Multilevel deflector-type bubble tower reactor and production process

The technology of a bubbling column and a reactor is applied in the field of improvement of reaction equipment and production process in chemical unit operation, and can solve the problems of not very large effective mass transfer area, high one-time investment cost, low overall efficiency of the reactor, etc. Achieve the effect of wide applicability, small footprint and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

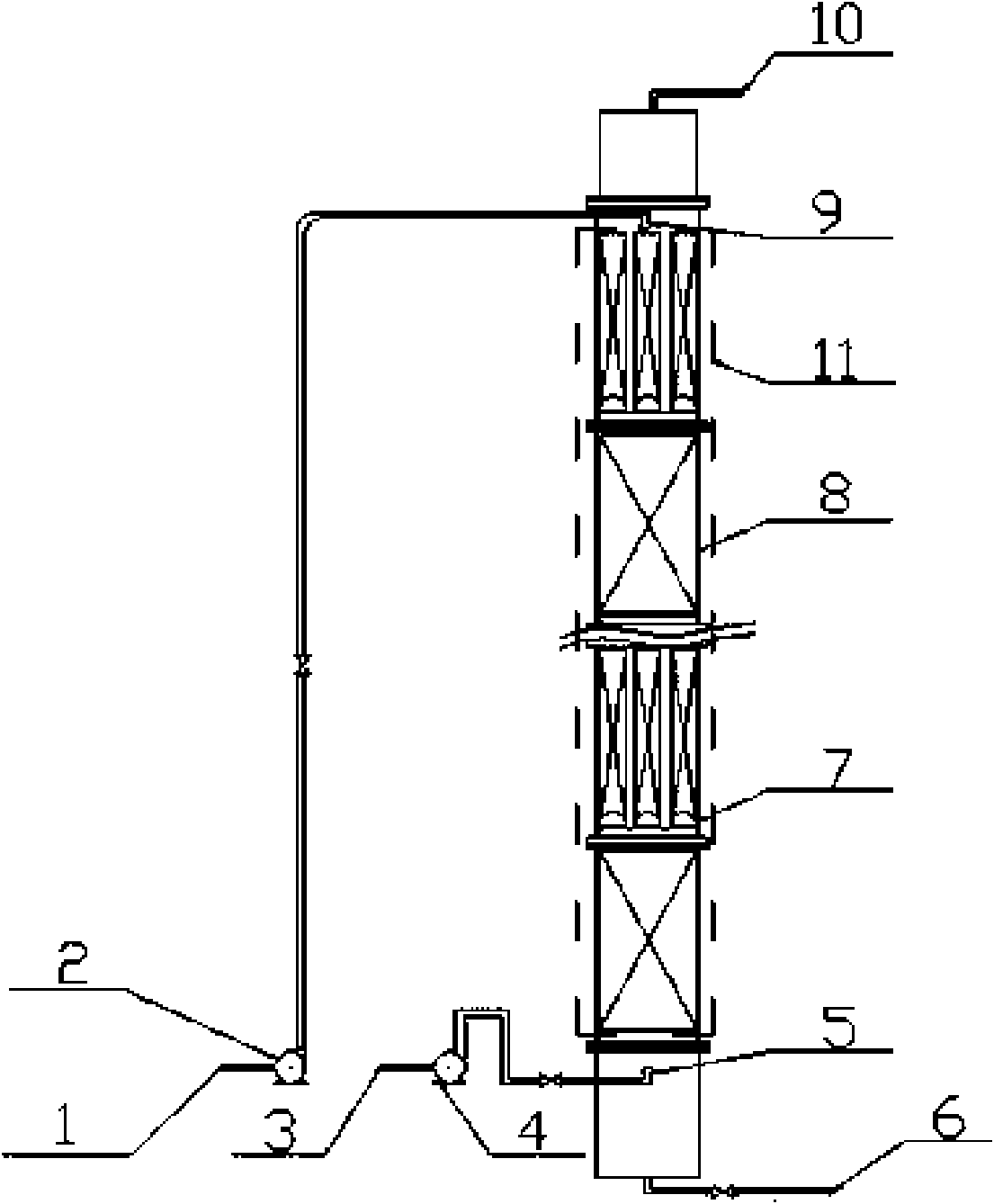

[0015] Embodiment 1: Chlorine and toluene react to generate trichlorotoluene, and its reaction formula is toluene+chlorine→trichlorotoluene. Such as figure 1 As shown, using the multi-stage diversion bubble column reactor production process of the present invention, firstly, under normal pressure, the raw material toluene and the catalyst ammonium chloride are uniformly mixed, and heated to 140 ° C, from the raw material liquid inlet 1 through the raw material pump 2. Enter the liquid phase distributor 9, and evenly distribute and flow into the reaction section 11. According to the requirements of the reaction yield, four reaction sections are adopted, and each reaction section contains three reaction columns 8 with built-in structured packing; 3. After the compressor 4 and the microbubble generator 5, it is injected into the tower, and reacts with the toluene flowing from top to bottom under the action of the deflector 7 and the catalyst to generate trichlorotoluene, product ...

Embodiment 2

[0016] Embodiment 2: the synthesis of p-nitroacetophenone, its reaction formula is p-nitroethylbenzene+air→p-nitroacetophenone. Such as figure 1 As shown, first at 5 atm, mix the raw material nitroethylbenzene and the catalyst acetate evenly, and heat it to 140°C, inject the liquid phase distributor 9 from the raw material liquid inlet 1 through the raw material pump 2, and evenly distribute it into the Reaction section 11, according to the requirements of reaction yield, adopts three-stage reaction section, and each stage reaction section contains two reaction columns 8 with built-in structured packing; , into the tower, and react with the nitroethylbenzene flowing from top to bottom under the action of the guide plate 7 and the catalyst to generate p-nitroacetophenone, and the product and unreacted nitroethylbenzene are discharged from the product outlet 6 is discharged, and the unreacted air is discharged from the gas phase outlet 10. The results show that the yield of ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com