Patents

Literature

74results about How to "Granularity adjustable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

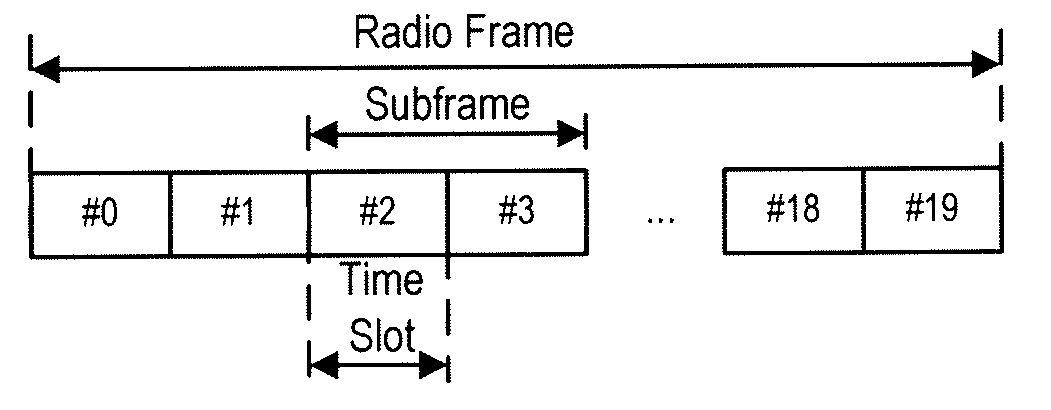

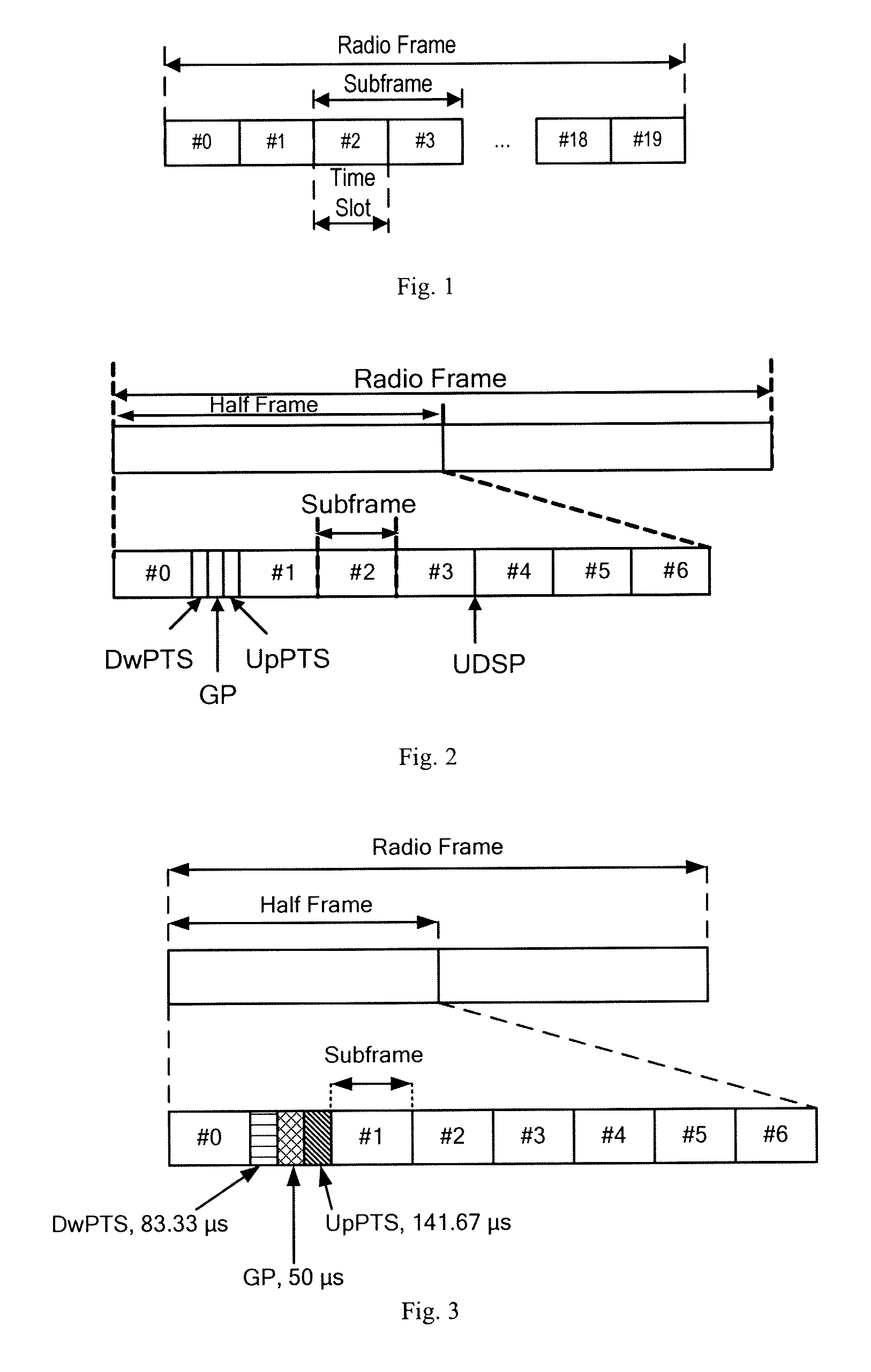

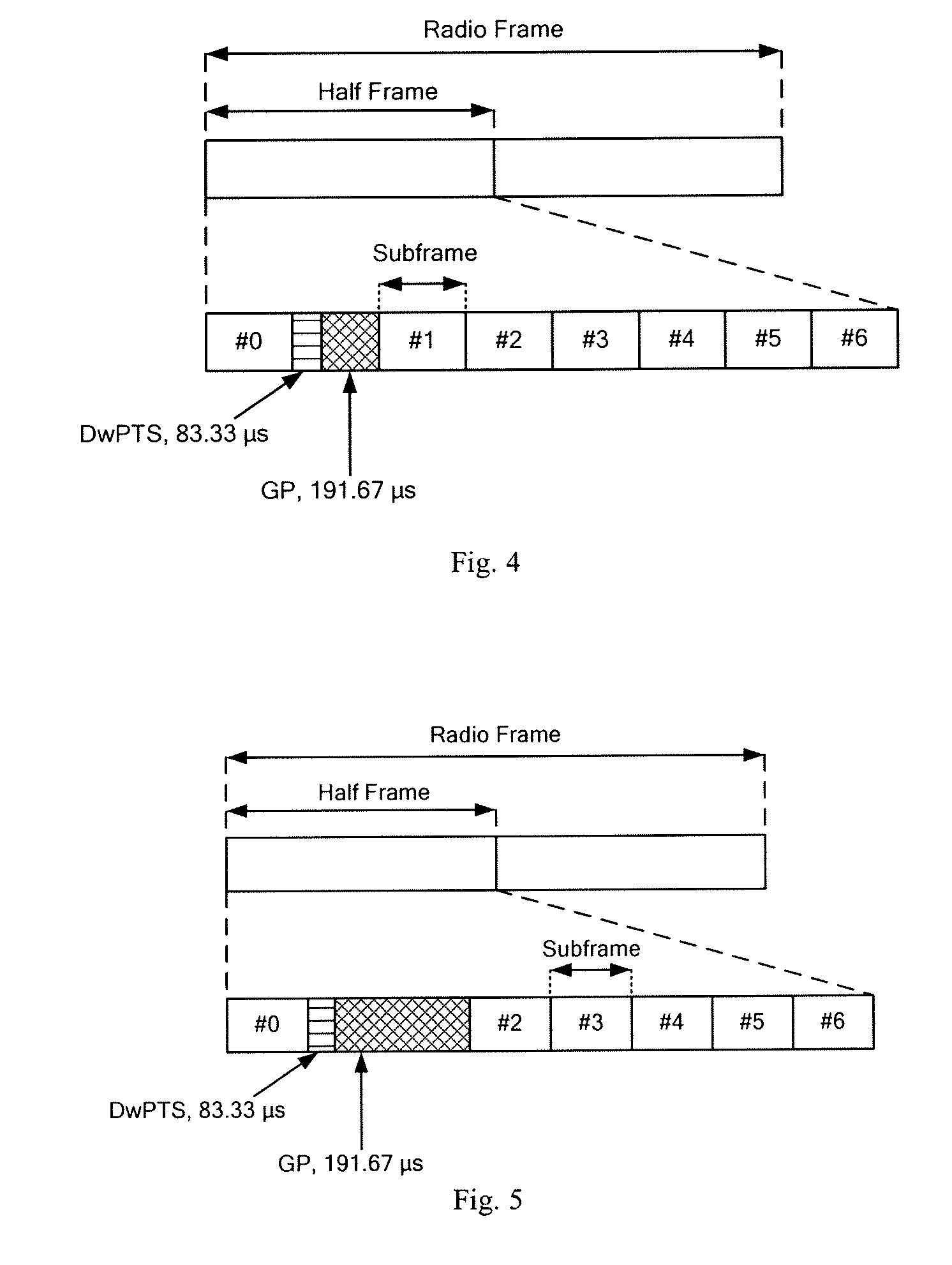

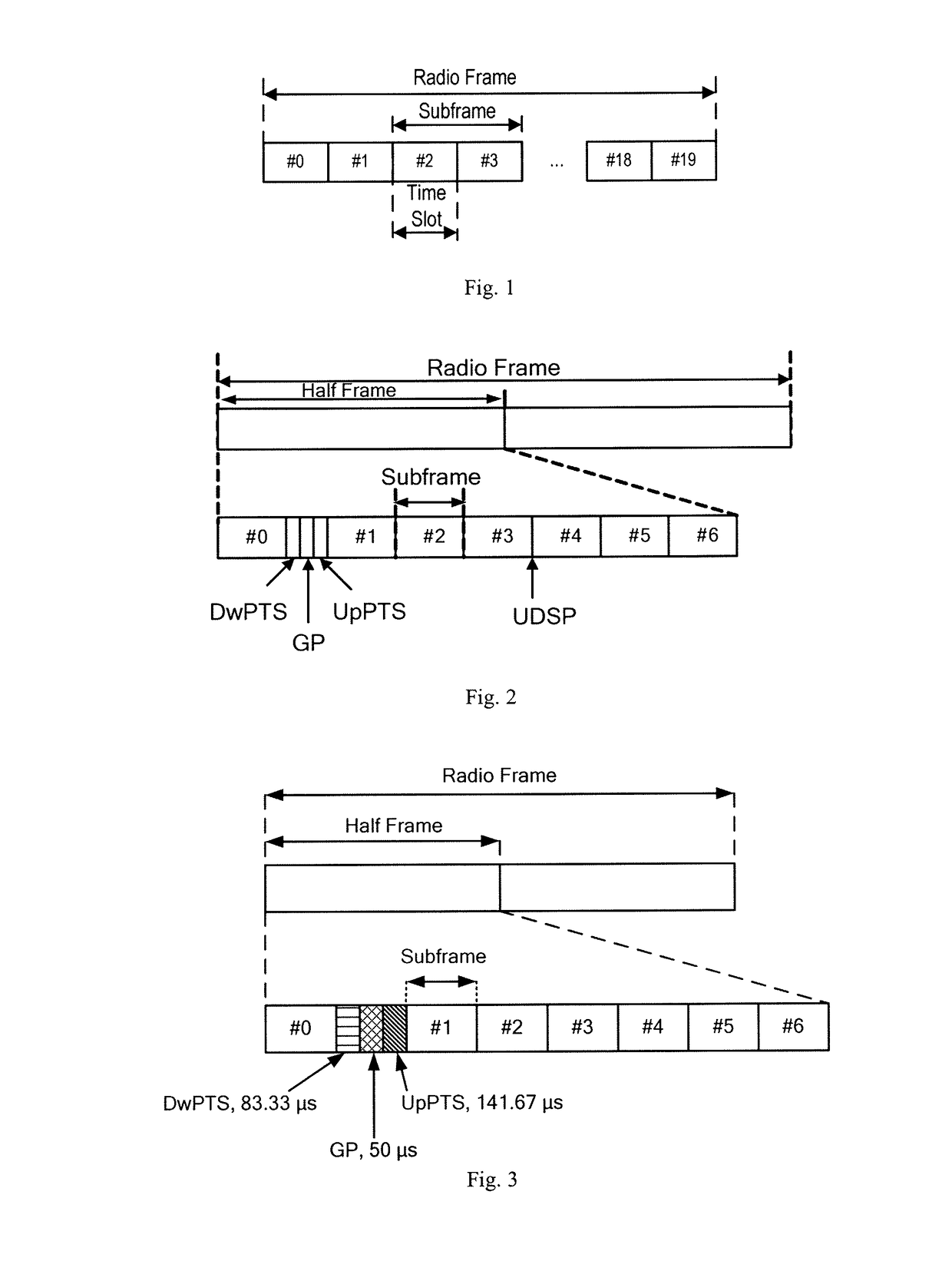

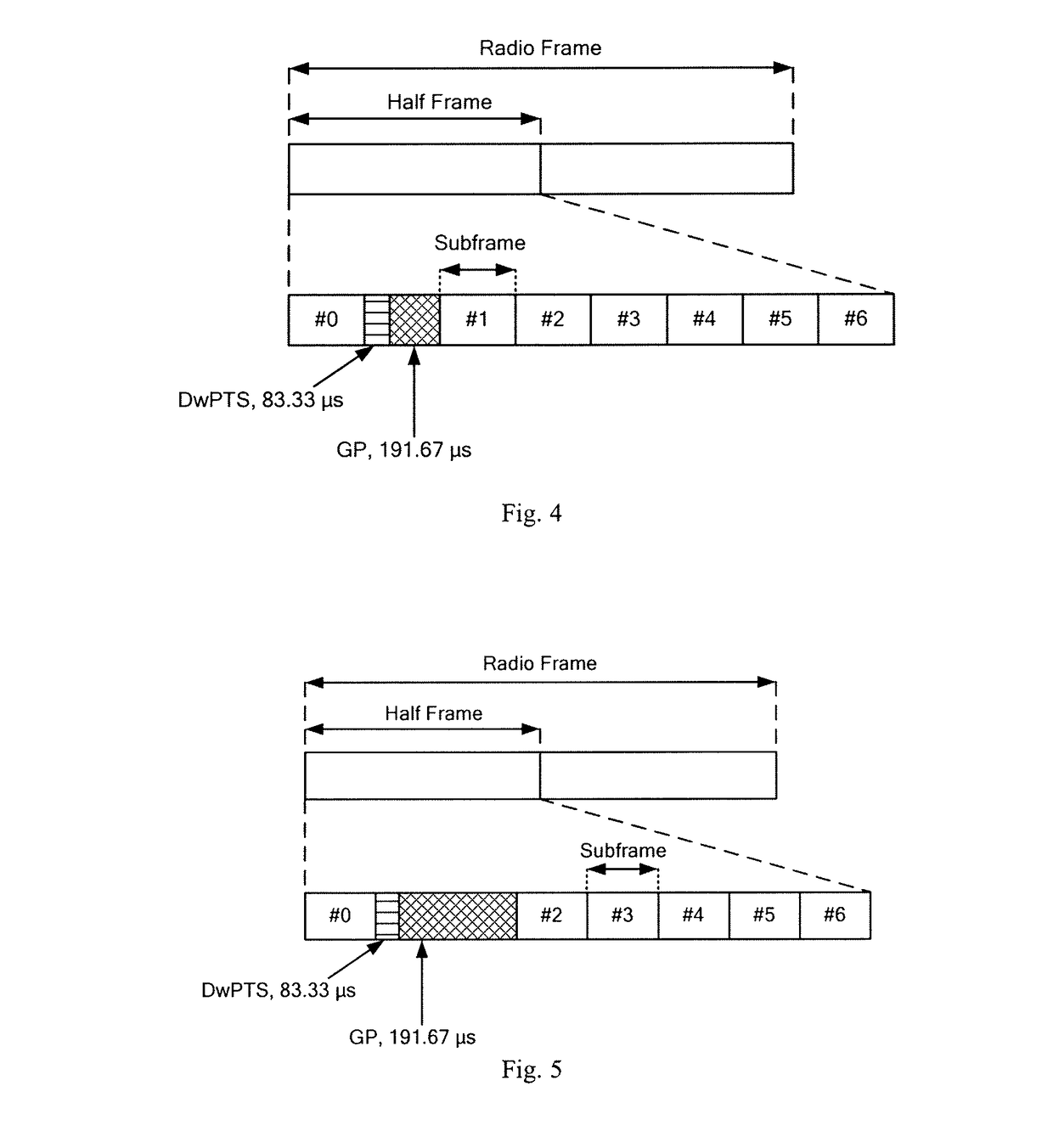

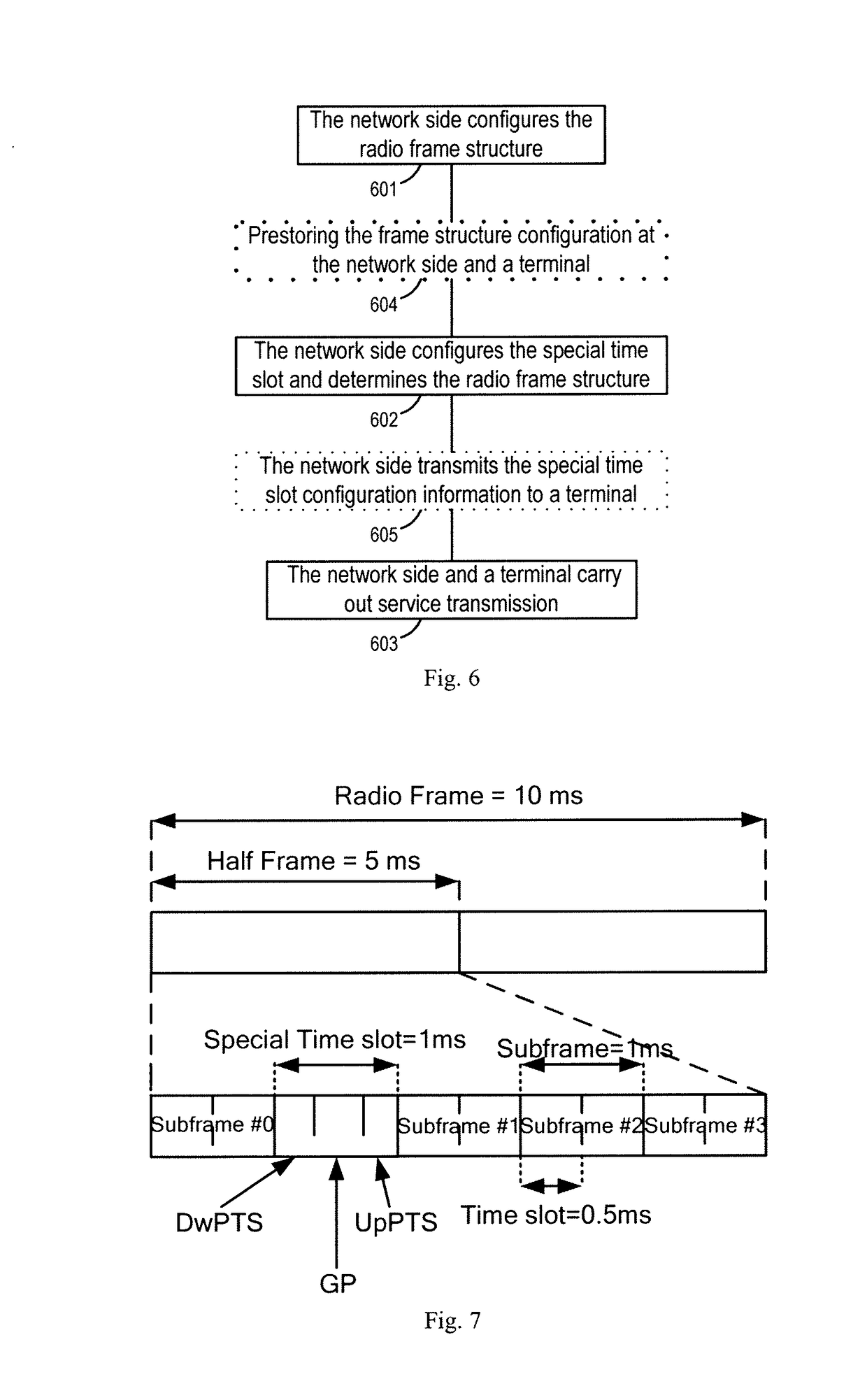

Method and an apparatus for determining the radio frame structure of time division duplex system

ActiveUS20100246456A1Improve interferenceFlexible supportSynchronisation arrangementTime-division multiplexEngineeringTime-division multiplexing

A method for determining the radio frame structure of a Time Division Duplex system is disclosed, which comprises: configuring, by the network side, the radio frame structure used for service transmission as containing two half-frames each of 5 ms, wherein each half-frame consists of eight service time slots of 0.5 ms and one special time slot field of 1 ms, two consecutive service time slots form a subframe of which the length is 1 ms, and the special time slot field contains a DwPTS, a GP and an UpPTS; determining the lengths of the DwPTS, the GP and the UpPTS in the special time slot field according to the requirements of the coverage range, and determining the radio frame structure used for service transmission. By reconfiguring the radio frame structure, the invention can flexibly support different coverage ranges, enhance the flexibility of satisfying different service requirements, and implement the coexistence of two types of TDD systems.

Owner:DATANG MOBILE COMM EQUIP CO LTD

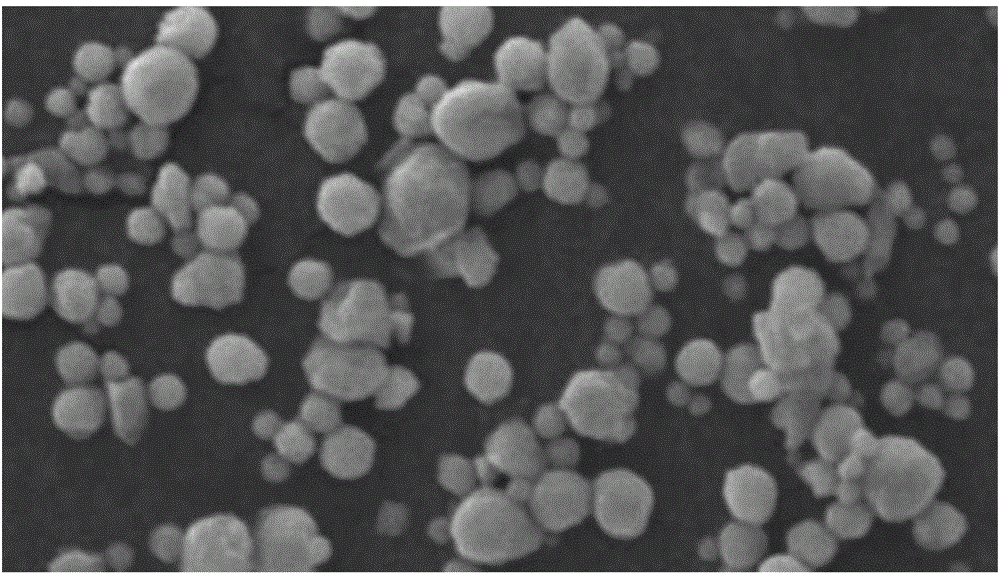

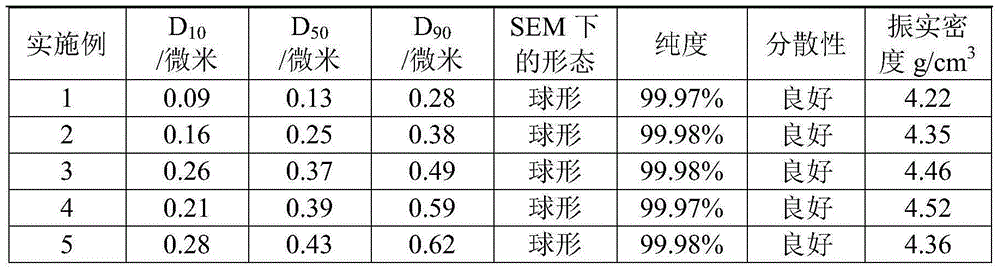

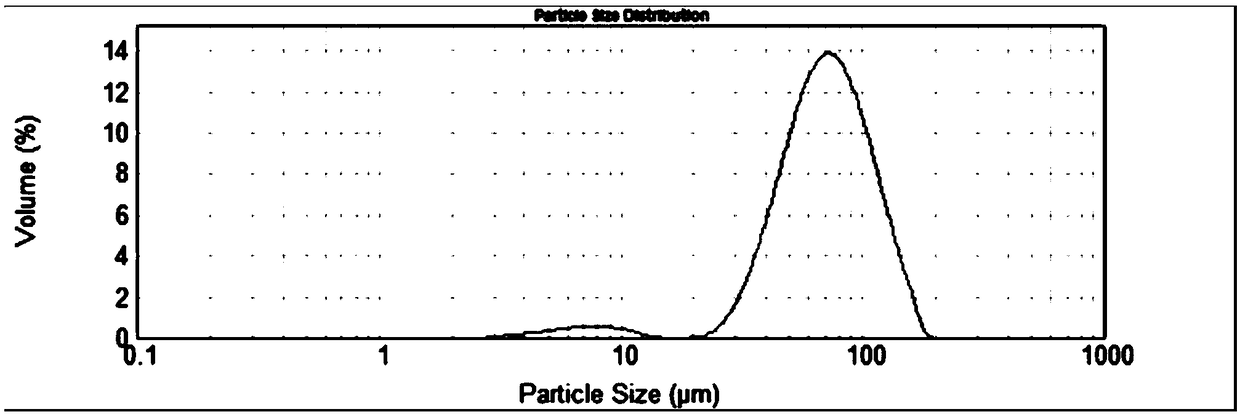

Spherical silver powder with controllable granularity and preparation method thereof

The invention relates to spherical silver powder with controllable granularity. The spherical silver powder has more than 99.9 percent of purity and more than 4.2g / cm<3> of tap density, and the granularity D90 of the spherical silver powder keeps being adjustable within an interval ranged from 0.2 mu m to 0.65 mu m based on a reaction system formula and reaction condition changes during a preparation method thereof. The preparation method of the spherical silver powder comprises the following steps of adopting soluble silver salt as raw materials, and preparing to obtain the nanoscale spherical silver powder through a hydrothermal method; adopting the nanoscale spherical silver powder as silver seed crystal, utilizing sediment reaction to induce the silver seed crystal to grow up uniformly, adjusting the growth degree of the silver seed crystal through controlling a reaction system formula and reaction conditions of the sediment reaction, and further obtaining the spherical silver powder with controllable granularity. The spherical silver powder is regular in shape, uniform in granularity, and can realize controllable granularity through process operation.

