Method for treating residual liquid after mother liquor distillation methanol recovery during production of sodium sulphoxylate by sodium formate process

A technology for sodium hydrosulfite and methanol recovery, applied in thiosulfate/dithionite/polythionite, combustion method, separation method, etc., and can solve problems such as large quantity, high COD concentration, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

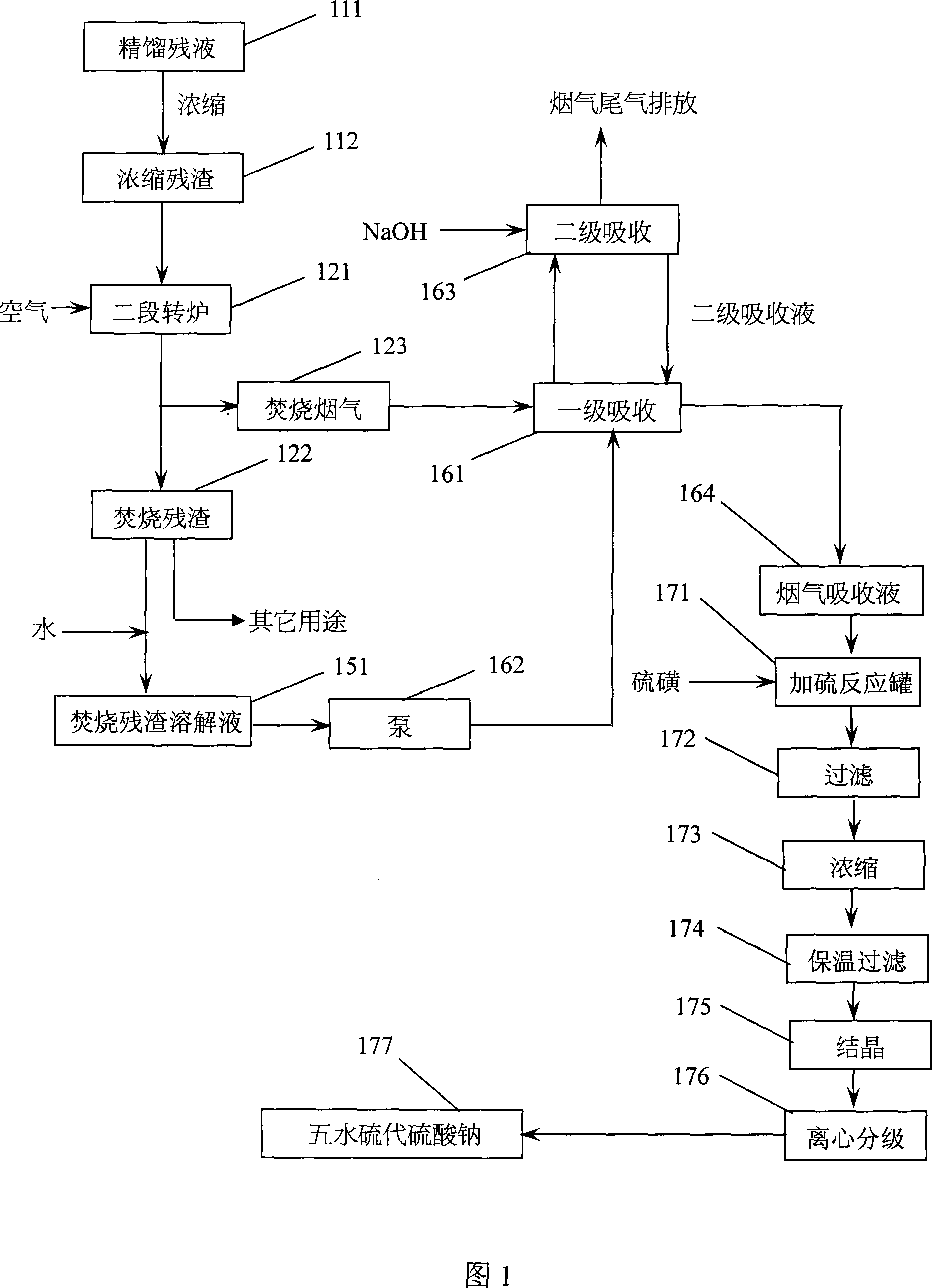

[0027] Referring to Fig. 1, the first embodiment of the present invention is realized according to the following steps:

[0028] Step 1, material concentration: the rectification raffinate 111 is obtained after the rectification of the mother liquor produced in the process of producing sodium dithionite by the sodium formate method to reclaim methanol, and the main component content of the rectification raffinate 111 is sodium formate 110g / l, sodium sulfite 8.9g / l l. Sodium thiosulfate 4.5g / l, methanol 6.5g / l, organic sulfide and other substances 61g / l, chemical oxygen demand (COD) 238000mg / l, take 10m 3 The above-mentioned rectification raffinate 111 is concentrated until a large amount of crystals appear, and the concentrated residue 112 in the form of a slurry is obtained after being released and cooled, with a weight of 2020 kg;

