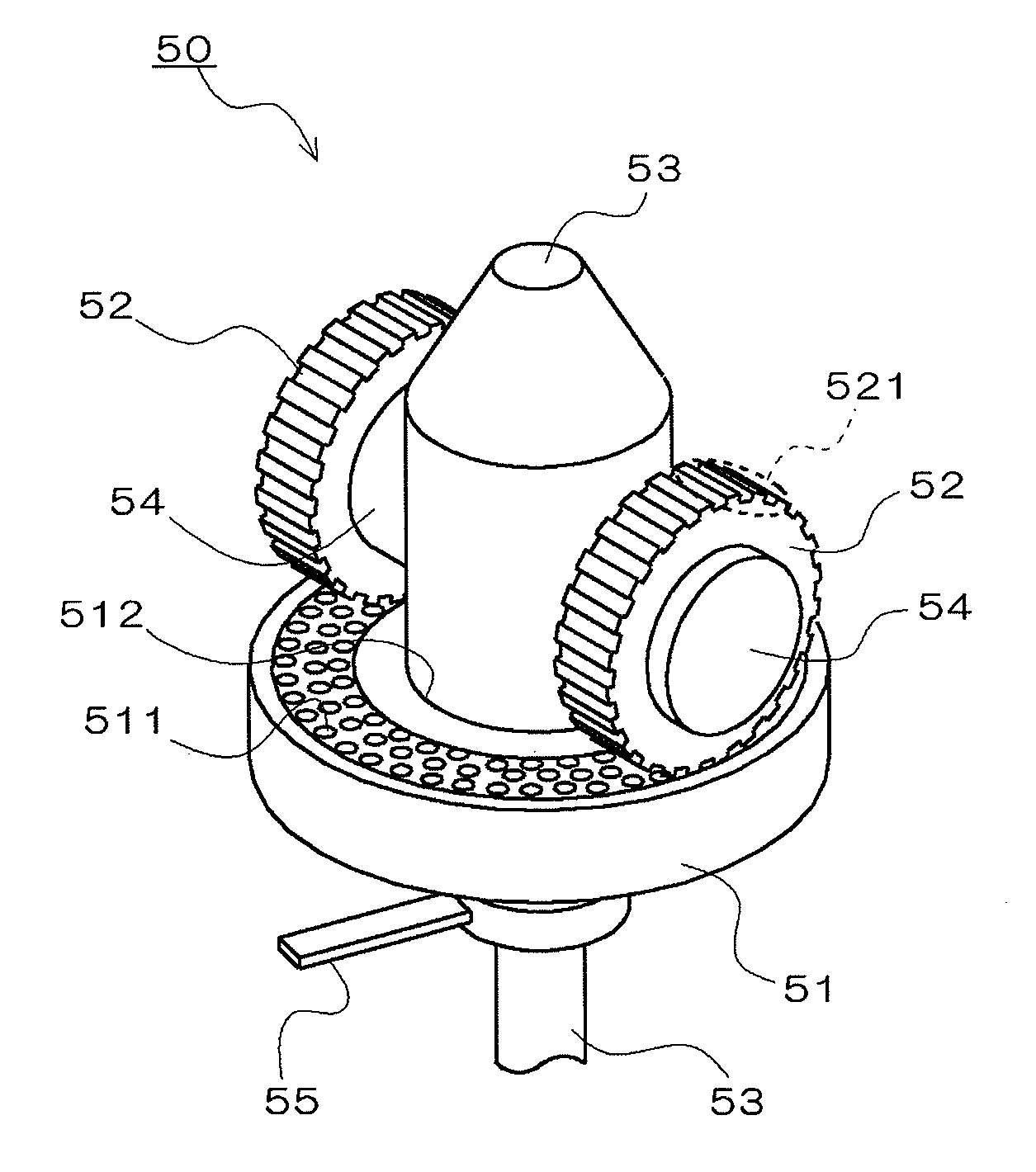

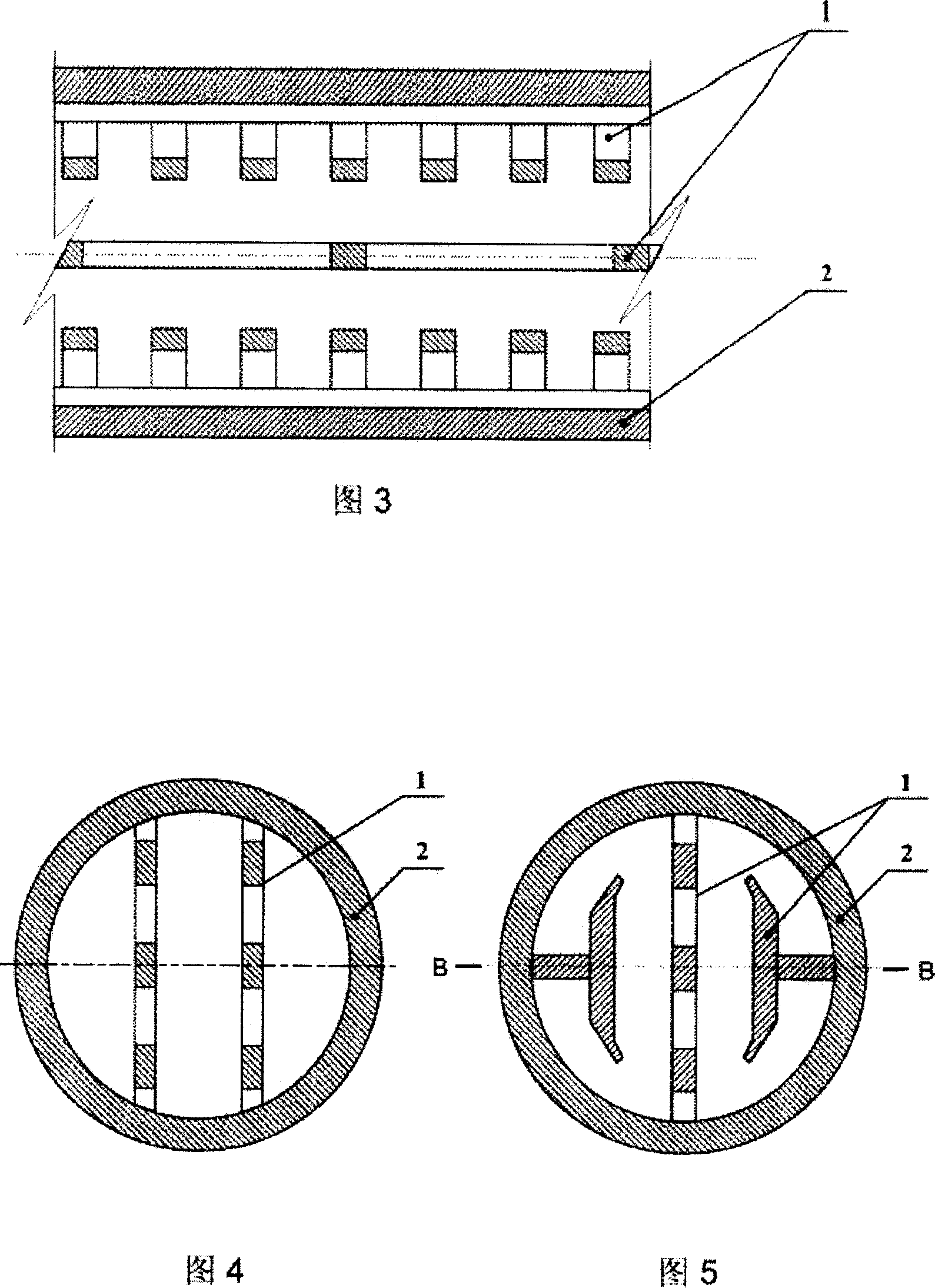

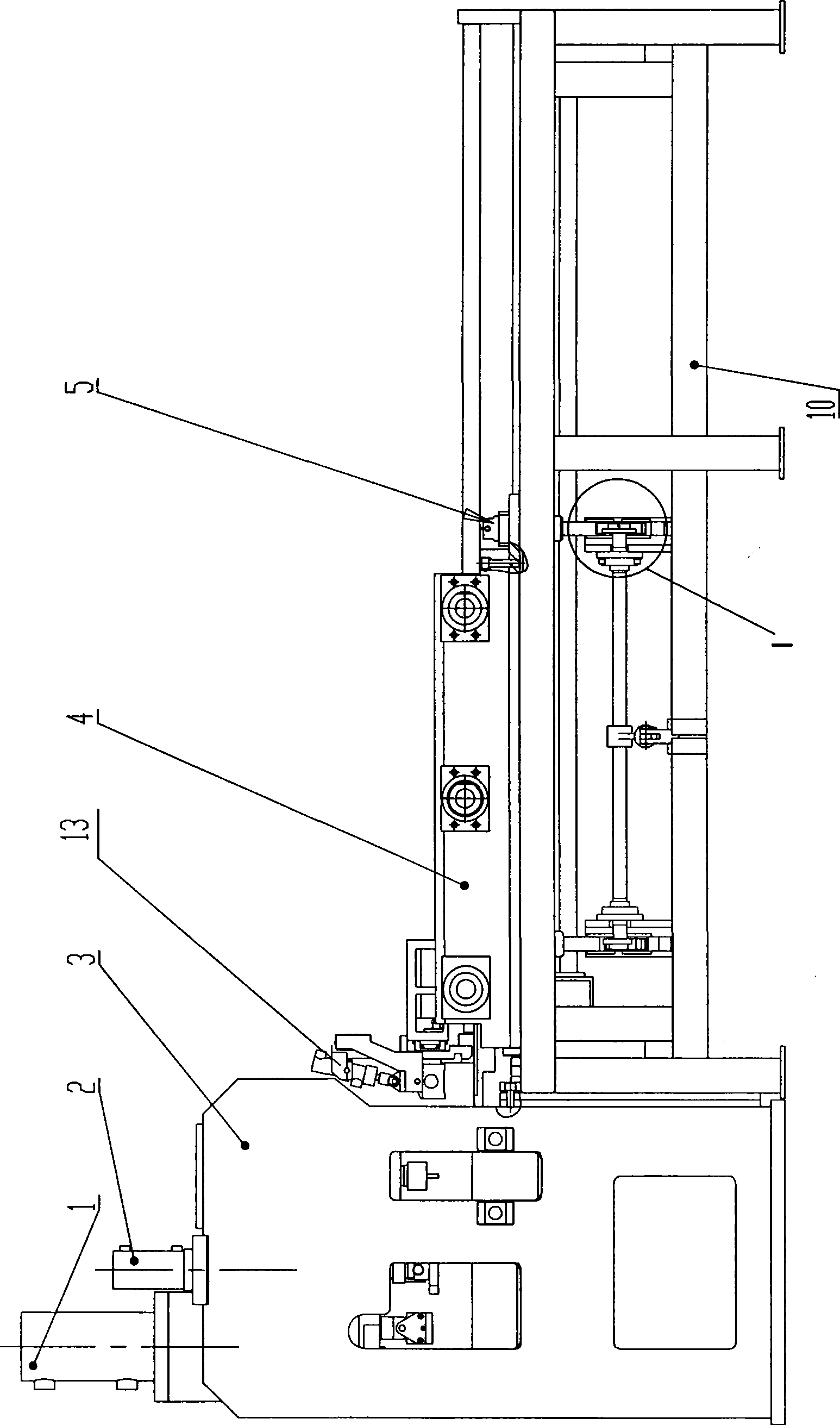

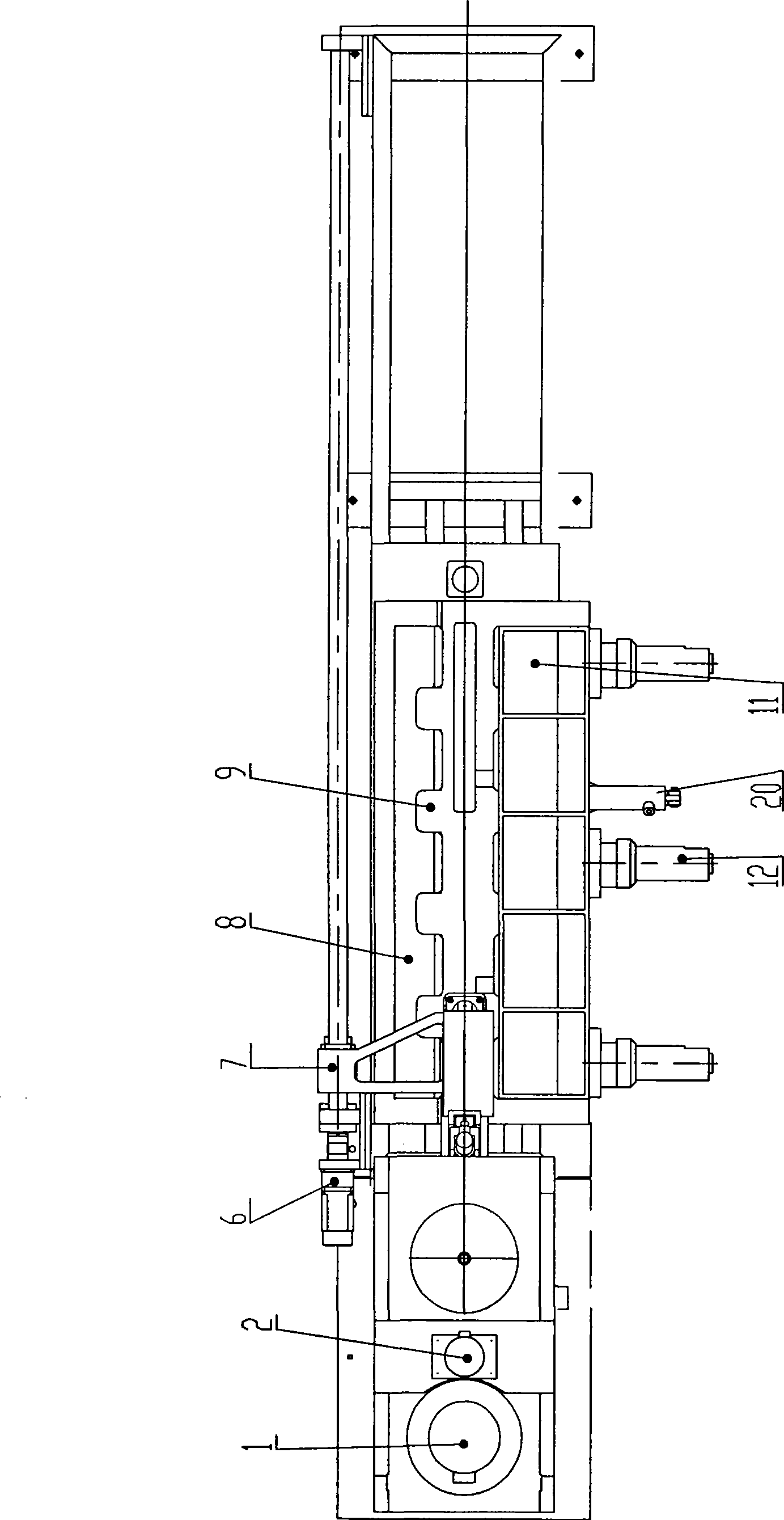

Overlarge type ring rolling machine

ActiveCN101823111AImprove rigidityGood rolling forceMetal rollingReciprocating motionProcessing cost

