Patents

Literature

71results about How to "Increase cold strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

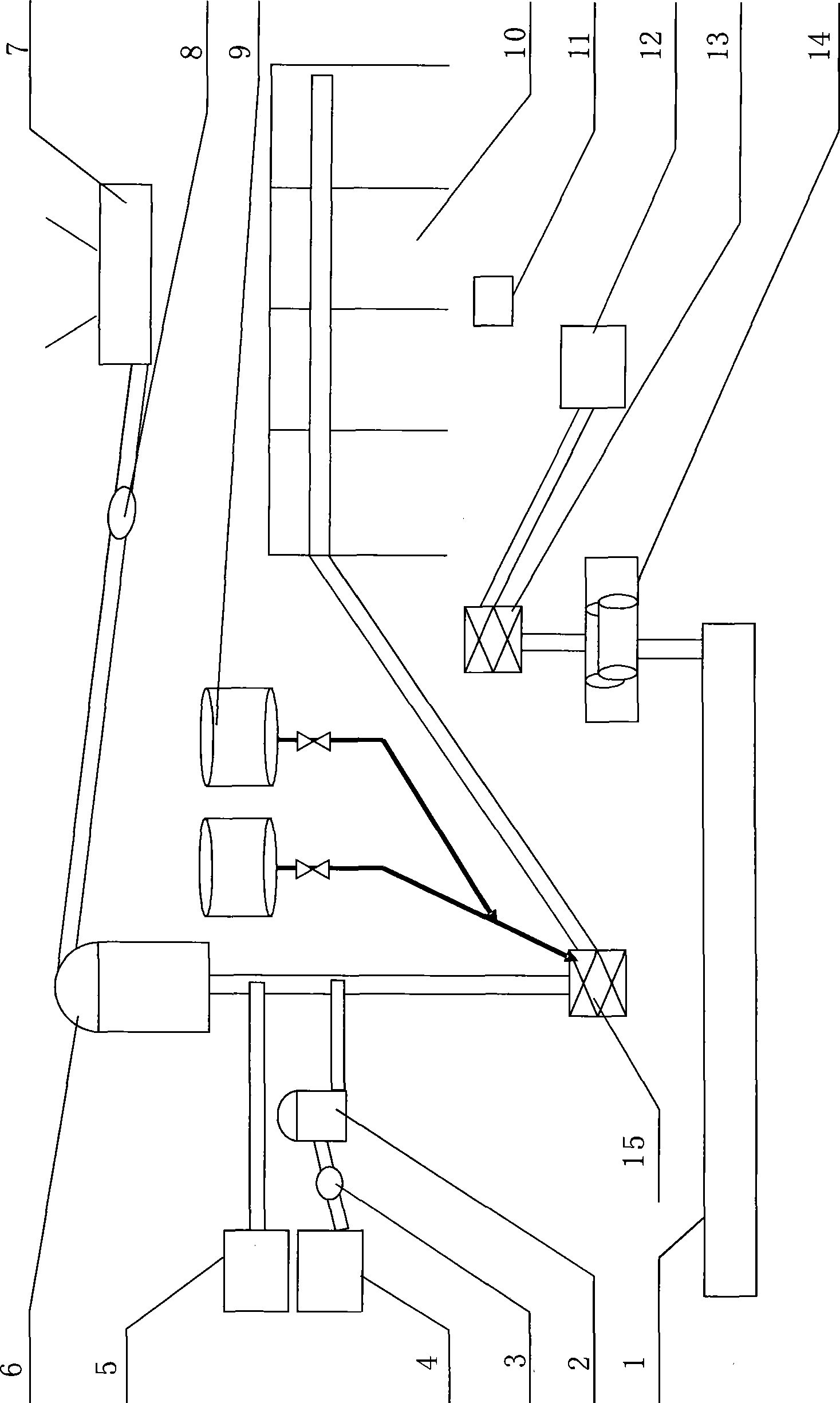

High-ore-matching-ratio brown iron ore sintering technology

The invention relates to a high-ore-matching-ratio brown iron ore sintering technology. The weight ratio of brown iron ore and powdered iron in raw material proportion is (5-19):1, the moisture content of the first mixing is controlled to be 7%-8%, the mixing time lasts for 2-3minutes, and the temperature of the mixture is 50-62 DEG C; the moisture content of second mixing pelletizing is controlled to be 7-9%, the pelletizing time lasts for 2-3.5minutes, and the temperature of materials is 52-65 DEG C; the thickness of grate-layer materials in distribution is 20mm, and a sintering material layer is 780-900mm thick; the ignition temperature for sintering is1050-1150 DEG C, and the ignition time lasts for 1.8-2.2minutes; and the negative pressure for sintering is 12-15kpa, the machine speed is 0.9-1.2m / min, the vertical sintering speed is 29-34mm / min, the air leakage rate is no more than 40%, the cooling negative pressure is 11-14kpa, the temperature of a cooling section of a sintering machine is reduced to 250 DEG C below. By using the high-ore-matching-ratio brown iron ore sintering technology, energy is saved, consumption is reduced, cost is decreased and benefit is increased.

Owner:唐山瑞丰钢铁(集团)有限公司

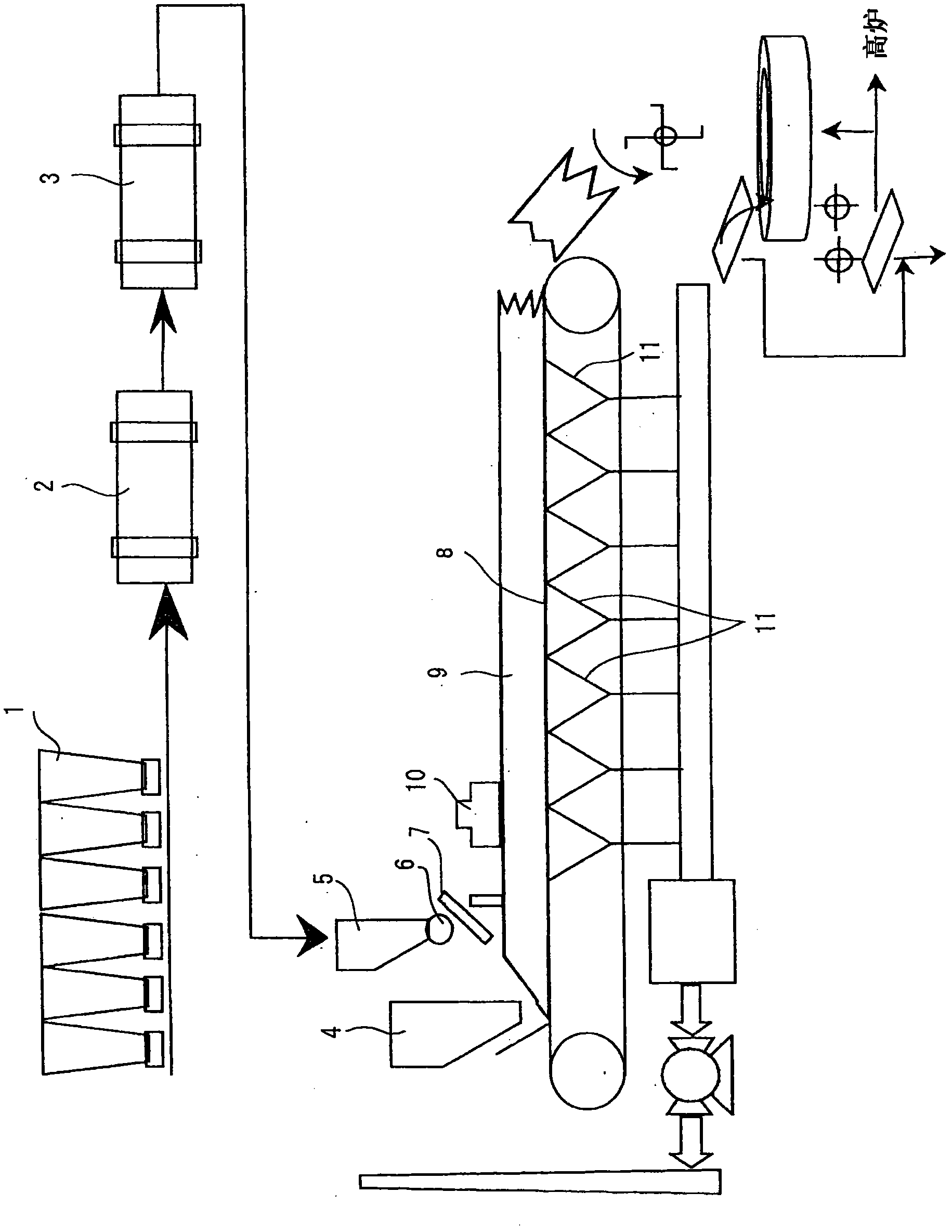

Process for producing sintered ore and sintering machine

A process for producing a sintered ore which comprises: a charging step in which a pallet traveling cyclically is charged with a raw sintering material comprising a powdery ore and a carbonaceous material to form a charge layer of the raw sintering material on the pallet; an ignition step in which the carbonaceous material present in the surface of the charge layer is ignited with an ignition furnace; a dilute-gaseous-fuel production step in which a gaseous fuel is supplied to the air present over the charge layer to dilute the fuel and thereby obtain a dilute gaseous fuel having a concentration not higher than the lower combustion limit concentration; and a combustion step in which the dilute gaseous fuel and air are sucked into the charge layer by the suction of a wind box disposed beneath the pallet to burn the dilute gaseous fuel in the sinter layer and, at the same time, burn the carbonaceous material contained in the charge layer with the aid of the air sucked into the charge layer, thereby produce a sinter cake.