Owner:GUIZHOU DALONG HUICHENG NEW MATERIAL CO LTD

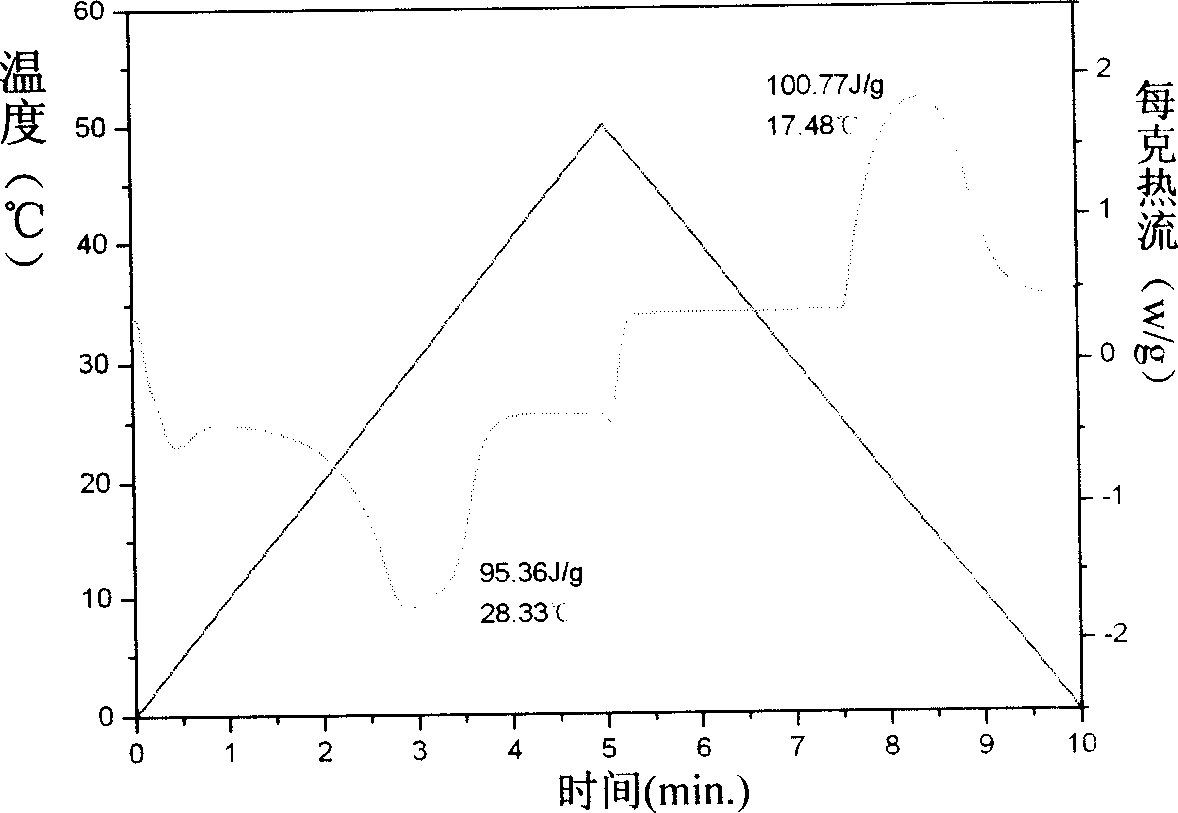

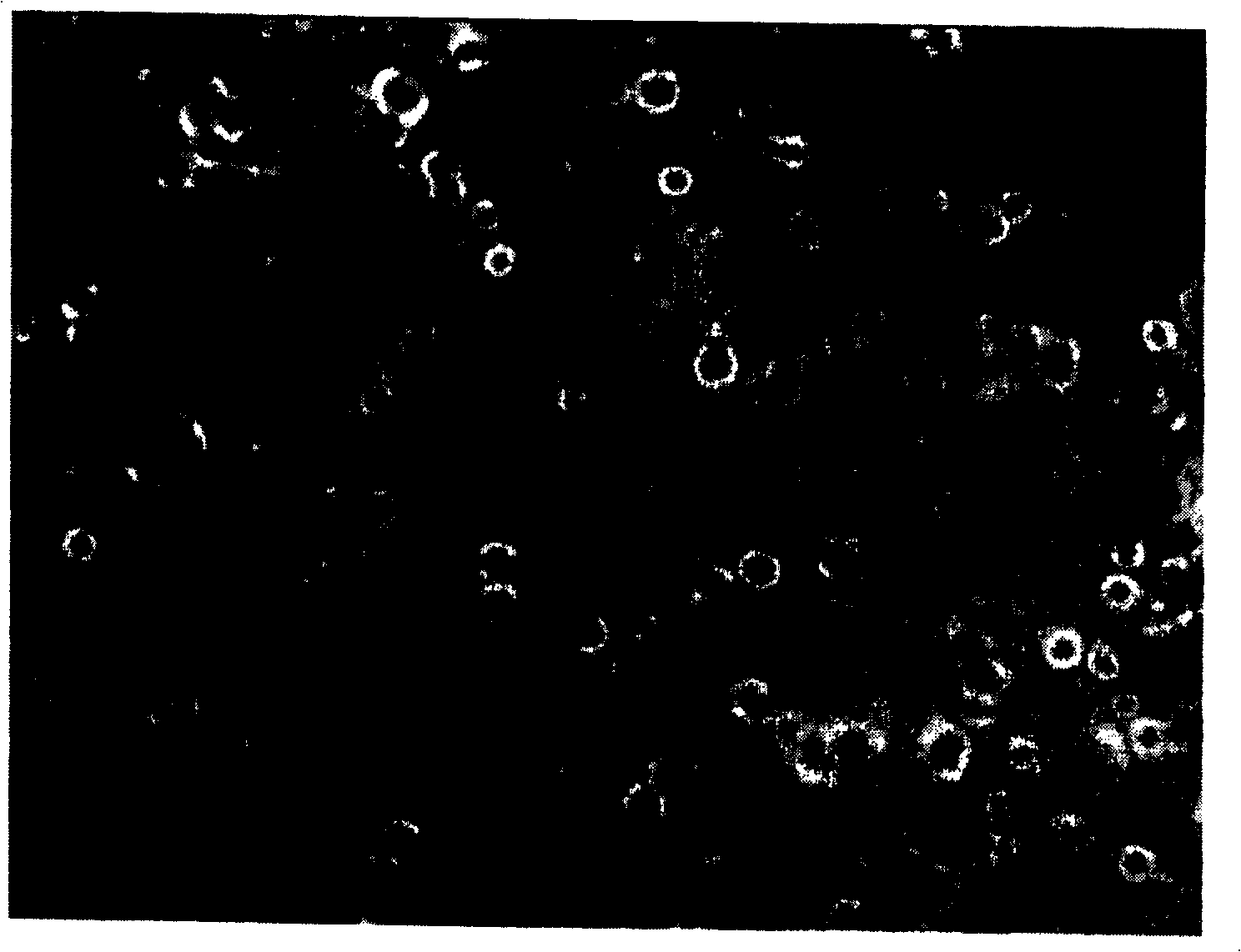

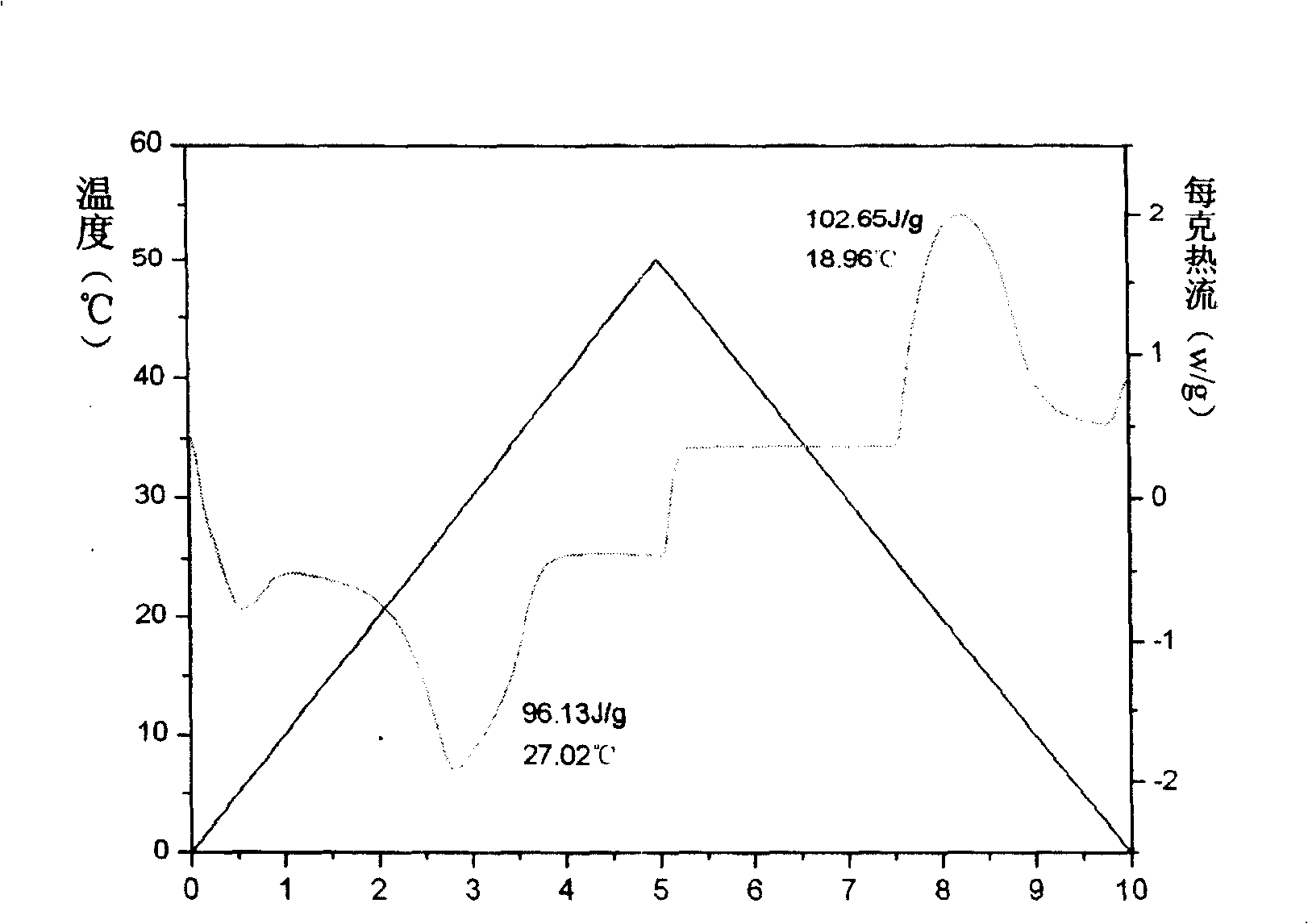

Phase-transition energy-storage microcapsules and their preparing process

InactiveCN1844269AExpand the scope of applicationSimple preparation processEmulsion paintsMicroballoon preparationPrepolymerSodium silicate

The phase-change storage microcapsule consists of capsule wall and phase-change material covered by it, in which the capsule wall is silicon dioxde deposit with 20-65 % of the total mass of the microcapsule and phase-change material with 80-35 % of the total mass of the microcapsule. The method for preparation of phase-change storage microcapsule includes: adding 0.5-3 parts of surface activator into finite quantities of distilled water, after the heating and the dissolution, then adding 4-12 parts of phase-change storage materials and 0-2 parts of cosurfactants, emulsifying under a condition of high-velocity agitation to obtain the lacte emulsion; dissolving the 3-10 parts of sodium silicate into finite quantities of distilled water, adding finite quantities of 1-2 parts of precipitant A under a condition of agitation to obtain sodium silicate prepolymer; slowly adding the emulsion into the said sodium silicate prepolymer, then adding 2-10 parts of precipitant B, placing the said mixture into a water bath to react for 3-5 hours, after the filtration and the scouring, obtaining the phase-change storage microcapsule.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

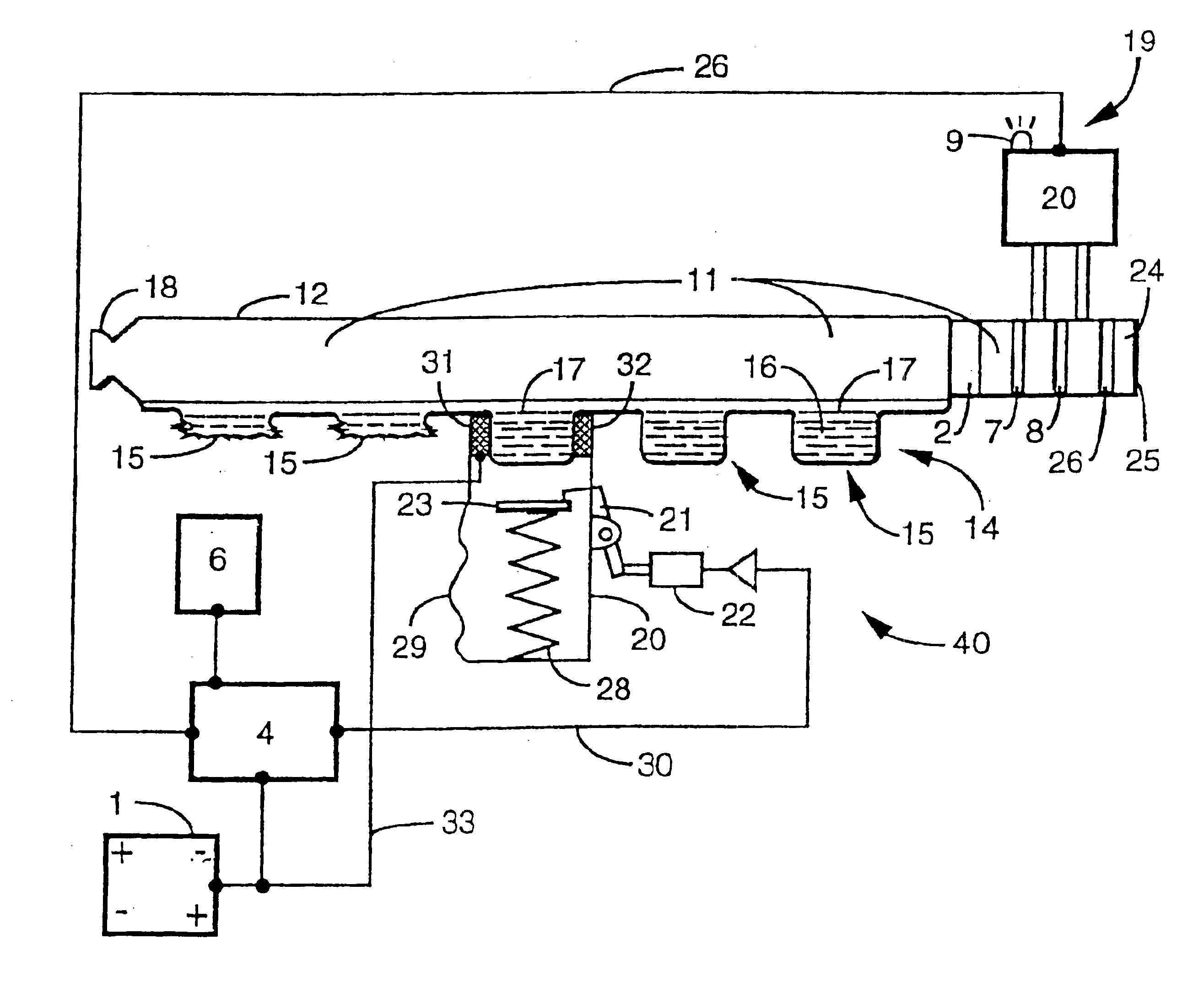

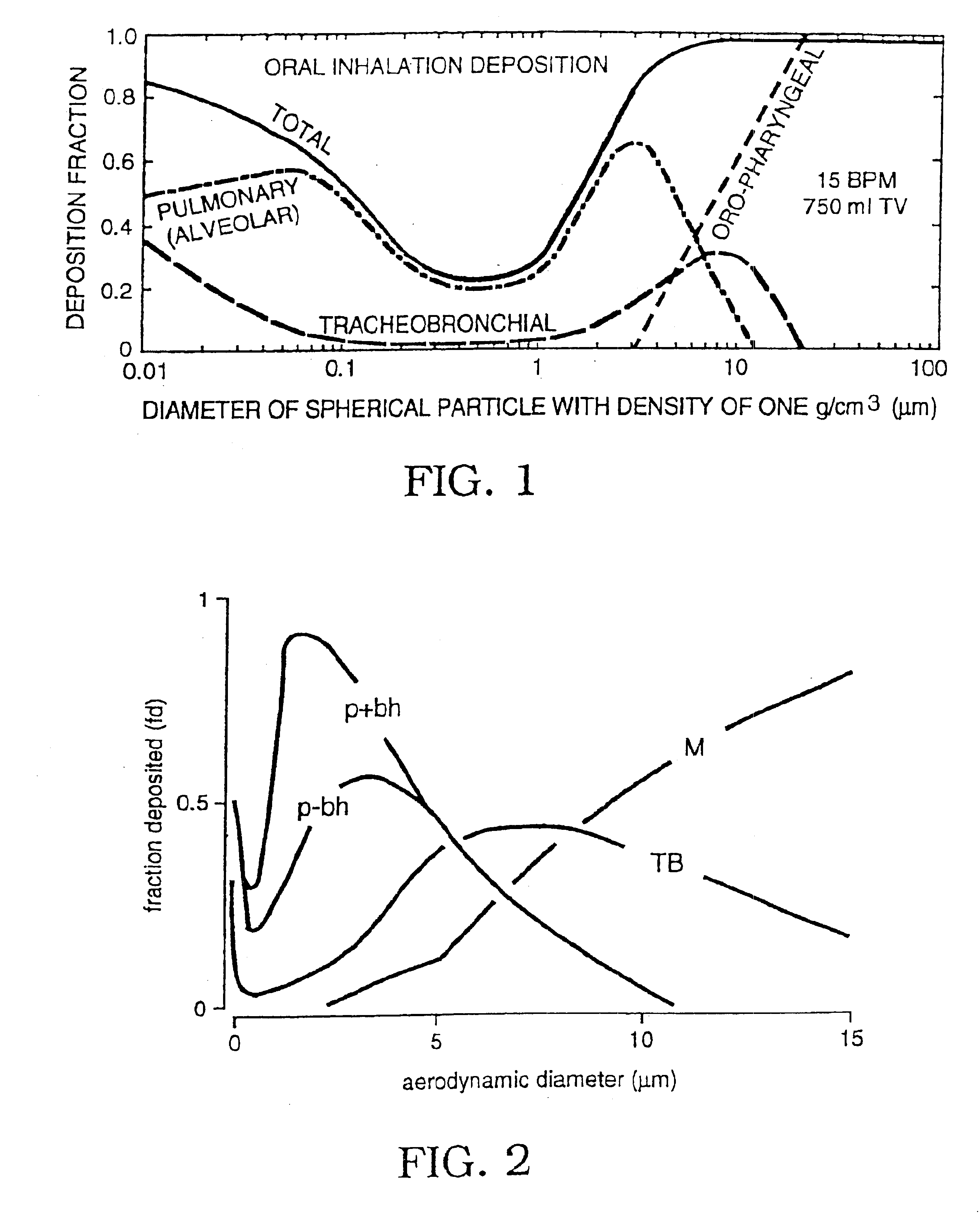

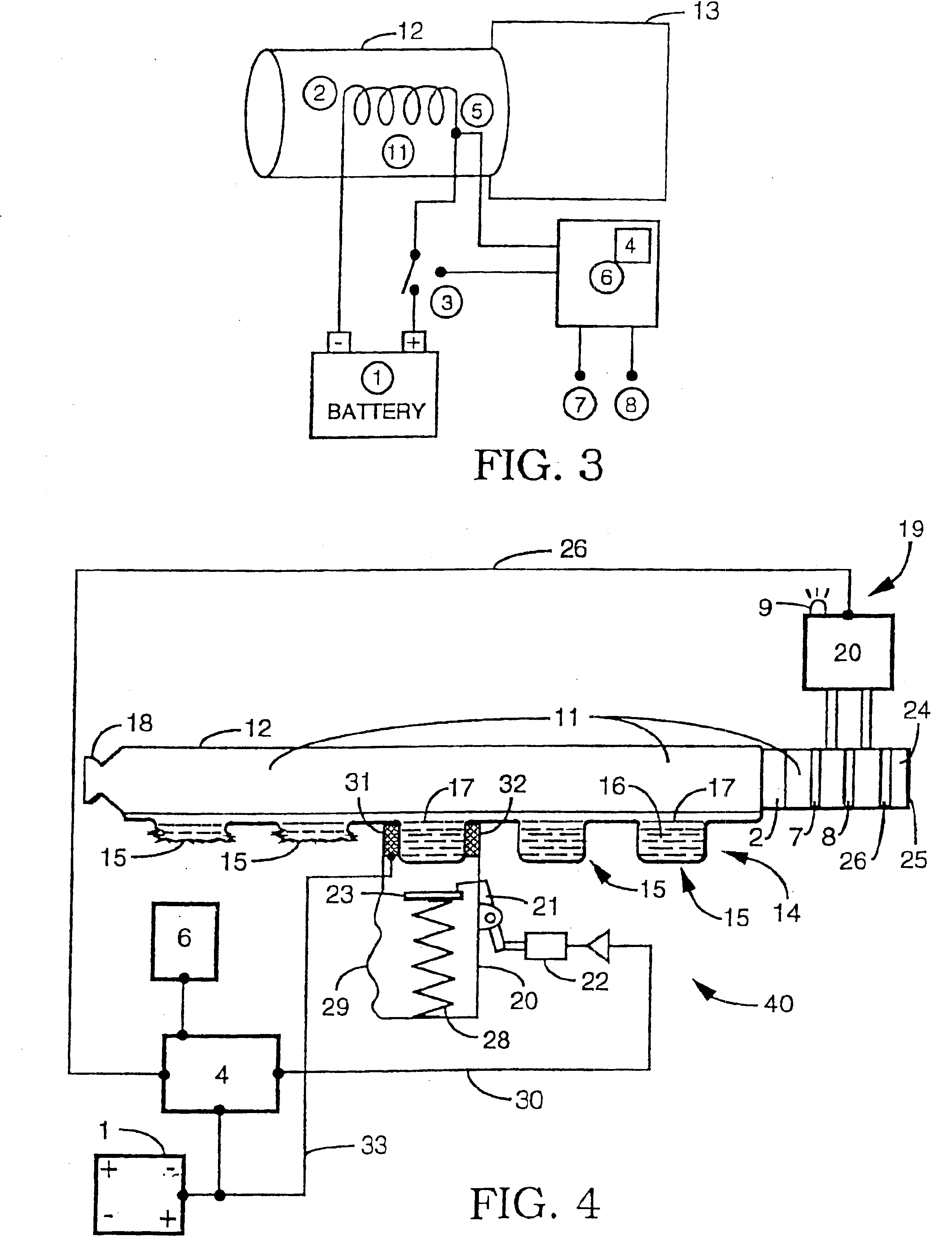

Temperature controlling device for aerosol drug delivery

InactiveUS6845216B2Improve drug delivery efficiencyGood repeatabilityRespiratorsMedical devicesTemperature controlMedicine

A portable air temperature controlling device useful for warming air surrounding an aerosolized drug formulation is described. Warming the air of an aerosol makes it possible to reduce the size of aerosol particles produced by an aerosol generation device. Additionally, warming the air forces the size of the aerosol particles to be in the range required for systemic drug delivery independent of ambient conditions. Smaller particles can be more precisely targeted to different areas of the respiratory tract.

Owner:ARADIGM

Method and an apparatus for determining the radio frame structure of time division duplex system

ActiveUS8472465B2Flexible supportDecreasing adjustment granularitySynchronisation arrangementTime-division multiplexEngineeringTime-division multiplexing

A method for determining the radio frame structure of a Time Division Duplex system is disclosed, which comprises: configuring, by the network side, the radio frame structure used for service transmission as containing two half-frames each of 5 ms, wherein each half-frame consists of eight service time slots of 0.5 ms and one special time slot field of 1 ms, two consecutive service time slots form a subframe of which the length is 1 ms, and the special time slot field contains a DwPTS, a GP and an UpPTS; determining the lengths of the DwPTS, the GP and the UpPTS in the special time slot field according to the requirements of the coverage range, and determining the radio frame structure used for service transmission. By reconfiguring the radio frame structure, the invention can flexibly support different coverage ranges, enhance the flexibility of satisfying different service requirements, and implement the coexistence of two types of TDD systems.