The invention relates to the field of metal pressure moulding and provides an overlarge type ring rolling machine which has large rolling force, good rigidity, high processing precision, high processing efficiency and low processing cost and can be suitable for the manufacturing requirement on a large cylindrical section. A stand of the overlarge type ring rolling machine comprises a drive side stand and an operating side stand which are longitudinally and oppositely arranged, both ends of each roll are supported, and axes are horizontally arranged; a drive roll is arranged at the lower part of the stand, and a core roll is positioned on the drive roll; at least one of double axial directions of the core roll is set to be a drawing direction of the core roll, one end of the core roll points to the other end along the drawing direction, the starting point end is a suspending end, and the terminal point end is a drawing end; a drawing unit comprises the core roll and a drawing end core roll bearing seat thereof or the core roll and core roll bearing seats at both ends of the core roll; the overlarge type ring rolling machine is provided with a roll drawing mechanism for doing reciprocating motion along the drawing direction of the core roll; and the roll drawing mechanism is provided with a detachable type fixing structure of the drawing unit. The invention is suitable for producing a large cylindrical section with large axial size, weight and wall thickness in the fields of large nuclear power, petrochemical container, aerospace, and the like.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

20Cr2Ni4A steel carburizing and nitrocarburizing multiplex heat treatment process

InactiveCN102021588AReduce heating timesReduce energy consumptionSolid state diffusion coatingQuenchingCorrosion

The invention discloses a 20Cr2Ni4A steel carburizing and nitrocarburizing multiplex heat treatment process, which comprises the following process flows of: putting components made of 20Cr2Ni4A steel into a carburizing furnace, carburizing at the temperature of between 900 and 930 DEG C for 4.5 to 6 hours, discharging and performing air cooling; performing heat treatment on the carburized components in a furnace at the temperature of between 560 and 600 DEG C, performing gaseous nitrocarburizing treatment for 3 to 5 hours, raising the temperature to between 780 and 840 DEG C together with the furnace, keeping the temperature for 2 to 4 hours, and performing oil quenching; and finally charging the quenched components in the furnace for low-temperature tempering at the temperature of between 160 and 200 DEG C, keeping the temperature for 3 to 4 hours, and performing air-cooling together with the furnace. Due to the carburizing and nitrocarburizing multiplex heat treatment, the hardness on the surfaces of the components is greatly improved, and the abrasion resistance, fatigue strength and corrosion resistance are enhanced. In addition, the component heating frequency is low, so the energy consumption is greatly reduced and the work efficiency is doubled.

Owner:JIANGSU AIRSHIP GEAR

Large-sized multi-nozzle pipe hot extrusion forming process formulation and mold design method

InactiveCN103537509AIncrease productivityShorten the manufacturing cycleExtrusion diesExtrusion containersStructure propertyEngineering

The invention discloses a large-sized multi-nozzle pipe hot extrusion forming process formulation and mold design method. Taking a double-nozzle pipe for example, the method comprises the following steps: determining the size of each part of an unmachined double-nozzle pipe after hot extrusion forming; determining the size of an initial pipe blank; determining the position of the center of a prefabricated hole and the size of the aperture; determining amount of compression in the axial direction of the pipe blank with the prefabricated hole, of which oxide skin is removed, required for finishing hot extrusion forming of a second nozzle; determining amount of compression in the axial direction of the pipe blank required for continuing to finish hot extrusion forming of a first nozzle; determining the dimensional parameter of a key part of the hot extrusion mold; selecting the structural form of the hot extrusion mold; determining the extrusion capacity parameter and selecting forming equipment; determining a technological flow of the double-nozzle pipe hot extrusion forming process. According to the method, a pipe inner hole and a nozzle inner hole can be directly formed, the structural strength at the nozzle is improved, the metal mechanic property and the structure property are improved, the manufacturing period is shortened, and the material utilization rate is improved.

Owner:UNIV OF SCI & TECH BEIJING

Tech. for forging forming of hook fastener flame of wagon and maould thereof

InactiveCN1792544AShorten the lengthSave materialForging/hammering/pressing machinesOther manufacturing equipments/toolsTruckRailway freight car

A technology for manufacturing the coupler tail frame of cargo train by forging includes such steps as blanking, heating, making raw coupler tail frame, die forging step by step, that is, forging one end and then another end, removing excessive edge, bending an welding. Its die set is composed of upper die with internal cavity whose length is equal to that of finished blank, and lower die with internal cavity having a central locating pit.

Owner:CHONGQING UNIV OF TECH

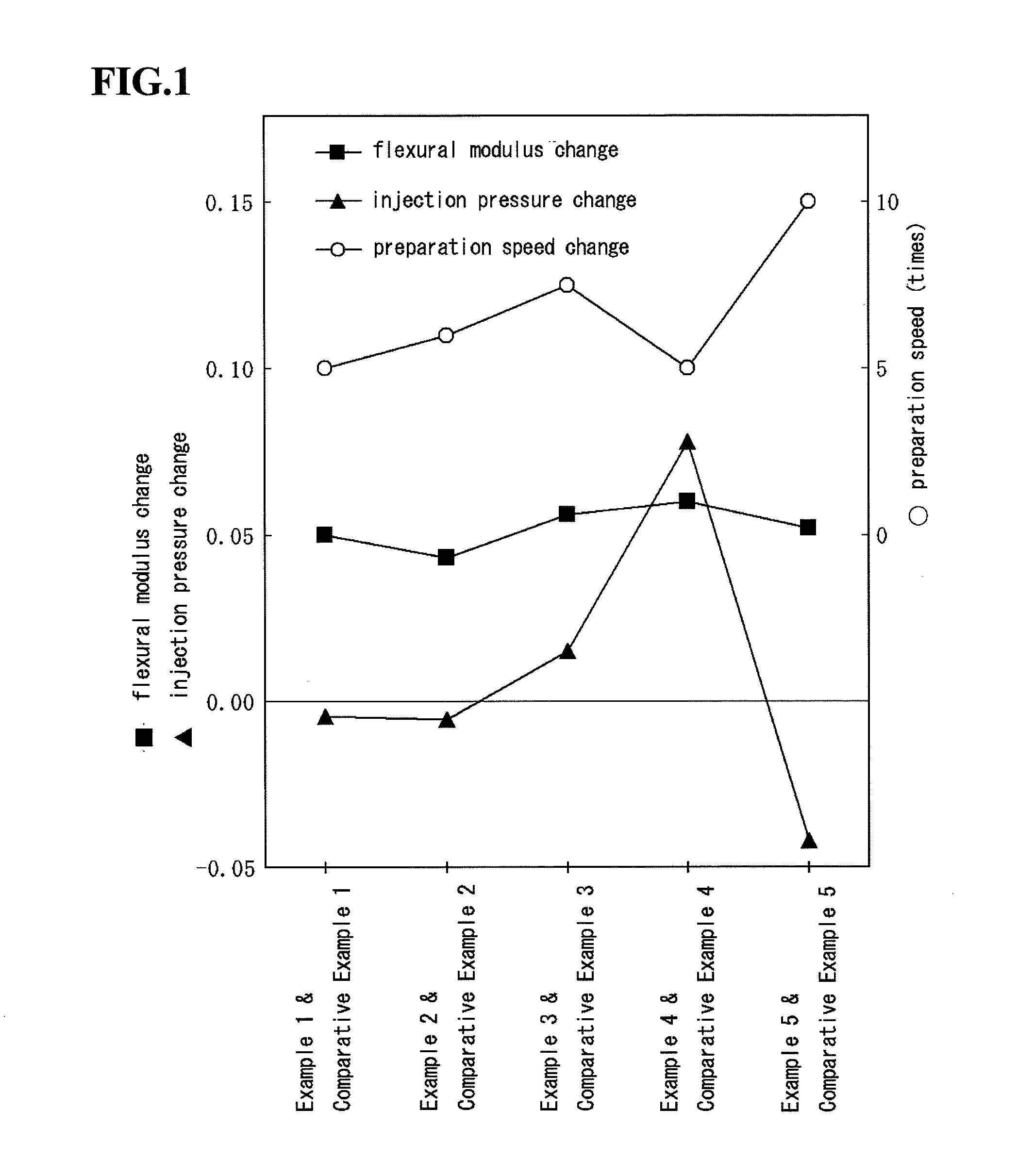

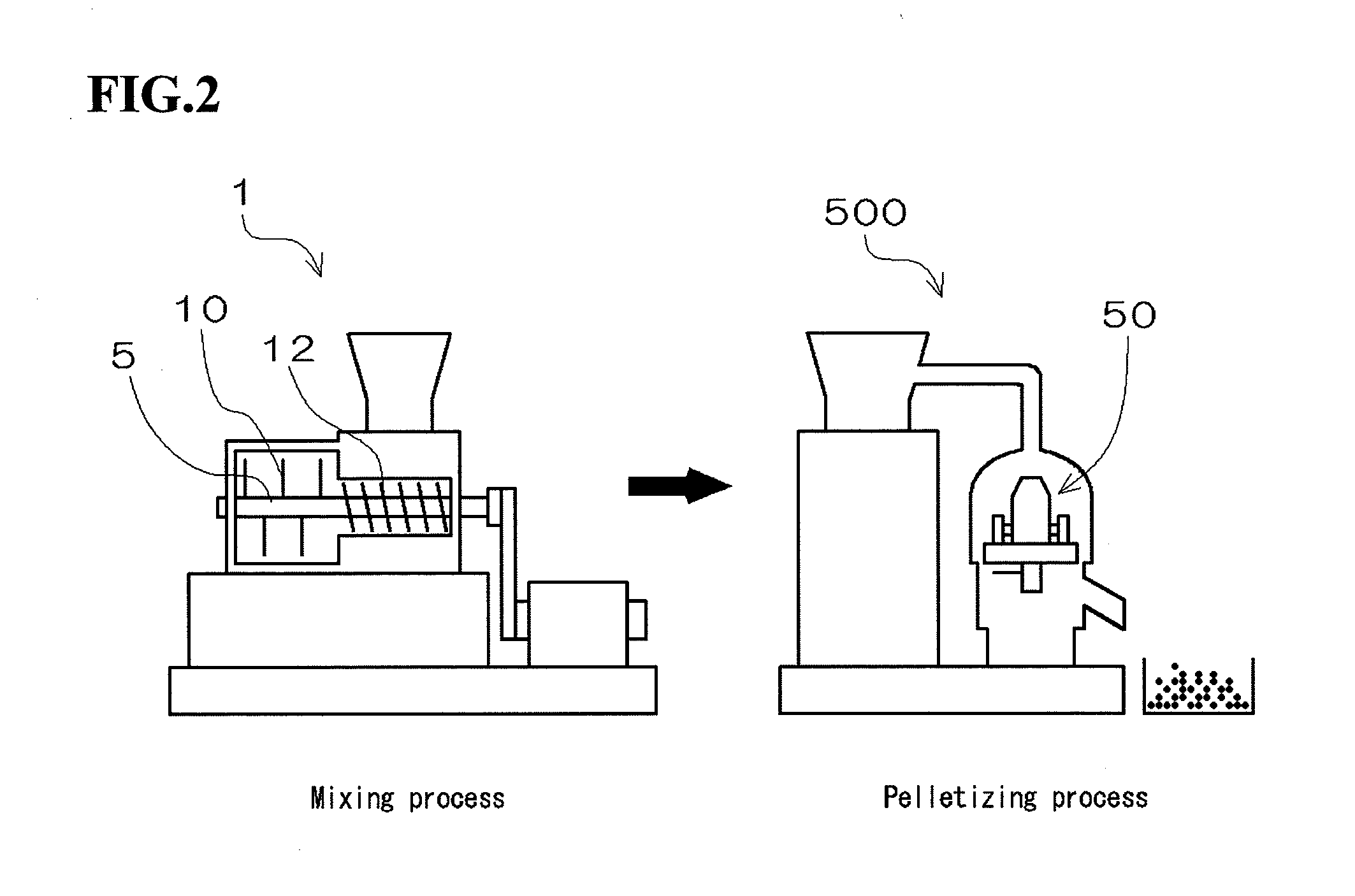

Process for producing thermoplastic resin composition and process for producing molded thermoplastic resin

InactiveUS20110109013A1High fluidityReduce numberRotary stirring mixersTransportation and packagingPolypropyleneVegetable material

The object of the present invention is to provide a method for producing a thermoplastic resin composition that contains a vegetable material in a large amount of 50% or more by weight and is capable of being pelletized so as to exhibit high fluidity, and to a method for producing a molded article of a thermoplastic resin. The present production method for the composition is one for producing a thermoplastic resin composition which comprises a vegetable material and a thermoplastic resin, and contains the vegetable material in an amount of 50% to 95% by weight based on 100% by weight of the vegetable material and the thermoplastic resin, and is characterized by comprising a mixing process for mixing the vegetable material such as kenaf core and kenaf fiber, and the thermoplastic resin such as polypropylene and polylactic acid using a mixer, and a pelletizing process for pressing the mixture obtained in the mixing process to form a pellet. In the present production method for the molded article, the thermoplastic resin composition is subjected to extrusion molding or injection molding to form a molded article.

Owner:TOYOTA BOSHOKU KK

Forging method for complex thin-rib stainless steel die forging with center hole

InactiveCN105215629AEnsure fair distributionSave raw materialsMetal-working apparatusPunch pressStress relieving

The invention relates to the field of structural member die forging and provides a forging method for a complex thin-rib stainless steel die forging with a center hole. The method includes the steps that a bar is blanked into a billet; burrs on the two end faces of the billet are ground and removed; the ground billet is heated and then forged to form a free-forging blank; the free-forging blank is heated and then pre-forged to form a pre-forged piece, a hole is punched in the center of the pre-forged piece through waste heat, and the size of the punched hole is smaller than the required size of an inner hole of the forging; surface defects of the pre-forged piece are ground; the pre-forged piece is heated and then is finish-forged and formed at a time to form the forging, and after forging is stopped, edge cutting is conducted on the forging through a punch press by means of waste heat; the forging is heated, the punch press and a final punching die are used for punching a triangular hole in the center of the forging; stress relieving, quenching, tempering and forging hardness detecting are conducted on the well-machined forging; and shot blasting de-scaling is conducted on the forging.

