Method for improving material heating speed in metallic vacuum smelting reverting pot and reverting pod thereof

A vacuum smelting and heating speed technology, applied in lighting and heating equipment, crucible furnaces, furnaces, etc., can solve the problems of long time-consuming reduction reaction heating, low production efficiency, and large energy consumption, so as to reduce heating time and improve production Efficiency, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

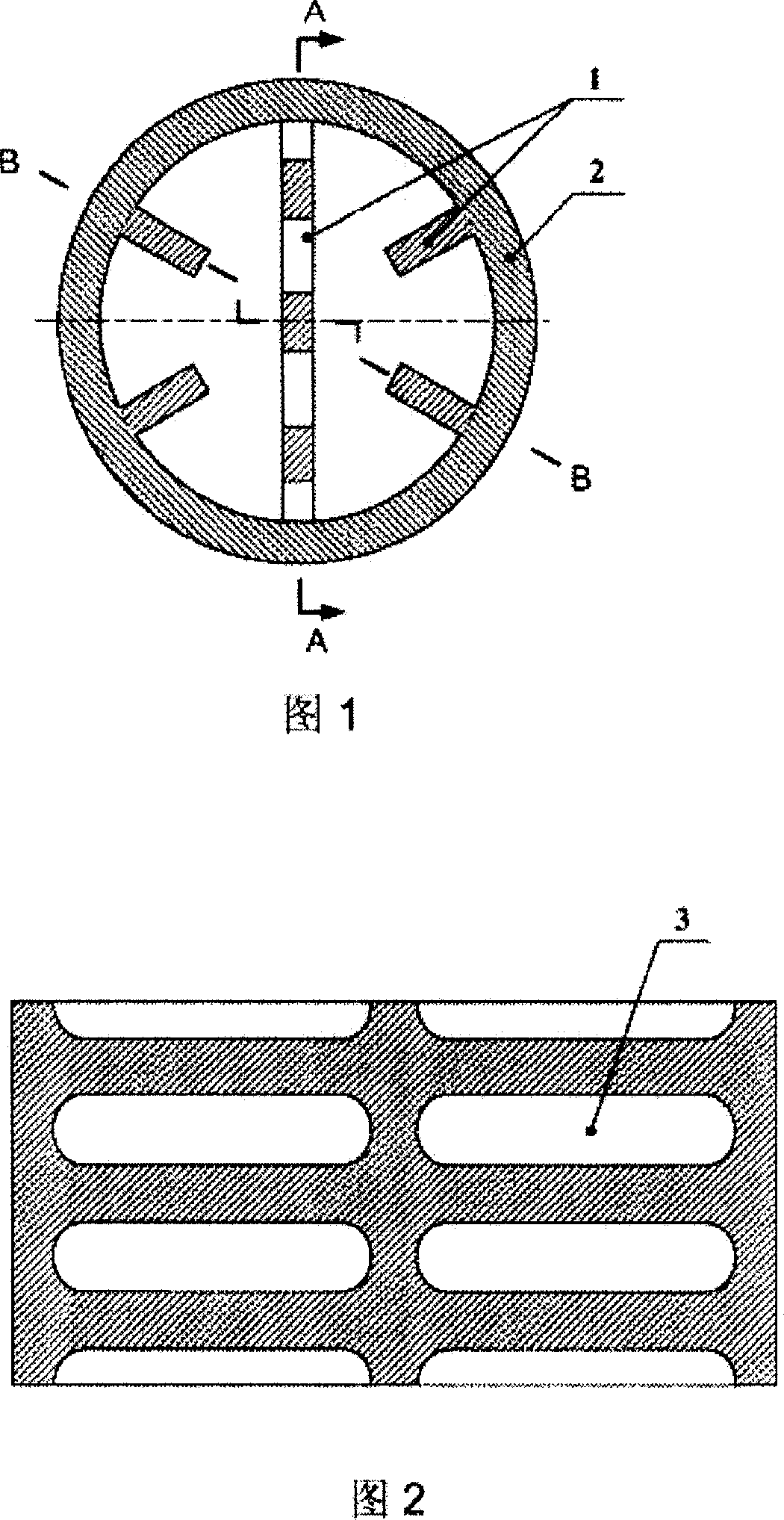

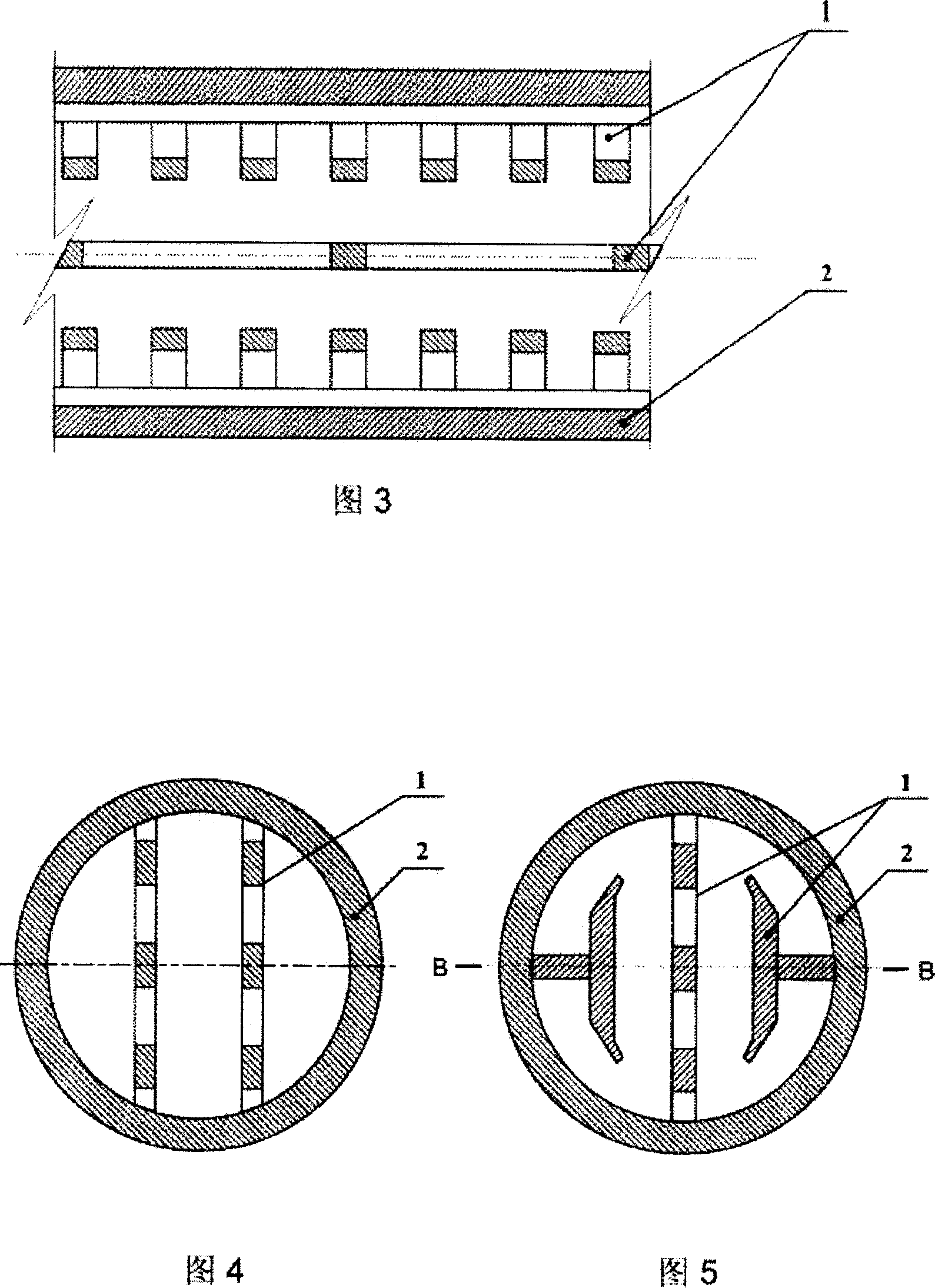

