Fluidized bed cathode solid oxide fuel cell

A solid oxide and fuel cell technology, which is applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of ineffective improvement of concentration polarization, inability to apply hydrogen-oxygen fuel cells, and difficulty in large-scale utilization, so as to reduce heat The possibility of stress destroying the battery, increasing the active sites of chemical reactions, and solving the effect of small stack capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment one: when using air as the fluidizing gas and hydrogen as the fuel gas, the specific implementation test steps are as follows:

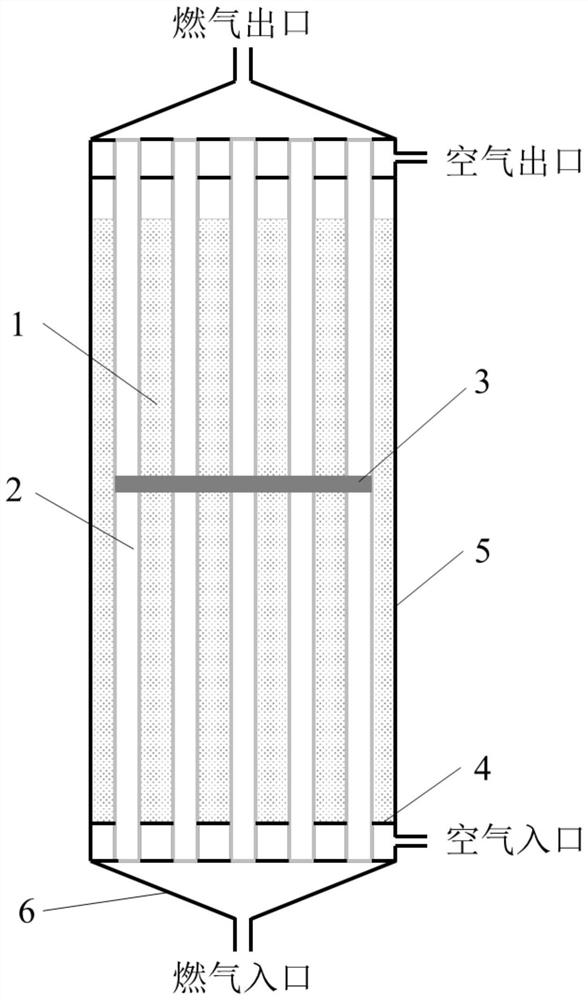

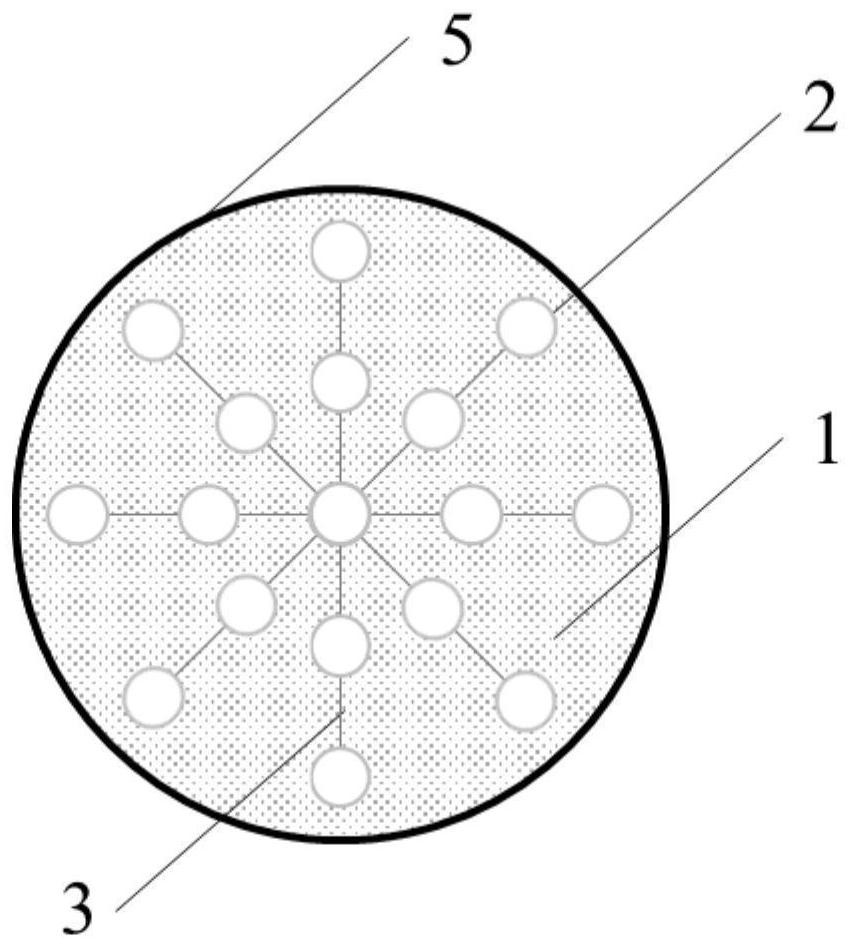

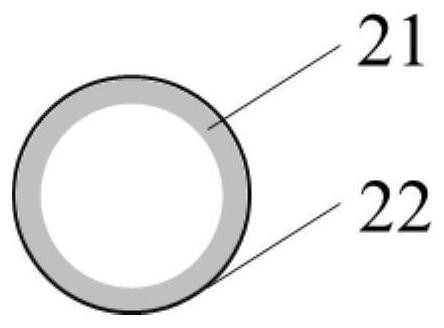

[0035] The anode support tube was prepared by extrusion molding, and then the battery single tube of the anode support structure was prepared by layer-by-layer calcination and spraying, wherein the anode material of the battery single tube was nickel oxide / 8% yttria stabilized zirconia (NiO / YSZ ), the electrolyte material is YSZ, the barrier layer material is GDC, the cathode chamber filling is a mixture of LSCF and YSZ, and the surface of the battery single tube is coated with silver paste and silver wire for current collection. The shell and cover are made of quartz material, the air distribution plate is made of porous quartz sand core, and all gaps are sealed with high-temperature ceramic glue. Before the experiment, the particles in the cathode chamber are filled to one-third of the height of the cathode chamber.

[0036] First, ...

Embodiment 2

[0040] Embodiment 2: When using air as the fluidizing gas and ammonia as the fuel gas, the specific fluidized bed cathode solid oxide fuel cell process steps are as follows:

[0041] A microtube single cell with an electrode support structure, the anode material is NiO / YSZ, the electrolyte material is YSZ, a layer of GDC is attached to the outside of the electrolyte as a protective layer, and the cathode chamber is filled with LSCF / GDC mixed powder, and the filling height is the height of the cathode chamber two-fifths of.

[0042] When the device is started, the external auxiliary burner is used to burn hydrogen in the air atmosphere, and then the exhaust gas is passed into the air inlet and gas inlet of the fuel cell to heat the device. Wait for the device to heat up to 800 o At C, switch the fuel gas inlet gas to nitrogen for purging; after the purge is clean, switch the gas inlet gas to ammonia, and the air inlet gas to air, and adjust the air flow on the cathode side so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com