Owner:AECC AVIATION POWER CO LTD

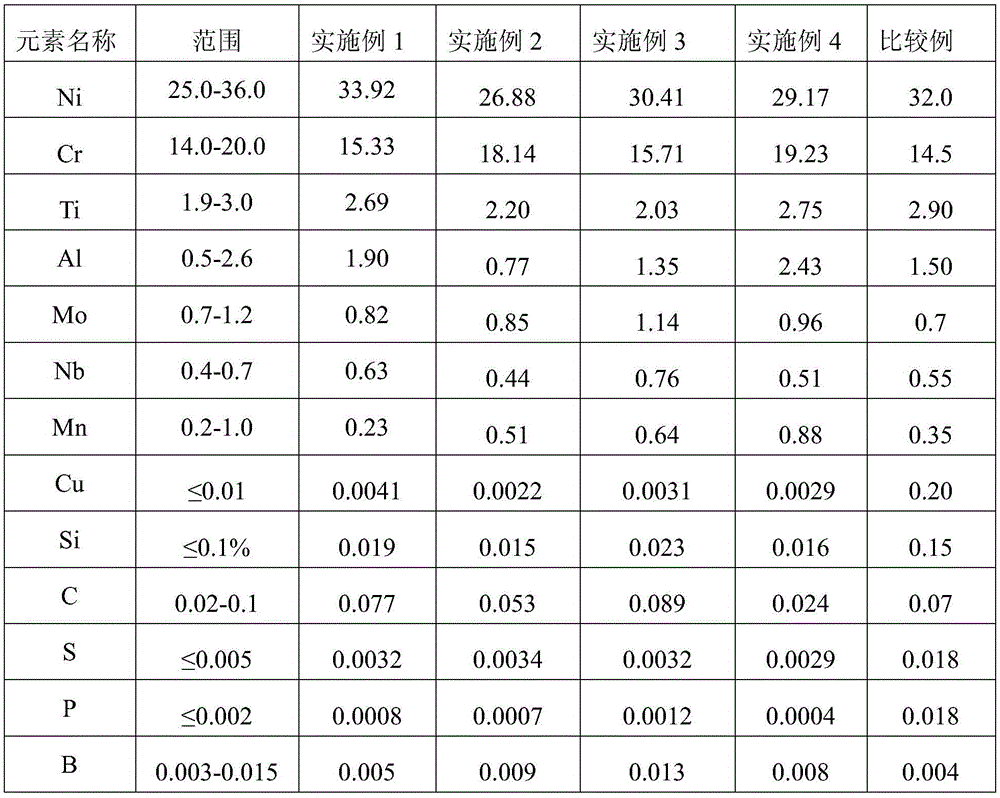

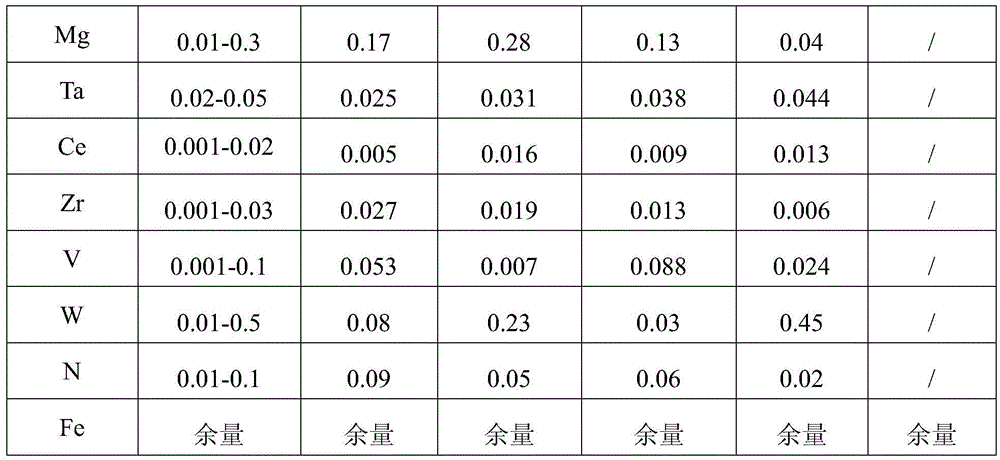

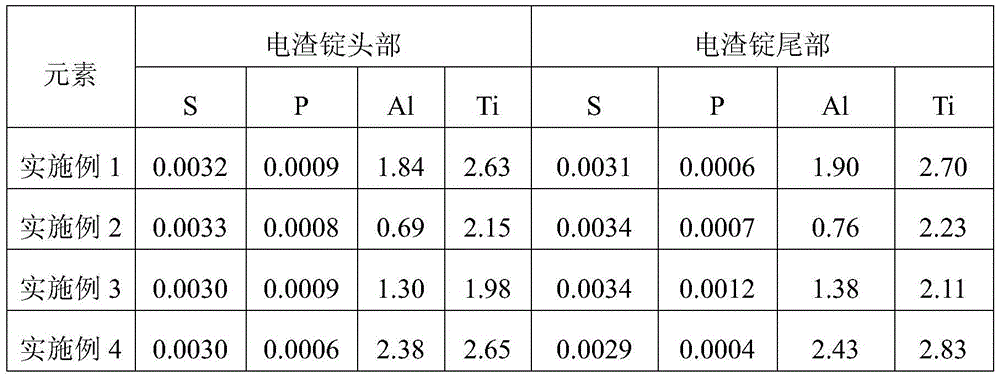

Micro-alloyed high-strength anti-oxidization iron-nickel alloy gas valve steel material and preparation method

The invention relates to a micro-alloyed high-strength anti-oxidization iron-nickel alloy gas valve steel material and a preparation method. The material comprises elements such as Ni, Cr, Ti, Al, Mo, Nb, Mn, C, B, Mg, Ta, Ce, Zr, V, W, N, Fe and the like. The material can be used in a working environment with a high temperature, high load, strong oxidization and strong corrosion, is low in nickel content, has good tensile strength, good endurance strength, good fatigue strength and excellent oxidization resistance, good corrosion resistance and good resistance to fuel gas, and can be used for preparing a gas inlet valve and a gas outlet valve of a medium-high-load engine.

Owner:CHONGQING MATERIALS RES INST

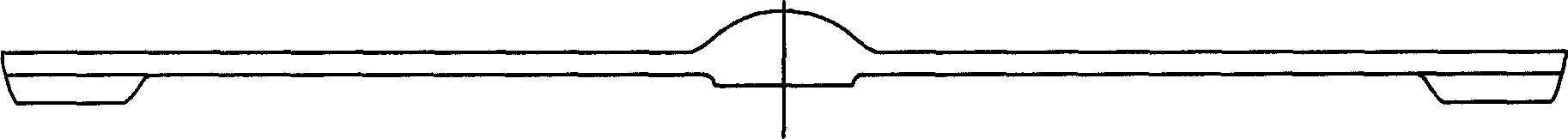

Steel ring billet casting technique based on casting and rolling combined forming

ActiveCN104439219AReduce heating timesSave blankingMolten metal pouring equipmentsFurnace typesTemperingCasting mold

The invention discloses a steel ring billet casting technique based on casting and rolling combined forming. The steel ring billet casting technique based on casting and rolling combined forming comprises the steps that firstly, a casting mold is manufactured by means of water glass sand, the casting mold is dried and sprayed with painting, casting raw materials of a steel ring are smelted and are poured into the casting mold, and normalizing, tempering and quenching-tempering heat treatment are conducted on a steel ring billet formed through pouring; secondly, the steel ring billet is cooled to the room temperature, and polishing and machining are conducted on the cooled steel ring billet; finally, the steel ring billet which can be directly used for casting and rolling combined forming is obtained. According to the steel ring billet cast according to the technique, the defects, such as shrinkage cavities, shrinkage porosity and segregation, appearing in the steel ring billet casting process can be reduced, grains are refined to the maximum extent, and the high-quality steel ring billet capable of meeting the requirement for the ring rolling performance is manufactured; due to the fact that the processes of the casting and rolling combined forming technique are simplified, the quality and performance of the ring rolling technique and a ring workpiece are guaranteed.

