Patents

Literature

183results about "Aerosol preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

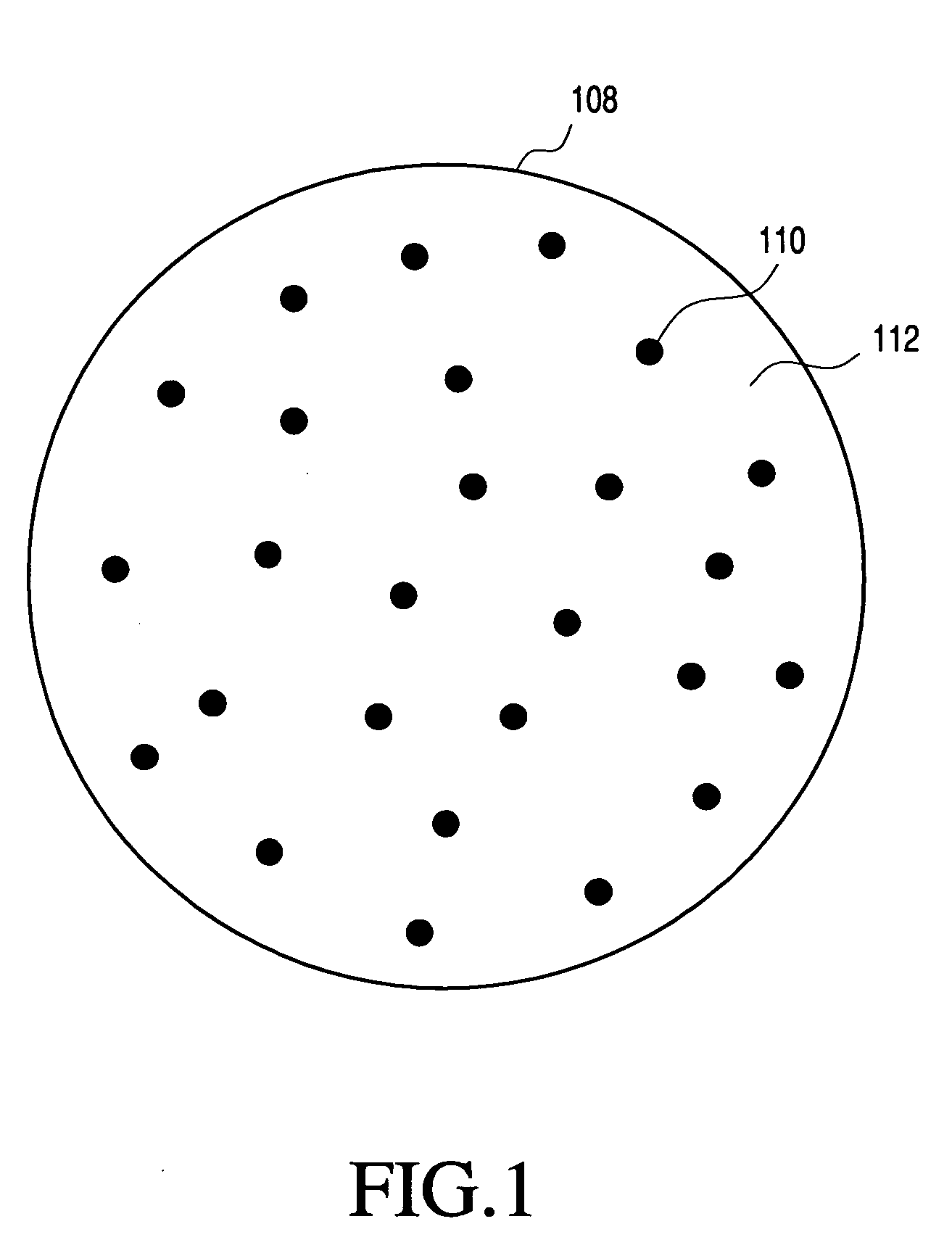

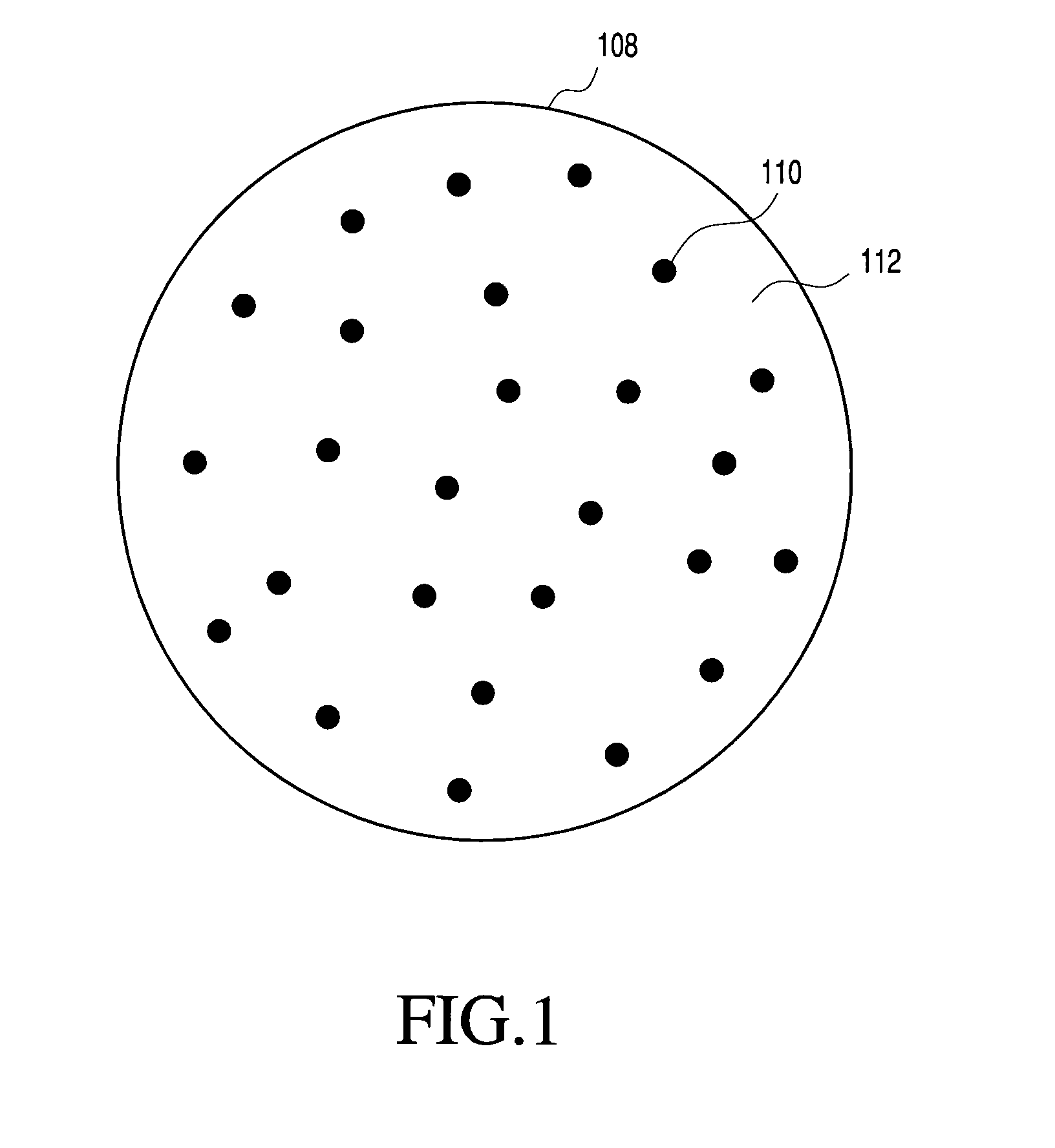

Multi-component particles comprising inorganic nanoparticles distributed in an organic matrix and processes for making and using same

Multi-component particles comprising inorganic nanoparticles distributed in an organic matrix and processes for making and using same. A flowing aerosol is generated that includes droplets of a precursor medium dispersed in a gas phase. The precursor medium contains a liquid vehicle and at least one precursor. At least a portion of the liquid vehicle is removed from the droplets of precursor medium under conditions effective to convert the precursor to the nanoparticles or the matrix and form the multi-component particles.

Owner:CABOT CORP

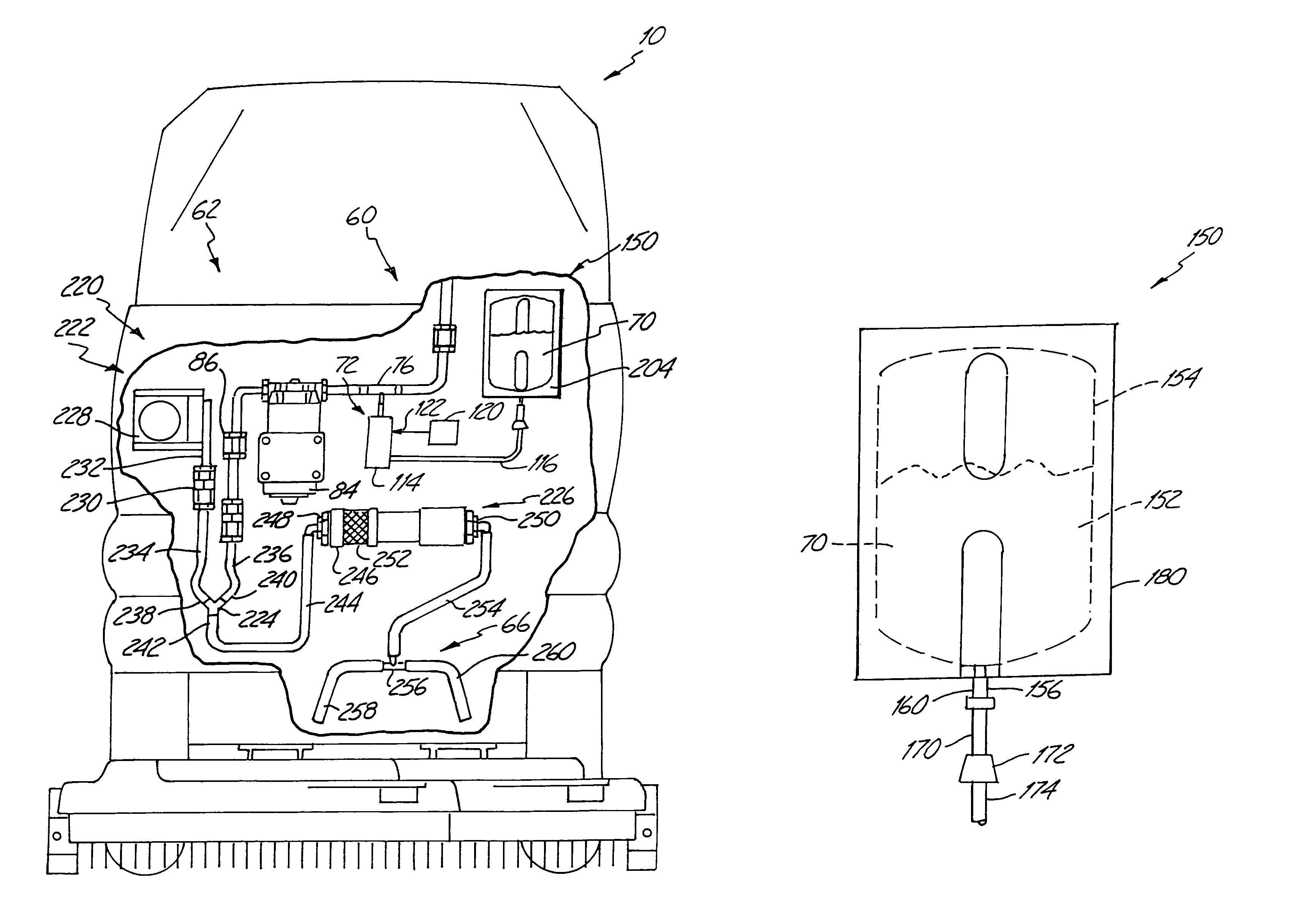

Cleaner cartridge

InactiveUS7051399B2Longer operational runtimeShort downtimeCarpet cleanersMixing methodsCatheterCleansing Agents

A cleaner cartridge includes a container having an interior cavity, in which cleaning agent can be stored. A first end of conduit is fluidically coupled to the interior cavity. A second end of the conduit is connectable to a chemical dispenser.

Owner:TENNANT COMPANY

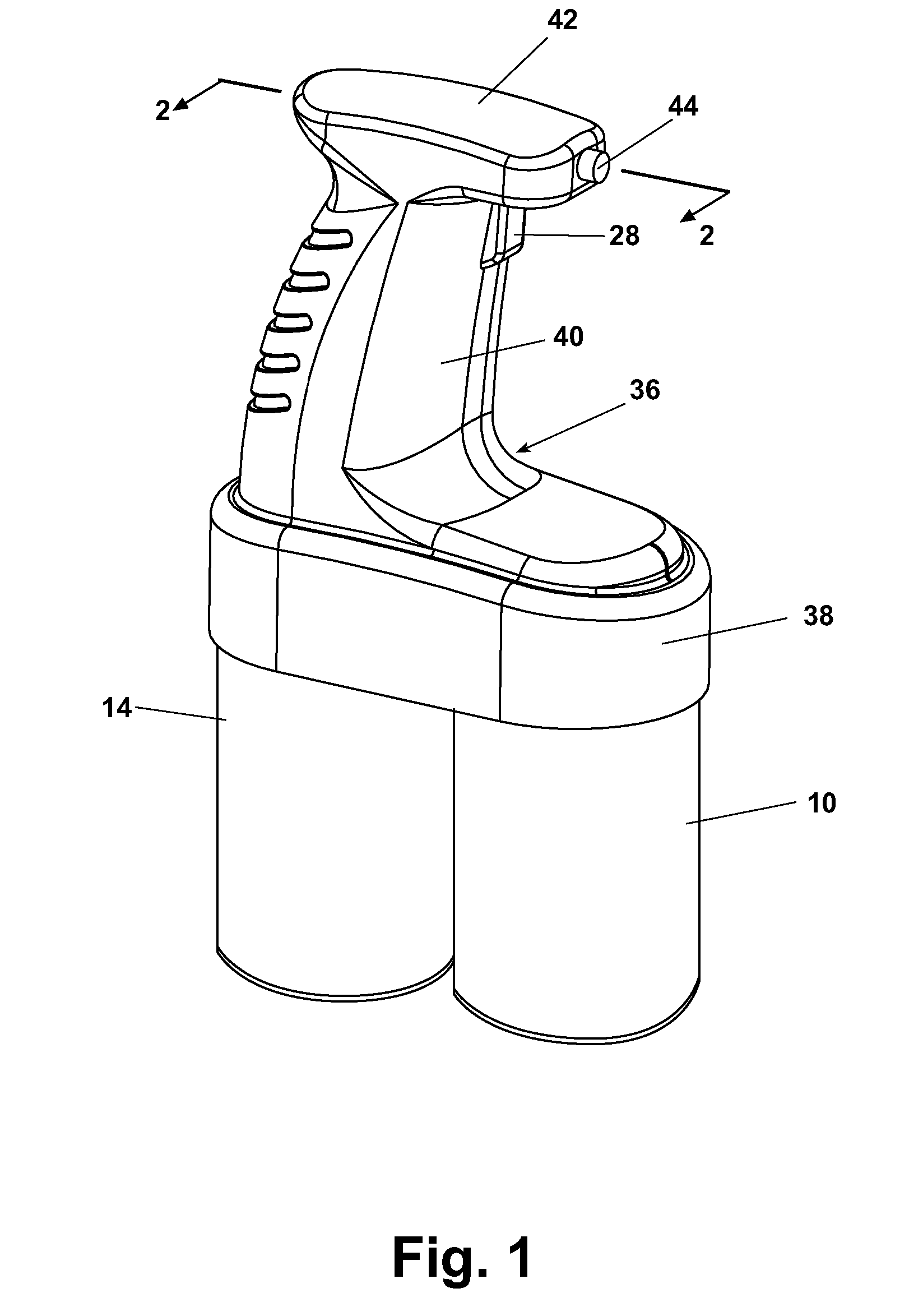

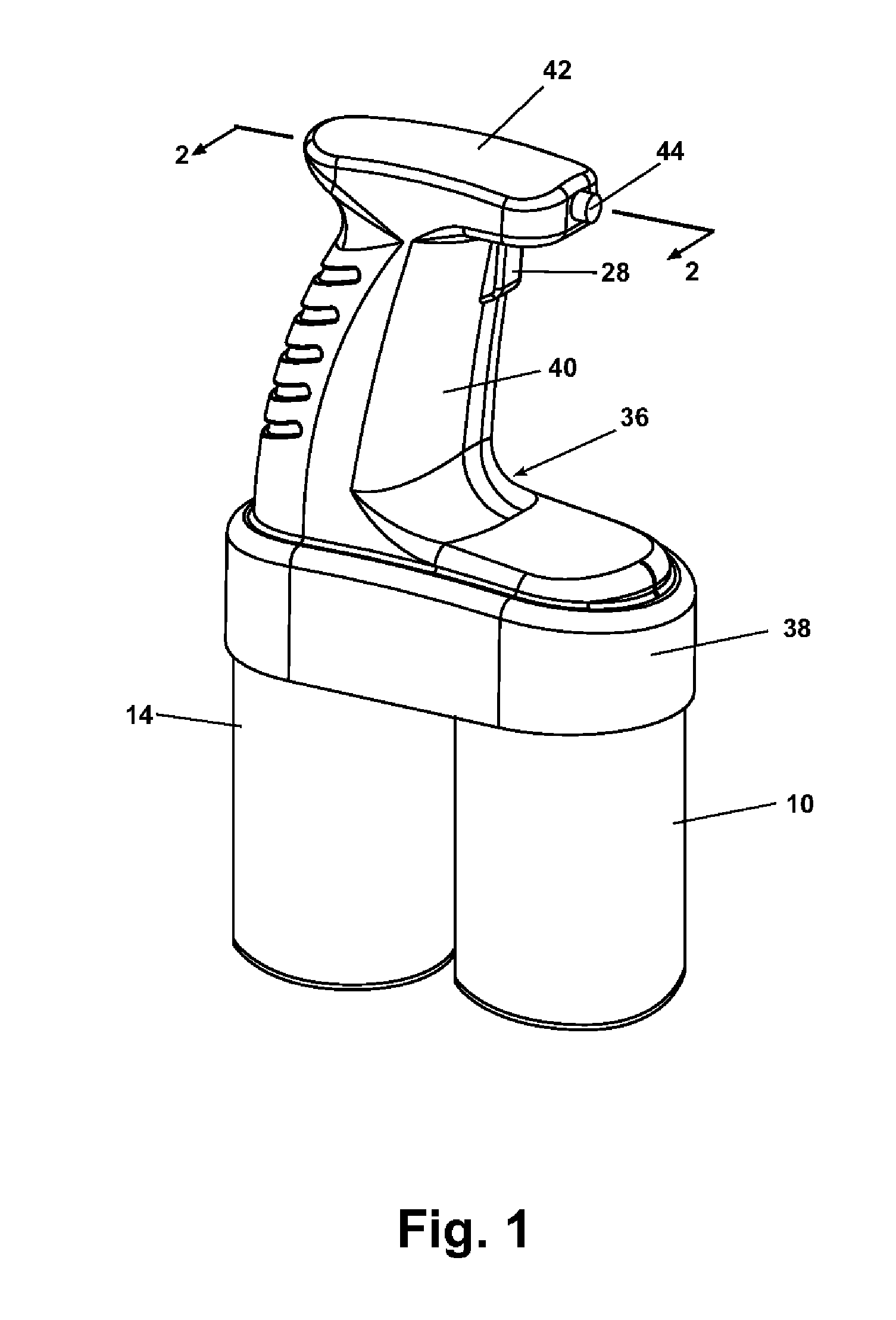

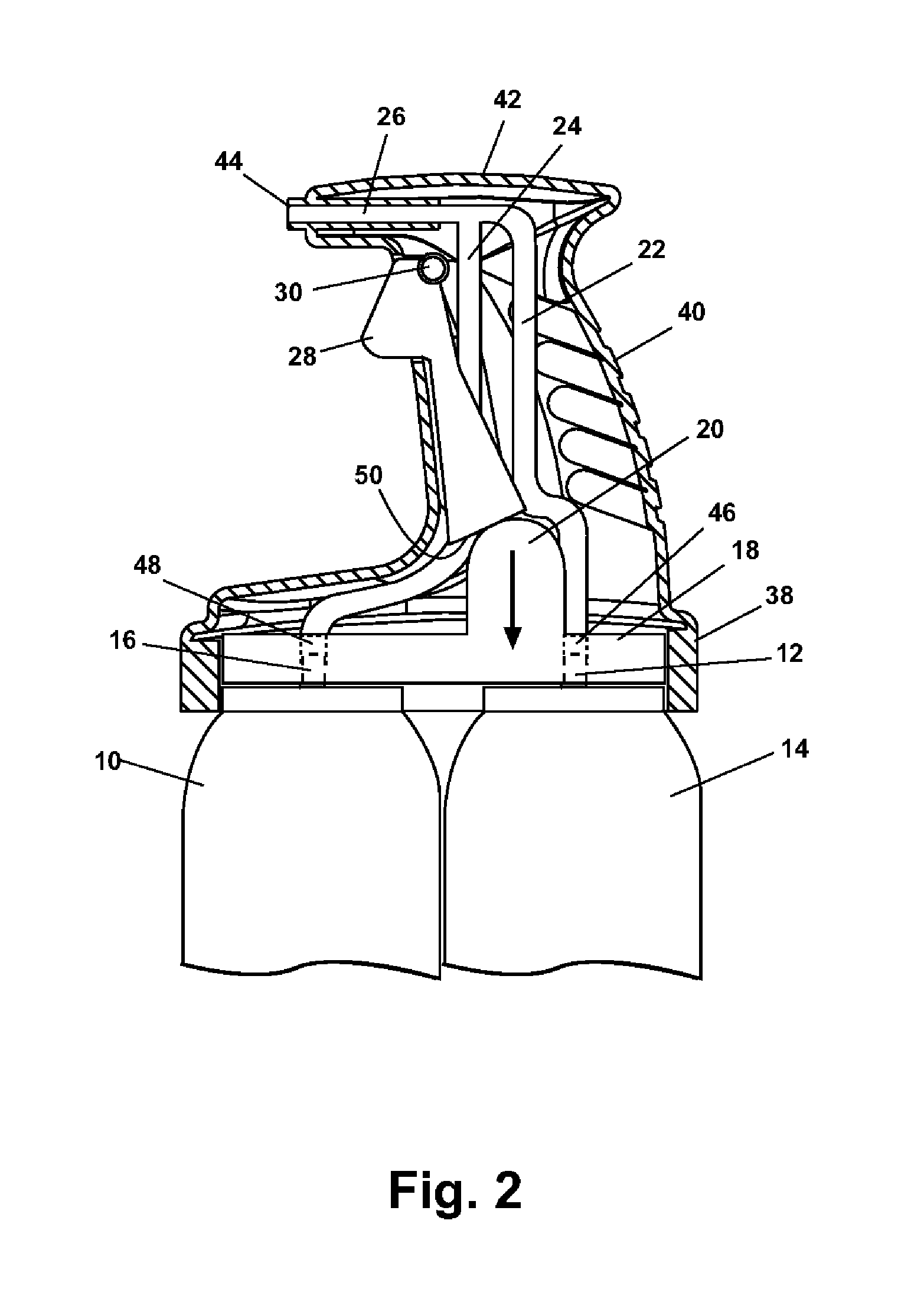

Manual spray cleaner

ActiveUS20040063600A1Reduce deliveryPacked tightlyCleaning machinesDry-cleaning apparatus for textilesEngineeringSpray bottle

Abstract of the Disclosure A manual spray cleaner for removing dirt and stains from fabrics and carpets comprising a spray bottle having two separate chambers and a single dispensing spray outlet for dispensing controlled amounts of liquids from each of the chambers. One of the chambers has a fabric / carpet cleaning composition therein and the other chamber has an oxidizing composition that enhances the cleanability of the fabric / carpet cleaning composition. The fabric / carpet cleaning composition and the oxidizing composition are simultaneously drawn from their respective chambers and mixed together at the time that they are dispensed from the spray bottle. At least one of the oxidizing composition and the fabric / carpet cleaning composition includes a fabric / carpet protectant. The two compositions are mixed before or after they are sprayed from the bottle. The two compositions can be pressurized with an aerosol propellant or drawn from their respective chambers by a mechanical pump.