Owner:JFE STEEL CORP

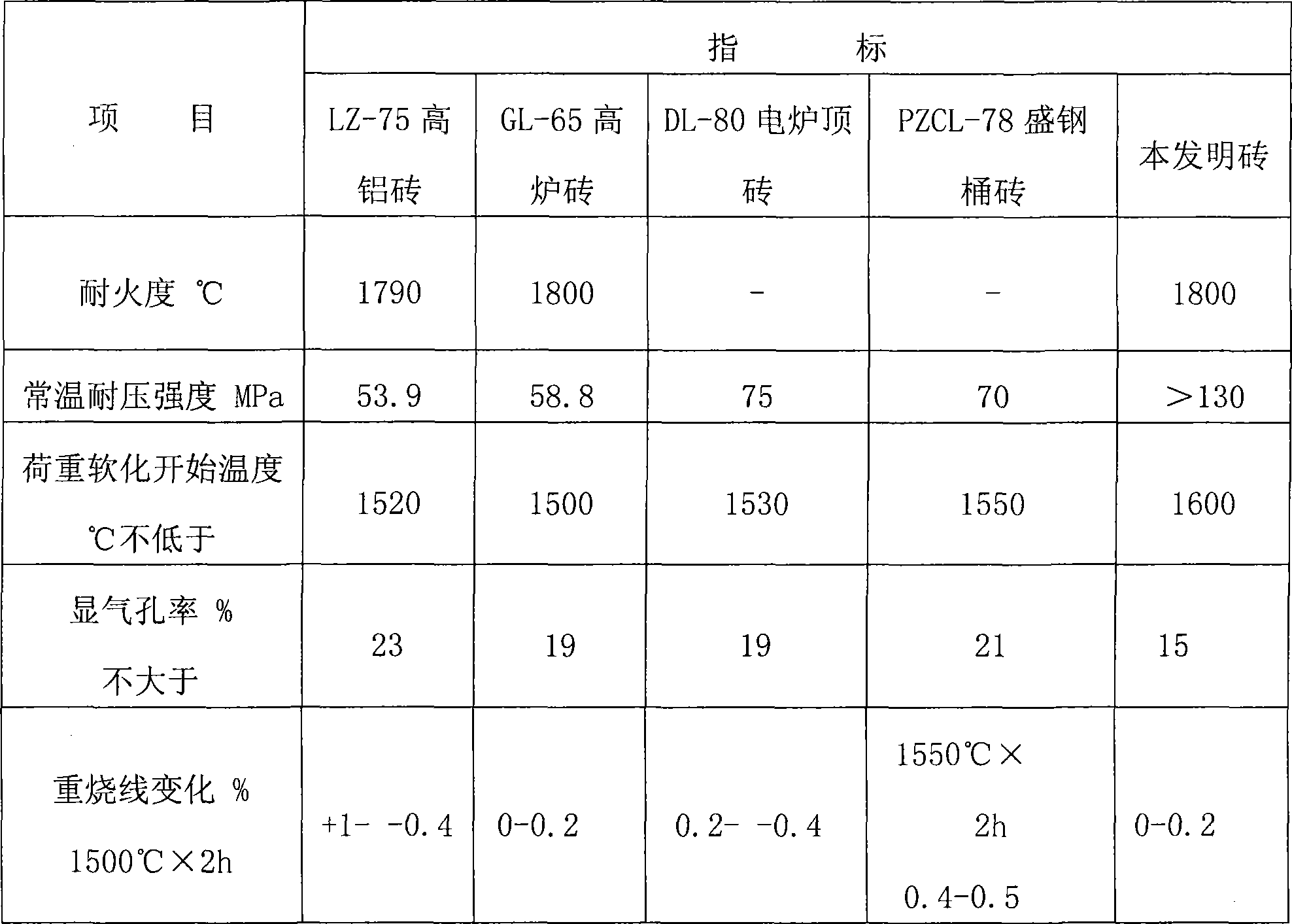

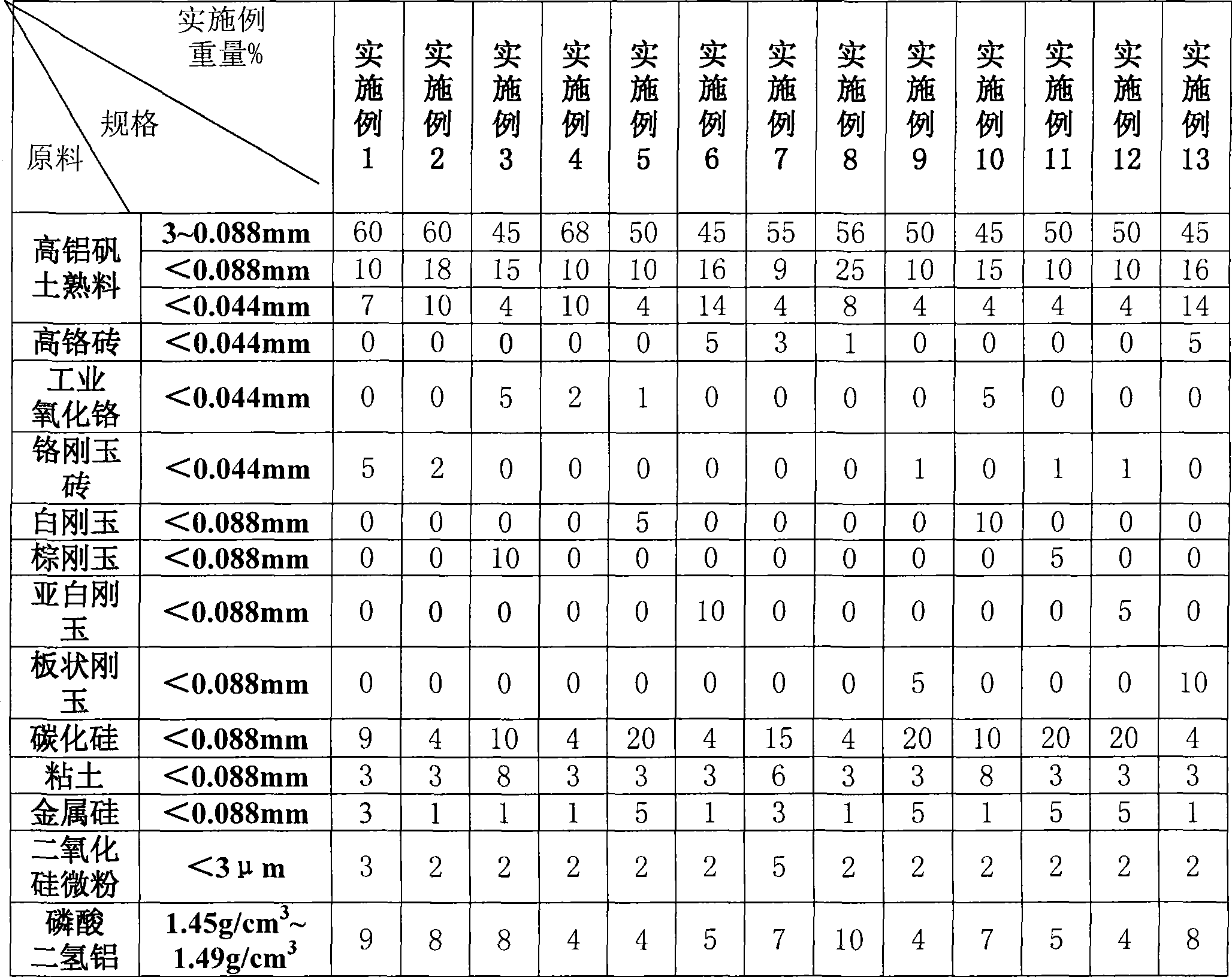

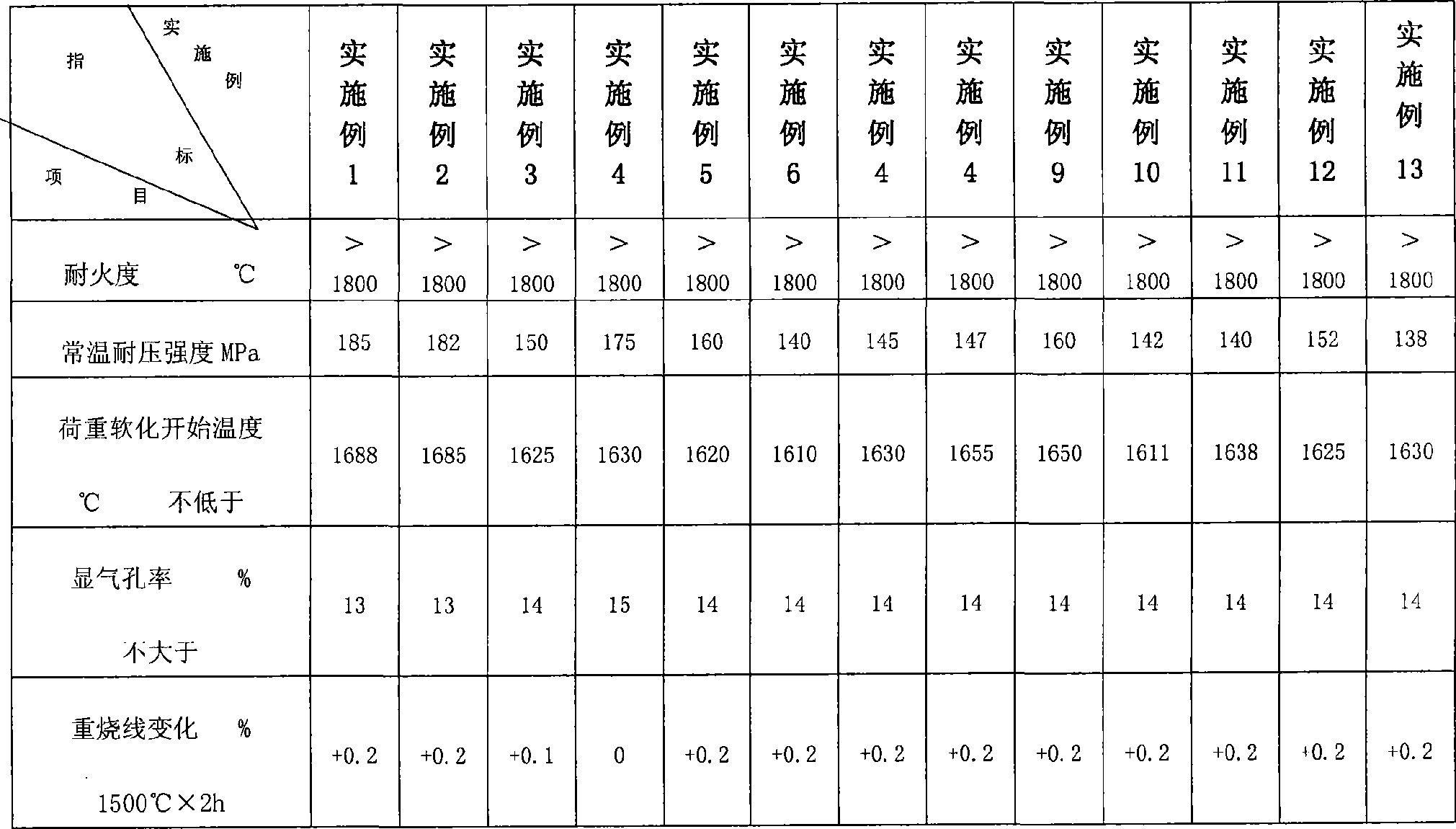

Phosphate-bonded aluminum silicon carbide brick and preparation method thereof

The invention discloses a phosphate-bonded aluminum silicon carbide brick, which is characterized by comprising main ingredients and a phosphate binder, wherein the main ingredients comprise the following raw materials by weight percentage: 45 to 68 percent of bauxite chamotte with a granularity of 3 to 0.088 mm, 10 to 25 percent of bauxite chamotte with a granularity of less than 0.088 mm, 4 to 14 percent of bauxite chamotte with a granularity of less than 0.044 mm, 0 to 10 percent of corundum, 1 to 5 percent of a chromic oxide-containing material, 4 to 20 percent of silicon carbide, 3 to 8 percent of clay, 2 to 5 percent of silicon dioxide micro powder, and 1 to 5 percent of metallic silicon; and the phosphate binder is added in an amount which is 4 to 10 percent of the weight of the main ingredients. The aluminum silicon carbide brick is made into high quality aluminum silicon carbide brick which has an apparent porosity of less than 15 percent, a cold crushing strength of more than 130MPa, a starting refractoriness under load of more than 1,600 DEG C and high inoxidability by ageing mixture, back rolling, forming, drying and baking.

Owner:巩义市金岭耐火材料有限公司

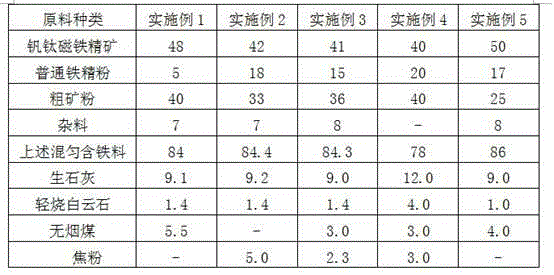

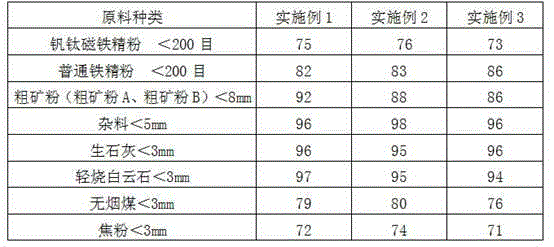

Medium-titanium high-strength sintered ore and preparation method thereof

The invention discloses a medium-titanium high-strength sintered ore which is formed by sintering the following ingredients by weight percentage: 78-86% of iron-bearing material, 9-12% of quicklime, 1-4% of lightly fired dolomite and 4-6% of fuel, wherein the iron-bearing material comprises the following components by weight percentage: 40-50% of vanadium titanium magnetite concentrate, 5-20% of common fine iron powder, 25-40% of coarse ore powder and 0-8% of miscellaneous material. The sintered ore is produced by taking a vanadium titanium magnetite and the vanadium titanium magnetite concentrate as main raw materials; the pelletizing performance of a mixture is improved by reasonably preparing and adding other iron ore powder and fluxes; component and phase composition of the sintered ore is controlled; an influence of higher TiO2 content in the sintered ore on the quality of the sintered ore is reduced; a tumbler index of the sintered ore reaches above 77% when the medium-titanium sintered ore is produced; the sintered ore is high in cold strength and low in return rate; and the sintered ore is smelted via a blast furnace, so that a fuel ratio is reduced and a utilization coefficient is increased.

Owner:HEBEI IRON AND STEEL

Preparation method of formed semicoke for calcium carbide

