Novel method for producing high-grade alloy steel seamless steel tube

A technology of seamless steel pipes and new methods, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the difficulty of processing medium and large-diameter high-end pipes, the adverse effects of finished product quality and yield, and the high requirements for machining equipment, etc. problems, to achieve the effect of reducing processing and operating costs, reducing forming equipment requirements, and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

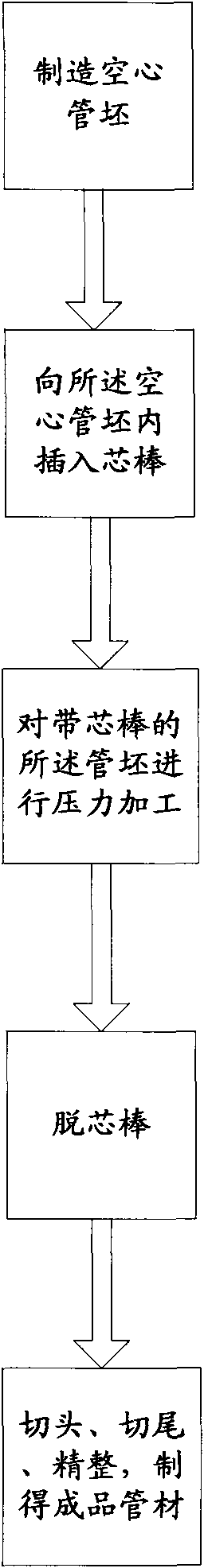

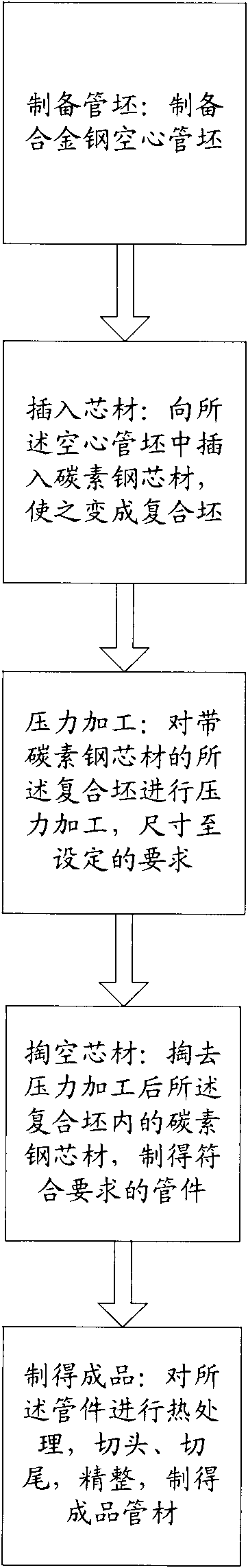

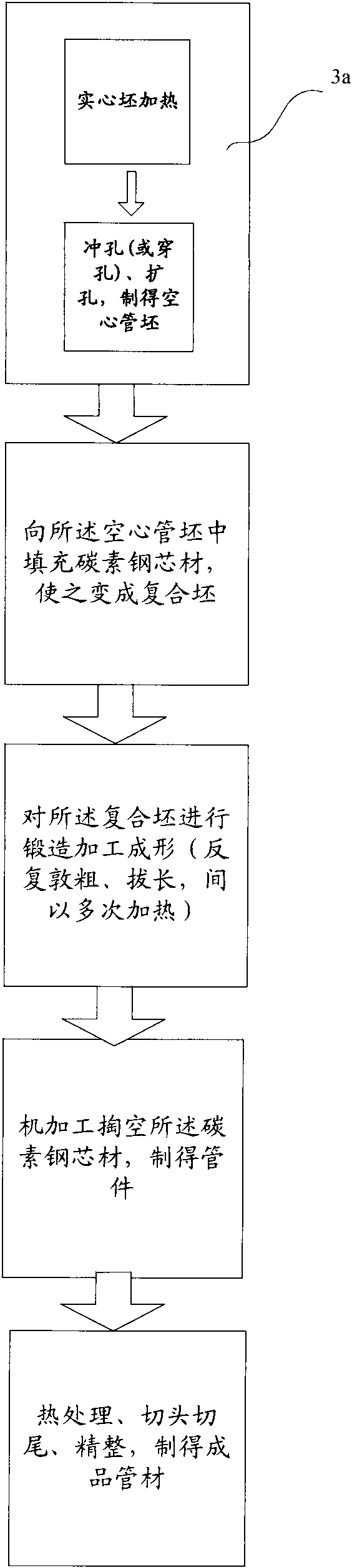

[0032] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0033] Figure 3a A block diagram of the process steps of an embodiment of the present invention is shown, for example, to manufacture Cr-Ni ferrite-austenite ultra-low carbon duplex stainless steel seamless steel pipes with a diameter of 489×55×6000 mm, and the specific steps include:

[0034] A. Preparation of hollow tube billet: This step is represented by 3a. Specifically, it is to heat a continuous casting steel ingot with a size of Φ720×1600mm or a round die-cast ingot after the riser is removed, and then perform punching after upsetting, The hollow tube blank with the size of Φ1300×175×1000mm is obtained by reaming.

[0035] B. Step of inserting the core material: Insert a common carbon steel core material with a size of Φ950×1800mm (the core material has a jaw with a length of 800mm), and make the inner common carbon steel core ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com