Owner:DATANG MOBILE COMM EQUIP CO LTD

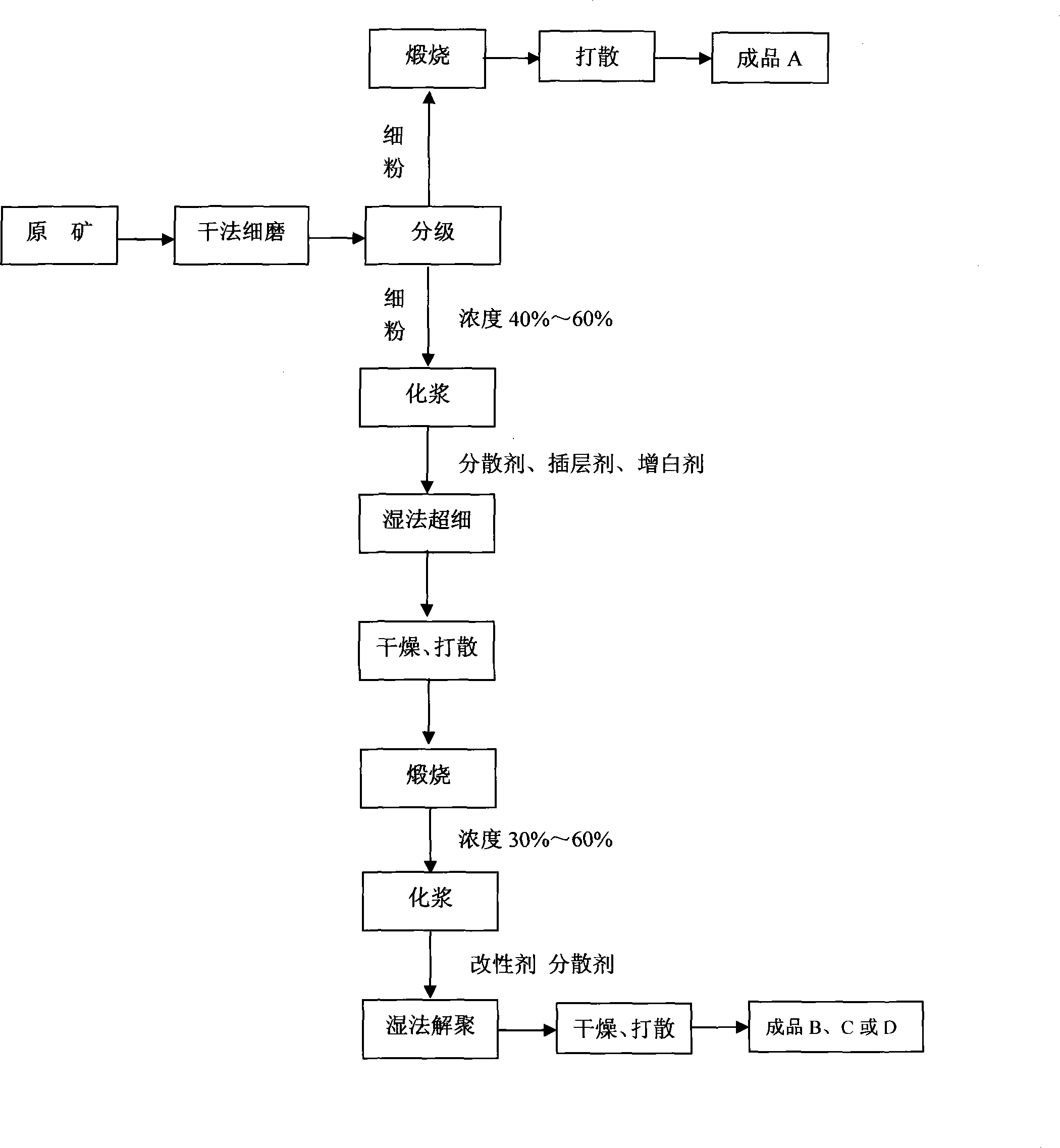

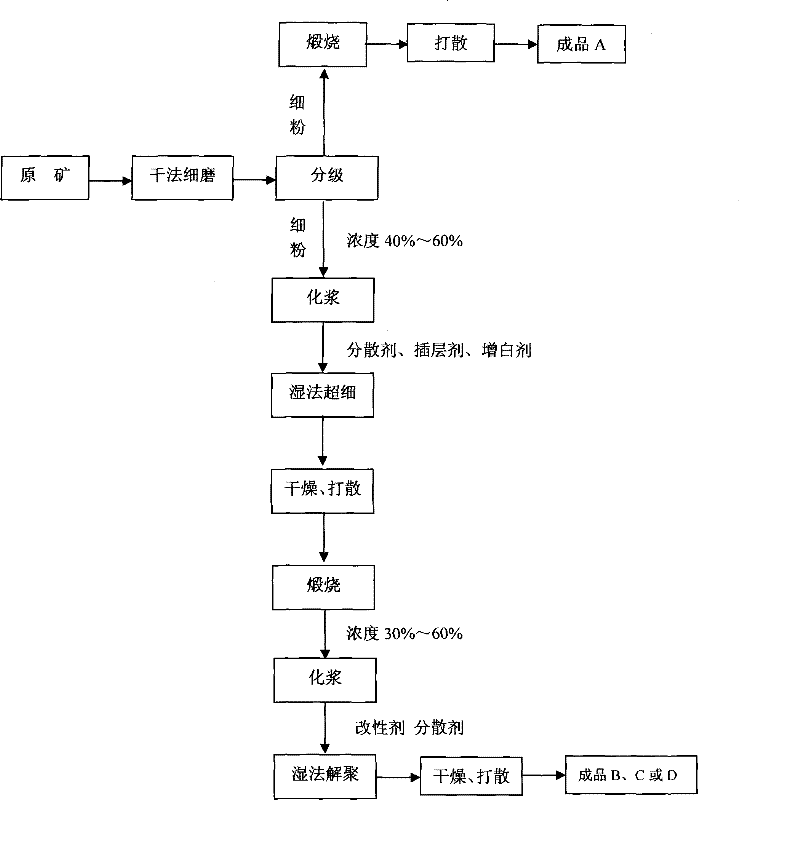

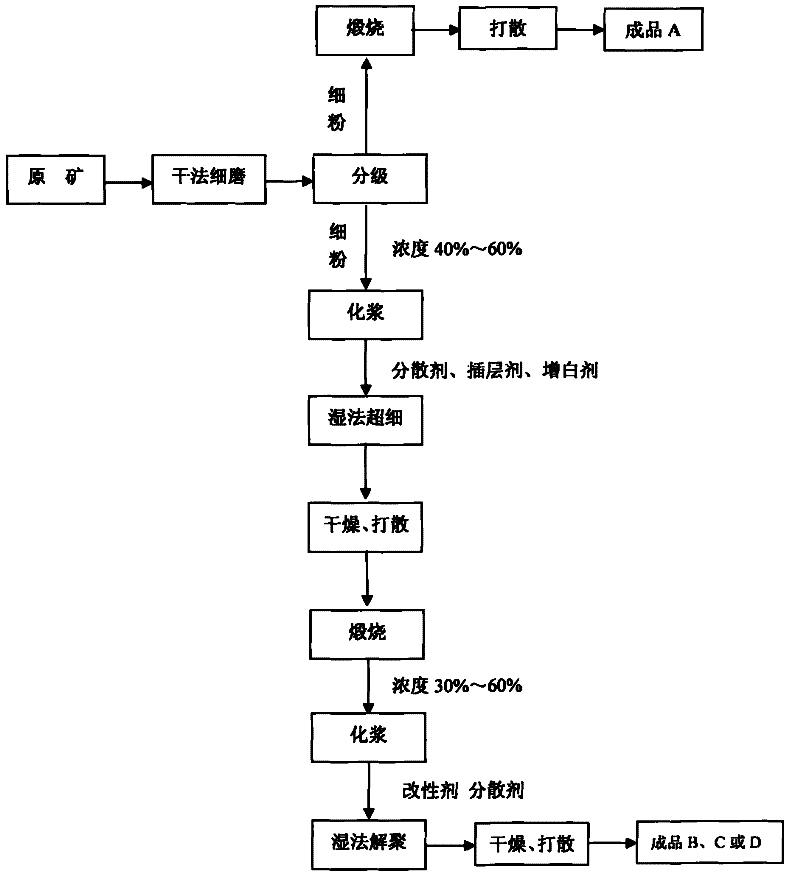

Method for producing ultra-fine calcination white bole with combination of dry and wet method

ActiveCN101244827AReduce energy consumptionImprove grinding efficiencySilicon compoundsWet grindingRotary kiln

The invention discloses a dry-wet combination method to prepare superfine calcined kaolin. After grinding by dry method, the kaolin raw ore grains are classified according to the grain size. The superfine with the grain greater than 1250 meshes can be made into a finished product by direct calcination. While for the meal with the grain less than 1250 meshes, dispersing agent, intercalation agent, and whitening agent can be added simultaneously under wet grinding, so as to improve the grinding efficiency, shorten the grinding time, and reduce the energy consumption during grinding process, as well as improve the mixing effect of the whitening agent and the kaolin. The meal scattered and dried after grinding, is sent into rotary kiln for calcinations. The kaolin is grinded again after calcination by wet grinding method. The dispersing agent and modifying agent are added simultaneously, to combine the superfine grinding and the modifying of product simultaneously. The modified powder is grinded to obtain the other finished product after drying and scattering. The invention allows superfine calcined kaolin with different specification during the same production line by the control of the process condition, thus reducing the working procedure, improving the added value of product, broadening the application field and product performance, so as to meet the requirements of different customers.

Owner:内蒙古蒙西高岭粉体股份有限公司

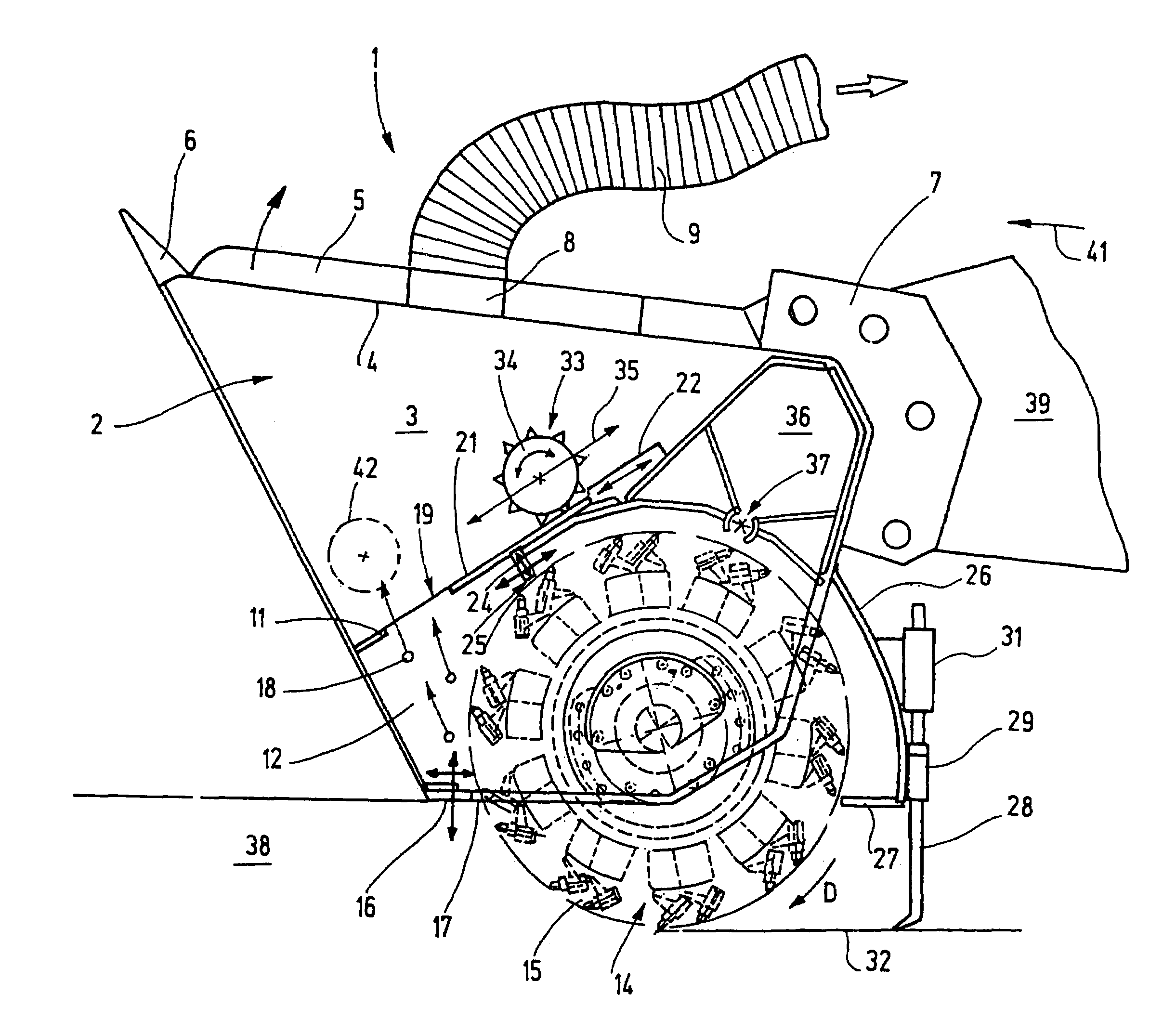

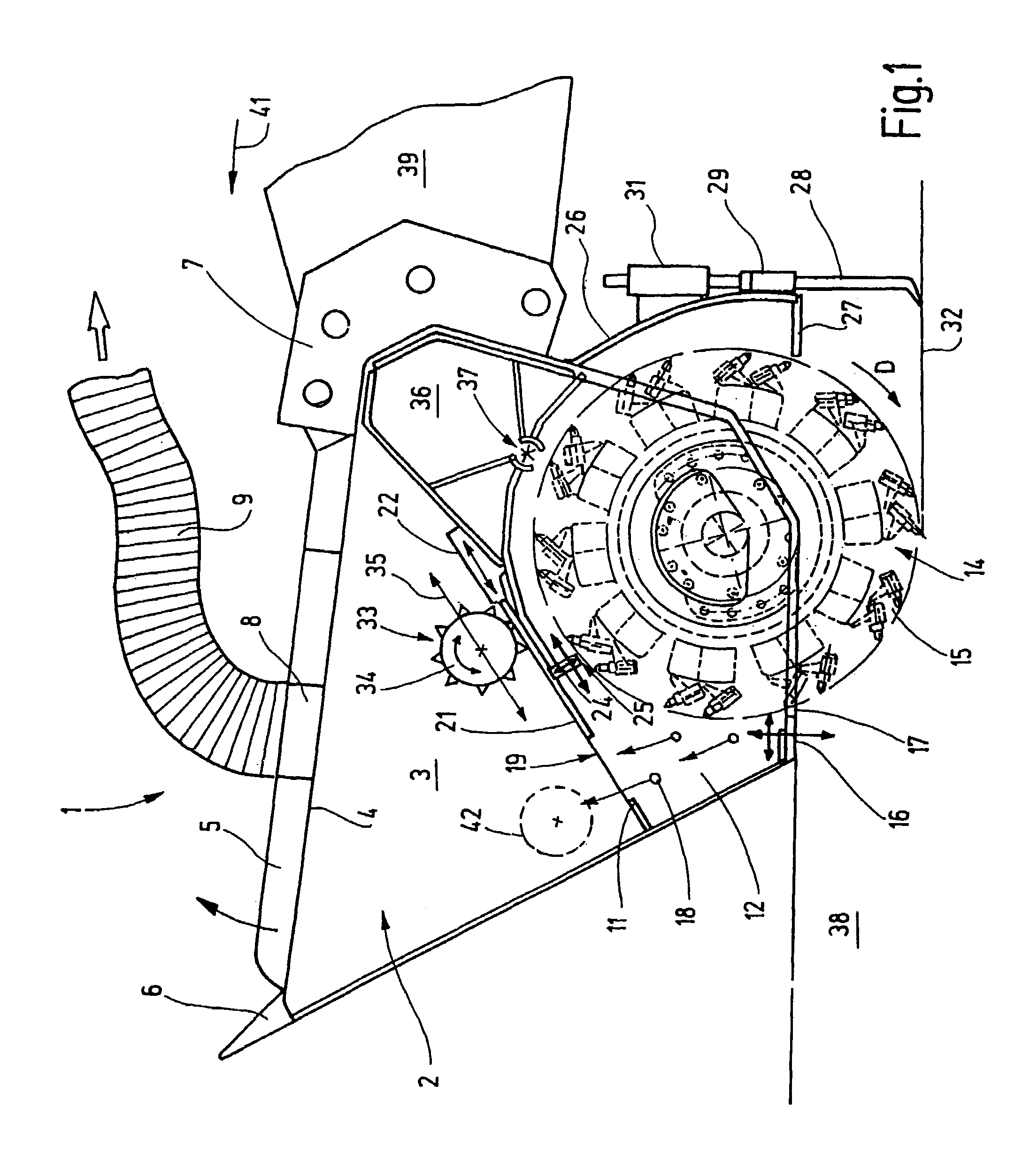

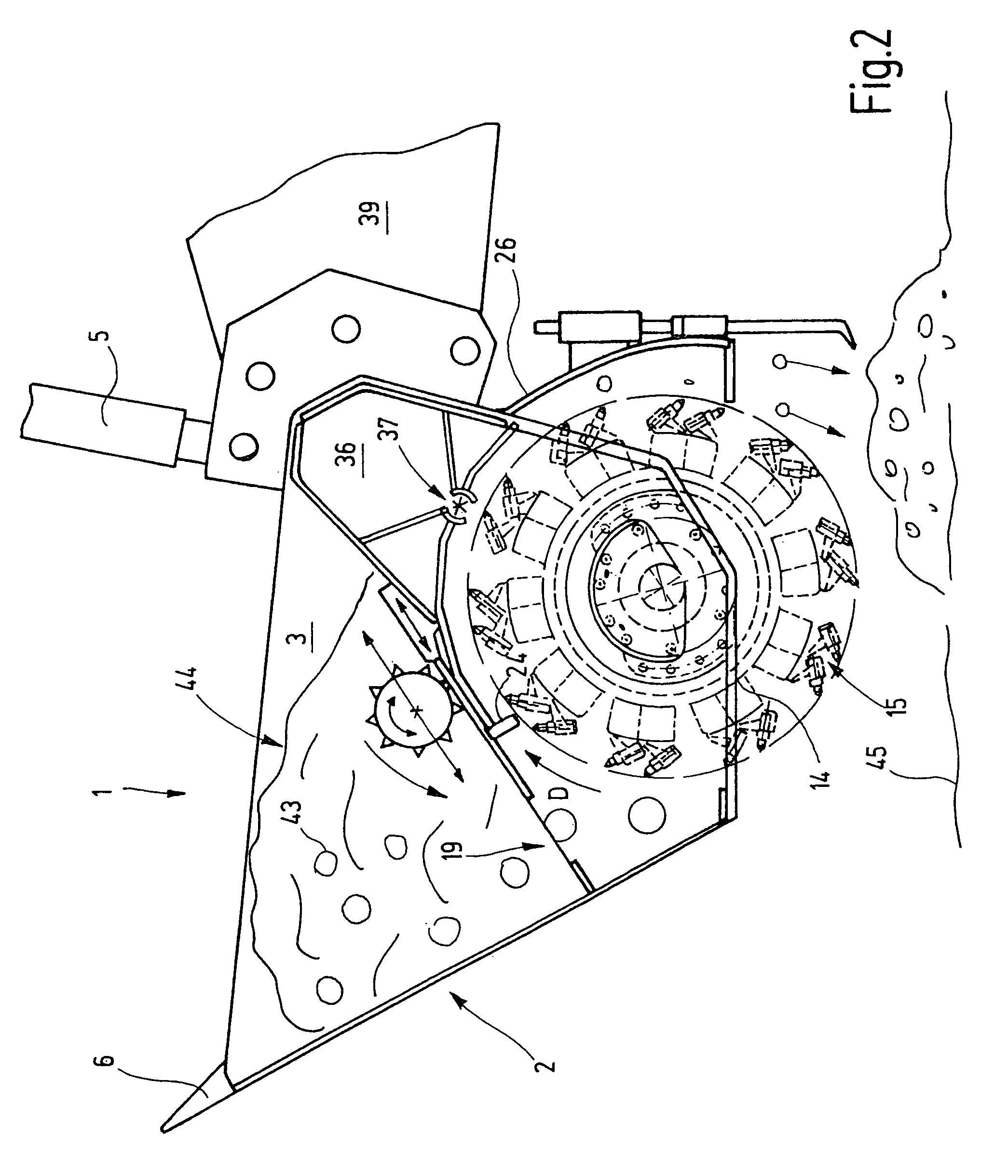

Milling device for floors, rock, excavated material or other material

InactiveUS7284345B2Versatile in useWide range of usesMechanical machines/dredgersRoads maintainenceOperation modeEngineering

The milling apparatus (1) has a bucket with a receiving chamber and has a milling unit with a milling rotor (14). The receiving chamber has a receiving opening (4) and is embodied as a bucket (2). On the bottom of the bucket (2), a through opening (19) is provided, which leads into a milling chamber (12). The milling rotor (14) can move material both into the receiving chamber and out of it again. To achieve both modes of operation, in a first embodiment a drive mechanism rotating in a predetermined direction (D) is provided; a beating arm (16) is associated with the first mode of operation, and a further beating arm (24) is associated with the second mode of operation. In another embodiment, which makes do with a single beating arm (16), the milling unit (54) can be operated in two different working positions via a turner. The positions differ from one another by a 180° rotation about a vertical axis that is perpendicular to the axis of rotation of the milling rotor (14).