Owner:BISSELL INC

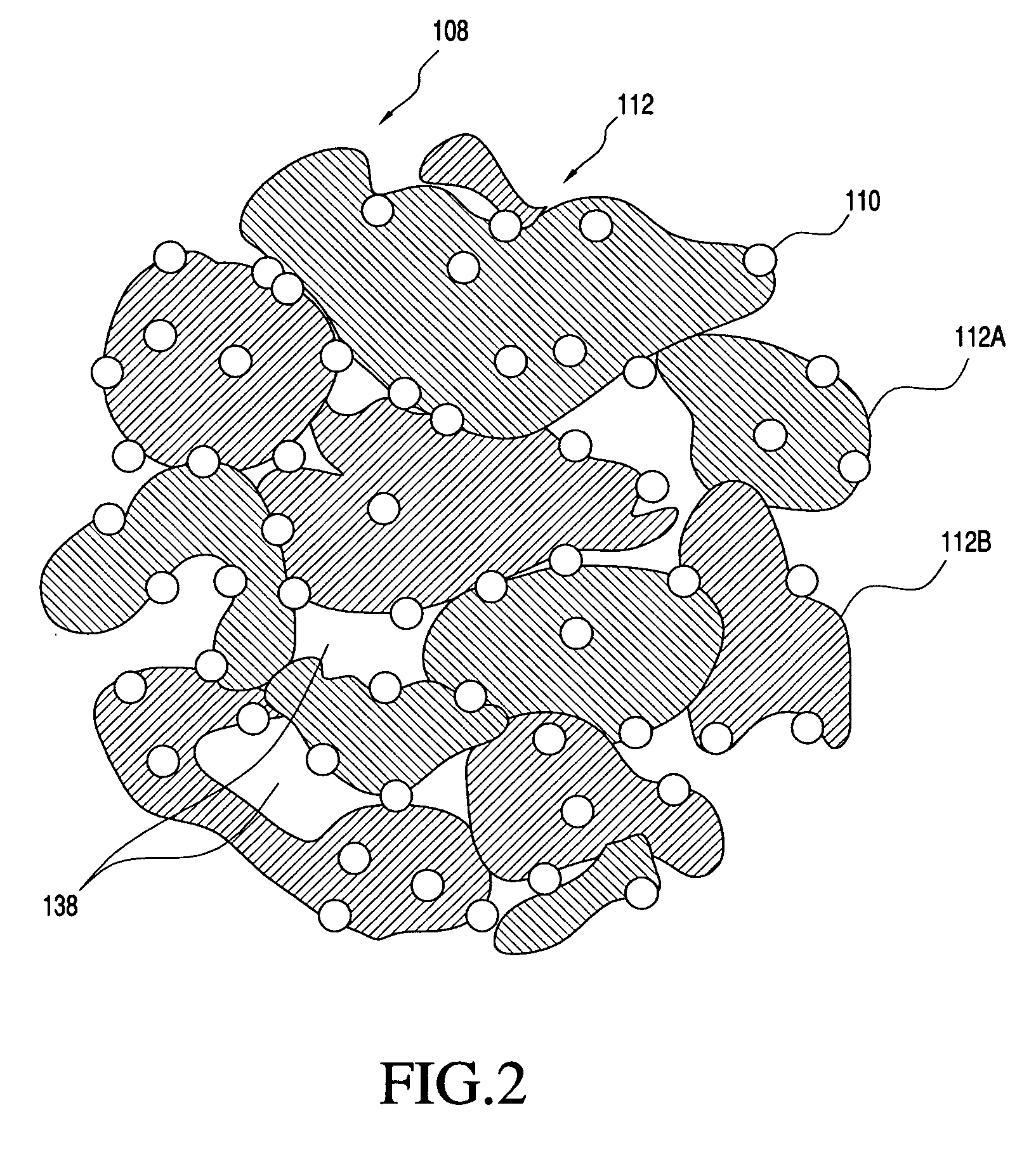

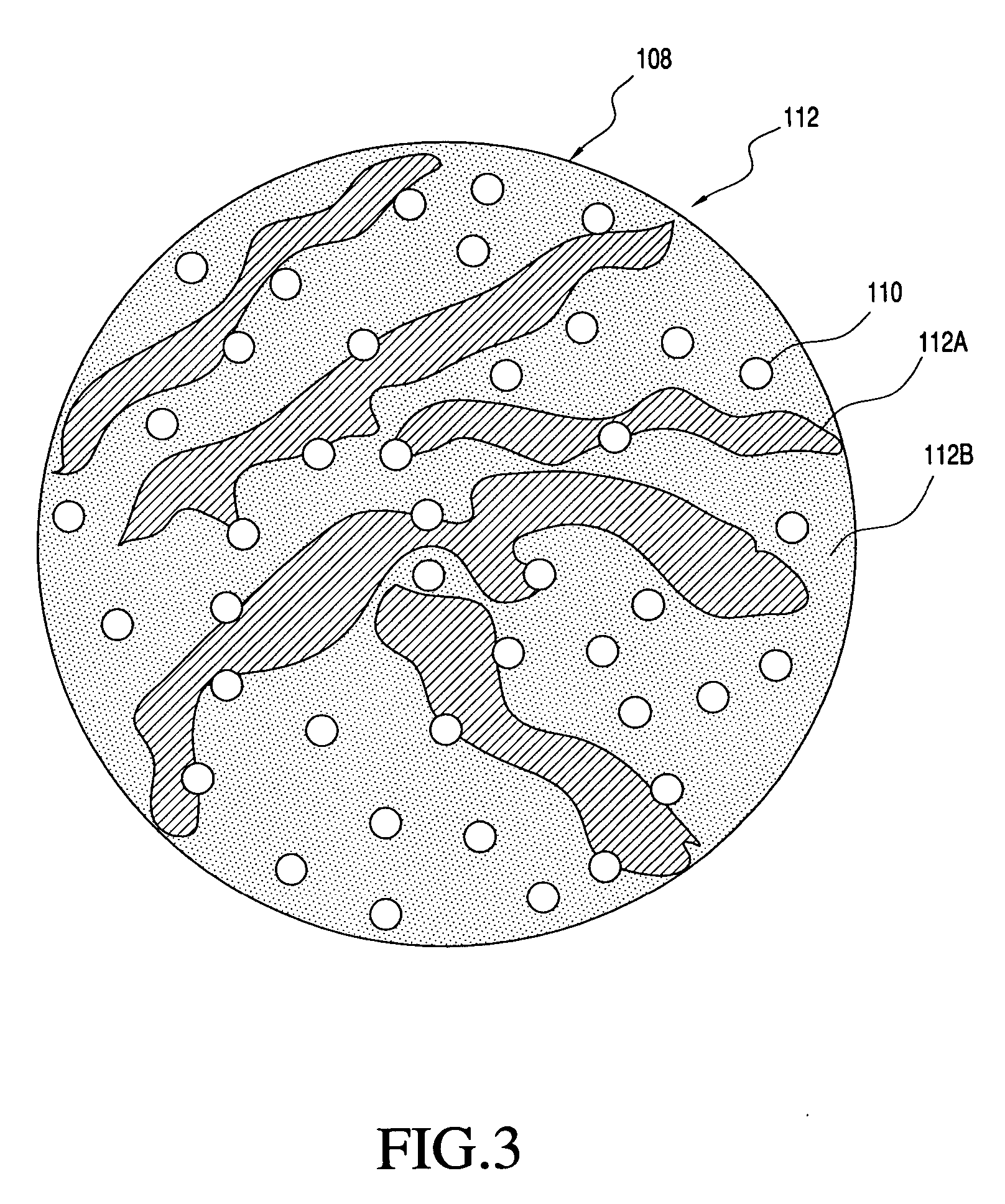

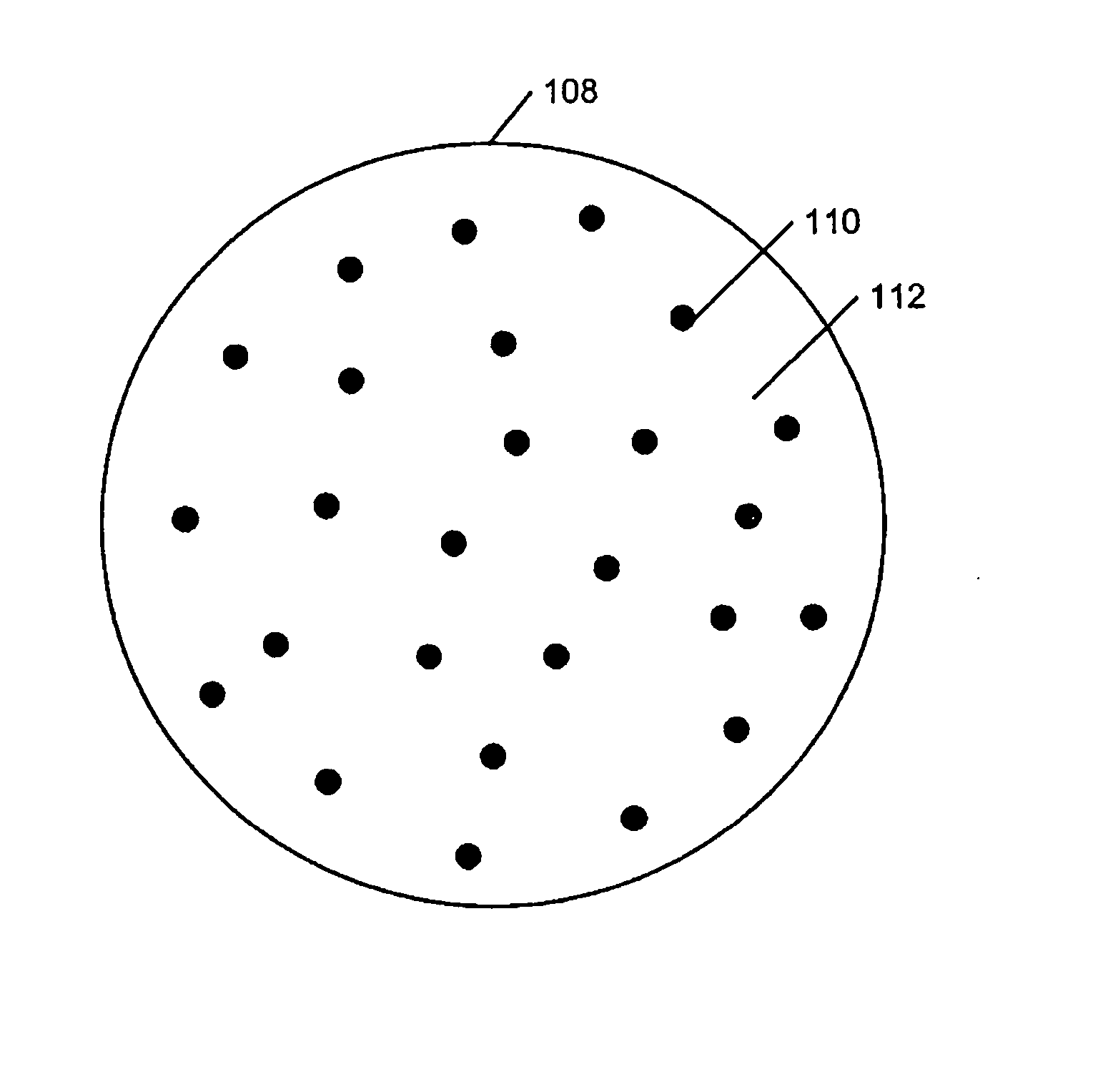

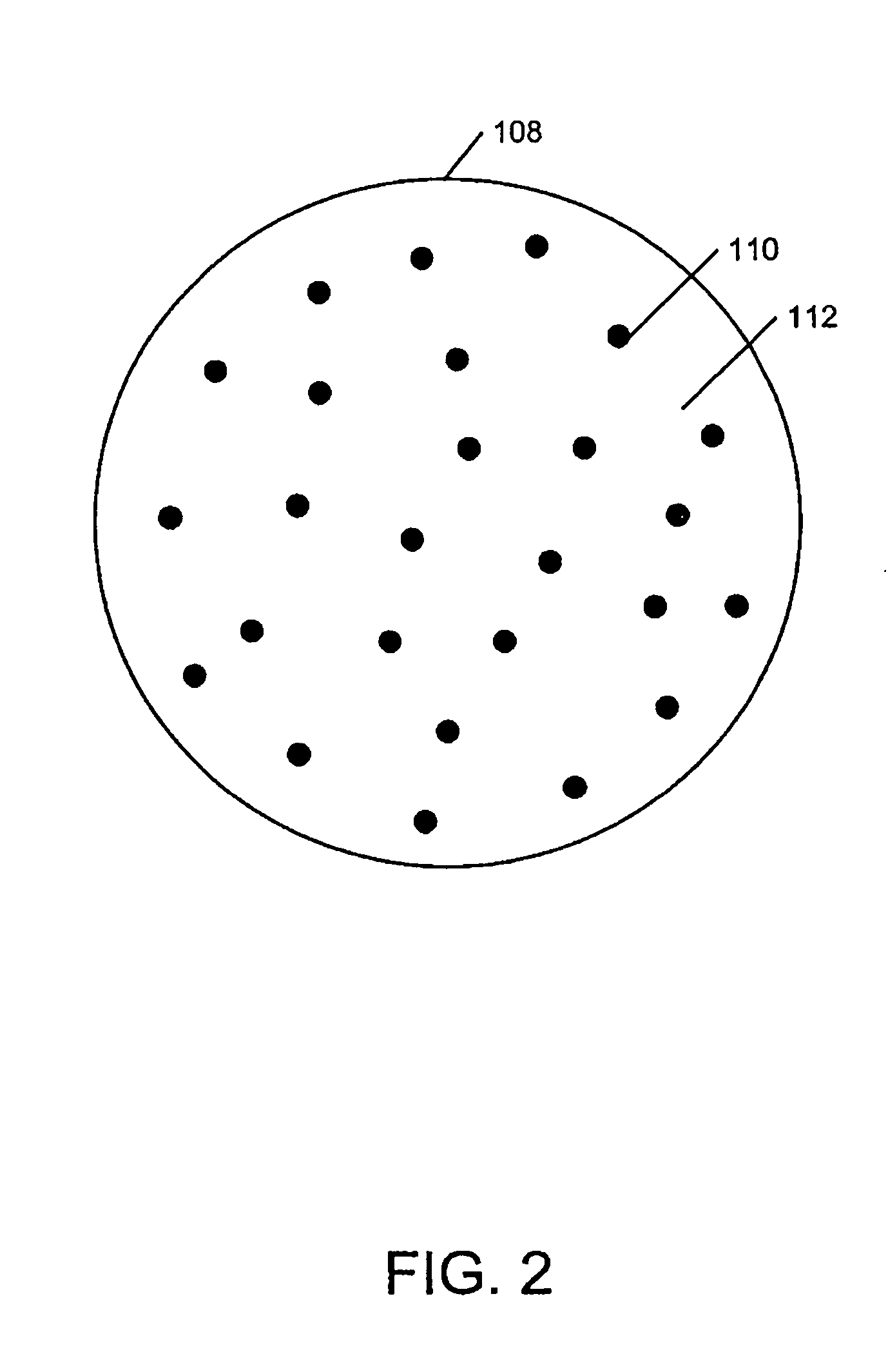

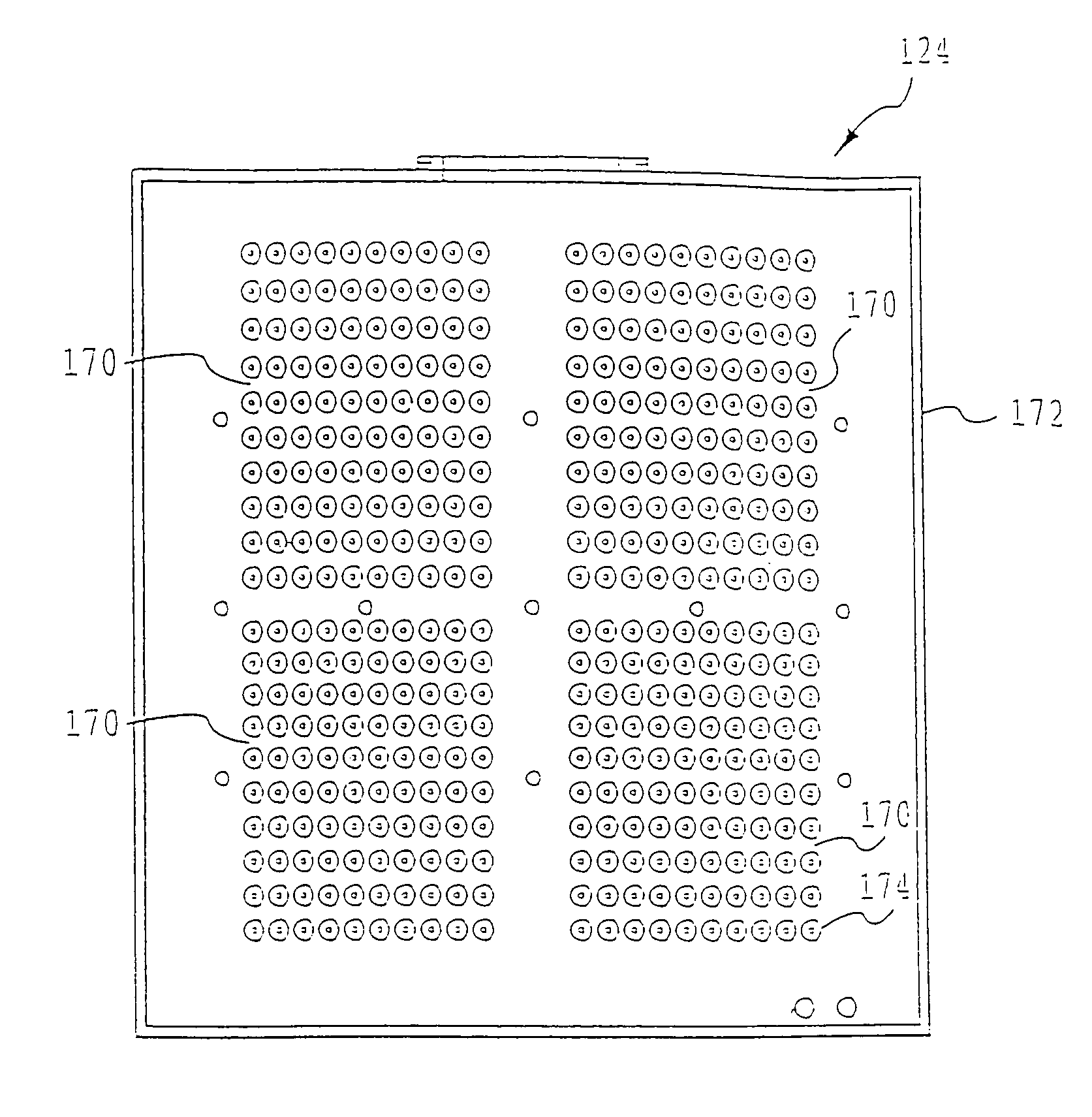

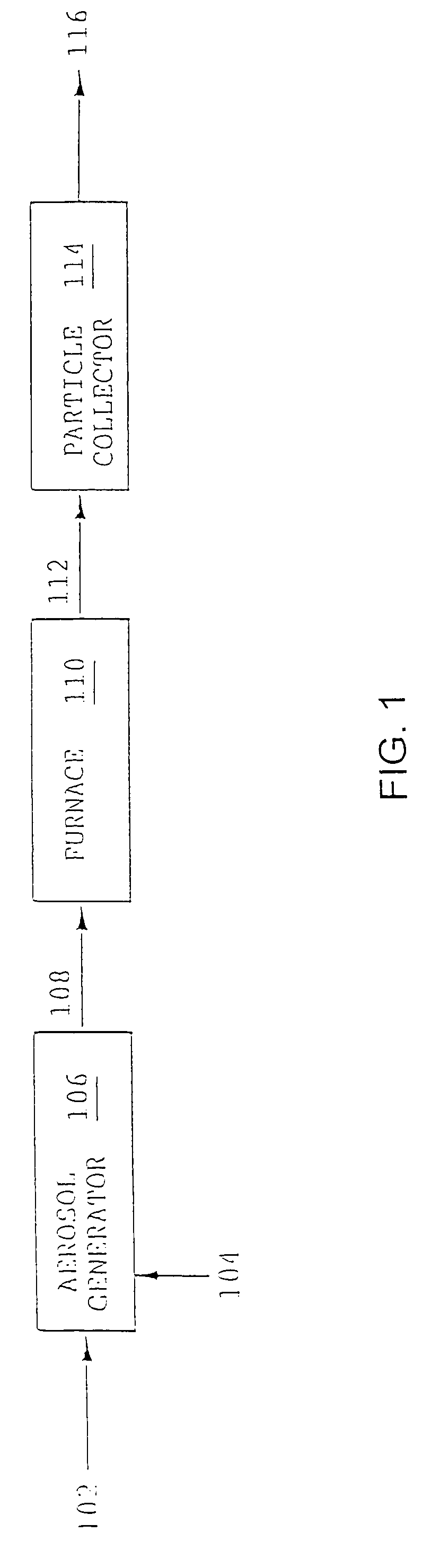

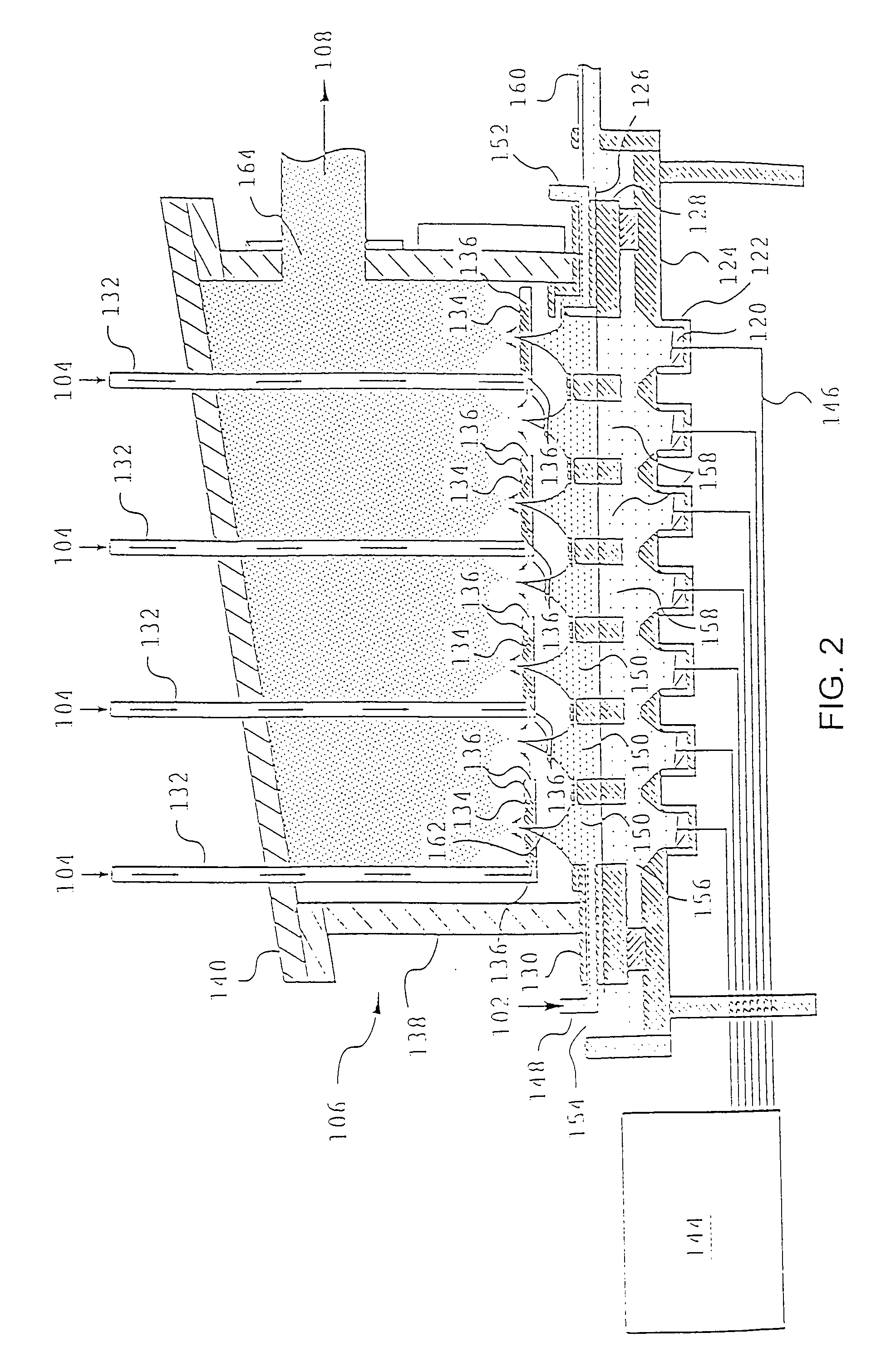

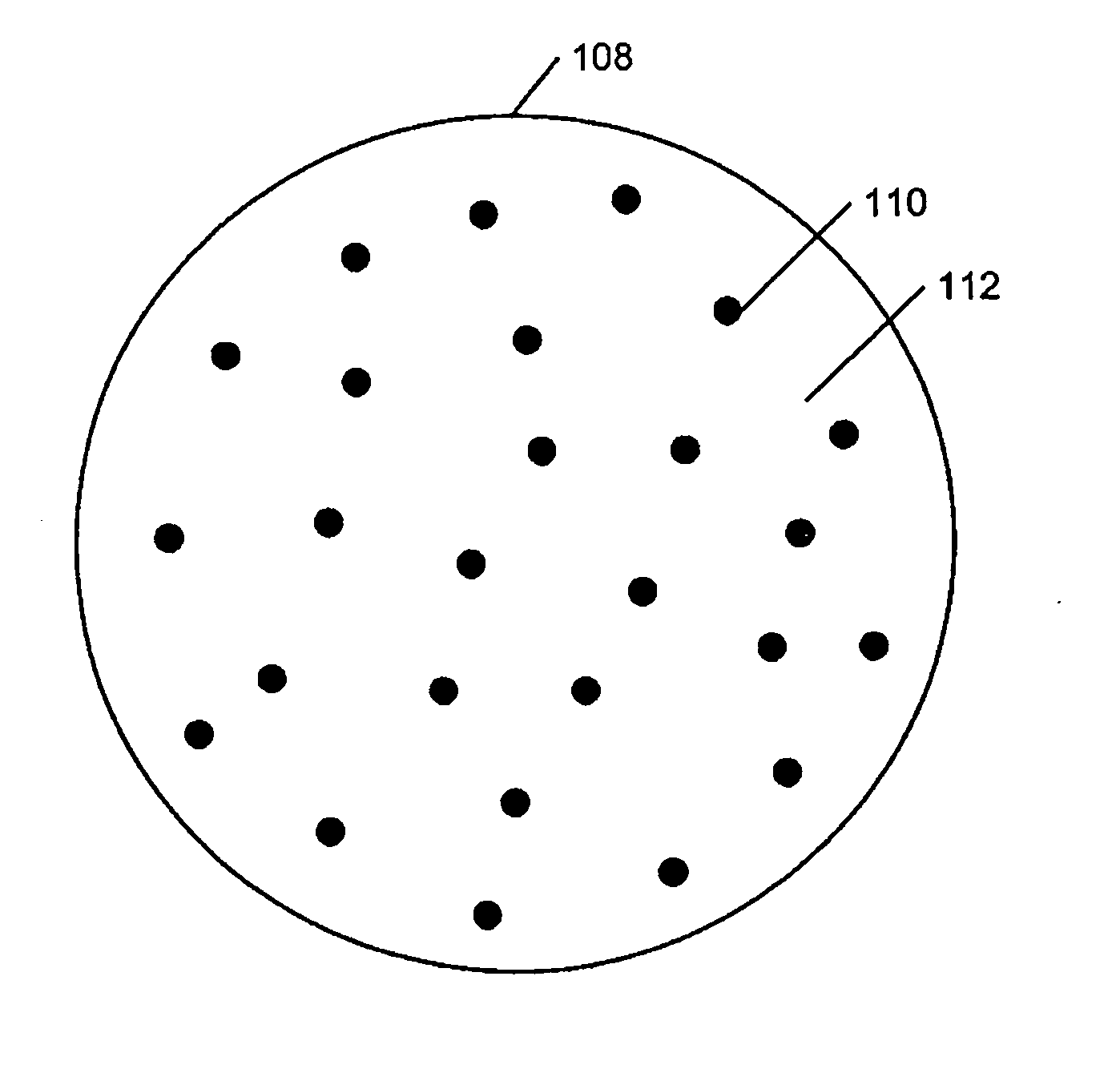

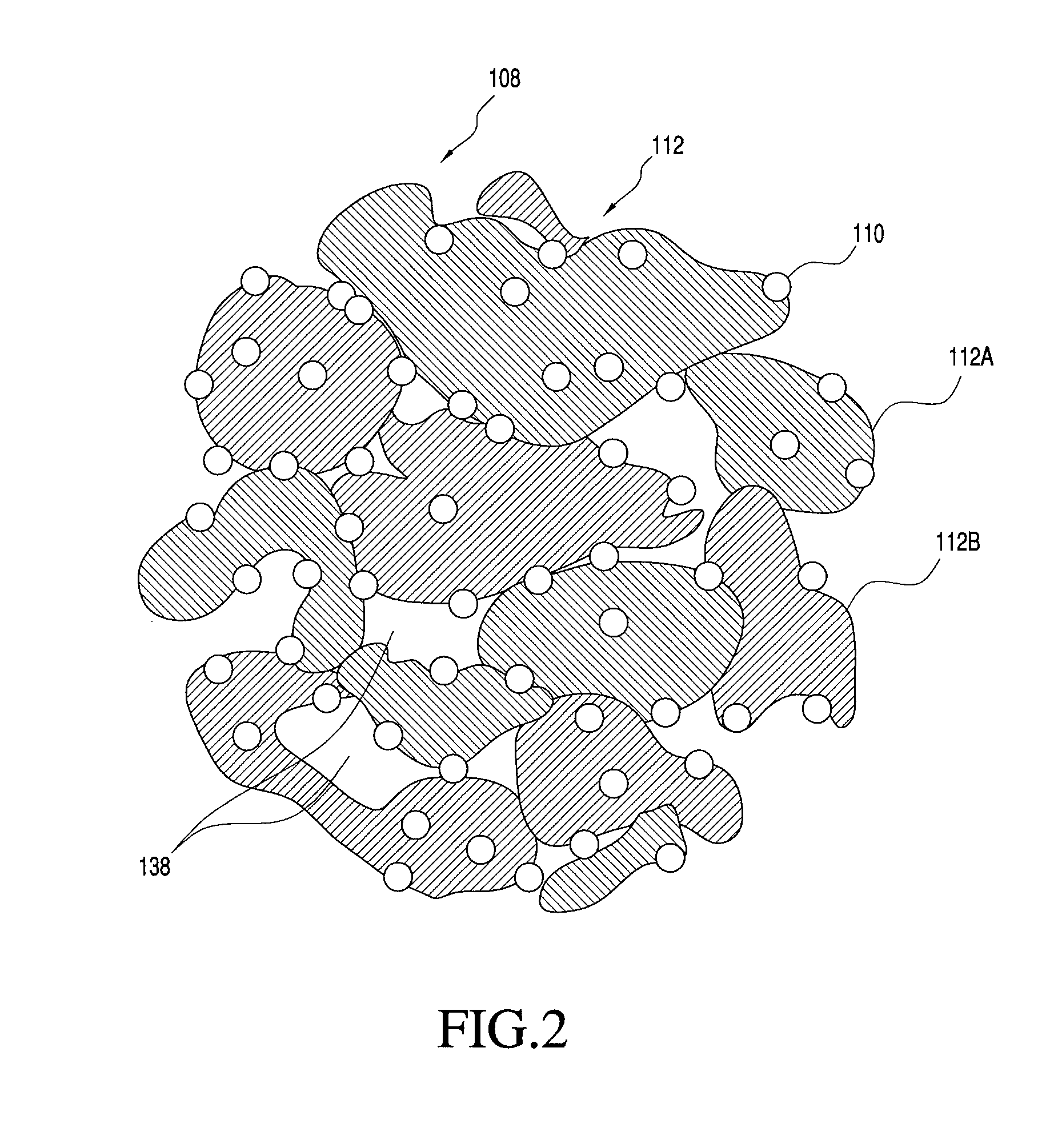

Gas dispersion manufacture of nanoparticulates, and nanoparticulate-containing products and processing thereof

In one aspect, the present invention relates to a method of making multi-phase particles that include nanoparticulates and matrix, which maintains the nanoparticulates in a dispersed state. A flowing gas dispersion is generated that includes droplets of a precursor medium dispersed in a gas phase. The precursor medium contains liquid vehicle and at least a first precursor to a first material and a second precursor to a second material. The multi-phase particles are formed from the gas dispersion by removing at least a portion of the liquid vehicle from the droplets of precursor medium. The nanoparticulates in the multi-phase particles include the first material and the matrix in the multi-phase particles includes the second material.

Owner:SICPA HLDG SA

Direct-write deposition of phosphor powders

InactiveUS7476411B1Improve automationHigh resolution displayRare earth metal oxides/hydroxidesMaterial granulation and coatingApparent densityPhosphor

A liquid suspension of phosphor particles and method for depositing the liquid suspension. The suspension advantageously has a low viscosity with a high solids-loading of phosphor particles. The apparent density of the phosphor particles is well-controlled to enable the particles to be dispersed in the liquid vehicle. The suspension is useful in direct-write tools such as ink-jet devices.

Owner:SICPA HLDG SA

Gas dispersion manufacture of nanoparticulates, and nanoparticulate-containing products and processing thereof

In one aspect, the present invention relates to a method of making multi-phase particles that include nanoparticulates and matrix, which maintains the nanoparticulates in a dispersed state. A flowing gas dispersion is generated that includes droplets of a precursor medium dispersed in a gas phase. The precursor medium contains liquid vehicle and at least a first precursor to a first material and a second precursor to a second material. The multi-phase particles are formed from the gas dispersion by removing at least a portion of the liquid vehicle from the droplets of precursor medium. The nanoparticulates in the multi-phase particles include the first material and the matrix in the multi-phase particles includes the second material.

