Patents

Literature

68results about How to "Strong impact toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

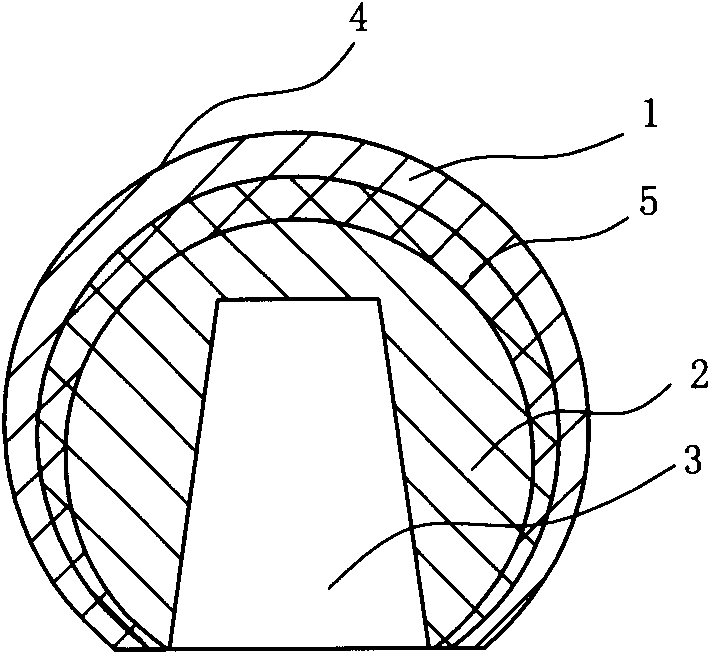

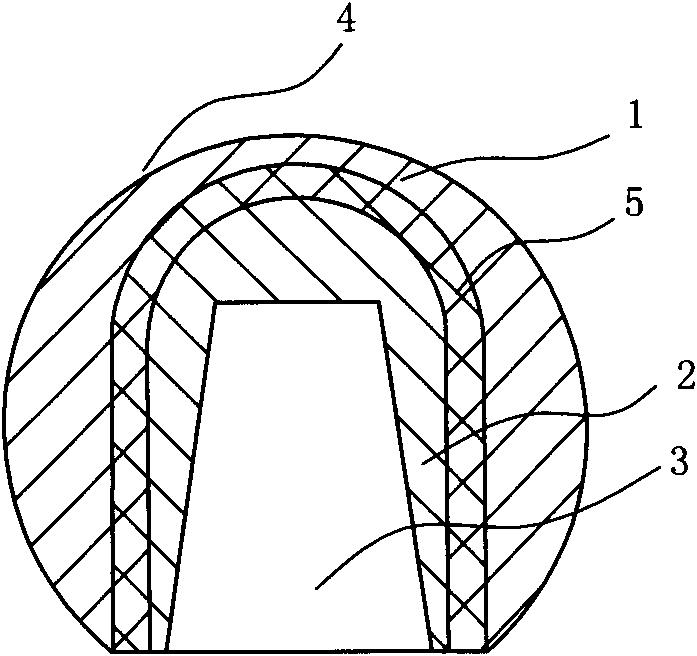

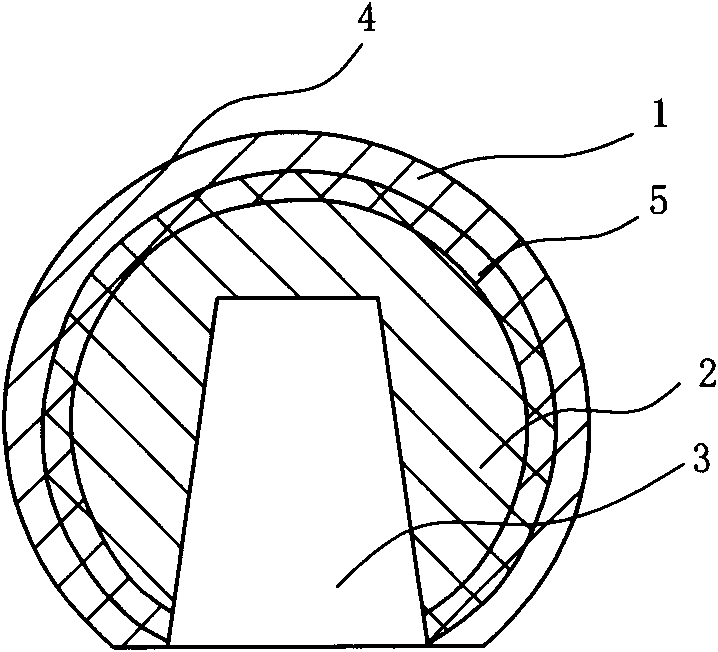

Manufacturing method of multilayer shell-core composite structural part

ActiveCN102009175AShell surface hardness is highHigh surface finishJoint implantsCeramic layered productsComposite constructionHigh surface

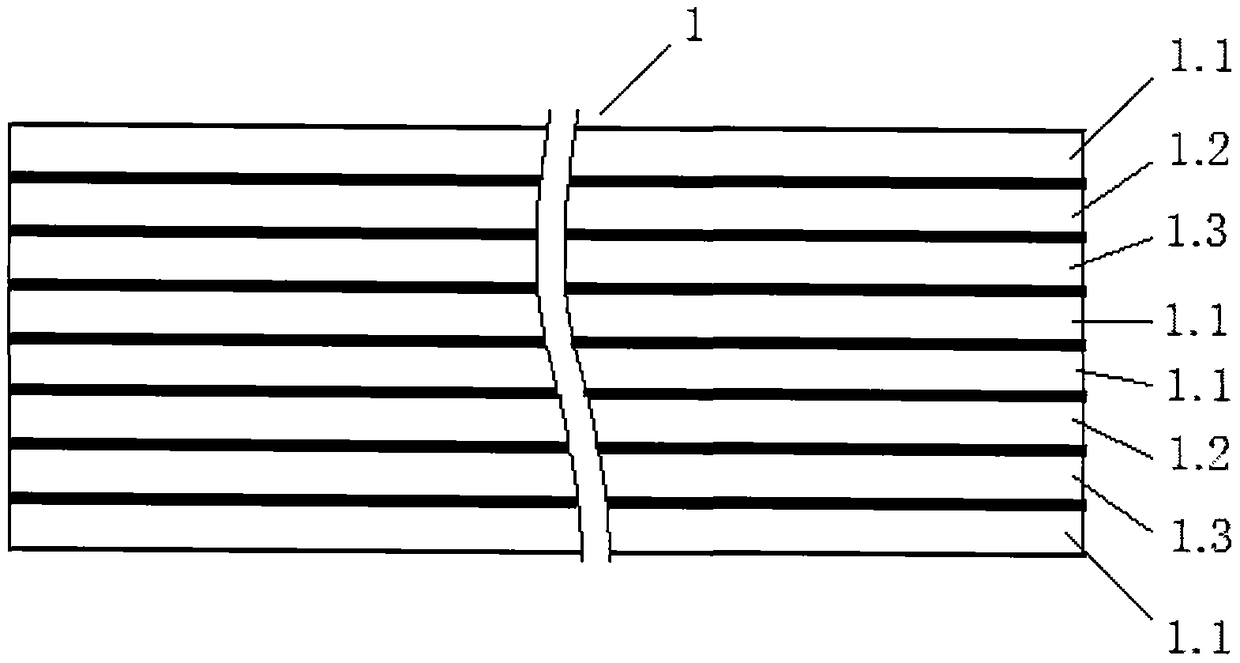

The invention discloses a manufacturing method of a multilayer shell-core composite structural part, which comprises the following steps of: (1) respectively preparing feed for injection forming of a core layer, a transition layer and a shell layer, wherein powder in the feed of the core layer and the powder in the feed of the shell layer are selected from one or a mixture of some of metal powder, ceramic powder, or toughened ceramic powder and are different from each other, and the powder in the feed of the transition layer is gradient composite powder; (2) respectively manufacturing blanks of the multilayer shell-core composite structural part layer by layer with a powder injection forming method; (3) degreasing the blanks; and (4) sintering the blanks to obtain the multilayer shell-core composite structural part. The multilayer shell-core composite structural part is manufactured with the powder injection forming method, and has the advantages of high surface hardness, abrasion resistance, uniform thickness of the shell layer, stable and persistent performance, strong binding force between the shell layer and the core layer due to the transition layer, good integral bending strength and good impact toughness and is difficult to crack.

