Phase-transition energy-storage microcapsules and their preparing process

A technology of phase-change energy storage and phase-change materials, which is applied in the field of phase-change energy storage materials and their preparation, can solve problems such as poor chemical stability, poor heat resistance of organic polymers, and non-durability, and achieve easy industrial production and preparation Simple process and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Measure 9 mL of 25# phase-change paraffin wax, whose phase-change temperature is 25°C. Add 1.5 grams of sorbitan oleate and polyoxyethylene sorbitan monooleate in a mass ratio of 0.45:0.55. Here, Span80 and Tween80 produced by Xilong Chemical Factory in Shantou City, Guangdong Province are produced at a mass ratio of 0.45. : 0.55 compounded emulsifier. Slowly add about 40mL of distilled water under heating conditions, and then add 1mL of 2.5mol / L sodium chloride, continue heating to 60°C while stirring for 30min to fully emulsify the emulsion.

[0026] After the emulsification is relatively complete, slowly add 10 drops of 10% acetic acid and 7 mL of ethyl orthosilicate, place it in a water bath at 60°C under stirring for 5 hours, age for 5 hours, filter and wash to obtain phase change energy storage microcapsules.

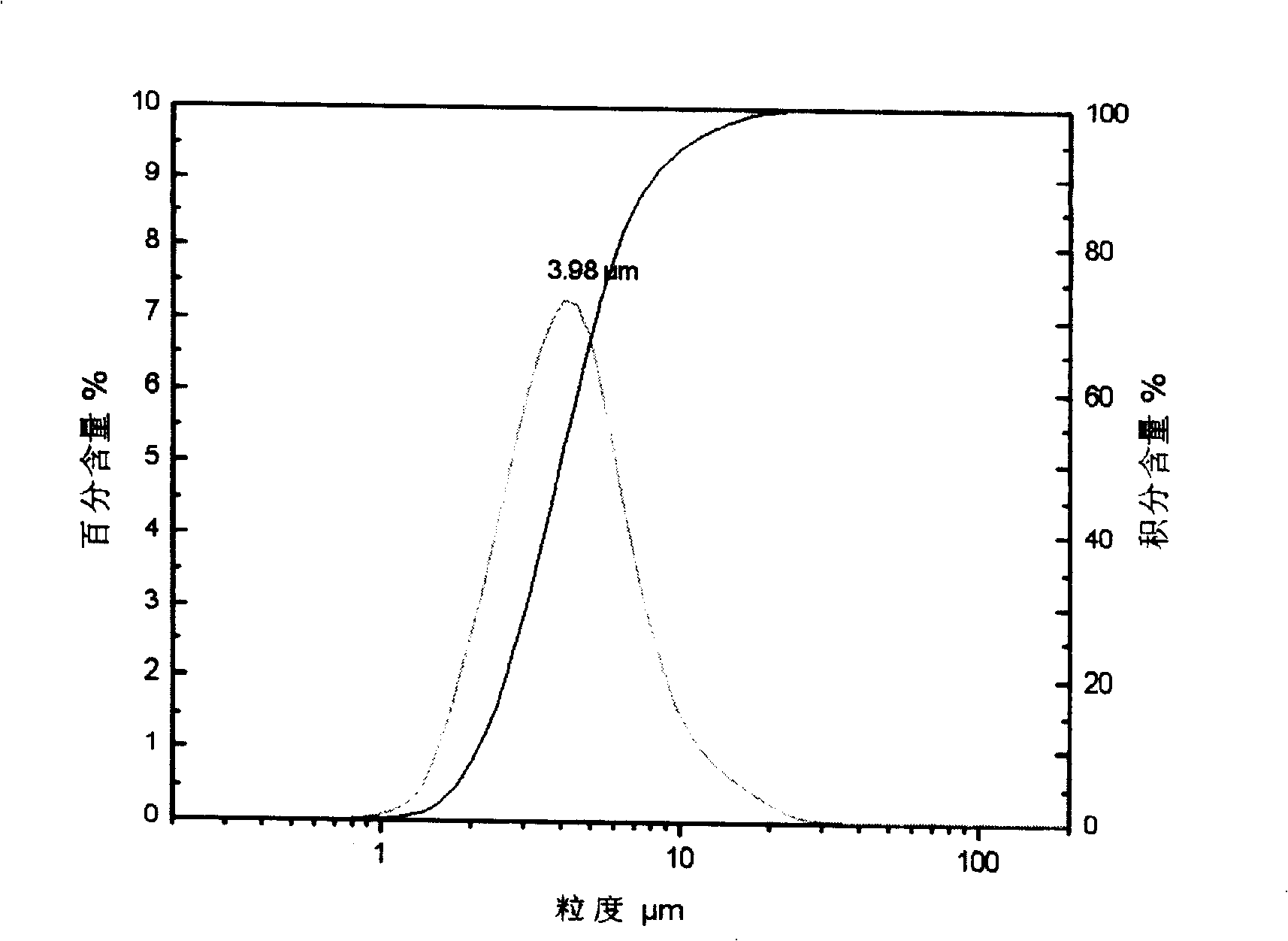

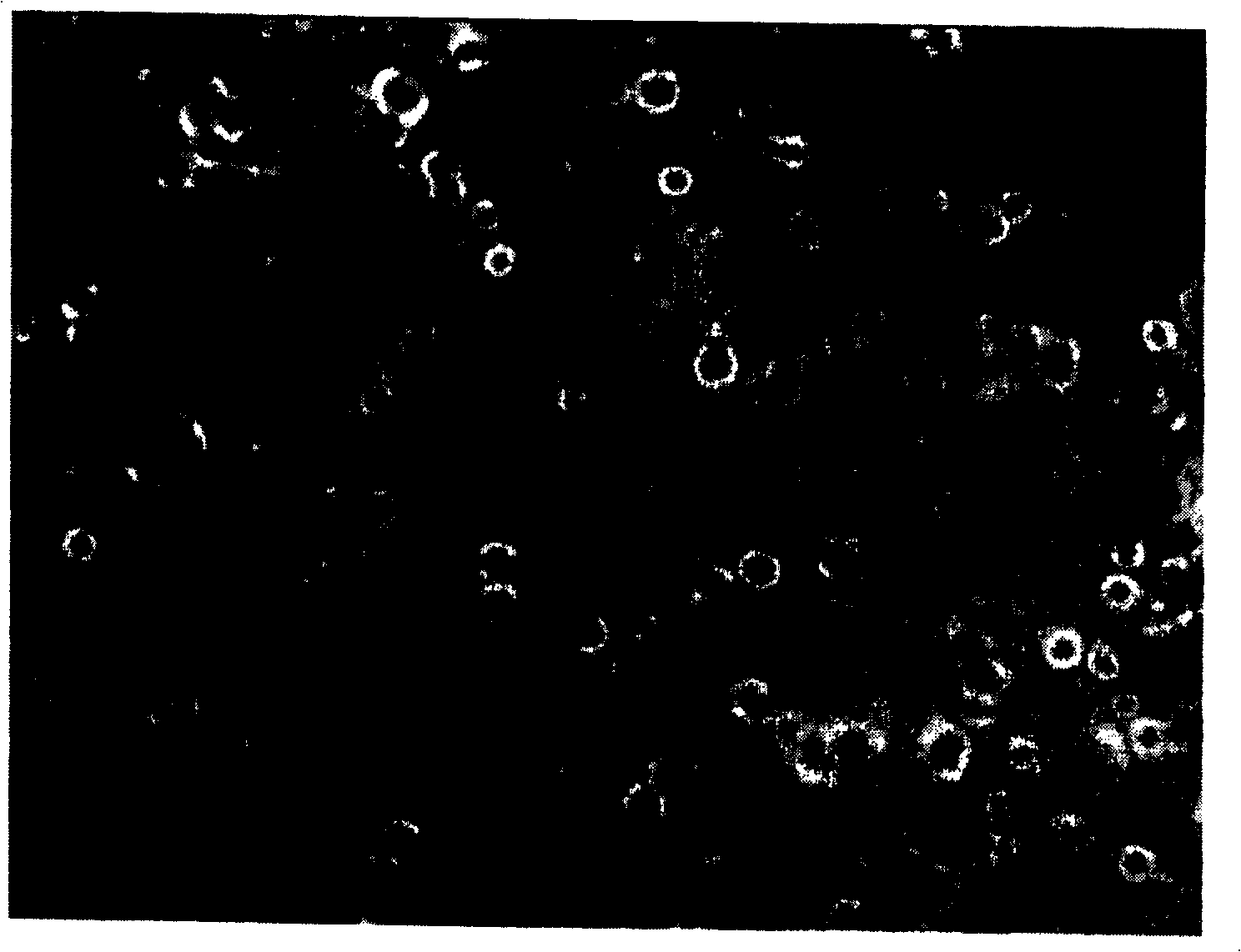

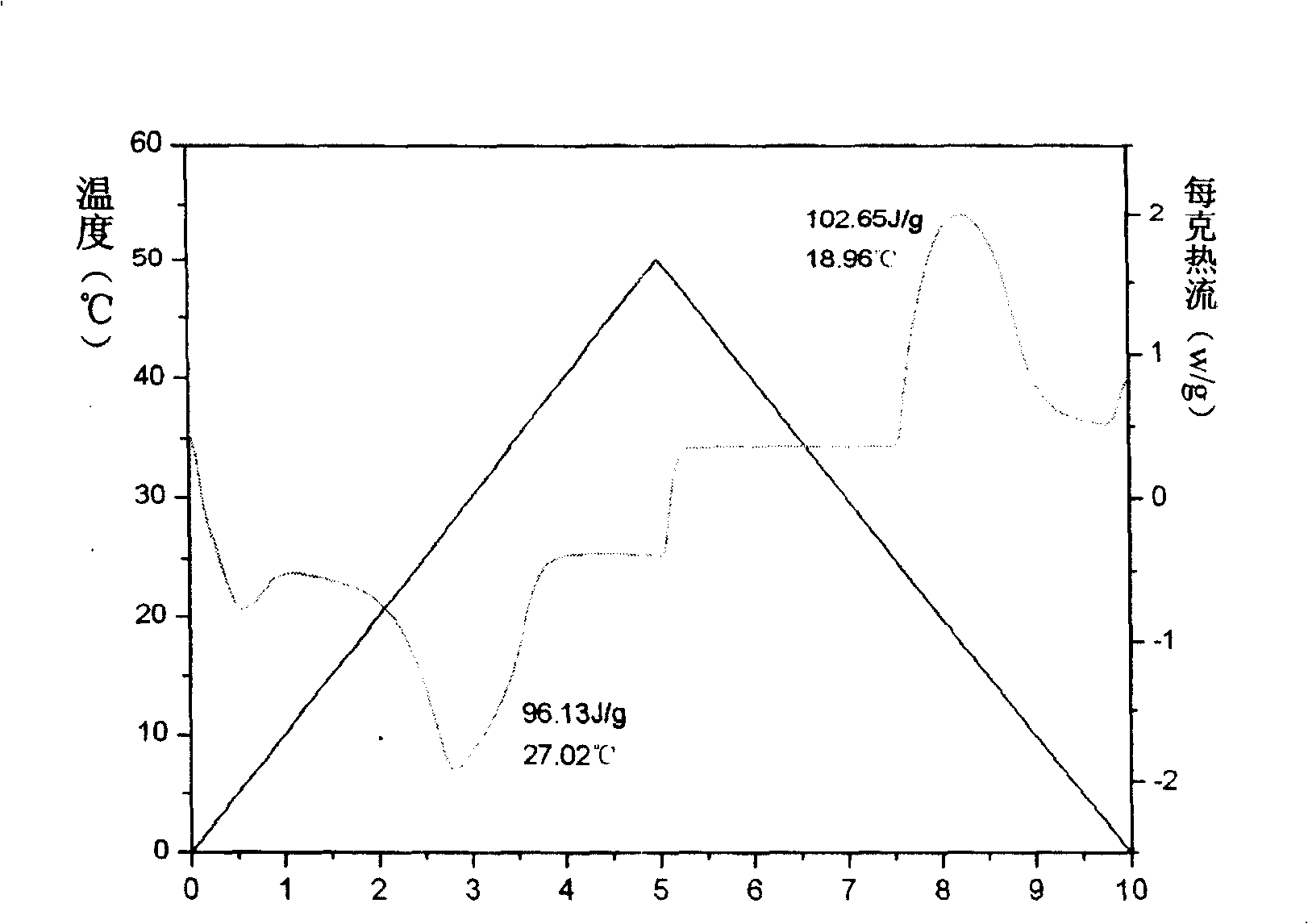

[0027] The particle size distribution of the prepared microcapsule phase change energy storage materials is as follows: figure 1 Shown, D 50 =8.95μm, th...

Embodiment 2

[0029] Measure 11 mL of 30# phase-change paraffin wax, whose phase-change temperature is 30°C. Add 1.5 grams of emulsifiers formulated with Span80 and Tween80 at a ratio of 0.45:0.55. Slowly add about 80mL of distilled water under heating conditions, and then add 1mL of 2.5mol / L sodium chloride, continue heating to 60°C while stirring for 30min to fully emulsify the emulsion.

[0030] After the emulsification is relatively complete, slowly add 5 drops of 1% hydrochloric acid and 6 mL of tetraethyl orthosilicate, place it in a water bath at 60°C under stirring for 7 hours, age for 4 hours, filter and wash to obtain phase change energy storage microcapsules.

[0031] The particle size of the prepared microcapsule phase change energy storage material is D 50 = 6.07 μm. Optical micrographs showed a capsule wall-covered capsule core structure. The enthalpy of the microcapsule during the phase change becomes 111.02 J / g, while the enthalpy of the capsule core 30# phase change para...

Embodiment 3

[0033] Measure 9 mL of 35# phase-change paraffin, whose phase-change temperature is 35°C. Add 1.5 grams of emulsifiers formulated with Span80 and Tween80 at a ratio of 0.4:0.6. Slowly add about 60mL of distilled water under heating conditions, and then add 0.5mL of 2.5mol / L sodium chloride, continue heating to 60°C while stirring for 30min to fully emulsify the emulsion.

[0034] After the emulsification is relatively complete, slowly add 5 drops of 1% hydrochloric acid and 7 mL of ethyl orthosilicate, place it in a water bath at 60°C under stirring for 3 hours, age for 4 hours, filter and wash to obtain phase change energy storage microcapsules.

[0035] The particle size of the prepared microcapsule phase change energy storage material is D 50 = 6.07 μm. Optical micrographs showed a capsule wall-covered capsule core structure. The enthalpy of the microcapsule during the phase change process becomes 87.90 J / g, while the enthalpy of the capsule core 35# phase change paraffi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com