Owner:CABOT CORP

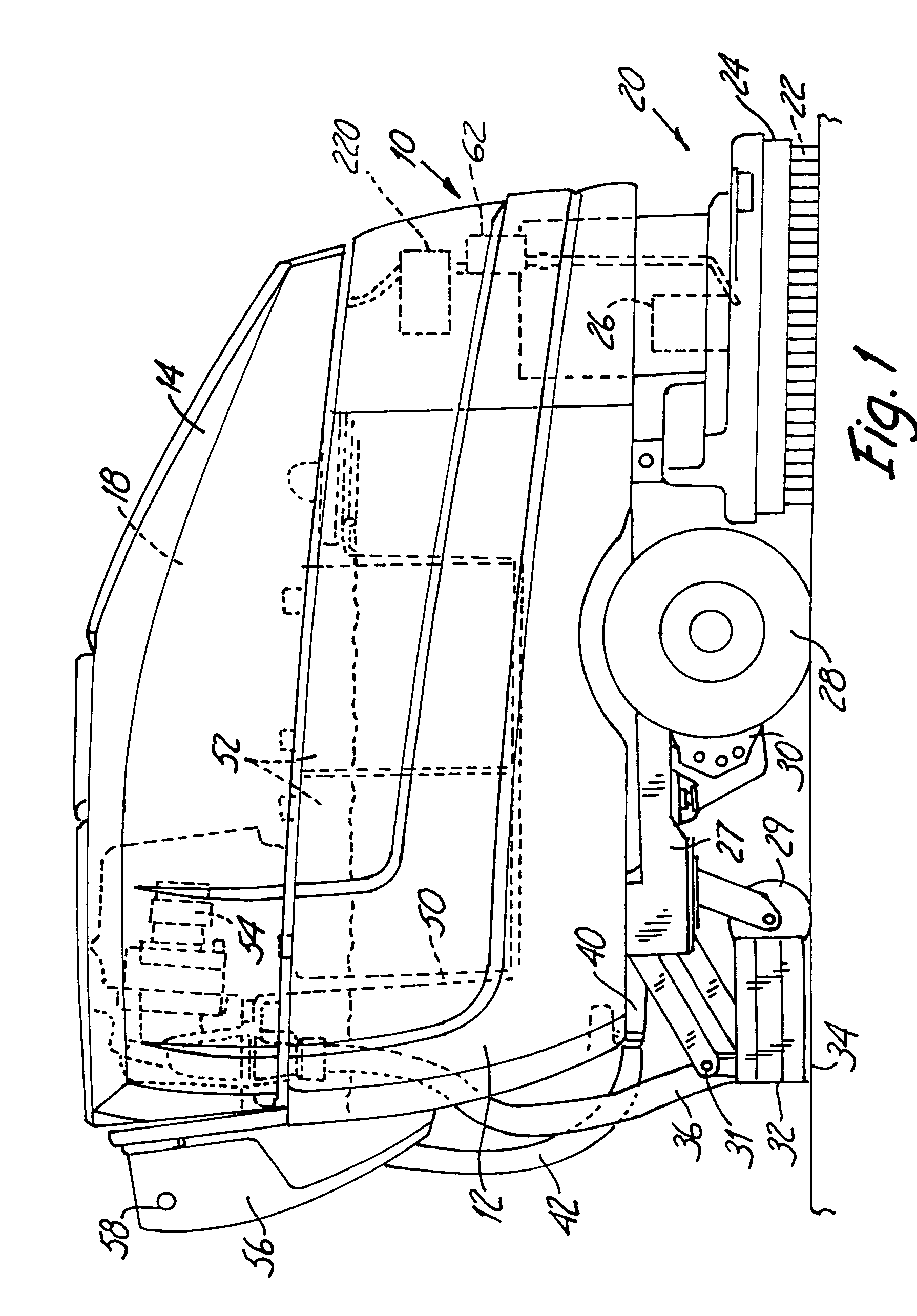

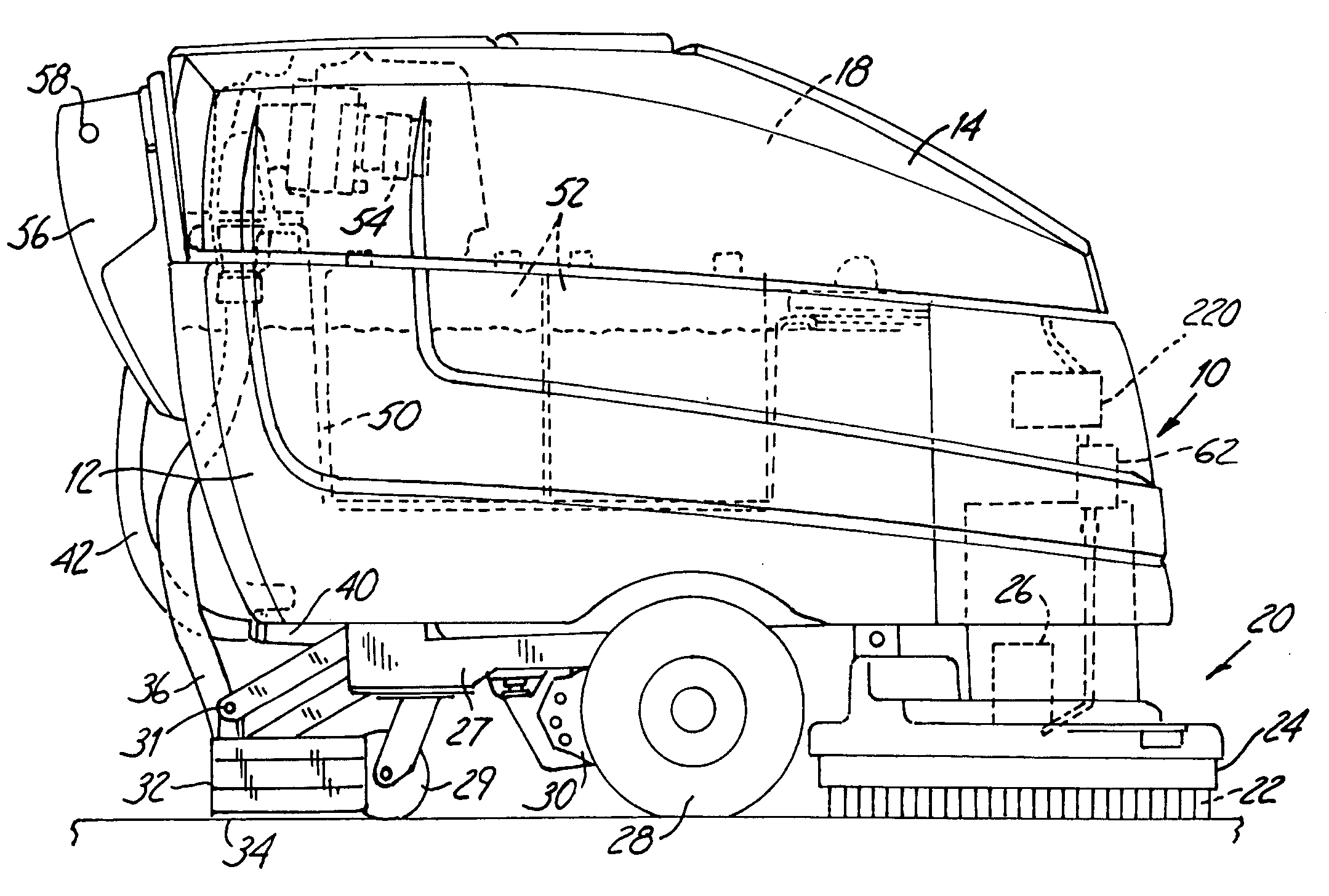

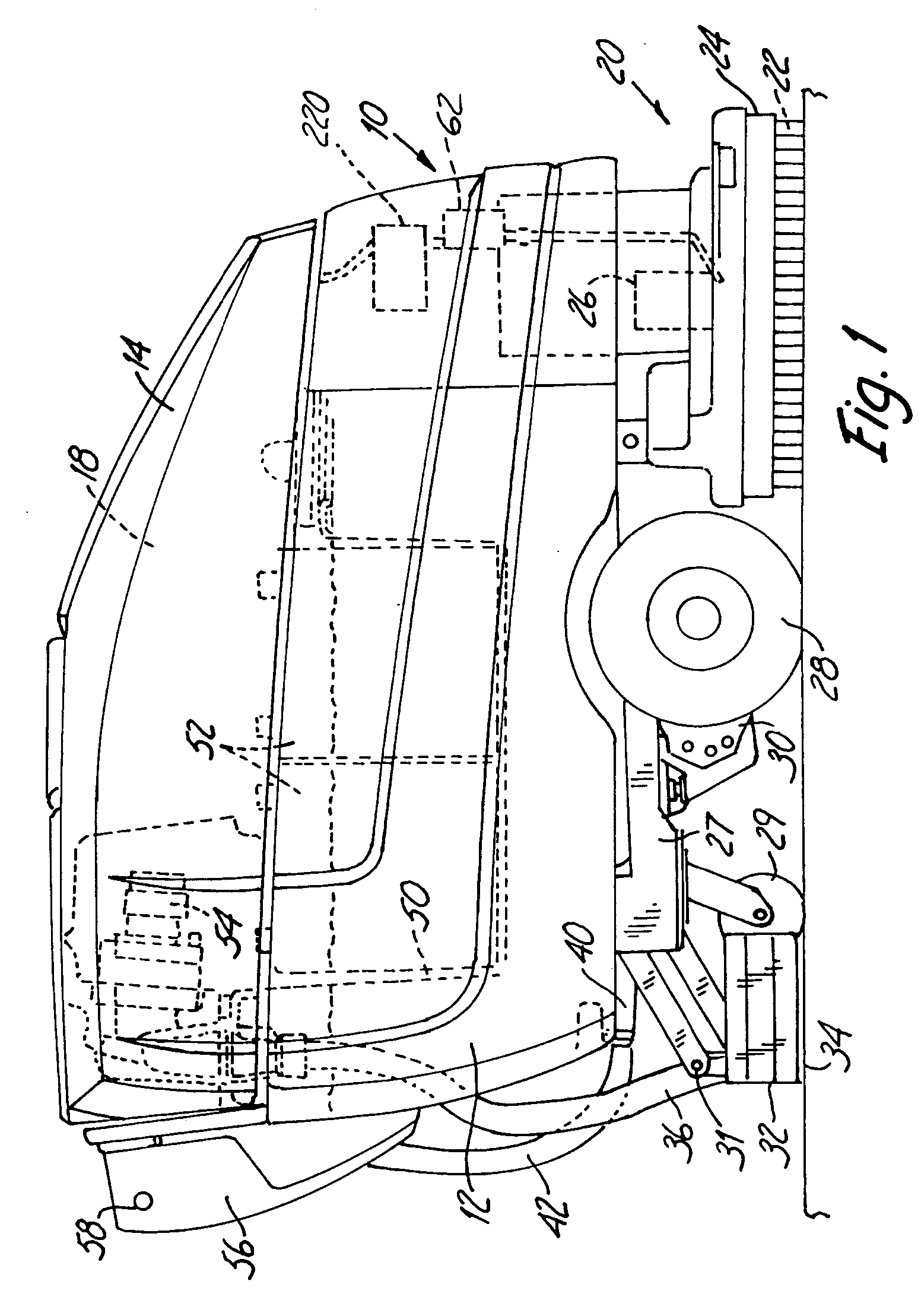

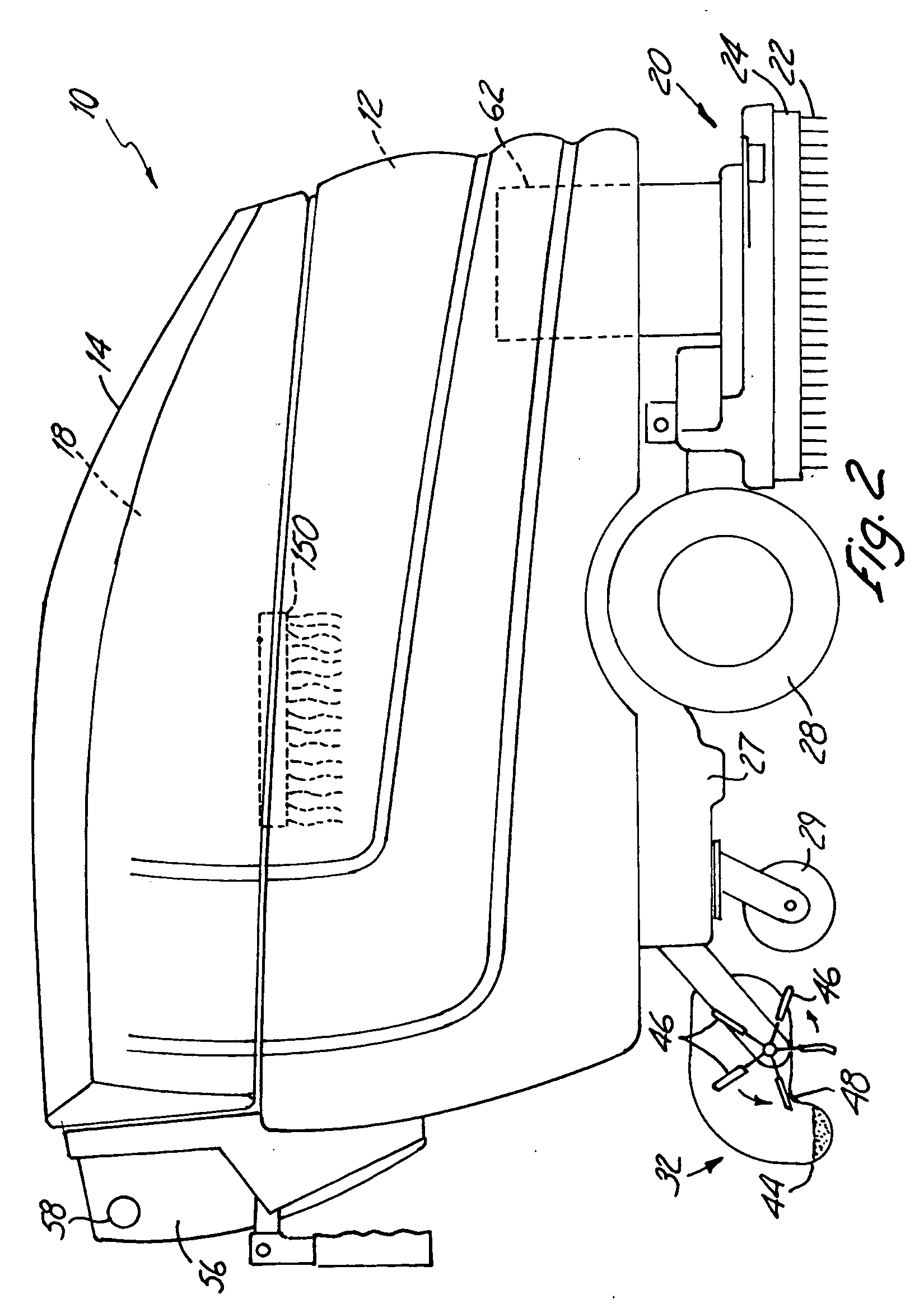

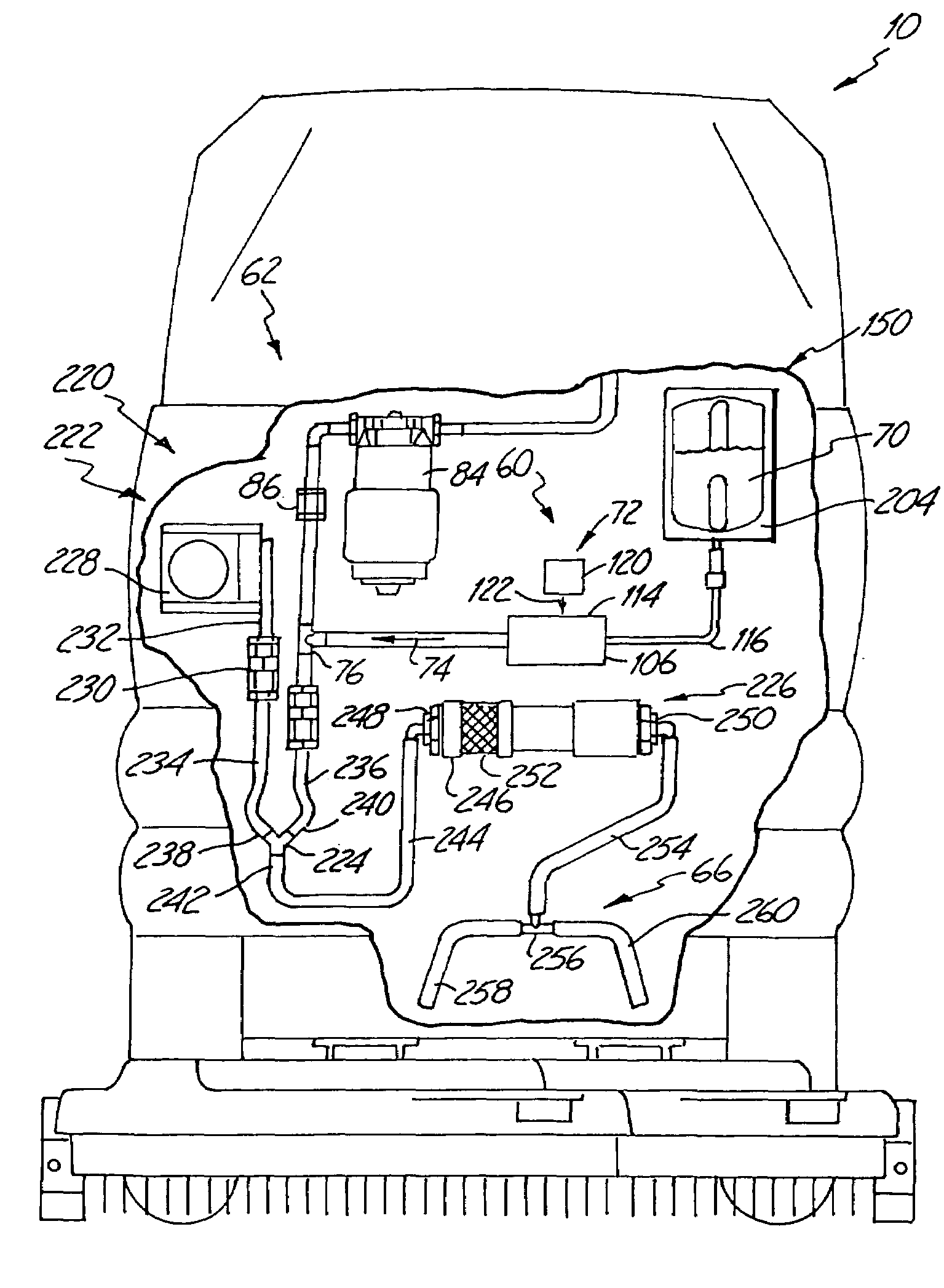

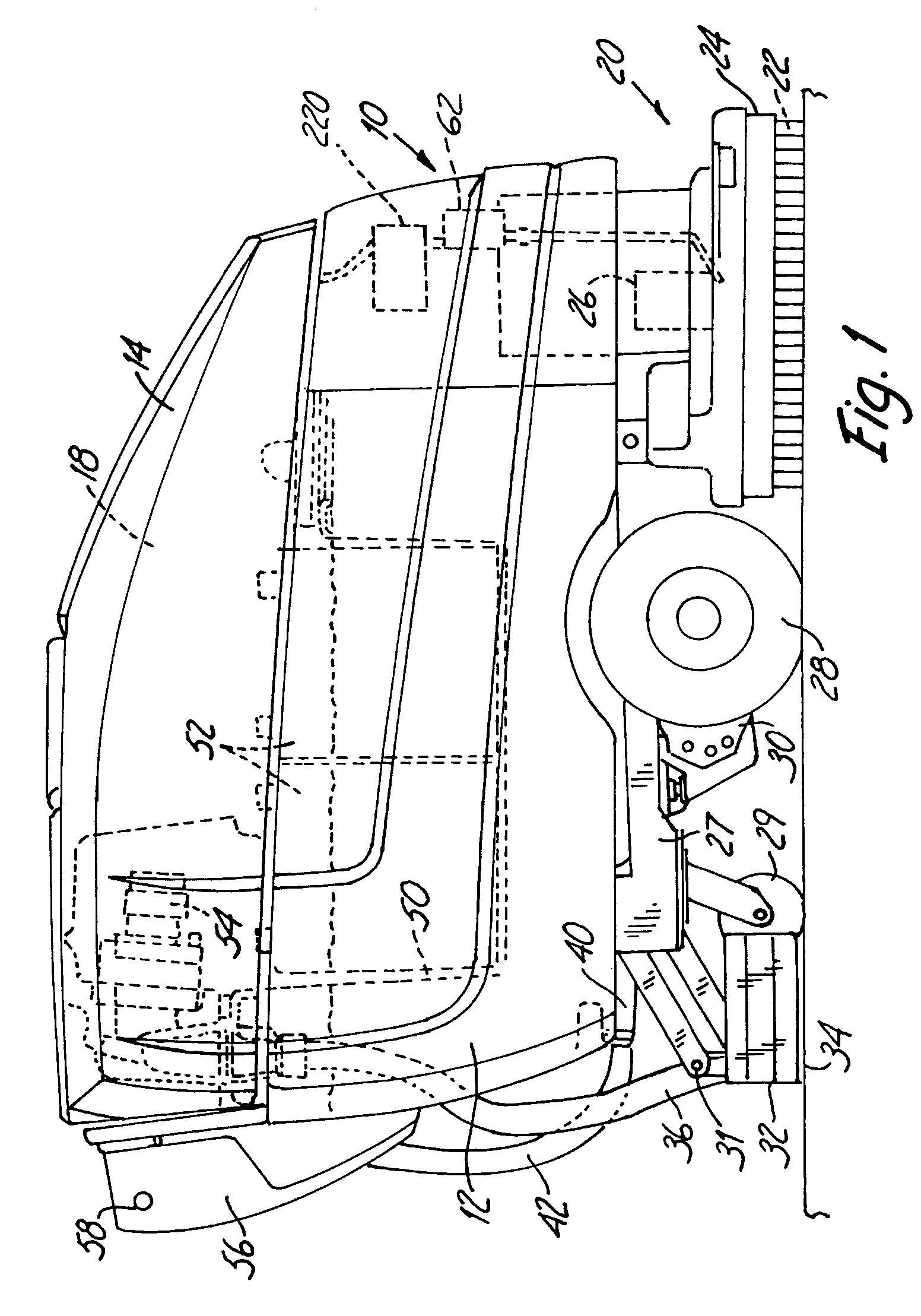

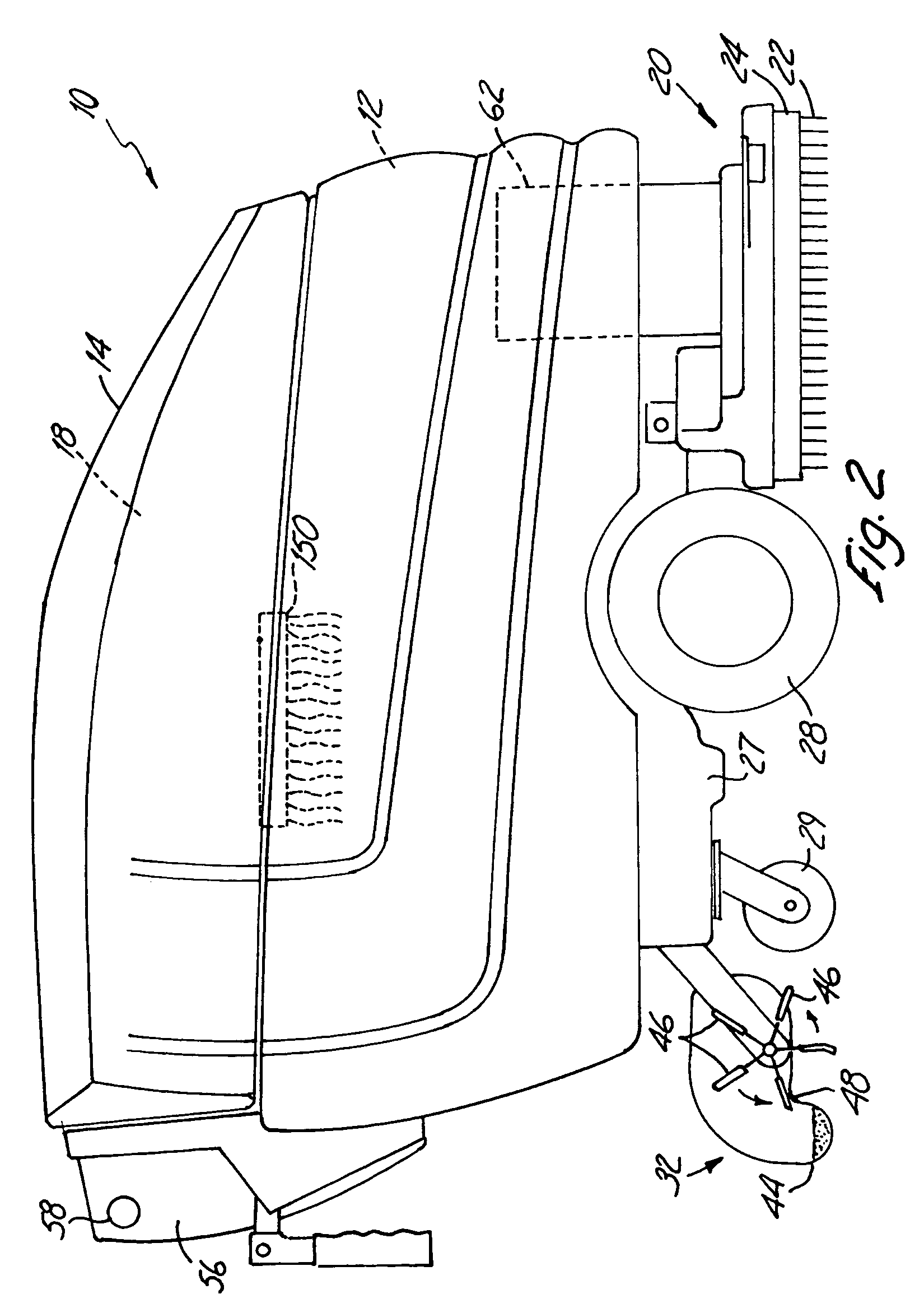

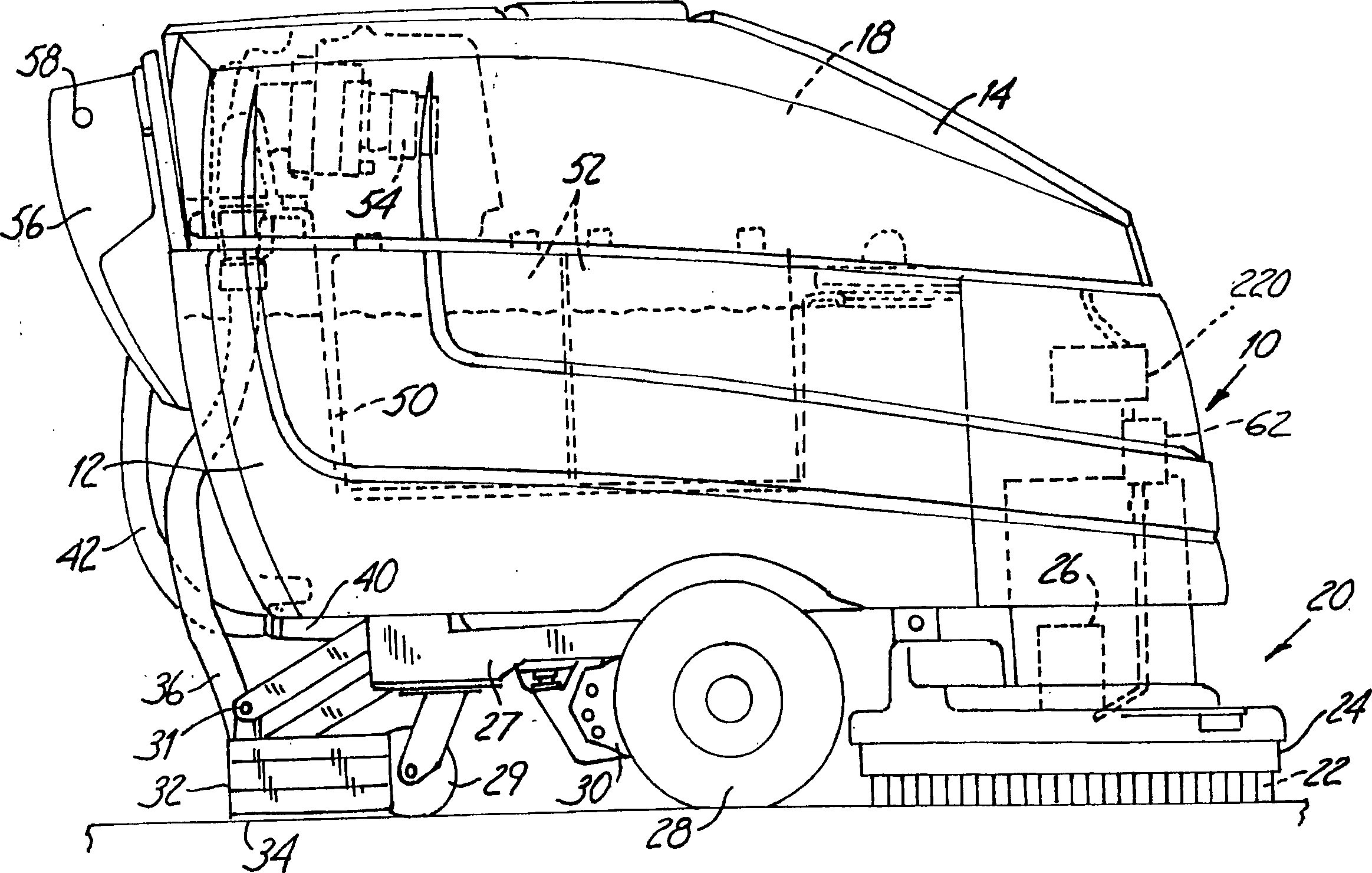

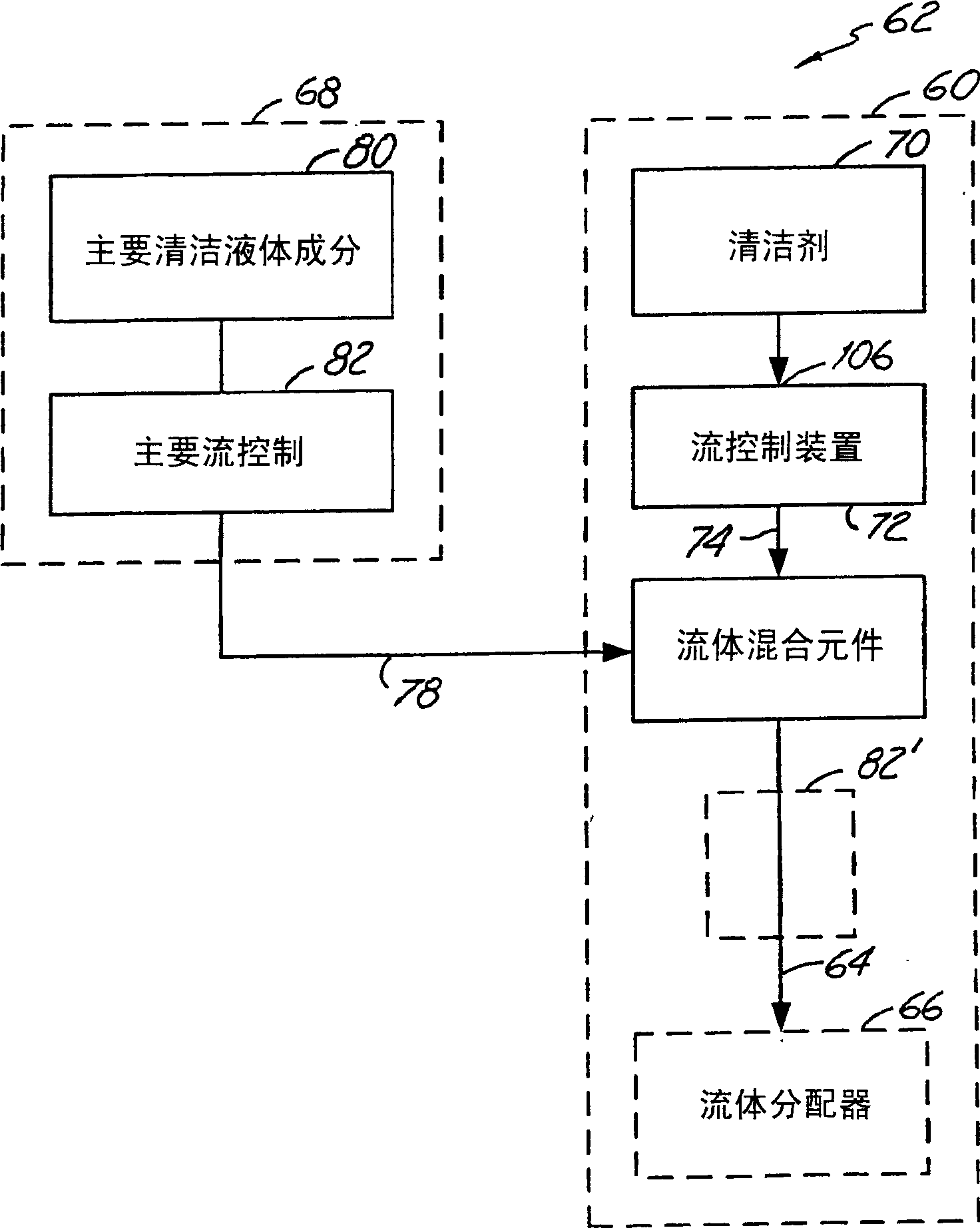

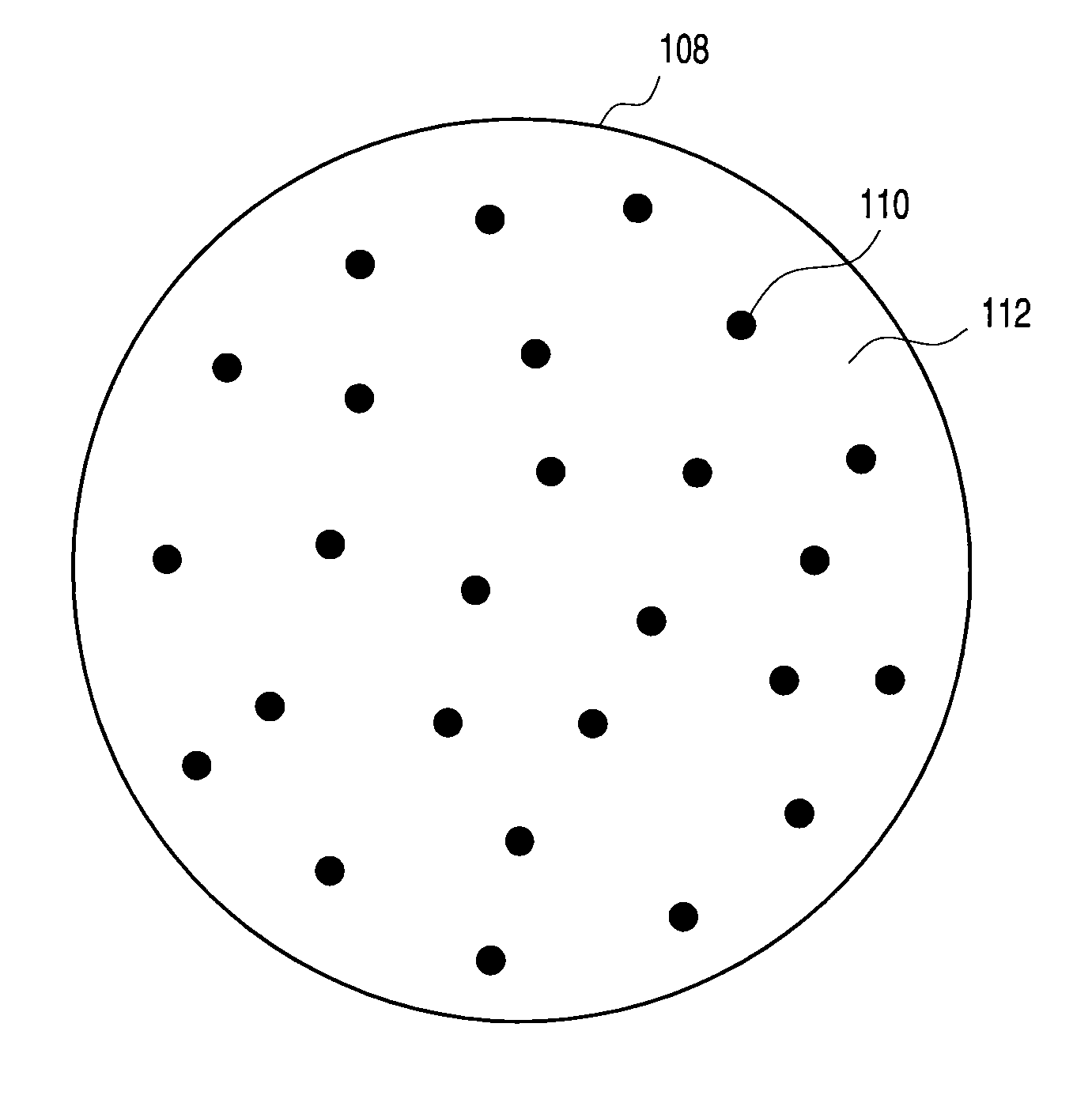

Cleaning liquid dispensing in a mobile hard surface cleaner

A hard surface cleaner includes a motorized scrub head, a fluid recovery device, a primary cleaning liquid component container, a cleaning agent container, a flow control device and a fluid flow path. The flow control device is configured to supply a flow of cleaning agent from the cleaning agent container at a flow rate of less than approximately cubic centimeters per minute to a flow of primary cleaning liquid component from the primary cleaning liquid component container. The fluid flow path is configured to receive a flow of cleaning liquid, which comprises the cleaning agent and the primary cleaning liquid component. A method of dispensing a chemical for use in a mobile hard surface cleaner includes driving a flow of cleaning agent from a cleaning agent container at a flow rate of less than approximately 10 cubic centimeters per minute, supplying a flow of primary cleaning liquid component from a cleaning liquid component container supported by the hard floor surface cleaner, combining the flow of cleaning agent and the flow of primary cleaning liquid component to form a flow of cleaning liquid, and dispensing the flow of cleaning liquid to either a motorized scrub head or a surface under the hard floor surface cleaner.