Owner:SUZHOU DINGAN ELECTRONICS TECH

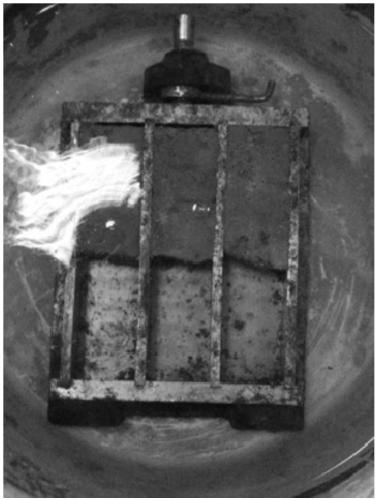

Co-sintering molding technology of MIM (metal injection molding) blank and metal product

The invention discloses a co-sintering molding technology of an MIM (metal injection molding) blank and a metal product. The technology comprises steps of preparation of the MIM blank, selection of the metal product, assembly, catalytic degreasing, sintering and discharging, wherein catalytic degreasing comprises procedures of preliminary washing, catalysis, secondary washing and post-washing, and sintering comprises negative pressure degreasing, vacuum sintering, partial pressure sintering and forced cooling. With the adoption of the molding technology, the technology is advanced, the process is simple and easy to control, existing degreasing sintering equipment can be used directly, great convenience is brought to production, labor and materials are saved, the production efficiency is substantially improved, the appearance of a prepared finished product is free of any abnormalities and defects, and the finished product is attractive and elegant in appearance, stable in quality, compact and uniform in structure, high in binding force, high in impact toughness and not prone to cracking, has the advantages of high mechanical bearing capacity and good perdurable stability and has the better economic benefit and the good application prospect.

Owner:杭州铭赫科技有限公司

Plant fiber-reinforced polypropylene composite material and preparation method thereof, and application of plant fiber-reinforced polypropylene composite material in preparation of automobile components

The invention discloses a plant fiber-reinforced polypropylene composite material and a preparation method thereof, and an application of the plant fiber-reinforced polypropylene composite material in preparation of automobile components. The composite material is prepared from the following raw materials in percentage by weight: 40%-77% of polypropylene, 20%-40% of a plant fiber, 1%-10% of vegetable oil, 1%-10% of a flexibilizer and 0.1%-5% of an assistant, wherein the plant fibers and the vegetable oil are from renewable biomass, and conform to the requirements of low-carbon, environment-friendly and sustained economic development. In addition, a low-density biomass material is capable of further promoting light weight of automobiles, and is of great significance in energy conservation and emission reduction. The plant fiber-reinforced polypropylene composite material for automobiles can be prepared by extrusion once, so that the method is simple, easy to operate and suitable for industrialized production.

Owner:NINGBO HOMELINK ECO ITECH CO LTD

High-performance multi-alloy wear-resistant ball, and preparation process and thermal treatment method thereof

ActiveCN103397279AImprove mechanical propertiesStrong impact toughnessFoundry mouldsFurnace typesWear resistantAlloy

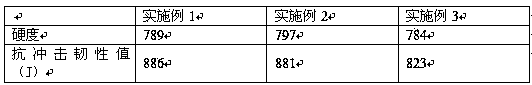

The invention discloses a high-performance multi-alloy wear-resistant ball, and a preparation process and a thermal treatment method thereof. The high-performance multi-alloy wear-resistant ball consists of the following components in percentage by weight: 2.0 to 2.6% of C, less than or equal to 1.0% of Si, 1.6 to 2.0% of Mn, more than or equal to 27% of Cr, 0.05 to 0.15% of Re, less than or equal to 0.05% of P, less than or equal to 0.05% of S, less than or equal to 0.3% of Mo, 0.1 to 0.3% of Ni, 0.05 to 0.08% of Al and the balance of Fe. When the high-performance multi-alloy wear-resistant ball is prepared, a metal mold sand coating process is adopted for formation, the thickness of a sand coating layer is controlled to be 1.5 mm to 3.5 mm, and the diameter of the wear-resistant ball is controlled to be phi 50 mm to phi 130 mm. According to the high-performance multi-alloy wear-resistant ball, and the preparation method and the thermal treatment method thereof, the high-performance multi-alloy wear-resistant ball obtained by adjusting the contents of C, Si, Mn, Cr, Re, P, S, Mo, Ni and Al elements, controlling the thickness of the sand coating layer in a preparation process and adjusting the thermal treatment method process in a thermal treatment process has high mechanical properties, strong impact toughness and small unit wear.

Owner:宁国东方碾磨材料股份有限公司

Medical coating powder containing nano material

InactiveCN1616105AOvercome the defects that the quality is difficult to guarantee, etc.Simple and fast operationPharmaceutical non-active ingredientsDrageesUltimate tensile strengthMaterials science

The medicinal coating powder containing nanometer material consists of hydromellose 55-65 wt%, copolymer of vinyl pyrrolidone and vinyl acetate 8 wt%, glycerin 15 wt%, Span 8 wt%, coloring agent 2-4 wt%, and nanometer titania 2-10 wt%. The medicinal coating powder containing nanometer material has simple production process, wide application, high performance / cost ratio, no physiological toxicity and many other advantages, and may meet the requirement of coating various solid Chinese medicine preparation.

Owner:GUANGDONG GUOFANG MEDICAL TECH

Cement-based elastic grouting material suitable for repairing concrete cracks in deep water and preparation method thereof

The invention relates to an engineering material and particularly relates to a grouting material for repairing concrete cracks in deep water. Cement, slag powder and rubber powder are taken as base materials, silica powder, gypsum powder, polyester fiber, a water reducing agent, water-based latex and a water-based curing agent are added according to a certain ratio, water is added, then the components are blended to form a groutable underwater non-dispersible plastomer, the plastomer is solidified to form an elastic solid capable of being bonded firmly to the interface of a concrete crack, andthe grouting material is mainly applied to the field of repair of concrete cracks in hydraulic engineering. The solidified cement-based elastic grouting material has the characteristics of high binding strength with underwater concrete, high head permeation resistance, high corrosion resistance, high elasticity, adaptability to concrete crack vibration and deformation, and the like.

Owner:NANJING HYDRAULIC RES INST

Production method of high-performance fiber composite product

The invention relates to a production method of a composite product which adopts high-performance fiber as a base material and is used for an automobile. The high-performance fiber comprises the following in percentage by weight: 15-30% of carbon fiber fabric, 10-20% of ultra strong polyethylene fiber fabric, 15-30% of high-strength glass fiber fabric, and 40-55% of unsaturated polyester resin or epoxy resin, the doses of the three high-performance fiber fabrics are 160-250g per square meter, respectively. The high-performance fiber composite product is prepared by a vacuum assisting molding technology or an RTM (resin transfer molding) technology. The high-performance fiber composite product has the advantages of light weight, high bending stress resistance, high elasticity modulus, high impact toughness, ultraviolet ray resistance, high-temperature resistance, low manufacturing cost, and the like, is mainly used for manufacturing automobile housing and parts, and is the optimal material suitable for energy conservation and emission reduction, and light weight equipment of new energy automobiles at present.

Owner:宁波大盛新材料有限公司

Heat treating method of high-hardness and wear-resistant cast-iron

The invention discloses a method for treating abrasion-resistant cast iron, which comprises the following heat treatment technological processes: firstly, annealing, namely a casting is directly heated to a temperature of between 920 and 960 DEG C, maintained for 1 to 8 hours at the temperature, slowly cooled until the temperature is between 700 and 750 DEG C, maintained for 4 to 10 hours at the temperature, slowly cooled until the temperature is less than 550 DEG C, and discharged for air cooling, so as to prevent segregation of compositions and eliminate the casting stress; secondly, quenching, namely the annealed casting is directly heated to the temperature of 1,100 DEG C, maintained for 2 to 6 hours at the temperature, and discharged for air cooling; and thirdly, tempering, namely the casting is maintained for 2 to 8 hours at a temperature of between 200 and 300 DEG C, and discharged for air cooling. The service life of the abrasion-resistant cast iron subjected to heat treatment is 1.3 to 1.6 times of that of abrasion-resistant cast iron prepared by the prior treatment method, and the hardness and the abrasion resistance of the material after heat treatment are further improved.

Owner:蔡柏林

Bamboo fiber reinforced nylon composite material and preparation method thereof

The invention discloses a bamboo fiber reinforced nylon composite material and a preparation method thereof. The bamboo fiber reinforced nylon composite material is prepared from the raw materials inpercentage by weight: 33-72% of PA6, 0-35% of PA1212, 10-40% of bamboo fiber, 1-6% of lysine based isocyanate, 2-10% of toughening agents and 1-8% of POE-g-MAH. The preparation method comprises the steps that the PA6, the PA1212, the bamboo fiber, the lysine based isocyanate, the toughening agents and the POE-g-MAH are mixed uniformly by using a mixing machine, and then the bamboo fiber reinforcednylon composite material is obtained after melt blending extrusion, bracing, air cooling and pelleting are carried out by using a twin-screw extruder. According to the bamboo fiber reinforced nylon composite material and the preparation method thereof, the material mechanical properties are excellent, the preparation cost is low, and the preparation technology is simple.