Owner:SCHENK JURGEN

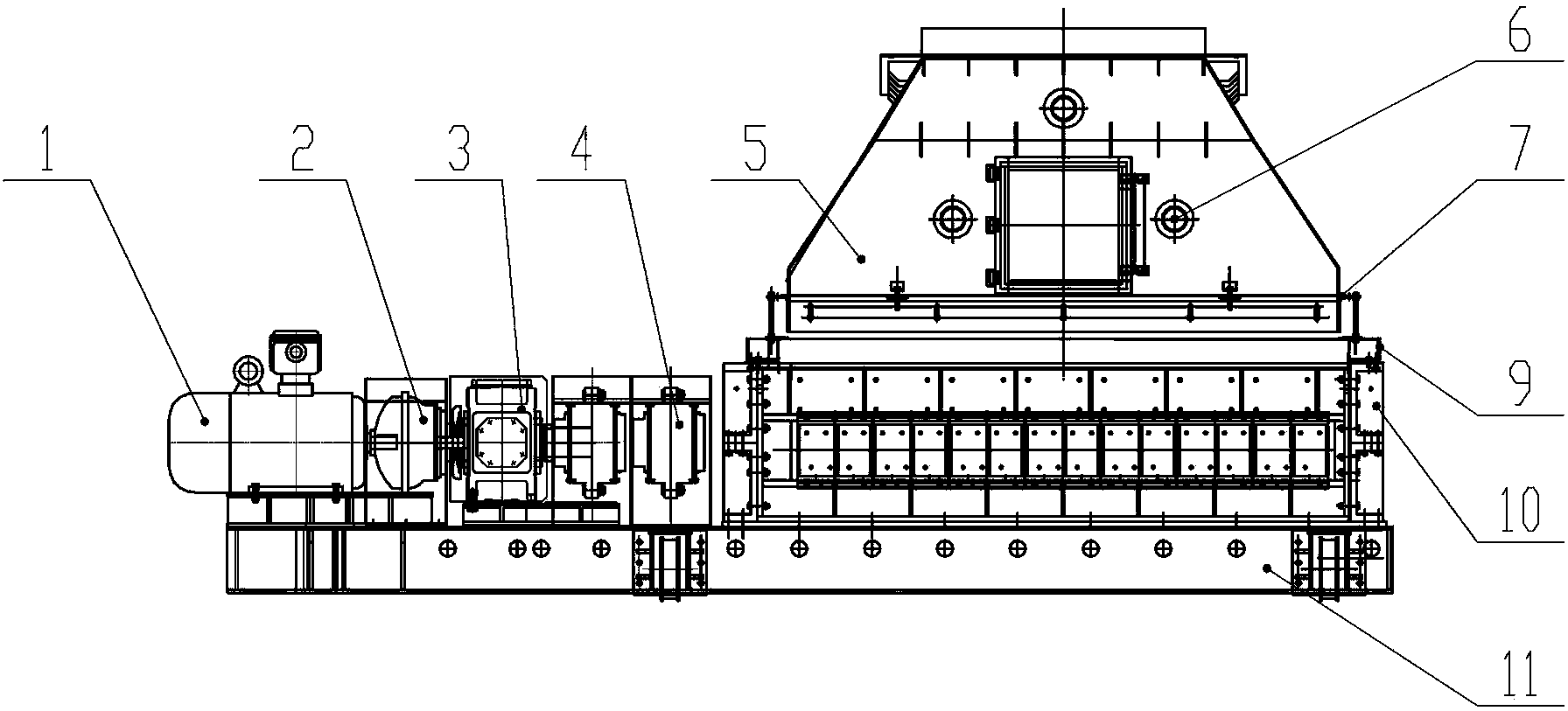

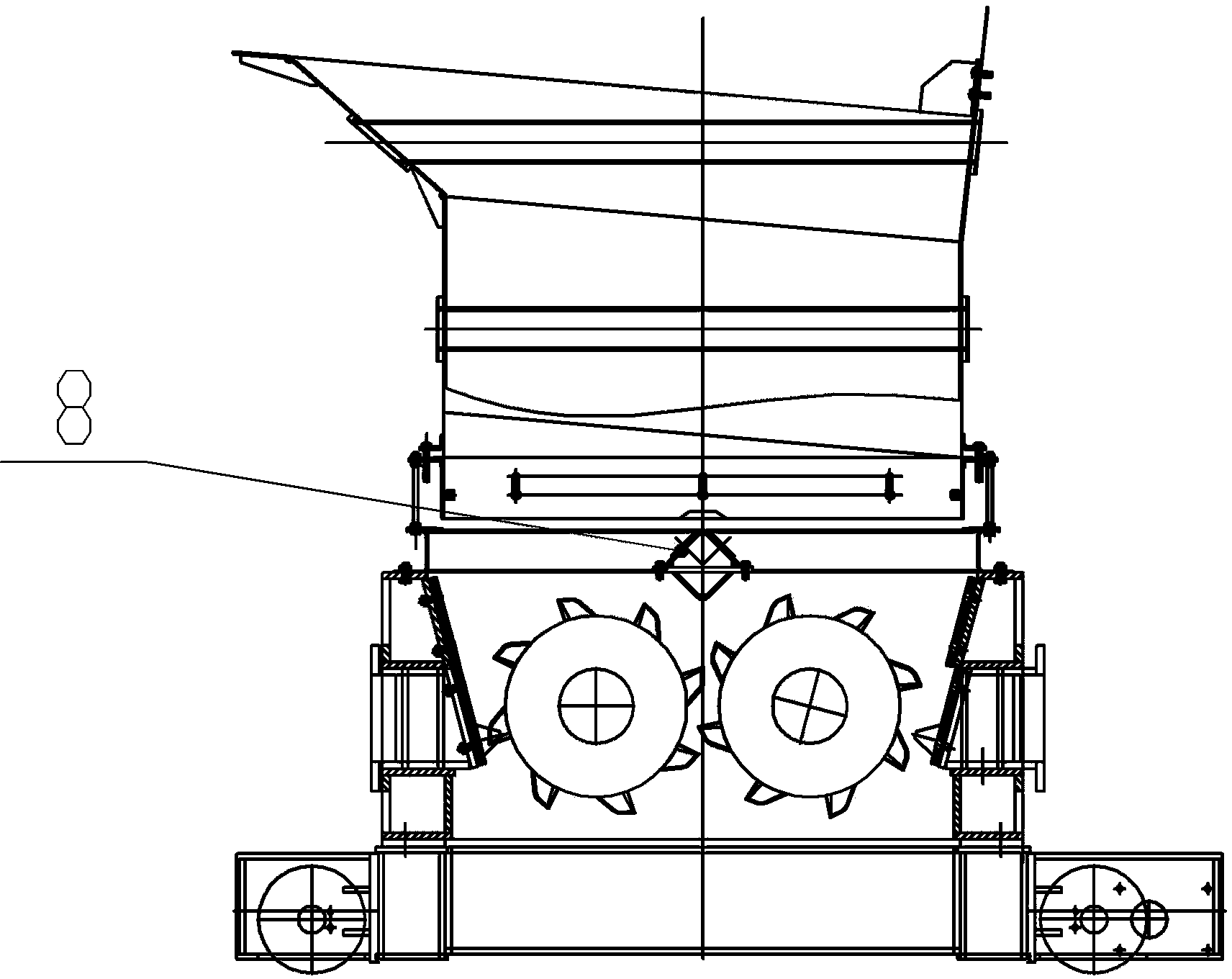

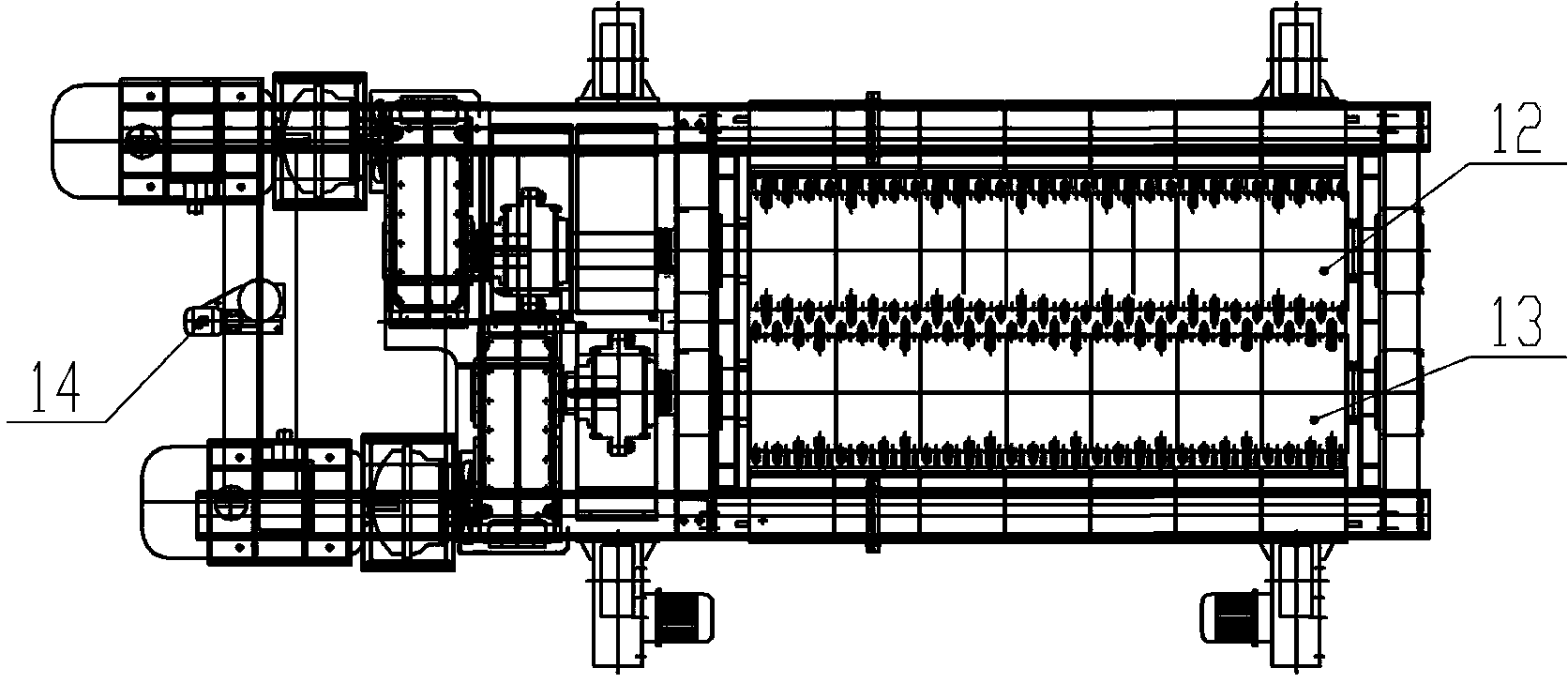

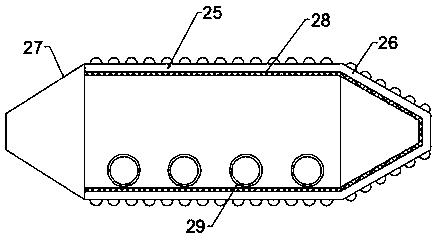

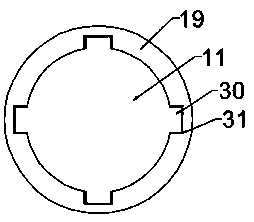

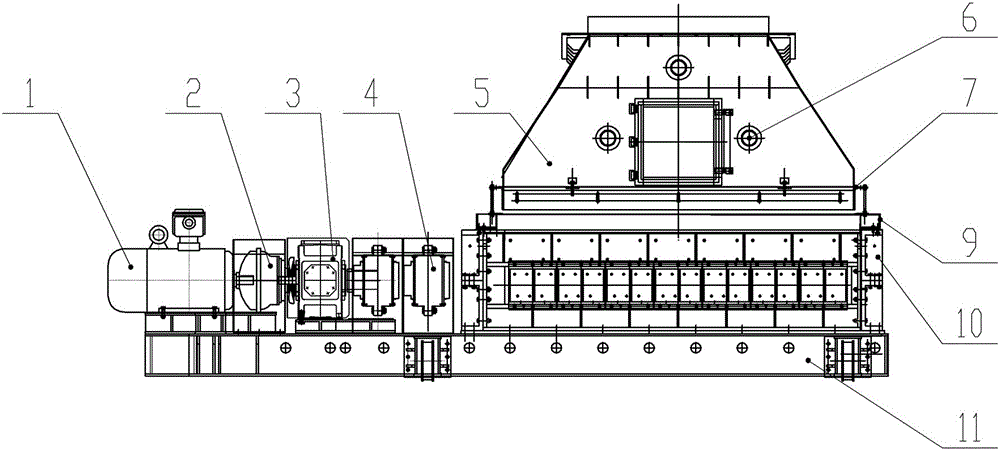

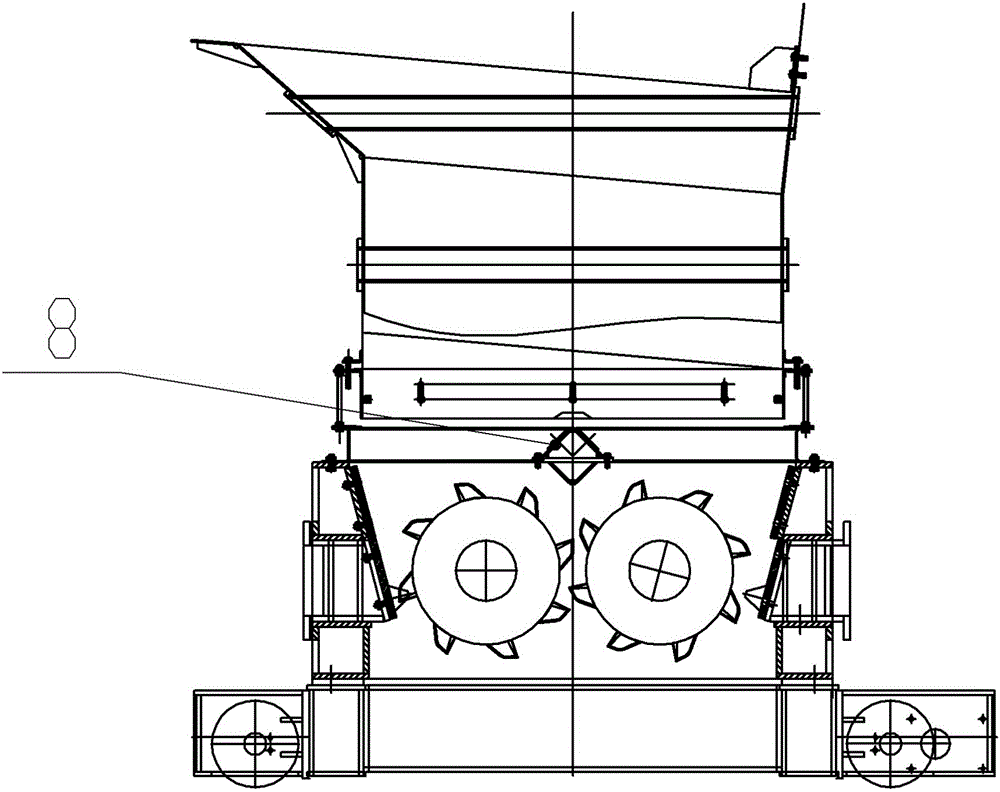

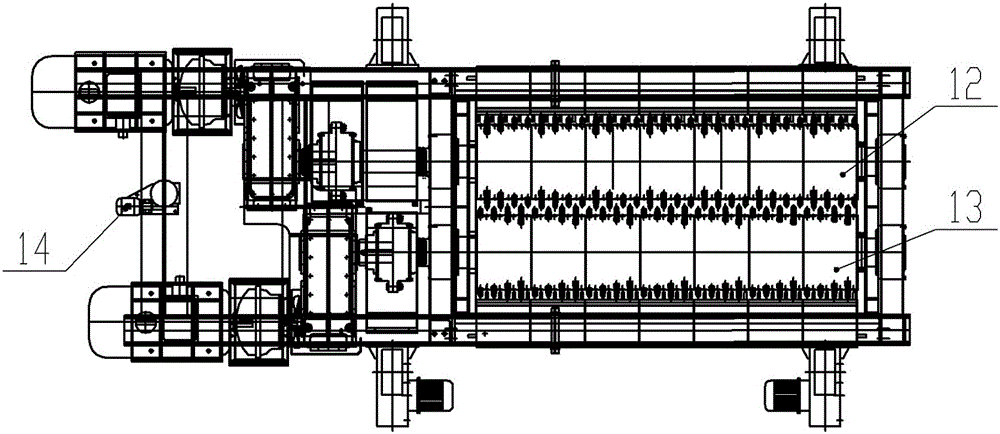

Large efficient screening-type double-toothed roll crusher provided with distribution device

The invention discloses a large efficient screening-type double-toothed roll crusher provided with a distribution device. The double-toothed roll crusher comprises a crushing device and the distribution device. The crushing device comprises a crushing drive motor, a fluid coupling, a reducer, a double-drum gear coupling, a crushing box, a base support, a left toothed roll, a right toothed roll and a lubricating grease pump, wherein the crushing drive motor, the fluid coupling, the reducer and the double-drum gear coupling form two sets of crushing drive units; and the two sets of crushing drive units are connected wit the left toothed roll and the right toothed roll inside the crushing box respectively. The distribution device comprises a distribution chute, an adjustable distribution stick, a movable connecting bracket, a distribution seat and a fixed connecting bracket, wherein the fixed connecting bracket and the distribution seat are fixed on the crushing box of the crushing device, the distribution chute is fixed at a discharge port of a material output belt machine head, and the distribution chute is connected with the crushing box through the movable and fixed connecting brackets. According to the large efficient screening-type double-toothed roll crusher, the problems of capital investment, equipment movement and the like of crushing equipment combined by a plurality of devices are solved fundamentally, the labor intensity of daily equipment maintenance is reduced, and the mining of surface mine materials is accelerated.

Owner:HENAN ZHENYUAN TECH

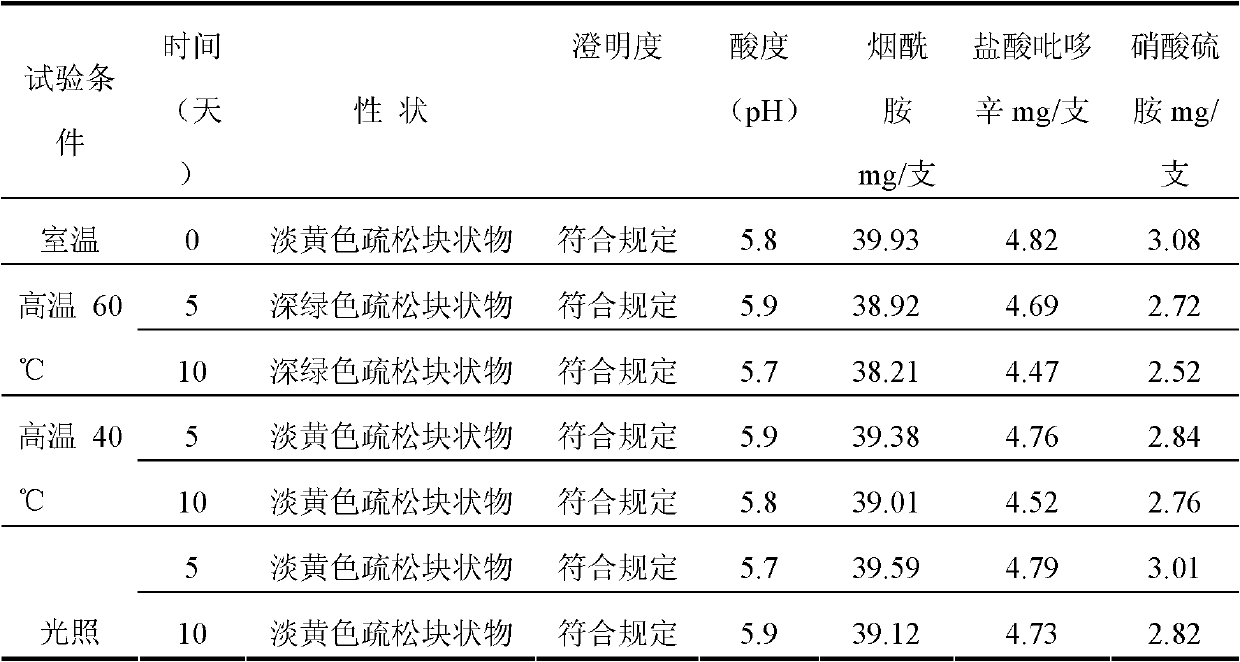

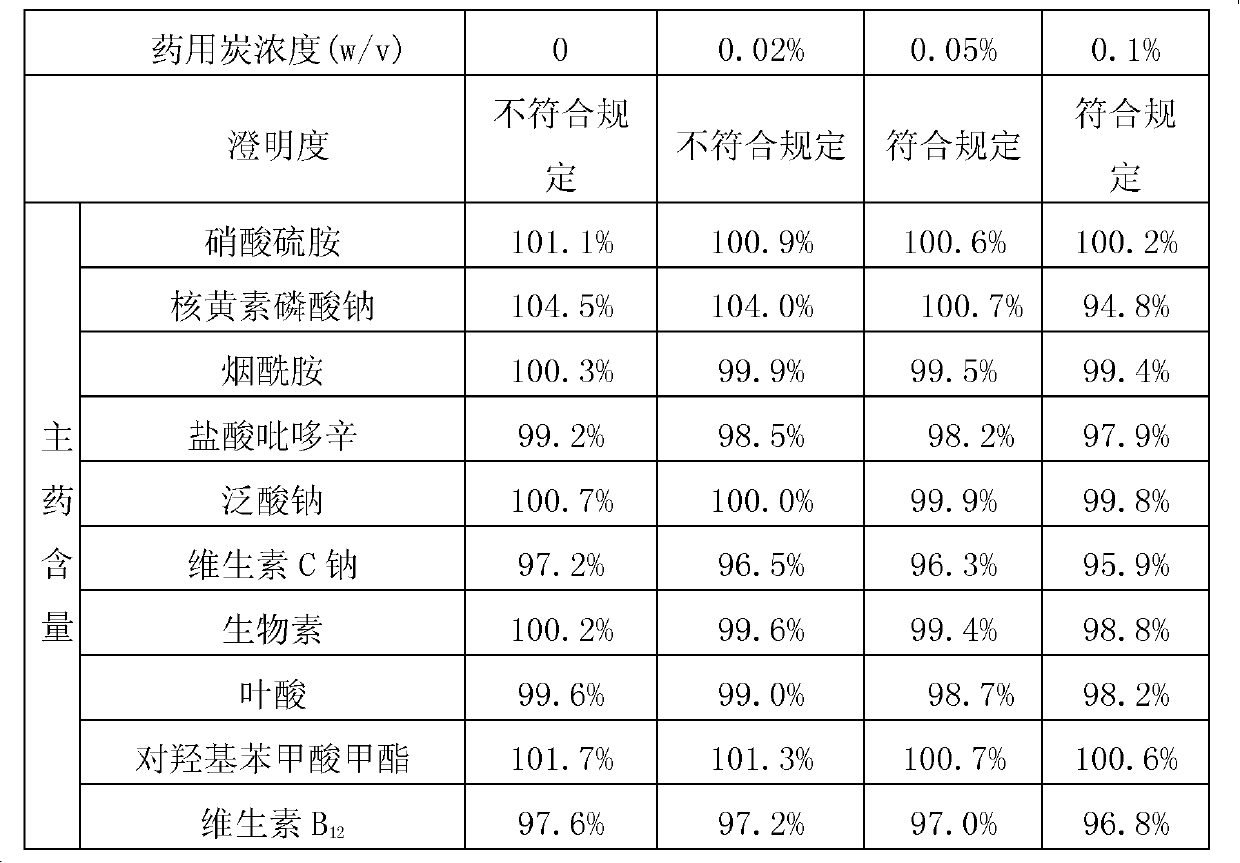

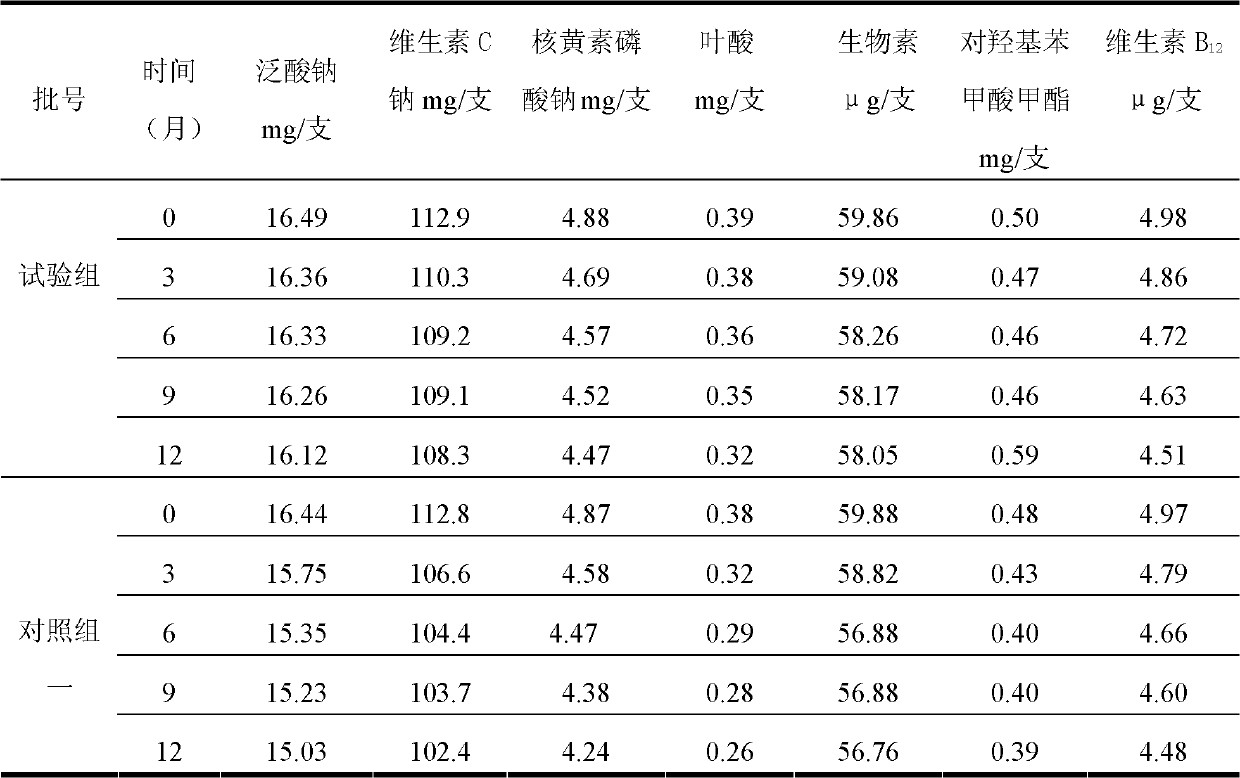

Water-soluble vitamin composition freeze-drying preparation for injection

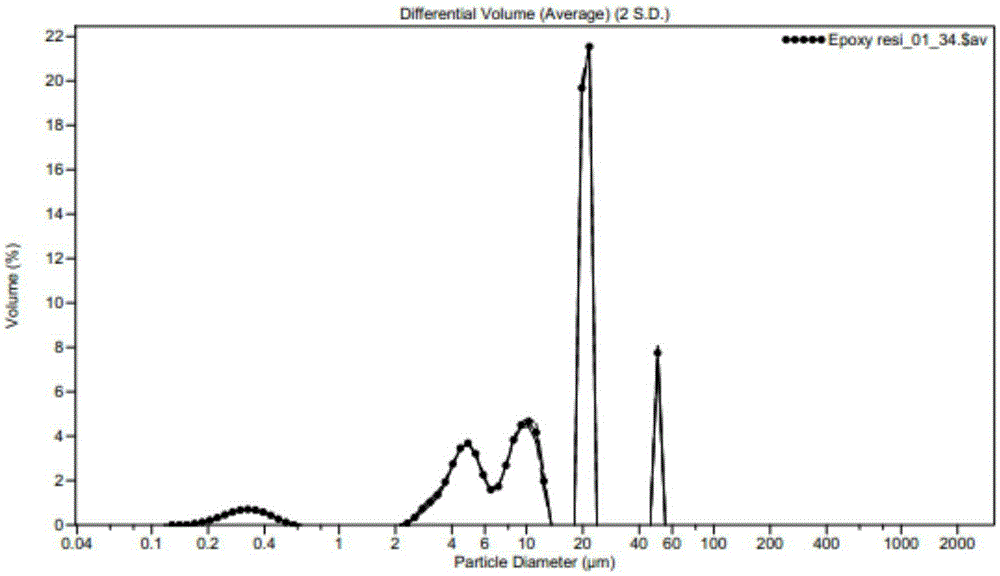

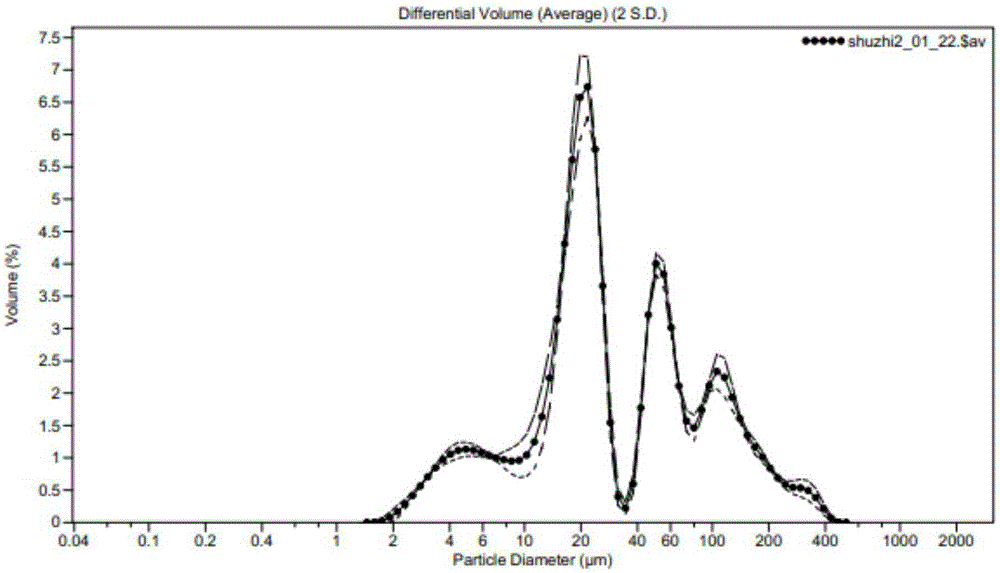

ActiveCN101904862AGranularity adjustableConcentrated particle size distributionPowder deliveryMetabolism disorderFreeze-dryingSodium pantothenate

The invention discloses a water-soluble vitamin composition freeze-drying preparation for injection. The freeze-drying preparation comprises the following raw materials and is prepared into 1,000 bottles: 2.8 to 3.4 grams of thiamine mononitrate, 36 to 44 grams of nicotinamide, 4.4 to 5.4 grams of pyridoxine hydrochloride, 14.8 to 18.1 grams of sodium pantothenate, 4.4 to 5.4 grams of riboflavin sodium phosphate, 102 to 124 grams of sodium vitamin C, 54 to 66 milligrams of biotin, 0.36 to 0.44 gram of folic acid, 124.5 to 6.0 milligrams of vitamin B, and 0.4 to 0.6 gram of methyl-p-hydroxy benzoate, wherein the nicotinamide is nicotinamide hydrate, and the sodium pantothenate is sodium pantothenate hydrate. The water-soluble vitamin for injection has adjustable grain size, concentrated grain size distribution, glabrous surface, high product fluidity, greatly improved stability and high dissolution rate, and a preparation process of the preparation is simple and is favorable for popularization and use.

Owner:SHANDONG YUXIN PHARMA CO LTD

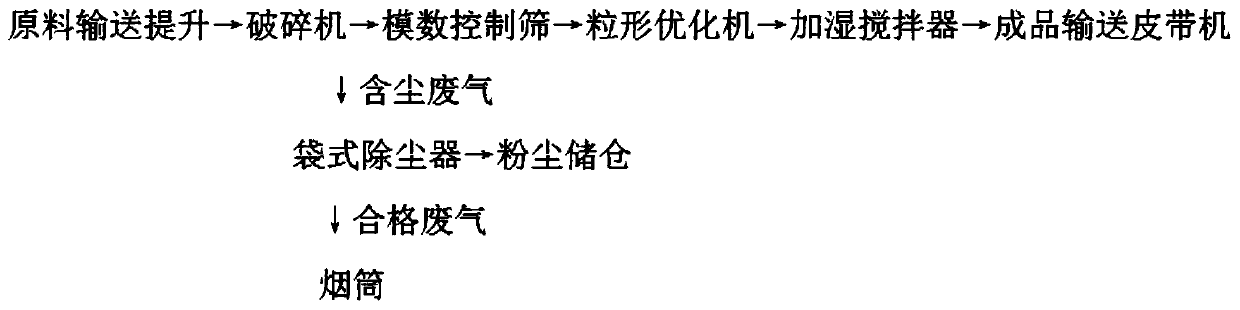

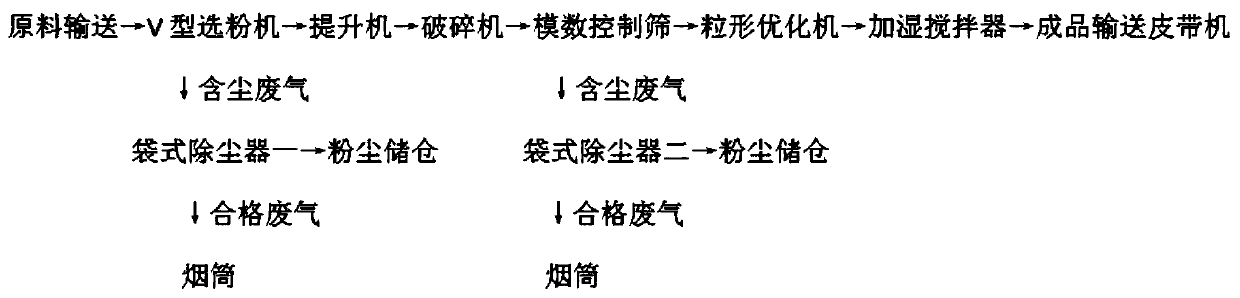

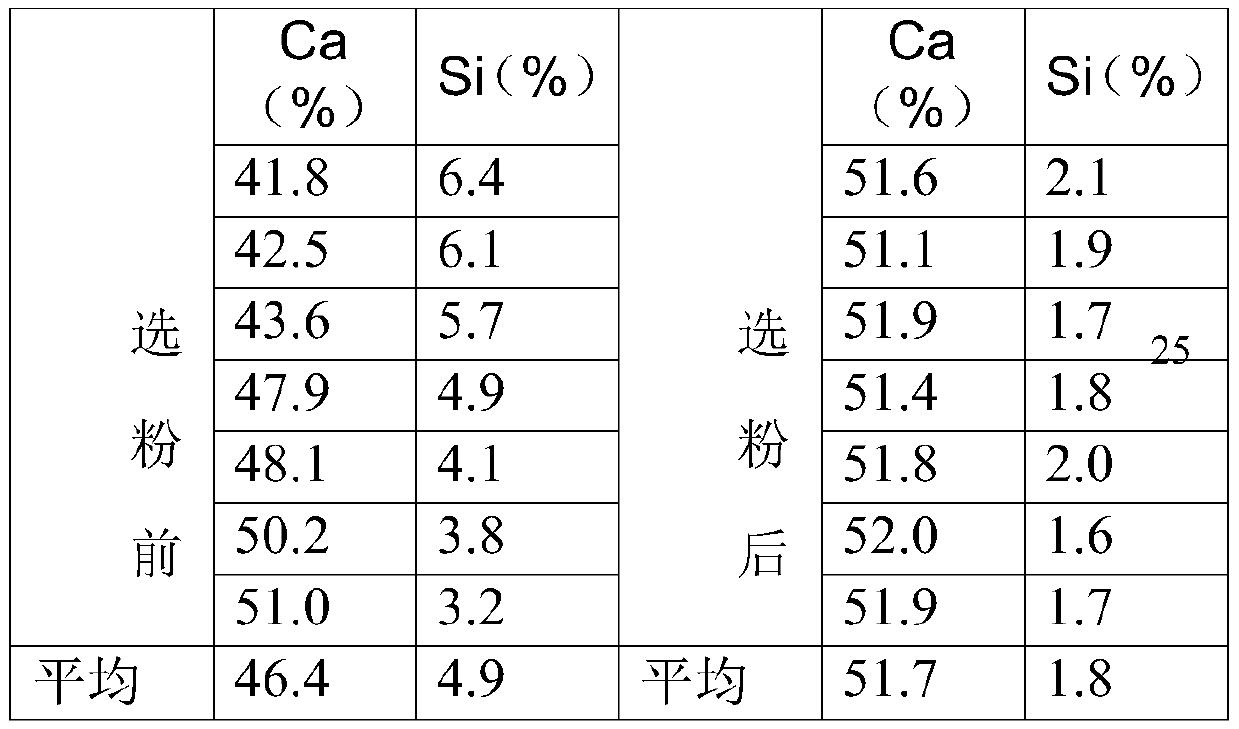

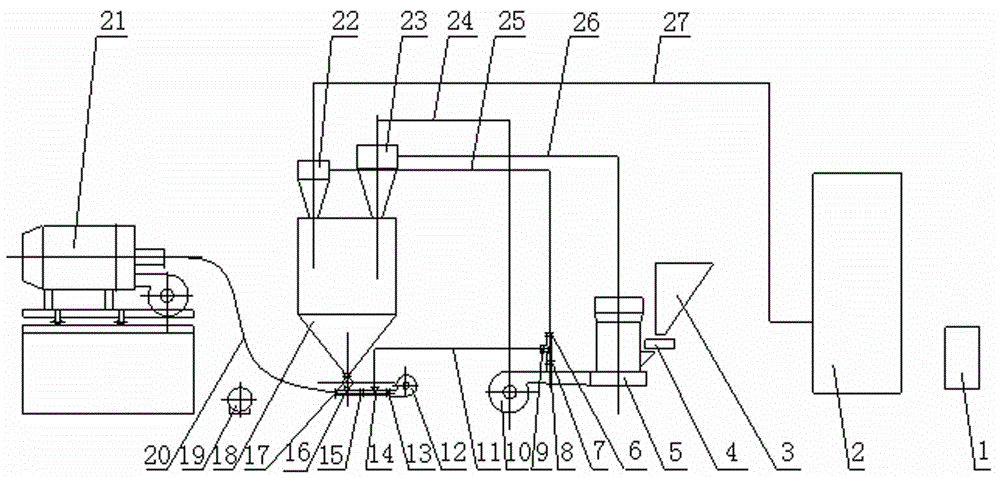

Production process method for machine-made sand aggregate

The invention discloses a production process method for machine-made sand aggregate and belongs to the field of sand aggregate production. The production process method solves the technical problem ofhow to remove clay impurities and improve the quality of the sand aggregate. According to the technical scheme, the method comprises the following steps: S1, conveying a raw material to a V-shaped powder concentrator to concentrate powder to obtain pre-treated raw material; S2, dedusting the pre-treated raw material by a bag type dust collector I while concentrating powder; S3, conveying the pre-treated raw material to a crusher to be crushed through a lifter to obtain a crushed material; S4, conveying the crushed material to an analogue-digital control screen to be screened to obtain a screened material; S5, dedusting the screened material through a bag type dust collector II while screening the material by the analogue-digital control screen; S6, conveying the screened material to a particle shape optimizing machine to granulate to obtain an optimized grain sand aggregate; and S7, conveying the optimized grain sand aggregate which is humidified by a humidifying stirrer to a belt conveyor.

