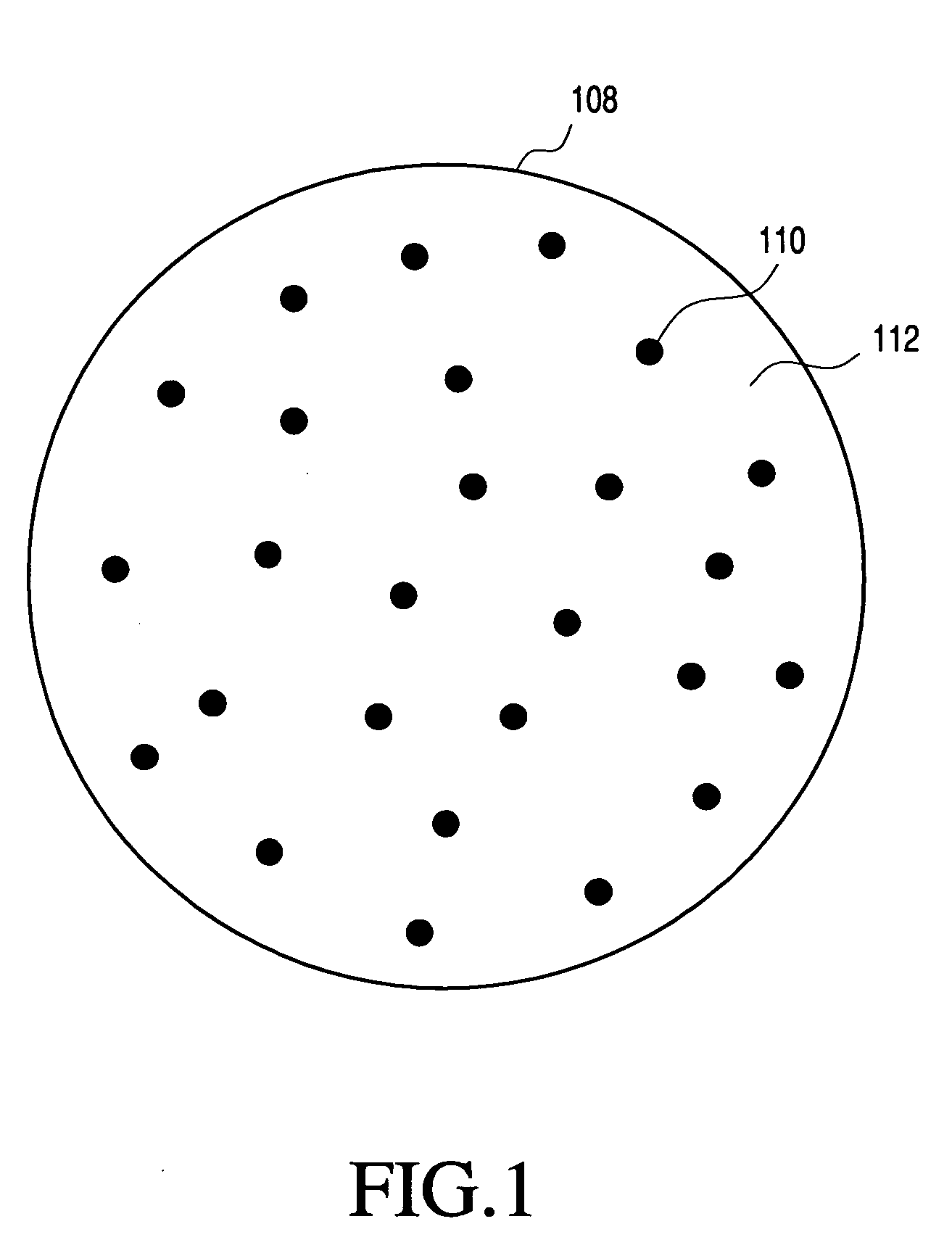

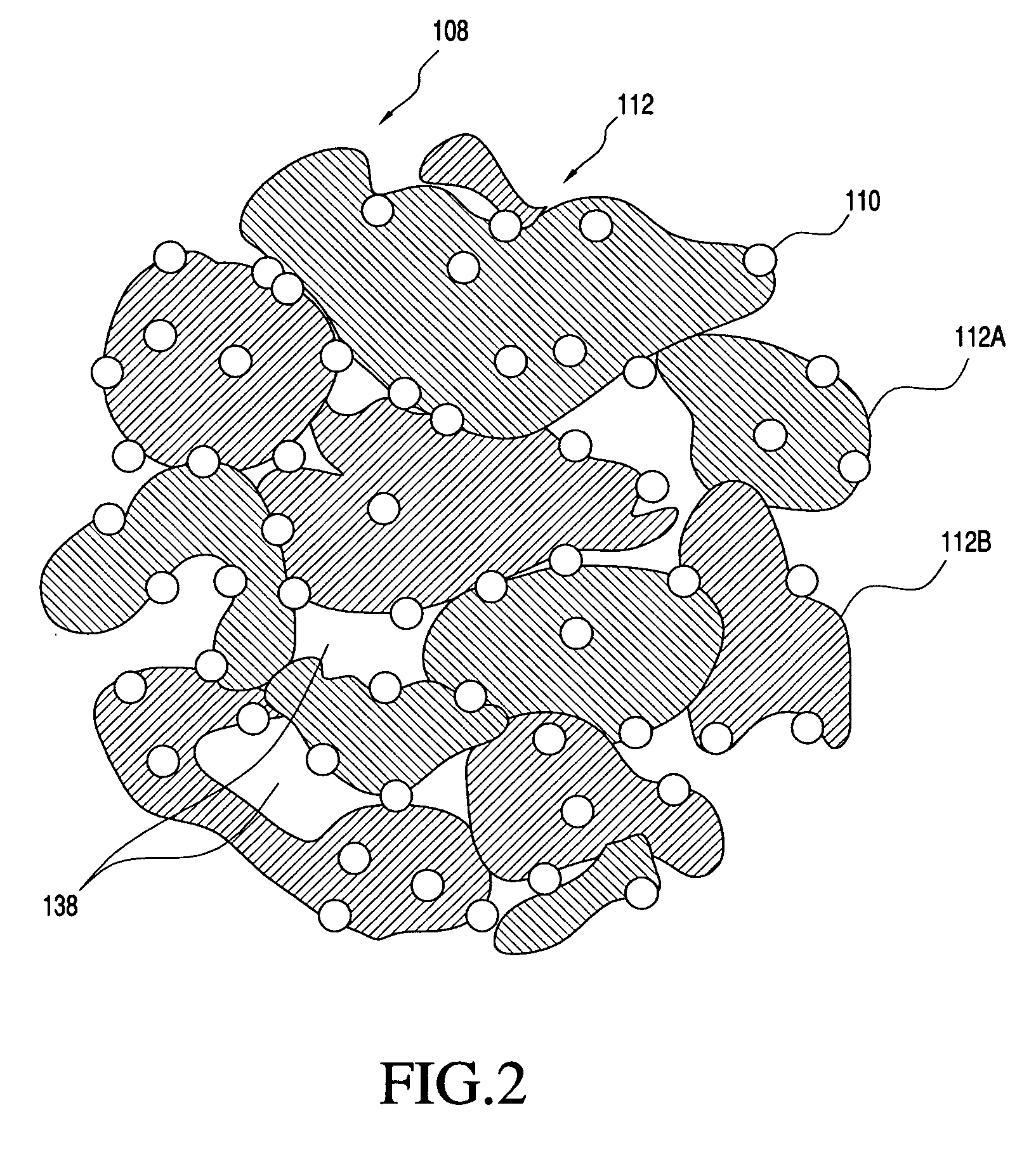

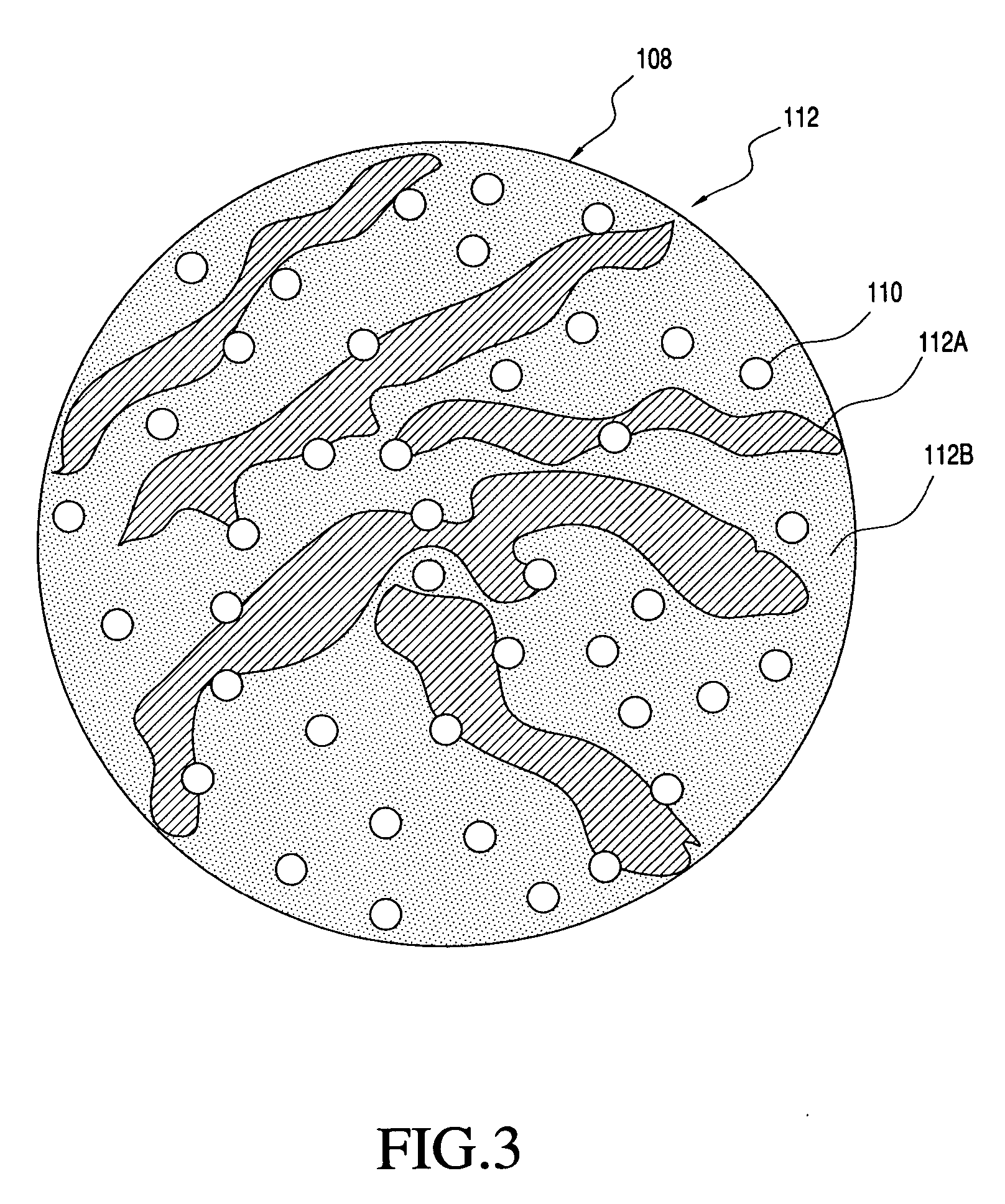

Multi-component particles comprising inorganic nanoparticles distributed in an organic matrix and processes for making and using same

a technology of organic matrix and multi-component particles, which is applied in the field of inorganic nanoparticles, can solve the problems of high limit in the choice of surfactants, polymers and/or additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

process examples

A. Process Examples

Example 1

Silver Nanoparticles and Polymer Matrix from AgNO3

[0251] A precursor medium containing silver nitrate, AgNO3 and PVP, dissolved in deionized water is prepared. The precursor medium contains:

AgNO37.5 gPVP0.5 gDeionized H2O 92 g

This precursor medium is designed for 8 wt % loading of solids, and to yield particles consisting of 46 vol % silver metal in a PVP matrix. The precursor medium is processed on the lab