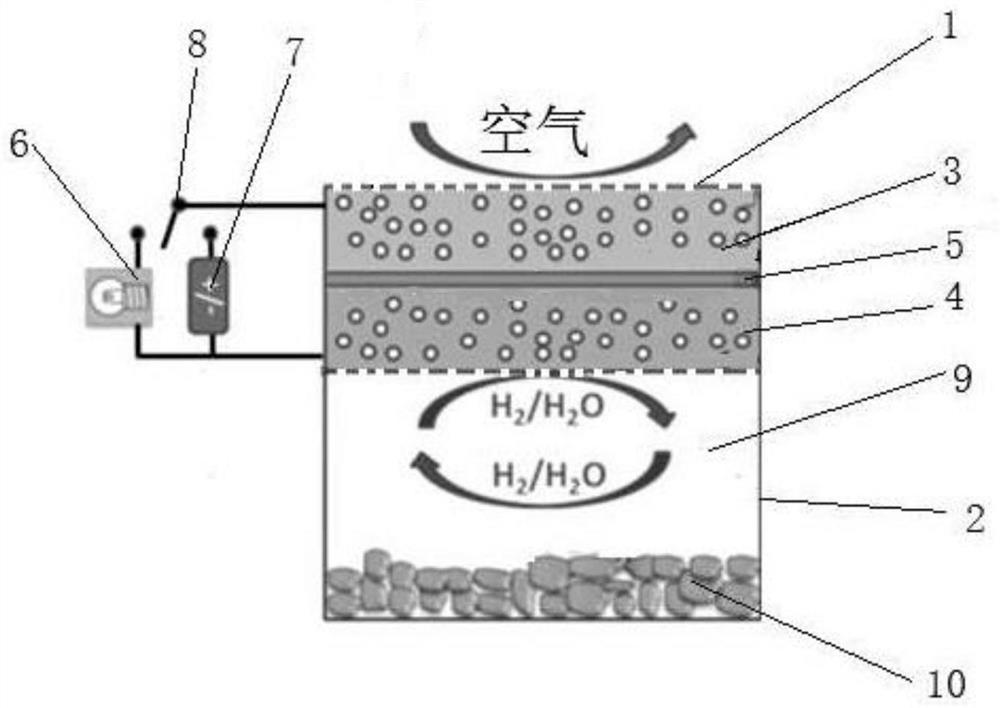

Hollow fiber pore-forming agent and application thereof in fuel cells

A hollow fiber and fuel cell technology, applied in the direction of battery electrodes, hollow filament manufacturing, fiber chemical characteristics, etc., to achieve the effects of increasing specific surface area, enhancing processability and flexibility, and reducing activation polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 (best example): the preparation method of fuel cell anode of the present invention:

[0035] S1. Preparation of fuel anode primary powder: Pre-fire the nickel-containing metal oxide powder at 600°C for 2 hours, then mix and grind it with 8% mol YSZ electrolyte powder for 2 hours to obtain the anode primary powder, in which the nickel-containing metal is oxidized The mass ratio of material and YSZ is 1:1; the nickel-containing metal oxide is NiO or Ni 2 o 3 one or a mixture of both;