Owner:ZHEJIANG XINLI NEW MATERIAL CO LTD

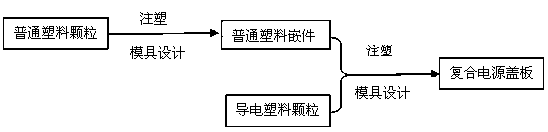

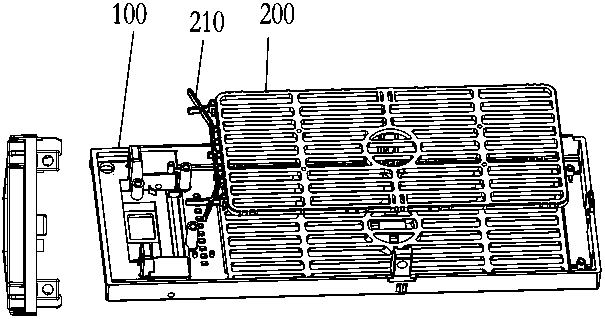

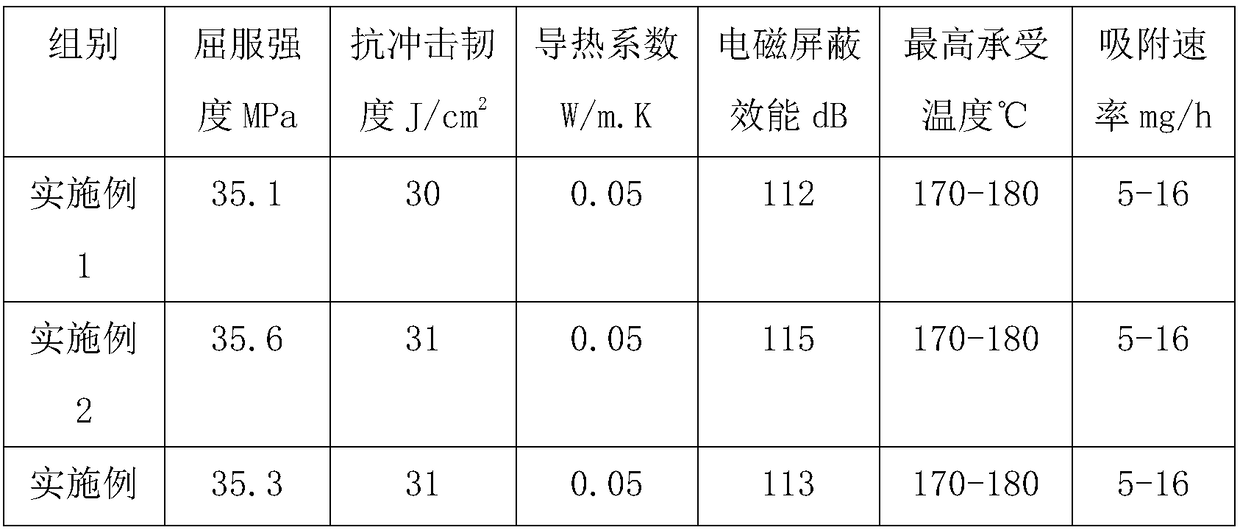

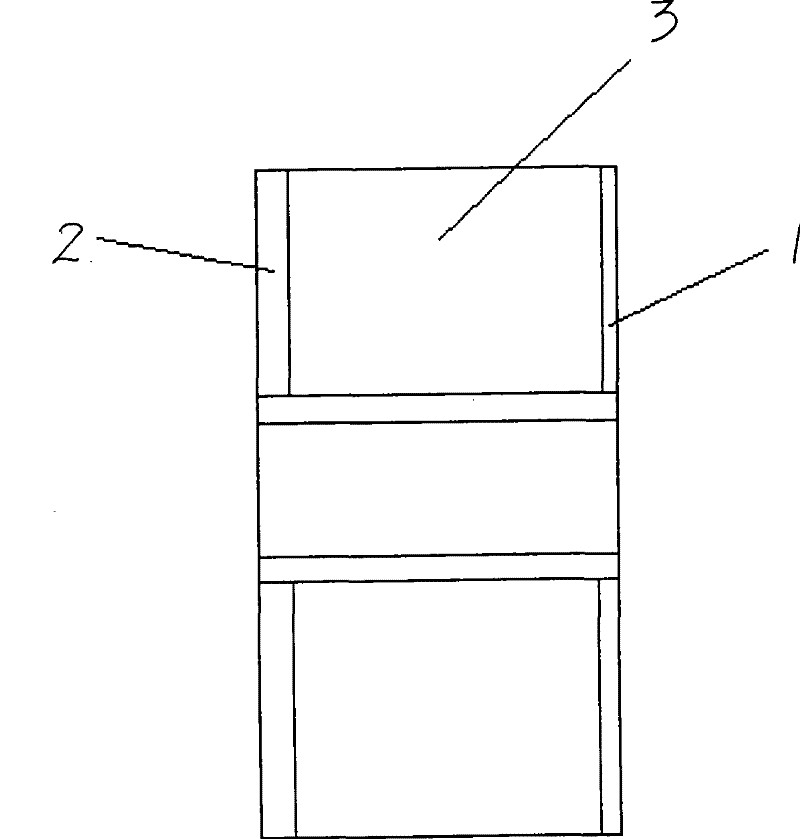

Combined power cover plate and preparation method thereof

ActiveCN103770269AImprove shielding effectStrong impact toughnessCoatingsElectromagnetic shieldingInjection molding machine

The invention discloses a combined power cover plate and a preparation method thereof. The combined power cover plate is obtained by performing injection molding on a conductive plastic piece with electromagnetic shielding performance into a common plastic piece with impact toughness in an embedded manner. According to the combined power cover plate, the cover plate strength is supplied through the common plastic piece, and the conductive plastic piece can supply shielding performance to the cover plate; furthermore, the common plastic piece and the conductive plastic piece are embedded to form the combined power cover plate through intramode injection molding or double-color injection molding forming technology, so that the problem that the conventional power cover plate cannot have the impact toughness and the shielding performance can be solved; therefore, the power cover plate disclosed by the invention is extremely high in shielding performance and excellent in impact toughness.

Owner:SHENZHEN FRD SCI & TECH

Novel multi-element alloy grinding forging and preparation method and heat treatment process thereof

ActiveCN103397258AImprove mechanical propertiesStrong impact toughnessFurnace typesHeat treatment furnacesAlloyMetal mold

The invention discloses a novel multi-element alloy grinding forging and a preparation method and a heat treatment process thereof. The novel multi-element alloy grinding forging comprises the following components in percentage by weight: 2.2 to 2.8 percent of C, less than or equal to 1.0 percent of Si, less than or equal to 0.8 percent of Mn, more than or equal to 10 percent of Cr, 0.05 to 0.15 percent of Re, less than or equal to 0.05 percent of P, less than or equal to 0.05 percent of S, 0.1 to 0.3 percent of V, 0.05 to 0.2 percent of Ti, 0.05 to 0.08 percent of Al, and the balance of Fe. The novel multi-element alloy grinding forging is formed by adopting a metal mold sand coverage process, the thickness of a sand coverage layer of the forging is between 3mm and 4mm, and the size of the novel multi-element alloy grinding forging is phi (40-60)mm*(50-70)mm. By adjusting the content of the C, Si, Mn, Cr, Re, P, S, V, Ni and Al elements, controlling the thickness of the sand coverage layer in the preparation process and adjusting the heat treatment process, the obtained novel multi-element alloy grinding forging has the advantages of good mechanical property, strong impact toughness and low unit abrasion.

Owner:宁国东方碾磨材料股份有限公司

Preparation method of boron modified phenolic resin adhesive

InactiveCN106675470AImprove heat resistanceStrong impact toughnessAldehyde/ketone condensation polymer adhesivesDistillationHeat stability

The invention relates to a preparation method of a boron modified phenolic resin adhesive. The method comprises the following steps: adding organosiloxane and boric acid to a styrene solvent, placing a whole reaction container in a closed container full of nitrogen, guaranteeing that the temperature in the closed container rises to 210 DEG C from 100 DEG C, and carrying out a reaction for 1-5 h; adding polyphenol to the reaction container, and carrying out a reaction to prepare polyborosiloxane; adding the prepared polyborosiloxane, a toughening modifier, a catalyst and formaldehyde to the reactor, and carrying out reduced pressure distillation to obtain modified phenolic resin; and uniformly mixing the polyborosiloxane with the modified phenolic resin to obtain the boron modified phenolic resin adhesive. The polyborosiloxane containing a large amount of terminal hydroxyl groups and having excellent heat stability is synthesized through polycondensation of organosiloxane, boric acid and polyphenol, and the modified phenolic resin has enough high impact toughness, cementability, heat resistance and flame resistance, so the solidification speed in the preparation process is improved.