Owner:TENNANT COMPANY

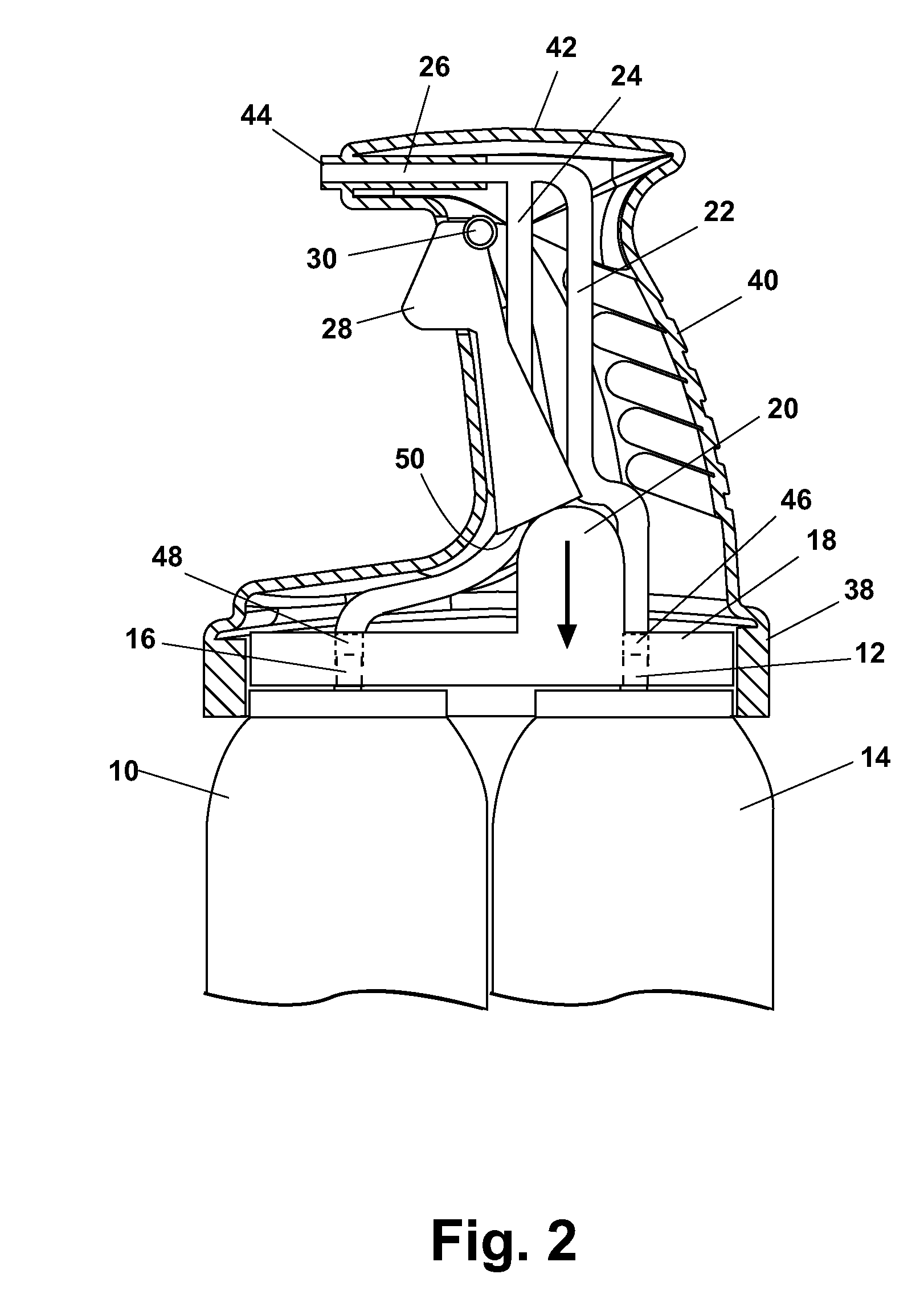

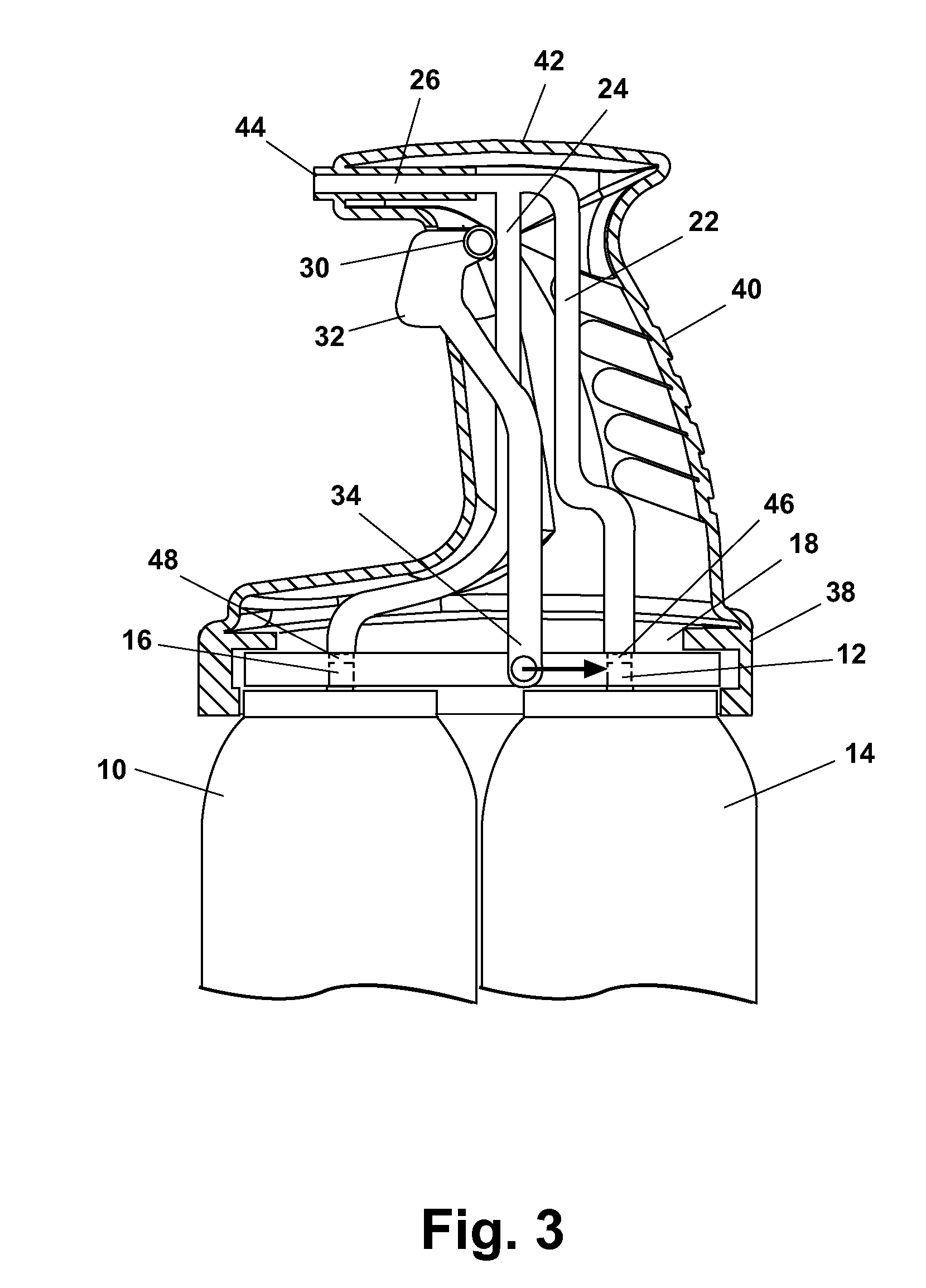

Aerosol package

InactiveUS20050029296A1Reduce the effective cross-sectional areaCleaning machinesDry-cleaning apparatus for textilesAerosol sprayEngineering

An aerosol spray cleaner comprises two containers and a dispenser with a single dispensing spray outlet. One container has a cleaning composition and the other has an oxidizing composition. An integrally molded actuator includes a resiliently cantilevered lever connected to container valves to simultaneously open the valves to dispense the two fluids through the dispensing spray outlet. A handle extends laterally of the containers so grasp the handle and depress the actuator with a thumb.

Owner:BISSELL INC

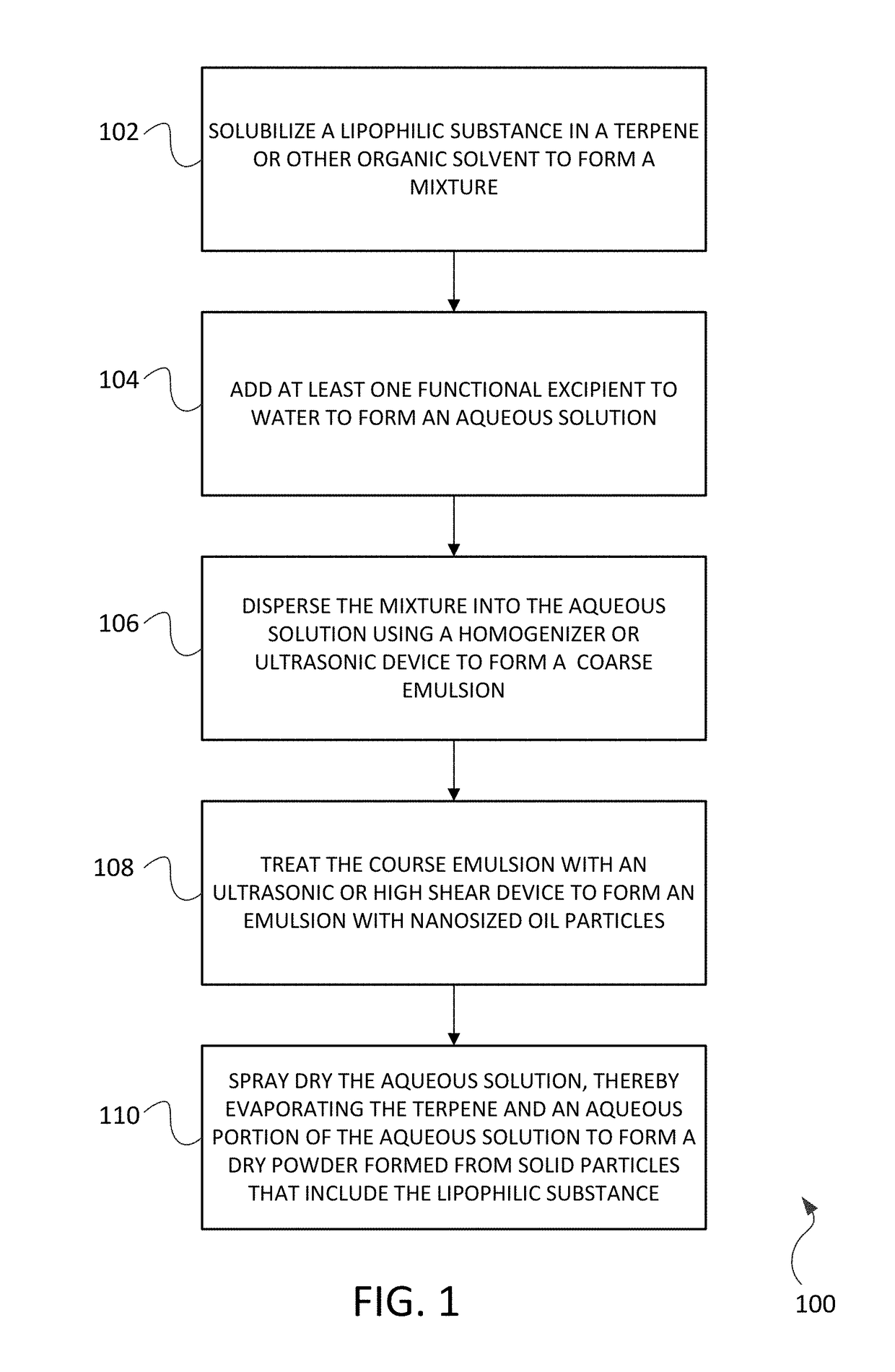

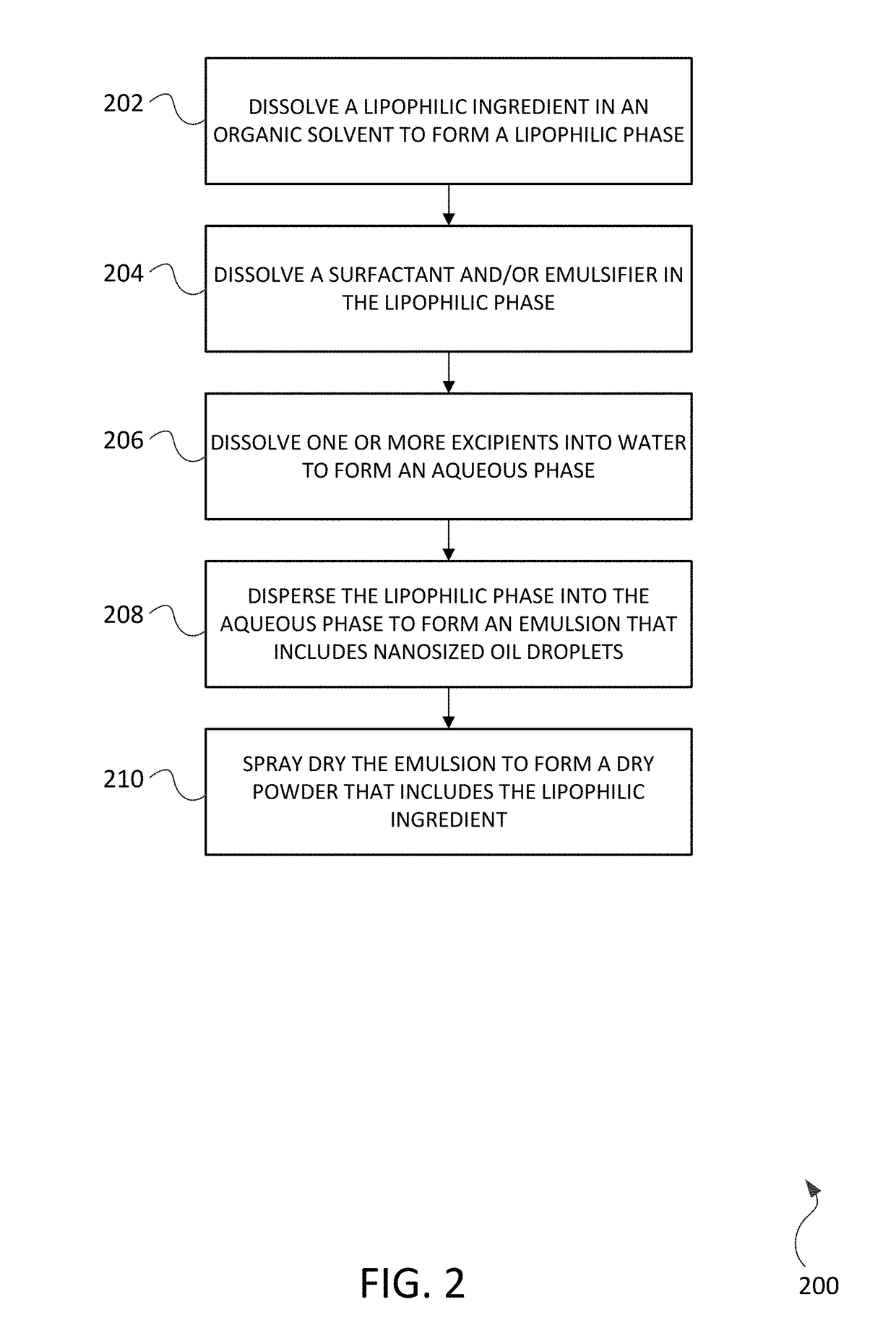

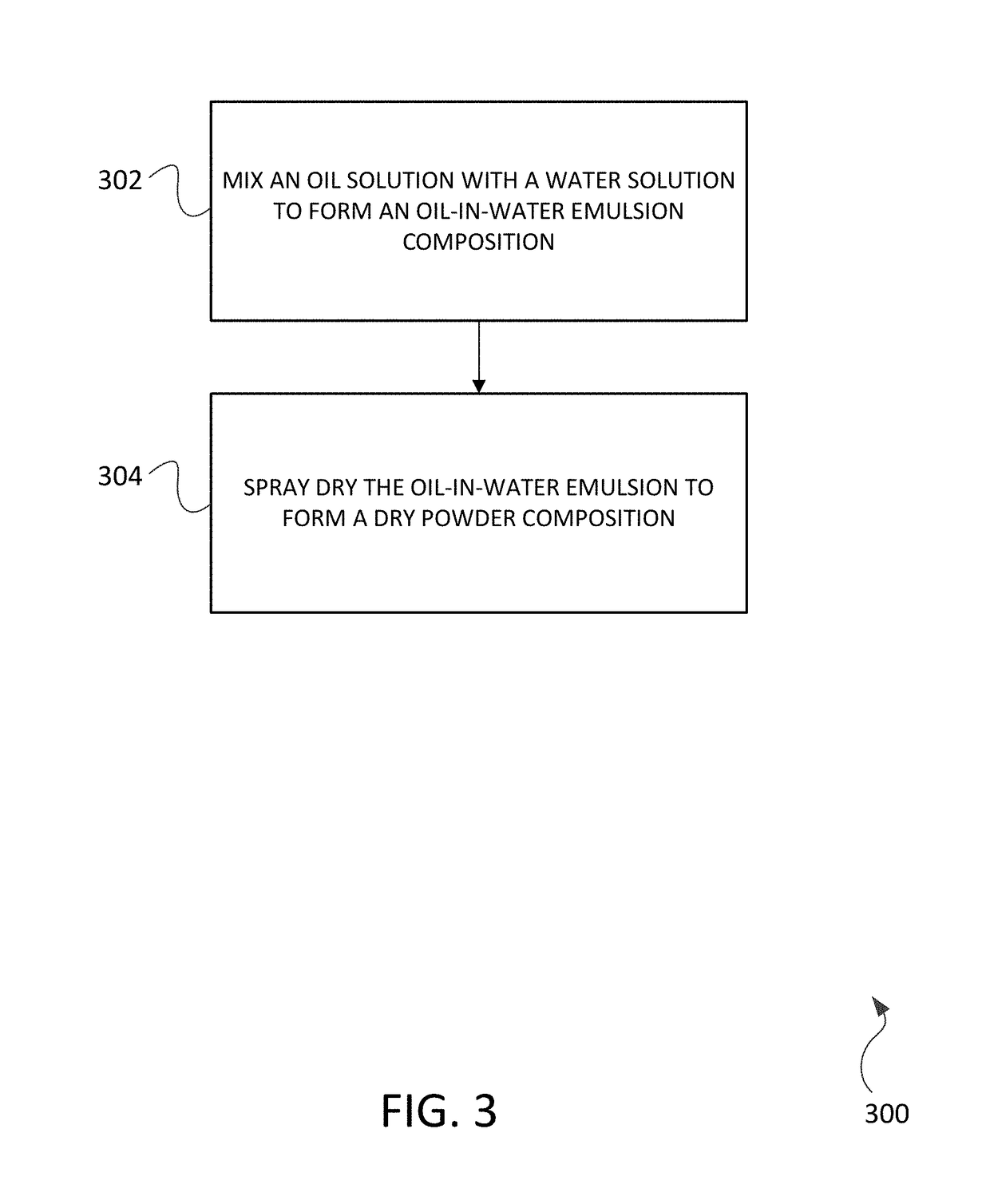

Encapsulation of lipophilic ingredients in dispensible spray dried powders suitable for inhalation

A method of manufacturing a flowable and dispersible powder includes solubilizing a lipophilic substance in a terpene to form a mixture and treating the mixture to form a nanoemulsion dispersed in an aqueous solution. The aqueous solution includes at least one functional excipient. The nanoemulsion is then spray dried, thereby evaporating first the aqueous portion and then the terpene to form a dry powder formed from solid particles comprising the lipophilic substance.

Owner:FLURRY POWDERS LLC

Cleaning liquid dispensing in a mobile hard surface cleaner

A hard surface cleaner includes a motorized scrub head, a fluid recovery device, a primary cleaning liquid component container, a cleaning agent container, a flow control device and a fluid flow path. The flow control device is configured to supply a flow of cleaning agent from the cleaning agent container at a flow rate of less than approximately 10 cubic centimeters per minute to a flow of primary cleaning liquid component from the primary cleaning liquid component container. The fluid flow path is configured to receive a flow of cleaning liquid, which comprises the cleaning agent and the primary cleaning liquid component.A method of dispensing a chemical for use in a mobile hard surface cleaner includes driving a flow of cleaning agent from a cleaning agent container at a flow rate of less than approximately 10 cubic centimeters per minute, supplying a flow of primary cleaning liquid component from a cleaning liquid component container supported by the hard floor surface cleaner, combining the flow of cleaning agent and the flow of primary cleaning liquid component to form a flow of cleaning liquid, and dispensing the flow of cleaning liquid to either a motorized scrub head or a surface under the hard floor surface cleaner.

Owner:TENNANT COMPANY

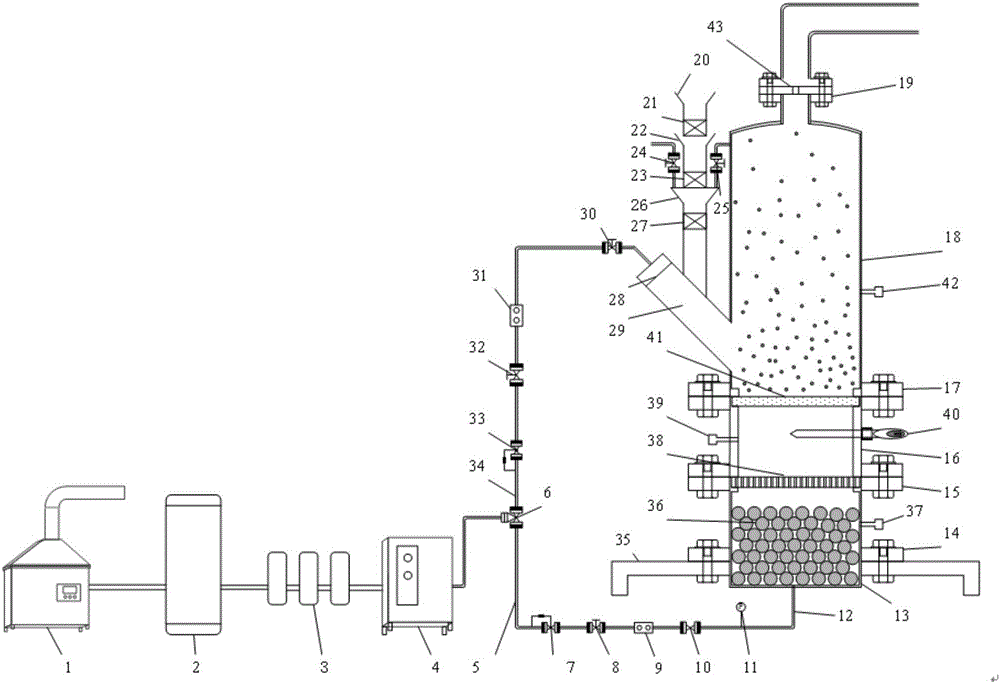

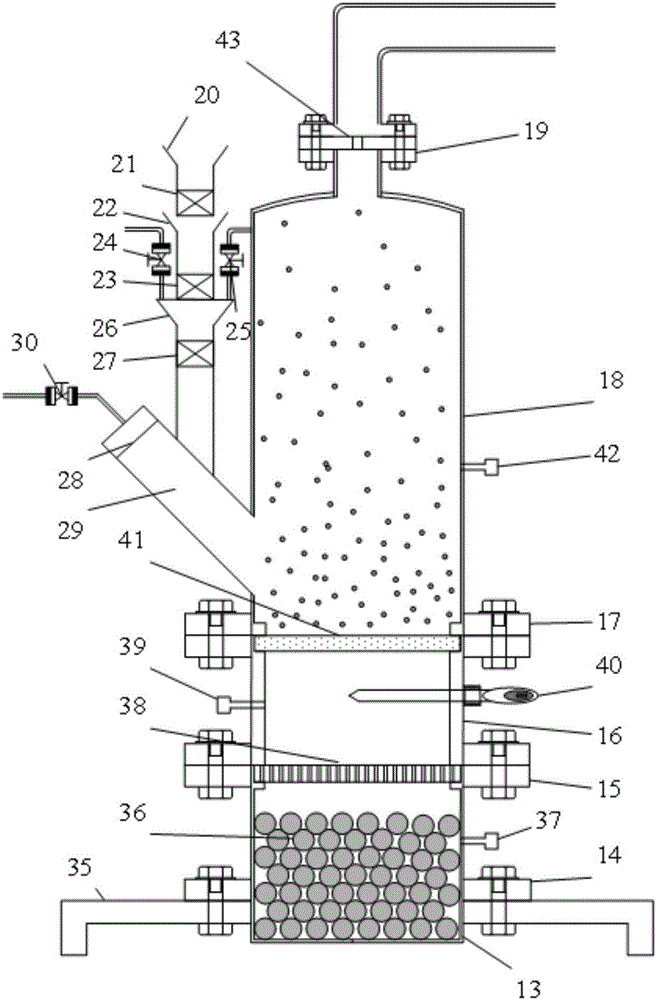

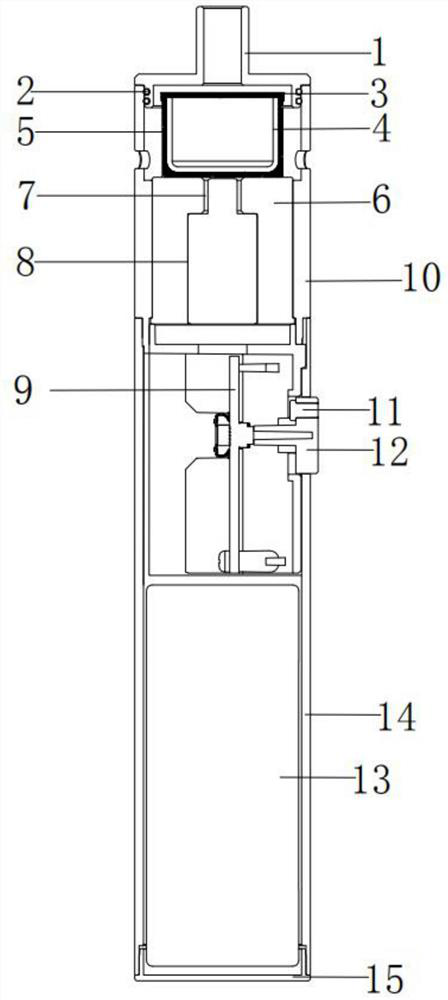

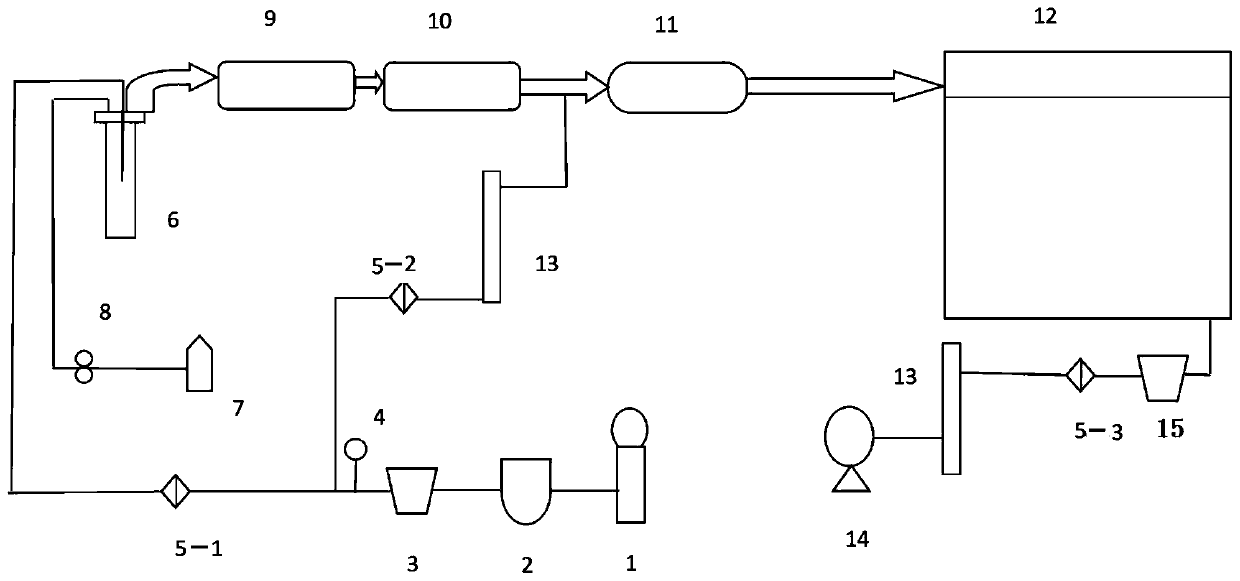

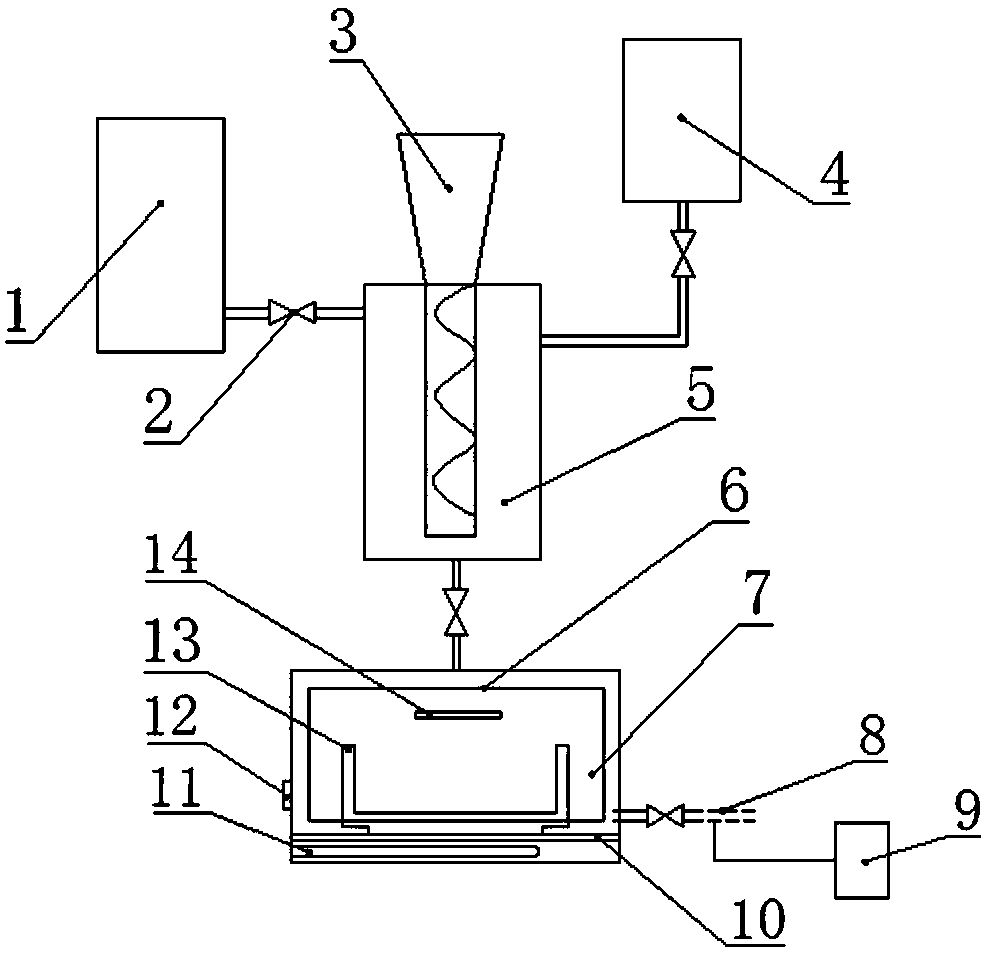

Long-term fluidized aerosol generating device with self-dispersing function

ActiveCN106512872AImprove uniformityAvoid cloggingColloidal chemistry detailsAerosol preparationEngineeringAerosol powder

The invention provides a long-term fluidized aerosol generating device with a self-dispersing function. The long-term fluidized aerosol generating device consists of an airflow supply part, an airflow drying part, a powder ebullition fluidizing part, a powder self-dispersing part and a powder online continuous supply part. Due to the unique design of the airflow drying section and an ebullition fluidizing plate, powder can be in a fluidized state under the action of the bubbling airflow of the fluidizing plate. In the self-dispersing section, part of lumpy powder is further dispersed under the action of high-speed airflow, so that the problems of viscous powder aggregation, clustering, vibrating caking and water absorbing deliquescence are effectively solved, the problems of particle unevenness and powder discharging discontinuity, which occur in the aerosol powder supply process, are effectively avoided, and the even and continuous supply of aerosol powder is ensured.

