Method for continuous production of liquid calcium chloride by using fluorine-containing by-product waste hydrochloric acid

A technology of waste hydrochloric acid and calcium chloride, applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., can solve the problems such as the technical enlightenment of producing liquid calcium chloride from waste hydrochloric acid containing fluorine, etc. Achieve the effect of meeting the requirements of large-scale processing, convenient operation, and not harsh process elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

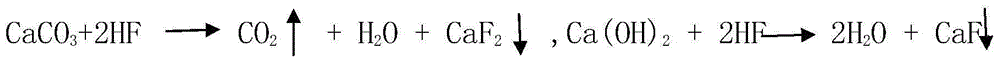

Method used

Image

Examples

Embodiment 1

[0019] The fluorine-containing by-product waste hydrochloric acid with a content of 800ppm in the process of producing fluorine chemical products such as difluorochloromethane (R22) produced by a fluorine chemical enterprise and a fluorine-containing by-product waste hydrochloric acid with a HCl mass % of hydrochloric acid of a concentration of 30% is used as a raw material. The reaction vessel (reaction kettle) with a stirring device reacts continuously with limestone and limestone with a particle size of 15m to 125mm. The specific working conditions are: the above-mentioned limestone is excessive at the beginning, and then the by-product hydrochloric acid is added continuously In the operating mode of the working condition, the pH value of the reaction completion liquid produced in the continuous reaction process is controlled to be pH1.5 and the reaction liquid is introduced (overflowed) into the liquid storage tank (neutralization stirring tank) in an overflow mode, and is c...

Embodiment 2

[0022] The fluorine-containing by-product waste hydrochloric acid with a content of 2000ppm of fluorine ion produced in the process of producing fluorine chemical products such as tetrafluoromonomer by a fluorine chemical enterprise and a HCl mass% of hydrochloric acid with a concentration of 12% is used as a raw material in a stirring device for reaction React continuously with limestone that tends to be powdery and has a particle size of 40μm to 2mm in the container (reactor). In the operating mode of the continuous reaction process, the pH value of the reaction completion liquid produced in the continuous reaction process is controlled to be pH3.5 and the reaction liquid is introduced into (neutralizing the stirring tank) liquid storage tank in an overflow mode, and is continuously injected into the liquid storage tank at the same time. Adding mass % specific concentration is 25% milk of lime to adjust the pH value of the reaction solution in the liquid storage tank to pH=8,...

Embodiment 3

[0024] The fluorine-containing by-product waste hydrochloric acid with a content of 20000ppm in the process of producing fluorine chemical products such as R32 (difluoromethane) produced by fluorine chemical enterprises and a HCl mass % of hydrochloric acid with a concentration of 26% is used as a raw material in a stirring tank. In the reaction vessel (reactor) of the device, there is a continuous reaction with limestone that tends to be small in shape and has a particle size of 0.5-2mm. In the working condition of adding limestone, the pH value of the reaction completion liquid produced in the continuous reaction process is controlled to be pH2.5 and the reaction liquid is introduced into (neutralizing the stirring tank) liquid storage tank in an overflow mode, and is continuously supplied to the storage tank in a continuous manner. Add lime milk with a mass % specific concentration of 55% in the liquid tank to adjust the pH value of the reaction liquid in the liquid storage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com