Cleaner cartridge

A technology of cleaners and detergents, applied in the direction of cleaning equipment, cleaning machinery, cleaning methods and utensils, which can solve the problems of poor cleaning solution flow control, high volume flow, low efficiency, mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

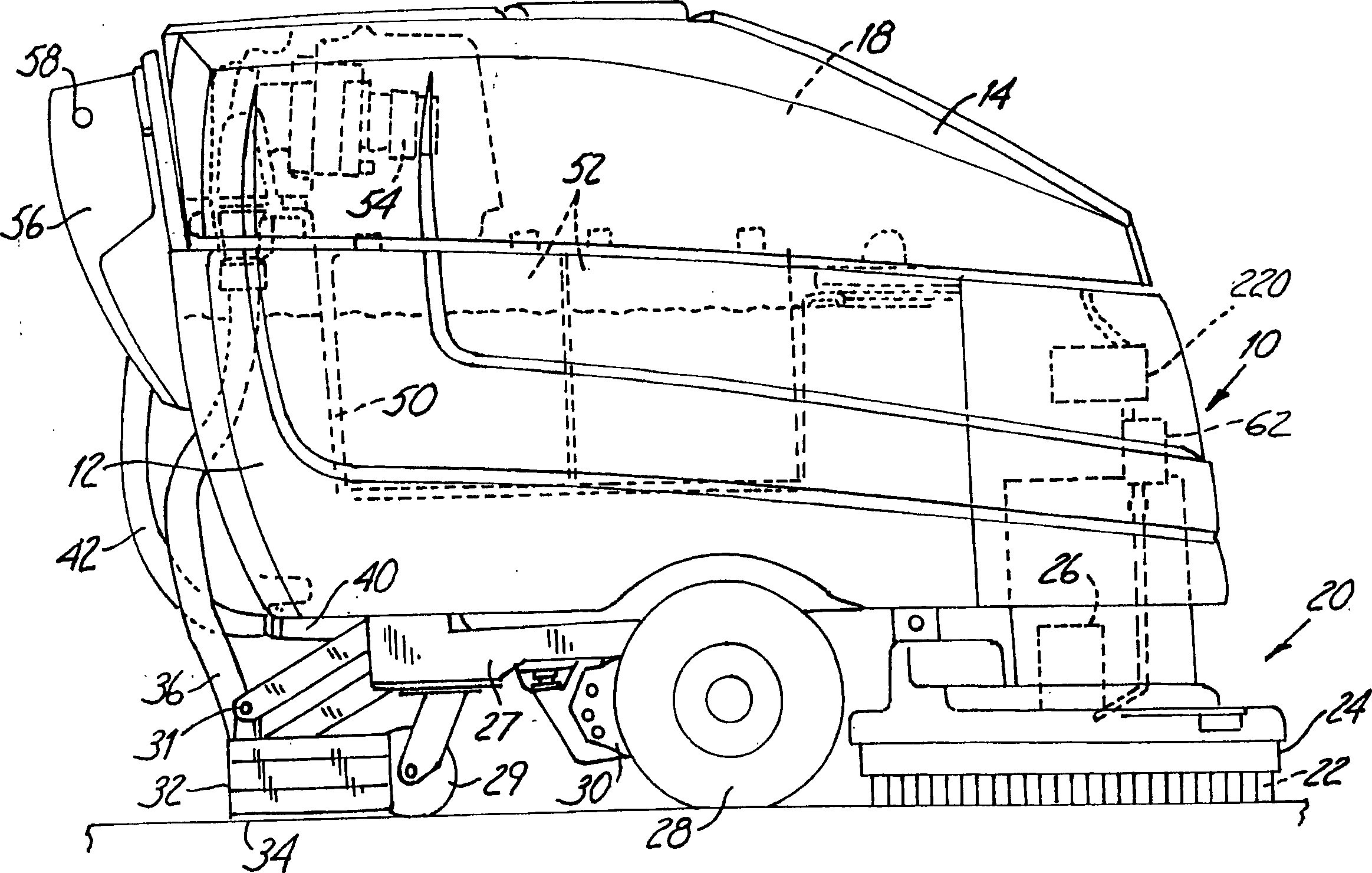

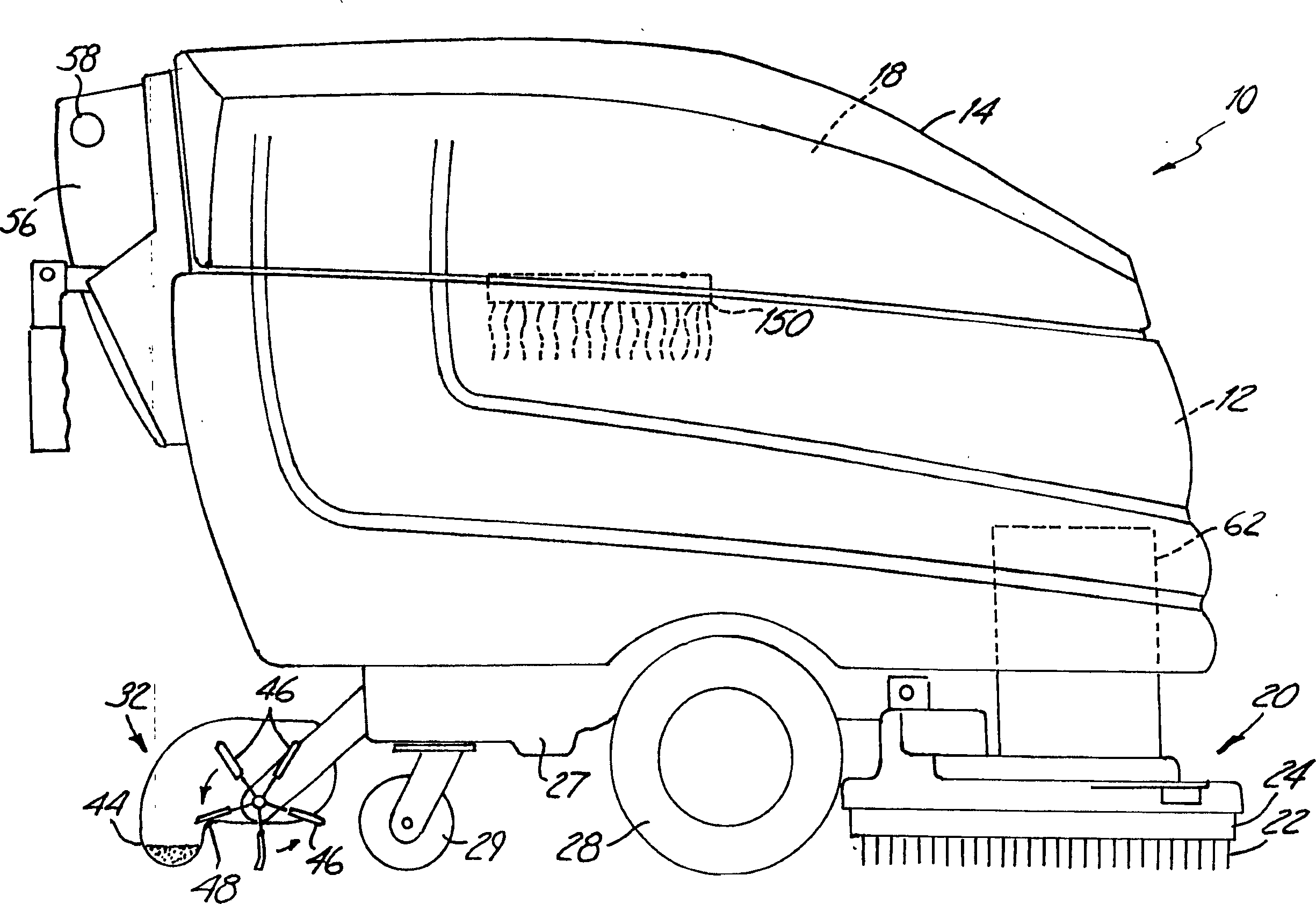

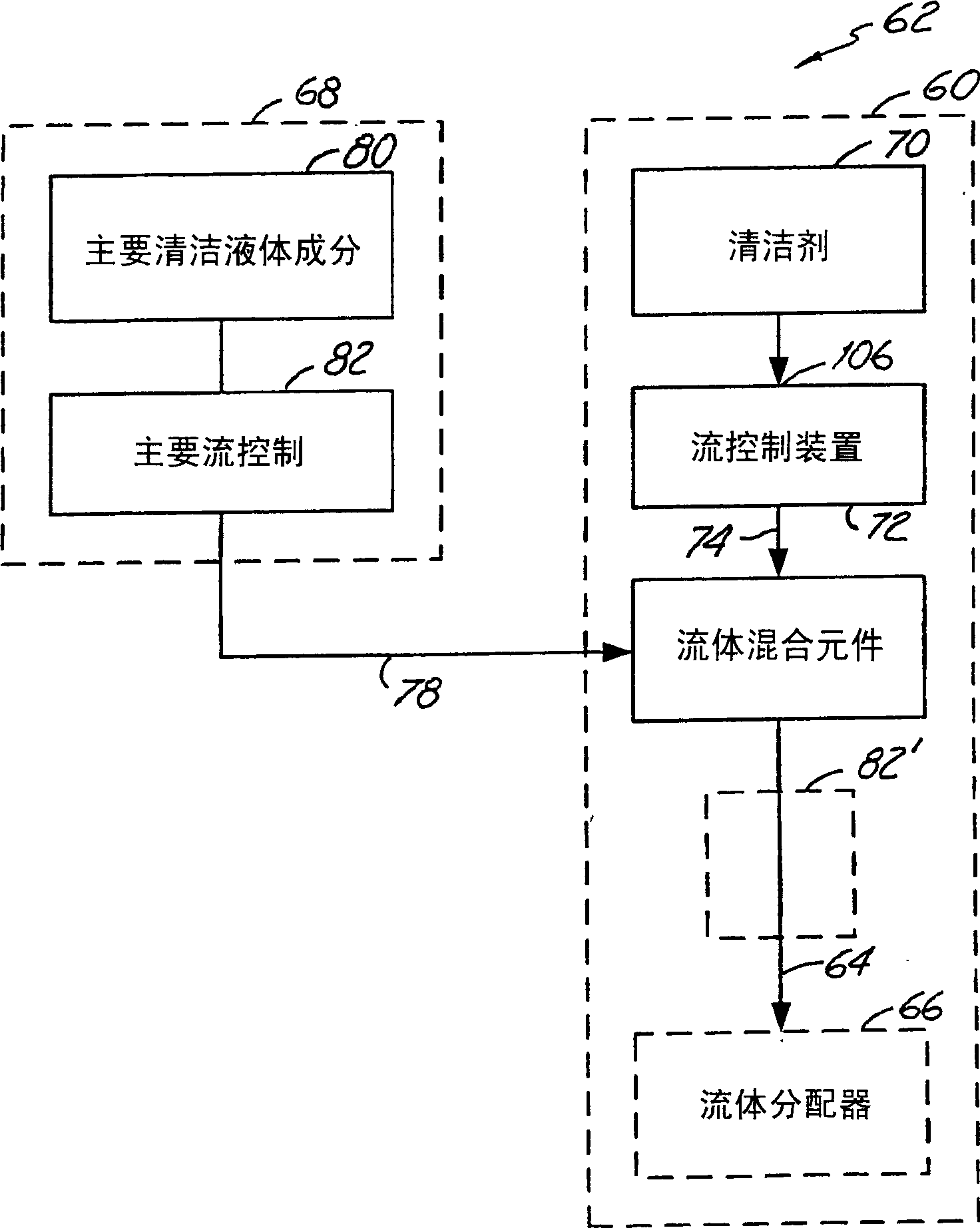

[0022] figure 1 A hard floor surface cleaner 10 is shown in which embodiments of the present invention may be used. The illustrated cleaner 10 is a walk behind cleaner for cleaning hard floor surfaces such as concrete, tile, vinyl, terrazzo and the like. Alternatively, cleaner 10 may be a ride-on or towed-behind cleaner that performs the scrubbing operations described herein. Cleaner 10 includes an electric motor powered by a built-in power source, such as a battery, or by an electrical cable. Alternatively, an internal combustion engine system can be used alone or in combination with an electric motor. Cleaner 10 generally includes a recovery tank 12 , and a cover 14 . The cover 14 is connected along one side of the recovery tank 12 by a hinge (not shown) so that the cover 14 can be turned upward to gain access to the inside of the tank 12 . The cleaner 10 also includes a tank 18 for containing the cleaning liquid or primary cleaning liquid composition that is applied to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com