Owner:泰安鲁珠保温建材有限公司

Method for preparing plate-like structure WC-Co composite powder by utilizing waste cemented carbide

The invention discloses a method for preparing plate-like structure WC-Co composite powder by utilizing waste cemented carbide. The method comprises the steps that (1) the waste cemented carbide is placed in a muffle furnace for oxidizing roasting in order to obtain a tungsten cobalt oxidation product; (2) the tungsten cobalt oxidation product is crushed in order to obtain tungsten cobalt composite oxide powder; (3) at least one of a tungsten oxide, a cobalt oxide and carbon is added into the tungsten cobalt composite oxide powder in order to regulate the content ratio between tungsten, cobaltand the carbon to reach a predetermined value; (4) inorganic salt is added into a mixture obtained from the step (3), and a molten salt reaction is conducted under inert gas protection in order to obtain a synthesized product; and (5) the synthesized product is rinsed in order to remove molten salt particles and obtain the plate-like structure WC-Co composite powder. The method has the advantagesof being simple in technological process and easy to operate, the prepared and obtained plate-like structure WC-Co composite powder is good in plate-like effect, high in purity and adjustable in composition and granularity, and the method can be used for preparing of high-performance plate-like grain cemented carbide.

Owner:CHONGYI ZHANGYUAN TUNGSTEN

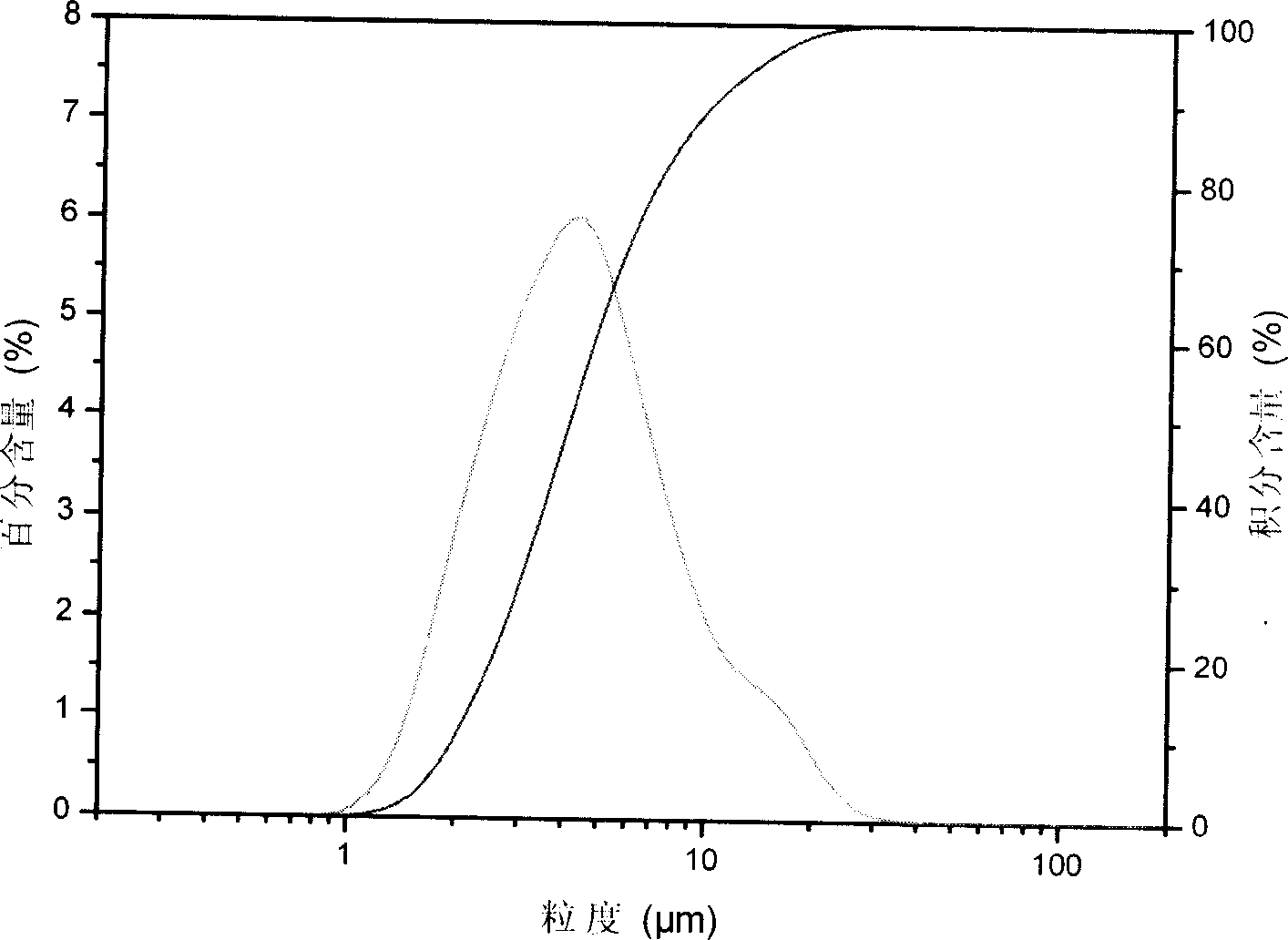

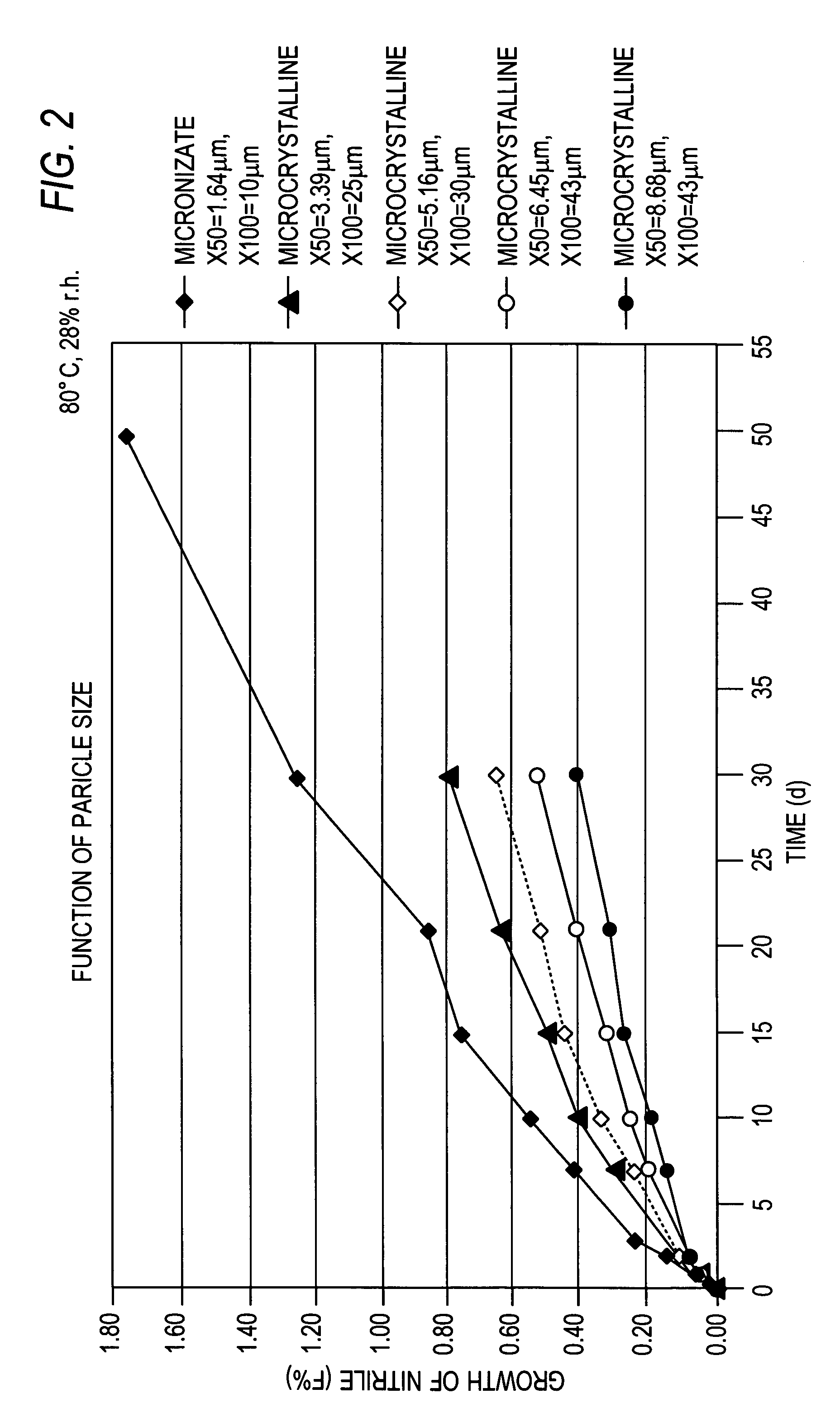

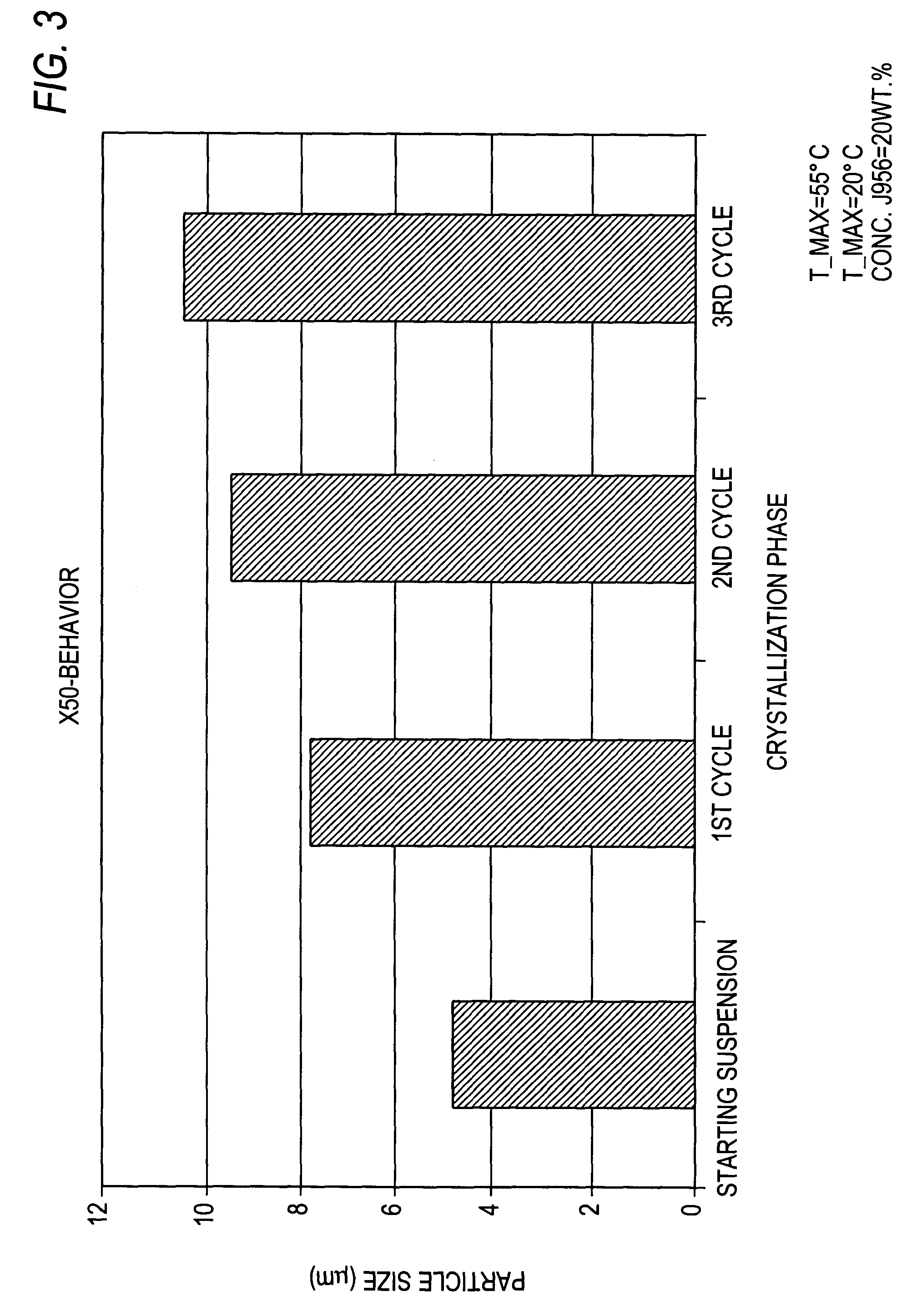

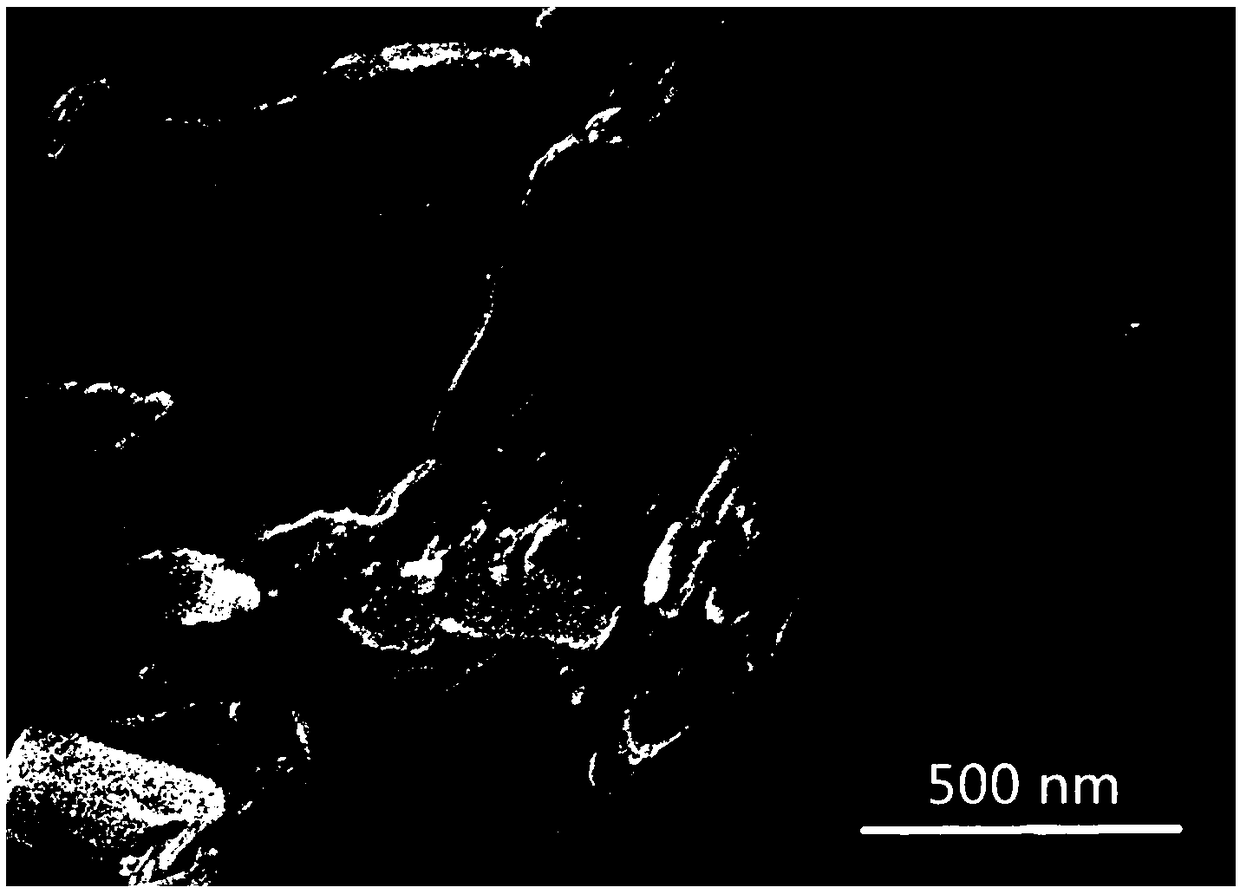

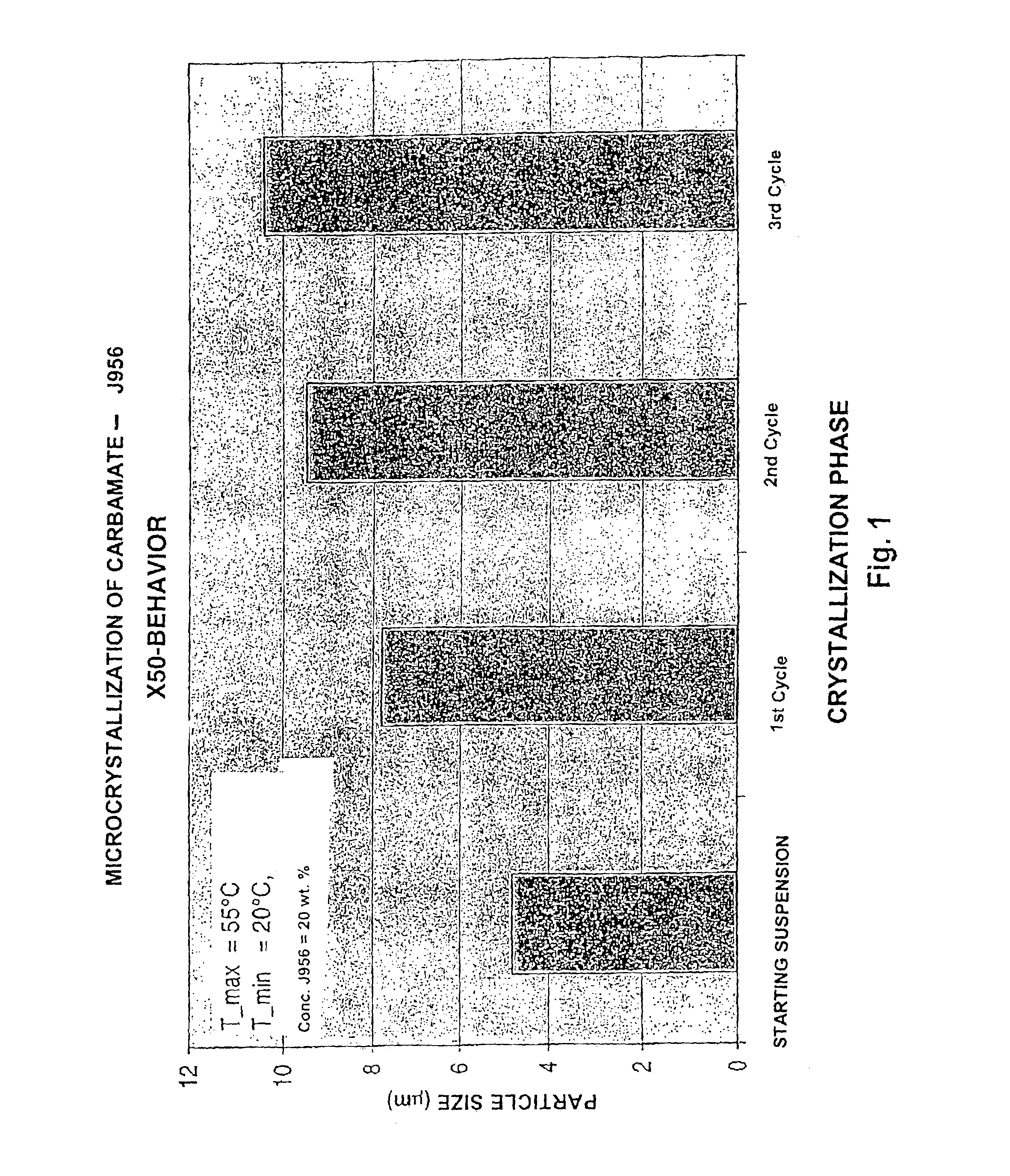

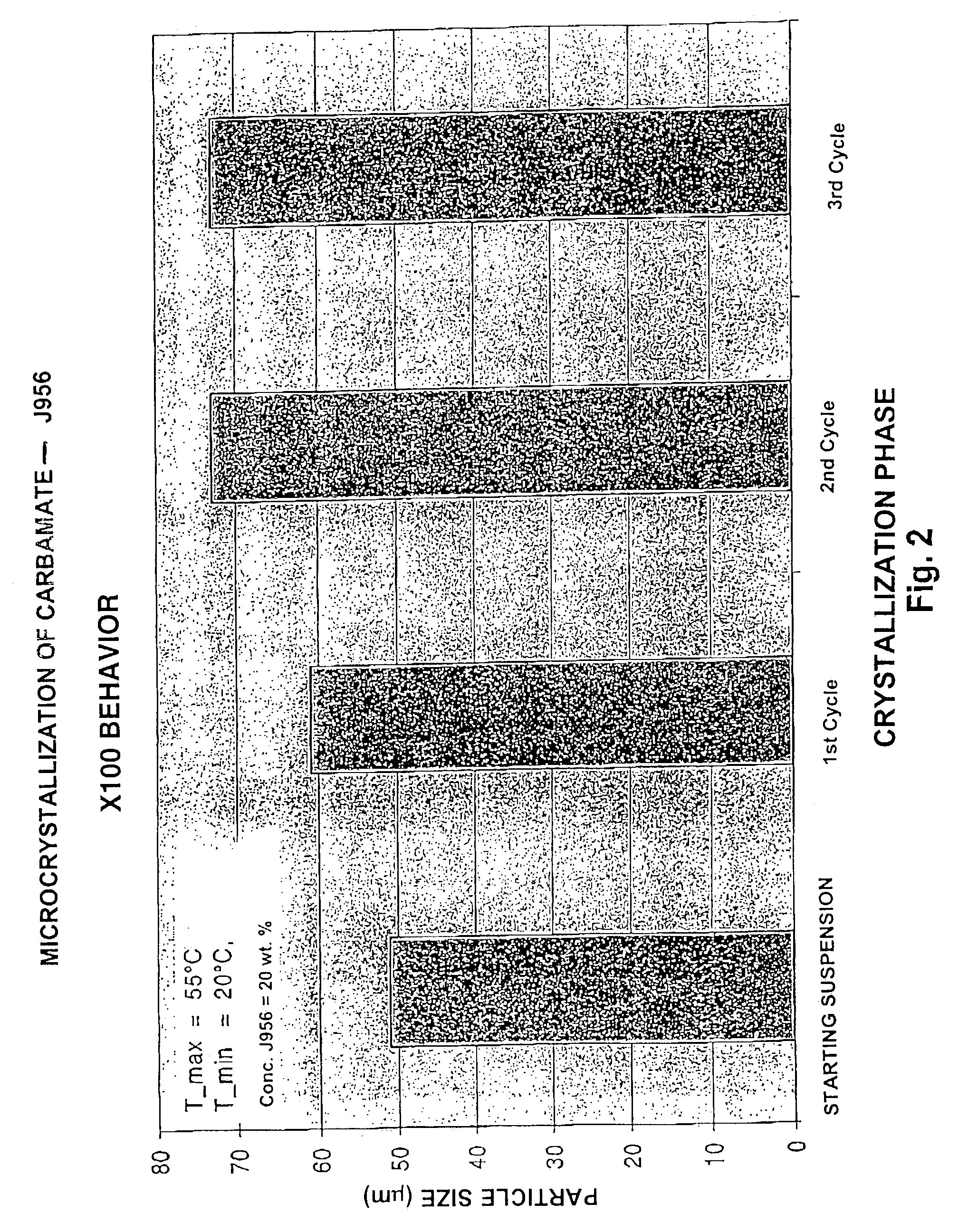

Process for production of crystals of 11mu-benzaldoxim-estra-4,9-diene derivatives, crystals obtained thereby and pharmaceutical preparations containing them

ActiveUS7192942B2High accuracy and reproducibilityCost-effectiveOrganic active ingredientsPowder deliveryDieneCrystal

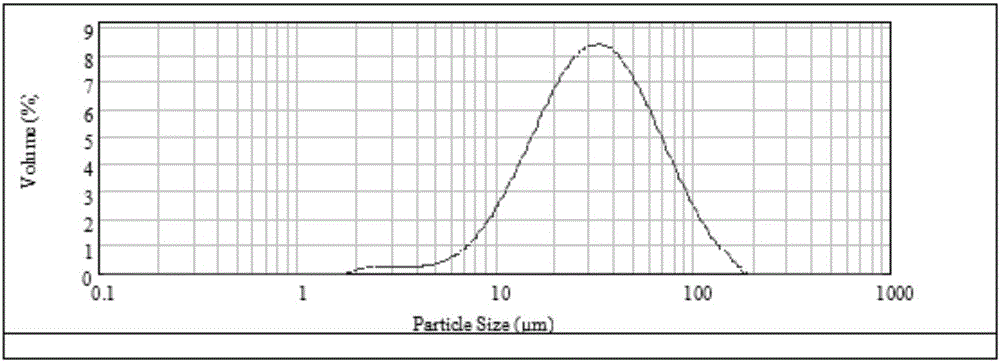

The process for making crystals of a 11 β-benzaldoxim-estra-4,9-diene derivative having an average particle size of from 3 μm to 25 μm and a maximum particle size of 100 μm, includes subjecting a supersaturated solution containing a special 11β-benzaldoxim-estra-4,9-diene derivative of formula (I) to a wet milling by a wet milling apparatus while crystallizing, In order to obtain a primary particle suspension. Crystals obtained according to this process and pharmaceutical preparations containing them are also described and are part of the invention.