Owner:HARBIN ENG UNIV

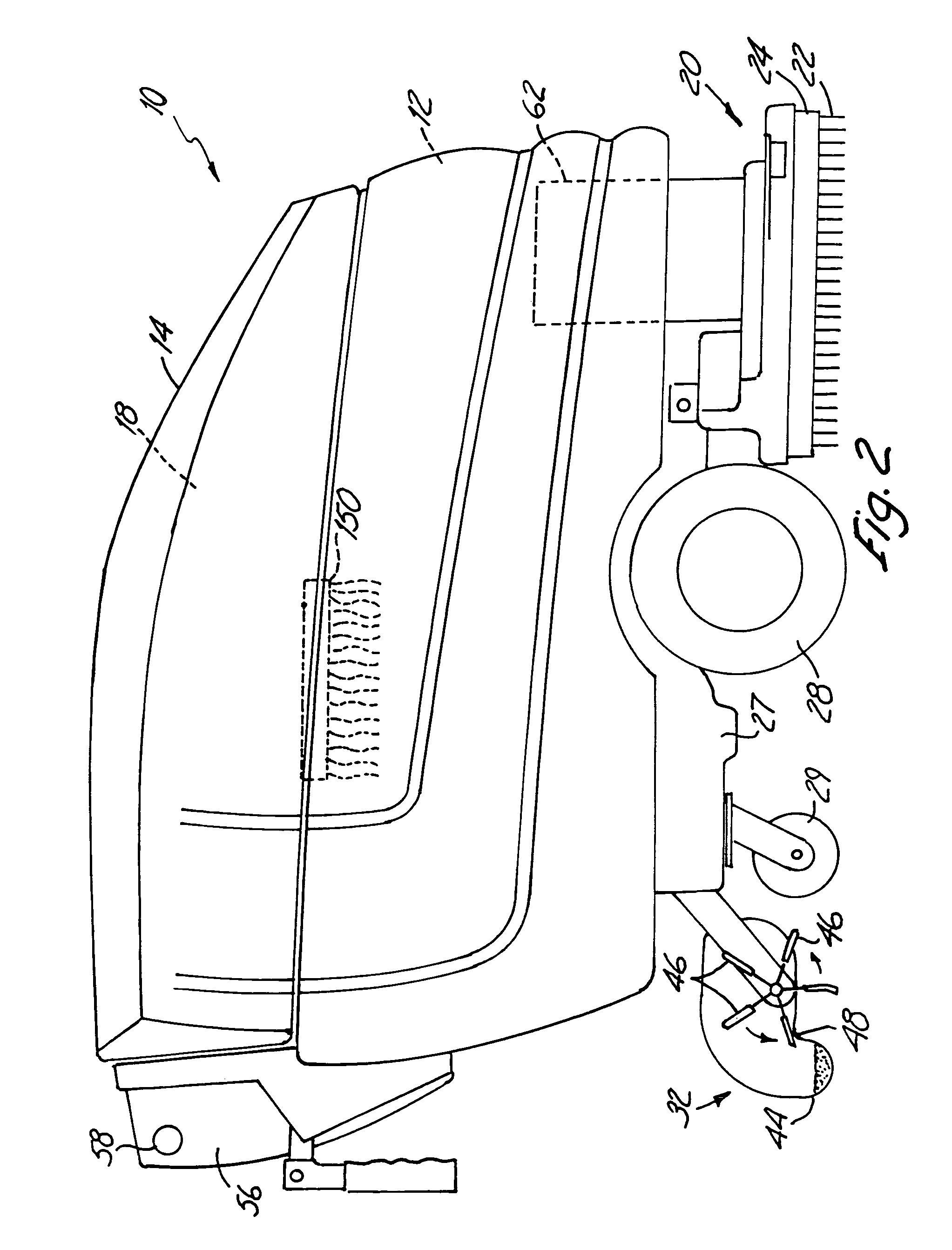

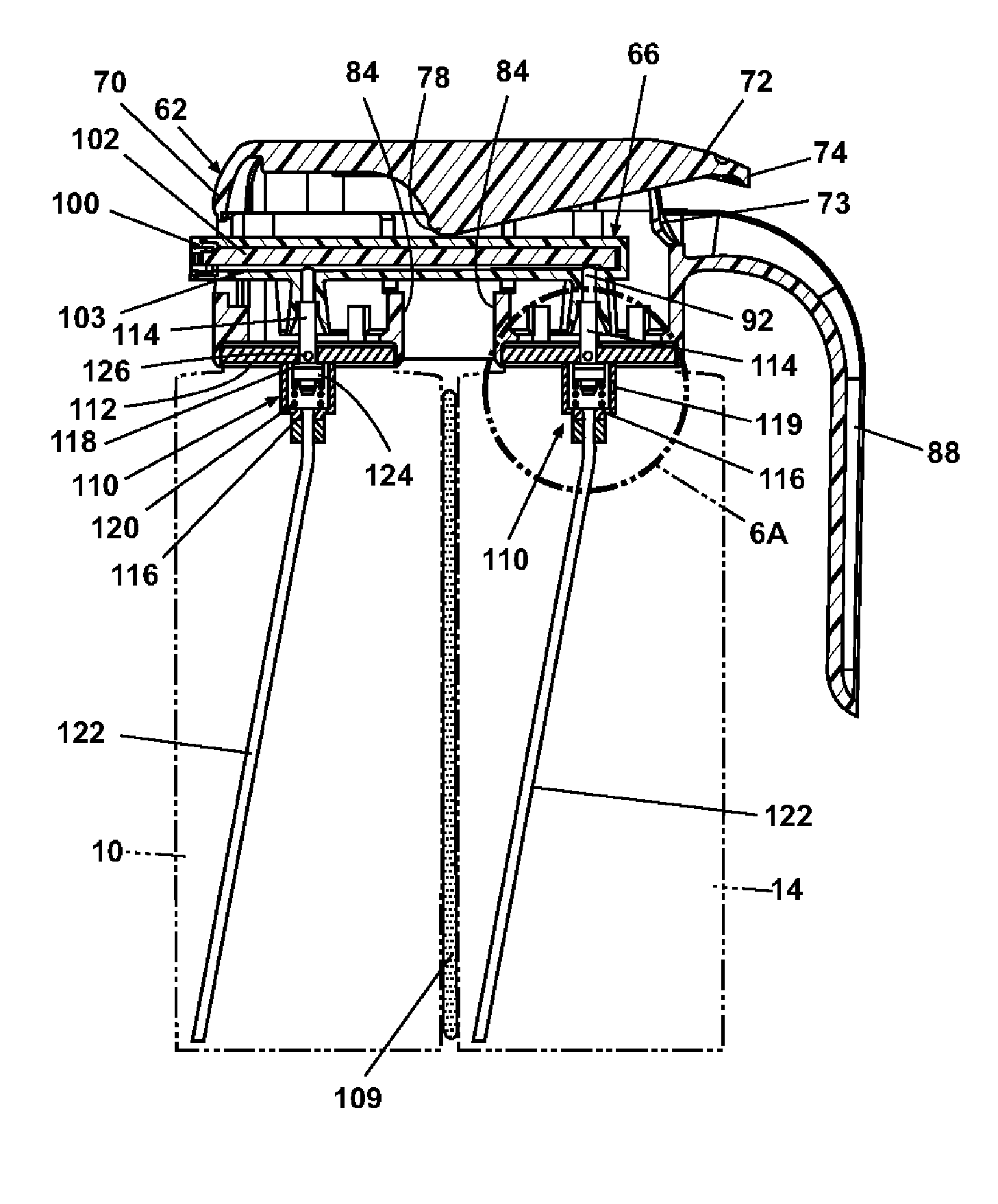

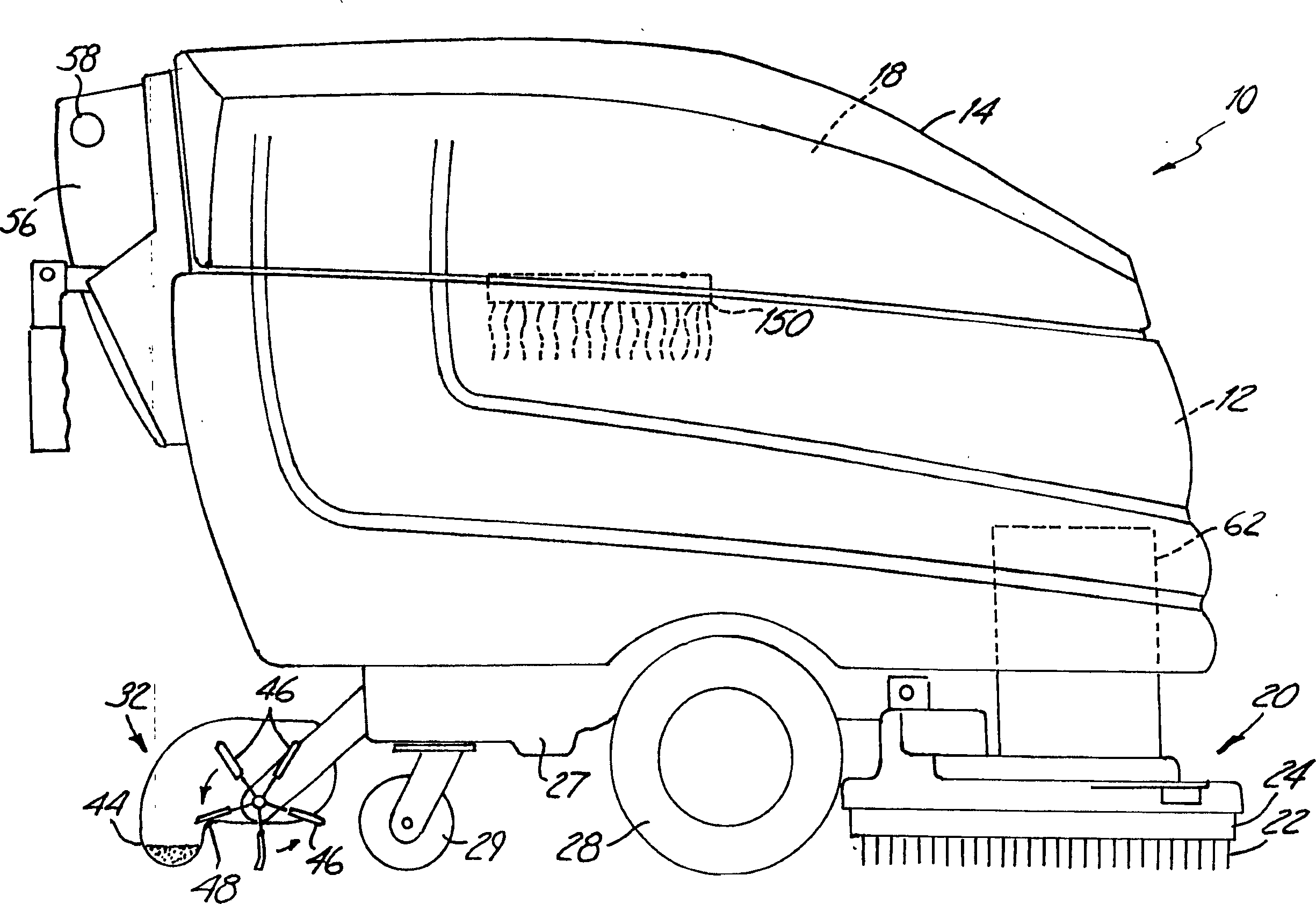

Cleaner cartridge

A cleaner cartridge (150) includes a container (152) having an interior cavity (154), in which cleaning agent can be stored. A first end (158) of conduit (156) is fluidically coupled to the interior cavity. A second end (160) of the conduit is connectable to a chemical dispenser (60).

Owner:TENNANT COMPANY

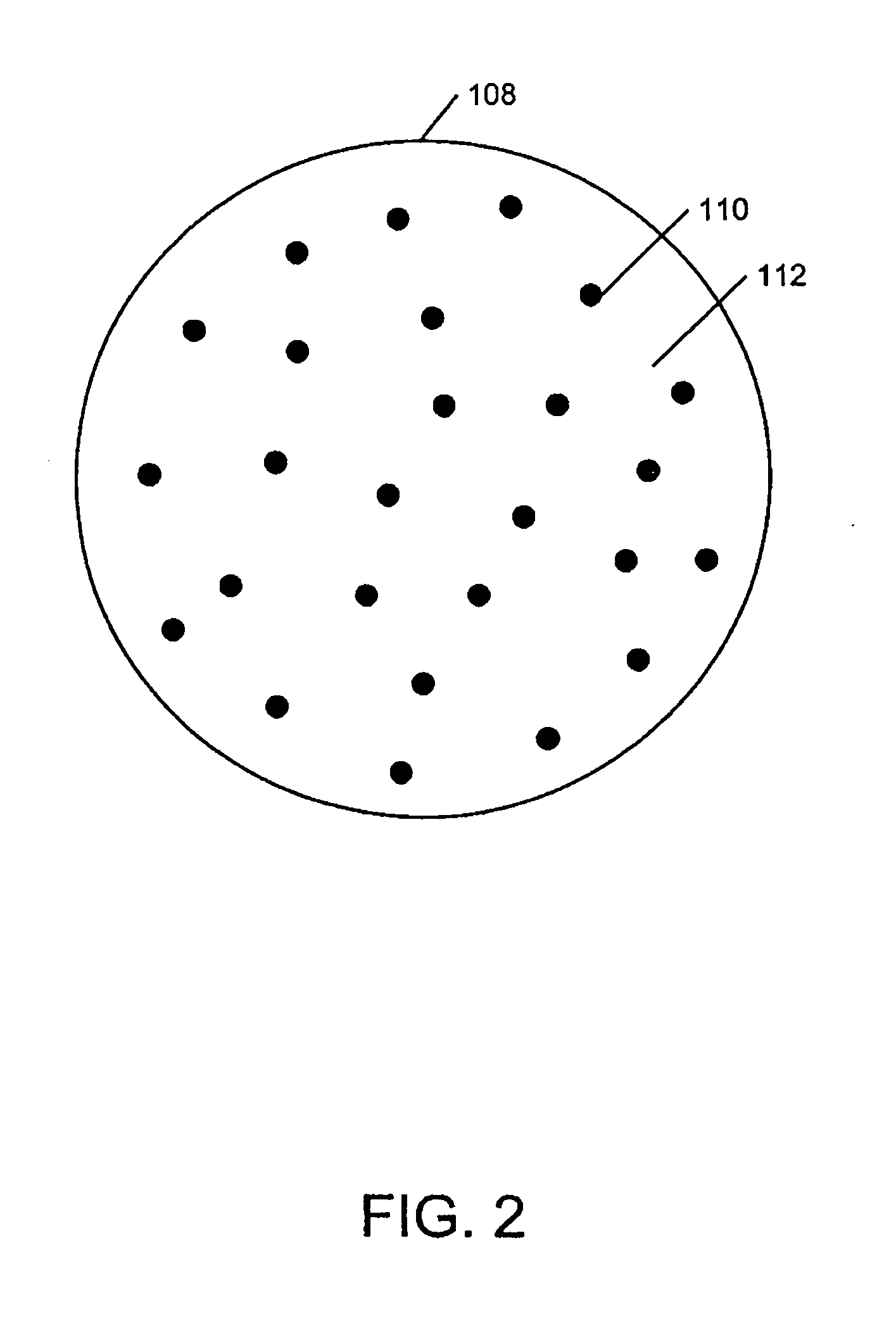

Multi-Component Particles Comprising Inorganic Nanoparticles Distributed in an Organic Matrix and Processes for Making and Using Same

ActiveUS20150307666A1Conductive materialNon-conductive material with dispersed conductive materialGas phaseMaterials science

Multi-component particles comprising inorganic nanoparticles distributed in an organic matrix and processes for making and using same. A flowing aerosol is generated that includes droplets of a precursor medium dispersed in a gas phase. The precursor medium contains a liquid vehicle and at least one precursor. At least a portion of the liquid vehicle is removed from the droplets of precursor medium under conditions effective to convert the precursor to the nanoparticles or the matrix and form the multi-component particles.

Owner:SICPA HLDG SA

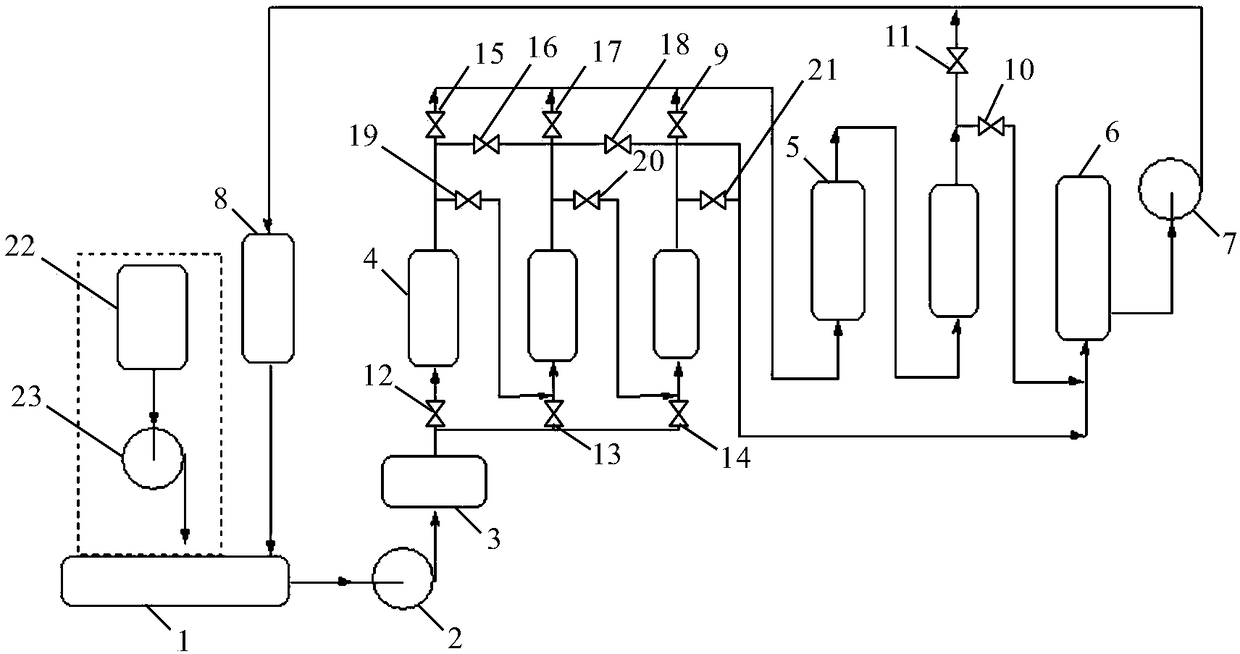

Method for preparing aerogel by supercritical drying method and device for supercritical drying

ActiveCN108636304AHigh strengthImprove hydrophobicityDrying gas arrangementsColloidal chemistry detailsSupercritical dryingPolymer science

The invention relates to a method for preparing aerogel by a supercritical drying method and a device for supercritical drying. The method comprises: placing wet gel containing a solvent in a drying kettle, making a supercritical drying fluid carry a functional modifier, uniformly dispersing the fluid by a homogenizer to supercritically drying the wet gel, and discharging the fluid so that the aerogel is obtained. The device comprises a circulating fluid storage tank for storing a supercritical drying fluid, a chemical reagent storage tank for storing a functional modifier, a pressure pump feeding the fluid into the chemical reagent storage tank, at least one drying kettle with a fluid inlet, at least one separation kettle, a recovery tank, a compression pump and a condenser, and the aboveparts are orderly communicated through a fluid communication method. The condenser is communicated with the circulating fluid storage tank. The homogenizer is arranged at the fluid inlet of the drying kettle. The method and device have high drying efficiency, can ensure uniform distribution of aerogel pore structures and can directly produce functional aerogel.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Hollow sphere metal oxides

Owner:STC UNM

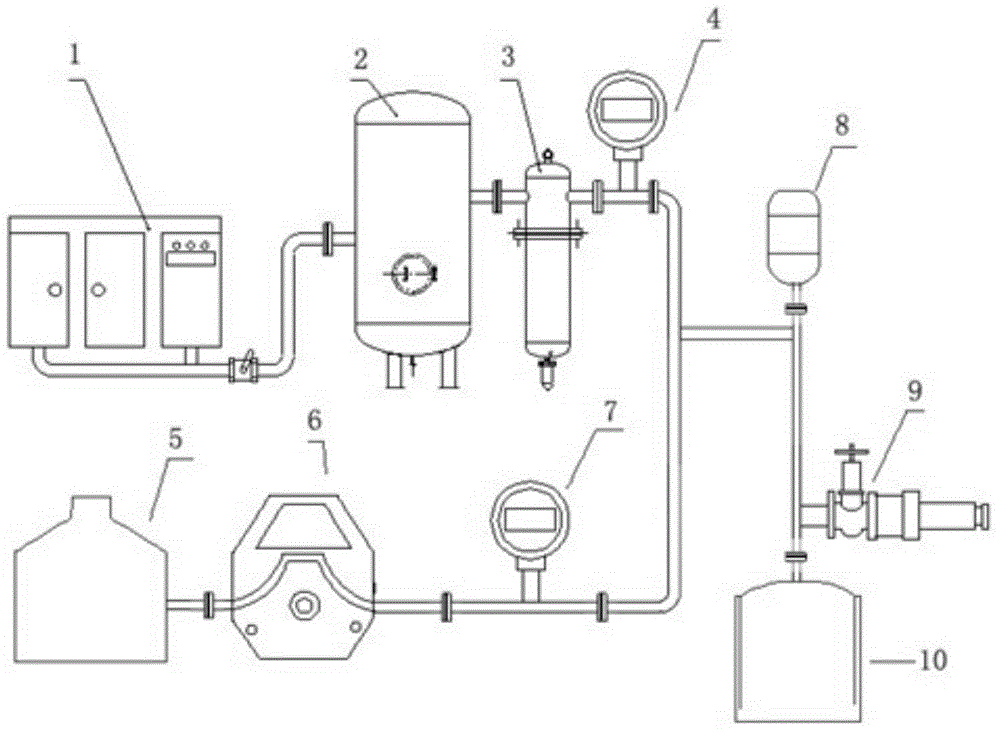

Bisphosphate microbial aerosol generator

InactiveCN104525065AEasy to makeEasy to produceMixing methodsColloidal chemistry detailsAir filterEngineering

The invention discloses a bisphosphate microbial aerosol generator. The bisphosphate microbial aerosol generator comprises an air compressor and an air storage tank, wherein the air compressor is connected with the air storage tank, and the air storage tank is connected with the air filter; a bisphosphate microorganism solution and a storage are connected with a liquid peristaltic pump, an air filter and the liquid peristaltic pump are connected with an aerodynamic sprayer and an aerosol generating device, and the aerodynamic sprayer and the aerosol generating device are connected with an aerosol recycling device; the air filter is also connected with an air rotor flow meter; the liquid peristaltic pump is also connected with a liquid flow meter; and the aerodynamic sprayer and the aerosol generating device are connected with a sampling controller. The bisphosphate microbial aerosol generator is applicable to simulated generation and preparation of experimental microbial aerosol and is frequently applied to preparation of a microbial aerosol animal model and research on microbial aerosol animal infection dosage, microbial aerosol survival recovery rate, an aerosol tracer agent, contrast between natural microbial aerosol and simulated microbial aerosol and the like.

Owner:SECOND AFFILIATED HOSPITAL OF COLLEGE OF MEDICINEOF XIAN JIAOTONG UNIV

Catalyst particle and method for producing thereof

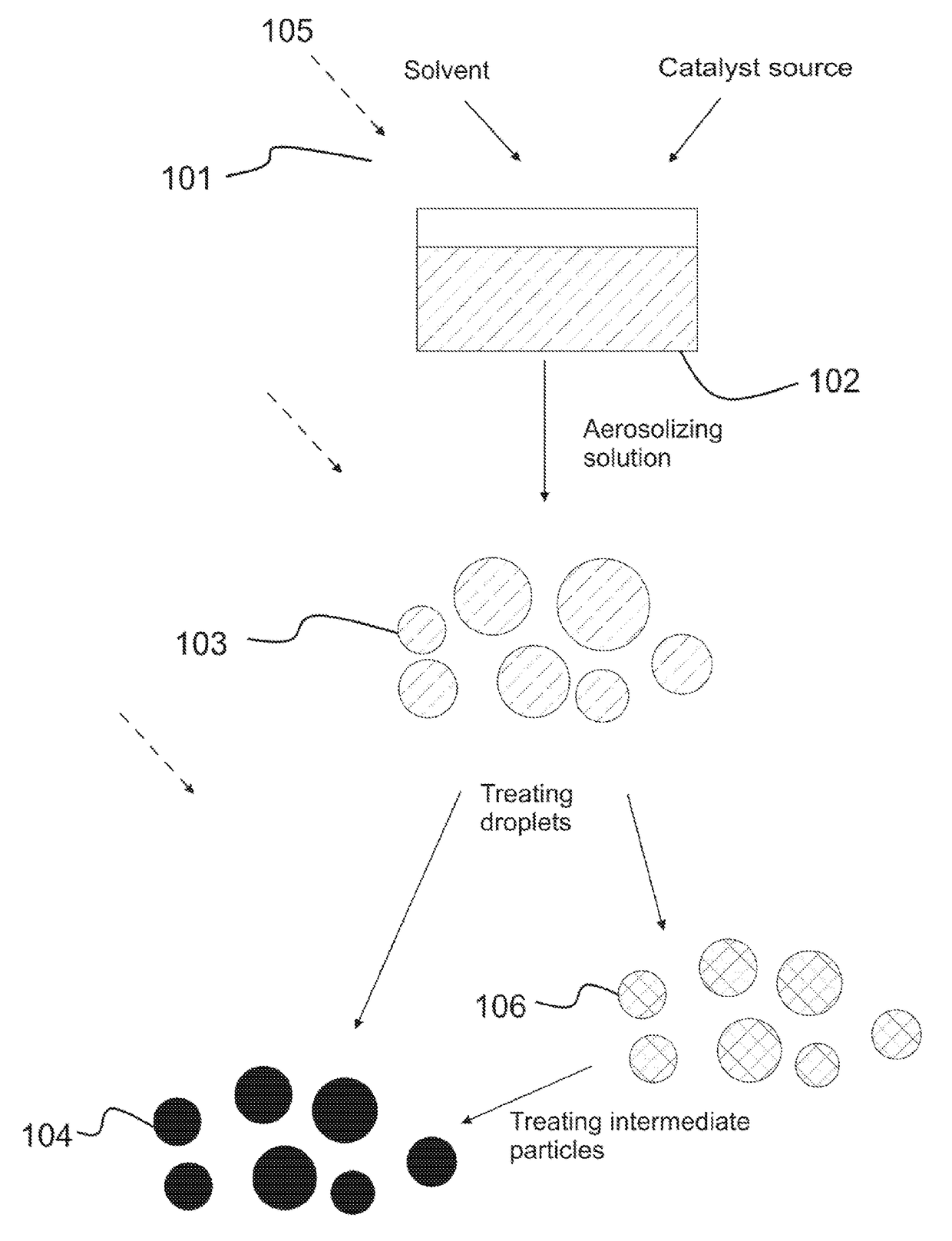

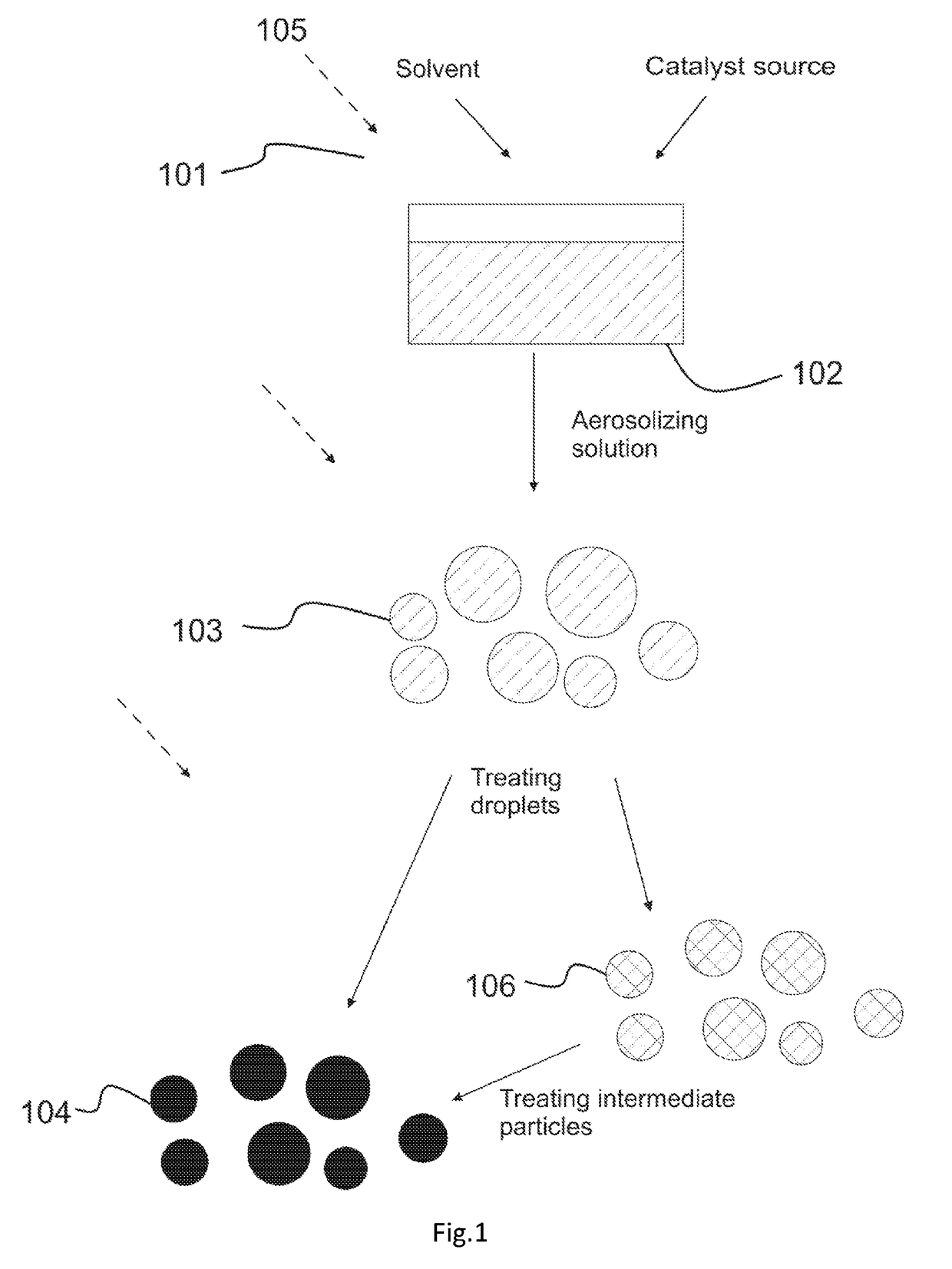

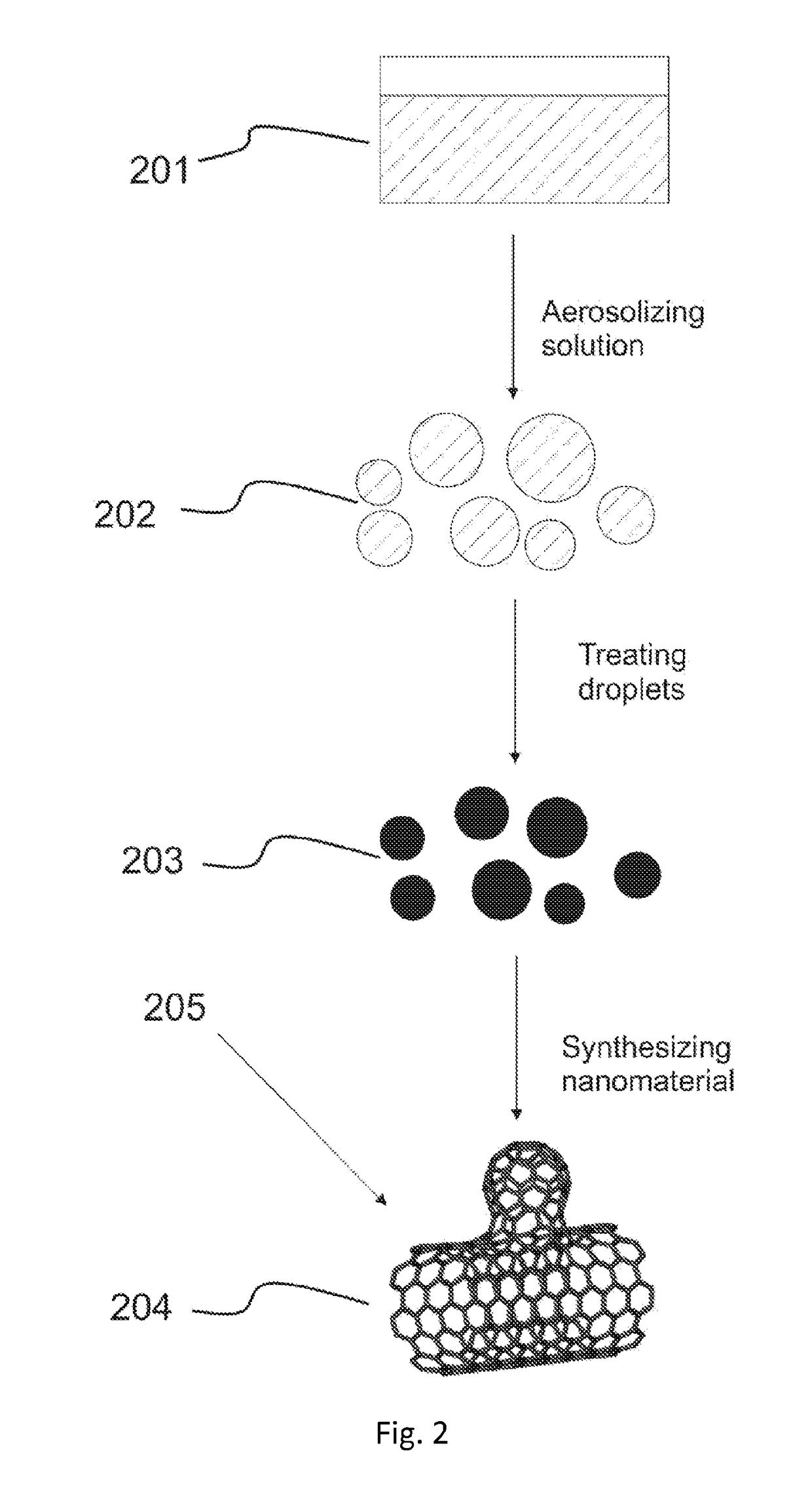

InactiveUS20170113213A1Increased and decreased solubilityMaterial nanotechnologyDrying solid materials with heatSolventForm solution

A method for producing catalyst particles is disclosed and includes forming a solution including a solvent and a material including catalyst material, wherein the material including catalyst material is dissolved or emulsified in the solvent; aerosolizing the formed solution to produce droplets including the material including catalyst material; and treating the droplets to produce catalyst particles or intermediate catalyst particles from the material including catalyst material comprised in the droplets. A method for producing nanomaterials, an apparatus, a catalyst particle and a solution droplet for the production of a catalyst particle are also disclosed.

