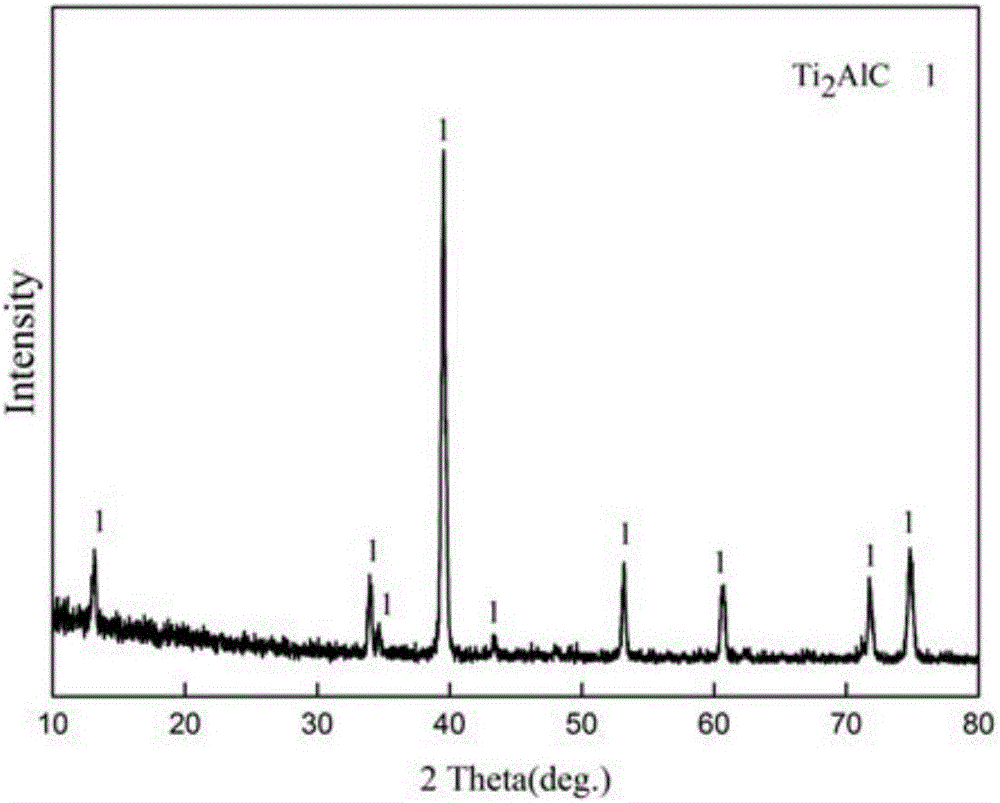

Method for preparing Ti2AlC ceramic powder from TiAl powder

A technology of ceramic powder and powder, which is applied in the field of Ti2AlC ceramic powder preparation, can solve the problems of inaccurate control of the reaction, complex process and long time, and complicated reaction, so as to facilitate popularization and large-scale production, avoid easy damage, The effect of reducing the difficulty of sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