Owner:BAYER INTPROP GMBH

Method for recycling wastes of high-temperature alloy powder

The invention relates to the technical field of recycling of high-temperature alloy powder, and discloses a method for recycling wastes of high-temperature alloy powder. The method comprises the following steps: selecting and blending pure metal powder of high-temperature alloy matrix elements with proper granularity and proportion into the wastes of the high-temperature alloy powder according todifference of high-temperature alloy powder matrixes; conducting uniform mixing and then carrying out compression molding; then calculating the amount of other elements required to be added into the powder subjected to compression molding according to the proportion of the original high-temperature alloy powder and the amount of the added matrix pure metal powder; and conducting remelting and casting to obtain a bar material which is the same as finished high-temperature alloy powder. According to the method, by properties of low hardness and low yield strength of the pure metal powder of thematrixes of the high-temperature alloy, a forming effect is achieved in a room-temperature pressure forming process. Since any binder is not used and other impurity elements are not introduced, the high-temperature alloy powder which cannot be directly used can be effectively recycled through the process, and the powder forming efficiency is improved.

Owner:江苏奇纳新材料科技有限公司

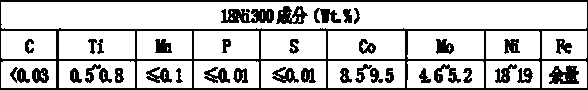

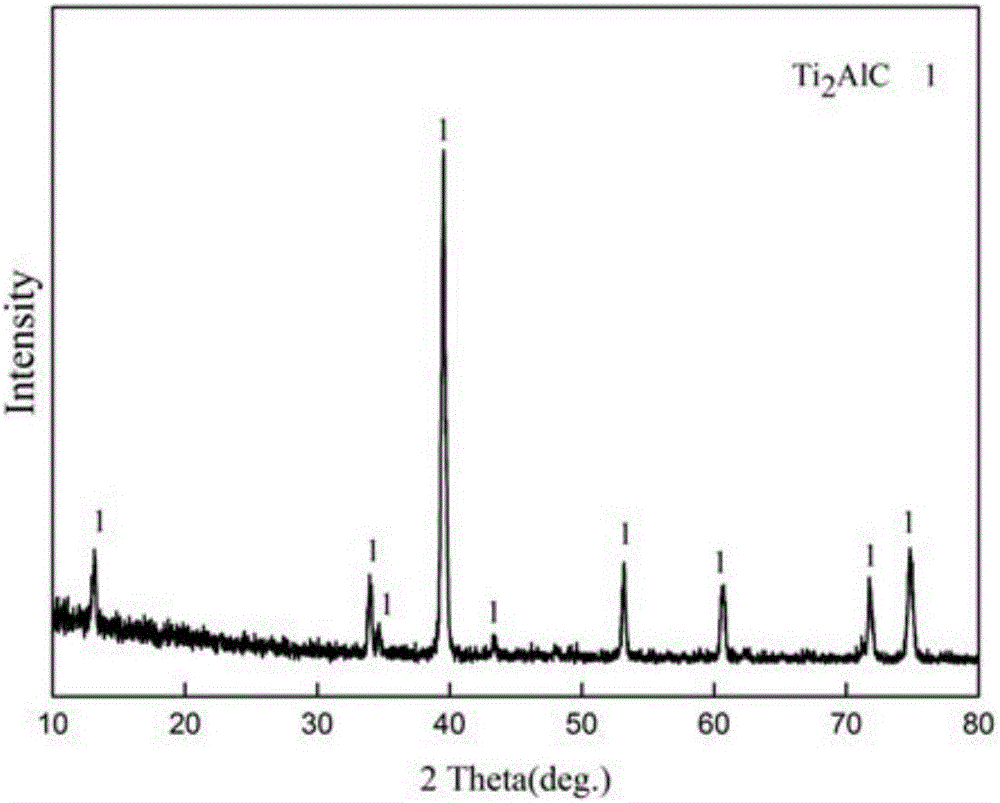

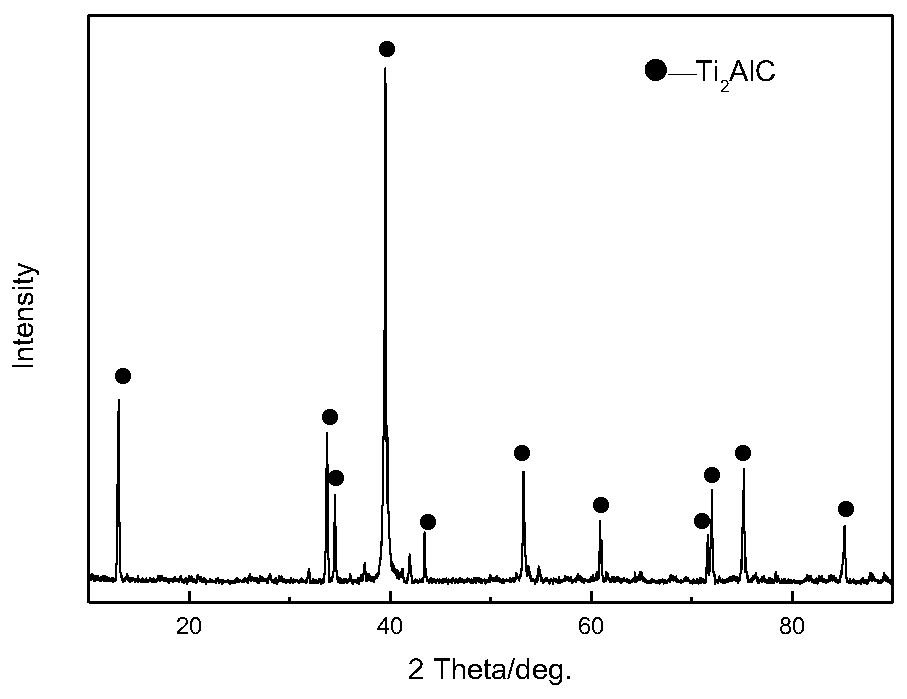

Method for preparing Ti2AlC ceramic powder from TiAl powder

The invention relates to the field of ceramic materials, in particular to a method for preparing Ti2AlC ceramic powder from TiAl powder. The method comprises the steps that TiAl powder and TiC powder are used as reaction raw materials, wherein the mole ratio of n(TiAl) to n(TiC) is 1:(0.8-1.0); the TiAl powder and the TiC powder are subjected to wet process ball milling to obtain paste; the paste is dried and dried at vacuum, and the dried powder is subjected to dry milling; the dry-milled powder is formed and encased into a cover for hot isostatic pressing sintering or encased into a graphite die for vacuum hot pressed sintering; the sintered material is machined to remove possible pollutant on the surface, and then is crushed, screened, pickled, dried and the like to obtain the power. By adopting TiAl powder as the raw material, the intermediate reaction step is omitted, the obtained material is good in quality and has the purity as high as 99wt%, and can be used as a surface engineering, reinforcing phase and novel binary layered material precursor and other materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

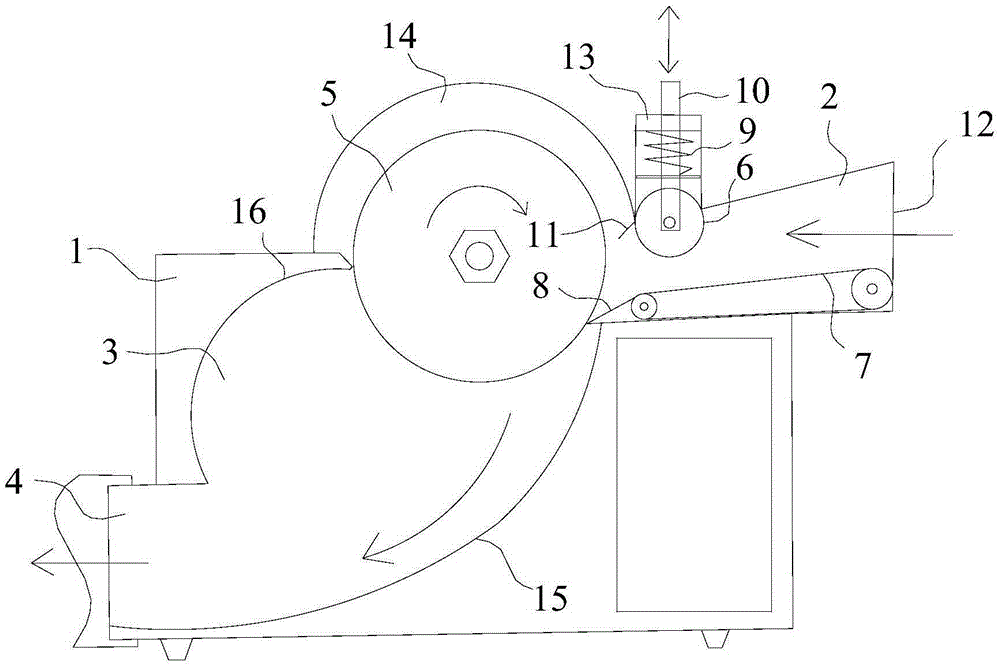

Smashing equipment for smashing of glass fiber composite material or rubber material

ActiveCN105381845ASolve the technical difficulties that are difficult to finely crushImprove crushing efficiencyPlastic recyclingGrain treatmentsGlass fiberDiamond cutting

The invention discloses mashing equipment for smashing of a glass fiber composite material or a rubber material. The equipment comprises a box body; a feeding cavity, a smashing cavity and a discharging cavity are sequentially arranged in the box body in the material conveying direction; a cutter is rotationally connected in the smashing cavity; a conveying belt for conveying materials is disposed in the feeding cavity; the output end of the conveying belt transits to the outer edge of the cutter through a joining plate; a material pressing wheel located above the conveying belt is disposed in the feeding cavity in a sliding mode through an elastic support; a material channel which joins the feeding cavity with the smashing cavity is disposed between the conveying belt and the material pressing wheel. A high-speed motor drives a smashing and cutting mechanism formed by combination of diamond cutting blades to smash strip-shaped and small blocky glass fiber composite material or rubber material at a time, and smashing particle diameter d50 of powder can be controlled to be about 20-30 micrometers. The technical difficulty of finely smashing of recycled materials in the industry is solved, and favorable conditions are created for recycling of the glass fiber composite material and part of the rubber material.

Owner:JIANGSU RUIKANG NEW MATERIAL TECH CO LTD

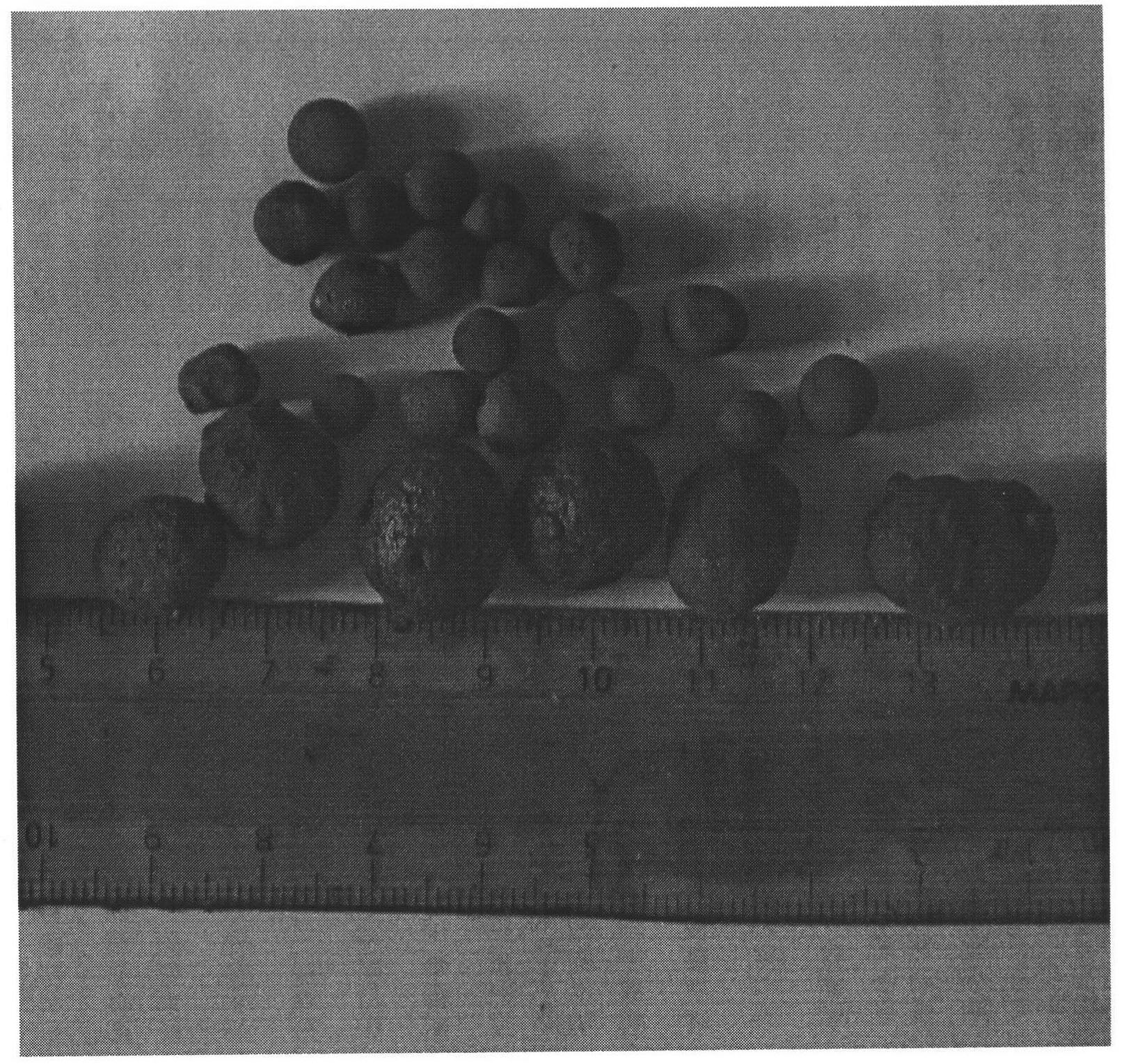

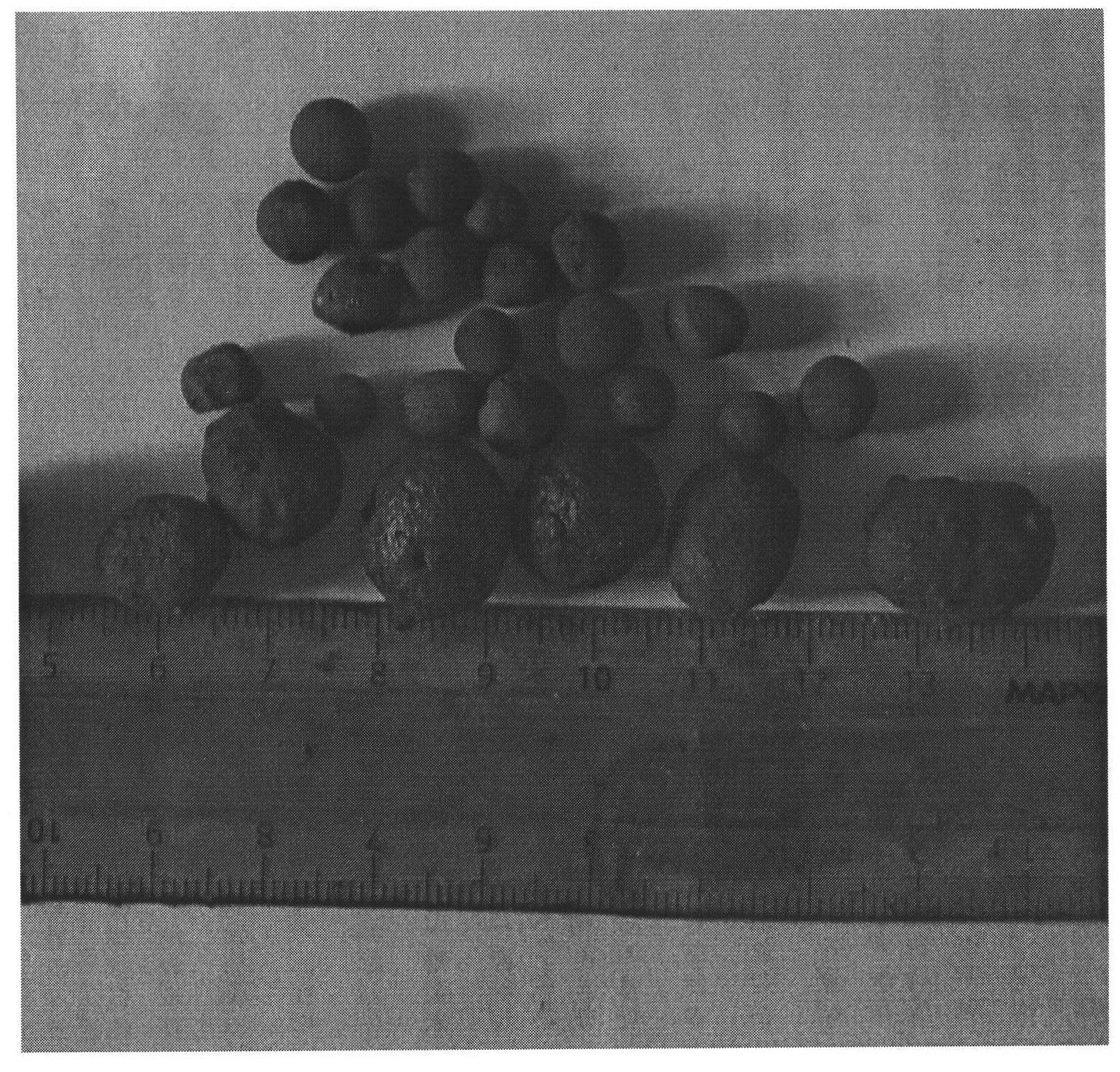

Method for preparing ultra-light high-strength ceramic aggregate from dredged bottom mud and nearshore high-sand content mud

ActiveCN102030491AHigh strengthOvercoming the disadvantages of low intensitySolid waste managementGranularityFree cooling

The invention provides a method for preparing ultra-light high-strength ceramic aggregate from dredged bottom mud and nearshore high-sand content mud, which comprises the following steps: (1) uniformly mixing dried bottom mud dredged from a lake, a river or an ocean and straws of water plants according to a volume ratio of 5-12:1-0.2 to obtain fresh pellets, adding nearshore high-sand content mud to the fresh pellets used as seed pellets, and rolling into finished fresh pellets; and (2) burning the prepared finished fresh pellets at 950-1350 DEG C for 30-60 minutes, and naturally cooling to obtain the ultra-light high-strength ceramic aggregate. The invention solves the problem of mass production caused by scarce resources, and solves the problem on stacking and processing polluted bottom mud dredged from lakes and rivers. At the same time, the invention overcomes the defect of the low strength of the traditional ultra-light ceramic aggregate, and achieves the purposes of the harmless processing and the recycling of waste. Besides, the prepared ultra-light high-strength ceramic aggregate has the characteristics of low specific gravity, adjustable particle size, high strength and high stability.

Owner:戴勇鹏

Temperature-controllable rotating pulverized coal combustion system integrating powder making, storage and supply

InactiveCN104089296AReduce the amount of pulverized coalShort storage timeLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationParticle mixingCoal

The invention provides a temperature-controllable rotating pulverized coal combustion system integrating powder making, storage and supply. The system comprises a powder making machine, a powder storage tank and a combustor. A small powder collector and a big powder collector are arranged on the upper portion of the powder storage tank. A powder feeder is arranged at a discharge port of the powder storage tank. A second fan is arranged below the powder feeder. A coal feeder is arranged at a feed hopper of the powder making machine. A first fan is arranged on the lower portion of the powder making machine. Wind paths are arranged between the powder making machine and the big powder collector, between the first fan and the small powder collector, between the first fan and the second fan and between the second fan and the combustor. The temperature-controllable rotating pulverized coal combustion system integrating powder making, storage and supply is controlled by an electric control system in a centralized mode, achieves integrated operation of powder making, powder storage, powder supply, air supply and combustion, and provides a powerful guarantee for application to an industrial furnace and asphalt particle mixing equipment; the whole process is carried out in a closed pipeline, so that the system is clean, free of pollution, easy to operate and convenient to use, and the furnace temperature is controllable.

Owner:赵怀竹

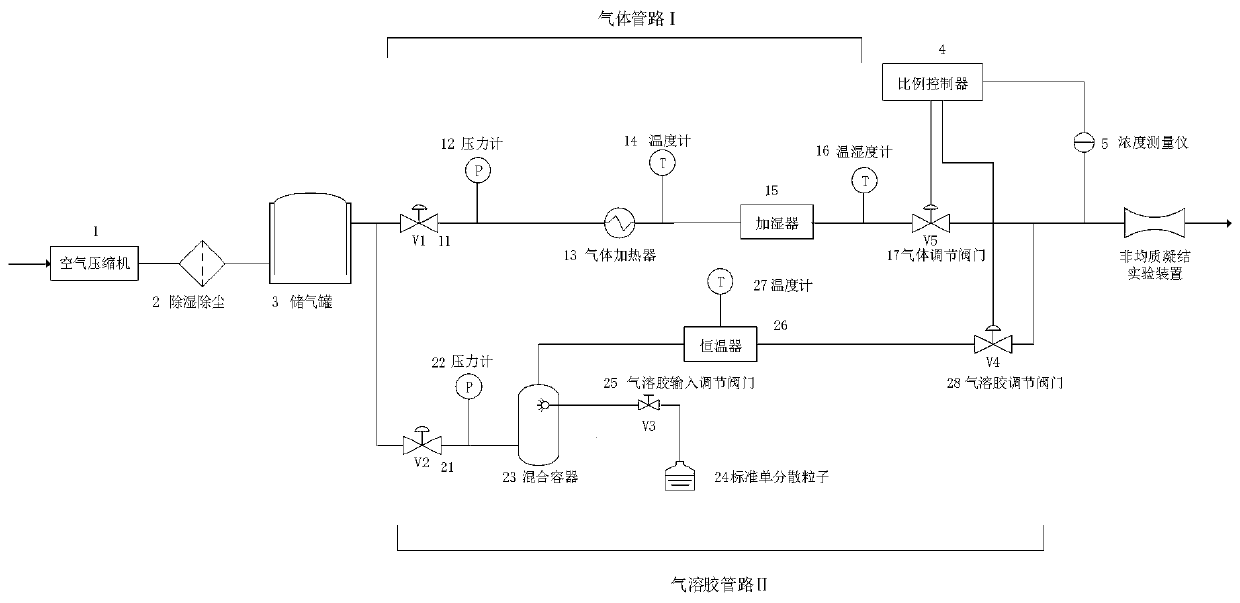

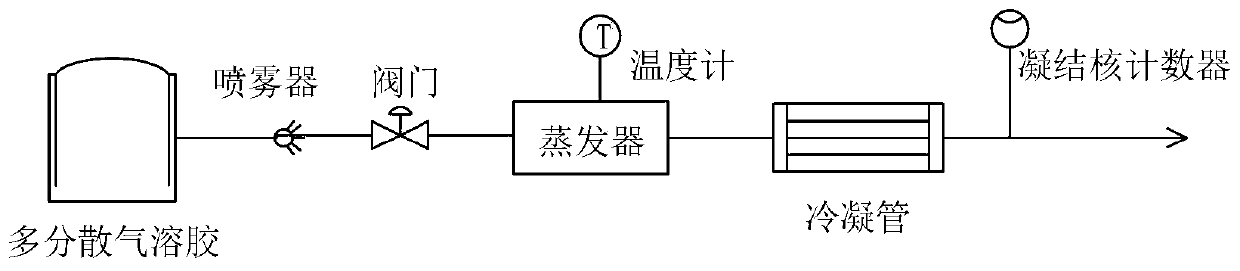

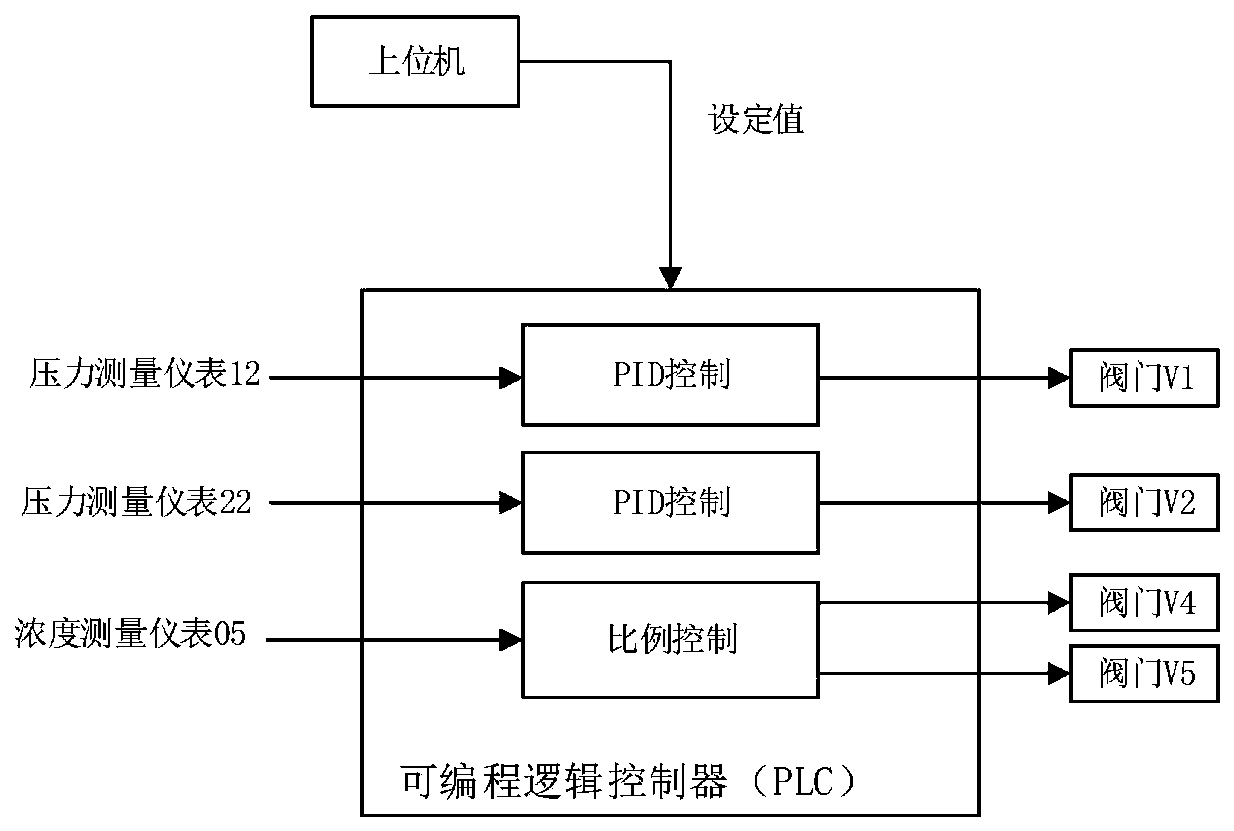

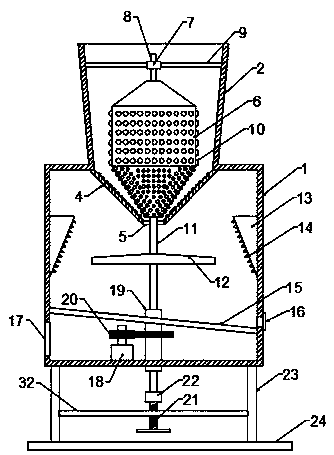

Heterogeneous condensation gas source system with adjustable granularity, concentration and flow

InactiveCN111203158AGranularity adjustableConcentration adjustableColloidal chemistry detailsAerosol preparationProportional controlGas heater

The invention relates to a heterogeneous condensation gas source system with adjustable granularity, concentration and flow. The heterogeneous condensation gas source system comprises a gas pipeline,an aerosol pipeline, a proportional controller, a concentration detector, a mixing pipeline for outputting a condensation gas source, and a control part. The aerosol pipeline comprises a mixing container and a thermostat, monodisperse aerosol enters the mixing container through a flow regulating valve and then is mixed with second input gas in the mixing container, then the temperature is regulated through the thermostat, and the monodisperse aerosol enters the mixing pipeline through the aerosol regulating valve; proper heating temperature values of the gas heater and the thermostat are set to ensure that the temperatures of the gas pipeline and the aerosol pipeline are consistent when the gas pipeline and the aerosol pipeline are mixed; and the flow valve is used for controlling the flowof the monodisperse aerosol entering the mixing container, the concentration detector is arranged on the mixing pipeline, and the proportion controller is used for carrying out adjustment during two-way mixing according to a preset value in order to control the proportion of the monodisperse aerosol in the mixing pipeline.

