Method for manufacturing tungsten-copper alloy rods and wires

A technology of tungsten-copper alloy and wire, which is applied in the field of material manufacturing, can solve the problems of waste of materials, high cost of tungsten-copper alloy rods and wires, and complicated process flow, so as to reduce energy consumption, stable product performance, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

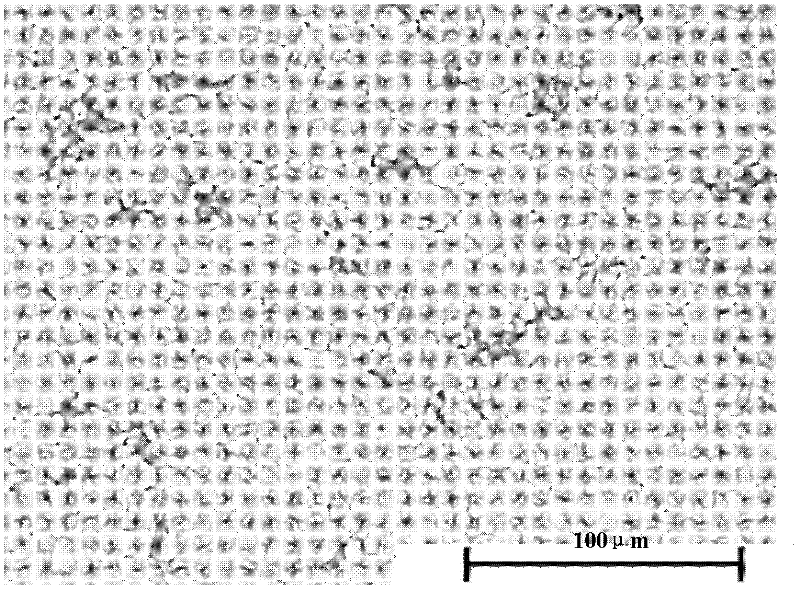

Embodiment 1

[0026] The tungsten-copper alloy with a copper content of 28% and tungsten as the corresponding balance prepared by the infiltration process has a diameter of φ14.5±0.5mm and a length of 400mm. Take it out after heating in the resistance furnace at 900℃ for 20 minutes, and feed it into a Y-shaped rolling mill unit with a nominal roll diameter of φ220mm. After 4 continuous rolling, it is processed into a tungsten-copper alloy rod wire A with a diameter of φ10±0.2mm at one time, 4 passes The continuous rolling unit moves as a whole, and its pass pattern changes as circle → triangle → hexagonal → arc triangle → circle, and the linear speed of the roll diameter is: 79.2 m / min, 97.88 m / min, 119.86 m / min, 146.88 m / min . Continue heating in a resistance furnace at a heating temperature of 800°C in a hydrogen atmosphere for 20 minutes, take it out, and send it to a single-head rotary hammer machine for single-channel rotary hammer processing. Repeat the steps of heating + rotary hamme...