Owner:JIANGSU GUOJIAO CHEM TECH

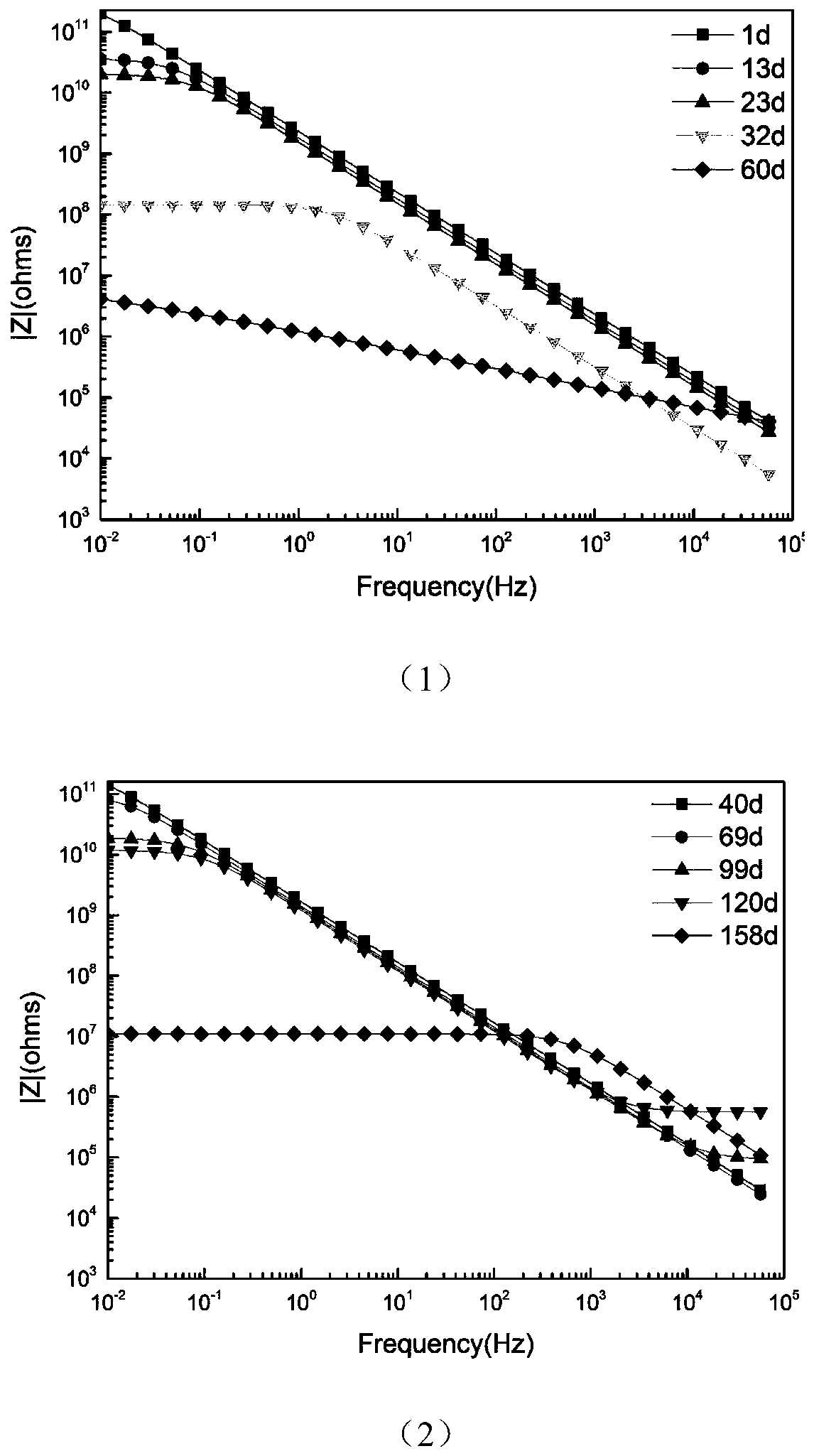

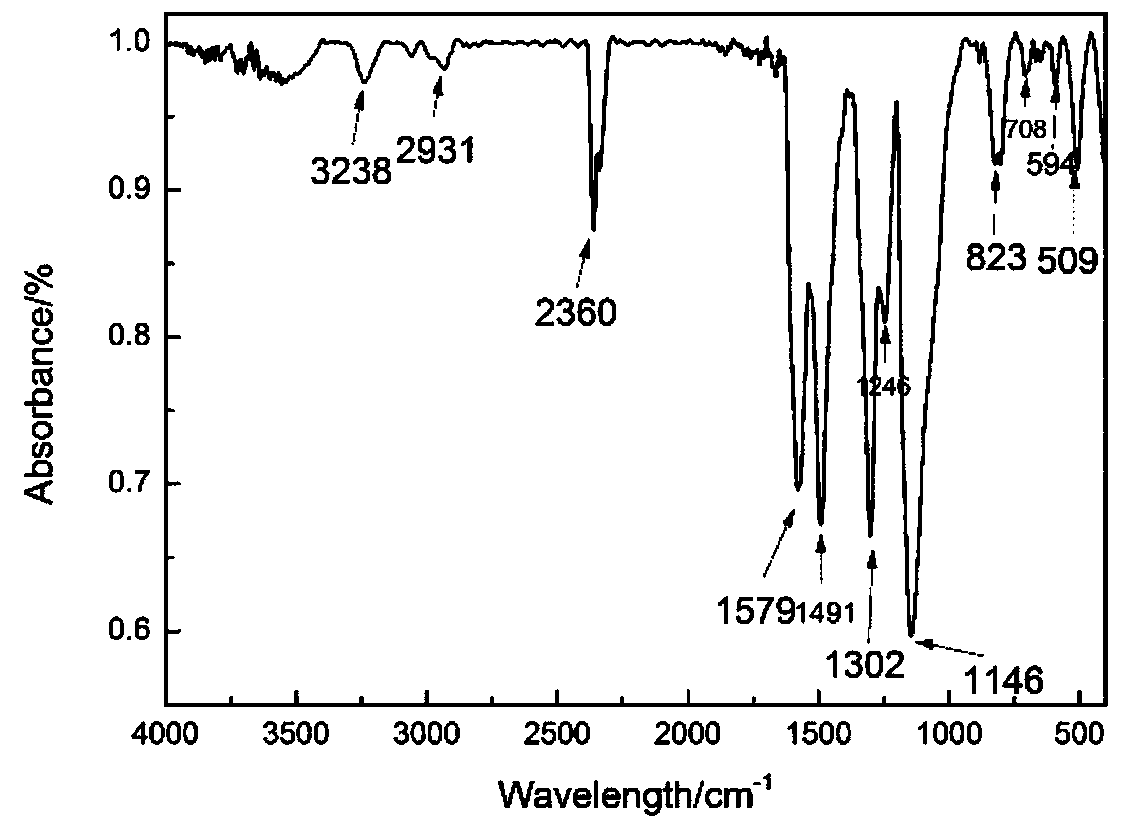

Phytic acid-doped polyaniline/polyphenylene sulfone coating composition and preparation method thereof

ActiveCN110684462AGood chemical stabilityStrong impact toughnessAnti-corrosive paintsPolymer sciencePhytic acid

The invention discloses a phytic acid-doped polyaniline / polyphenylene sulfone coating composition and a preparation method thereof, belonging to the technical field of coatings. The phytic acid-dopedpolyaniline / polyphenylene sulfone coating composition with excellent corrosion resistance is prepared by firstly preparing phytic acid-doped polyaniline and then adding the phytic acid-doped polyaniline into polyphenylene sulfone. According to the invention, the corrosion resistance of the polyphenylene sulfone coating is improved in the manner of forming a passive film between polyaniline and metal by utilizing the unique oxidation-reduction capability of the phytic acid-doped polyaniline; meanwhile, polyphosphoric acid groups carried by phytic acid are used for further promoting the coatingto form the passive film, so the corrosion resistance and adhesive force of the coating are enhanced, and a certain rust inhibition effect is achieved in the surface drying period of the coating.