Owner:TIANJIN UNIV

Sand making machine capable of adjusting sand granularity

InactiveCN109331969AAvoid fine unevennessGranularity adjustableGrain treatmentsGranularityPulp and paper industry

The invention discloses a sand making machine capable of adjusting sand granularity in the technical field of sand making machine. The sand making machine comprises a sand making cylinder body and a feeding cylinder body. A rotating motor is arranged on the inner bottom wall of the sand making cylinder body. Two transmission gears are arranged on an output shaft of the rotating motor and the outerside wall of a rotating casing correspondingly and are meshed with each other. A grinding cylinder body is composed of a grinding column head, a box cover and a cylinder body. A grinding annular conecylinder with a funnel structure is arranged at the communication position between the feeding cylinder body and the sand making cylinder body. The bottom of the grinding annular cone cylinder is provided with a material via opening allowing sand grains to pass through. The outer side wall of the grinding column body and the inner side wall of the grinding annular cone cylinder are provided withgrinding protrusions. The lower side of the sand making cylinder body is provided with a base substrate. Fixing plates are fixedly connected between a plurality of supporting leg columns and providedwith adjusting screw rods spirally matched with the fixing plates. The sand making machine is simple in structure, can adjust the granularity of sand made of gravel to gradually make the sand with even sand grains through grinding, and is convenient to operate and strong in practicability.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

High-efficiency screening type large-scale double-toothed roller crusher with self-contained material distribution device

Owner:HENAN ZHENYUAN TECH

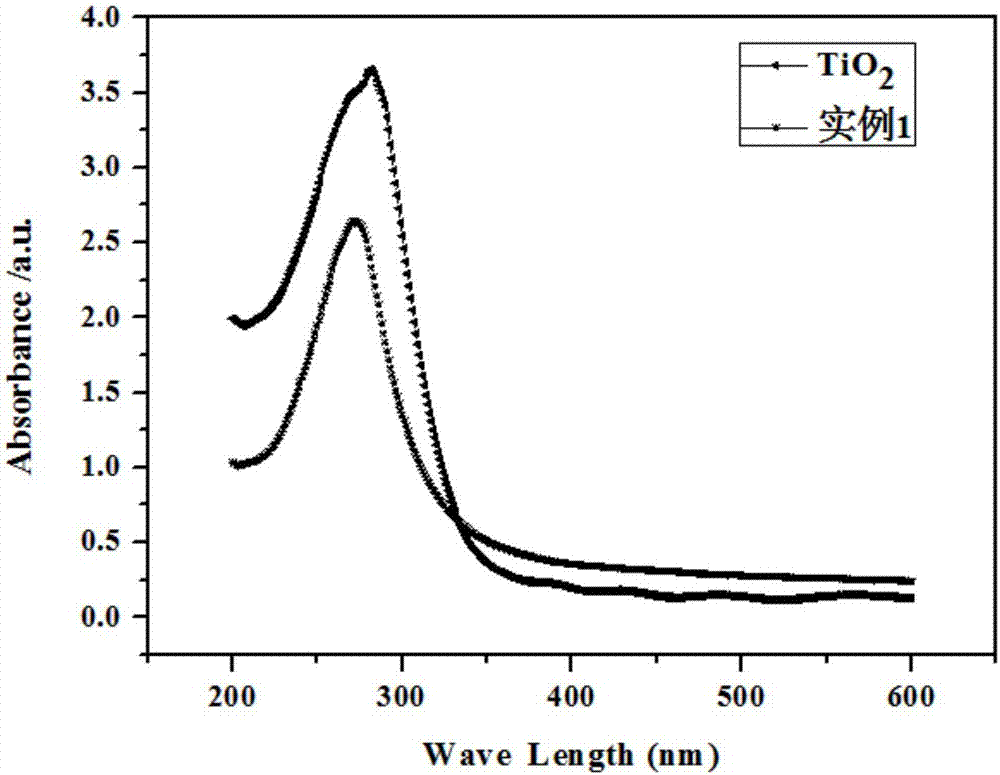

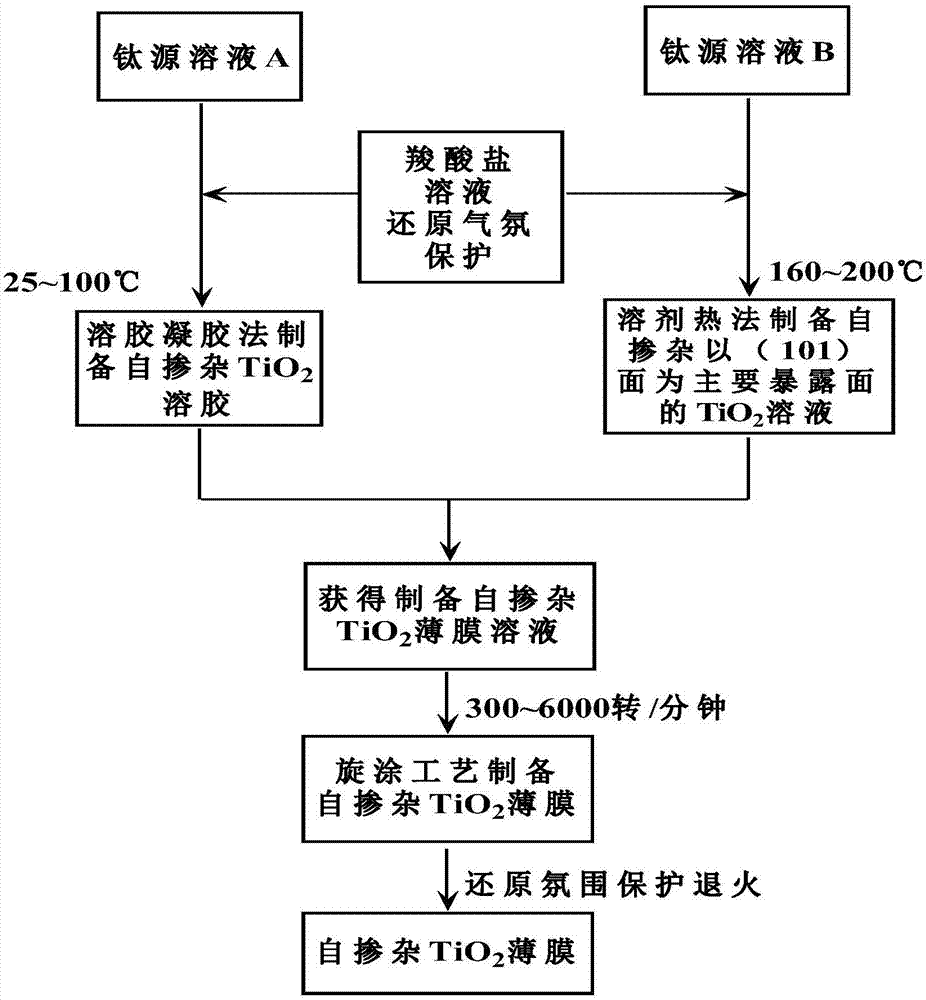

Preparation method of self-doped anatase type titanium dioxide film

InactiveCN107487783AWide spectral absorption rangeWide absorption rangeTitanium dioxideCoatingsSolventCrystallinity

The invention relates to a preparation method of a self-doped anatase type titanium dioxide film, wherein the preparation method is the further improvement on the basis of the two inventions about anatase type titanium dioxide preparation (patent application numbers are 201603151133150 and 201701200140860). According to the present invention, Ti<4+> is reduced into Ti<3+> by using metal ions on the basis of a sol-gel method and a solvothermal method to prepare the self-doped Ti<3+>-TiO2, wherein the prepared self-doped anatase type titanium dioxide sol and a self-doped anatase type titanium dioxide dispersion liquid using (101) surface as a main expose surface are homogeneously dispersed to obtain a Ti<3+>-TiO2 solution, a film is prepared through a rotary coating process, and the self-doped titanium dioxide film is sintered in a reducing atmosphere. According to the present invention, the method is simple, the prepared self-doped titanium dioxide film has advantages of substantially improved crystallinity, substantially improved chemical stability, substantially improved particle size, substantially improved uniformity and substantially improved light absorption range, and the prepared solution can directly form the film on the substrates of various materials, and can further be used as the photocatalytic environmental-protection coating material capable of being excited by visible light.

Owner:YUNNAN UNIV

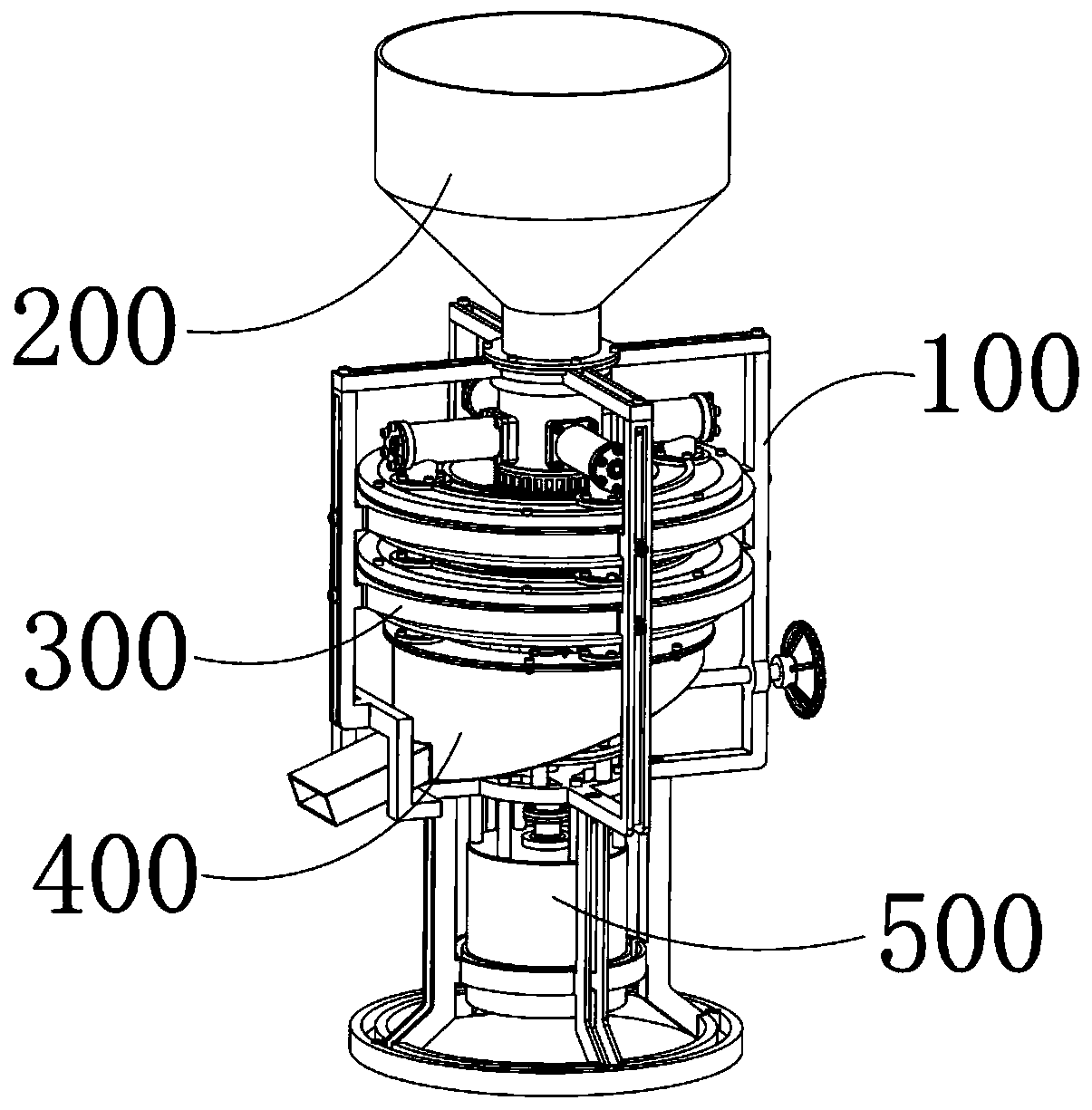

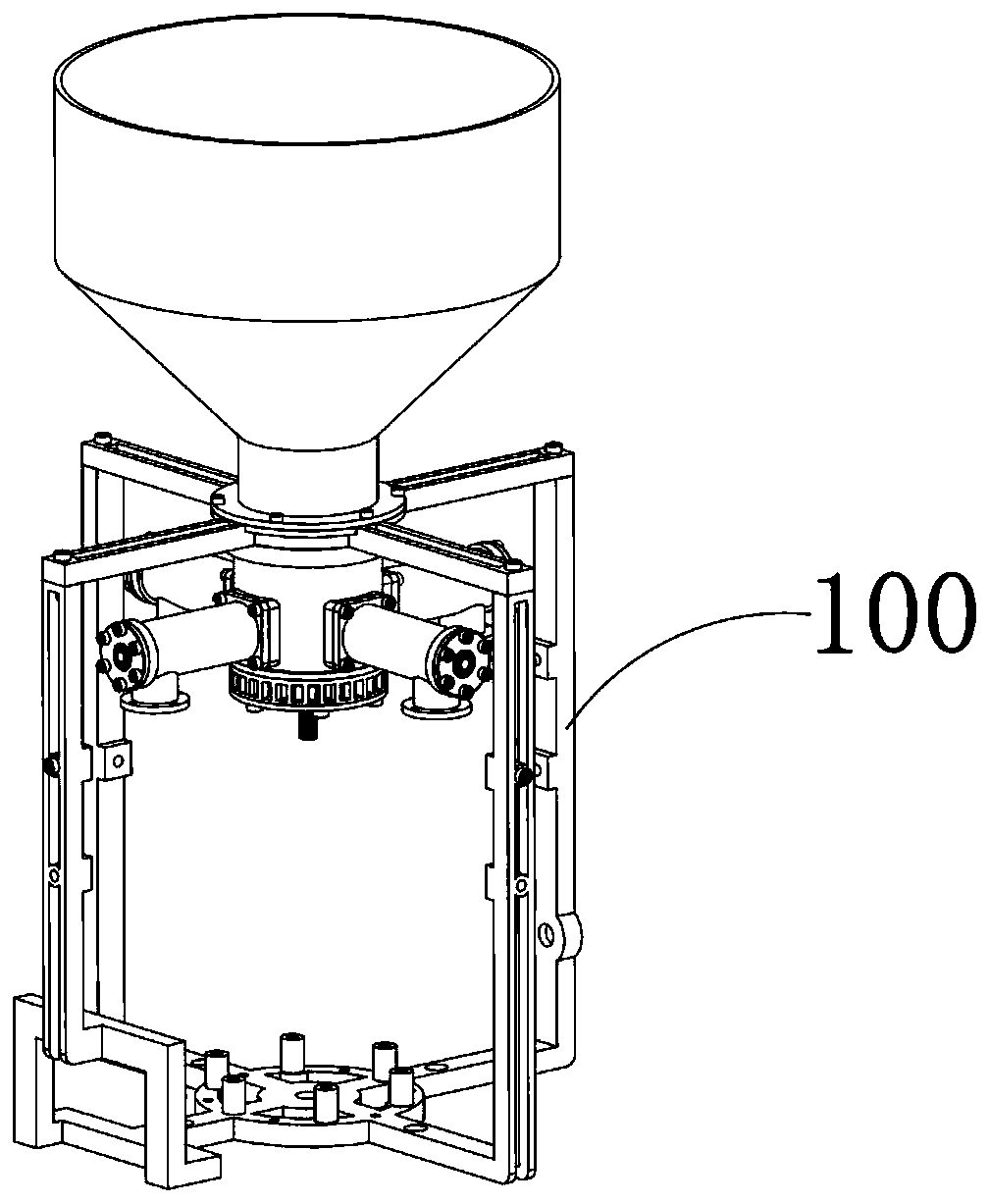

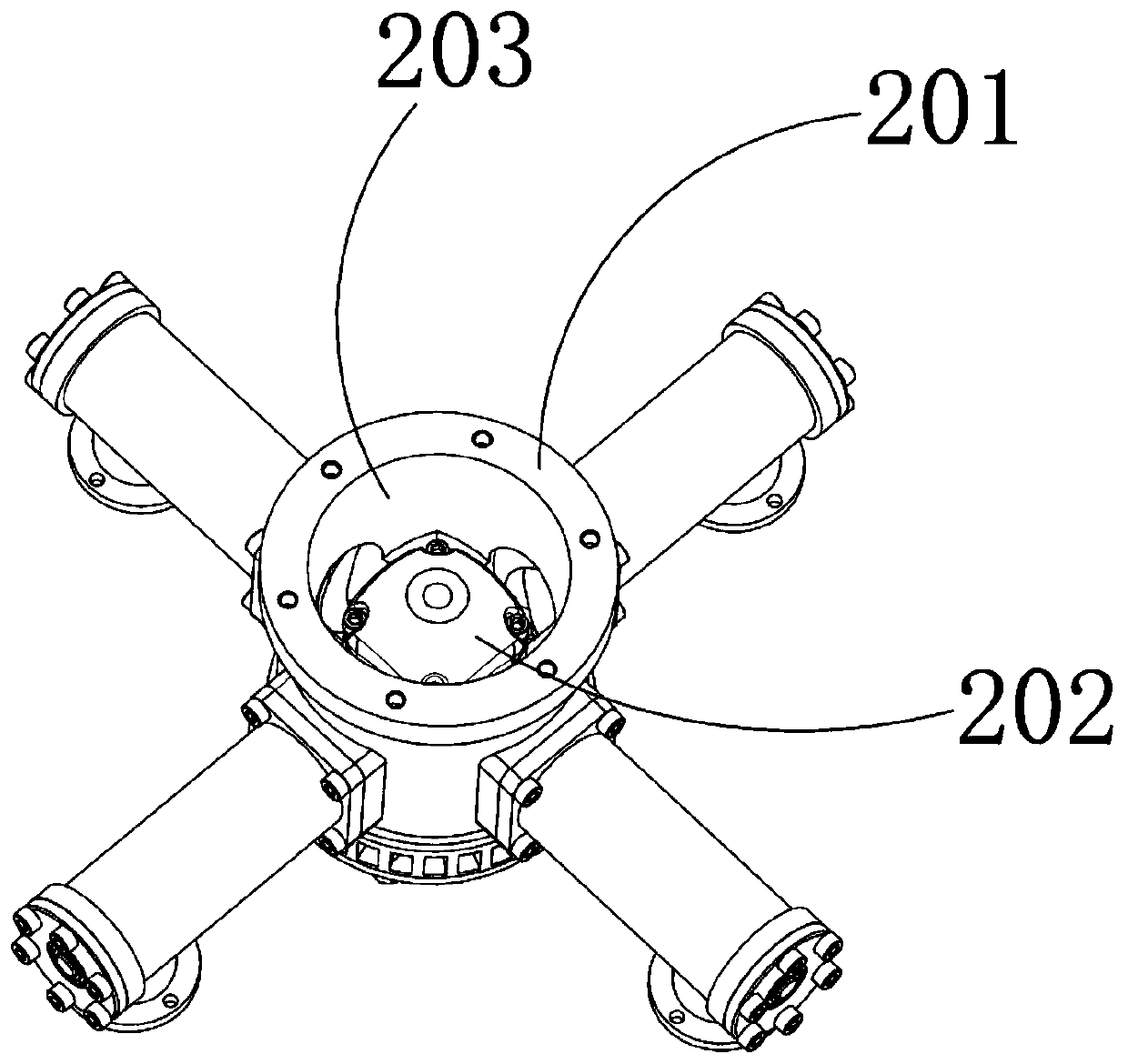

Double-layer multi-channel grain millstone crusher

The invention provides a double-layer multi-channel grain millstone crusher that comprises a mounting frame, and a feeding part, a grinding device, a discharging part and a motor that are fixedly arranged on the mounting frame and are sequentially arranged from top to bottom; the grinding device comprises a coarse grinding mechanism used for conducting coarse grinding machining on grains, a fine grinding mechanism used for conducting fine grinding machining on the grains and an adjusting mechanism used for adjusting the grinding granularity of the coarse grinding mechanism and the fine grinding mechanism. The input end of the feeding part is opened upwards, and the output end of the feeding part communicates with the input end of the coarse grinding mechanism; the output end of the coarsegrinding mechanism is connected and communicated with the input end of the fine grinding mechanism, the output end of the fine grinding mechanism is connected and communicated with the input end of the discharging part, the output end of the discharging part points to a discharging point, and the motor is used for providing motive power for the feeding part and the grinding device.

Owner:广东富舟农业科技有限公司

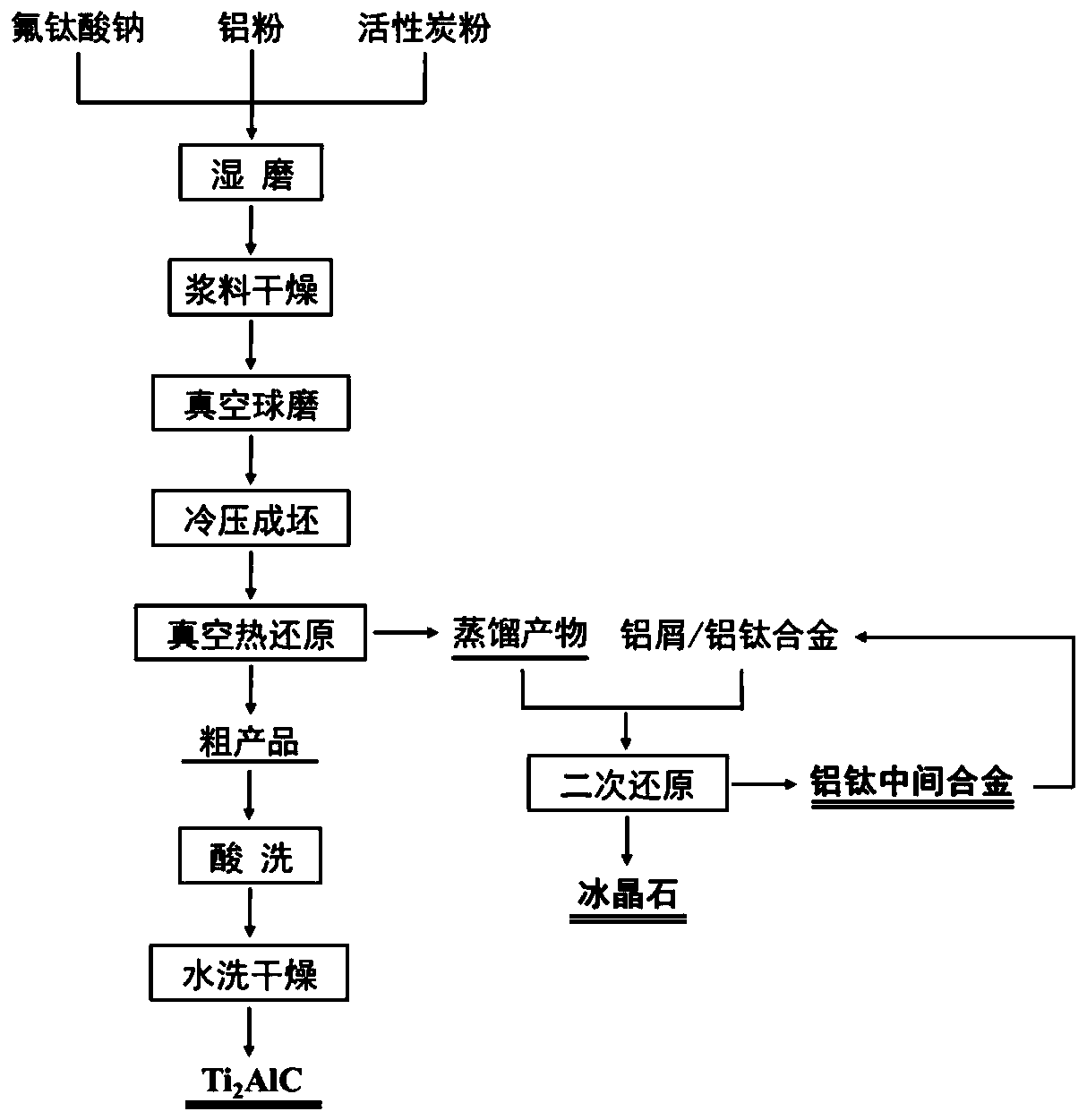

Method for preparing Ti2AlC ceramic powder through aluminothermic reduction

ActiveCN111498849AHigh purityGranularity adjustableCarbon compoundsActivated carbonActivated charcoal powder

The invention discloses a method for preparing Ti2AlC ceramic powder by aluminothermic reduction. The method is characterized by comprising the following steps: with fluorotitanate, aluminum powder and activated carbon powder in a mass ratio of 1: (0.16-0.38): (0.02-0.05) as raw materials, performing mixing and grinding; carrying out thermal reduction reaction and vacuum distillation; and then removing impurities. The method has the advantages of simple raw material requirements, wide sources, lower cost, shorter process flow, higher reaction efficiency, better controllability, full-element utilization and the like.

