Method for preparing light ceramsite by adopting DSD acid industrial sludge

A light ceramsite and acid sludge technology, applied in the environmental field, can solve the problems of small particle density, large specific surface area, and low water absorption rate, and achieve the effect of large specific surface area, simple process, and low water absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

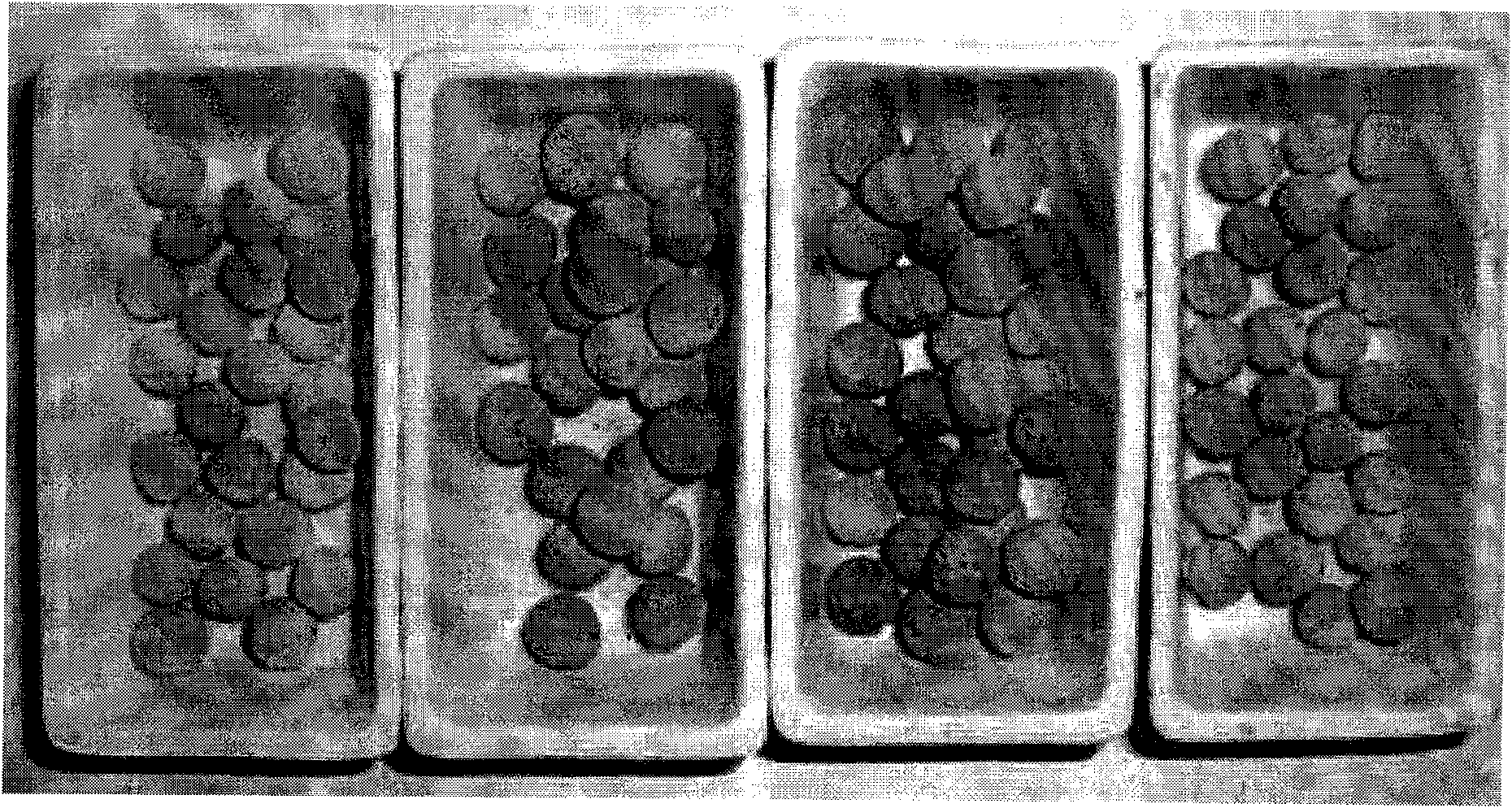

Image

Examples

Embodiment 1

[0013] (1) The DSD acid sludge is dried, the clay is dried, and the two raw materials are crushed and screened with a 100-mesh sieve (particle diameter ≤ 0.15mm);

[0014] (2) The flux and expansion agent are sieved with a 300-mesh sieve (particle diameter ≤ 0.05mm);

[0015] (3) Take binder, flux, expansion agent and dry DSD acid sludge with the ratio of weight ratio 5: 0.5: 0.5: 4, granulate with water as binder in the drum granulator, Make raw meal balls with a diameter of about 5mm;

[0016] (4) Place the raw meal balls at room temperature and dry for 10 hours;

[0017] (5) Put the raw material balls into a box-type resistance furnace at 350°C, preheat for 15 minutes, quickly transfer to a tube-type resistance furnace at 1080°C and burn for 10 minutes, and cool the ceramsite at room temperature to obtain DSD acid sludge lightweight ceramsite.

[0018] The appearance of the prepared lightweight ceramsite is yellow spherical solid with rough surface, and the bulk density ...

Embodiment 2

[0020] (1) The DSD acid sludge is dried, and after the clay is dried, the two raw materials are crushed and screened with a 100-mesh sieve (particle diameter ≤ 0.15mm)

[0021] (2) The flux and expansion agent are sieved with a 300-mesh sieve (particle diameter ≤ 0.05mm);

[0022] (3) Take binder, flux, expansion agent and dry DSD acid sludge with the ratio of weight ratio 5: 0.5: 0.5: 5, carry out granulation with water as binder in the drum granulator, Make raw meal balls with a diameter of about 5mm;

[0023] (4) Dry the raw meal balls at room temperature for 13 hours;

[0024] (5) Put the raw material balls into a box-type resistance furnace at 365°C, preheat for 16 minutes, quickly transfer to a tube-type resistance furnace at 1100°C and burn for 12 minutes, and cool the ceramsite at room temperature to obtain DSD acid sludge lightweight ceramsite.

[0025] The appearance of the prepared lightweight ceramsite is yellow spherical solid with rough surface, and the bulk d...

Embodiment 3

[0027] (1) The DSD acid sludge is dried, and after the clay is dried, the two raw materials are crushed and screened with a 100-mesh sieve (particle diameter ≤ 0.15mm)

[0028] (2) The flux and expansion agent are sieved with a 300-mesh sieve (particle diameter ≤ 0.05mm);

[0029] (3) Take binder, flux, expansion agent and dry DSD acid sludge with the ratio of weight ratio 4: 0.5: 0.5: 5, carry out granulation with water as binder in the drum granulator, Make raw meal balls with a diameter of about 5mm;

[0030] (4) Place the raw meal balls at room temperature and dry for 15 hours;

[0031] (5) Put the raw material balls into a box-type resistance furnace at 385°C, preheat for 18 minutes, quickly transfer to a tube-type resistance furnace at 1110°C for 14 minutes, and place the ceramsite at room temperature to cool, and you can get DSD acid sludge lightweight ceramsite.

[0032] The appearance of the prepared lightweight ceramsite is yellow spherical solid with rough surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com