[0029] Step 2, incineration feeding stage: use the second-stage converter 121 to incinerate, use a heavy oil burner to first raise the temperatu...

no. 2 example

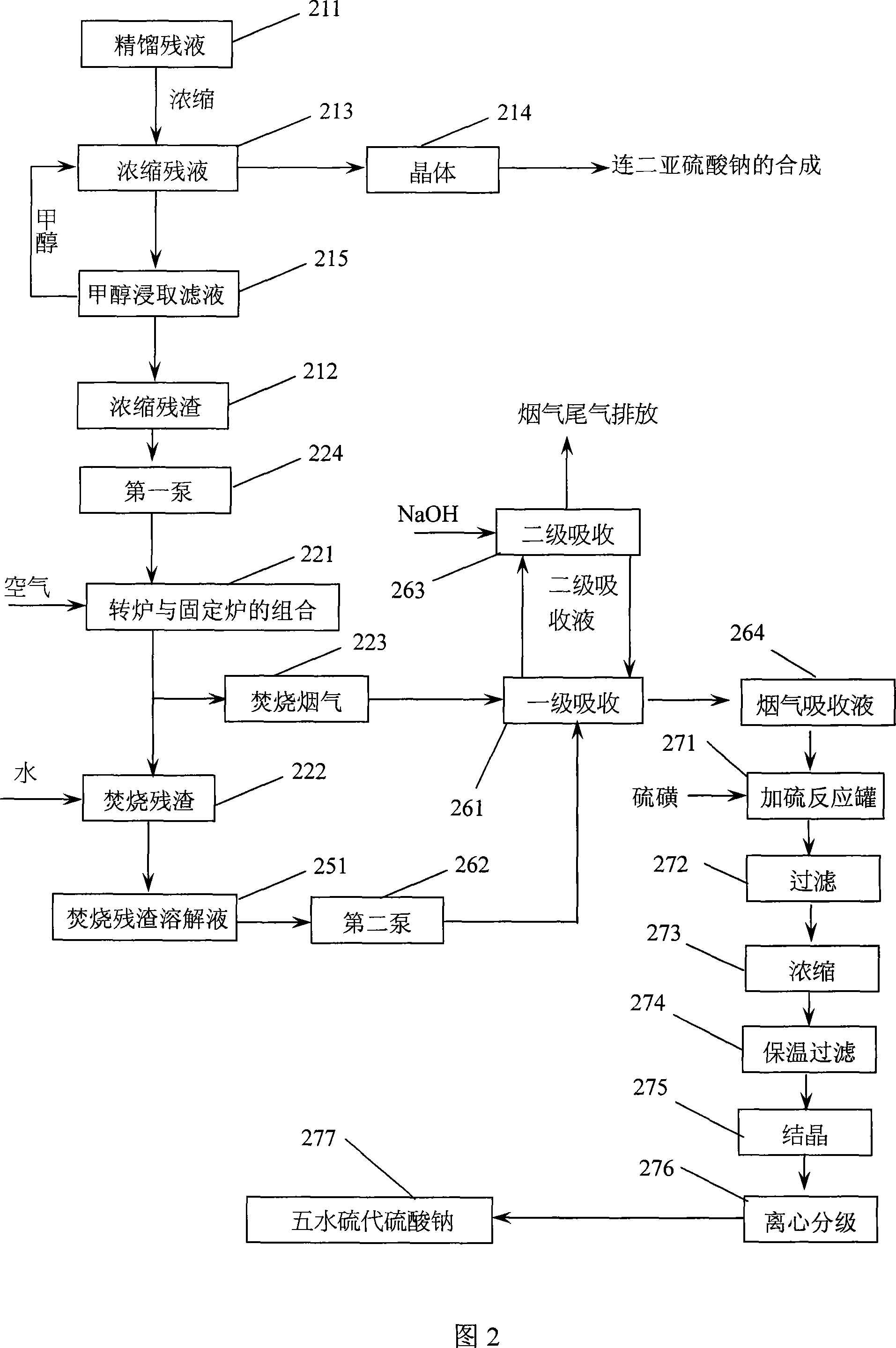

[0036] Referring to Fig. 2, the second embodiment of the present invention is realized according to the following steps:

[0037] Step 1, material concentration: the rectification raffinate 211 is obtained after the rectification of the mother liquor produced in the process of producing sodium dithionite by the sodium formate method to reclaim methanol, and the main component content of the rectification raffinate 211 is sodium formate 120g / l, sodium sulfite 7.8g / l l. Sodium thiosulfate 5.6g / l, methanol 5.8g / l, organic sulfide and other substances 63g / l, chemical oxygen demand (COD) 252000mg / l, take 10m 3 The above-mentioned rectification raffinate 211 is concentrated until a large amount of crystals appear to become a concentrated raffinate 213, and methanol is added to the concentrated raffinate 213 to filter out the crystal 214 with sodium formate and sodium sulfite as the main components to obtain a methanol leaching filtrate 215. The weight of the crystal 214 is 1120kg. Its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com