Double-layer multi-channel grain millstone crusher

A multi-channel, pulverizer technology, applied in grain processing, food science, cocoa, etc., can solve the problems of single grain and uncontrollable grain size of grain milling, and achieve the effect of convenient operation and use, ingenious structure and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

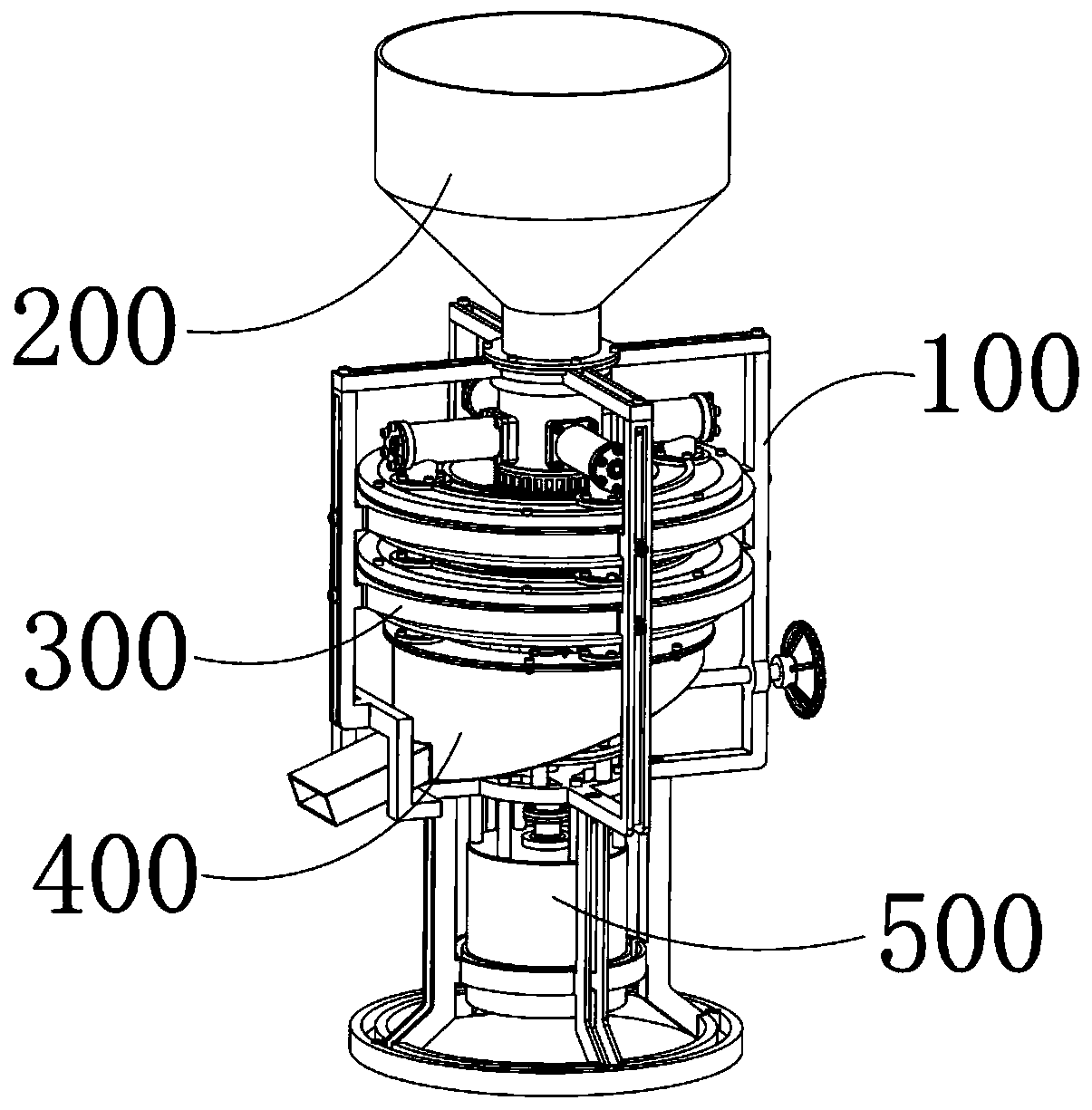

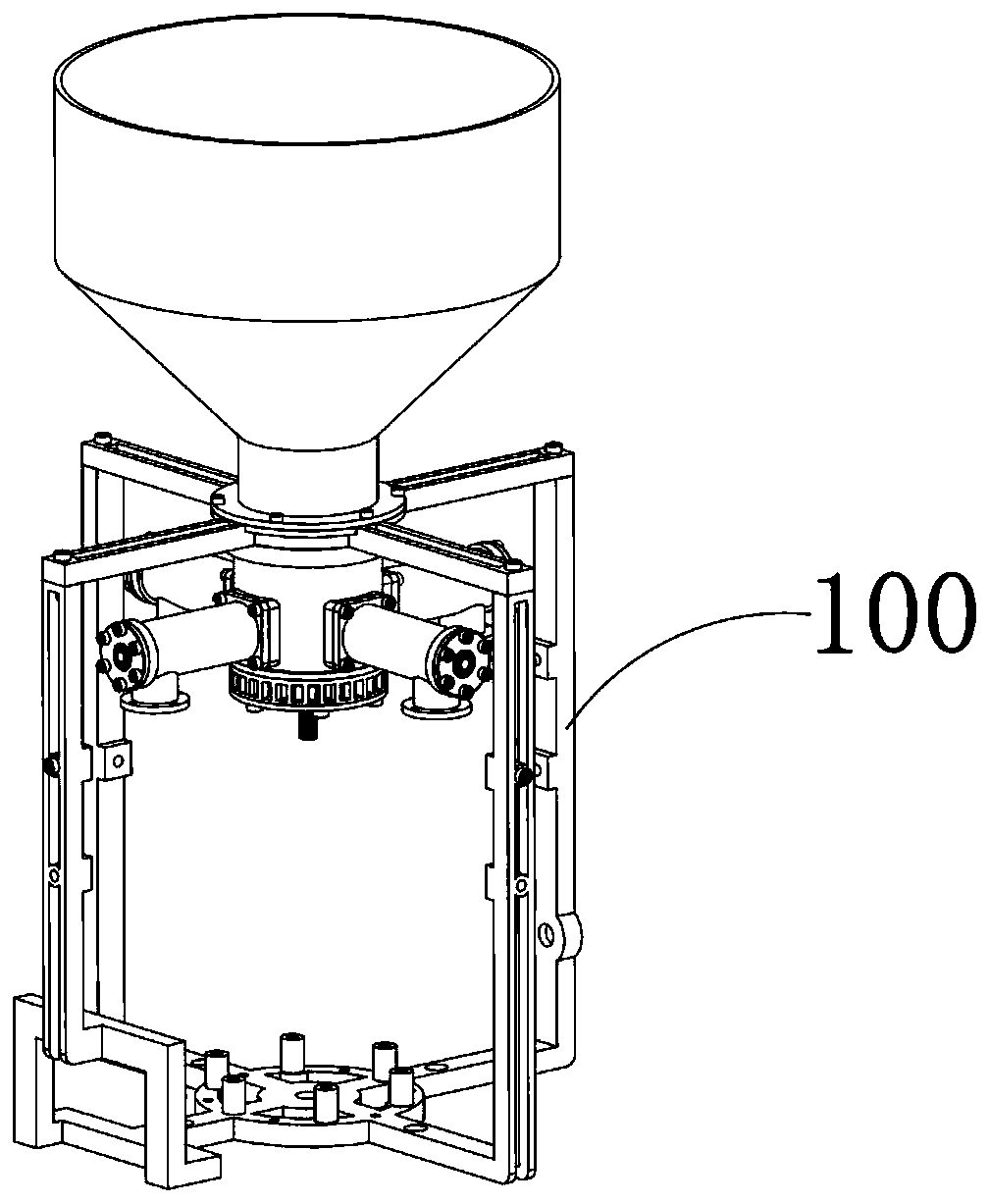

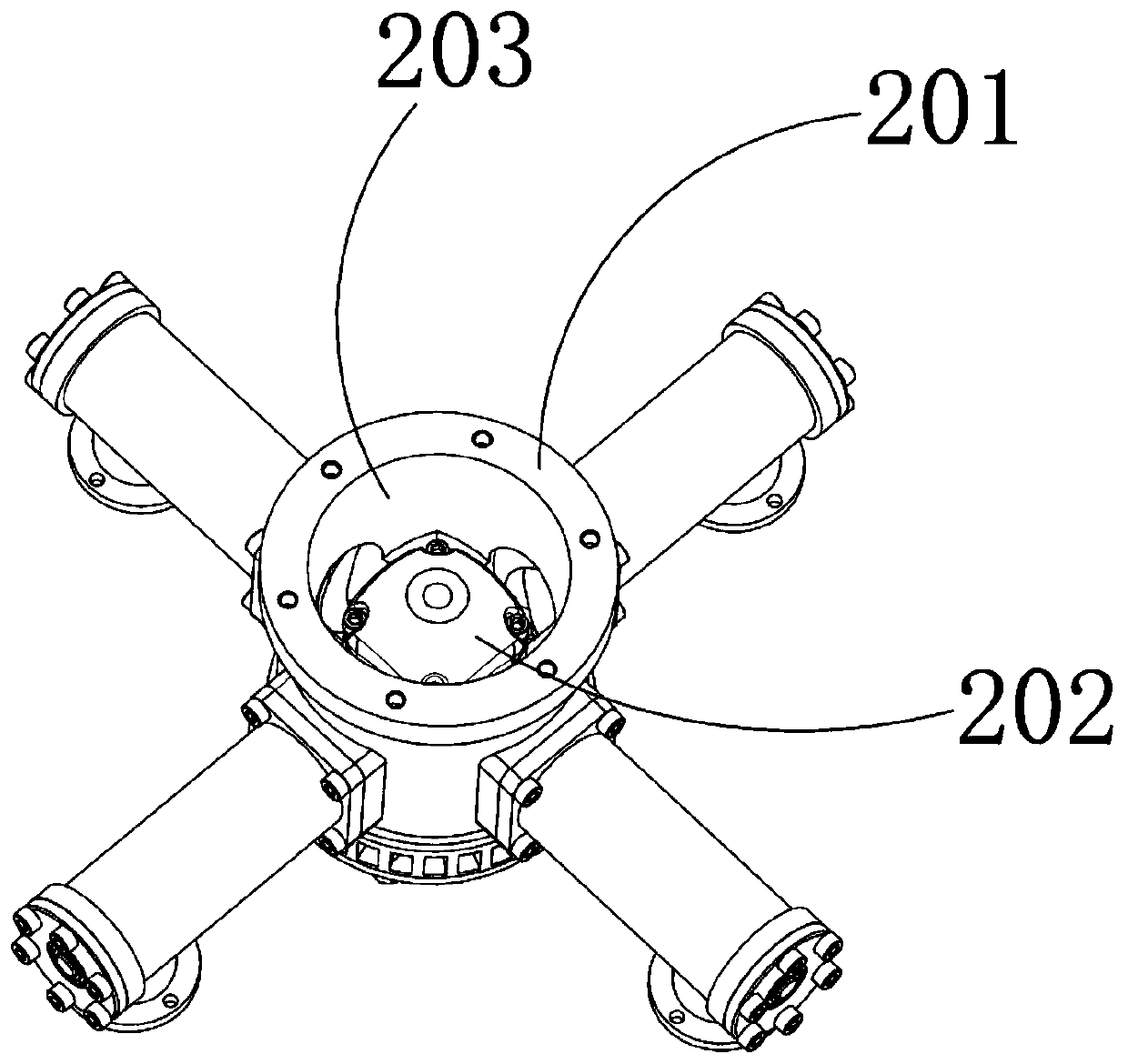

[0055] A double-layer multi-channel grain disc grinder, which includes a mounting frame 100, a feeding part 200, a grinding device 300, a discharging part 400 and a motor 500 fixedly arranged on the mounting frame 100 and arranged from top to bottom in sequence, The grinding device 300 includes a coarse grinding mechanism 310 for coarse grinding of grains, a fine grinding mechanism 320 for fine grinding of grains, and an adjustment mechanism for adjusting the grain size of the coarse grinding mechanism 310 and fine grinding mechanism 320 330, the opening of the input end of the feeding part 300 is arranged upwards, the output end is connected to the input end of the coarse grinding mechanism 310, the output end of the coarse grinding mechanism 310 is connected to the input end of the fine grinding mechanism 320, and the fine grinding mechanism 320 The output end of the discharge unit 400 is connected to the input end of the discharge unit 400, the output end of the discharge un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com