High-efficiency and high-recovery-rate method for recovering industrial tin powder

A high recovery rate, industrial technology, applied in the chemical industry, can solve the problems of difficult remelting and recycling, fine particle size of tin powder, large amount of returned materials, etc., to achieve the effect of reducing energy consumption, rapid smelting, and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

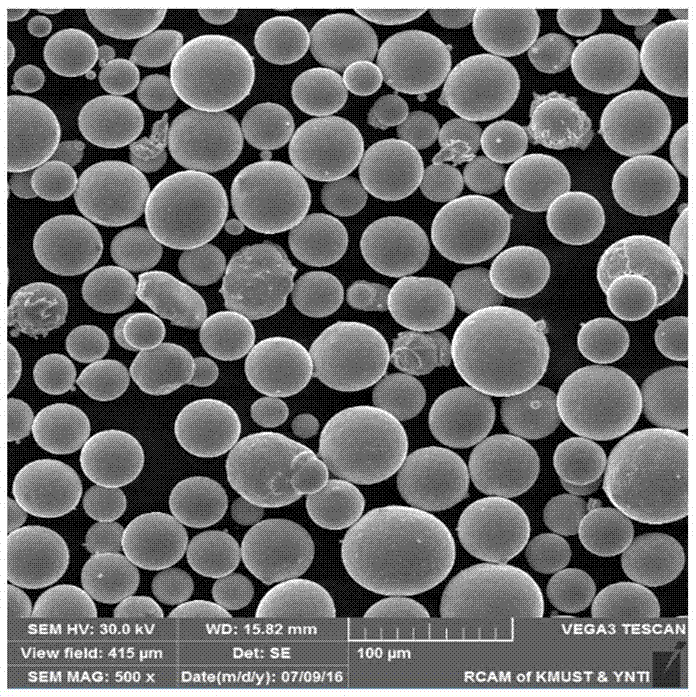

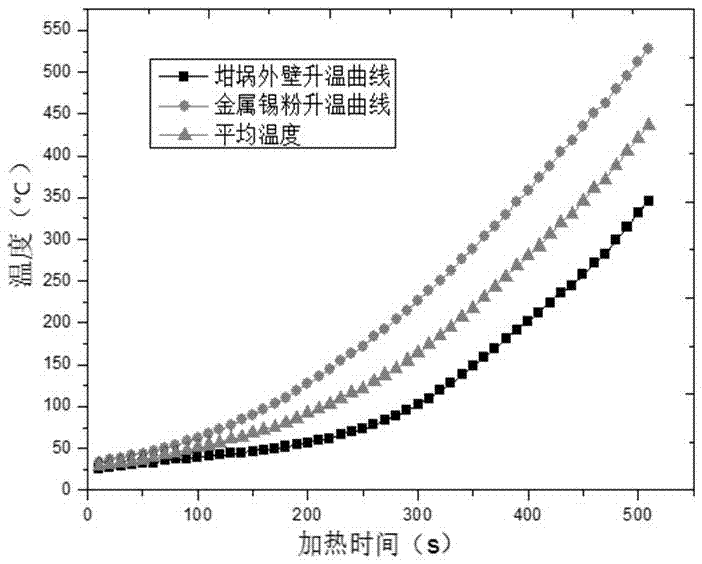

[0029] Use microwave melting to recover 18Kg of lead-free solder alloy powder, first weigh 18Kg of lead-free tin alloy powder to be recovered, the particle size of the tin powder is mainly 38~150µm, the mass percentage of tin is 96%, and the mass percentages of silver and copper are respectively 3% and 1%, pour metal tin powder into a silicon carbide crucible, place the crucible in a microwave-tight reaction chamber, evacuate until the vacuum degree is less than 1000Pa, and then fill it with nitrogen protection, the air pressure is 1.35×10 5 Pa, and then fed into the microwave, the microwave frequency is 2450±50MHz, and the total microwave power is 16 kW. After smelting for 8 minutes, the tin powder reaches above 500°C (as attached figure 2 shown), after 2 minutes of heat preservation, turn off the microwave source, stop feeding the protective gas, take out the crucible and cast an ingot (as shown in the attached image 3 shown). The average heating rate is 62.12℃ / min, the...

Embodiment 2

[0031] Use microwave melting to recover 20Kg of lead-free solder alloy powder. The particle size of tin powder is mainly 38~100µm, the mass percentage of tin is 96%, and the mass percentage of silver and copper is 3% and 1% respectively. Pour the metal tin powder into silicon carbide crucible, and place the crucible in a microwave-tight reaction chamber, vacuumize until the vacuum degree is less than 1000Pa, then fill it with nitrogen protection, the air pressure is 1.28×10 5 Pa, and then fed into 20kW microwave, the microwave frequency is 2450±50MHz. After smelting for 10 minutes, the tin powder reached 550°C. After 3 minutes of heat preservation, the microwave source was turned off, and the crucible was taken out for ingot casting. The average heating rate is 55℃ / min, the unit energy consumption of microwave melting tin powder is 0.17 (kW h / Kg), the tin recovery rate is 98.14%, and the slag rate is 1.55%.

Embodiment 3

[0033] Using microwave melting to recover 1.5Kg of lead-containing solder alloy powder, first weigh 1.5Kg of lead-containing tin alloy powder to be recovered. The particle size of the tin powder is mainly 38~75µm, the mass percentage of tin is 63%, and the lead content is 37%. Pour metal tin powder into a silicon carbide crucible, place the crucible in a microwave-tight reaction chamber, evacuate until the vacuum degree is less than 1000Pa, and then fill it with nitrogen protection, the air pressure is 1.33×10 5 Pa, and then fed into the microwave, the microwave frequency is 2450±50MHz, and the microwave power is 2.2 kW. The temperature rose to 234°C in 6 minutes of smelting, and 524°C in 11 minutes (see attached Figure 4 shown), turn off the microwave source after 4 minutes of heat preservation, take out the crucible and carry out ingot casting. The average heating rate is 47.63°C / min, the unit energy consumption is 0.26 (kW·h / Kg), the tin recovery rate is 97.79%, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com