Owner:JILIN UNIV

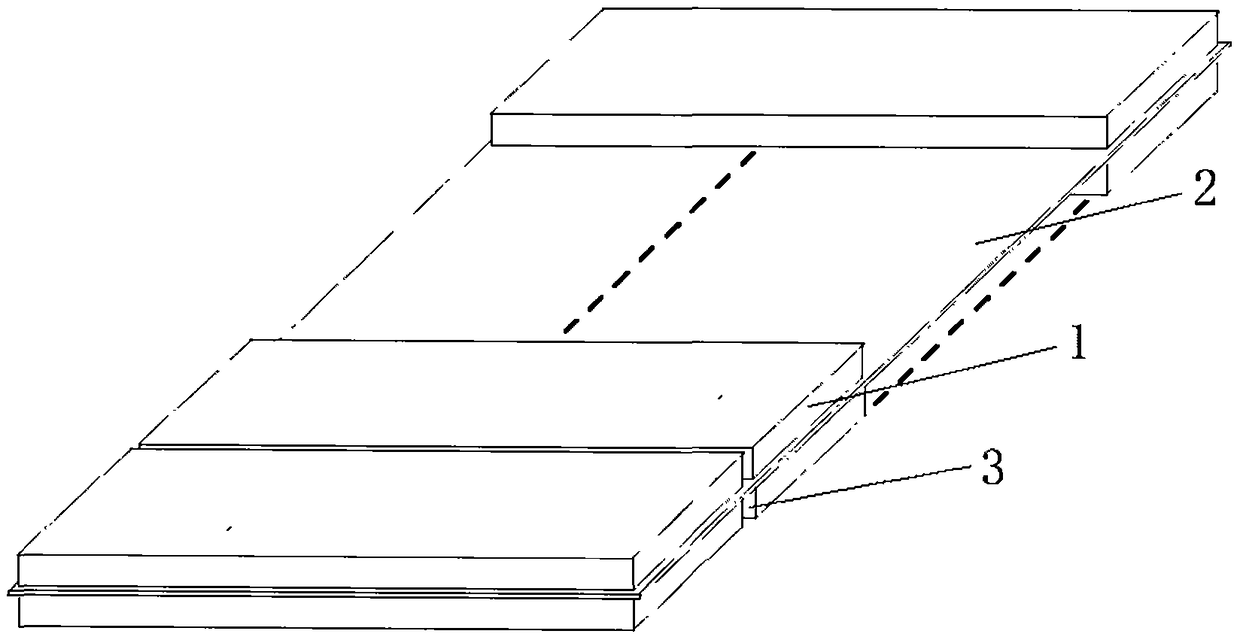

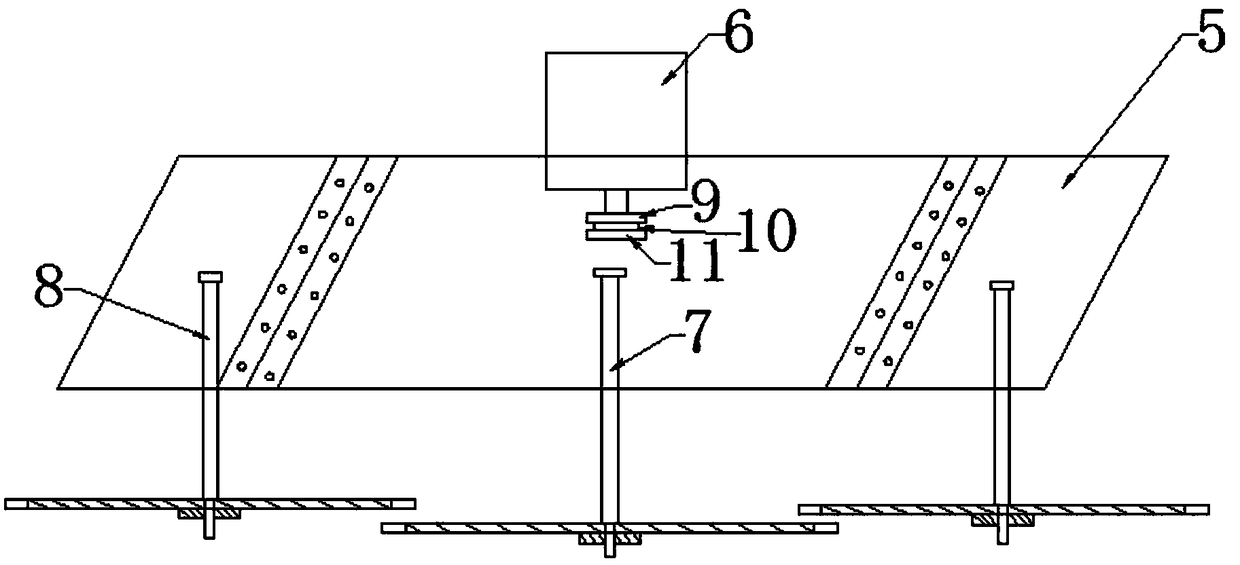

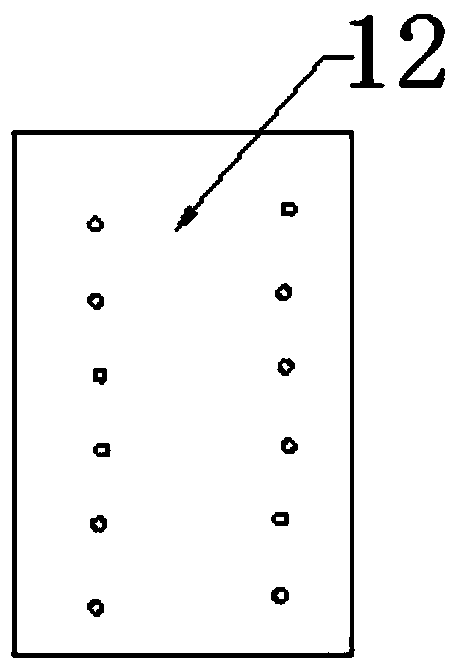

Folding-type airport emergency repair and construction composite combination way panel and manufacturing method thereof

ActiveCN109235177AHigh molecular weightHigh molecular weight polyethylene fiber, which has tensile breaking strengthHelicopter landing platformSynthetic resin layered productsFiberEpoxy

The invention provides a folding-type airport emergency repair and construction composite combination way panel and a manufacturing method thereof. The composite combination way panel is composed of asingle board and a connecting cloth. The veneer is a rectangular plate, which is laid side by side on the upper and lower surfaces of the connecting cloth, and the veneers on the upper and lower surfaces are symmetrically arranged; The veneer and the connecting cloth are bonded together by epoxy resin; Each veneer is made of composite fiber material, glass fiber cloth, ultra-high molecular weightpolyethylene fiber cloth and carbon fiber cloth. The composite pavement slab is light in material, the density is only 1.15-1.17, and the density is less than one sixth of ordinary steel plate. The bending strength of the panel is higher than 280MPa and the impact toughness is higher than 240K j / m2. The strength of the panel can satisfy the bearing capacity of the third generation fighter and allkinds of armed helicopters. The panel has the advantages of high bending strength, strong impact toughness, light material quality, large area, good anti-aging durability, simple and convenient repair pavement, time-saving and high efficiency of emergency repair, and can be used repeatedly.

Owner:NINGBO DACHENG ADVANCED MATERIAL +1

A kind of high-performance multi-element alloy wear-resistant ball and its preparation process and heat treatment method

ActiveCN103397279BImprove mechanical propertiesStrong impact toughnessFoundry mouldsFurnace typesAlloyMetal mold

Owner:宁国东方碾磨材料股份有限公司

Method for recycling and reproducing waste airbags

The invention belongs to the technical field of airbag recovery and in particular relates to a method for recycling and reproducing waste airbags. The method comprises the following steps: dissolvingto remove impurities, evaporating, reacting with cashew nut shell oil and preparing a bumper material. Compared with the existing technology, the method disclosed by the invention has the advantages that the waste airbags are evaporated by using a phenol-glacial acetic acid solution so as to remove impurities in the airbags, and one part of unavailable components are separated, so that the activeingredients in the airbags can be fully utilized; due to a reaction with the cashew nut shell oil under a vacuum condition, the bonding strength and a melting range of a recycled nylon 66 material arechanged, effective compatibility to raw materials such as polypropylene can be facilitated, a thermodynamic homogeneous system is formed, and the overall performance of the obtained material is improved. The material is high in impact toughness and has high oil resistance and aging resistance, the requirements on automotive bumper materials can be met, convenience is brought to processing, the environmental pollution is reduced, and the waste airbags are effectively recycled.

Owner:金寨宏伟新材料有限公司

Improved nodular cast iron rail finishing roll and production method thereof

PendingCN110273100AIncreased roll density and red hardnessStrong impact toughness and thermal crack resistanceRollsMetal rolling arrangementsHardnessImpact toughness

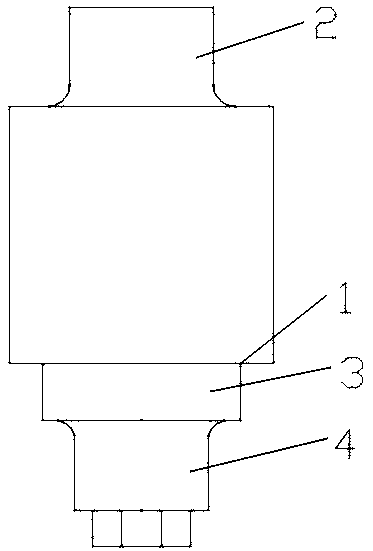

The invention relates to the technical field of finishing rolls, in particular to an improved nodular cast iron rail finishing roll and a production method of the improved nodular cast iron rail finishing roll. The improved nodular cast iron rail finishing roll is provided with a stepped roll body. An upper roll neck is fixed to the upper end of the roll body. A lower roll neck is fixed to the lower end of the roll body. A transmission end is fixed to the lower end of the lower roll neck. According to the improved nodular cast iron rail finishing roll and the production method of the improved nodular cast iron rail finishing roll, the density and red hardness of the roll are greatly improved, the impact toughness and the thermal crack resistance are high, the hardness drop is reduced, and the service life of the roll is prolonged. The production method is simple, the process is reasonable, and wide popularization and use can be conveniently realized.

Owner:常州市中宇合金轧辊厂

Composite for polyethylene film and preparation method of composite

InactiveCN109370007AGood anti-adhesion smooth effectImprove mechanical propertiesMethacrylateAntioxidant

The invention discloses a composite for a polyethylene film and a preparation method of the composite. The composite for the polyethylene film comprises the components in percentage by mass: 70%-85% of polyethylene, 3%-10% of nanometer talcum powder, 2%-8% of toughening agent, 1%-5% of anti-blocking agent, 1%-5% of slipping agent, 0.1%-1% of ethylene bis-stearamide and 0.1%-0.5% of antioxidant, and the toughening agent is one of methacrylate-acrylate copolymer, a methyl methacrylate-butadiene-styrene ternary grafted copolymer, an ethylene-vinyl acetate copolymer and an ethylene-acrylate-epoxyglycidyl ester copolymer. The composite has the beneficial effects of good antiblocking and slipping effects, good mechanical properties, strong impact toughness as well as good using effect and development prospect when being applied to the production of polyethylene film or blown film products.