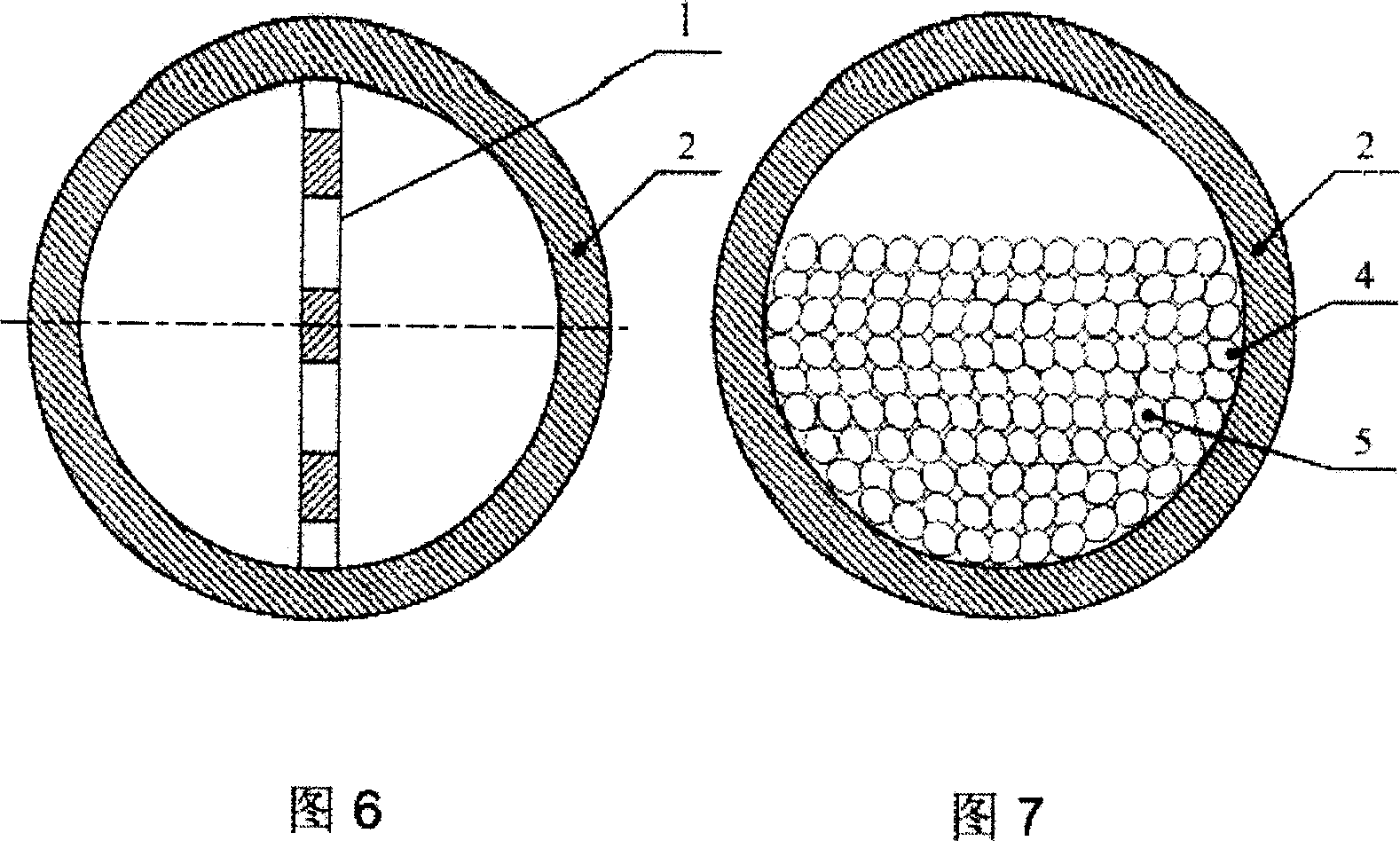

[0018] Embodiment: the existing reduction tank is a tubular hollow structure, as shown in Figure 7, the temperature of the reduction material 4 in contact with the tank body 2 in the reduction tank rises rapidly, and the reduction material 5 that cannot be in contact with the tank body 2 can only pass through The reducing materials in contact with it transfer heat and radiate heat to increase the temperature to reach the reaction temperature to realize the reduction reaction. The temperature of these reducing materials relying on indirect heat conduction rises slowly, and it takes a long time to reach the reaction temperature. The method of the present invention is to add a heat conductor 1 connected to the tank body 2 in the reduction tank, increase the heat conduction area inside the reduction tank and reduce the heat conduction distance between the heat conductor 1 and the reduced material, thus increasing the contact area between the reduced material and the heat source , a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com