Owner:CANATU OY

Aerosol gels

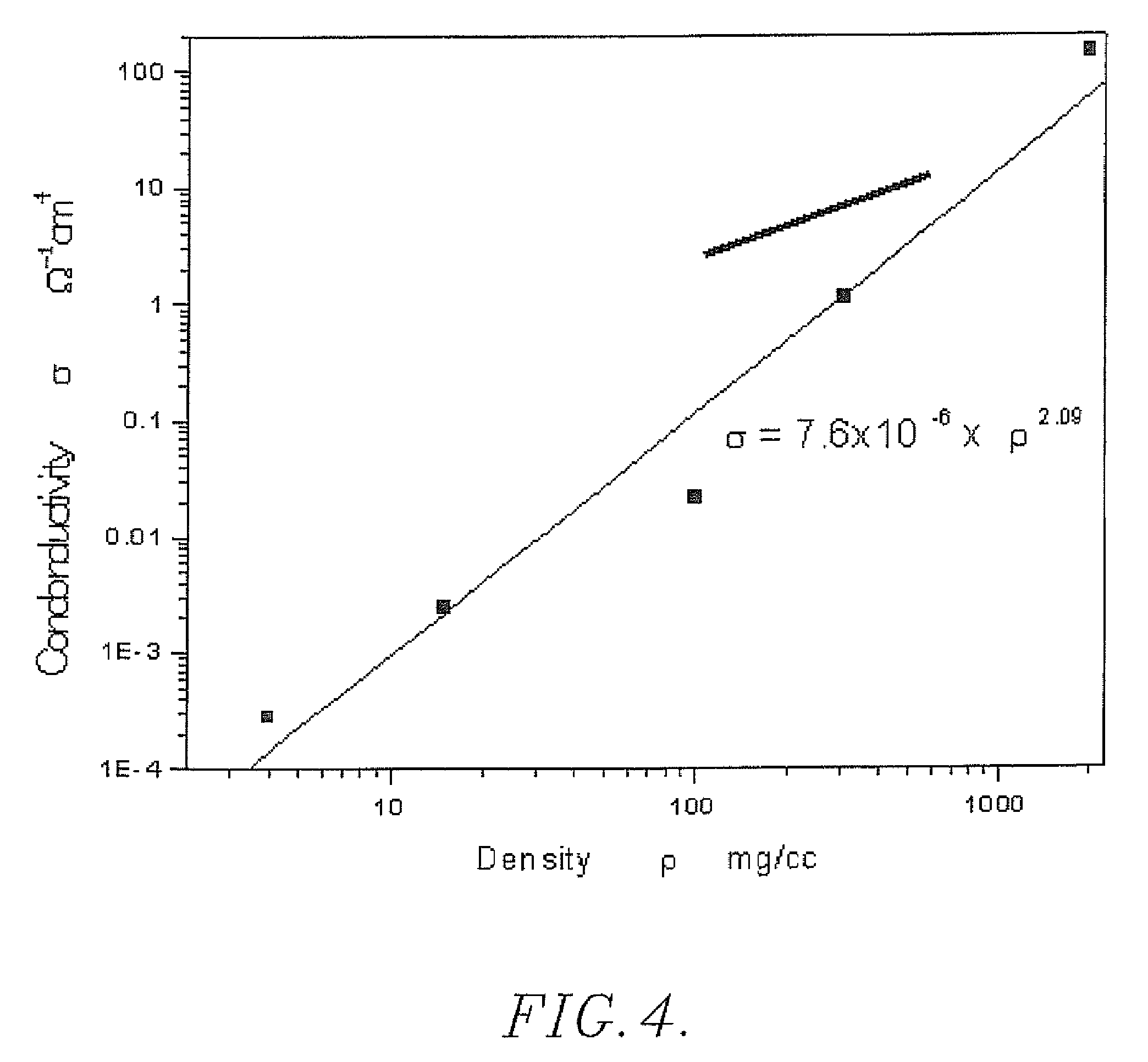

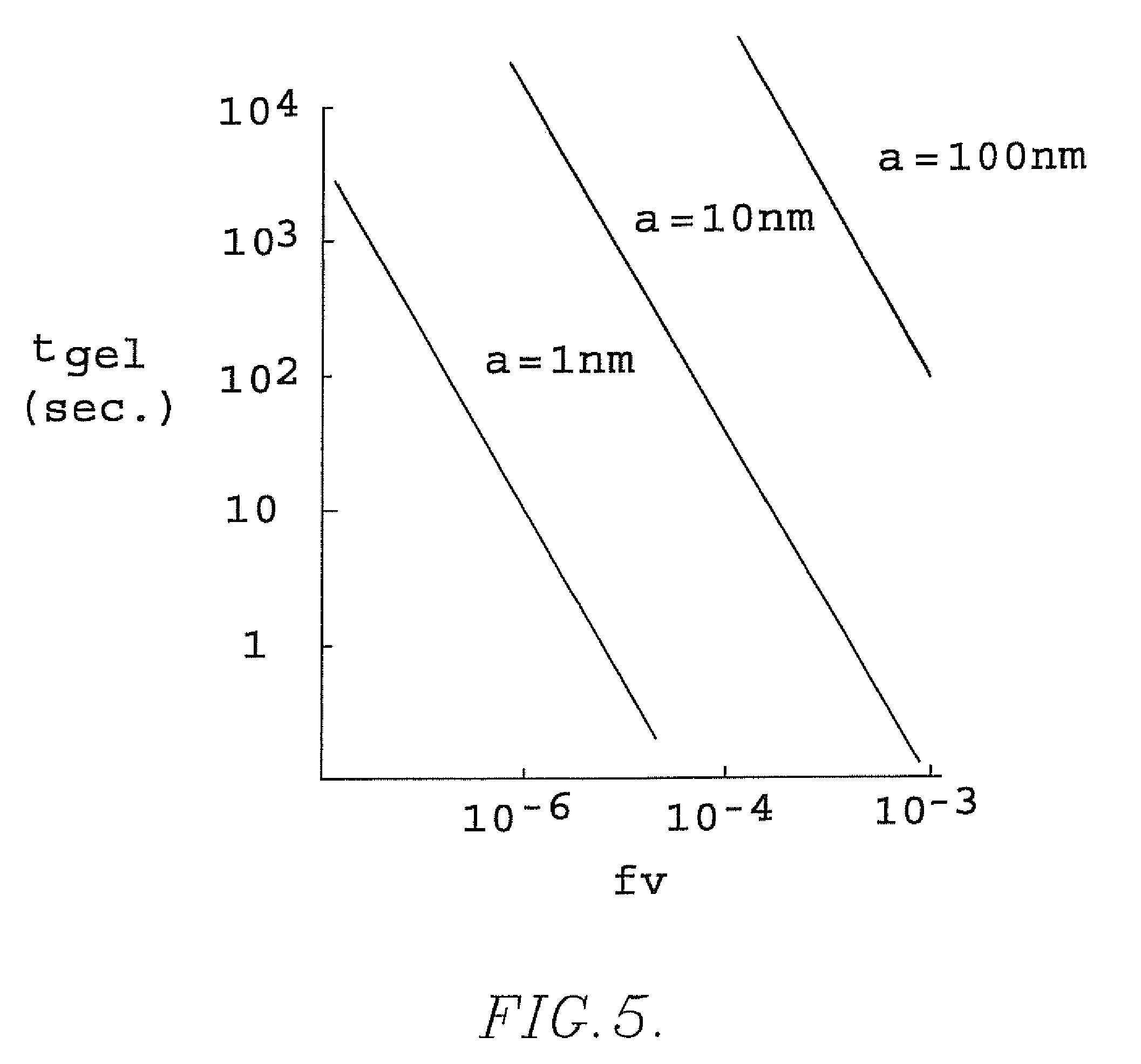

An improved process for the production of ultralow density, high specific surface area gel products is provided which comprises providing, in an enclosed chamber, a mixture made up of small particles of material suspended in gas; the particles are then caused to aggregate in the chamber to form ramified fractal aggregate gels. The particles should have a radius (a) of up to about 50 nm and the aerosol should have a volume fraction (fv) of at least 10−4. In preferred practice, the mixture is created by a spark-induced explosion of a precursor material (e.g., a hydrocarbon) and oxygen within the chamber. New compositions of matter are disclosed having densities below 3.0 mg / cc.

Owner:KANSAS STATE UNIV RES FOUND

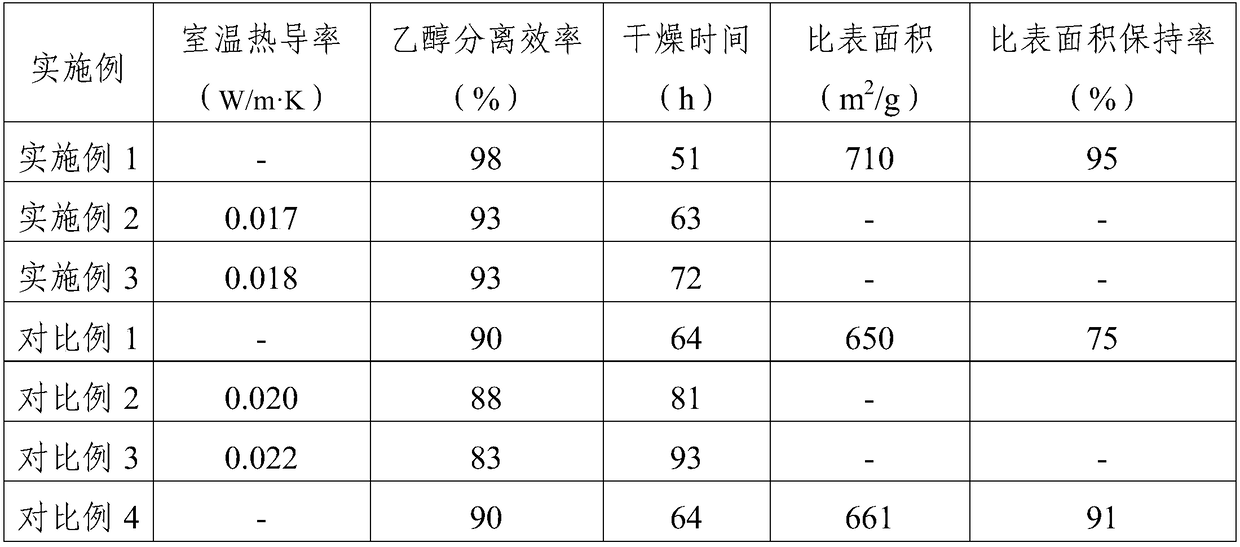

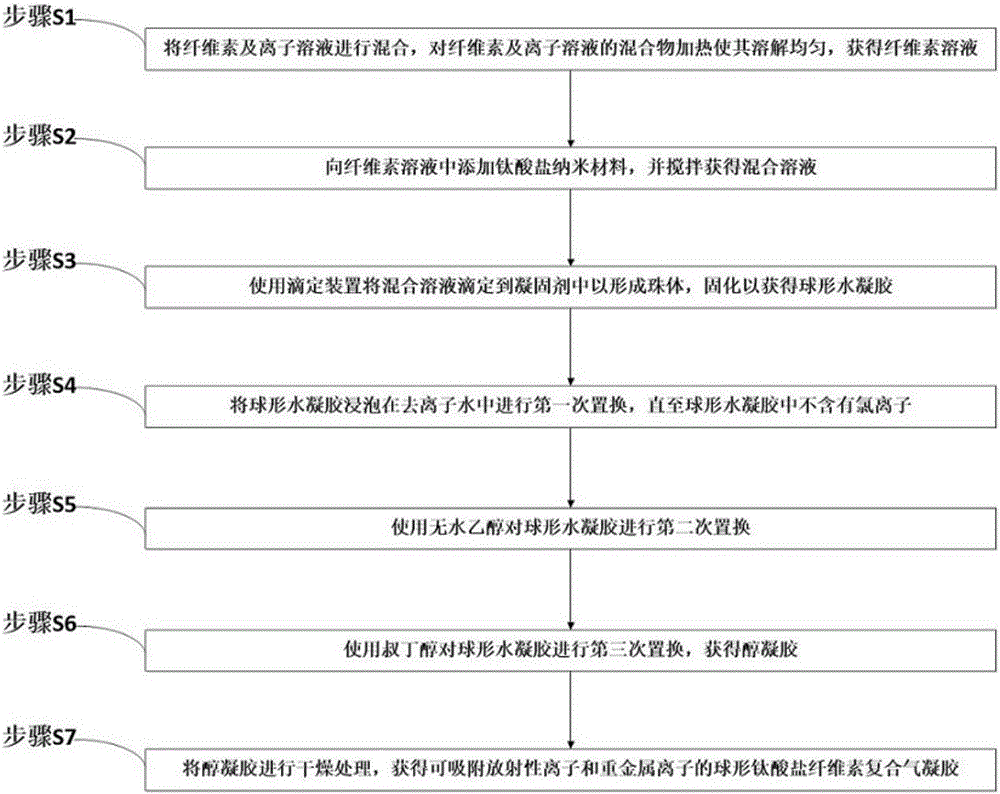

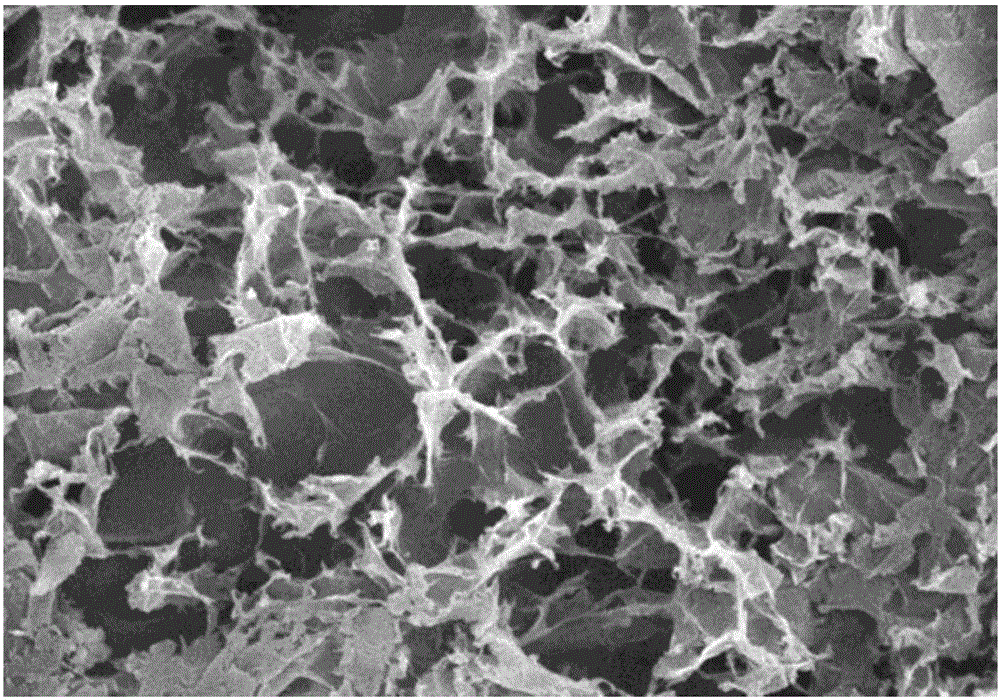

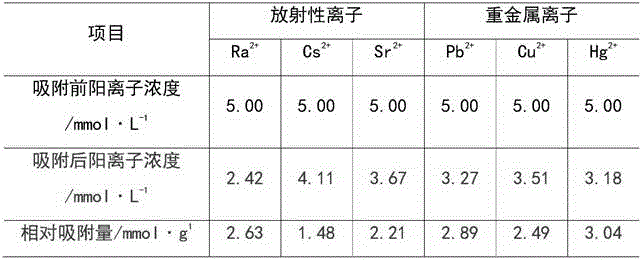

Preparation method of spherical titanate cellulose composite aerogel capable of adsorbing radioactive ions and heavy metal ions

InactiveCN106512957AFast co-captureQuick snapOther chemical processesRadioactive contaminantsCelluloseIon exchange

The invention belongs to the technical field of aerogel materials, and relates to a preparation method for spherical titanate cellulose composite aerogel capable of adsorbing radioactive ions and heavy metal ions. Cellulose composite aerogel in which a titanate nano material is loaded is formed by combining the titanate nano material with cellulose. According to the preparation method for the spherical titanate cellulose composite aerogel capable of adsorbing the radioactive ions and the heavy metal ions, with a large specific surface area and certain shape and appearance, the prepared spherical titanate cellulose composite aerogel can quickly capture the radioactive ions and the heavy metal ions in water, and is also favorable for solid-liquid separation to fulfill the aim of safe post-treatment. The spherical titanate cellulose composite aerogel prepared by the method internally fixes the radioactive ions such as Ra<2+>, Cs<2+> and Sr<2+> and the heavy metal ions such as Pb<2+>, Cu<2+> and Hg<2+> through ion exchange.

Owner:ZHEJIANG FORESTRY UNIVERSITY

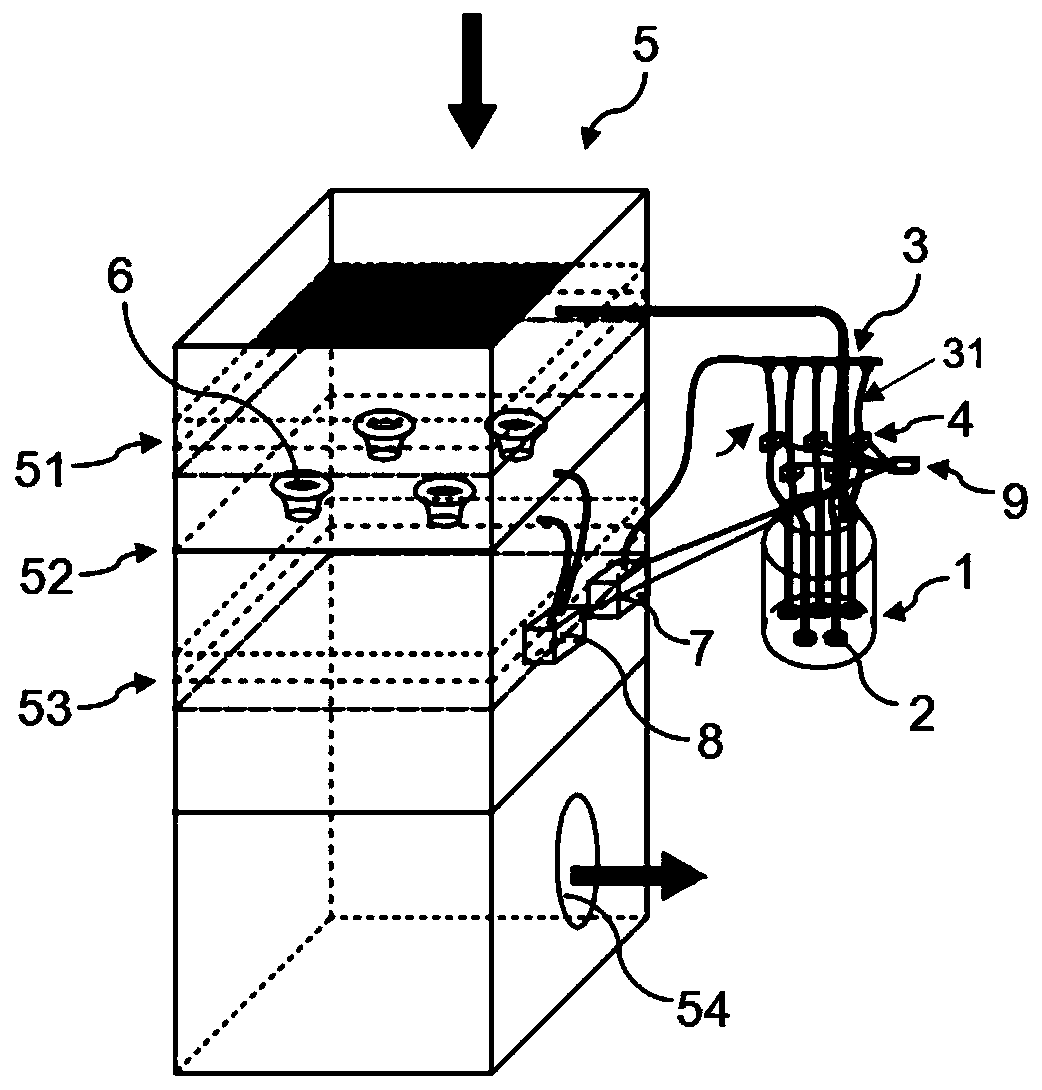

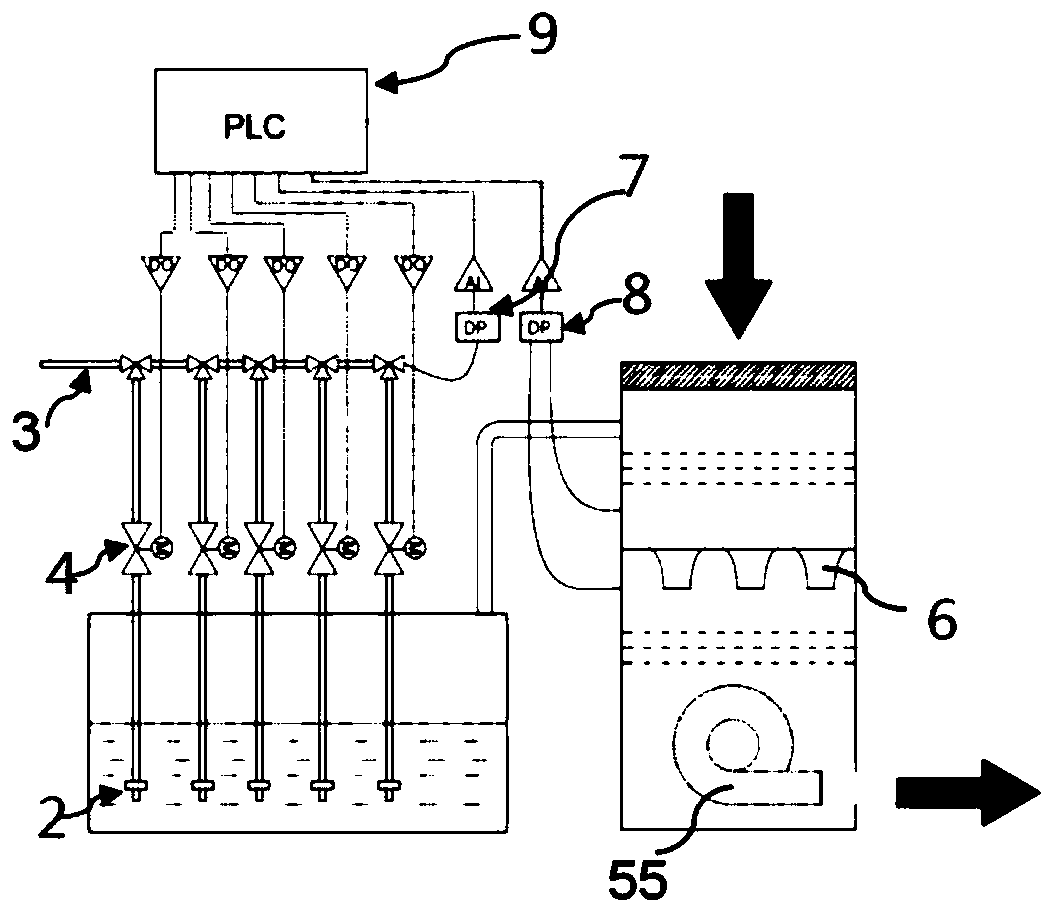

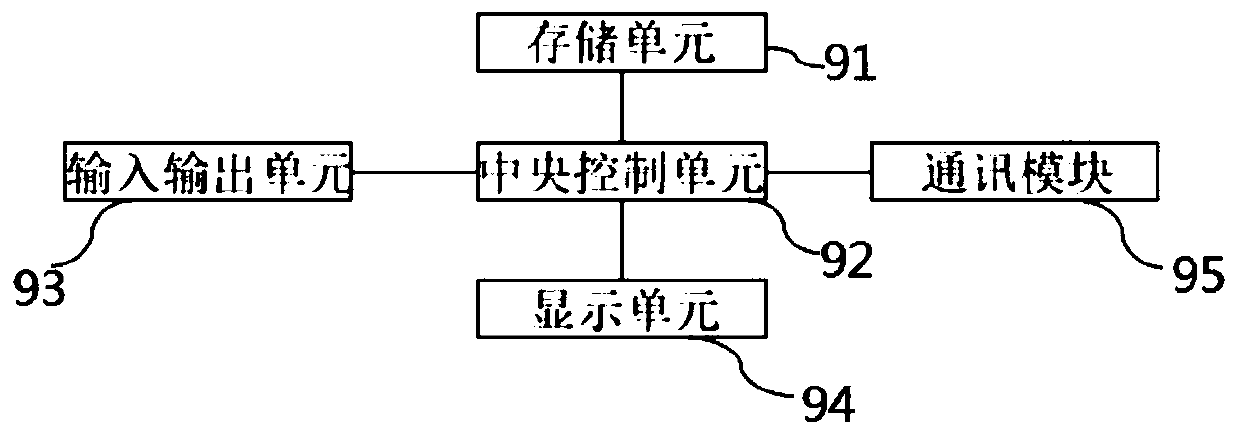

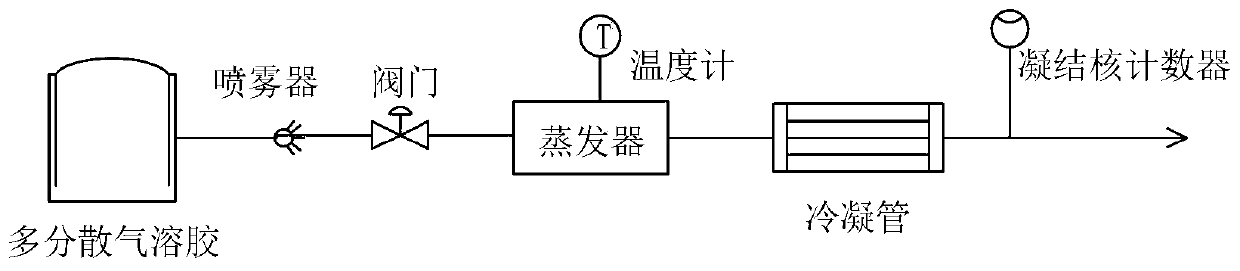

Aerosol generating apparatus

ActiveCN111185127AIncrease productionPreparing sample for investigationColloidal chemistry detailsLiquid storage tankEngineering

The invention belongs to the field of filter detection, and provides an aerosol generating apparatus. The apparatus comprises an aerosol liquid storage tank, at least two nozzles, at least two electromagnetic valves, a compressed air pressure sensor, a flow nozzle pressure difference sensor, a fan box and a control part, wherein the compressed air pressure sensor is used for testing the pressure of compressed air; the flow nozzle pressure difference sensor tests pressure difference between two ends of a flow nozzle; the control part is in communication connection with the compressed air sensor, the flow nozzle pressure difference sensor and the electromagnetic valves. The control part calculates the number of the electromagnetic valves needing to be opened according to the pressure of thecompressed air and the pressure difference between the two ends of the flow nozzle so as to control the opening of the electromagnetic valves. Due to the fact that the number of the opened electromagnetic valves can control the generation intensity of aerosol and the number of the electromagnetic valves needing to be opened can be rapidly calculated, the particle concentration of the front end ofa detected filter can be stably and rapidly achieved, and the advantages of stablity, rapidness, convenience to use and visuality are achieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