Owner:湖北冠誉塑料包装制品有限公司

Improved type aluminum alloy profile steel finished product roller and manufacturing method thereof

PendingCN111790755AImprove wear resistanceStrong impact toughnessFurnace typesRollsCrack resistanceWear resistance

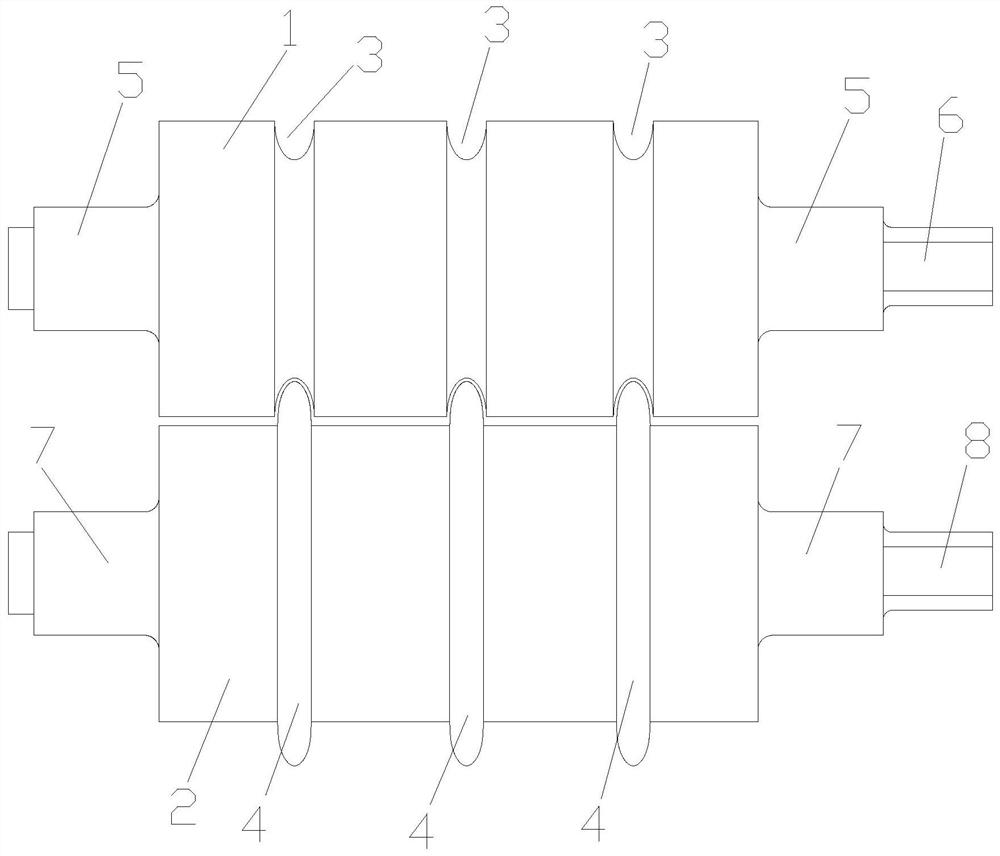

The invention relates to the technical field of rollers, in particular to an improved type aluminum alloy profile steel finished product roller and a manufacturing method thereof. The improved type aluminum alloy profile steel finished product roller comprises an upper roller and a lower roller which are arranged in parallel, wherein at least one group of ring-shaped grooves is formed in the length direction of the upper roller; ring-shaped bulges are fixedly arranged on positions, opposite to the ring-shaped grooves, in the length direction of the lower roller; the ring-shaped bulges are embedded into the ring-shaped grooves; and spacing between the ring-shaped bulges and the ring-shaped grooves defines profile steel holes. According to the improved type aluminum alloy profile steel finished product roller and the manufacturing method thereof disclosed by the invention, the roller is good in wear resistance, is strong in impact toughness and crack resistance, and increases roller on-machine operation rolling amount by five times or more. The manufacturing method is reasonable in layout, is simple in process, can effectively guarantee use quality of the roller and the service life,and is widely popularized and used conveniently.

Owner:常州市瑞宏轧辊有限公司

Structural alloy material and preparation method thereof

The invention relates to a structural alloy material and a preparation method thereof. The structural alloy material comprises the following components in percentage by weight: 0.6-0.8% of Mg, 0.3-0.4% of Rb, 0.1-0.2% of Hf, 0.2-0.3% of Pd, 0.5-0.8% of Co, 3.3-3.6% of Ni and the balance of Fe. The preparation method of the structural alloy material comprises the steps of material taking, vacuum melting, press forming and cooling. The obtained structural alloy material has very high hardness and impact resistance and can be used for structural parts of large scale equipment to increase the hardness and the impact resistance of the equipment.

Owner:SUZHOU INST OF TRADE & COMMERCE

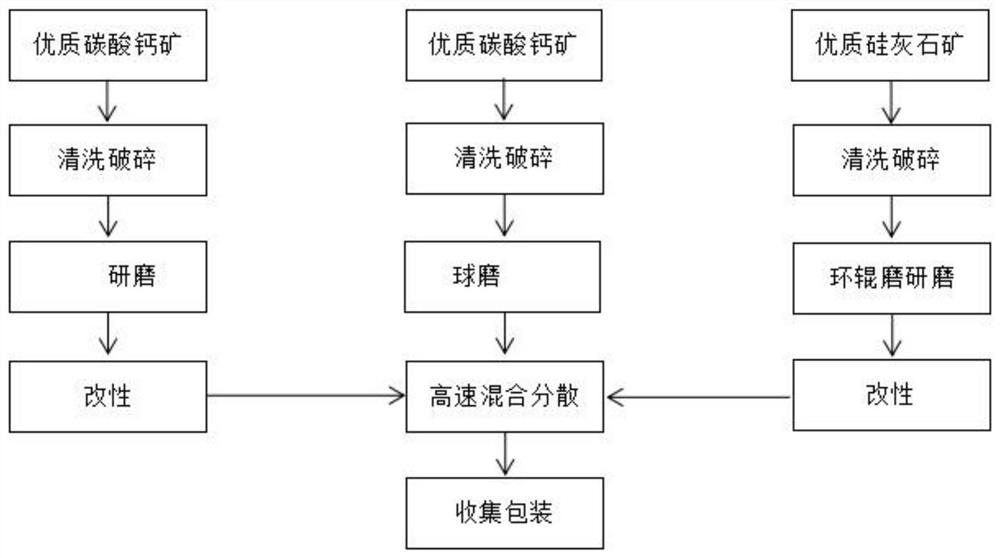

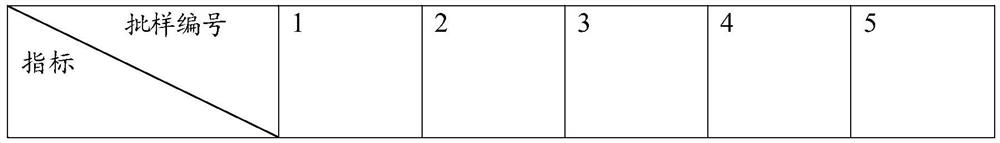

Special filler for marble glue and preparation method thereof

PendingCN114573866AFilled tightlyImprove plasticizing effectSolid waste managementWollastoniteColloid

The invention provides a special filler for marble glue and a preparation method thereof, and belongs to the technical field of fine chemical engineering. Mixing calcium carbonate ore with sodium acrylate, and grinding to obtain first powder; the particle size of the first powder is 4-6 [mu] m; mixing calcium carbonate ore with sodium acrylate, and performing ball milling to obtain second powder; the particle size of the second powder is 1.2 to 2.5 [mu] m; the preparation method comprises the following steps: crushing wollastonite to obtain wollastonite powder; mixing the first powder, titanate and stearic acid for first modification to obtain first modified powder; mixing the wollastonite powder with titanate, and carrying out second modification to obtain second modified powder; and mixing the second powder, the first modified powder and the second modified powder to obtain the special filler for marble glue. By controlling the particle size of the powder, the filler is more compact during filling, and the oil absorption value of the filler is reduced, so that the plasticizing effect during colloid curing is improved, and the toughness is improved.