Embodiment 2

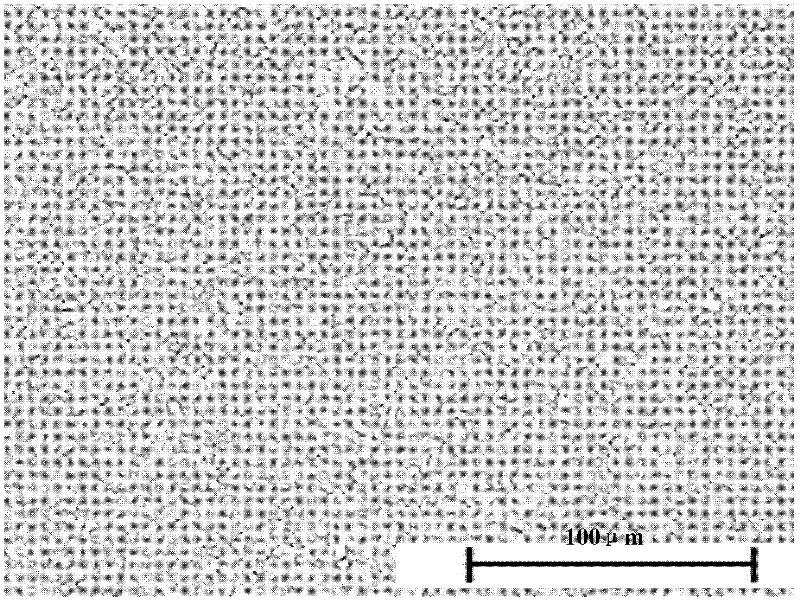

[0030] The tungsten-copper alloy with a copper content of 28% and tungsten as the corresponding balance prepared by the infiltration process has a diameter of φ14.5±0.5mm and a length of 400mm. Take it out after heating in the resistance furnace at 850℃ for 20 minutes, and feed it into a Y-shaped rolling mill unit with a nominal roll diameter of φ220mm. After 4 continuous rolling, it will be processed into tungsten-copper alloy rod wire A with a diameter of φ10±0.2mm at one time, 4 passes The continuous rolling unit moves as a whole, and its pass pattern changes as circle → triangle → hexagonal → arc triangle → circle, and the linear speed of the roll diameter is: 79.2 m / min, 97.88 m / min, 119.86 m / min, 146.88 m / min . Continue heating in a resistance furnace at a heating temperature of 750°C in a hydrogen atmosphere for 20 minutes, take it out, and send it to a single-head rotary hammer machine for single-channel rotary hammer processing. Repeat the steps of heating + rotary ha...

Embodiment 3

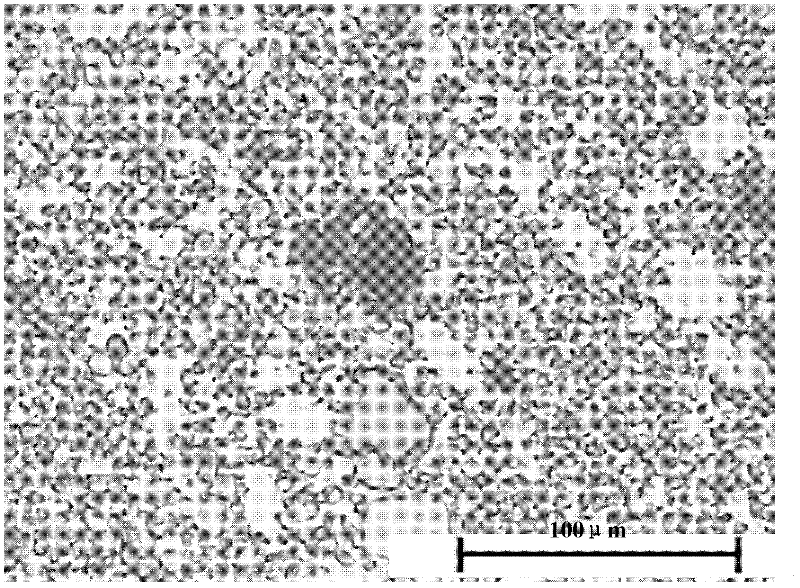

[0032]The tungsten-copper alloy with a copper content of 28% and tungsten as the corresponding balance prepared by the infiltration process has a diameter of φ14.5±0.5mm and a length of 400mm. Take it out after heating in the resistance furnace at 900℃ for 20 minutes, and feed it into a Y-shaped rolling mill unit with a nominal roll diameter of φ220mm. After 4 continuous rolling, it is processed into a tungsten-copper alloy rod wire A with a diameter of φ10±0.2mm at one time, 4 passes The continuous rolling unit moves as a whole, and its pass pattern changes as circle → triangle → hexagonal → arc triangle → circle, and the linear speed of the roll diameter is: 79.2 m / min, 97.88 m / min, 119.86 m / min, 146.88 m / min . Continue heating in a resistance furnace at a heating temperature of 800°C in a hydrogen atmosphere for 20 minutes, take it out, and send it to a single-head rotary hammer machine for single-channel rotary hammer processing. Repeat the steps of heating + rotary hammer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com