The invention relates to a preparation method of formed semicoke for calcium carbide, belonging to a method for producing formed semicoke for calcium carbide. The preparation process comprises the following steps: preparing semicoke into semicoke powder of which the particle size is less than 3 millimeters, and preparing quicklime into lime powder of which the particle size is less than 1 millimeter; weighing the quicklime, and adding excessive water to sufficiently slake the lime; filtering the supernatant, and taking the underlayer slaked lime slurry, namely a binding agent; weighing the semicoke powder and the binding agent (the weight percents of the semicoke powder and the binding agent are respectively 70-80% and 20-30%), pouring the binding agent into the semicoke powder, sufficiently stirring, and evenly mixing; pressing the mixture with a roll-type forming machine to obtain spheroidal formed semicoke; and placing the pressed formed semicoke in a briquette carbonization tank, continuously introducing CO2 preheated to 40 DEG C through a heat exchanger into the carbonization tank via the tank bottom for about 7 hours, and determining the dropping strength of the formed semicoke. According to the invention, the reutilization of the semicoke powder is realized, a powder coal forming technology and calcium carbide production are combined, the calcium carbide production process is simplified, and the production cost is lowered.

Owner:CHINA UNIV OF MINING & TECH

Low-cost blast furnace iron-smelting method

The invention relates to a low-cost blast furnace iron-smelting method, which is characterized in that: blocky carbon-lan (semi-coked) and rammed coke are matched and used for blast furnace iron smelting, and at the same time, small-particle or powdery carbon-lan (semi-coked) is used as an injected fuel to be used for blast furnace iron smelting. In the method, rammed coke is adopted, thus the consumption of high-quality coking coal is reduced, and the cost of the coking blend is lower than that of the top charging coke; and at the same time, a part of non-coking coal carbonization product, namely carbon-lan (semi-coked) is matched, thus the production cost of steel enterprises is lowered to a greater extent and high-quality coking coal is saved. In addition, small-particle or powdery carbon-lan (semi-coked) is used as the injected fuel, thus the problems that anthracite, lean coal and meager lean coal resources are limited and expensive are alleviated and the production cost of the steel enterprises is further lowered. According to the invention, the problems of shortage in high-quality coking coal resources and high-quality blowing coal resources in China are solved to a certain extent, and a new way is opened for persistent health development of the steel enterprises.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Industrial briquette and technique for producing the same

The invention discloses an industrial molded coal and a manufacture process thereof, which uses soft coal with high moisture and high volatilization as raw material, coking coal, sodium humic acid and clay as caking agents. The method comprises the following steps: iron is removed from the raw material soft coal, and the raw material soft coal is crushed with the crushed particle less than or equal to 3mm; solid caking agents clay and coking coal are added to the crushed soft coal, and the liquid caking agent sodium humic acid is added to the crushed soft coal to be stirred and mixed; a storage stack is retted for aging for more than 24 hours; the aged coal is subjected to a secondary stirring; the aged coal is shaped at the pressure 10-30MPa; and the shaped coal is dried at a temperature lower than 90 DEG C to manufacture the molded coal. The industrial molded coal can be used for a fixed layer pressure coal gasification furnace.