Owner:JIANGXI GUANGYUAN CHEM +1

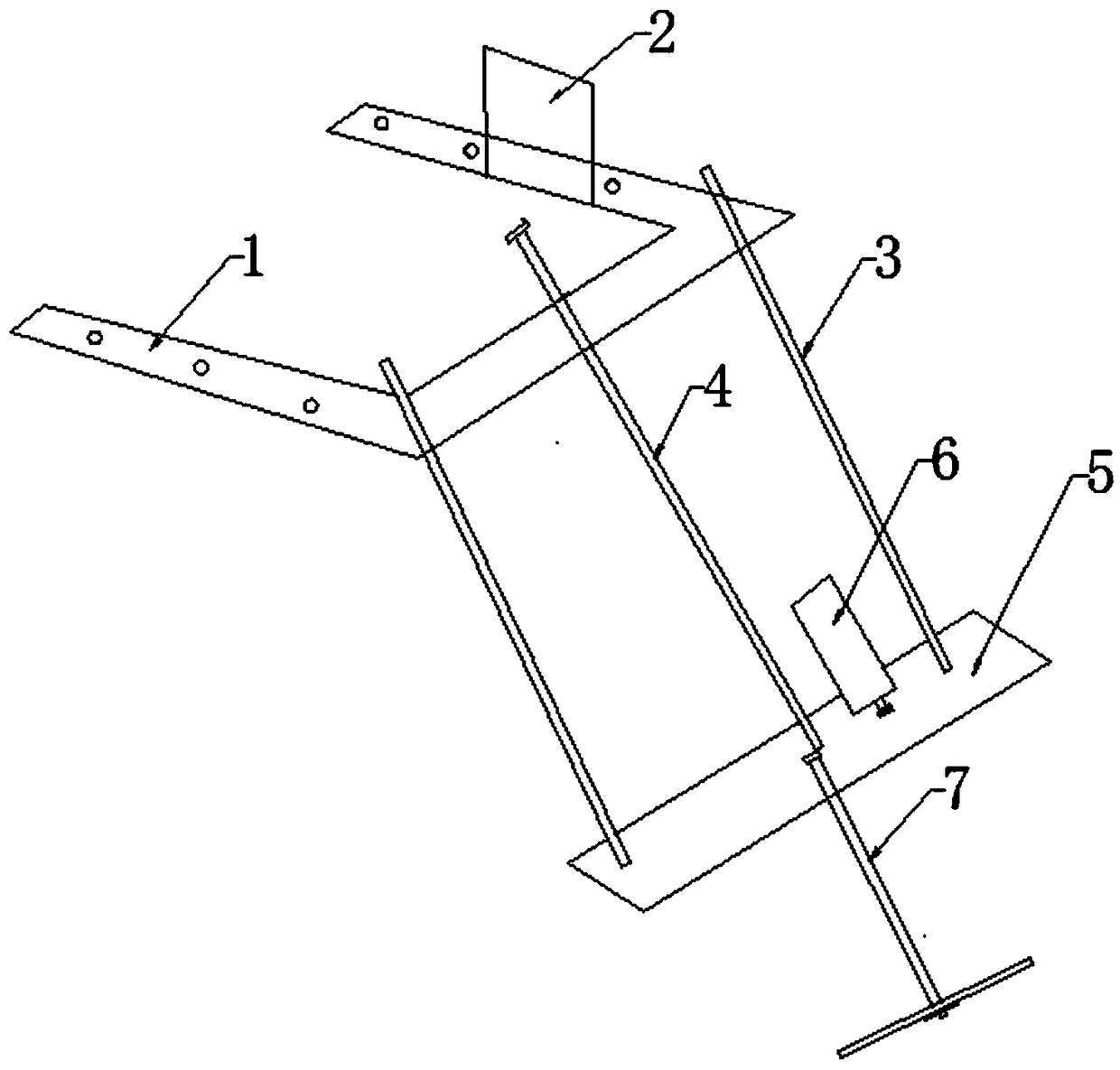

Combined underwater mower

The invention discloses a combined underwater mower. The combined underwater mower can be quickly and detachably arranged on an unused hull through a base; meanwhile, a rotary mowing part of the underwater mower is composed of a main mowing part and two sub mowing parts, wherein the two sub mowing parts can be selectively installed as required. The combined underwater mower has the advantages of being simple in structure, convenient to operate, wide in application range and high in mowing efficiency.

Owner:NAN COUNTY WEIYE MACHINERY MFG

Preparation method of cold stamping die for steel hub

InactiveCN107217203AImprove mechanical propertiesIncrease stiffnessShaping toolsFurnace typesCrucibleFree cooling

The invention discloses a preparation method of a cold stamping die for a steel hub. The preparation method comprises the following steps: performing mixed smelting on a die material used for production of the cold stamping die at a high temperature, and performing casting to obtain a casting with the required dimension used for production of the die; processing the casting in strict accordance with the drawing to obtain the cold stamping die for the hub; placing mixed salt in an inner heating crucible, heating at a high temperature for melting, and performing heat preservation to obtain a melting liquid; utilizing a cleaning solution to clean the surface of the cold stamping die for the hub thoroughly, and performing high temperature preheating to obtain the preheating die; and placing the preheating die in the heat preservation melting liquid for soaking, performing quenching and tempering treatment in sequence after soaking, and finally naturally cooling to room temperature to obtain the cold stamping die for the steel hub. Compared with the prior art, the preparation method of the cold stamping die for the steel hub has the benefits as follows: the raw material cost is low, the processing and manufacturing cost is low, and the prepared cold stamping die has the advantages that the impact toughness is high and the service life is long; besides, the prepared cold stamping die for the steel hub prepared by adopting the preparation method can be used for production of steel hubs, and further has the advantages of being high in production efficiency, high in the qualified rate of finished products and worth to be popularized.

Owner:滁州市东华模具制造有限公司

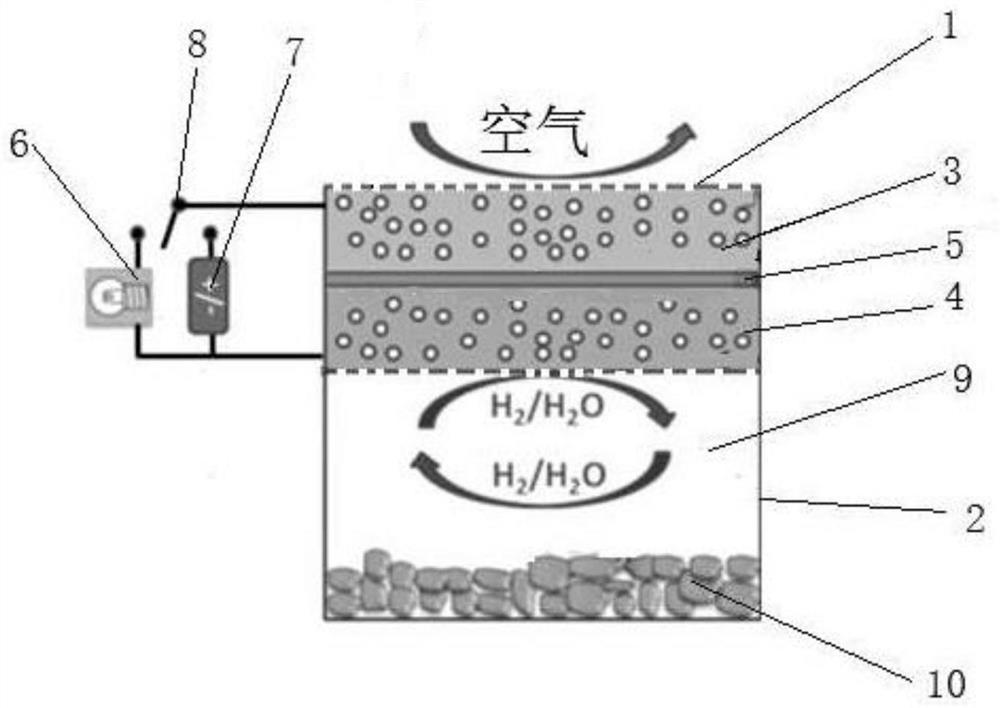

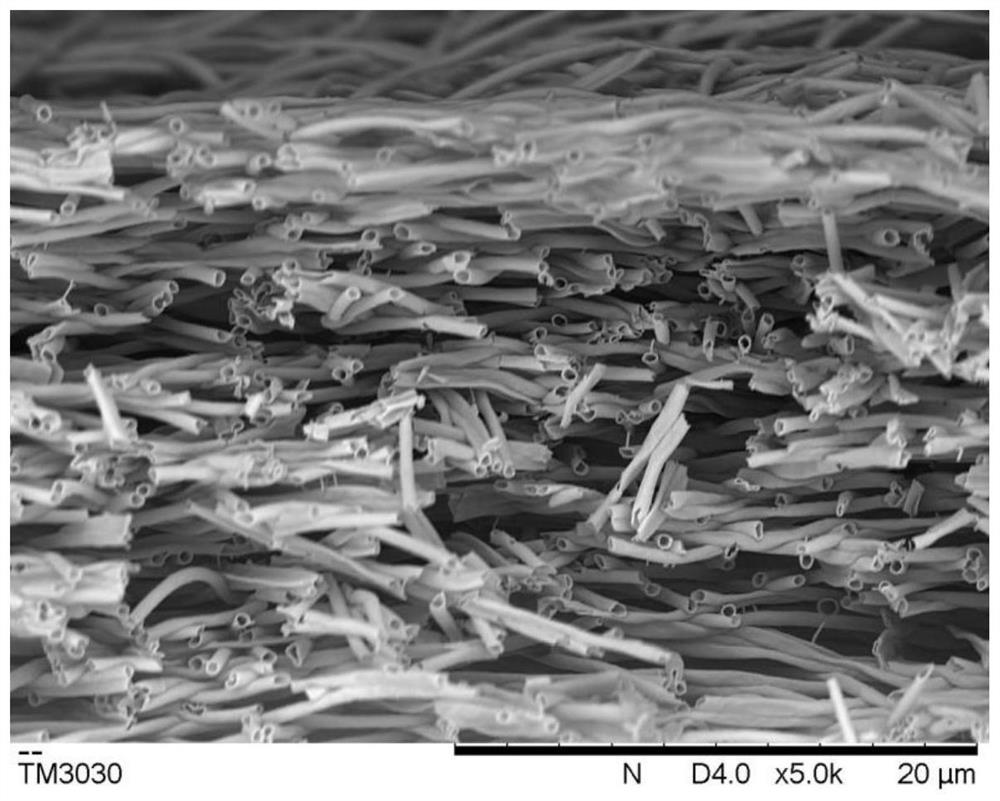

Hollow fiber pore-forming agent and application thereof in fuel cells

ActiveCN112853530AReduce activation polarizationLower internal resistanceHollow filament manufactureCell electrodesElectrochemical responseFiber

