Method for treating high boron content terrestrial heat tail water

A treatment method and technology for geothermal tail water, applied in the field of high boron-containing geothermal tail water treatment, can solve the problems of insufficient recovery rate of waste water, easy damage of boron removal equipment, and discharge up to standard, so as to improve the quality of tail water treatment and production. The effect of aging, reducing investment cost, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

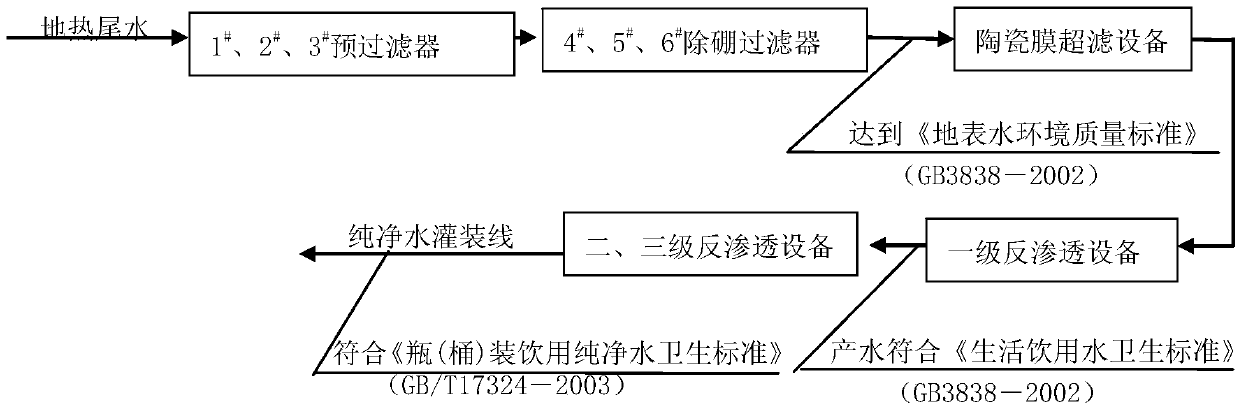

[0034] A certain geothermal tail water comes from a geothermal well with a depth of more than 3000 meters. Its water quality components are complex: salinity is 4000-6000 mg / L, tail water temperature is 55-60 °C, boron content is 20-130 mg / L, and total hardness is 200-260 mg / L. L. Soluble solid 4000~5000mg / L, soluble silicon dioxide 40~50mg / L, sodium silicate 30~60mg / L, fluorine 2~2.5mg / L.

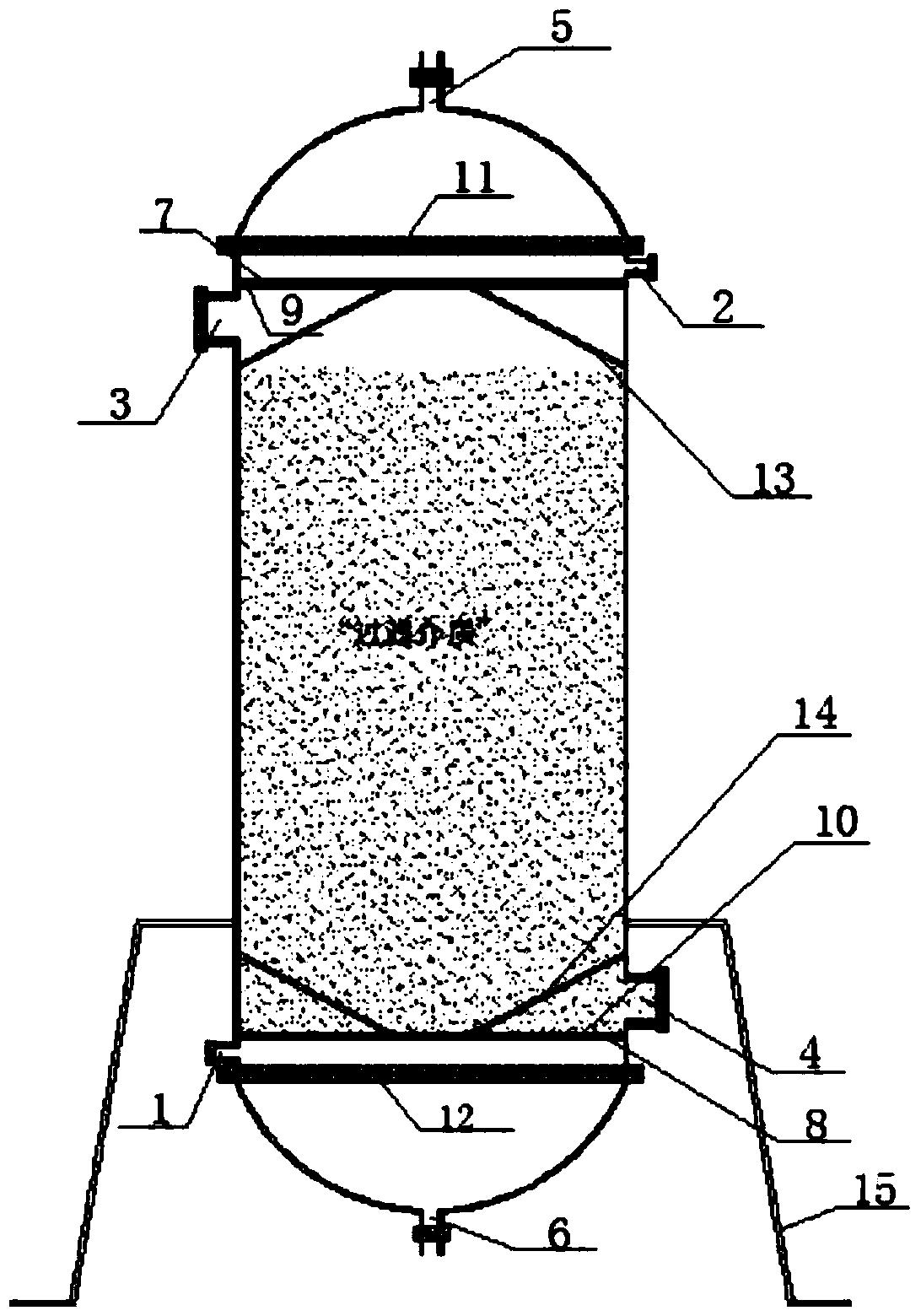

[0035] The geothermal tail water first passes through the preprocessor (1#, 2#, 3#), and the filter medium filled by the preprocessor is ZD-01 from Xuzhou Zhengdi Energy Auxiliary Co., Ltd. (ZD-01 is made of diatomaceous earth, activated carbon and other materials through high temperature, high pressure, and catalyzed a series of reactions to generate inorganic filter materials). The operating conditions of the preprocessor are: the amount of water inflow is 20-25m 3 / h, the amount of water produced is 20~25m 3 / h, the product water quality is clear and transparent visually, the working ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com