Owner:盐城市大丰区生产力促进中心

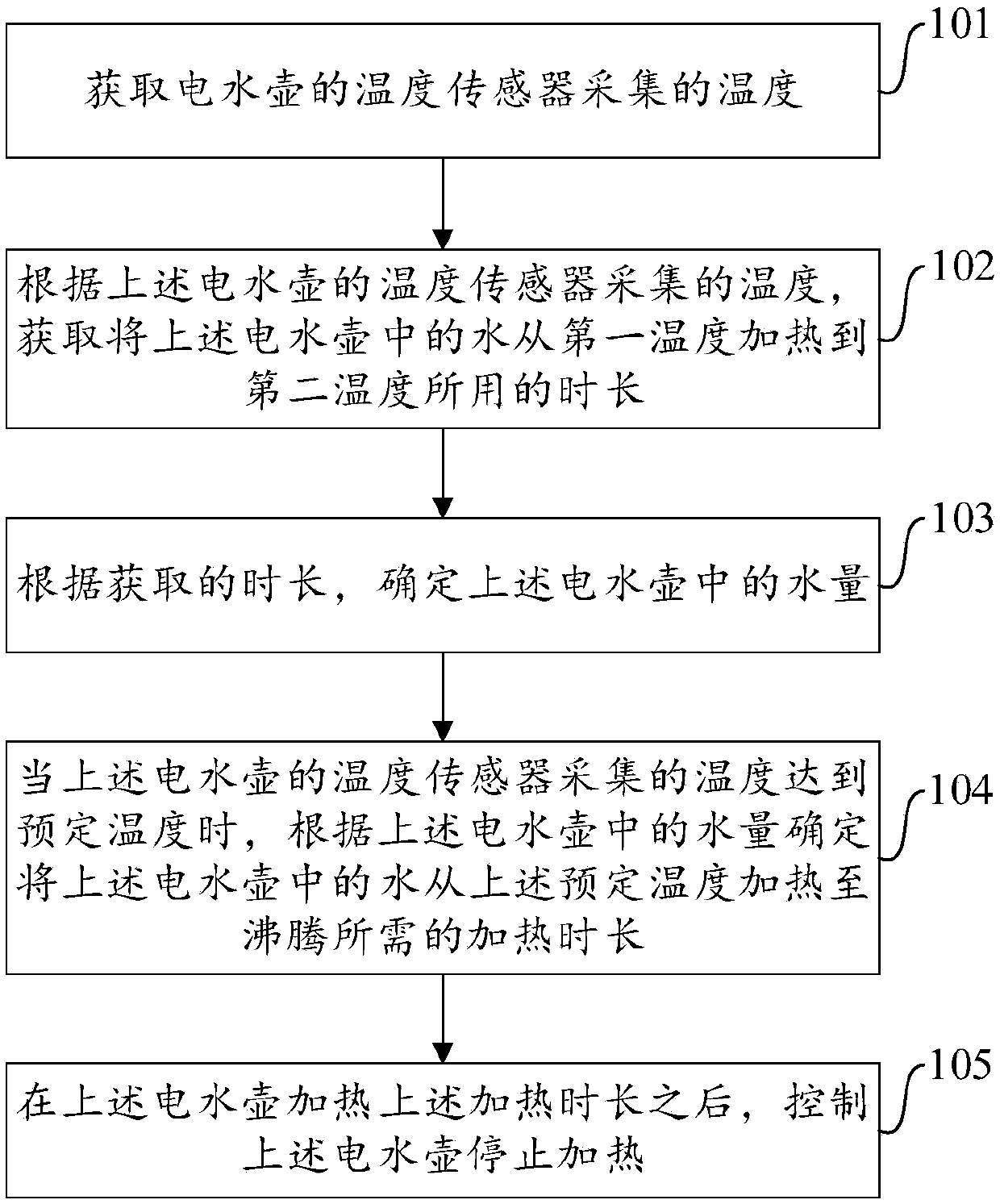

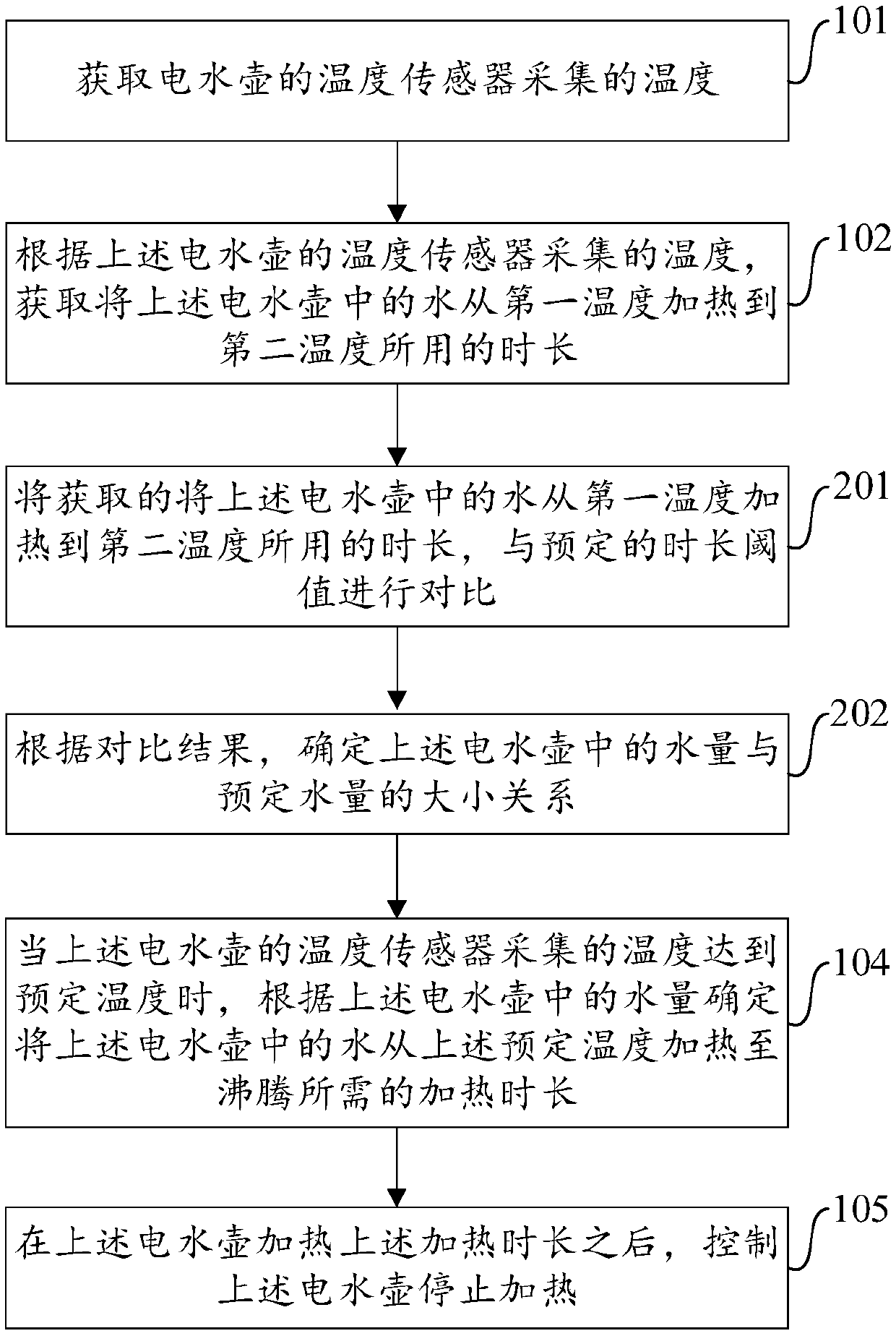

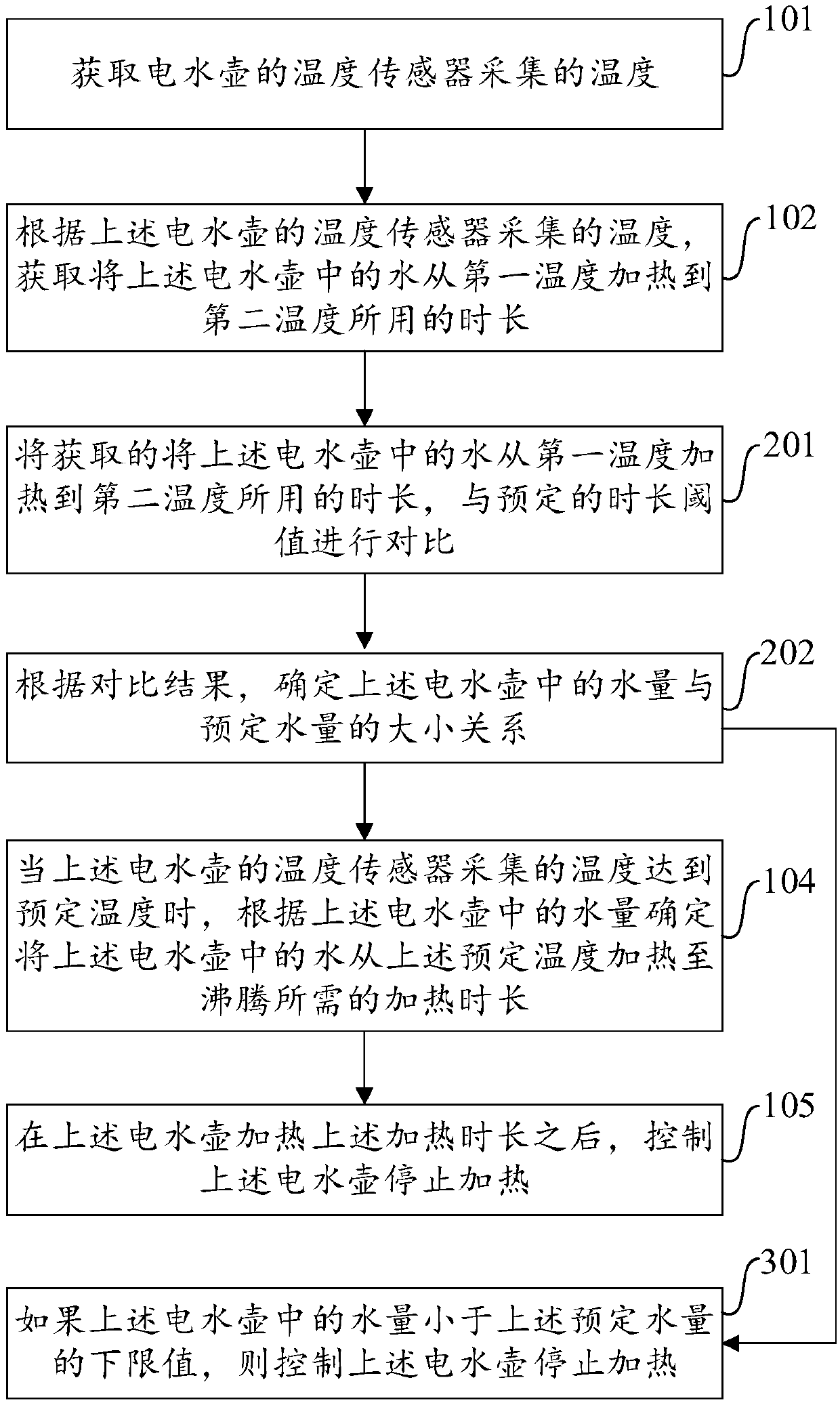

Heating control method and device and electric kettle

PendingCN110840246AImprove experienceExcellent time controlWater-boiling vesselsTemperature controlEngineering

The invention provides a heating control method and device and an electric kettle. The heating control method comprises the following steps that the temperature collected by a temperature sensor of the electric kettle is acquired; according to the temperature collected by the temperature sensor of the electric kettle, the duration required for heating water in the electric kettle from a first temperature to a second temperature is acquired; according to the obtained duration, the water quantity in the electric kettle is determined; according to the water quantity in the electric kettle, the heating duration required to heat water in the electric kettle from a preset temperature to a boiling state is determined; and after the electric kettle heats for the heating duration, the electric kettle is controlled to stop heating. According to the method, the heating duration required for heating water in the electric kettle to the boiling state can be determined according to the water quantityin the electric kettle; and after the heating duration is reached, the electric kettle is controlled to stop heating, and the time control is better than the temperature control in a control mode ofstopping heating of the electric kettle, so that the heating time consumption is reduced, the power consumption is lowered, and the user experience is improved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Integral forging method of variable-wall-thickness thick-wall end socket of high flange

The invention discloses an integral forging method of a variable-wall-thickness thick-wall end socket of a high flange. The method comprises the following steps that shape sizes of forging blanks andforging molds are determined through calculation according to relevant data of the target end socket, corresponding molds are manufactured, after steel ingots are heated to a forging temperature, thesteel ingots are subjected to upsetting and drawing to obtain cylindrical blanks conforming to calculation, the cylindrical blanks are put into a set concave die and a cylindrical die, and are subjected to upsetting and deforming to a set height by using a circular flat plate, after the upset blanks are heated again, the blanks are put back into the concave die and the cylindrical die, a rotary punching head is used for carrying out punching deformation on the blanks, the punched blanks are re-heated and are put back into the concave die and the cylindrical die, an annular inner pressing ringand an annular outer pressing ring are used for compressing and deforming upper end metal of the extruded blanks to a set height, and therefore the required size of a forged piece is met. According tothe integral method, in-mold forming is adopted, and the obtained forged piece is regular in shape and good in performance; and the method is short in technological process, does not have special requirements on forging devices, and is convenient to popularize and apply.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

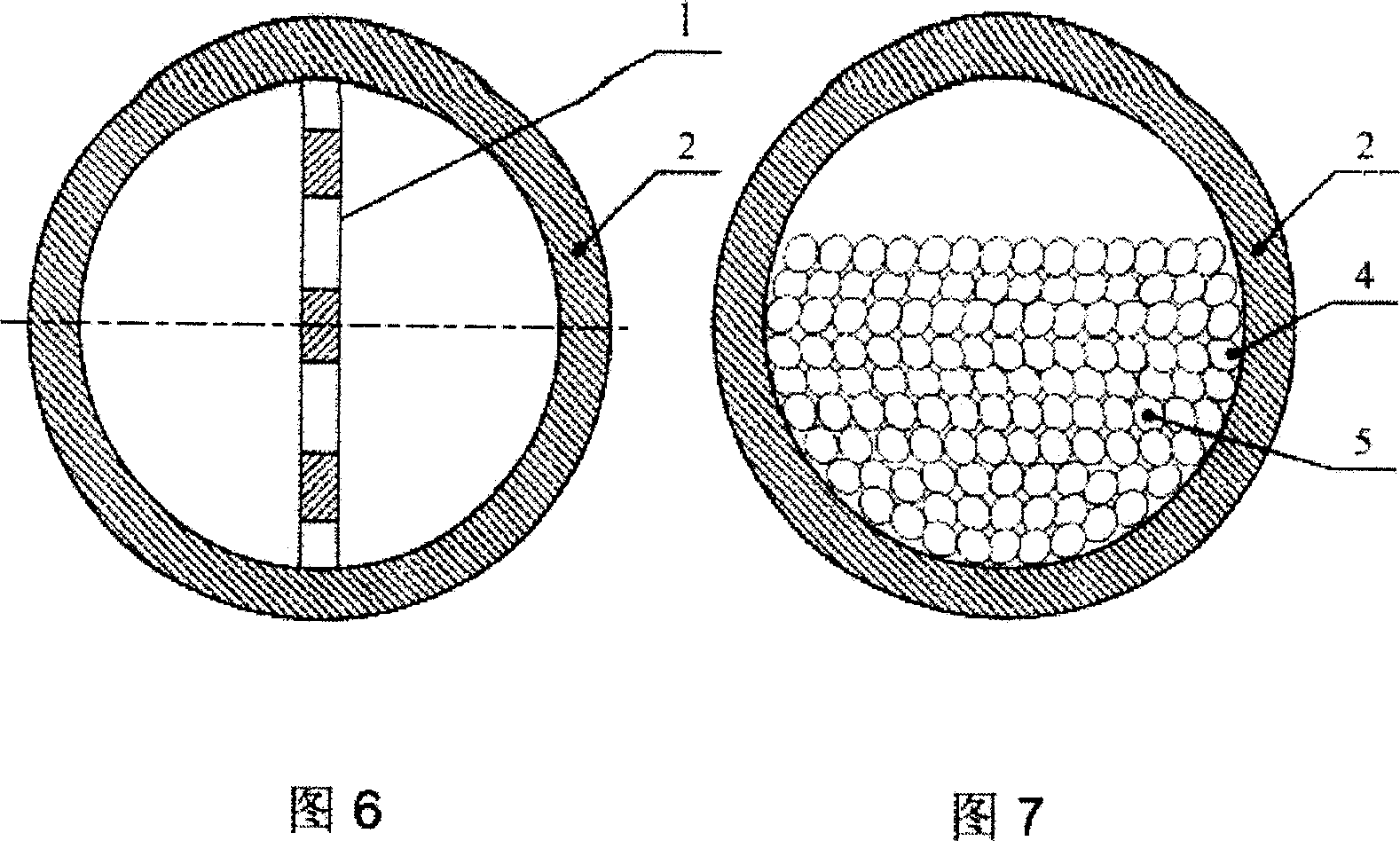

Method for improving material heating speed in metallic vacuum smelting reverting pot and reverting pod thereof

The invention discloses a material heating speed increase method in a metal vacuum smelting reduction pot and a reduction pot. The invention is provided with a heat conductor connected with the pot body inside the metal vacuum smelting reduction pot to increase the heat conduction area and decrease the distance between the heat conductor and the reduction material and therefore the heating speed of the reduction material is enhanced. Under the condition of having no effect to the reduction reaction, the heat conductor shape and setting mode are arbitrary. By adding the heat conductor inside the reduction pot, the invention is not only capable of shortening the heating time consumption during the reduction reaction, improving the production efficiency of unit time, decreasing the energy consumption and production cost, but also capable of enhancing the strength of the reduction pot and prolonging the service life. The invention can be applied in the metal production of the magnesium, strontium, zinc, beryllium, etc. through the vacuum smelting heat reduction.