Owner:高恒 +1

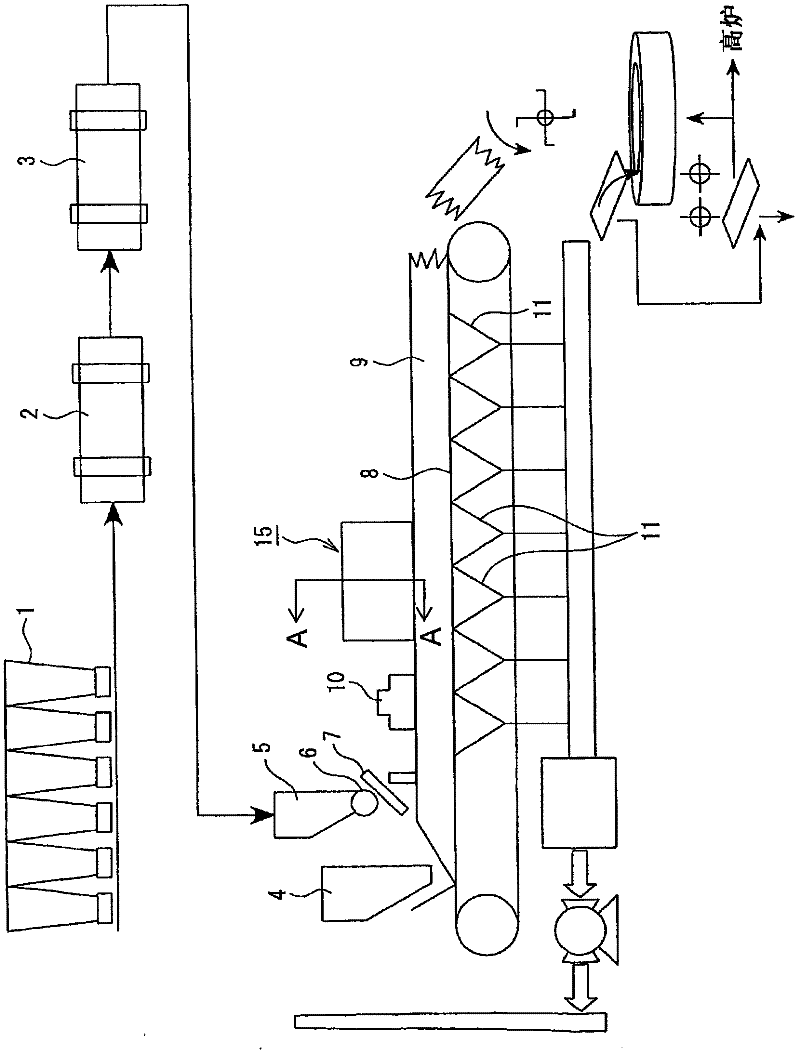

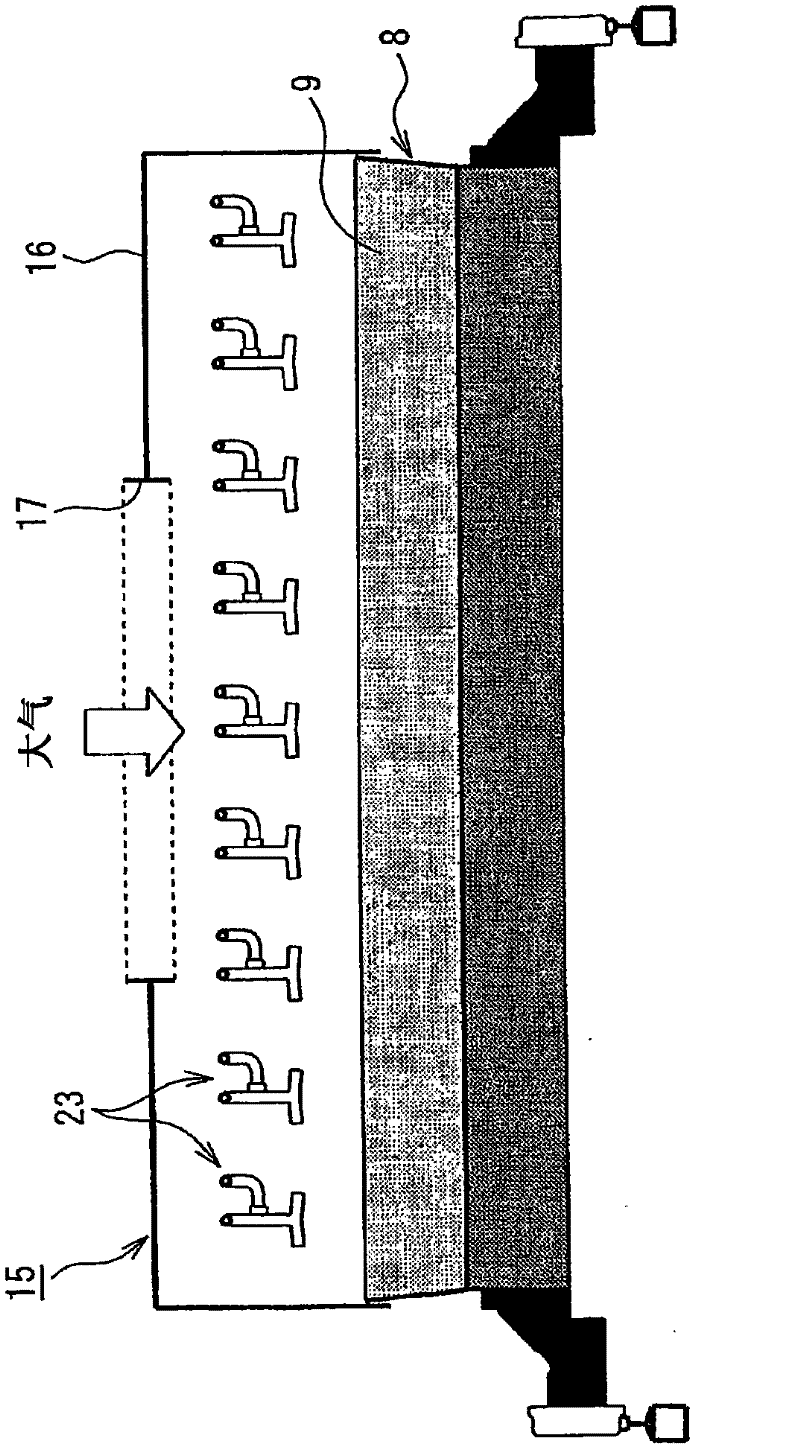

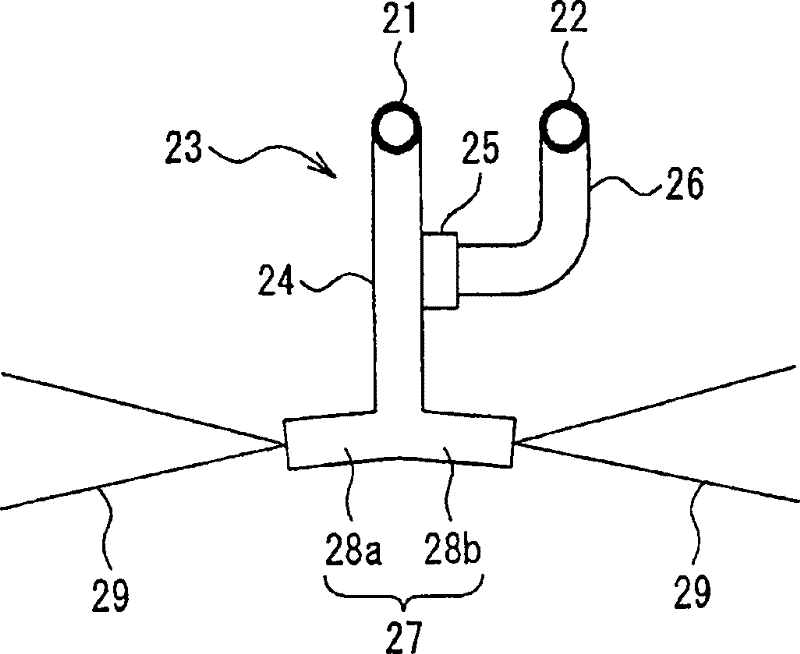

Process for producing sintered ore and sintering apparatus

A process for sintered-ore production in which high-quality sintered ore having high strength can be safely produced in a high yield with a sintering apparatus of a downward suction type; and the sintering apparatus. The process for sintered-ore production comprises: placing a raw material to be sintered comprising fine ore and a carbon material, on a circulating pallet (8) to form a raw-material layer (9); igniting the carbon material of the raw-material layer in an ignition furnace; and sucking air with a wind box disposed under the pallet to thereby produce sintered ore. After the raw-material layer (9) has been ignited in the ignition furnace, a liquid fuel is atomized to a particle size of 100 [mu]m or smaller and supplied to over the raw-material layer (9), and the atomized liquid fuel is supplied from over the raw-material layer (9) into the raw-material layer (9) after having been diluted at least to the lower limit of ordinary-temperature combustion concentrations. The sintering apparatus has, disposed downstream from the ignition furnace, a liquid-fuel injector which injects the liquid fuel over the raw-material layer.

Owner:JFE STEEL CORP

Method for producing carbonized coal/coke for gasification by large tamping briquette on coke oven

InactiveCN103992807AReduce pollutant contentReduce contentSolid fuelsSpecial form destructive distillationGeneration rateAdhesive

The invention discloses a method for producing carbonized coal / coke for gasification by a large tamping briquette on a coke oven. The method comprises the steps of adding a coal modified adhesive and a spheroidizing agent into non-caking feed coal; humidifying a mixed coal material, conveying to a high-density tamping molding machine, and pressing to obtain a large briquette of which the density is 1.15-1.30g / cm<3>; then conveying the tamped large briquette into a tamping coke oven carbonization chamber, and carbonizing for 15-30 hours at 850-1100 DEG C to obtain the carbonized coal / coke for gasification. The method disclosed by the invention realizes large-scale production of the carbonized coal / coke for gasification; a product has the characteristics of high mechanical strength, good thermal stability, high gas generation rate, less pollutant emission and the like, and is a high-quality fixed bed gasification raw material.