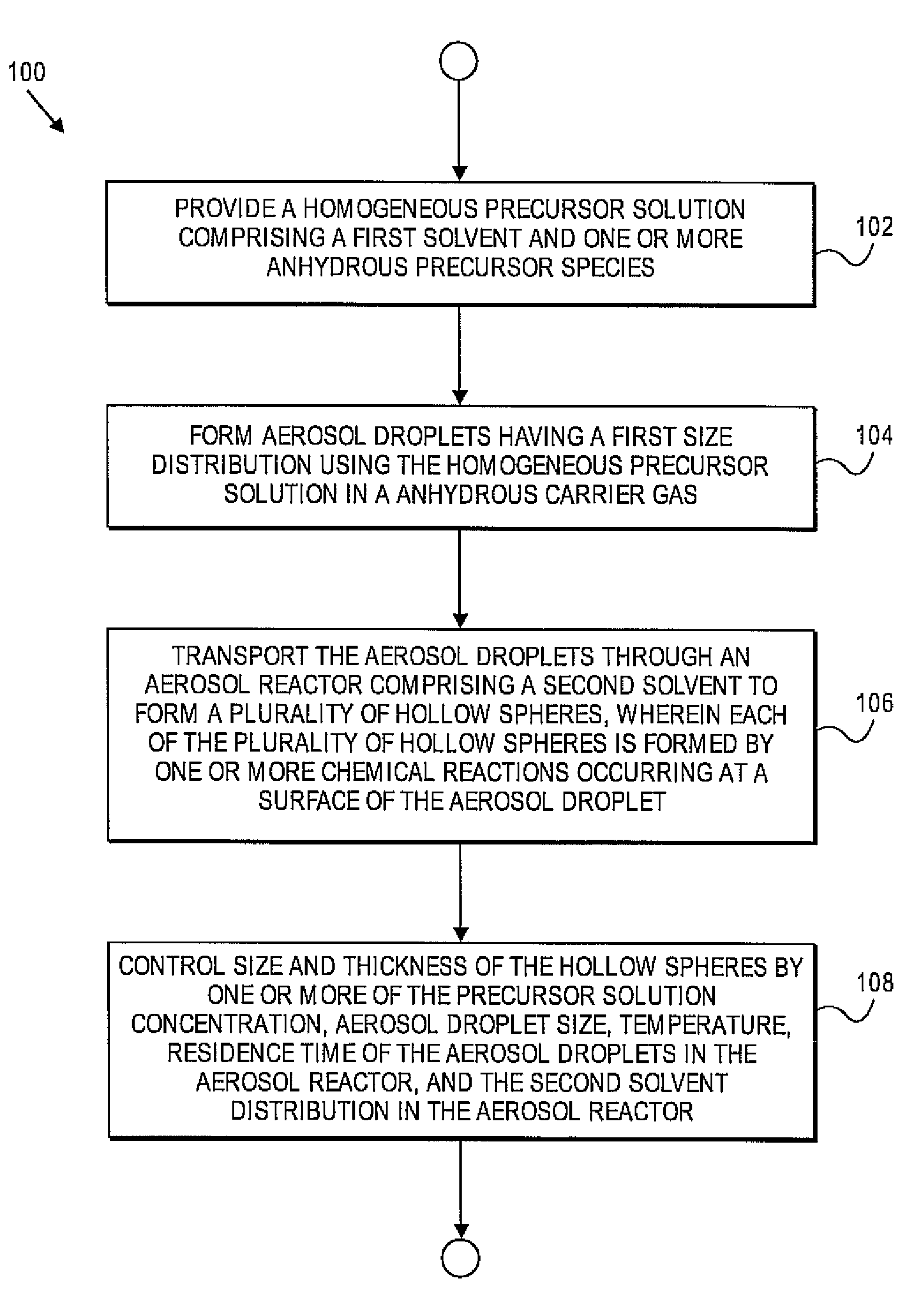

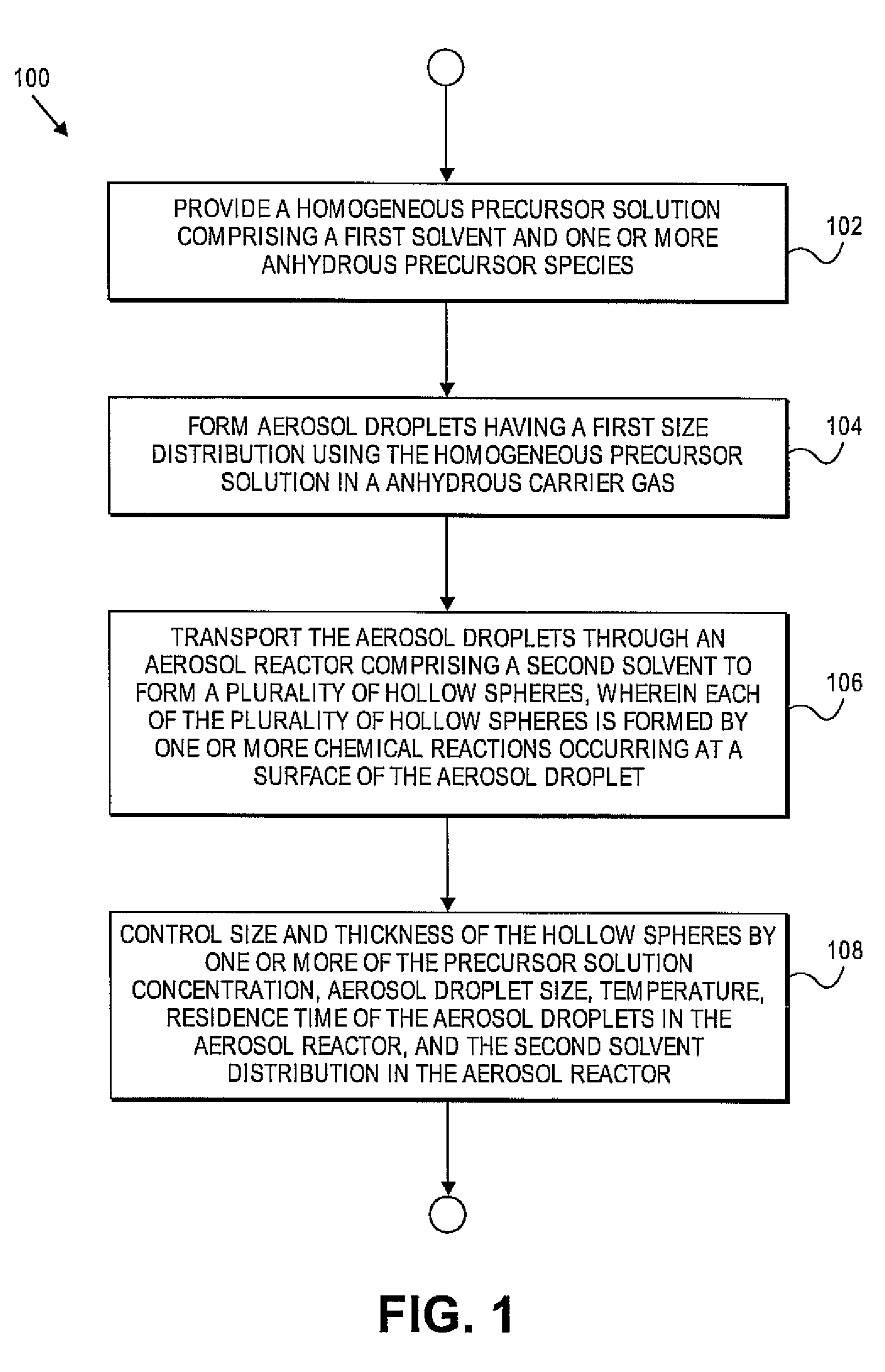

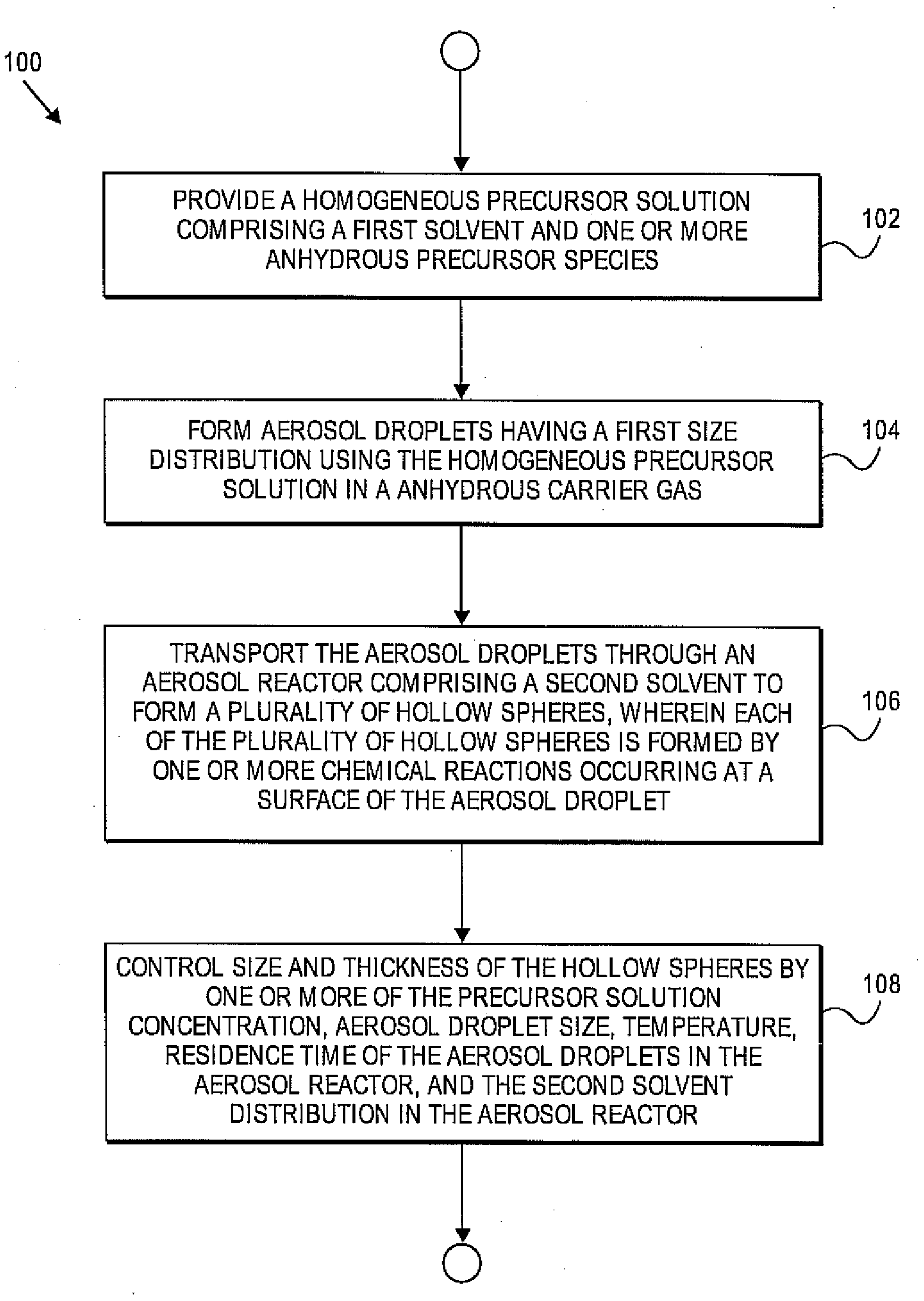

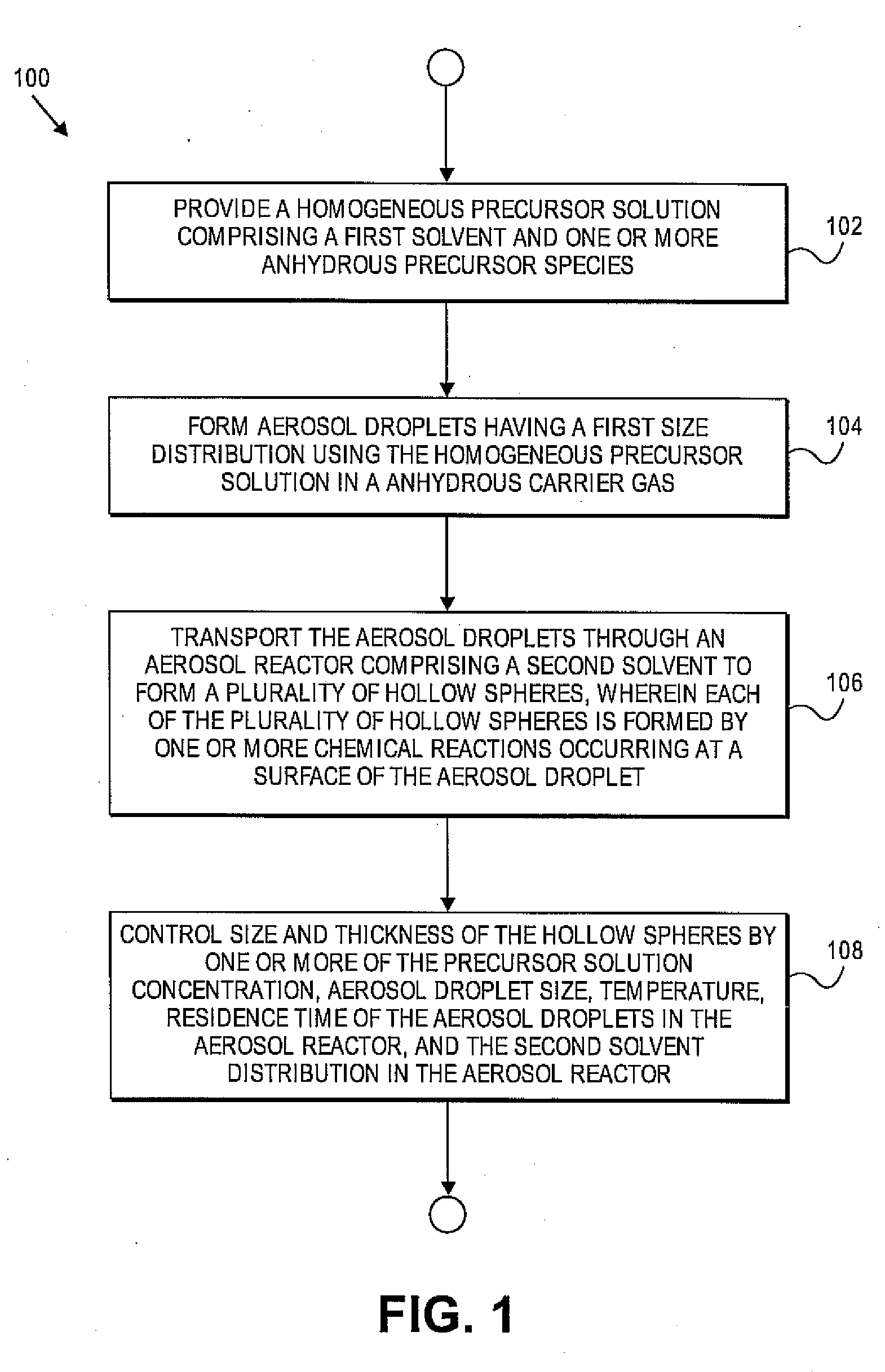

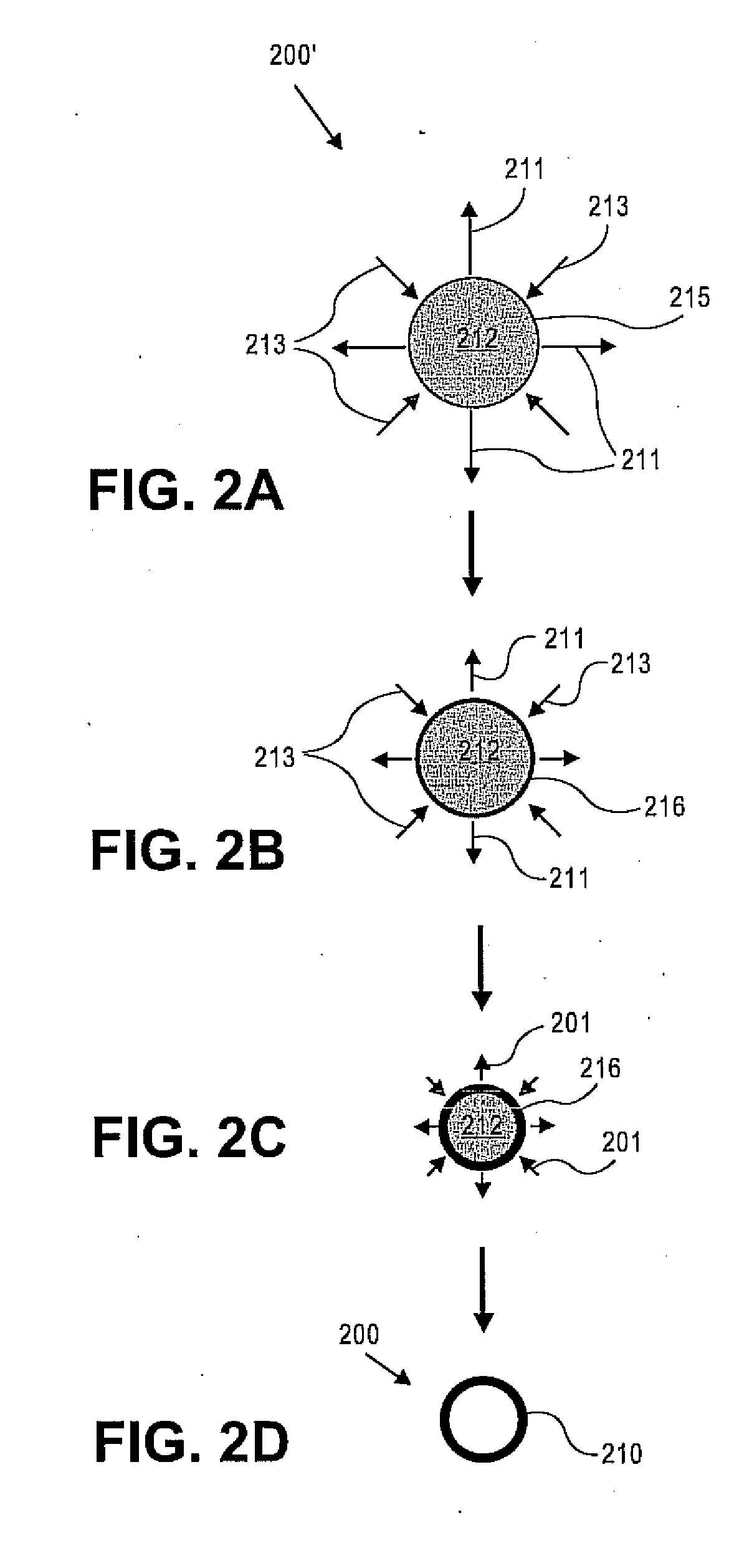

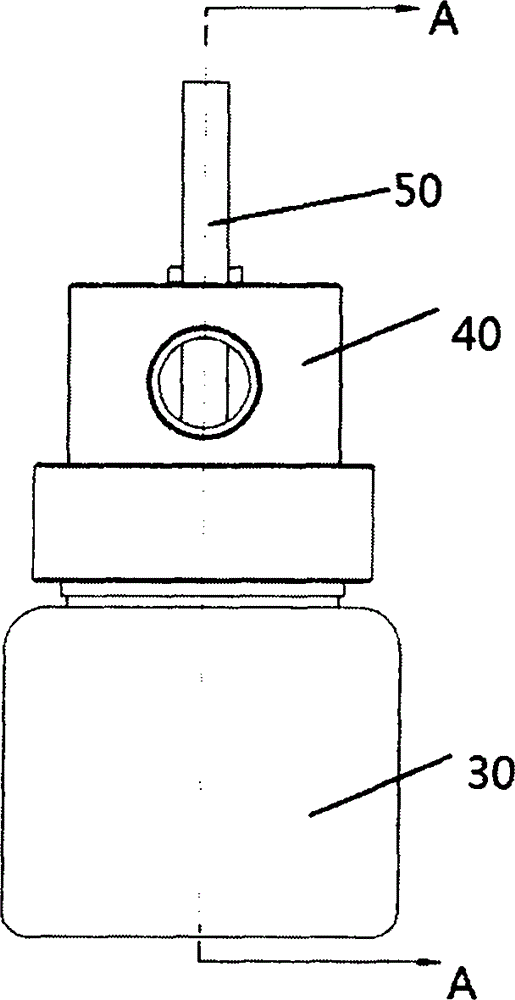

Hollow sphere metal oxides

In accordance with invention, there are methods for fabricating hollow spheres and nanofoams. The method for making hollow spheres can include providing a homogeneous precursor solution including a first solvent and one or more anhydrous precursor species and forming aerosol droplets having a first size distribution using the homogeneous precursor solution in an anhydrous carrier gas. The method can also include transporting the aerosol droplets through an aerosol reactor including a reactant to form a plurality of hollow spheres, wherein each of the plurality of hollow spheres can be formed by one or more chemical reactions occurring at a surface of the aerosol droplet. The method can further include controlling size and thickness of the hollow spheres by one or more of the precursor solution concentration, aerosol droplet size, temperature, residence time of the aerosol droplets in the aerosol reactor, and the reactant distribution in the aerosol reactor.

Owner:STC UNM

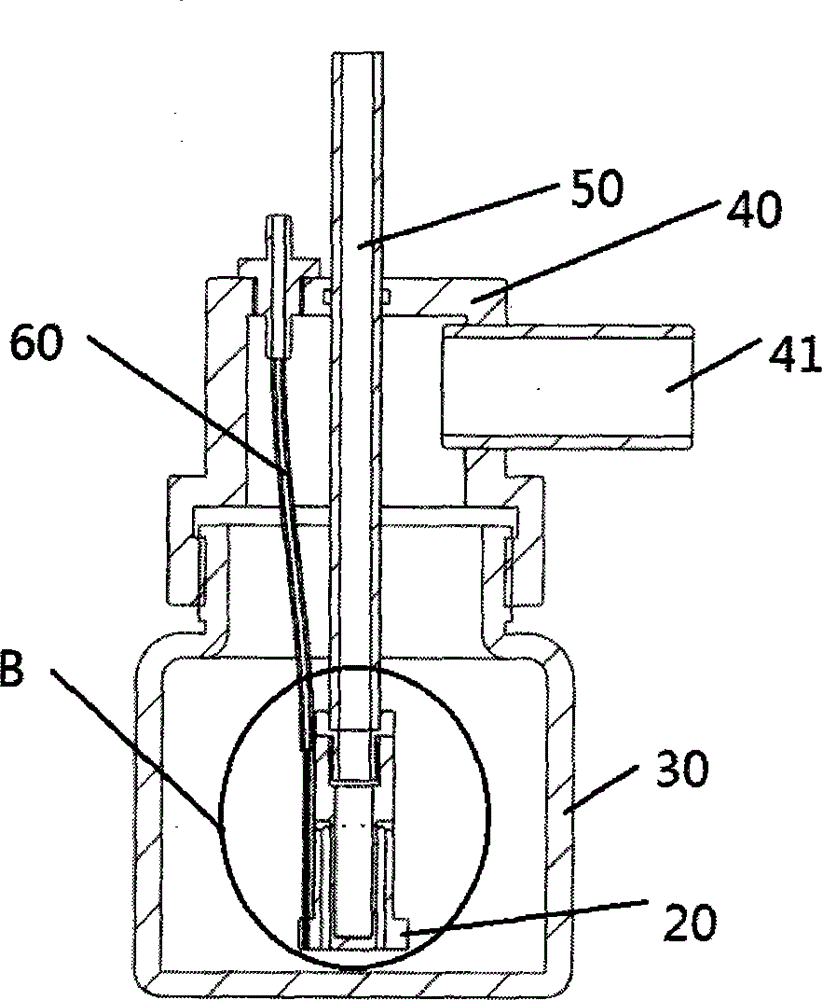

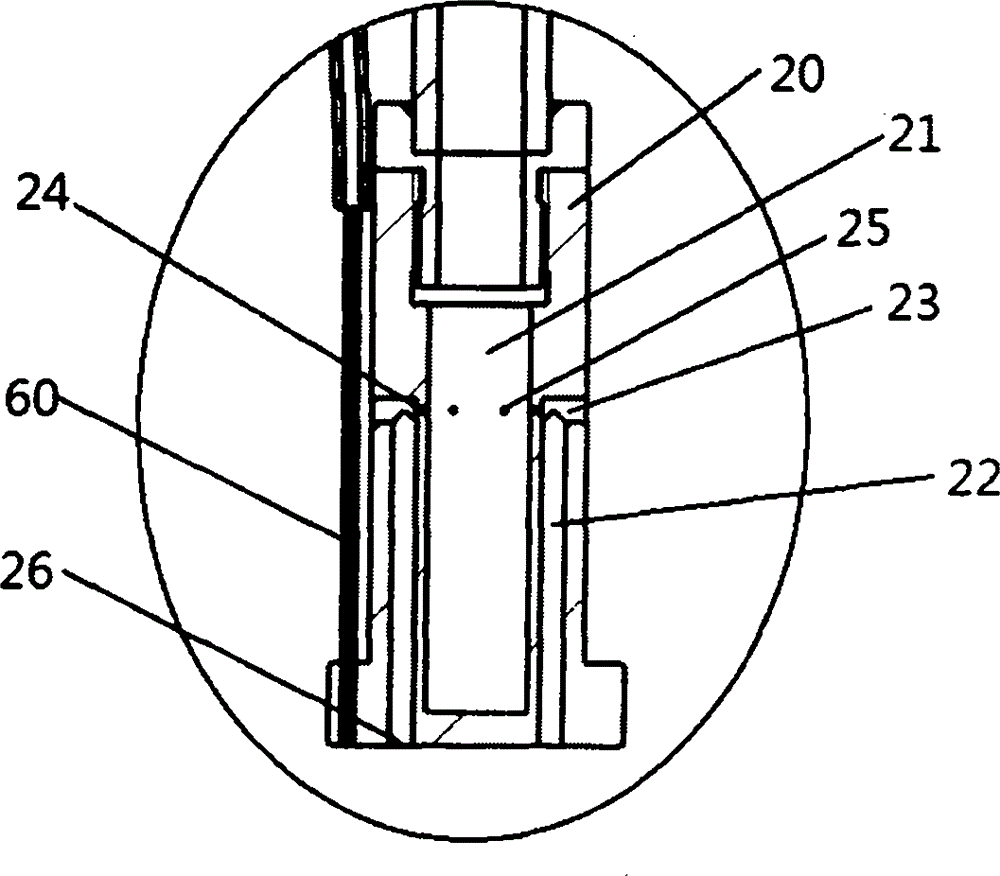

Aerosol generating device

InactiveCN104645903ASolve technical problems that ariseIncrease the cross sectionFlow mixersMixing methodsEngineeringProduct gas

The invention provides an aerosol generating device, comprising a gas pipeline, a liquid pipeline and an aerosol pipeline. A gas outlet is arranged in the pipe wall of the gas pipeline; the gas pipeline is communicated with the end opening located at the first end of the aerosol pipeline through the gas outlet; the pipe wall of the aerosol pipeline is provided with a liquid inlet; the liquid pipeline is communicated the aerosol pipeline through the liquid inlet; the diameter of the gas pipeline is greater than the diameter of the aerosol pipeline; the diameter of the aerosol pipeline is greater than the diameter of the gas outlet; and the liquid inlet is close to the first end. According to the aerosol generating device, high pressure gas first passes through the gas pipeline at first, then through the gas outlet with a small diameter and finally through the aerosol pipeline; because of high pressure of the gas, the flow rate at the small outlet increases sharply, cross section increases from the small outlet to the aerosol pipeline, so siphonage is generated, which allows medicinal liquid to be sucked from the liquid pipeline to places surrounding air flow; and the high-speed air flow cuts the liquid into particles of various sizes and ejects the particles out at a high speed, thereby forming aerosol.

Owner:BEIJING HUIRONGHE TECH

Aerosol generating device heated by microwaves

The invention discloses an aerosol generating device heated by microwaves. The device is characterized in that a microwave heating assembly is arranged in the aerosol generating device, and the microwave heating assembly releases microwaves to heat a tobacco material in a power-on state until smoke is generated; the smoke can be sucked out of the aerosol generating device along with airflow and then sucked in; and the aerosol generating device can be charged.

Owner:SHENZHEN EIGATE TECH CO LTD

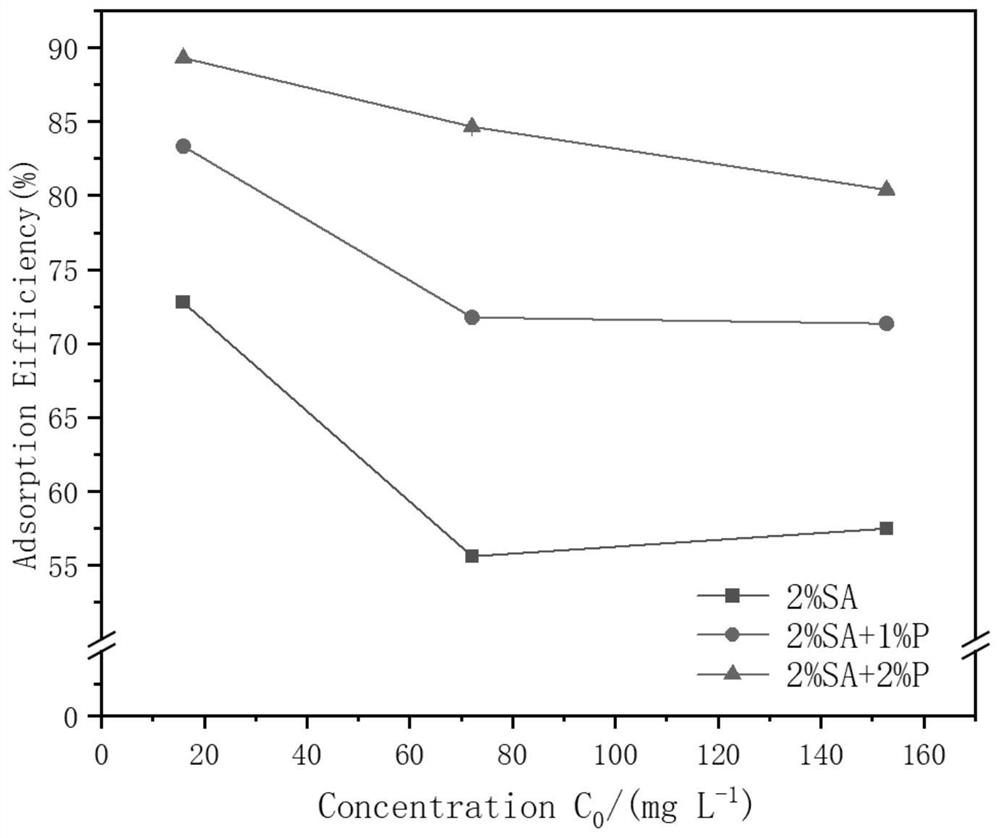

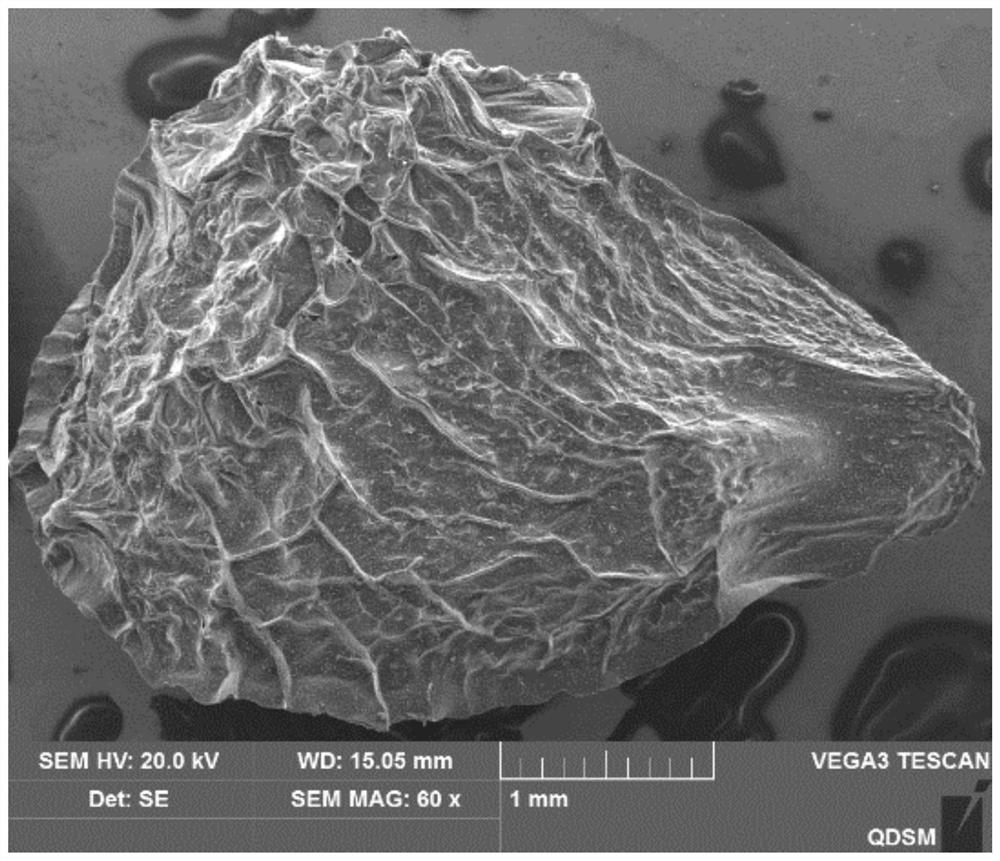

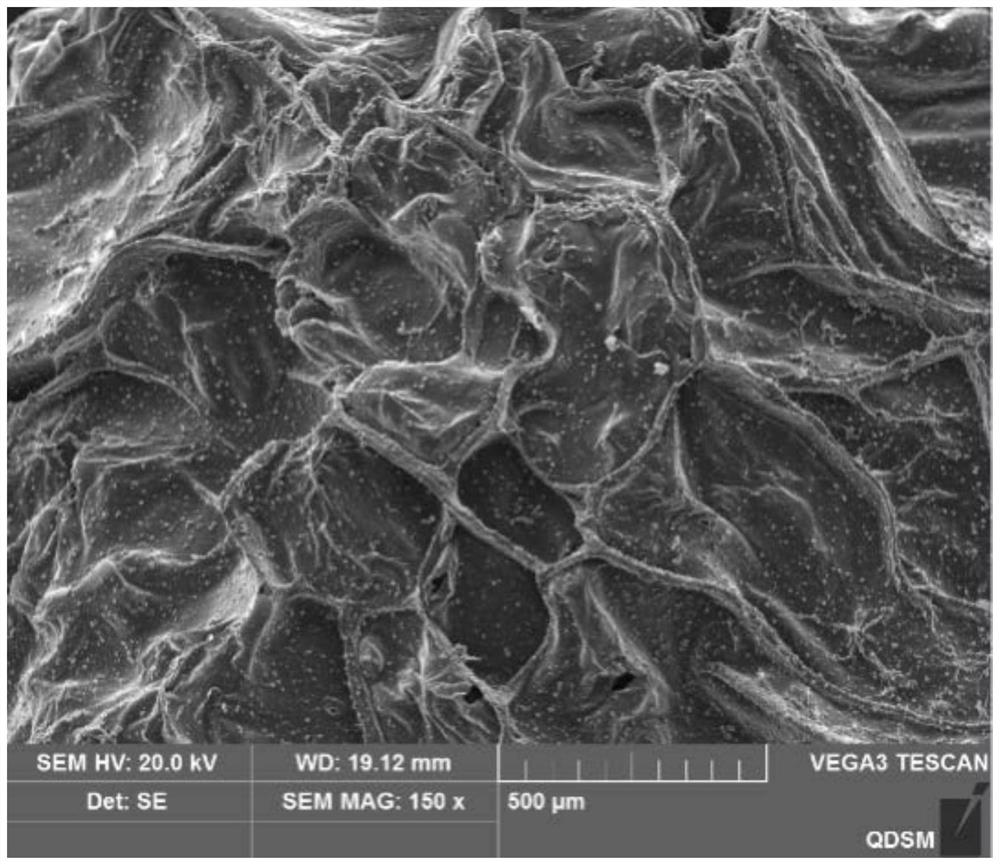

Preparation and application of sodium alginate-based aerogel

ActiveCN113477193ALarge specific surface areaHigh porosityOther chemical processesWater contaminantsPeristaltic pumpFreeze-drying

The invention discloses preparation and application of sodium alginate-based aerogel globules. The adsorbent material is prepared by a method including the steps of: well mixing sodium alginate and pectin powder, adding deionized water and stirring well, standing, dropwise adding the mixed aqueous solution into a calcium salt aqueous solution at a constant speed by using a peristaltic pump, soaking for several hours, separating out hydrogel globules, washing the hydrogel globules with deionized water, air-drying the hydrogel globules, and freeze-drying the hydrogel globules. The aerogel globules prepared by the method have a good adsorption effect on heavy metal ions such as Cd (II), Pb (II) and Cr (III), are an environment-friendly adsorption material, can be applied to multiple fields such as sewage treatment, food processing and biochemical engineering, and have the outstanding advantages of simplicity in preparation, high safety, low cost, easiness in separation, high adsorption capacity, stable adsorption effect and the like.

Owner:OCEAN UNIV OF CHINA

Engineering nanoscale particle aerosol generating system and working method thereof

PendingCN111408324ASmall particle sizeIncrease profitColloidal chemistry detailsAerosol preparationNanoparticleAerosolize

The invention belongs to the field of aerosol generation, and provides an engineering nanoscale particle aerosol generation system and a working method thereof. The engineering nanoscale particle aerosol generation system comprises an air compressor, a condenser, a filter, an atomizer, a multi-stage diffusion dryer and a charge neutralizer which are sequentially connected in series, the atomizer is further connected with a nano-particle solution generating device, and the atomizer is used for mixing the air flow purified by the filter and the nano-particles generated by the nano-particle solution generating device, atomizing the mixture and uniformly sending the mixture to the multi-stage diffusion dryer; air flow purified by the filter is directly introduced into the charge neutralizer,the charge neutralizer is used for neutralizing the nano-particle mixed air flow dried by the multi-stage diffusion dryer and forming nano-scale particle aerosol, and the purified air flow is used forspraying the nano-scale particle aerosol into a body cavity for storage; and the body cavity is connected with a negative pressure pump, and the negative pressure pump is used for pumping redundant nanoscale particle aerosol to maintain the pressure of the body cavity so as to improve the disinfection and sterilization effect.