Owner:GUIZHOU SHIJI TIANYUAN MINING IND

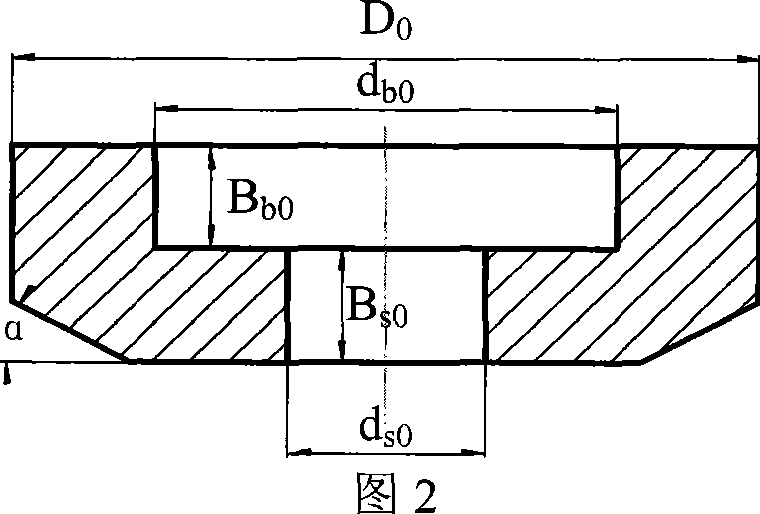

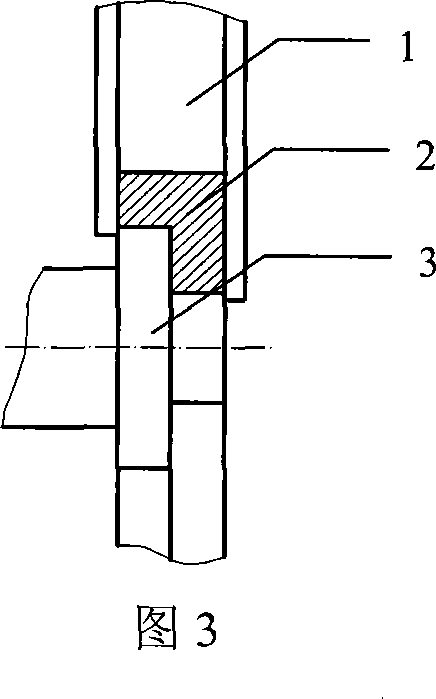

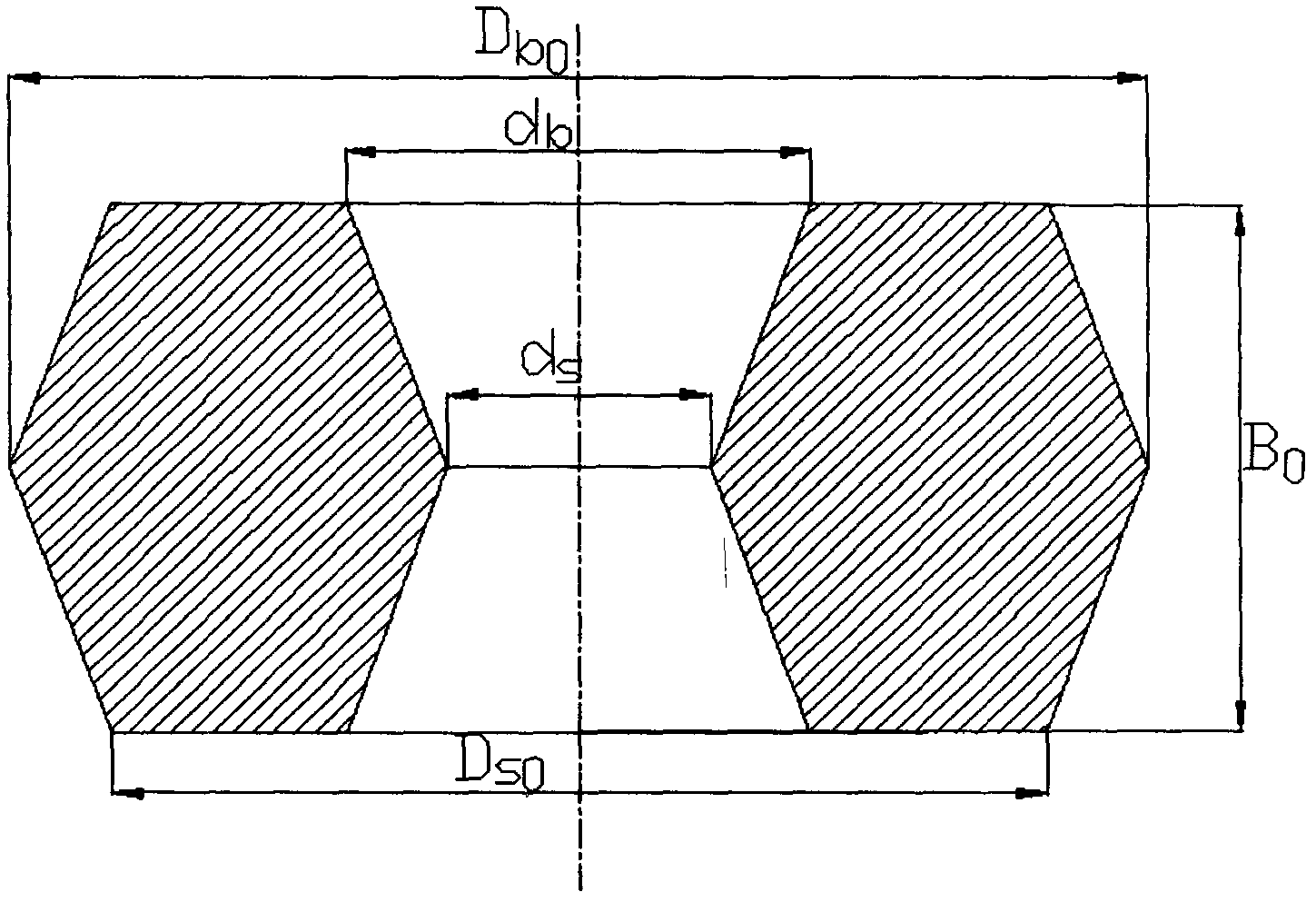

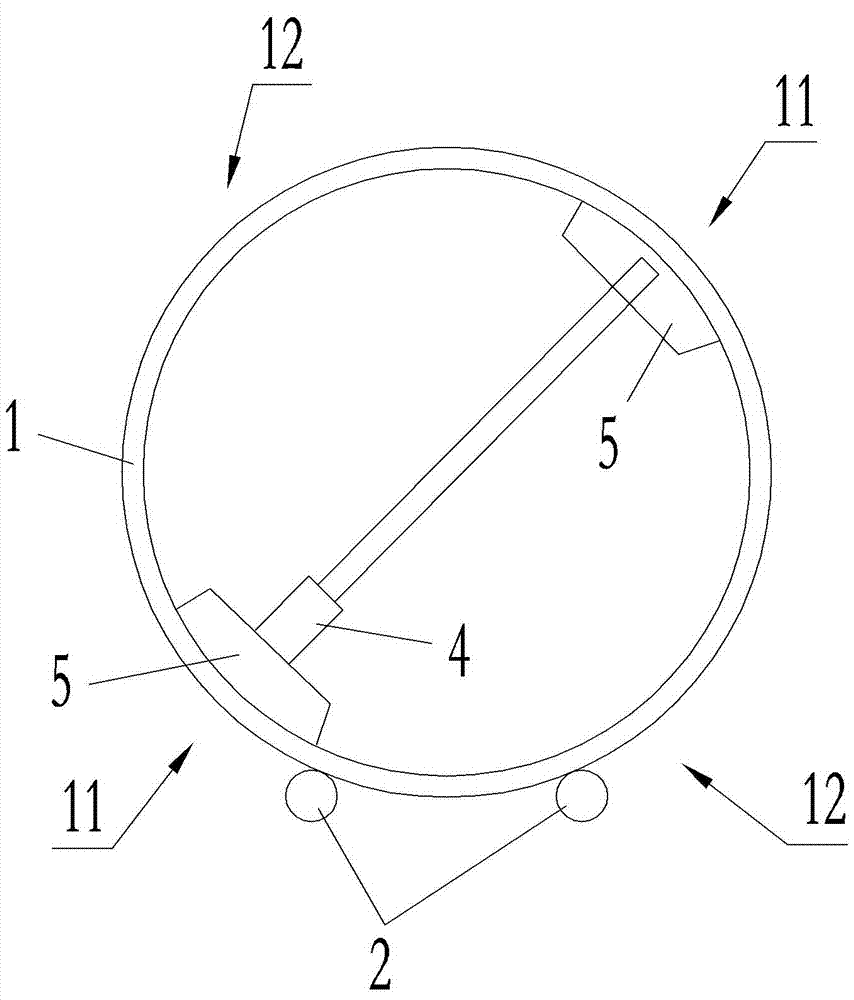

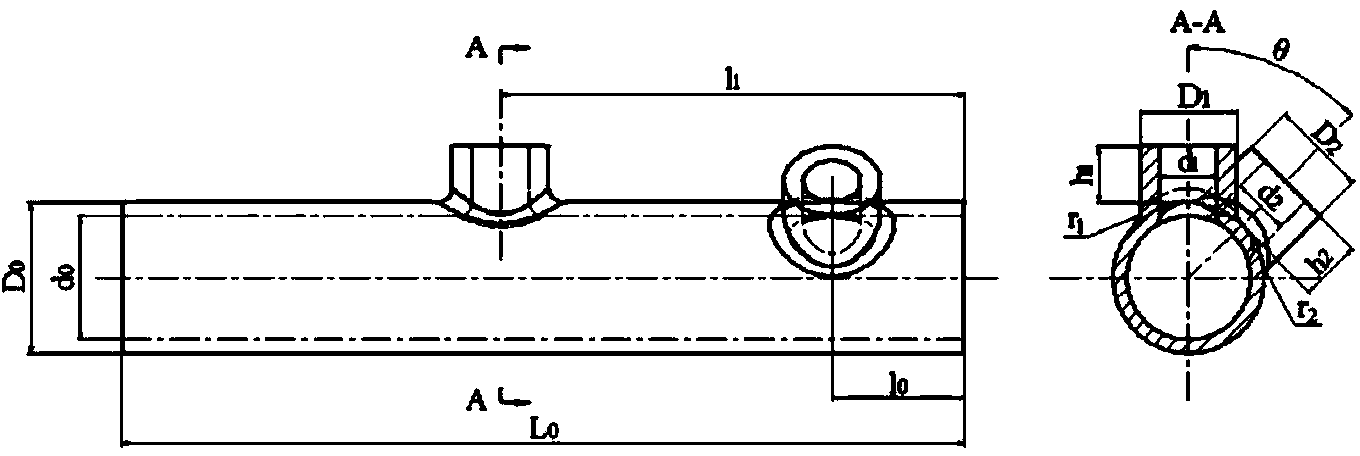

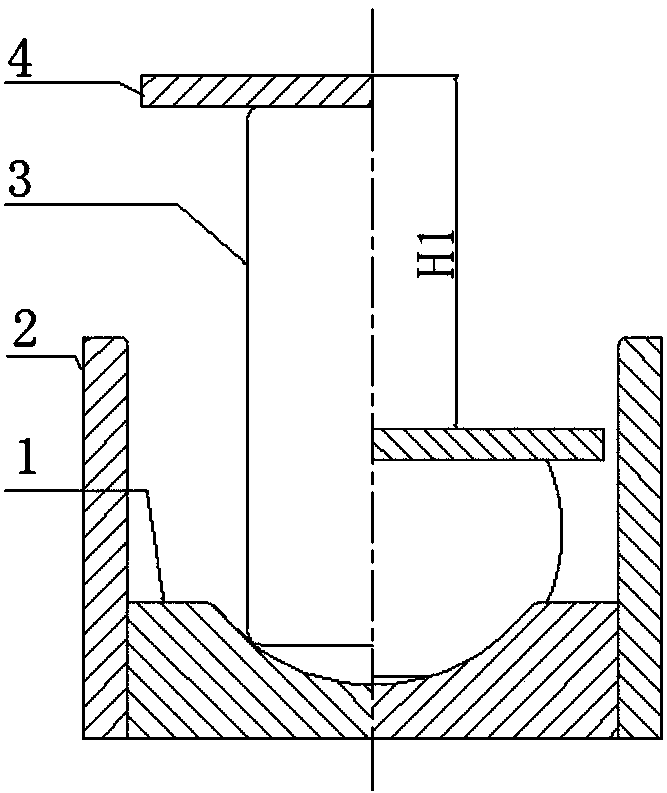

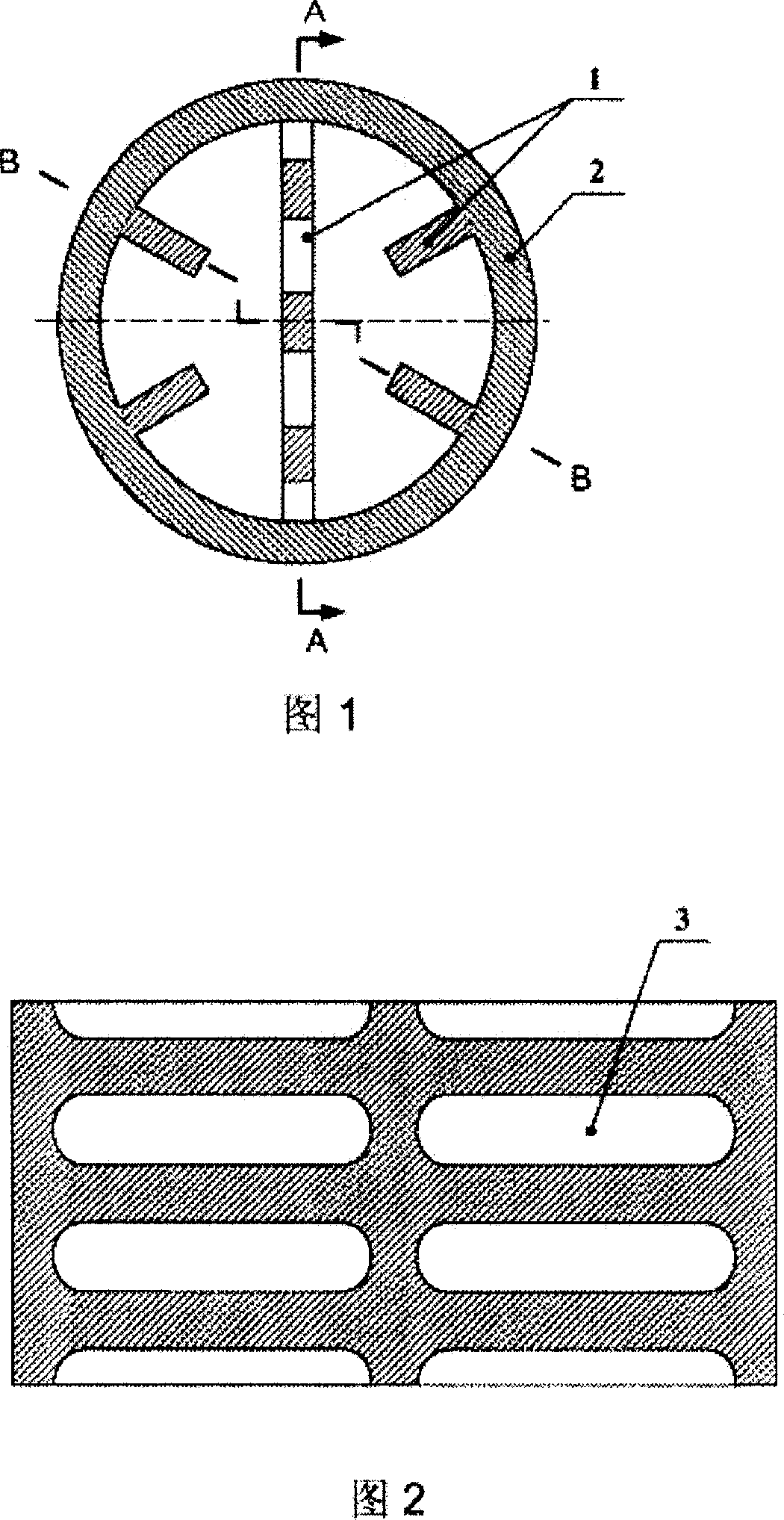

Master roller and core roller active-active twist-roll forming method for bearing outer ring for aviation main shaft cylindrical roller

ActiveCN104707924AReduce heating timesReduce distortionBearing componentsScrew-threads articlesHeat deflection temperaturePunching