Owner:太原四联重工股份有限公司

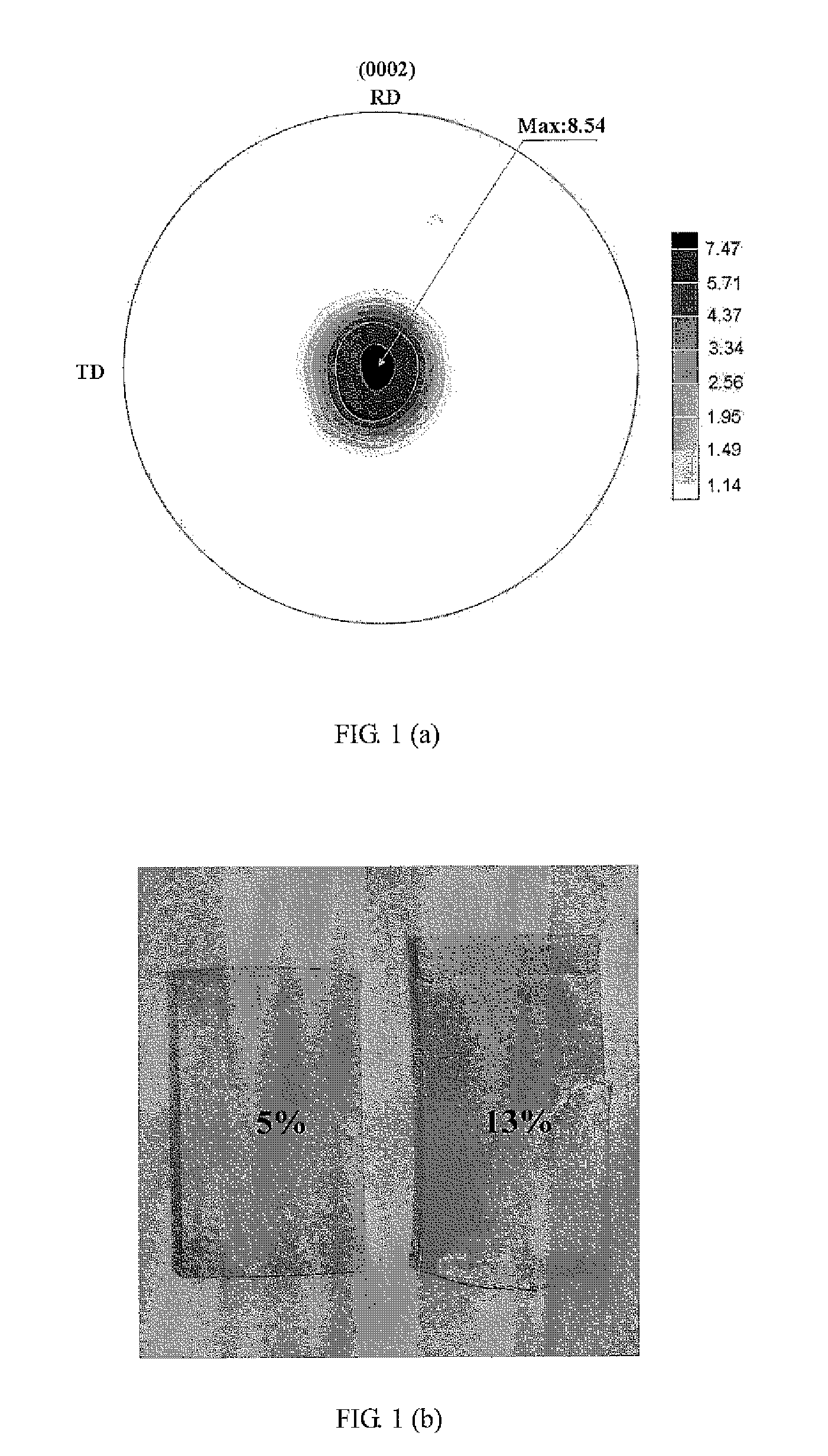

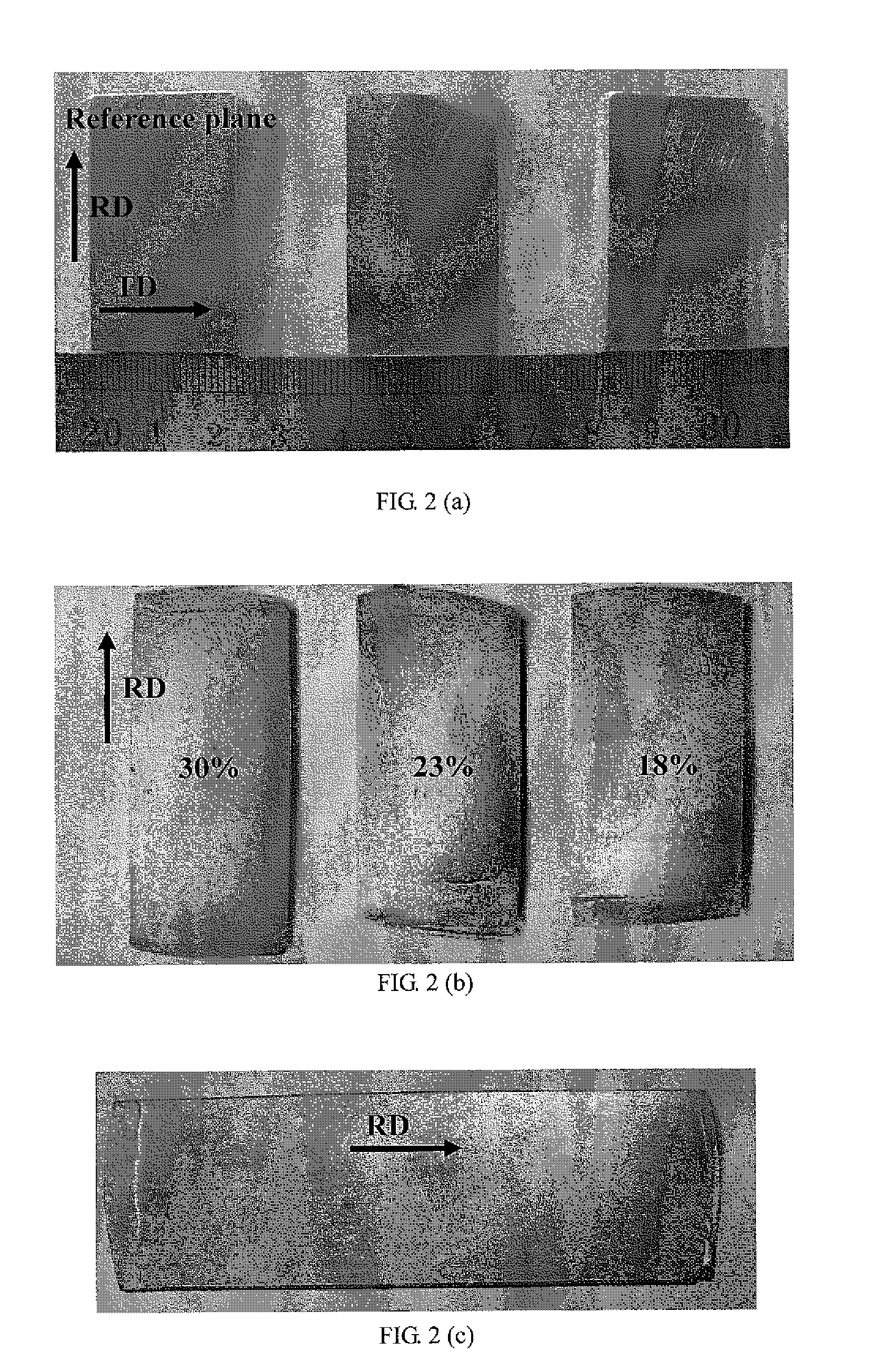

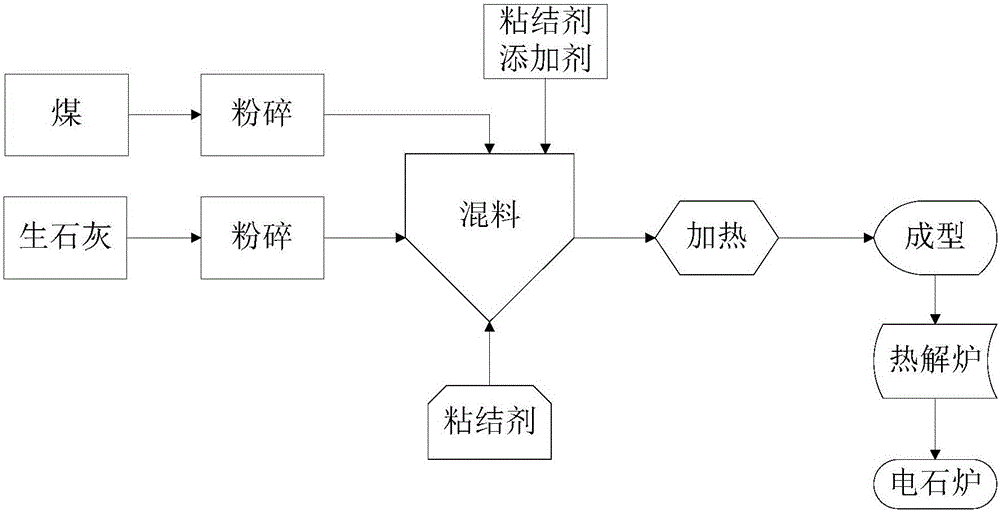

Cold-rolling method for a wrought mg alloy with weak/non-basal texture and a cold rolled sheet

InactiveUS20120288398A1Easy to manipulateEasy to controlMetal rolling arrangementsRoom temperatureSingle pass

The present invention relates to a cold-rolling method for cold-rolling a wrought Mg alloy with a weak or non-basal texture as well as a cold-rolled sheet, the method comprising the steps of: pre-treating a billet of the wrought Mg alloy with a weak or non-basal texture, and then cold rolling it; wherein the weak or non-basal texture plane of said billet is selected as a rolling plane, and the rolling direction is parallel to the rolling plane; and said billet is cold rolled at room temperature to a sheet or foil with a thickness of 0.1 to 100 mm, wherein single-pass or multi-pass rolling is used, and the cold rolling is followed by an annealing at 200 to 400° C. for 10 min to 48 h.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

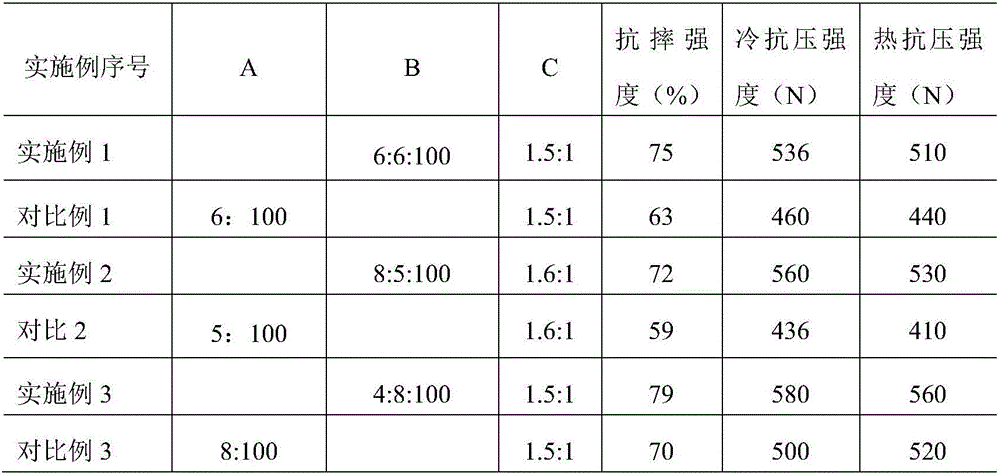

Binder additive and method for preparing calcium carbide by applying binder additive

InactiveCN106010355AWide variety of sourcesLow priceMacromolecular adhesive additivesAnthraceneNitrile rubber

The invention discloses a binder additive and a method for preparing calcium carbide by applying the binder additive. The binder additive is prepared from one of anthracene oil, waste nitrile rubber powder and regenerated phenolic resin particles. The binder additive is wide in raw material source, and therefore the price is low. The calcium carbide raw material prepared from the binder additive has the advantages that not only is the cold strength improved, but also the heat strength is improved to different extents, and the requirements of a novel heat accumulating type high temperature fuel gas melting calcium carbide production technology are met.