The invention relates to a hollow fiber pore-forming agent and application thereof in fuel cells. The pore-forming agent is PAN-PVP coaxial hollow fiber prepared from peroxyacetyl nitrate and polyvinylpyrrolidone as raw materials, and a preparation method of the pore-forming agent comprises the following steps of preparing a PAN-PVP mixed solution from peroxyacetyl nitrate and polyvinylpyrrolidone; and then operating on a coaxial high-voltage electrostatic spinning machine, placing methyl silicone oil in an inner needle hole, placing the PAN-PVP mixed solution in an outer needle hole, and rotating a roller collector to collect the PAN-PVP coaxial hollow fiber. The PAN-PVP hollow fiber can form a three-dimensional network cross-linked cavity after a fuel cell anode is fired to remove the fiber, so that the connection of the anode in the hole is improved, the internal specific surface area of an electrolyte is increased, the activation polarization of the cell is integrally reduced, the electrochemical reaction area is increased, the internal resistance of the cell is reduced, and the substance diffusion is accelerated, and therefore, the output performance of the cell is finally improved, and attenuation of specific capacity is slowed down.

Owner:XIAMEN UNIV

Vegetation concrete for slope protection and preparation method thereof

InactiveCN112010592AStrong impact toughnessHigh strengthSolid waste managementGrowth substratesSoil scienceSilicic acid

The invention discloses vegetation concrete for slope protection and a preparation method of the vegetation concrete. The vegetation concrete comprises the following components in parts by weight: 78-94 parts of cement, 75-86 parts of gravels, 23-27 parts of a mineral mixture, 33-38 parts of a plant-growing matrix, 31-34 parts of grass seeds, 85-100 parts of water and 0.3-0.5 part of a water reducing agent. The mineral mixture is mainly prepared from 11 parts of fly ash, 9 parts of blue algae, 8 parts of zeolite, 7 parts of attapulgite, 7 parts of magnesium silicate and 6 parts of polypropylene. The plant-growing matrix is prepared from natural soil, plant ash, ferrous sulfate and zeolite. By stirring and mixing the cement, the gravels, the mineral materials, the water and the water reducing agent step by step, flattening by a press machine, curing to form porous concrete, pouring the vegetation matrix slurry, and sowing grass seeds to obtain vegetation concrete, the vegetation concrete has the characteristics of high porosity and high compressive strength, and can be applied to slope protection.

Owner:于鹏飞

Palygorskite powder-added wood-plastic door and window material and preparation method thereof

The invention discloses a palygorskite powder-added wood-plastic door and window material and a preparation method thereof, and relates to the technical field of door and window materials. The wood-plastic door and window material comprises the following raw materials: a PVC waste material, a PE waste material, fly ash, palygorskite powder, chabazite powder, diatomite, porous SiO2, coconut charcoal fiber, broussonetia papyrifera wood chip powder, borax, calcium lignosulfonate, low-molecular weight polyethylene wax, sucrose fatty acid ester, a curing agent, a foaming agent, a foam stabilizing agent and a coupling agent. The preparation method comprises the following steps: mixing and extruding the raw materials and the like to obtain the wood-plastic door and window material. The wood-plastic door and window material has excellent comprehensive performance, not only can achieve the purposes of noise reduction and energy saving relatively well, but also can effectively purify air and shield electromagnetic waves, so that the wood-plastic door and window material improves the quality of indoor working and living environments, and is durable, practical and wide in application field.

Owner:合肥市旺友门窗有限公司

A kind of preparation method of high-performance fiber composite material product

The present invention relates to a production method for an automobile composite article with a high-performance fibre as a base material. The matching weight ratios of the materials are: 15-30% of a carbon fibre fabric, 10-20% of an ultra-strength polyethylene fibre fabric, 15-30% of a high-strength glass fibre fabric, and 40-55% of an unsaturated polyester resin or epoxy resin, wherein the three high-performance fibre fabrics used above are of 160-250 g per square metre. The high-performance fibre composite article is prepared by a vacuum-assisted forming process or an RTM forming process (a resin transfer moulding forming process). The high-performance fibre composite article prepared in the present invention has the advantages such as a low material mass, a strong bending stress resistance, a high elastic modulus, a strong impact toughness, ultraviolet resistance, a high temperature resistance, a low preparation cost etc., is mainly used for manufacturing automobile housings and parts, and is an optimum material which fulfils the energy conservation and emission reduction and lightweight equipment requirements of new energy automobiles at present.

Owner:宁波大盛新材料有限公司

Aqueous adhesive

InactiveCN106675450AIncrease surface active tensionStrong impact toughnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveFatty alcohol

The invention relates to an aqueous adhesive which comprises the following components: carboxy styrene-butadiene latex, a tackifier, an anti-aging agent, a curing agent, an antifoaming agent, a wetting agent and water, wherein a superfine rosin modified resin is adopted as the tackifier; propyl gallate is adopted as the anti-aging agent; acetone is adopted as the curing agent; emulsified silicone oil is adopted as the antifoaming agent; fatty alcohol polyoxyethylene ether is adopted as the wetting agent. The aqueous adhesive has the advantages that a raw material for preparing the aqueous adhesive comprises the carboxy styrene-butadiene latex, and a great number of air bubbles can be generated in a preparation stirring process, so that the antifoaming agent is added into the raw material to eliminate the air bubbles and simultaneously enhance the surface activity and tension of the raw material; the emulsified silicone oil is adopted as the antifoaming agent, so that the generated air bubbles can be eliminated, formation of the air bubbles can also be suppressed, and the bonding strength of the prepared adhesive is strengthened.

Owner:JIANGSU GUOJIAO CHEM TECH

Flame-retardant PC/PET composite material

The invention discloses a flame-retardant PC / PET composite material which comprises the following components in percentage by mass: 30-60% of PC, 10-30% of PET, 2-5% of a compatilizer, 5-15% of a flame retardant, 0.1-0.5% of an anti-melting dropping agent, 5-10% of a toughening agent, 0.1-0.5% of an antioxidant and 0.5-1.5% of a lubricant. The flame-retardant PC / PET composite material has the beneficial effects of being respective advantages of PC and PET, and good in compatibility, high in flame retardancy efficiency, high in impact resistance and low in cost.

Owner:QINGDAO TONGCHUANG ENERGY SAVING ENVIRONMENTAL PROTECTION ENG

A kind of manufacturing method of pure glass fiber reinforced plastic fan

ActiveCN101274489BHigh tensile strengthStrong impact toughnessDomestic articlesPlatinumChemical industry

The invention relates to a method for manufacturing a pure glass fiber reinforced plastic fan. It is characterized in that: after resin is impregnated with felt, platinum fiber cloth and steel wire cloth, the outermost layer is used as felt, and then platinum fiber cloth and felt are pasted alternately inside. Among them, two layers of symmetrically arranged platinum fiber cloth are replaced by steel wire cloth. When the felt, platinum fiber cloth, and steel wire cloth are pasted on adjacent layers, the fiber lines are cross-distributed. The resin content of the felt is 50-75% of the weight of the felt, the resin content of the steel cloth is 35-50% of the weight of the steel cloth, and the resin content of the platinum fiber cloth is 25-50% of the weight of the platinum fiber cloth. —40%. The resin content of the felt is 65% of the weight of the felt, the resin content of the steel wire cloth is 45% of the weight of the steel wire cloth, and the resin content of the platinum fiber cloth is 35% of the weight of the platinum fiber cloth. The curing time of the resin is 15-50 minutes. The demoulding time after pasting is at least 10 hours. The invention has the advantage that the front and rear discs and fan blades of the manufactured fan have strong tensile strength and impact toughness, which meets the needs of the chemical industry for corrosion-resistant fans.

Owner:SHANGHAI CHAOHUI VENTILATION & ENVIRONMENT PROTECTION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com