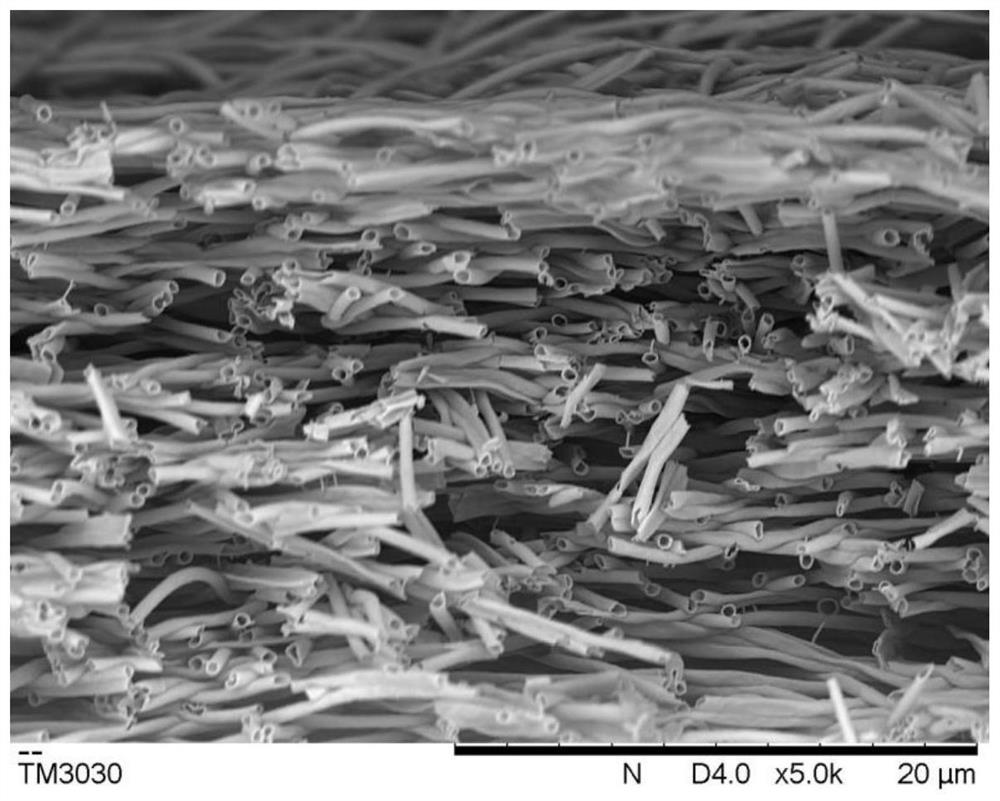

[0036] S2, preparation of PAN-PVP coaxial hollow fiber:

[0037] Dissolve 1gPAN and 1gPVP in 20ml dimethylformamide, stir at 45°C for 12h, and the stirring speed is 90rmin -1 Form a uniform PAN-PVP mixed solution;

[0038] Operated on a high-voltage electrospinning machine, a coaxial spinneret is made with a common medical syringe. The diameter of the inner pinhole is 0.7mm, and the diameter of the outer pinhole is 1.6mm. The inner pinhole is placed with methyl silicone oil...

Embodiment 2-10

[0041] Embodiment 2-10: the preparation method of the fuel cell anode of the present invention:

[0042] S1, prepare anode initial powder: same as embodiment 1;

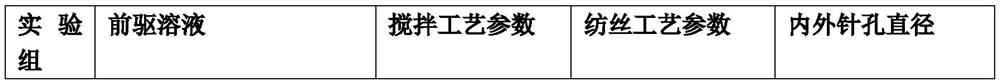

[0043] S2. Preparation of PAN-PVP coaxial hollow fiber: the steps are the same as in Example 1, and the specific experimental parameters are designed as shown in Table 1;

[0044] S3, anode initial powder and PAN-PVP coaxial hollow fiber: same as embodiment 1;

[0045] S4, preparing fuel cell anode: same as Example 1;

[0046] The preparation process parameter contrast of each embodiment of table 1

[0047]

[0048]

Embodiment 11

[0049] Embodiment 11 electrochemical performance test

[0050] The fuel cell anodes prepared in the above examples are used to prepare fuel cell anodes coated with a solid electrolyte on one side. The method is as follows: first prepare the electrolyte slurry, and then use the slurry spin coating method to place a drop of the electrolyte slurry on the In the center of the outer surface of the anode side of the above-mentioned fuel cell, the speed of the homogenizer is 6000r min -1 , the running time is set to 60s, and the centrifugal force generated by the high-speed rotation of the fuel electrode driven by the glue homogenizer makes the electrolyte slurry evenly coated on the outer surface of the fuel cell anode side, and then the fuel cell anode with a layer of electrolyte slurry attached is placed at 400 After drying, spin-coat the second layer and the third layer on the formed first layer of electrolyte film. Each layer must be dried at 400°C. Finally, there will be a tota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com