Owner:SHENWU TECH GRP CO LTD

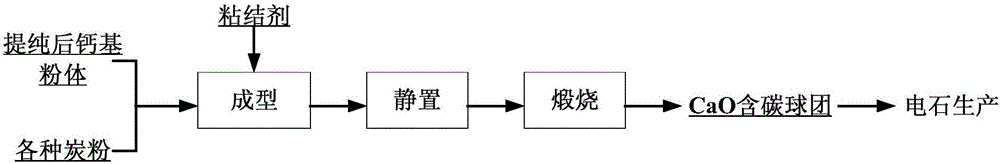

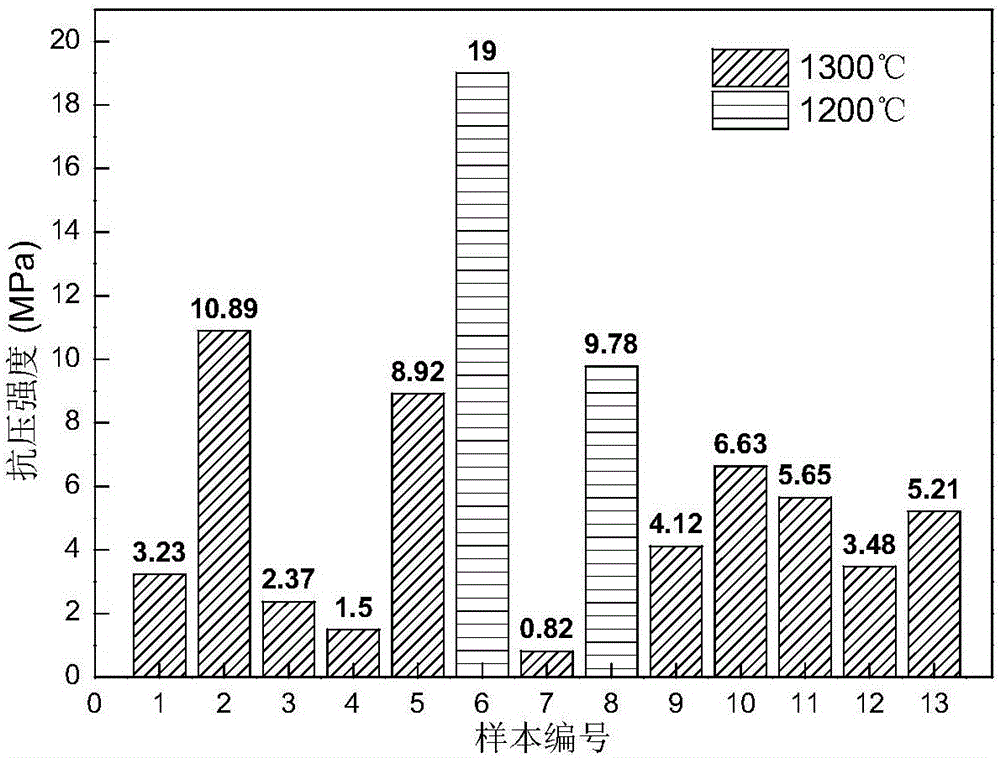

High-thermal-intensity CaO carbon-containing pellets and preparation method and application thereof

InactiveCN105819447AReduce manufacturing costIncrease cold strengthCalcium carbideCoal chemical industryEnergy consumption

The invention provides a high-heat-strength CaO carbon-containing pellet and its preparation method and application. The preparation method of the CaO carbon-containing pellet is: after mixing calcium-based powder, carbon-containing powder, inorganic binder and water The calcium-based carbon-containing pellets are obtained by cold pressing; the calcium-based carbon-containing pellets are optionally placed for a certain period of time, and then dried and calcined under control to obtain the CaO carbon-containing pellets. The thermal strength of the CaO carbon-containing pellets can reach up to 19Mpa at 1200°C, and can be greater than 10MPa at 1300°C; since the raw material is powder, the temperature for preparing calcium carbide is greatly reduced, and can be at 1800‑2000 ℃ to prepare calcium carbide; it solves the problem of large-scale recycling of solid waste in the coal chemical industry, and at the same time prepares high-performance and high-quality raw materials for calcium carbide production, reducing the energy consumption of calcium carbide production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

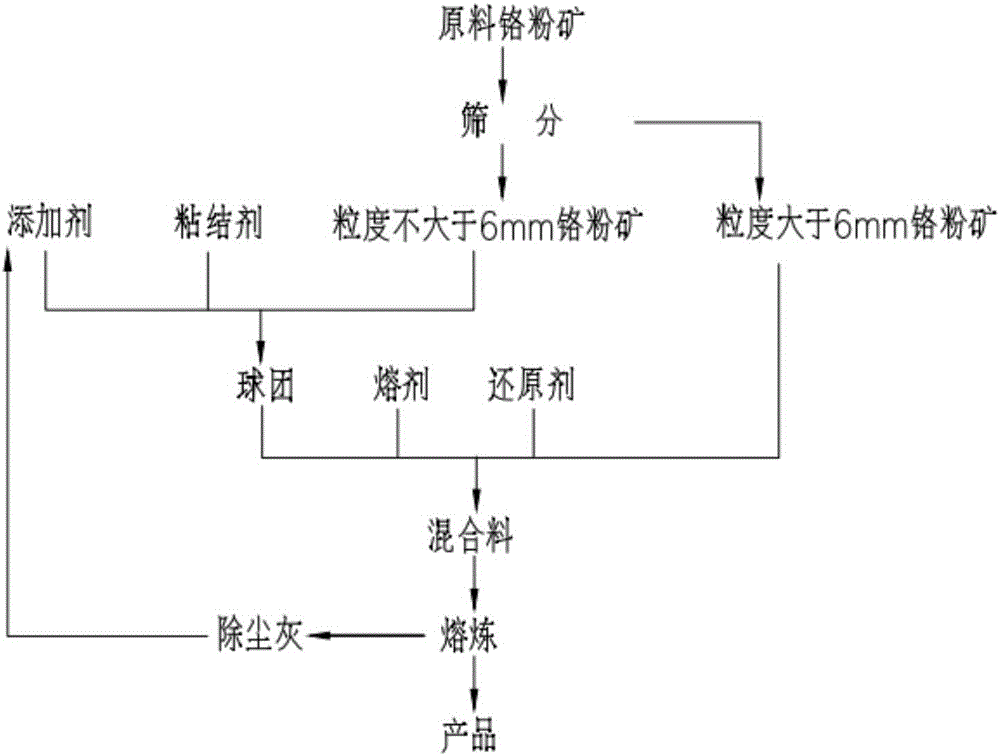

Method for preparing high carbon ferro-chrome by fusible chrome fine ore

The invention provides a method for preparing high carbon ferro-chrome by fusible chrome fine ore. The method comprises the following steps that screening is conducted, specifically, raw material chrome fine ore is screened, and chrome fine ore with the granularity being equal to or less than 6 mm and chrome fine ore with the granularity being larger than 6 mm are obtained; pelletizing is prepared, specifically, mixture is obtained after the granularity being equal to or less than 6 mm is evenly mixed with binder, and then the mixture is pressed into the pelletizing; burdening is conducted, specifically, the pelletizing, the chrome fine ore with the granularity being larger than 6 mm, flux and reducing agent are evenly mixed, and then mixture is obtained; and smelting is conducted, specifically, the mixture is placed into a submerged arc furnace to conduct smelting.

Owner:BERIS ENG & RES CORP

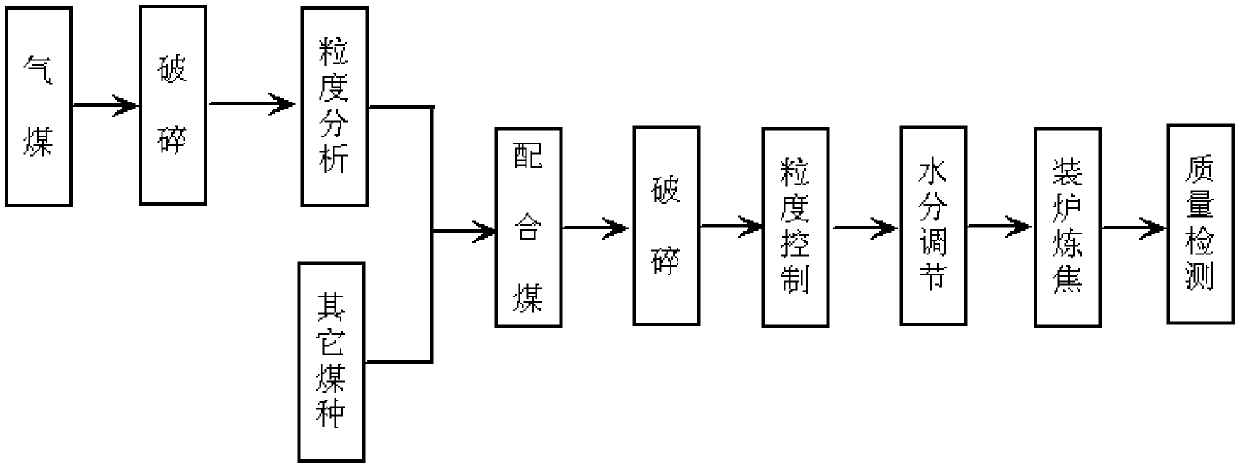

Method for improving cold strength of coke

InactiveCN110607184AIncrease cold strengthImprove quality requirementsCoke ovensMass ratioGranularity

The invention discloses a method for improving the cold strength of coke, which comprises the following steps: 1, gas coal crushing: gas coal with the granularity of less than 6 mm from a production plant is fed into a crusher for crushing, performing screening analysis on the granularity of the gas coal after crushing according to the requirement of the proportion of the granularity of less than3 mm in the crushed gas coal to be 48-53%; 2, blending of blended coal: the crushed gas coal is blended with 1 / 3 coking coal, fat coal and lean coal according to the requirements of coal blending, themass ratio of the gas coal in the whole blended coal is 25.5-27%, the ash content Ad of the blended coal is 8-10%, and the volatile matter VMd of the blended coal is 26-28%; 3, crushing and mixing ofthe blended coal: the blended coal is added into a crusher for repeated crushing, the groove spacing of the crusher is 3-4 mm, and the mass ratio of the blended coal with the particle size smaller than 3 mm after crushing is 84-86%; and 4, moisture adjustment and preparation of high-strength coke.