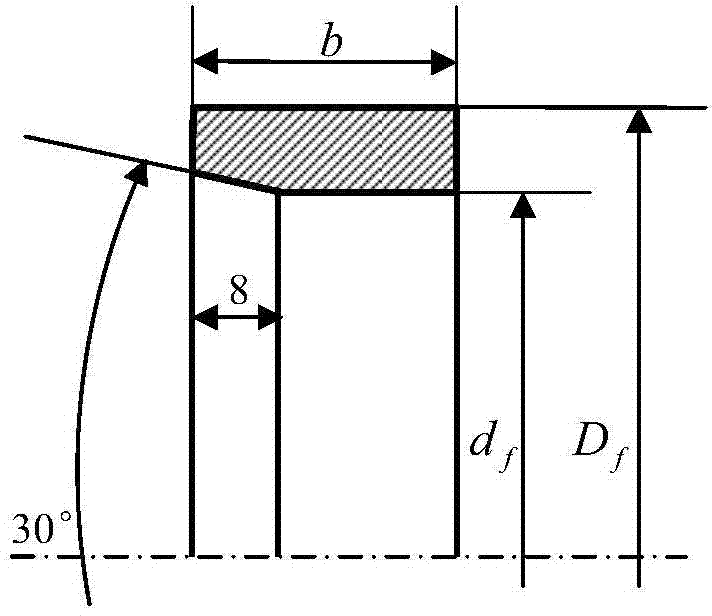

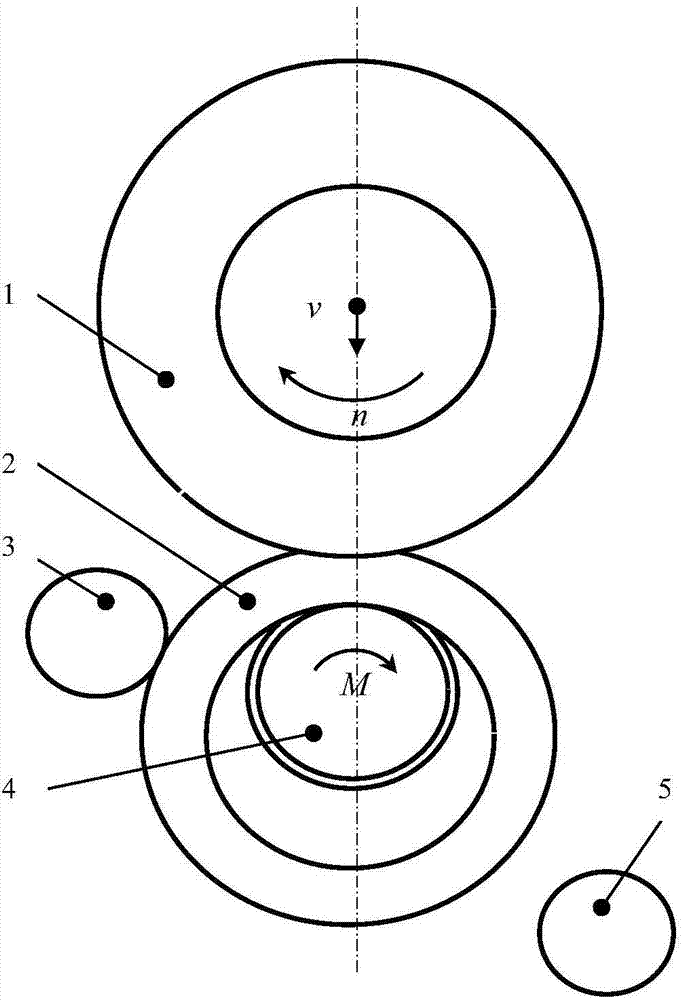

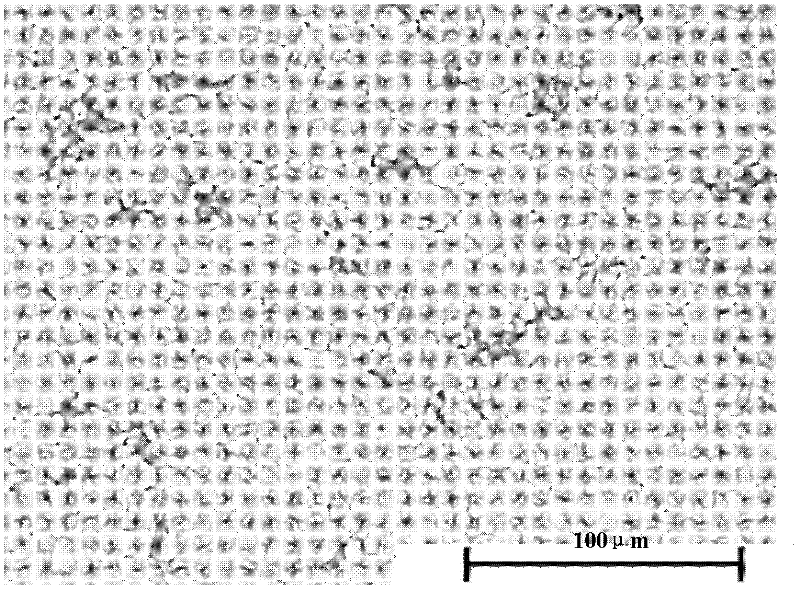

The invention relates to a forming method for a bearing outer ring for an aviation main shaft cylindrical roller. A master roller and core roller active-active twist-roll forming method for the bearing outer ring for the aviation main shaft cylindrical roller is characterized by comprising the steps of 1, blanking, wherein bars are sawn into material sections; 2, blank making, wherein the material sections are heated to heat distortion temperature from indoor temperature, conducting upsetting, punching and wad punching on the hot material sections, and obtaining ring blank for rolling; 3, conducting master roller and core roller active-active twist-roll forming by means of a ring rolling machine, wherein the ring blank is placed into a heating furnace to be heated, taken out when temperature rises to the heat distortion temperature, and then placed in a hole of the ring rolling machine, a master roller and a core roller are driven at the same time for twist-roll forming, sound lubrication is kept between the ring blank and the rollers during rolling, and a ring forging with a rectangular section is obtained through multiple turns of rolling of the ring blank; 4, conducting mechanical cutting on the forging to obtain the bearing outer ring for the aviation main shaft cylindrical roller. The method has the advantages that plastic deformation quality is high, cost is low, and production efficiency is high.

Owner:WUHAN UNIV OF TECH

Method for manufacturing tungsten-copper alloy rods and wires

InactiveCN102500615ANo lossSimple preparation processMetal rolling arrangementsContinuous rollingMaterials science

The invention discloses a method for manufacturing tungsten-copper alloy rods and wires. Tungsten-copper alloy circular ingots are processed into tungsten-copper alloy rods and wires by an even number of times of unwrapped continuous rolling or an even number of times of unwrapped single rolling with a Y-shaped rolling mill unit. The method for manufacturing the tungsten-copper alloy rods and wires has a simple preparation process, and no material loss occurs during the process; compared with a traditional rotary forging process, the heating times are reduced, the energy loss is reduced, no manual feeding is needed, and the performance of manufactured products is stable; compared with an extrusion process, the lengths of the ingots which can be processed are not restricted by the extrusion ratio; after rolling, the Y-shaped rolling mill unit can also manufacture finished rods and wires with the diameters being 3.0mm to 10mm by single-head rotary hammering and chain-type wire drawing; and the products are in various and comprehensive specifications, and the method for manufacturing the tungsten-copper alloy rods and wires is applicable to different scope of application.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

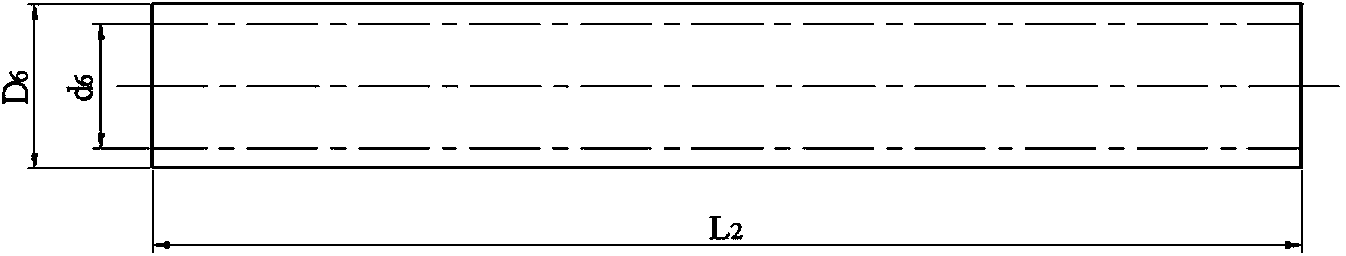

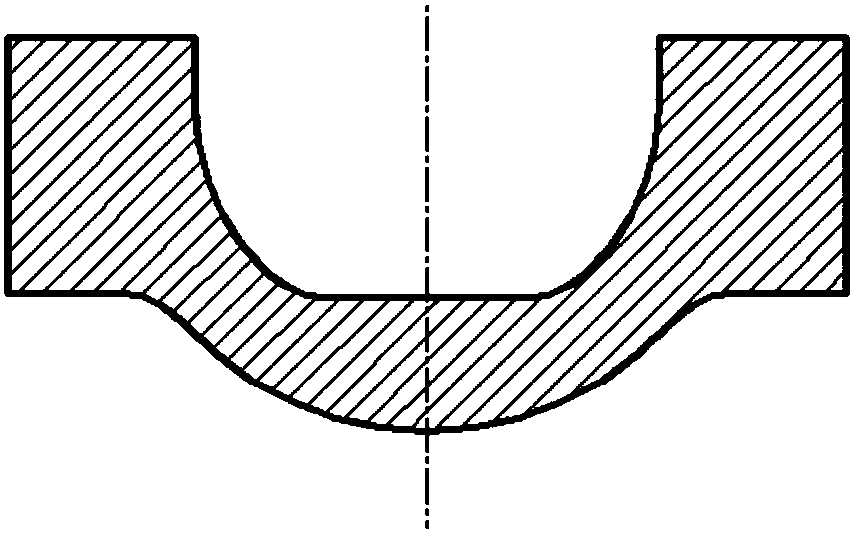

Short-flow casting and rolling composite forming method for ferrule piece

The invention relates to a short-flow casting and rolling composite forming method for a ferrule piece, which belongs to a machining and forming method for a large-sized ferrule piece and mainly overcomes the technical difficulty that the conventional rolling method has high material waste and serious energy waste. The invention adopts the technical scheme that the short-flow casting and rolling composite forming method for the ferrule piece comprises the steps of alloy melting, molten steel refining, centrifugal casting of a ring blank, hot rolling and expanding, rough machining, heat treatment and finish machining, wherein the molten steel refining refers to external refining with an LF furnace and argon stirring to obtain high-purity molten steel; the centrifugal casting of the ring blank comprises that the refined molten steel is centrifugally cast at the temperature of 1,600 DEG C to form the ring blank, and meanwhile the cast blank grains are thinned by adopting electromagnetic stirring; and the hot rolling and expanding comprise that when the ring blank casting is solidified and the temperature drops to initial forging temperature of 1,200 DEG C, the rolling and expanding are directly performed on a rolling and expanding machine, the feeding amount is controlled during rolling and expanding, and the rolling-expanding ratio is 2 to 3.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Manufacturing method of blade type product die forging clot

ActiveCN102756063AImprove blank qualityReduce sizeMetal-working apparatusEngine componentsMachining processDumbbell shaped

The invention provides a manufacturing method of a blade type product die forging clot. The blade type product die forging clot is dumbbell-shaped and is formed by connecting large-end discs at left and right ends and a middle-section rod member, wherein the large-end discs and the middle-section rod member are in smooth connection with one another through transition cambered surfaces; the clot is prepared by using an upset forging machining process; a cylindrical rod material is arranged in a mould; the mould has a horizontal double-opening mould structure; the size of a cavity after closing of an upper die and a lower die is consistent with the size of the clot; the left end and the right end of the cavity are provided with a left upset head and a right upset head respectively; and the left upset head and the right upset head move oppositely to extrude the two ends of the rod, so that the rod is made into the clot in the mould through upset forging. The manufacturing method has the comprehensive advantages of die forging and extrusion; the limitation of free forging hammer and radial forging is broken through; the backwardness of large coating, large margin and tolerance and fatness of normal clots is changed; fine production of the clot can be realized; the manufacturing process is finished at one time; the operation time is short; the forming accuracy of the clot is high.

Owner:DONGFANG TURBINE CO LTD

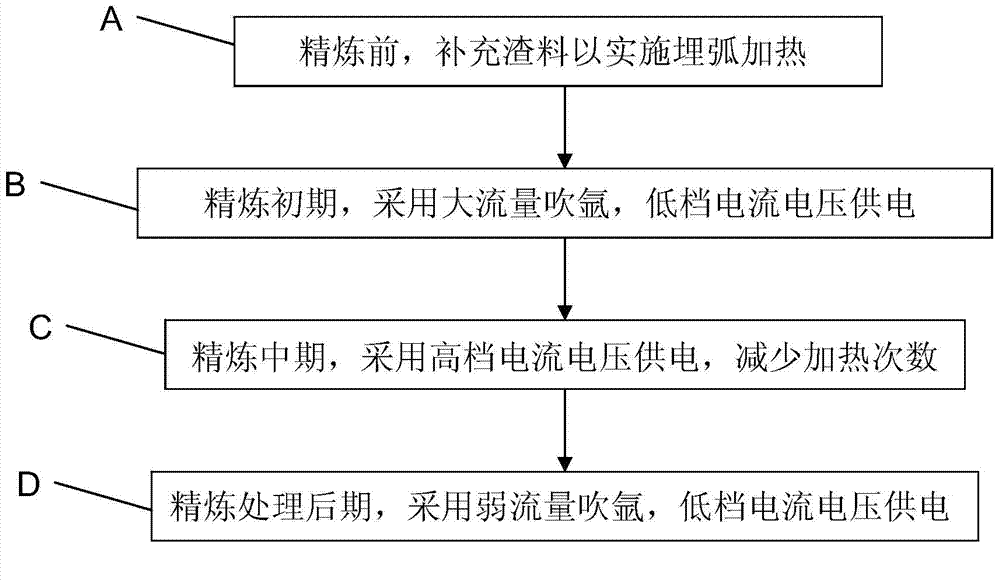

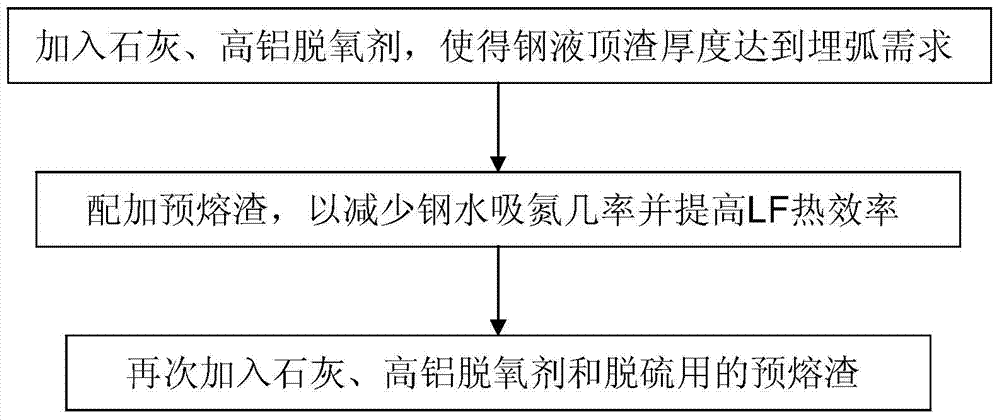

Control method for preventing nitrogen increasing in LF refining treatment

The invention discloses a control method for preventing nitrogen increasing in LF refining treatment. The control method comprises: before refining, performing submerged-arc heating via replenishing slag materials; in an initial stage of refining, producing white slag via ladle bottom high-flow-argon blowing, and adopting a low-current and low-voltage power supply; in an intermediate stage of refining, adopting a high-current and high-voltage power supply, and reducing frequency of heating and frequency of opening a furnace door for temperature measurement and sampling in order to improve the temperature raising efficiency; and in a later stage of refining, adopting ladle bottom small-flow-argon blowing, and the low-current and low-voltage power supply. The control method adopts the ways above for preventing nitrogen increasing, so that nitrogen increasing of an LF during a working process is effectively prevented; the average amount of nitrogen increasing is controlled in a range of 3-5ppm; and the quality of molten steel is further improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Clamp nut casting technology based on casting and rolling combined forming

The invention discloses a clamp nut casting technology based on casting and rolling combined forming. According to the casting technology, casting ingredients are mixed by the ratio of carbon steel: scrap iron=89-90%:10-20%, a clamp nut is directly formed through rolling and expanding in the casting process, and the working procedures of blanking, forging and punching in an existing technology are omitted. According to the designed clamp nut casting technology based on casting and rolling combined forming, in the casting process, the defects of shrinkage, porosity, segregation and the like of a casting blank are reduced, and grains are refined as much as possible, so that the high-quality clamp nut capable of meeting the requirement for rolling and expanding forming performance is manufactured; the clamp nut is provided with an obvious yielding platform which does not disappear along with time, the delayed fracture resistance is high, plasticity is high, machining and manufacturing pollution is small, and cost is low.

