Battery anode material and preparation method thereof and lithium battery

A battery negative electrode, electrochemical technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of high energy density of high-performance lithium-ion batteries, it is difficult to greatly improve the space, and damage the electrochemical stability of materials , to achieve good cycle stability, good structural stability and chemical stability, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

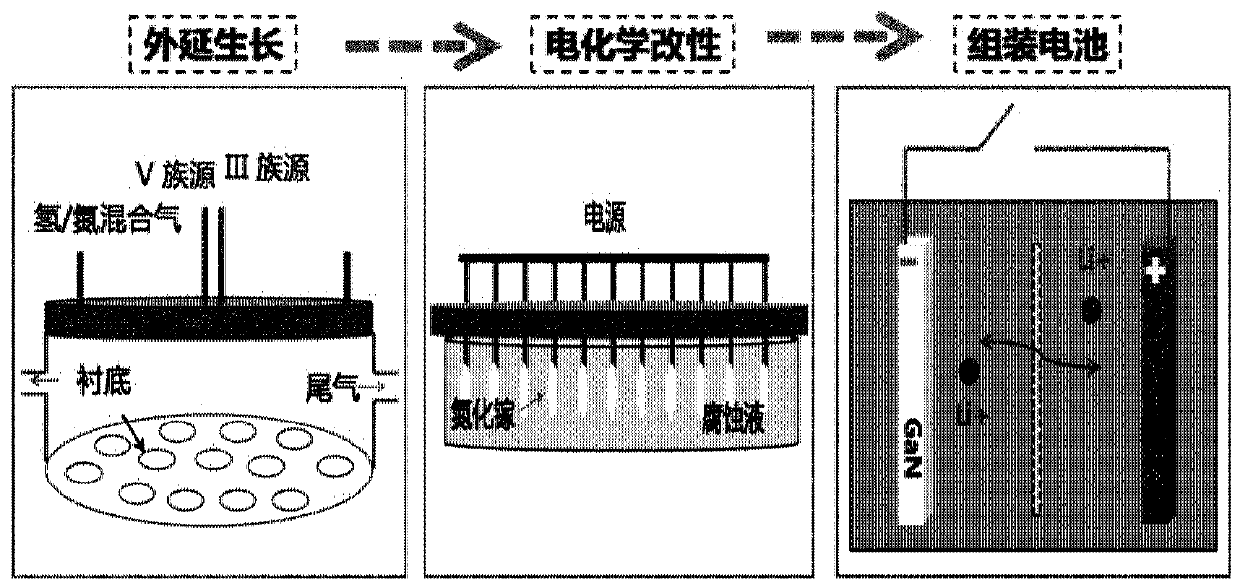

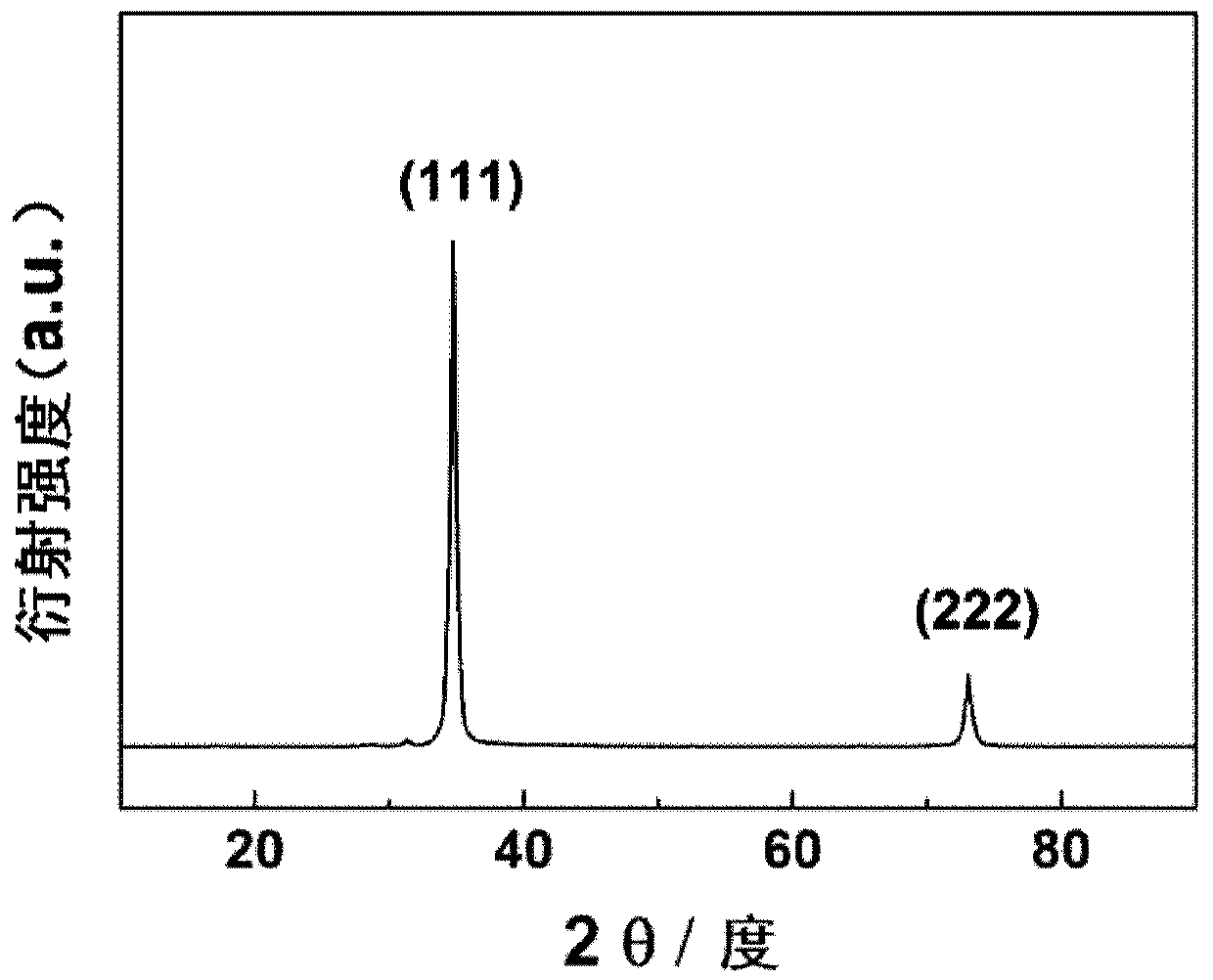

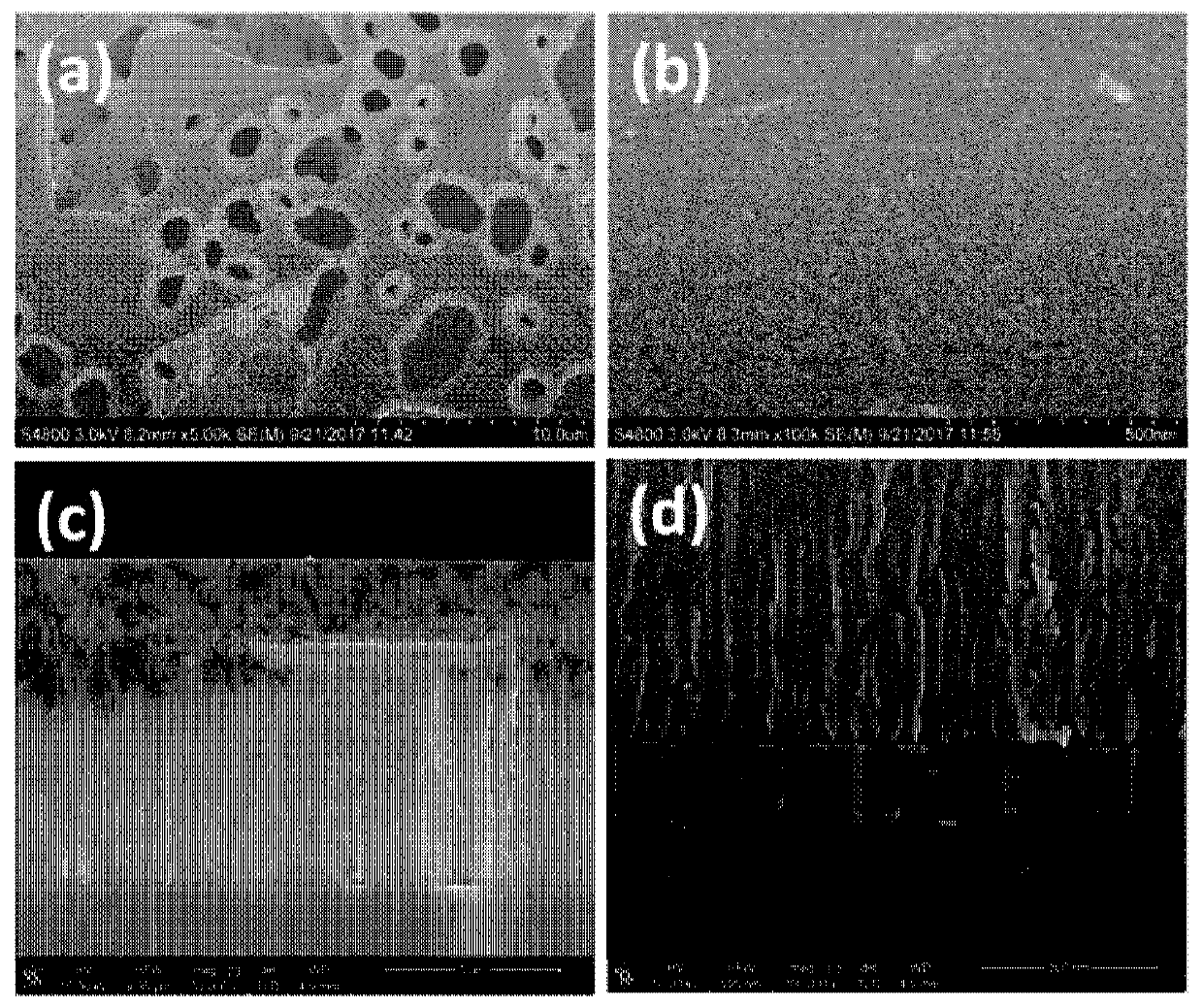

[0036] Crystal gallium nitride is the third-generation wide-bandgap semiconductor material after Si and GaAs. It has the advantages of large bandgap, high breakdown electric field, large thermal conductivity, high electron saturation mobility, and strong radiation resistance. Its application is mainly concentrated in the field of optoelectronics, and it is rarely reported as an energy storage material. Through experimental research and overcoming preparation difficulties, the present application proposes to use crystalline gallium nitride as a battery negative electrode material and can be directly used as an electrode in a lithium battery.

[0037] Crystalline Gallium Nitride has a similar Zn 3 N 2 , CrN, Cu 3 N and Ni 3 Due to the electrochemical properties of N, the storage of lithium ions can be realized through a redox-like process during cycling. However, there is currently no mature technology to prepare crystalline GaN electrodes. In this application, a high-condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com