Owner:BAOSHAN IRON & STEEL CO LTD

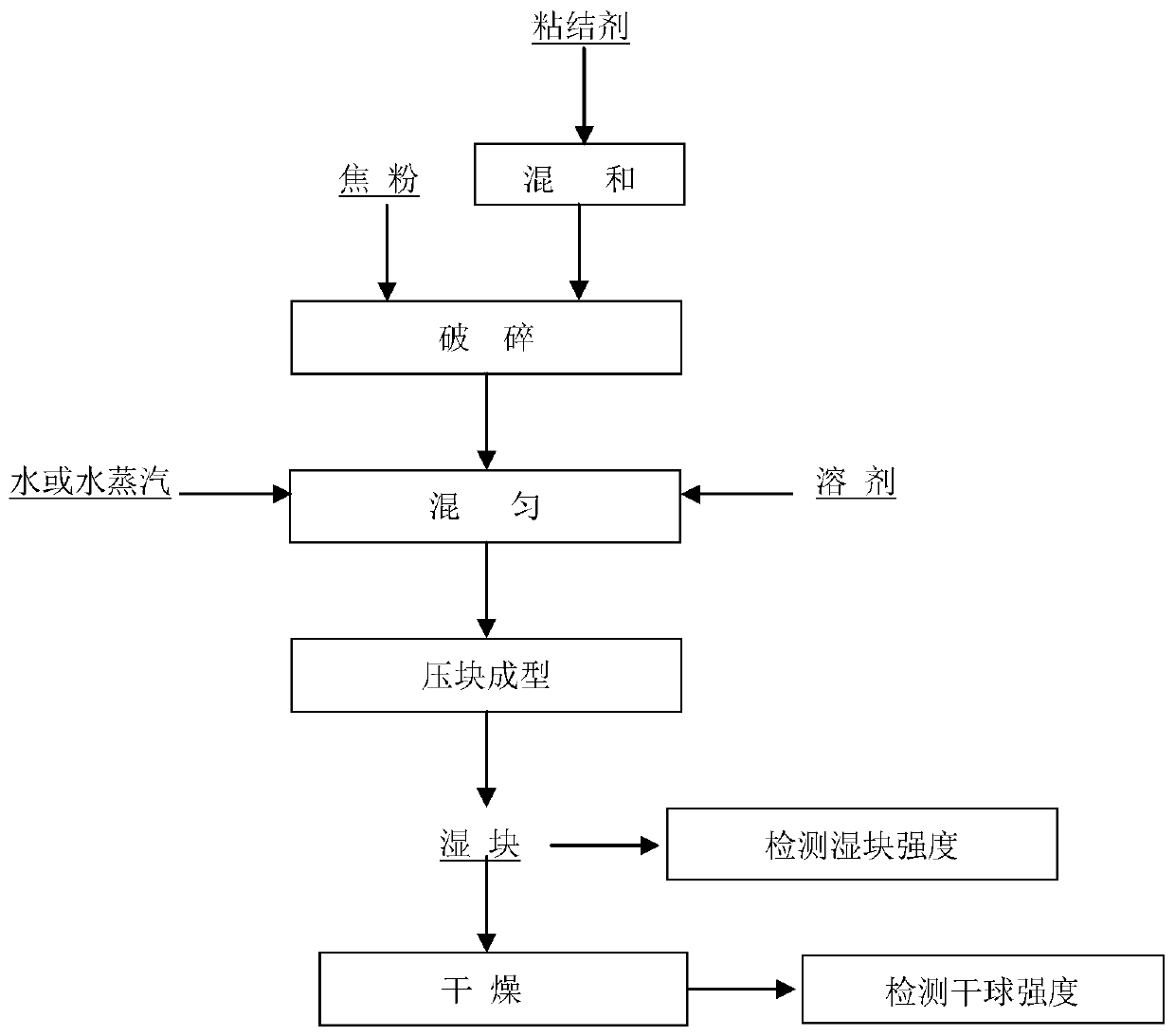

Briquette for gas producer produced by high volatile bituminous coals and method

InactiveCN101805650AIncrease cold strengthNo reduction in fixed carbon contentSolid fuelsBulk chemical productionFixed bedAnthracite

The invention relates to a briquette for a gas producer produced by high volatile bituminous coals and a method. The briquette can meet the requirements of the two-stage fixed bed gas producer for coal quality. The briquette is characterized in that: aiming at the characteristics of high bituminous coal forming elasticity, anthracite coal with the weight 10-20% of that of the bituminous coal is added by weight percentage and is taken as a carbon skeleton, thereby improving the cold strength of the briquette formed by the bituminous coals; modified clay with the weight 4-6% of that of the bituminous coal is added by weight percentage and is taken as a thermal intensifier, and simultaneously a sodium humate binder with the weight 4-6% of that of the bituminous coal is formed by cold pressing, thereby not only improving the cold strength of the briquette, but also not reducing the fixed carbon content of the briquette so as to ensure the heating value and gas production quantity of the briquette; and a small amount of modified clay is added to improve the thermal strength and thermal stability of the briquette, and can be used as a catalyst in the gasification process simultaneously,thereby improving the gasification activity of the briquette.