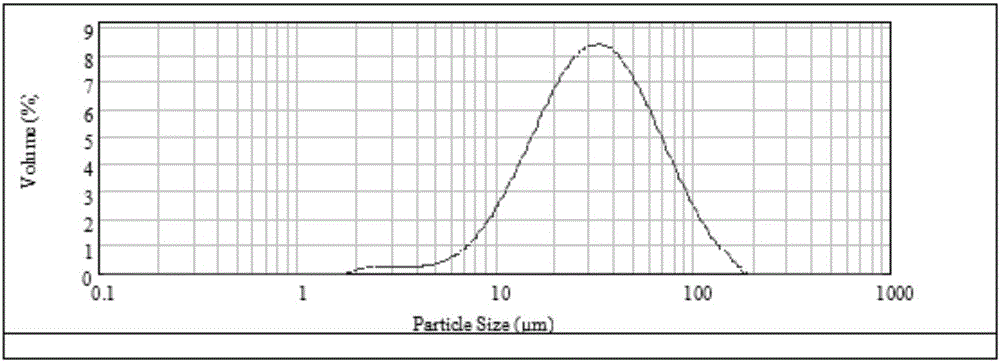

Embodiment 1

[0031] The raw material powder is mixed according to the molar ratio n(TiAl):n(TiC)=1:0.9, the raw materials are 4 kg in total, mixed evenly, add 3L of absolute ethanol, put into a 10L vibration ball mill, vibration frequency 50Hz, amplitude 5mm, ball mill Time 30 minutes. Pour out the ball-milled slurry, put it into a blast drying oven for low-temperature drying, and heat and dry it when the alcohol content drops below 85 wt%. The dried powder is then put into a vibrating ball mill and dry-milled with the same parameters for 10 minutes to obtain a uniformly mixed powder raw material. Put the raw material into a graphite mold with a diameter of 150mm and put it into a hot press sintering furnace, first apply a pressure of 5MPa, when the vacuum degree reaches 10 -3 At Pa, start to raise the temperature and pressurize again, raise the temperature to 1400°C, pressure 30MPa, hold the temperature for 2 hours and then cool with the furnace. Use a lathe to remove the surface of the...

Embodiment 2

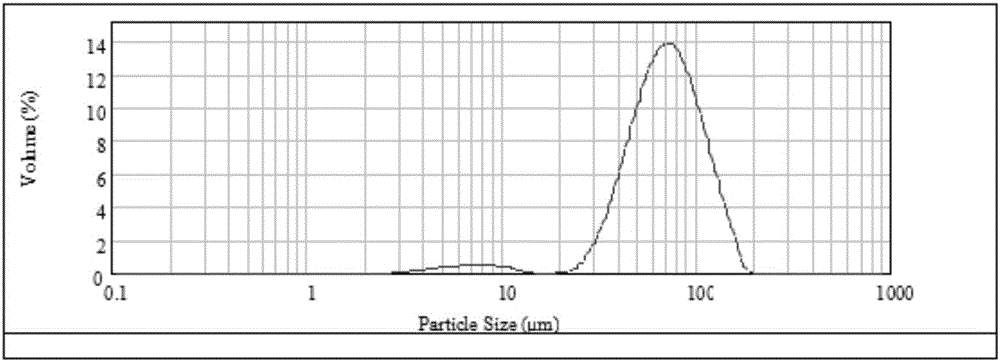

[0033]The raw material powder is mixed according to the molar ratio n(TiAl):n(TiC)=1:0.95, the total raw material is 4 kg, mixed evenly, add 3L of absolute ethanol, put into a 10L stirring ball milling device, the stirring speed is 250r / min, the ball milling time 30 minutes. Pour out the ball-milled slurry, put it into a blast drying oven for low-temperature drying, and heat and dry it when the alcohol content drops below 90 wt%. The dried powder is put into a stirring ball mill and dry-milled with the same parameters for 10 minutes to obtain a uniformly mixed powder raw material. The prepared powder raw materials are dry-pressed with a hydraulic press and a stainless steel mold. Put 10 times of batching and molding and blocks into pure titanium sheaths with a diameter of 100mm and a length of 200mm, put these sheaths into a large-scale hot isostatic pressing sintering furnace, first vacuumize and then pass in argon protection to heat up To 1350 ℃ pressure 100MPa, heat prese...

Embodiment 3

[0035] The raw material powder is mixed according to the molar ratio n(TiAl):n(TiC)=1:0.925. The raw materials are 4 kg in total, mixed evenly, added with 3L of absolute ethanol, and loaded into a 10L vibrating ball mill with a vibration frequency of 50Hz and an amplitude of 5mm. Time 30 minutes. Pour out the ball-milled slurry, put it into a blast drying oven for low-temperature drying, and heat and dry it when the alcohol content drops below 90 wt%. The dried powder is then put into a vibrating ball mill and dry-milled with the same parameters for 10 minutes to obtain a uniformly mixed powder raw material. Put the raw material into a graphite mold with a diameter of 120mm and put it into a hot-press sintering furnace, first apply a pressure of 5MPa, when the vacuum degree reaches 10 -3 Argon gas was introduced at Pa, and the temperature was raised and the pressure was increased again, the temperature was raised to 1400°C, the pressure was 15MPa, and the pressure was maintai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com