High-thermal-intensity CaO carbon-containing pellets and preparation method and application thereof

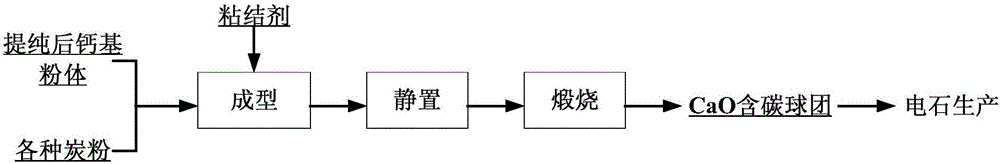

A technology of carbon pellets and pellets, applied in the field of high thermal strength CaO carbon-containing pellets and its preparation, inorganic binders to improve the thermal strength of CaO carbon-containing pellets, can solve the problem of inconvenient operation and the strength of CaO carbon-containing pellets Reduce other problems and achieve the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

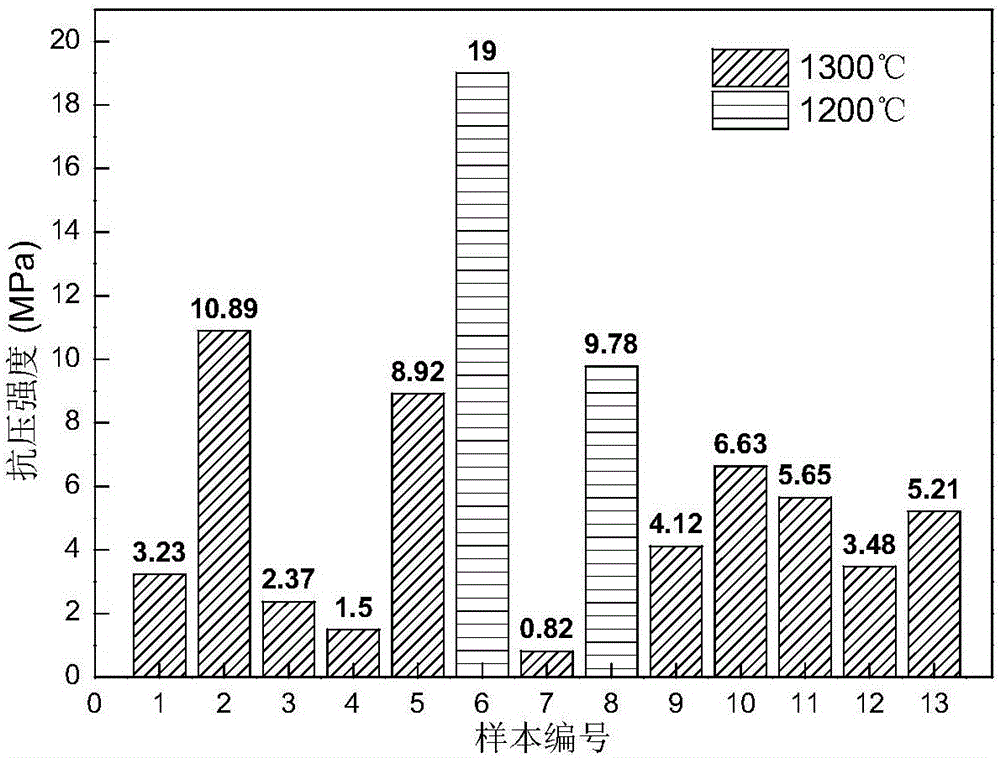

Examples

Embodiment 1

[0069] A CaO carbon-containing pellet, the CaO carbon-containing pellet is mainly prepared from the following raw materials in parts by weight:

[0070]

[0071] Among them, the inorganic binder is sulfuric acid. Carbon-containing powder is petroleum coke powder. The main component of calcium-based powder is calcium oxide. Carry out physical removal of impurities on calcium oxide (CaO purity greater than 90%), and then crush and sieve; use a sieve to sieve petroleum coke powder, and select petroleum coke powder and calcium oxide with a particle size of less than 200 μm and a purity greater than 90% as raw materials .

[0072] The preparation method of the CaO carbon-containing pellets comprises the steps of:

[0073] (1) Mix the above-mentioned calcium oxide and coke powder evenly, then add water, then add an inorganic binder and mix evenly;

[0074] (2) Put the mixed material into an inserting machine for cold pressing molding (molding pressure is 30MPa), get 15g of cy...

Embodiment 2

[0078] A CaO carbon-containing pellet, the CaO carbon-containing pellet is mainly prepared from the following raw materials in parts by weight:

[0079]

[0080] Among them, the inorganic binder is Ca(H 2 PO 4 ) 2 . The main component of calcium-based powder is calcium carbide slag, and the physical removal of impurities (Ca(OH) 2 The purity is greater than 95%), and then crushed and sieved to select calcium carbide slag with a particle size of less than 100 μm; sieve coke powder with a sieve, and select coke powder with a particle size of less than 200 μm and a purity greater than 89% as raw materials.

[0081] The preparation method of the CaO carbon-containing pellets comprises the steps of:

[0082] (1) Mix the above calcium carbide slag and coke powder evenly according to the mass ratio of 7:3, add water accounting for 25% of the weight of calcium carbide slag and coke powder, and then add inorganic binder accounting for 8% of the weight of calcium carbide slag and...

Embodiment 3

[0087] A CaO carbon-containing pellet, the CaO carbon-containing pellet is mainly prepared from the following raw materials in parts by weight:

[0088]

[0089] Among them, the inorganic binder is Ca 3 (PO 4 ) 2 . The main component of calcium-based powder is stone powder (CaCO 3 ), physically remove impurities (CaCO 3 The purity is greater than 90%), and then crushed and sieved; the coke powder is sieved with a sieve, and the coke powder and stone powder with a particle size of less than 150 μm and a purity greater than 90% are selected as raw materials.

[0090] The preparation method of the CaO carbon-containing pellets comprises the steps of:

[0091] (1) Mix the above-mentioned stone powder and coke powder according to the mass ratio of 6:4, add water accounting for 40% of the weight of stone powder and coke powder, and then add inorganic binder accounting for 4% of the weight of stone powder and coke powder and mix evenly ;

[0092] (2) Put the mixed material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com