Owner:SHANDONG UNIV

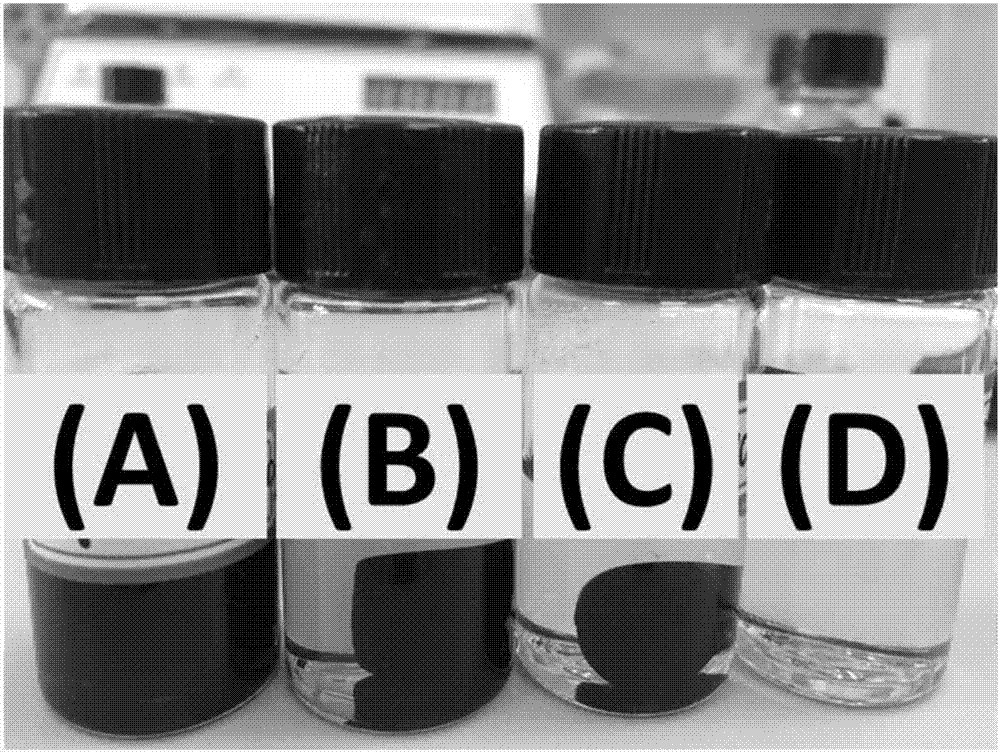

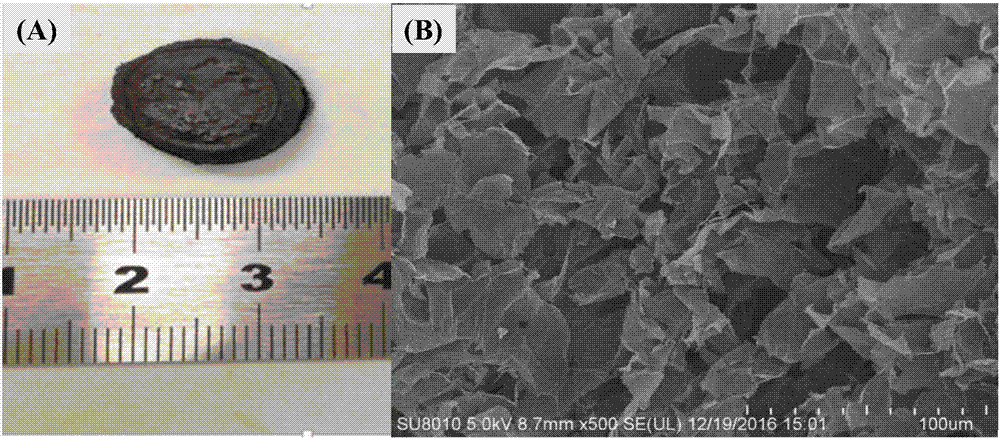

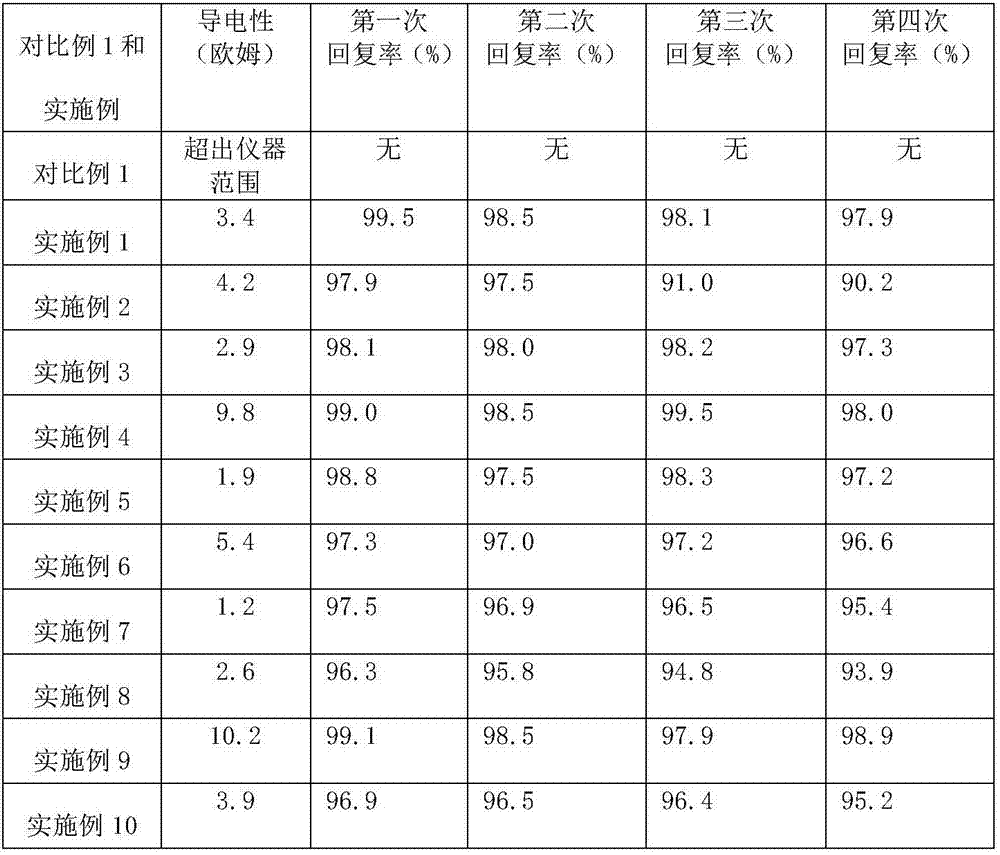

Graphene/black phosphorus nanosheet/sulfur-containing ionic liquid composite aerogel and preparation method thereof

ActiveCN107416846AAvoid reunionGood dispersionCarbon compoundsSulfur compoundsBlack phosphorusCvd graphene

The invention discloses graphene / black phosphorus nanosheet / sulfur-containing ionic liquid composite aerogel, which includes a graphene three-dimensional framework, as well as black phosphorus nanosheets and a sulfur-containing ionic liquid that are supported thereon; the black phosphorus nanosheets are coated with the sulfur-containing ionic liquid. The graphene / black phosphorus nanosheet / sulfur-containing ionic liquid composite aerogel has a three-dimensional porous network structure and has high elasticity, high resilience, high electric-conductivity and excellent stability. The composite aerogel increases products of black phosphorus and broadens application range of the black phosphorus. The invention also provides a preparation method of the graphene / black phosphorus nanosheet / sulfur-containing ionic liquid composite aerogel.

Owner:SHENZHEN UNIV

Preparation equipment of graphene composite material aerogel

InactiveCN107694489ALarge specific surface areaHigh porosityShaking/oscillating/vibrating mixersTransportation and packagingPorosityLine tubing

The invention discloses preparation equipment of graphene composite material aerogel. The equipment comprises a first mixing tank, a second mixing tank, a liquid storage tank and a reaction chamber which are connected through pipelines, wherein both the first mixing tank and the liquid storage tank are provided with rapid stirring blades; an ultrasonic processor is arranged in the second mixing tank; a cavity is arranged inside the reaction chamber; a heating tube is arranged at the bottom of the cavity; the heating tube is fixedly connected with the bottom of the inner wall of the left side of the reaction chamber; a heating plate is arranged on the heating tube; a reaction vessel is arranged on the heating plate; a groove is formed inside the reaction vessel; a temperature adjustment button is arranged on the outer wall of the left side of the reaction chamber; a nitrogen conveying pipeline penetrates through the bottom of the outer wall of the right side of the reaction chamber; a vacuum pump is connected with the nitrogen conveying pipeline. The equipment is simple to operate and low in cost; the prepared graphene composite material aerogel has the characteristics of high specific surface area, large porosity, wide pore size distribution and good conductivity.

Owner:CHENGDU GELAIFEI TECH

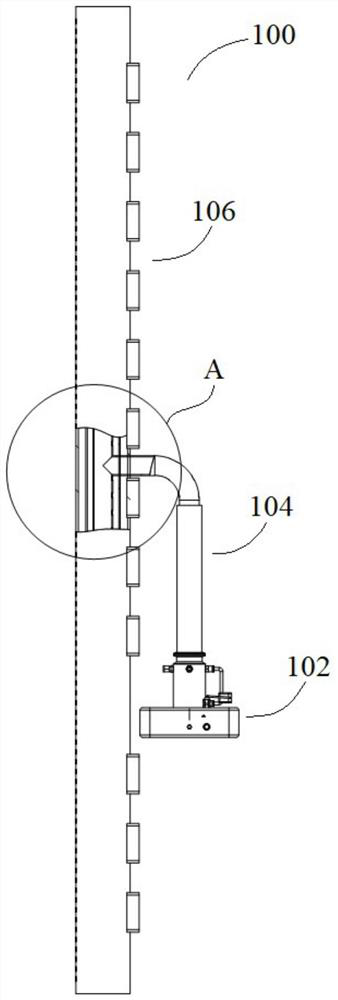

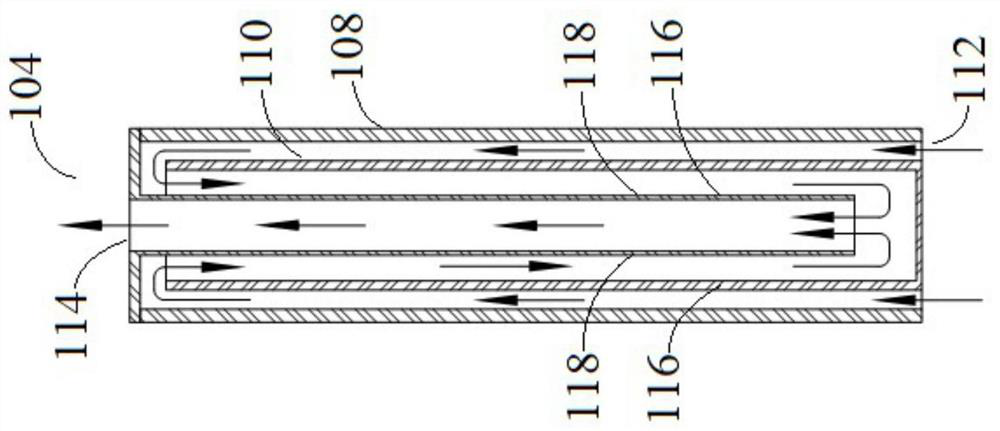

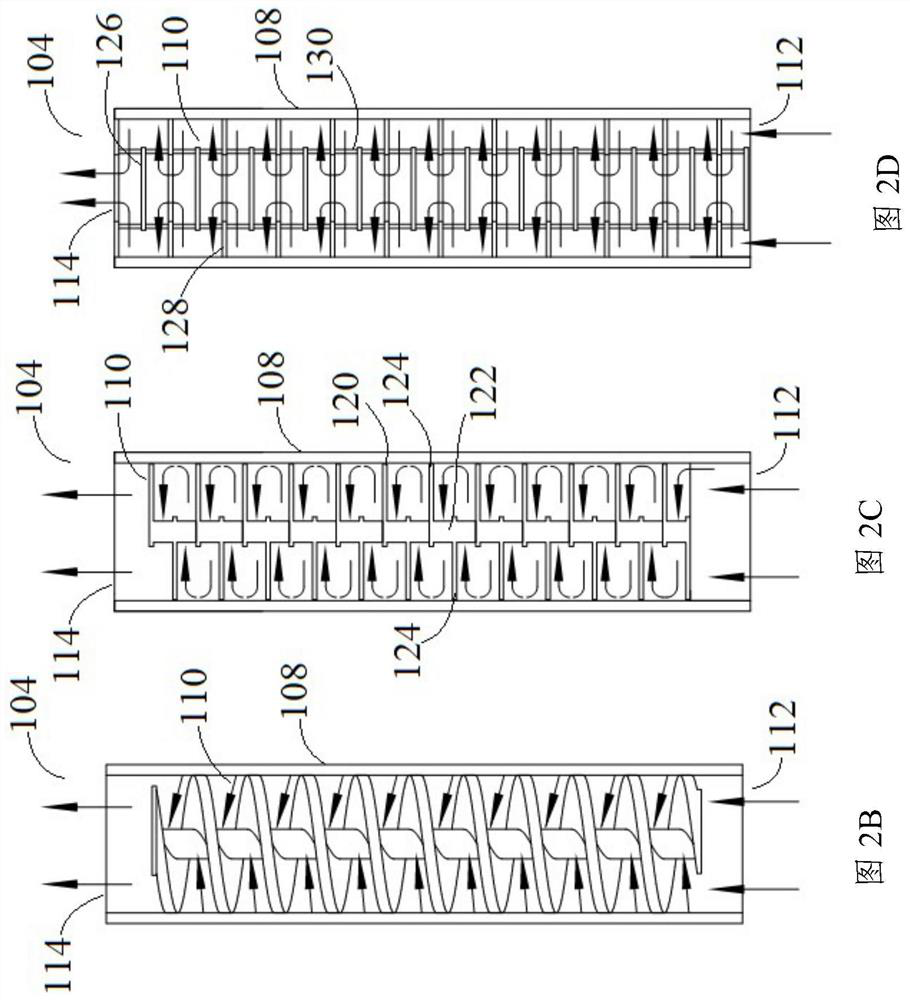

Nanometer aerosol disinfection equipment

The invention relates to the field of disinfection of air and object surfaces, in particular to nanometer aerosol disinfection equipment capable of converting a disinfectant into nanometer aerosol. The nanometer aerosol disinfection equipment comprises an atomization device, a screening device and a distribution device, wherein the atomization device is used for generating aerosol spray; the screening device communicates with the atomization device, and a barrier part capable of forming a carrier gas flow path, which extends crookedly, in the screening device is arranged in the screening device; and the distribution device comprises a spray chamber which communicates with the screening device, a gas flow chamber which is separated from the spray chamber, a co-gasification area which communicates with the spray chamber and the gas flow chamber, and a spray nozzle which communicates with the co-gasification area. The provided nanometer aerosol disinfection equipment can effectively convert the disinfectant into the nanometer aerosol spray without equipment of heating device and the like so that the nanometer aerosol spray can be used for disinfection operation.

Owner:东方金荣(北京)环保科技有限公司

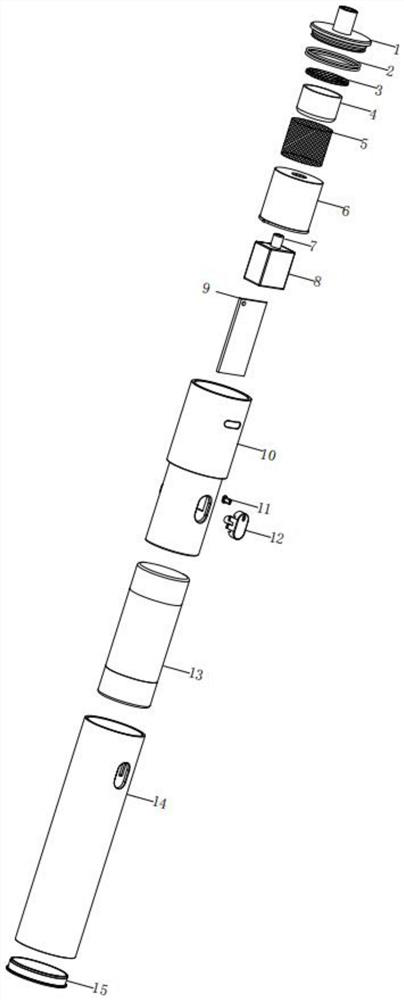

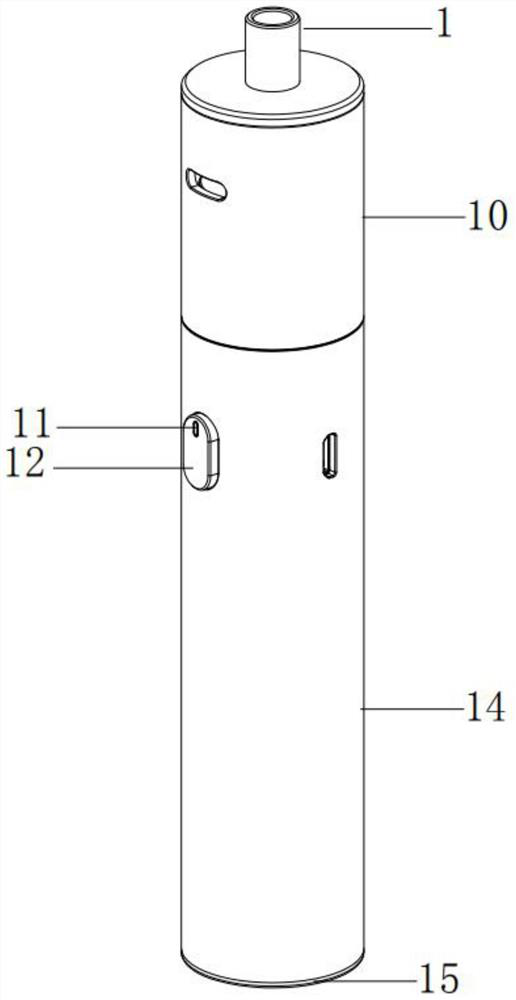

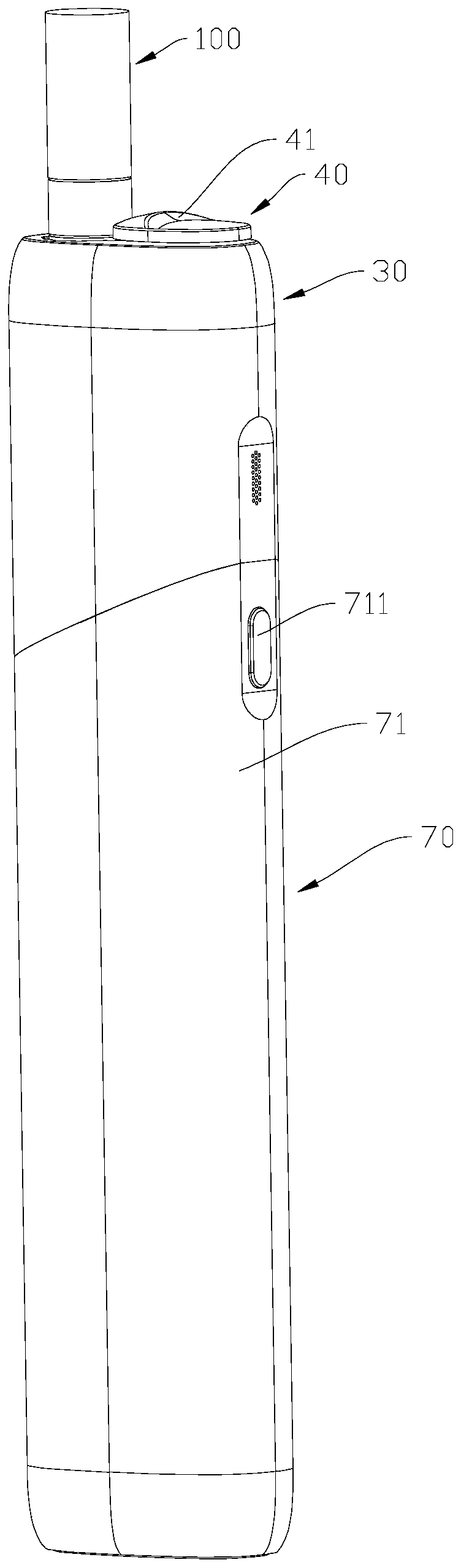

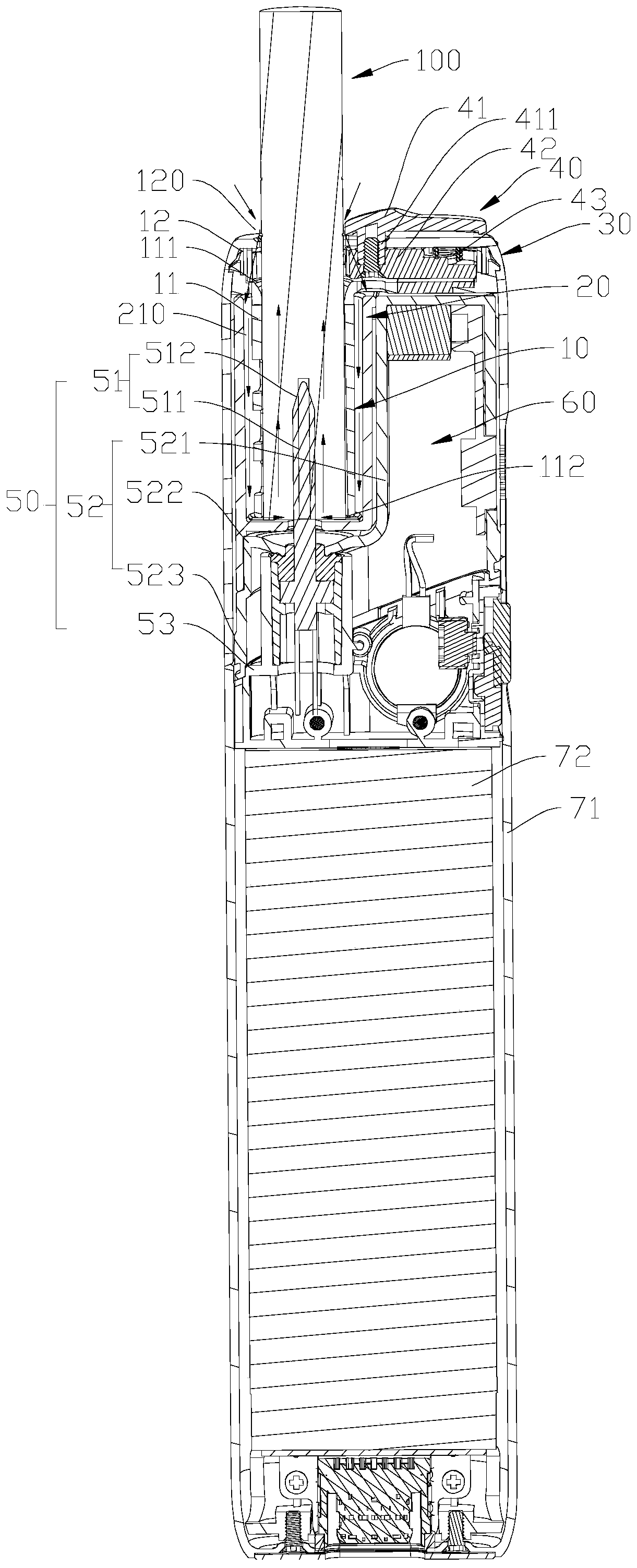

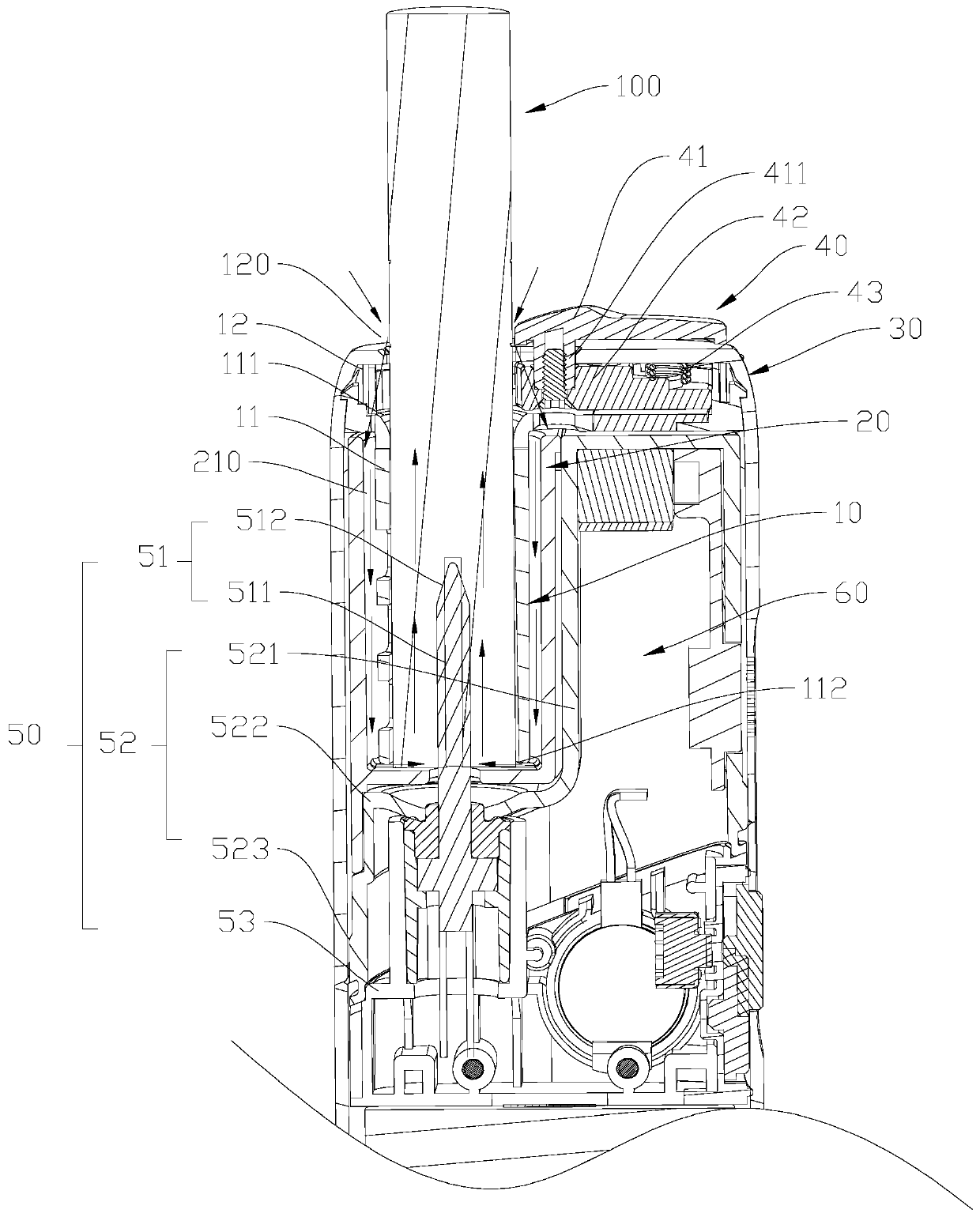

Aerosol generating device

PendingCN111420621AEasy and quick to pull outTobaccoColloidal chemistry detailsEngineeringMechanical engineering

The invention relates to an aerosol generating device. The aerosol generating device comprises a fixing pipe used for fixing an aerosol forming base body, an air channel pipe arranged on the peripheryof the fixing pipe in a sleeving mode and a heating assembly. The fixing pipe is hollow and is of a structure with the two ends communicated. The two ends are provided with a first opening and a second opening communicated with the first opening respectively. A supporting wall for supporting the aerosol forming substrate is arranged at one end of the air channel pipe, and the supporting wall is opposite to the second opening. The aerosol forming base body can extend into the fixing pipe from the first opening, and the heating assembly can penetrate through the supporting wall and be insertedinto the aerosol forming base body from the second opening to heat the aerosol forming base body. When the aerosol forming base body retreats from the interior of the fixing pipe to the first opening,the heating assembly is separated from the aerosol forming base body. The aerosol generating device can be rapidly and conveniently pulled out of the fixing pipe without damaging the aerosol formingbase body, and has the advantage of being easy and convenient to disassemble and assemble.

Owner:SHENZHEN MERIT TECH CO LTD

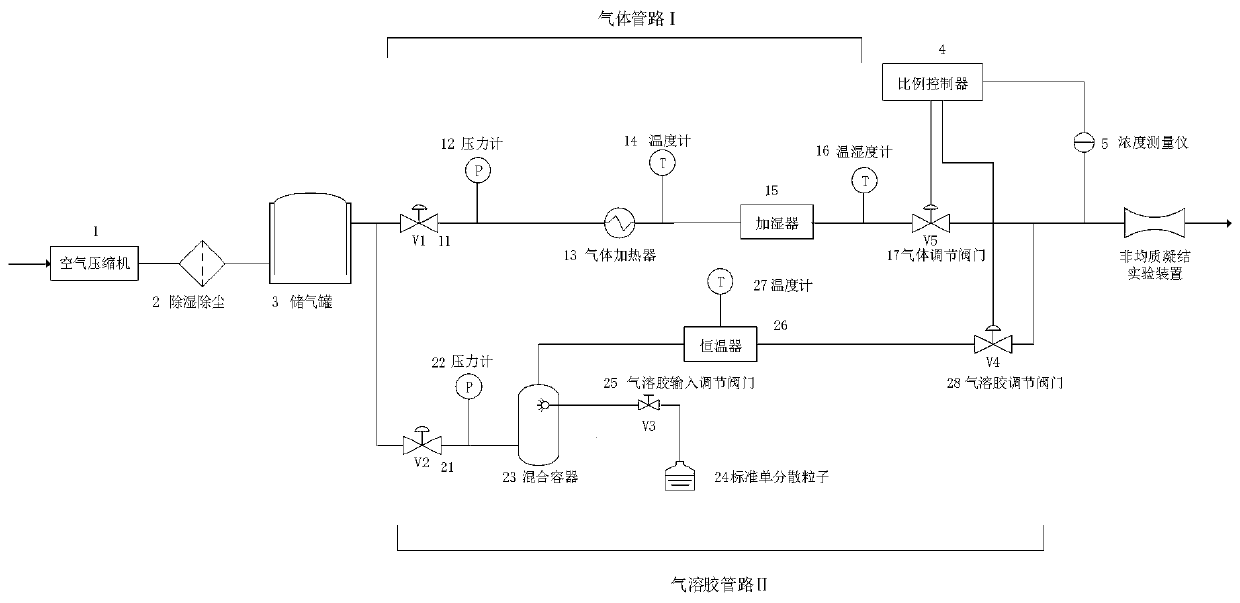

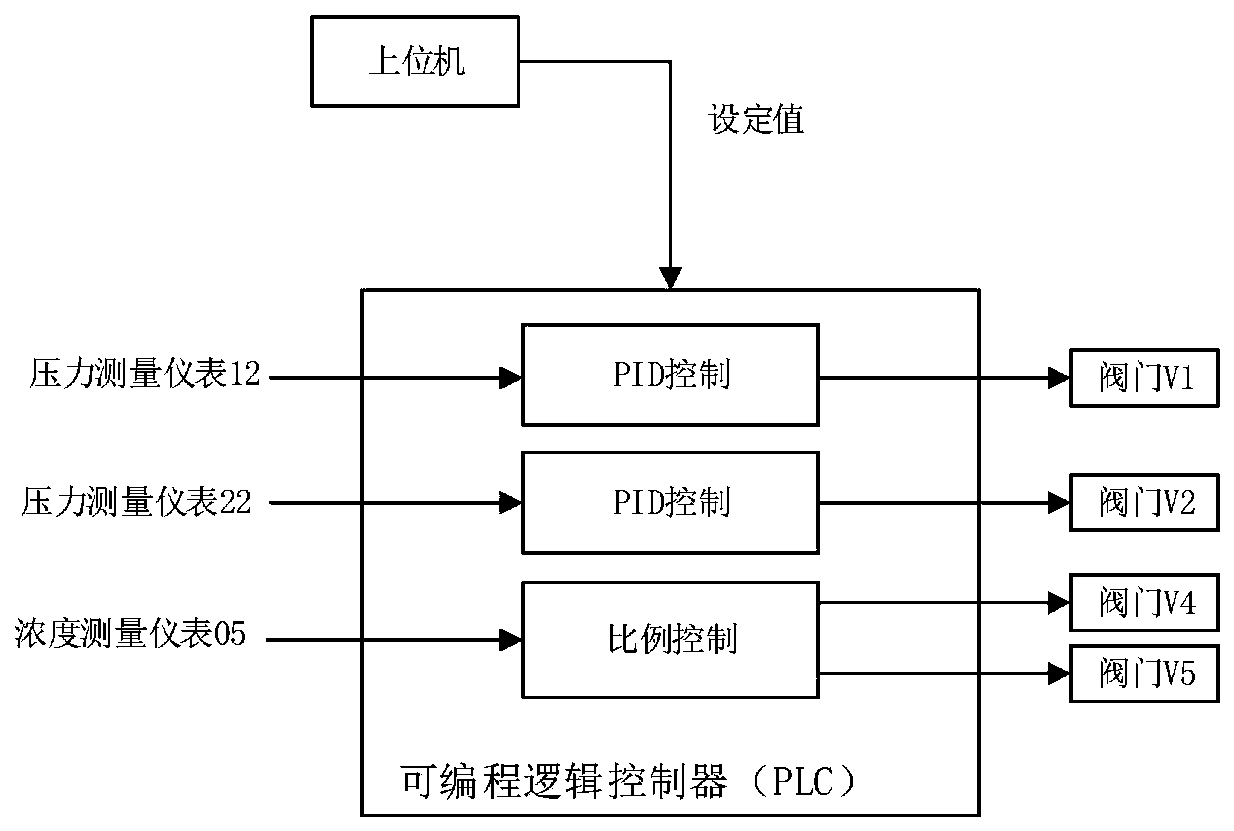

Heterogeneous condensation gas source system with adjustable granularity, concentration and flow

InactiveCN111203158AGranularity adjustableConcentration adjustableColloidal chemistry detailsAerosol preparationProportional controlGas heater

The invention relates to a heterogeneous condensation gas source system with adjustable granularity, concentration and flow. The heterogeneous condensation gas source system comprises a gas pipeline,an aerosol pipeline, a proportional controller, a concentration detector, a mixing pipeline for outputting a condensation gas source, and a control part. The aerosol pipeline comprises a mixing container and a thermostat, monodisperse aerosol enters the mixing container through a flow regulating valve and then is mixed with second input gas in the mixing container, then the temperature is regulated through the thermostat, and the monodisperse aerosol enters the mixing pipeline through the aerosol regulating valve; proper heating temperature values of the gas heater and the thermostat are set to ensure that the temperatures of the gas pipeline and the aerosol pipeline are consistent when the gas pipeline and the aerosol pipeline are mixed; and the flow valve is used for controlling the flowof the monodisperse aerosol entering the mixing container, the concentration detector is arranged on the mixing pipeline, and the proportion controller is used for carrying out adjustment during two-way mixing according to a preset value in order to control the proportion of the monodisperse aerosol in the mixing pipeline.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com