scale system described above, at a temperature of 400° C. and a carrier gas flow rate of 15 liter per minute (lpm). XRD analysis of the resulting powder shows strong peaks of silver with the presence of small amount of silver nitrate.

example 2

Silver Nanoparticles and Polymer Matrix from AgNO3 With Use of Ethanol

[0252] A precursor medium containing silver nitrate, AgNO3 and PVP, dissolved in deionized water is prepared. The precursor medium contains:

AgNO315.0 gPVP 0.5 gDeionized H2O74.5 gEthanol10.0 g

This precursor medium is designed for 15.5 wt % loading of solids, and to yield particles consisting of 64 vol % silver metal in a PVP matrix. The precursor medium is processed on the lab scale system described above, at a temperature of 400° C. and a carrier gas flow rate of 15 liter per minute (lpm). XRD analysis of the resulting powder shows strong peaks of silver with the presence of silver nitrate.

example 3

Silver Nanoparticles and Polymer Matrix from AgNO3 With Use of Ethylene Glycol

[0253] A precursor medium containing silver nitrate, AgNO3 and PVP, dissolved in deionized water is prepared. The precursor medium contains:

AgNO315.0 gPVP 0.5 gDeionized H2O74.5 gEthylene glycol15.0 g

This precursor medium is designed for 15.5 wt % loading of solids, and to yield particles consisting of 64 vol % silver metal in a PVP matrix. The precursor medium is processed on the lab scale system described above, at a temperature of 250° C. and a carrier gas flow rate of 15 liter per minute (lpm). Under these conditions, the vapor quickly condensed onto the filter paper, as a result, the pressure built up quickly in less than 5 min. XRD analysis of the resulting powder shows strong peaks of silver with the presence of silver nitrate.

[0254] The precursor medium is also processed on the lab scale system at 400° C. and a carrier gas flow rate of 15 lpm. XRD pattern for this powder shows mainly silver pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com