Owner:YANGTZE NORMAL UNIVERSITY

Method for producing ultra-fine calcination white bole with combination of dry and wet method

The invention discloses a dry-wet combination method to prepare superfine calcined kaolin. After grinding by dry method, the kaolin raw ore grains are classified according to the grain size. The superfine with the grain greater than 1250 meshes can be made into a finished product by direct calcination. While for the meal with the grain less than 1250 meshes, dispersing agent, intercalation agent,and whitening agent can be added simultaneously under wet grinding, so as to improve the grinding efficiency, shorten the grinding time, and reduce the energy consumption during grinding process, as well as improve the mixing effect of the whitening agent and the kaolin. The meal scattered and dried after grinding, is sent into rotary kiln for calcinations. The kaolin is grinded again after calcination by wet grinding method. The dispersing agent and modifying agent are added simultaneously, to combine the superfine grinding and the modifying of product simultaneously. The modified powder is grinded to obtain the other finished product after drying and scattering. The invention allows superfine calcined kaolin with different specification during the same production line by the control of the process condition, thus reducing the working procedure, improving the added value of product, broadening the application field and product performance, so as to meet the requirements of different customers.

Owner:内蒙古蒙西高岭粉体股份有限公司

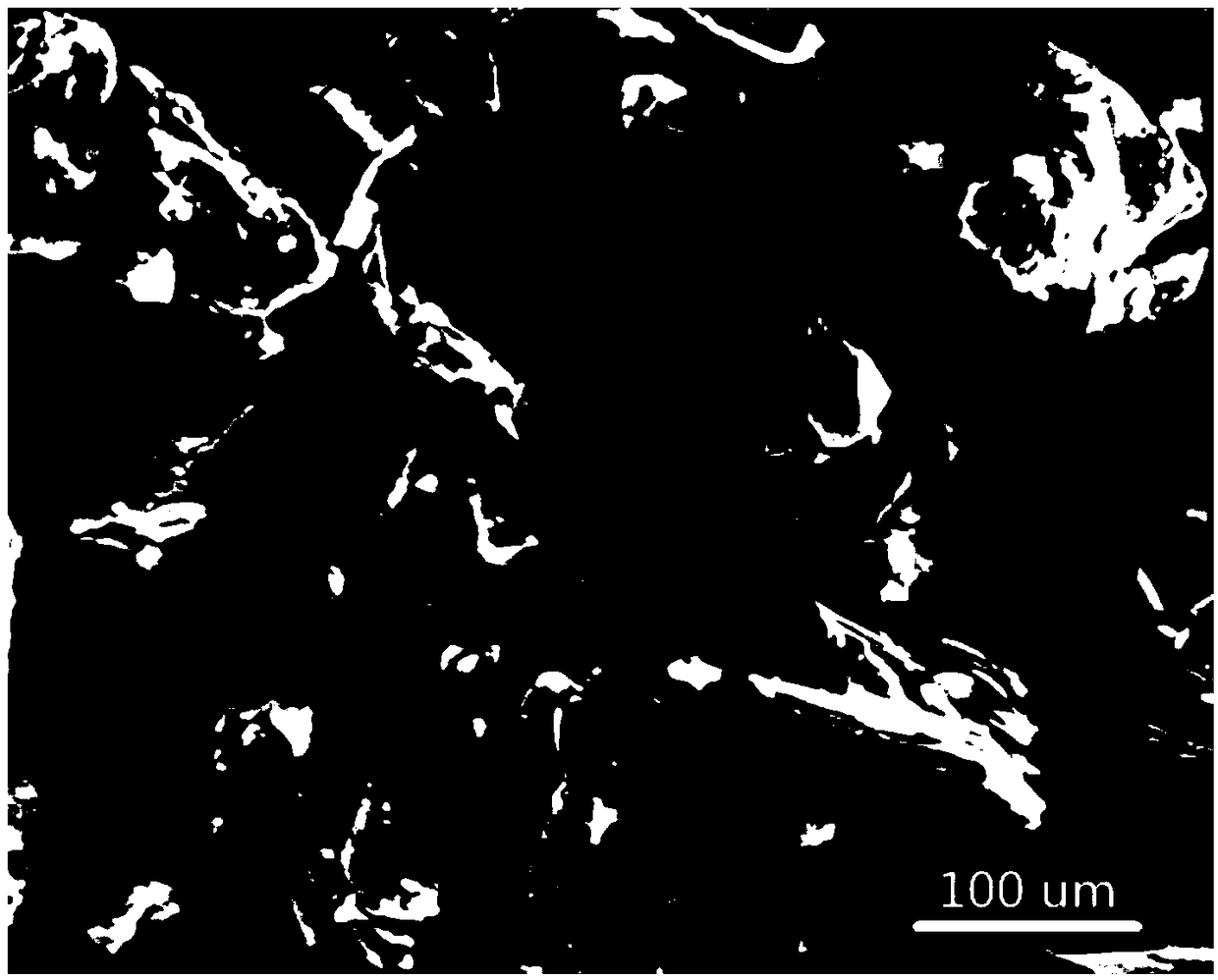

Method for preparing nanometer MAX phase ceramic powder with laminated structure or slurry through ball milling and regulating oxygen content of powder

ActiveCN109289995AWide technical adaptabilityThe technical method is simpleGrain treatmentsLiquid stateOxide composite

The invention relates to the field of ceramic materials, in particular to a method for preparing nanometer MAX phase ceramic powder with a laminated structure or a slurry through ball milling and regulating the oxygen content of the powder. Micron-sized MAX phase ceramic coarse powder is adopted as a raw material, and during ball milling, a gas or a liquid-state gas with a special effect is fed into a ball milling tank. Through multi-dimensional functions and adjustment such as ball milling parameters and gas reaction, the nanometer laminated MAX phase ceramic powder or the slurry containing the component are obtained, so that the particle size adjustment control of the powder is realized, and meanwhile, the surface components and the activated state of the powder are regulated. The finally obtained powder or slurry can be used as a precursor so as to meet the demands on high-end MXenes material stripping and functionalization, or can be used as MAX phase ceramic nanometer raw materialpowder so as to be used for sintering and preparing the in-situ synthesis nanometer MAX phase / oxide composite ceramic with the regulatable oxide content.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Phase-transition energy-storage microcapsules and their preparing process

InactiveCN100432179CGranularity adjustableSimple preparation processHeat-exchange elementsMicroballoon preparationDistilled waterThermal stability

The invention provides a phase transformation energy-storage microcapsule and its preparing process, wherein the microcapsule comprises a capsule shell and phase-change material coated thereby, the capsule shell is made of silicon dioxide gel 20-65 wt% of the microcapsule, the phase-change material being organic material amounting to 80-35 wt% of the microcapsule. The raw materials for preparing the microcapsule also include 0.5-3 parts of emulsifying agent, 30-80 parts of distilled water, 0-1 part of addition agent, 5.6-11.2 parts of n-ethyl silicate and 0.05-1 part of catalyst.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

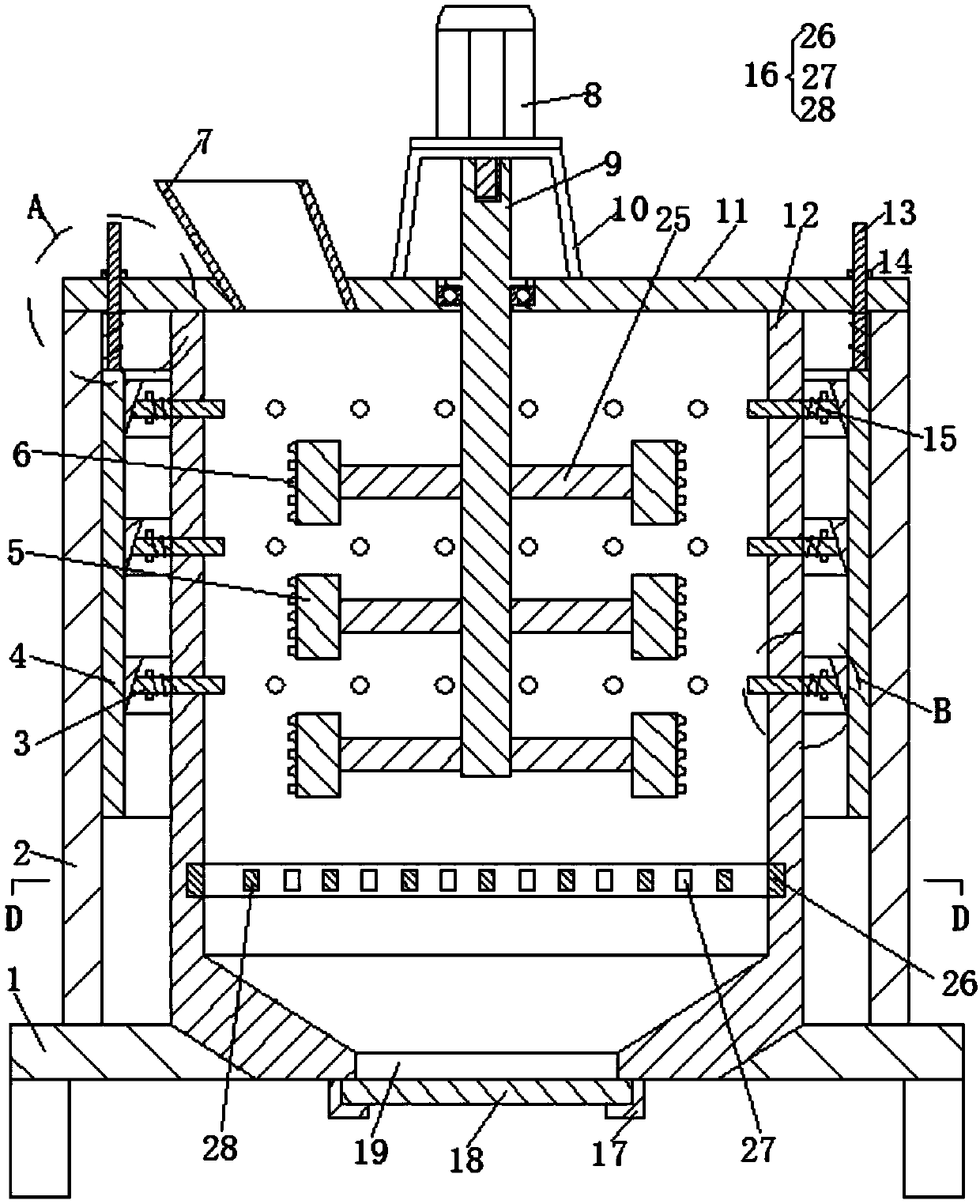

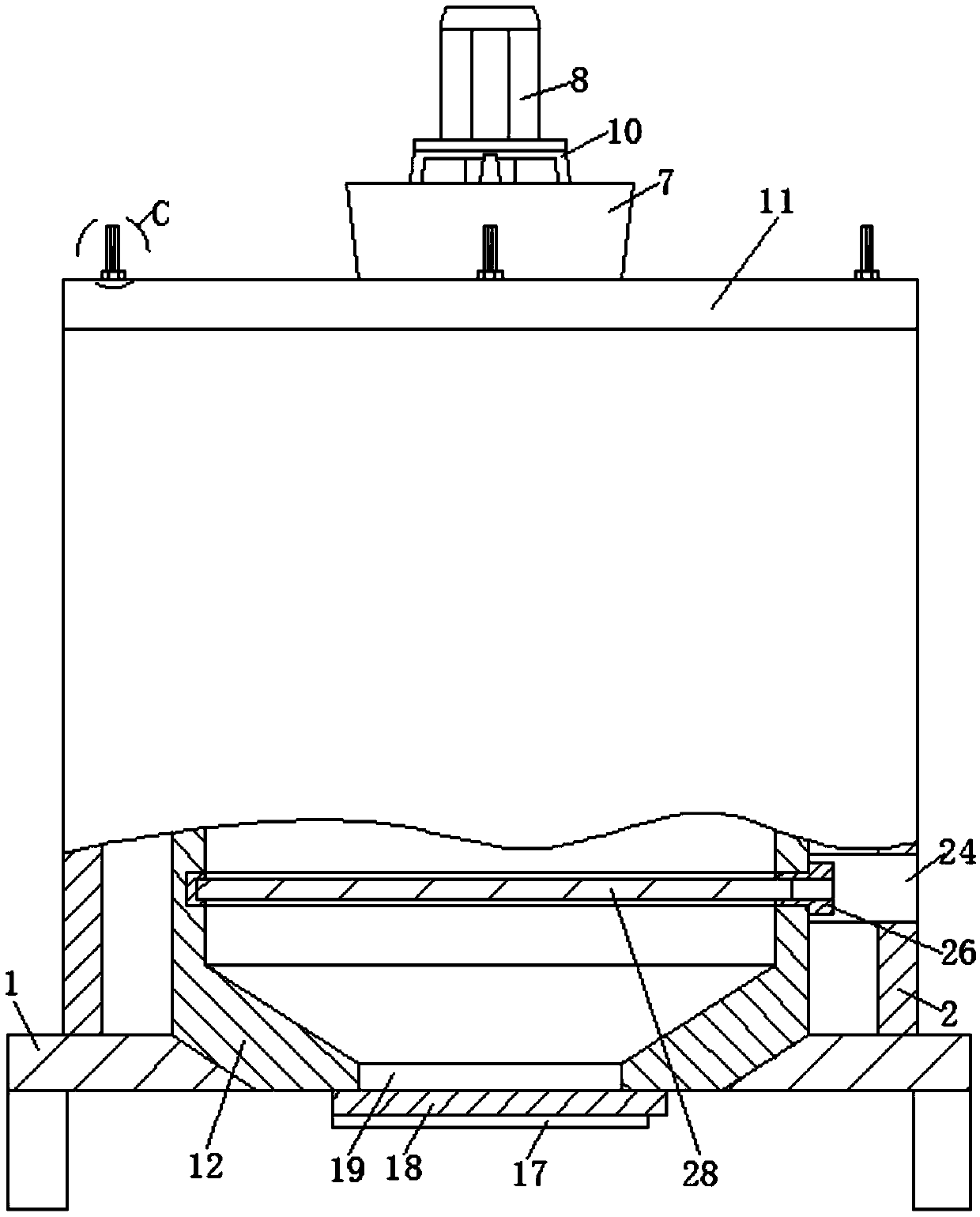

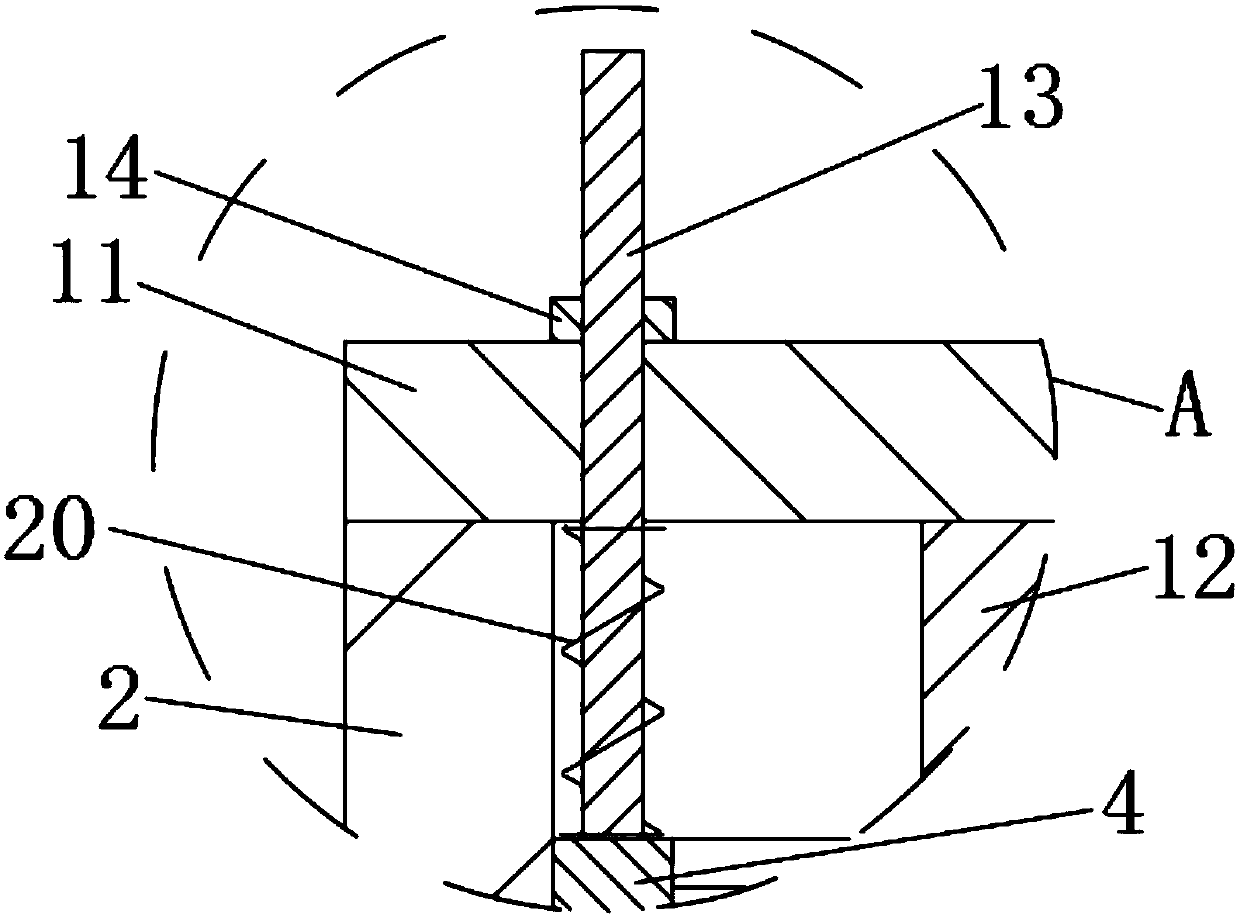

Particle size adjustable ore crusher

InactiveCN110833893AGranularity adjustableAdjustable height adjustmentGrain treatmentsMining engineeringStructural engineering

The invention relates to the technical field of ore crushers, in particular to a particle size adjustable ore crusher. The particle size adjustable ore crusher comprises a supporting seat, wherein a crushing box is arranged on the upper end face of the supporting seat, a box cover is arranged at the upper end of the crushing box, and a feeding hopper is arranged on the left side of the upper end face of the box cover; a crushing barrel is arranged inside the crushing box, and the outer side of the crushing barrel is sleeved with an adjusting sleeve; crushing rods are uniformly arranged on theinner side wall of the crushing barrel; the crushing rods penetrate through the side wall of the crushing barrel to be sleeved with a baffle, the outer side of the portion, between the baffle and theouter side wall of the crushing barrel, of each crushing rod is sleeved with a first spring, and wedge-shaped plates are evenly arranged on the portions, corresponding to the crushing rods, of the inner side wall of the adjusting sleeve from top to bottom; and adjusting screws are uniformly arranged on the upper end face of the adjusting sleeve, and the other end of each adjusting screw penetratesthrough the box cover to be sleeved with an adjusting nut. The particle size adjustable ore crusher has the advantages that the crushing particle size can be adjusted, and the crushing efficiency ishigher.

Owner:五河县科迈佳机械科技有限公司

Preparation process of zirconium silicate ball filler

PendingCN112457006AImproves Strength and ToughnessStrong impact toughnessCatalyst carriersOther chemical processesChemical industryStrong acids

The invention discloses a preparation process of a zirconium silicate ball filler. The preparation process comprises the following steps of: step 1, adding zircon sand, alumina powder, a fluxing agentand charcoal powder into an aqueous solution, and mixing the materials to form a mixture; 2, introducing argon into a hearth for atmosphere protection, gradually adding the mixture into the hearth, and heating the mixture to be in a molten state, and forming a molten mixture; and step 3, pouring the mixture in the molten state out of the hearth, blowing the molten mixture flowing out of a launderof the hearth by using compressed air, blowing the molten mixture into balls, performing cooling, solidifying and heat preservation to obtain zirconium silicate ball fillers with different particle sizes. The zirconium silicate ball filler provided by the invention has compressive strength of more than 30MPa, strong acid corrosion resistance and impact toughness, and micron-sized through apparentporosity of 25-40%, and is suitable for chemical industry, water treatment filtration and inorganic salt adsorption.

Owner:CHANGSHA XINGUANG SPECIAL CERAMIC CO LTD

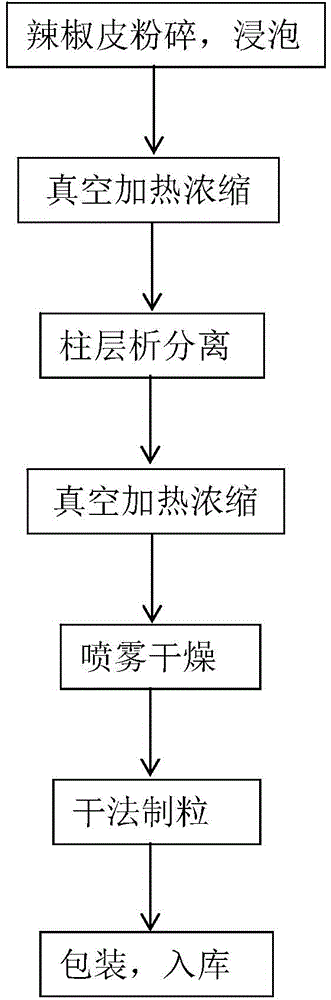

Capsaicin particle preparing method

InactiveCN104642985AUniform particlesGranularity adjustableCarboxylic acid amide separation/purificationFood shapingSolubilityOrganic solvent

The present invention provides a capsaicin particle preparing method which contains the following steps: grinding, soaking, concentration, column chromatography, concentration, drying and granulation, and capsaicin particle obtaining by the present invention. The capsaicin particles produced by the present invention have a granular shape with uniform particles and adjustable sizes, are convenient for storage, transportation and use, have excellent water solubility with 1 g capsaicin particle dissolved in 100 g water to form a clear solution free of suspended matter, have an adjustable spicy degree, a stable quality and a soft and mellow spicy sense, is safe and reliable, and contains no organic solvent residue and no emulsifiers.

Owner:天津市天联调味制品有限公司

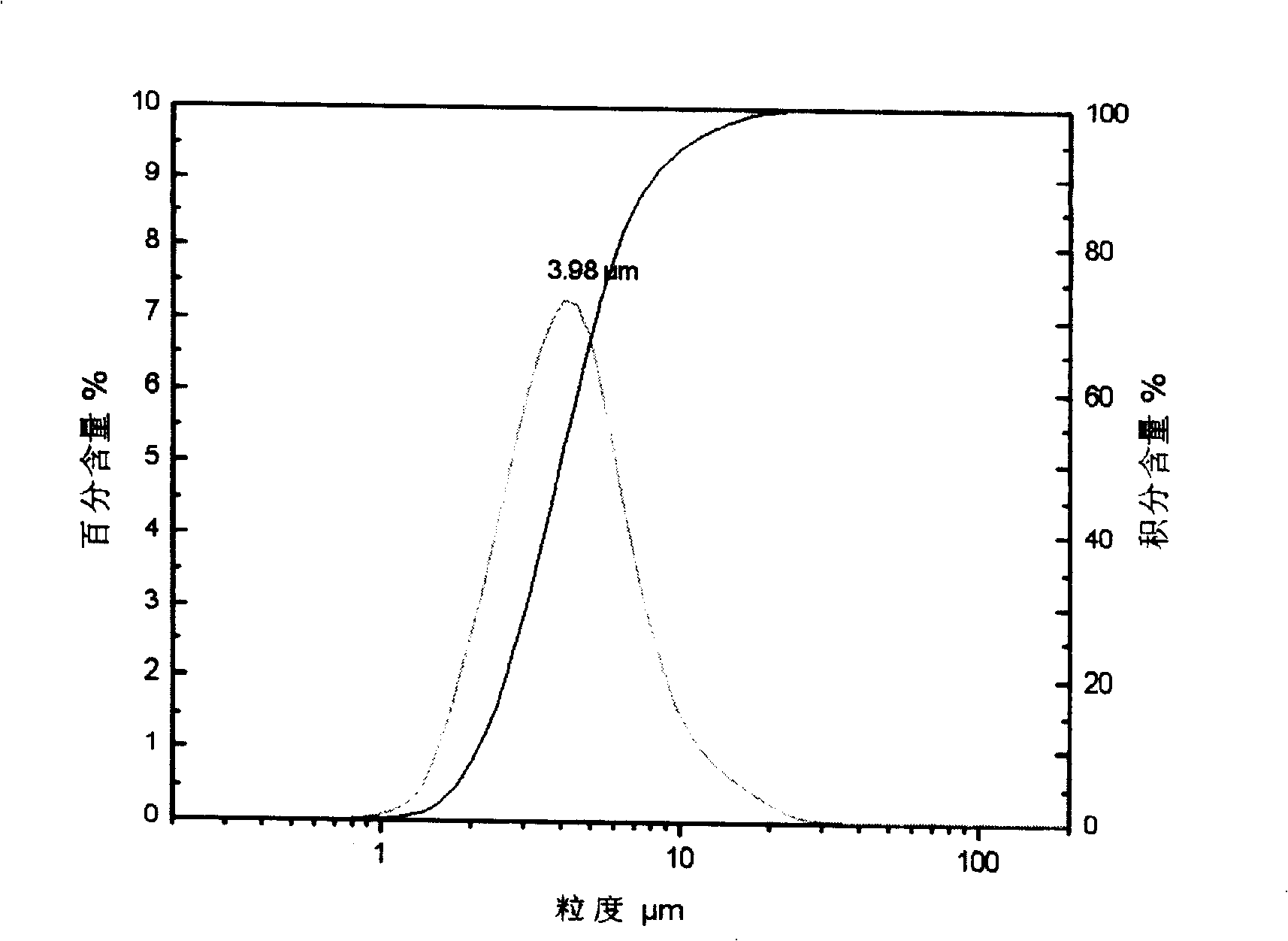

Process for production of steroid crystals, steroid crystals obtained thereby and pharmaceutical preparations containing them

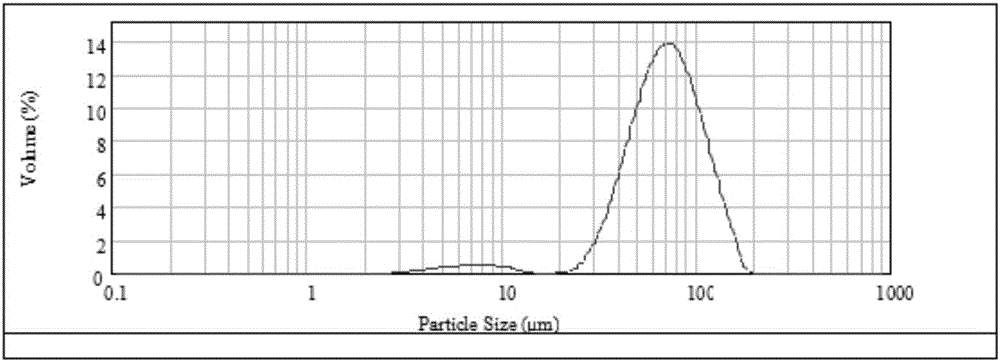

ActiveUS7148212B2Improve accuracyGood reproducibilityOrganic active ingredientsBiocideMedicinePharmaceutical formulation

The process for making steroid crystals having a predetermined average particle size of from 1 μm to 25 μm and a maximum particle size that does not exceed a predetermined maximum value of 100 μm, includes subjecting a supersaturated solution containing a steroid to a wet milling by wet milling apparatus while crystallizing, in order to obtain a primary particle suspension. Crystals obtained according to this process and pharmaceutical preparations containing them are also described.

Owner:BAYER INTELLECTUAL PROPERTY GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com