Owner:佛山市南海区冠辉机电设备实业有限公司

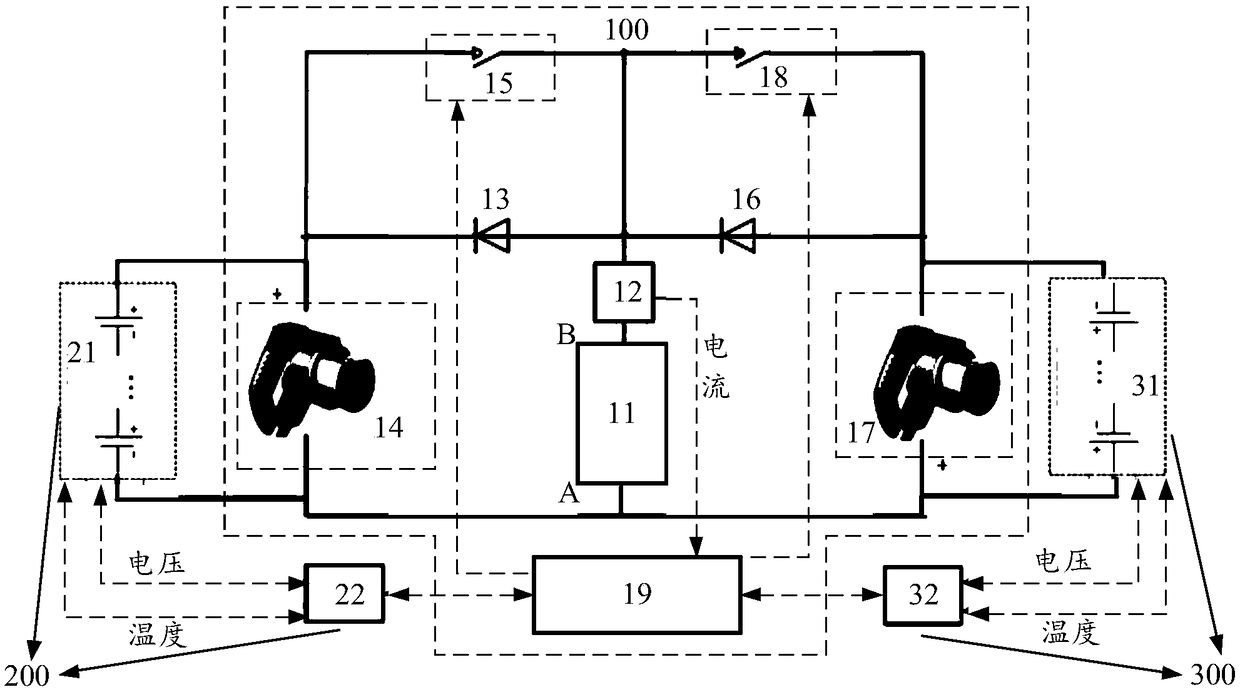

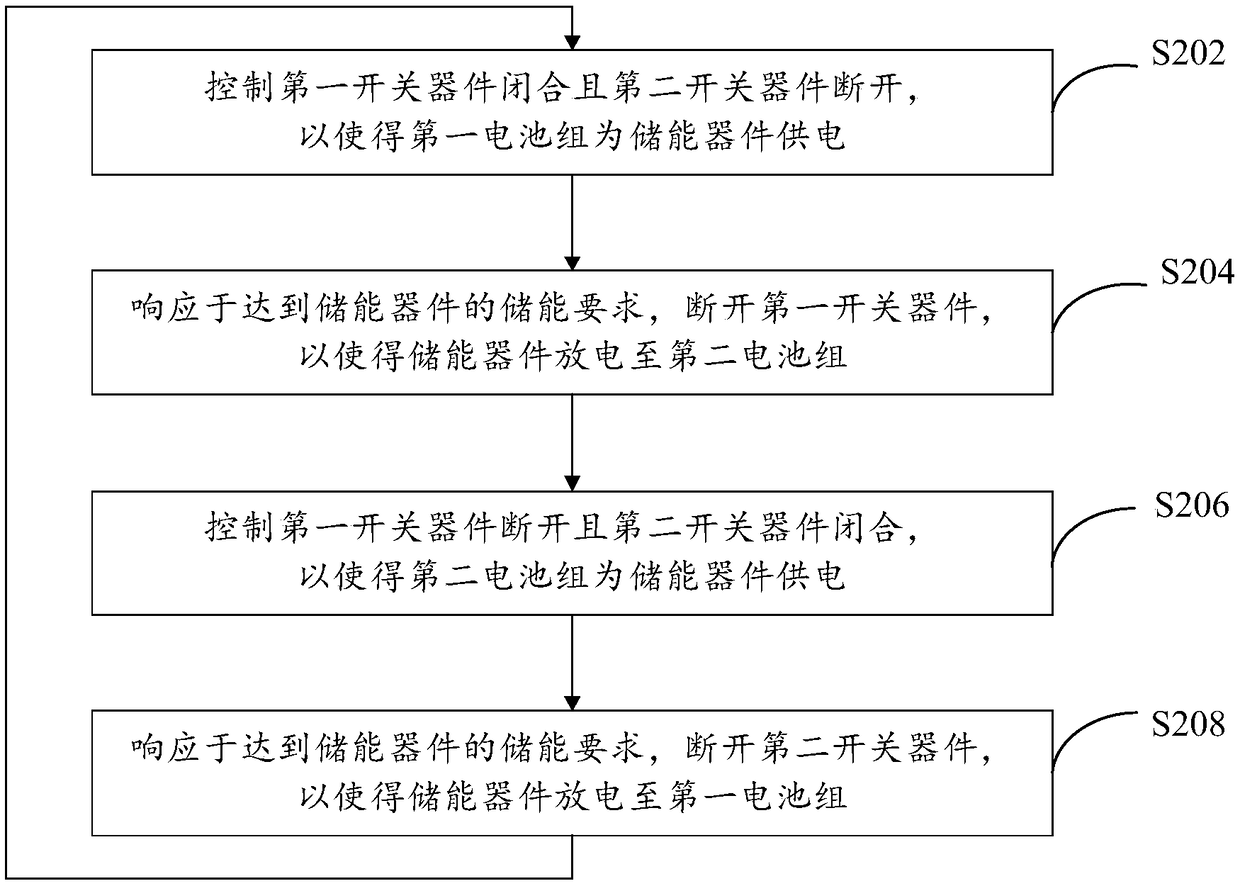

Battery pack heating device and control method for dual-car heating

ActiveCN108666713AShorten the durationRealize the effect of direct heatingSecondary cellsVehicular energy storageCurrent sensorSingle vehicle

The embodiment of the invention provides a battery pack heating device and control method for dual-car heating. According to the embodiment of the invention, the battery pack heating device is portably arranged at the exterior of a vehicle and comprises an energy storage device, a current sensor, a first diode, a first heating interface, a first switching device, a second diode, a second heating interface, a second switching device, and a heating control module; an input end of the first diode is connected with a second end of the current sensor; the first switching device is connected betweenthe second end of the current sensor and a positive pole of the first heating interface; an output end of the second diode is connected with the second end of the current sensor; the second switchingdevice is connected between the second end of the current sensor and a negative pole of the second heating interface; and the heating control module is used for controlling the opening and closing states of the first switching device and the second switching device. Therefore, the technical scheme provided by the embodiment of the invention can solve the problem that the single vehicle indirect heating mode can only heat one vehicle and is relatively low in heating efficiency in the prior art.

Owner:CONTEMPORARY AMPEREX RUNZHI SOFTWARE TECH LTD NINGDE CITY

Preparation method for tea flavored boiled eggs

The invention provides a preparation method for tea flavored boiled eggs. The tea flavored boiled eggs boiled by the method have crispy yolks and fresh and tender egg white, and have a short time interval of a processing process. The specific scheme is as follows: the tea flavored boiled eggs comprise main materials and auxiliary materials; the main materials are raw eggs; the auxiliary materials comprise green tea, anises, cinnamons, peppers, gingers, bay leaves, dark soy sauce, cumin powder and sugar. The preparation method comprises the following steps: (1) clearly washing shells of taken 10 eggs; putting the eggs into a boiler and pouring clean water until the clean water covers the eggs; (2) adding a half kilogram of the water into the auxiliary materials and boiling for later use so as to guarantee that the boiled water can cover the eggs; (3) boiling the eggs by the clean water until the egg white is condensed; fishing out and immersing by cold water for 2 minutes; slightly cracking until the shells are crushed and are connected with egg membranes; (4) fishing out the eggs and putting the eggs into the auxiliary materials to immerse for 2 hours; and (5) adding a half kilogram of the boiled water into the boiler and boiling the eggs to be 90% cooked by gentle wire; turning off the fire, keeping the heat and immersing for 2 hours to obtain the edible tea flavored boiled eggs.

Owner:扬州美瑞食品有限公司

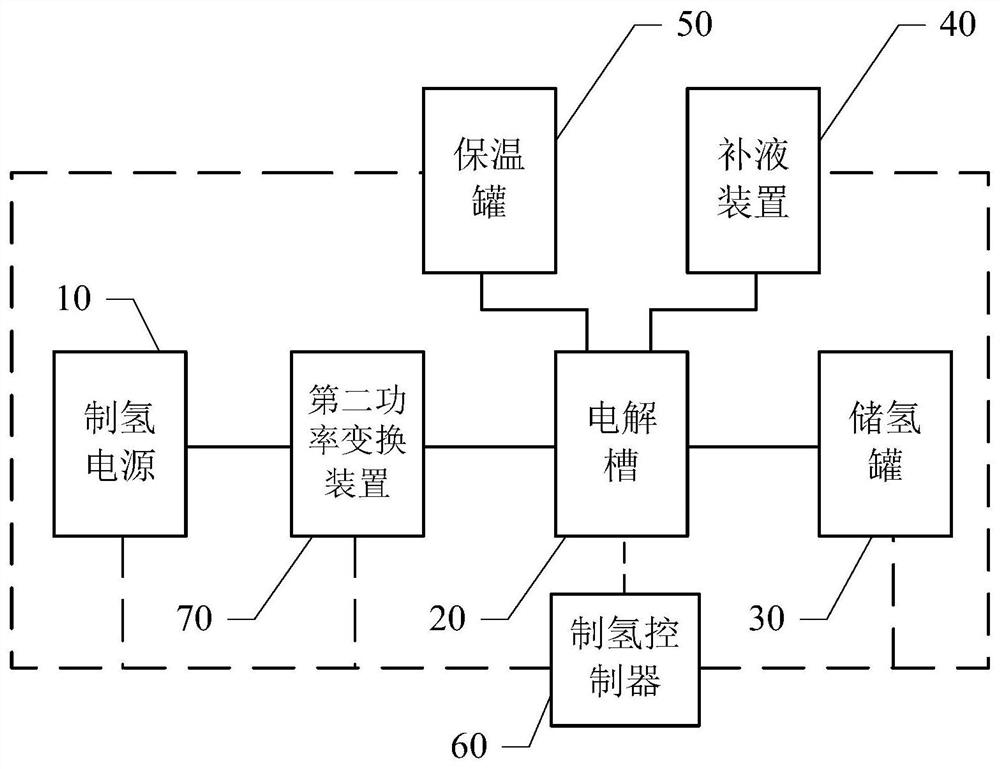

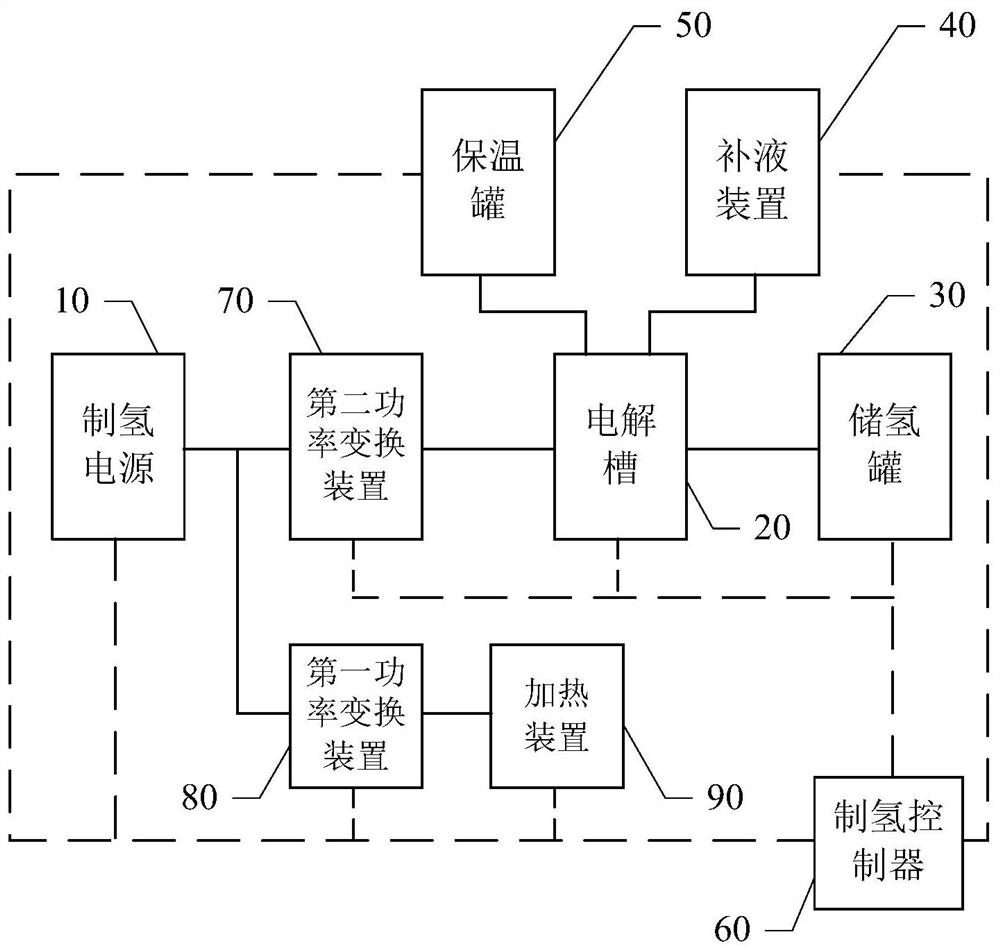

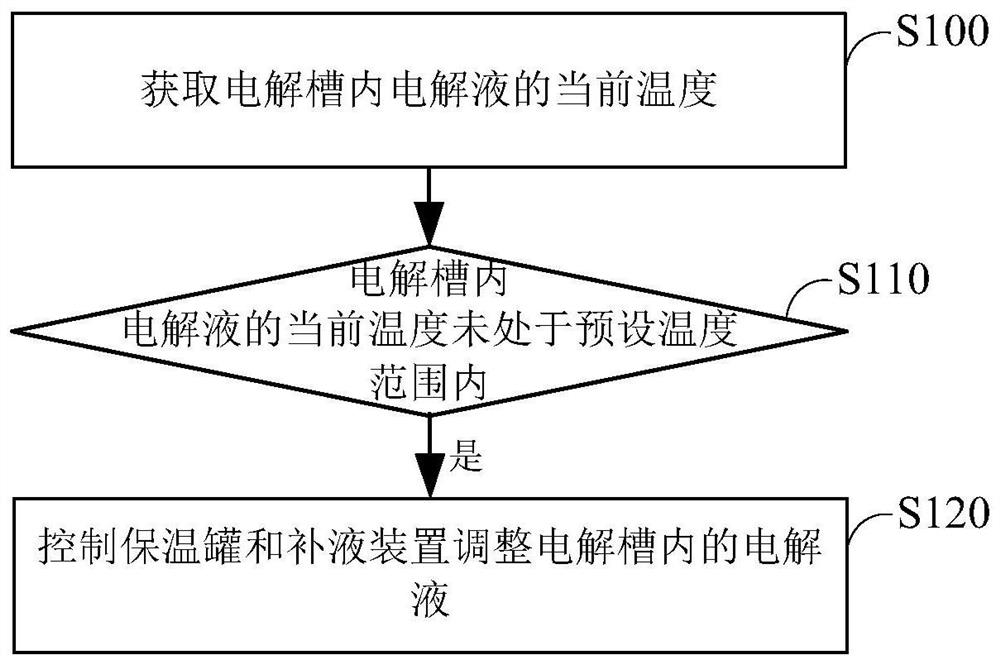

Hydrogen production electrolyte temperature control method and hydrogen production system

PendingCN113430570AIncrease temperatureImprove hydrogen production efficiencyCellsElectrolytic agentTemperature control

The hydrogen production electrolyte temperature control method and the hydrogen production system provided by the invention are applied to the technical field of hydrogen preparation. According to the method, after the current temperature of the electrolyte in the electrolytic bath is obtained, if the current temperature of the electrolyte is not within a preset temperature range, a heat preservation tank and a liquid supplementing device are controlled to adjust the electrolyte in the electrolytic bath; as the temperature of the electrolyte in the heat preservation tank is higher than that of the electrolyte in the liquid supplementing device, the average temperature of the electrolyte in the electrolytic bath can be increased through cooperation of the heat preservation tank and the liquid supplementing device, then the electric energy needed for heating the electrolyte to the preset temperature range is reduced, meanwhile, the heating time is shortened, and the hydrogen production efficiency is improved.

Owner:HEFEI SUNGROW RENEWABLE ENERGY SCI & TECH CO LTD

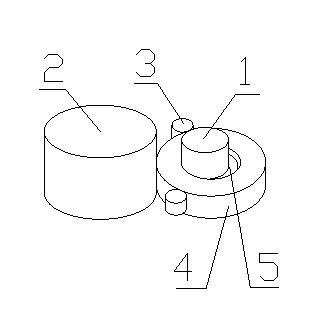

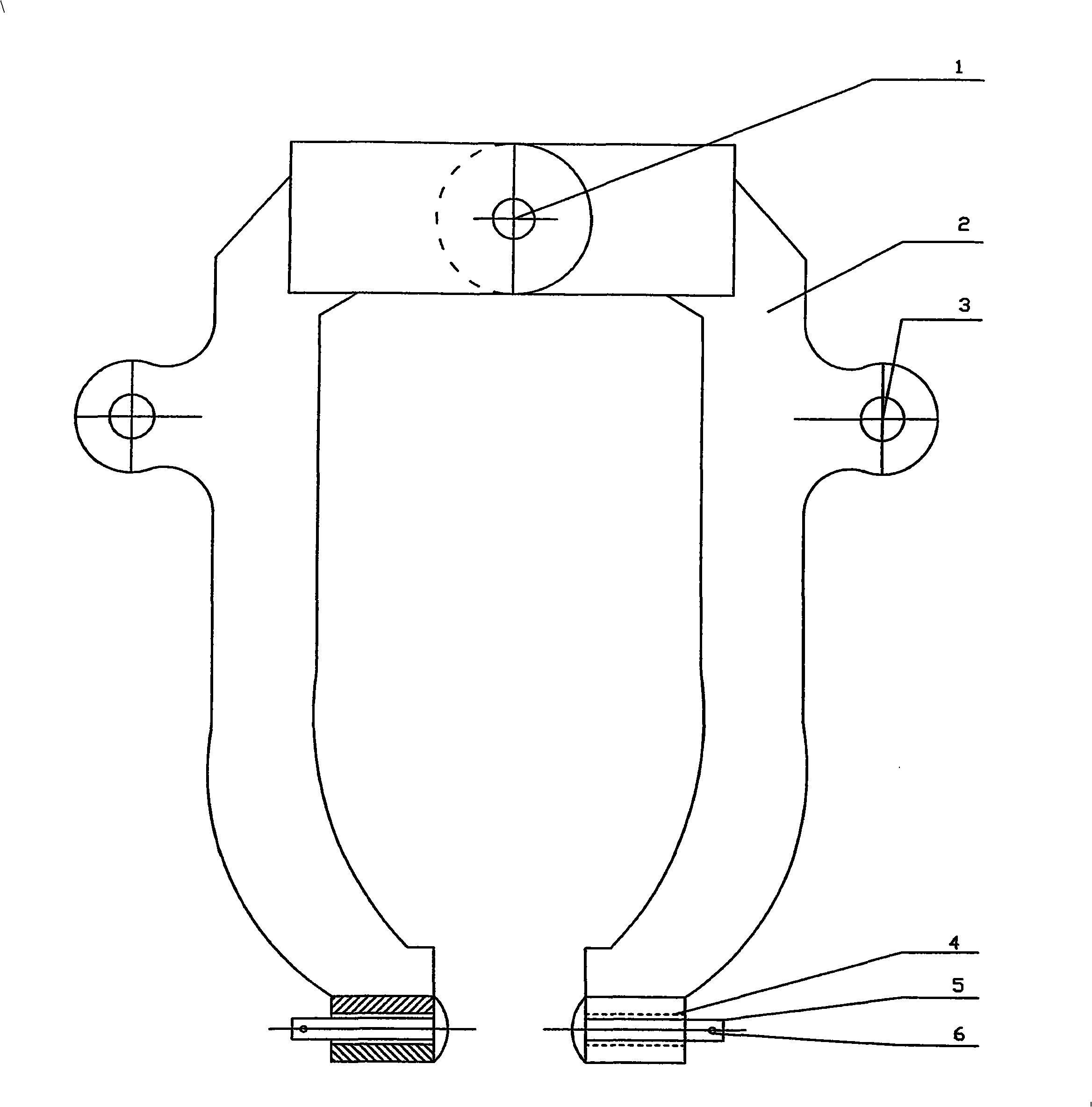

Non-flash groove, non ingot tail smithing method for large-scale wind power principal axle

InactiveCN101293269AGood clamping functionEasy to turn functionForging/hammering/pressing machinesEngine componentsElectricityIngot

The invention relates to a no-riser and no-ingot tail forging method for a large-scale wind power main shaft; before heating and forging, a riser and a ingot tail of a steel ingot are cut off by a saw, then a jaw of pliers of a manipulator is used for clamping the steel ingot without the riser and the ingot tail, and then the processes of upsetting, drawing out, rolling circle, forging steps and upsetting flange are carried out; the jaw of the pliers of the manipulator includes pliers arms (2), sleeve seats (4) and ball-head cylinders (5); the number of the pliers arms (2), the sleeve seats (4) and the ball-head cylinders (5) is two, one piece is at the left and the other piece is at the right, one end of the left pliers arm (2) is articulated with one end of the right pliers arms (2) by a gemel (1), the other ends thereof are respectively provided with the left sleeve seat (4) and the right sleeve seat (4), the left ball-head cylinder and the right ball-head cylinder (5) are respectively pass through the left sleeve seat (4) and the right sleeve seat (4); the ball-head ends of the left ball-head cylinder and the right ball-head cylinder (5) are arranged at the inner sides of the left sleeve seat (4) and the right sleeve seat (4) in a left and right antithetic manner, and the other ends thereof are provided with a fixed pin (6) by inserting along the radial direction. The method of the invention can reduce forging processes, improve production efficiency, shorten forging time and enhance forging precision and forging quality.

Owner:JIANGYIN LEGAO ENERGY EQUIP

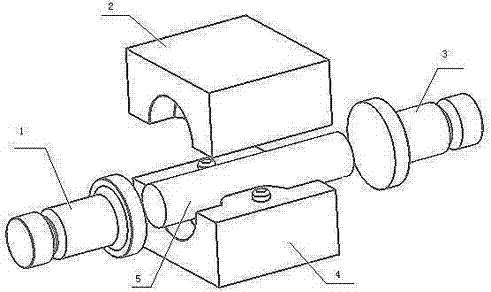

Equipment for finishing aligning, end-cutting and hole-punching at one time after rolling single end of vehicle plate spring

InactiveCN101462145AReduce process transferImprove labor productivityMetal-working feeding devicesPositioning devicesSheet steelEngineering

The invention relates to a device for finishing straightening, cropping and punching once after rolling a single end of an automobile steel plate spring. The device mainly comprises a pressing machine, a straightening mechanism, a lifting table, a length positioning mechanism, and a stander, wherein the pressing machine is positioned at the front end of the device and provided with a cropping cylinder and a center hole punching cylinder; the stander is positioned at the back end of the device and connected with the pressing machine, one end of the stander close to the pressing machine is provided with the straightening mechanism; the lifting table is arranged at a longitudinal center position of the stander, the upper end of the lifting table passes through the straightening mechanism, and the lifting table is connected with a lifting device; and the length positioning mechanism is arranged at one side of the stander, and the length positioning mechanism is provided with a clamping jaw. After a rolled reed is transferred to a straightening position, the reed is subjected to straightening motion firstly; and then the reed is fed forward by the length positioning mechanism, and subjected to cropping and center hole punching motion on the pressing machine in turn. The device reduces working procedure transfer during processing, and improves labor production efficiency.

Owner:山东中元自动化设备有限公司

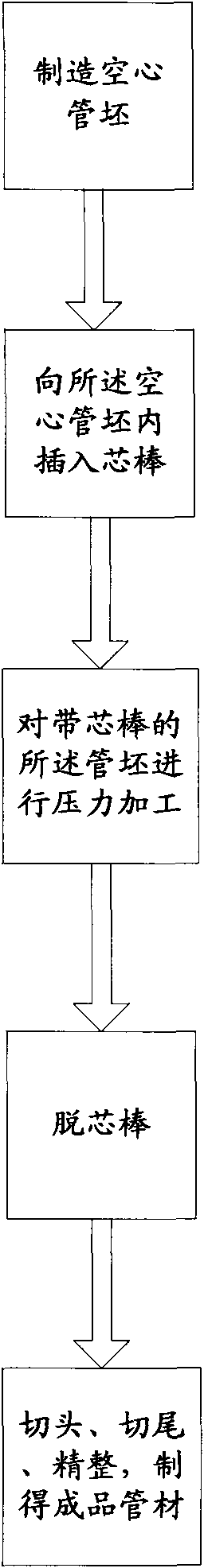

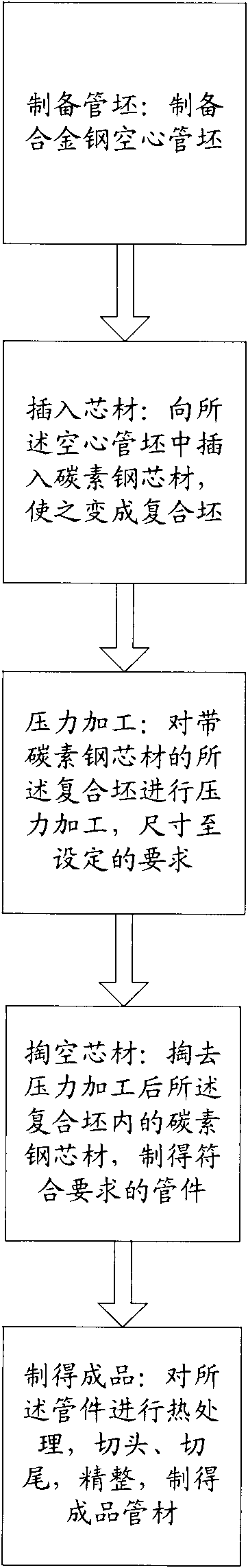

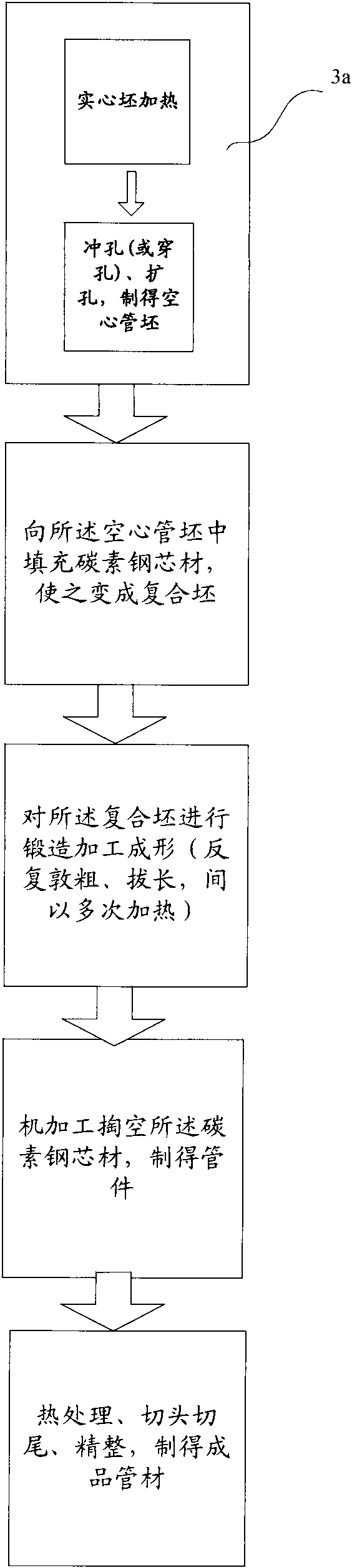

Novel method for producing high-grade alloy steel seamless steel tube

InactiveCN101633115ASimple craftMinimal TechnologyOther manufacturing equipments/toolsOperational costsQuality control

The invention relates to a novel method for producing a high-grade alloy steel seamless steel tube, which comprises the following steps: A. manufacturing an alloy steel hollow pipe blank; B. inserting a common carbon steel core material into the hollow pipe blank so that the hollow pipe blank is changed into a compound blank with the carbon steel core material; C. carrying out pressure processing on the compound blank till the size conforms to the set requirement; D. pulling out the compound blank after pressure processing, integrally pulling out the common carbon steel core material in the compound blank after the pressure processing and processing the compound blank into a pipe conforming to the requirement; and E. carrying out heat treatment, heat and tail cutting and finishing on the pipe to manufacture the finished pipe. Because the common carbon steel core material is added into a pierced pipe, the method provides a new opportunity for carrying out more reasonable and concise forging-rolling deformation by a centrifugal casting blank and other hollow blanks, can greatly save valuable alloy metal, improve the yield of finished products, reduce the material cost and improve the product quality; the processing process flow is shortened, and the tonnage requirement of equipment is shortened, thereby saving energy, reducing consumption and processing and operating cost and improving the production efficiency; the pressure processing of the pipe is converted into the pressure processing of a bar, thereby reducing the technical difficulty of process and quality control.

Owner:刘怀文 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com