Owner:河南中美铝业有限公司

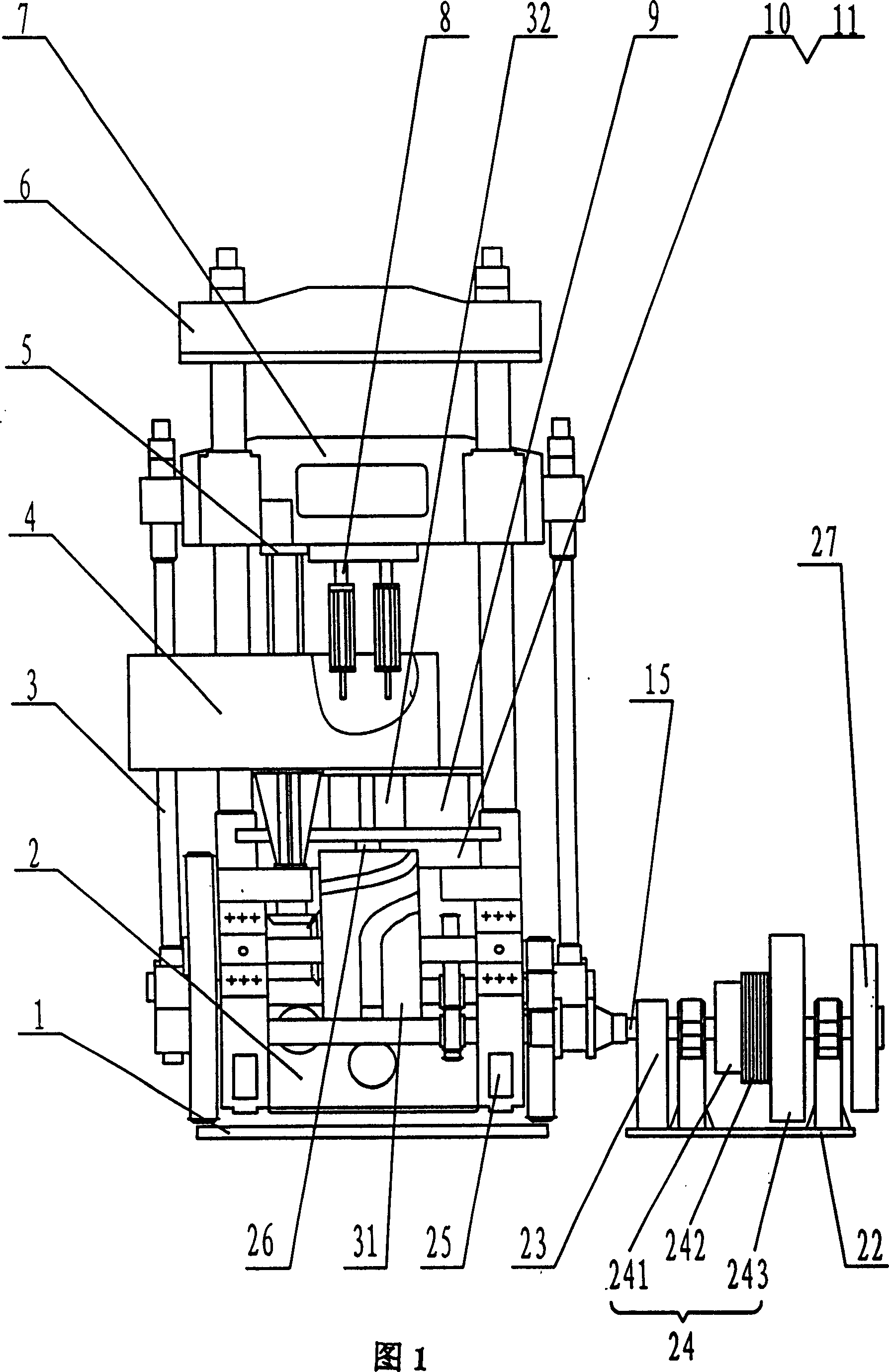

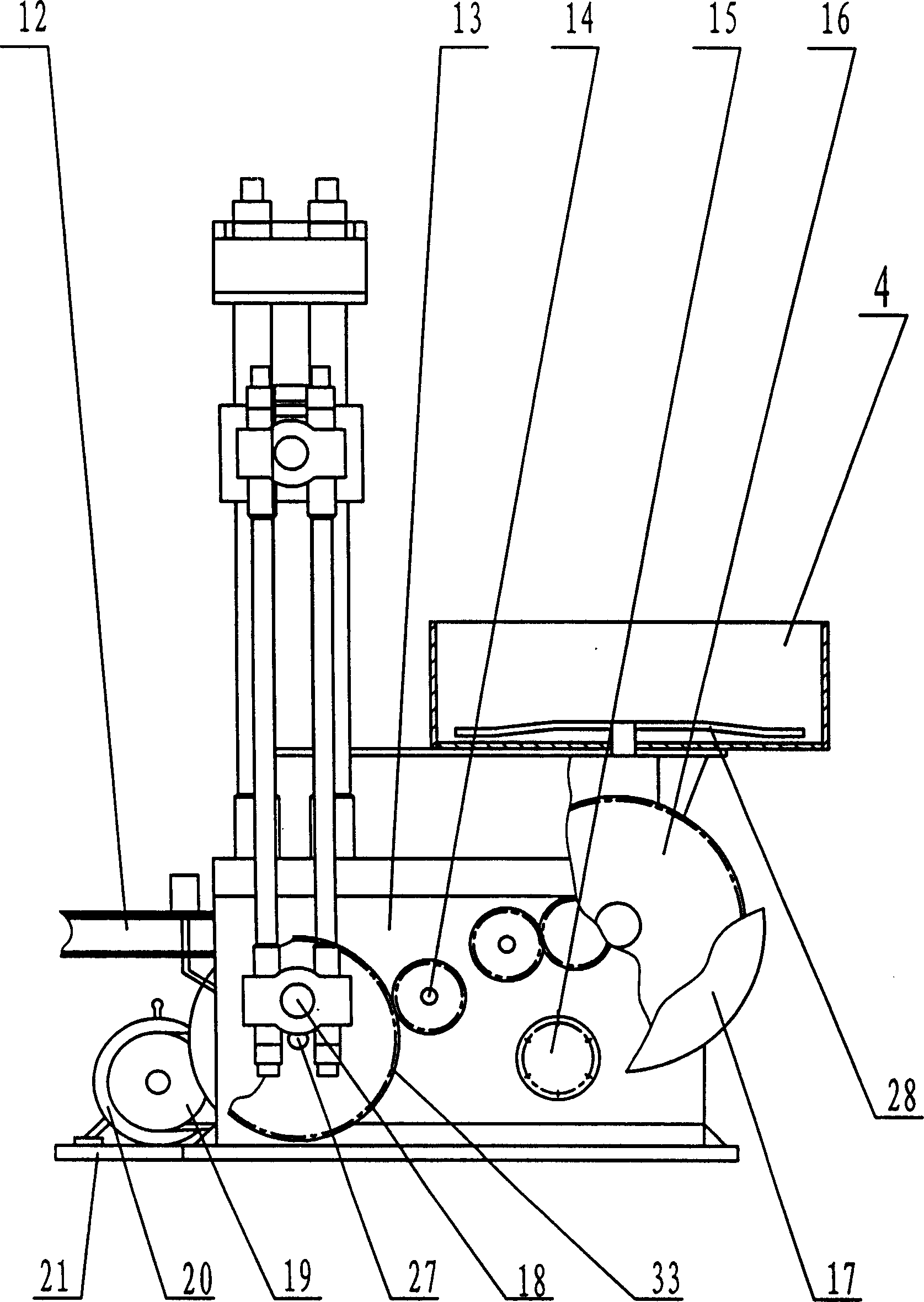

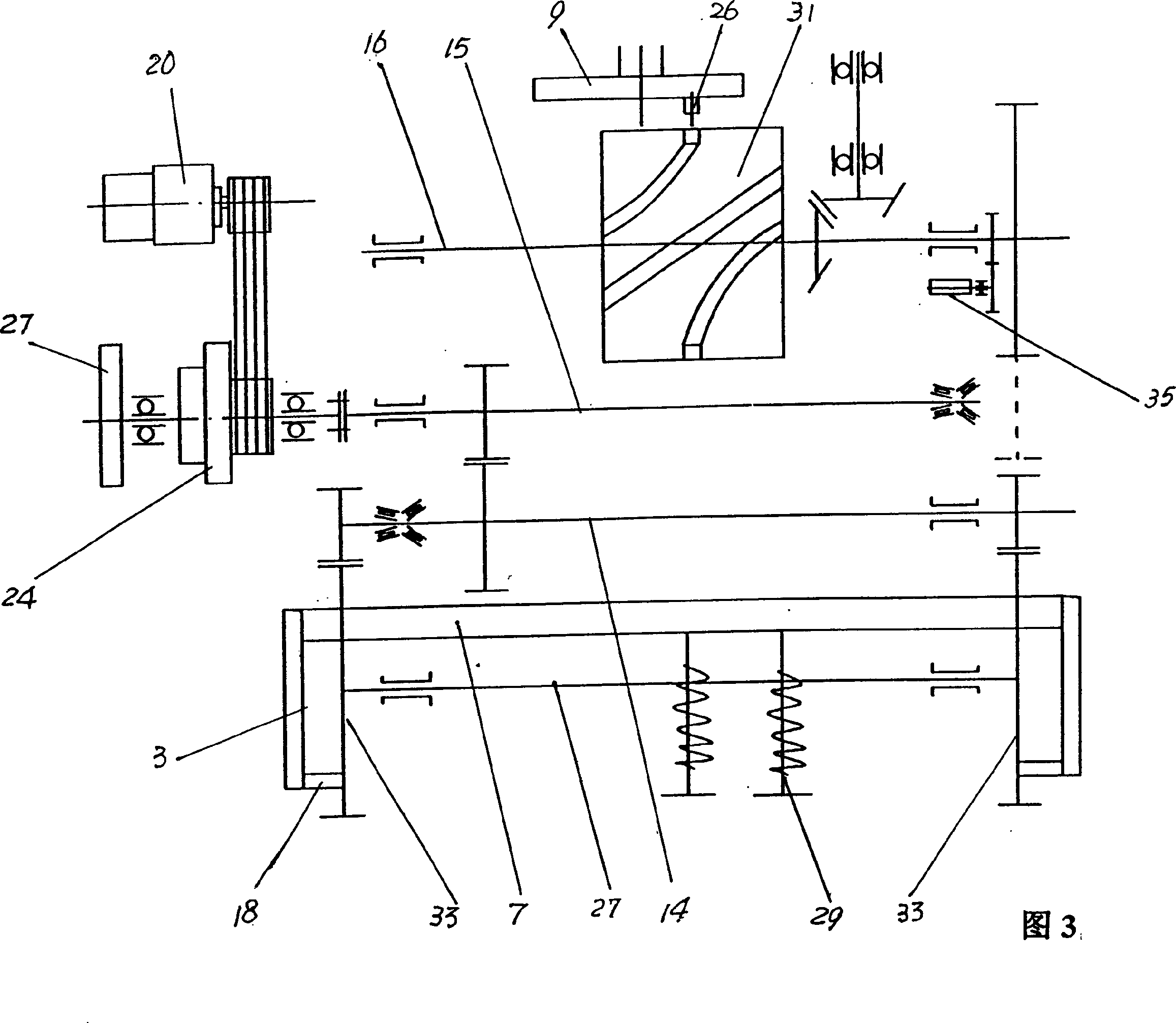

Multistation punch for producing fomed semi-finsished casting coke product

A punching machine with multiple working positions for producing the semifinished casting coke composed of anthracite, other coal and adhesive has the punching arm on the guide post of guiding unit fixed to machine frame, the puching die and stripper installed on said punching arm, the mainshaft driven by motor, flywheel on the extended end of mainshaft, the left and right crank-slide block mechanisms with crank axles, the left and right connecting rods pivoted to said crank axle and punching arm, the cam axle with a cam matched with the roller in rotary disk unit, and the wing in the rotary disk unit for stirring materials. Its product features high uniformity, smooth surface, and high cold strength.

Owner:商丘市普天工贸有限公司煤化工研究所

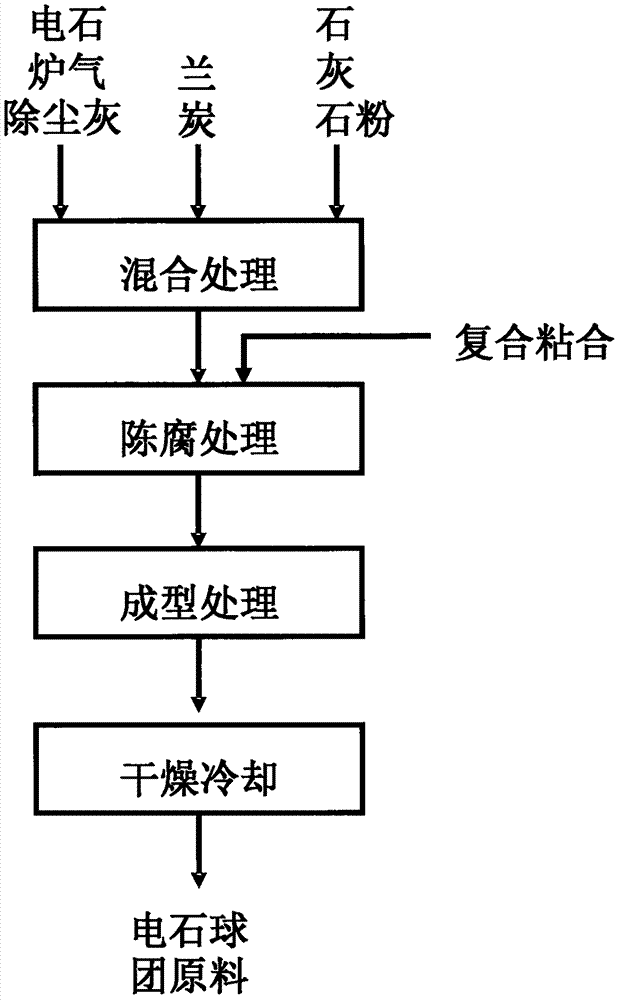

Method for producing calcium carbide pellet raw material by recycling calcium carbide furnace gas fly ash, semi-coke powder and lime powder

The invention relates to a method for producing calcium carbide pellet raw material by recycling calcium carbide furnace gas fly ash, semi-coke powder and lime powder. The method comprises the following steps: (1) uniformly mixing the calcium carbide furnace gas fly ash, semi-coke powder and lime powder in a proper ratio according to composition of the raw material, so that a mixture is obtained; (2) adding water into the mixture and humidifying, adding composite adhesive at the same time, uniformly stirring by adopting a stirring machine and then carrying out ageing and homogenizing treatment; (3) feeding the aged powdery product into a roll-type forming machine to be formed, so that solid pellets in a certain shape are obtained; and (4) drying the solid pellets by utilizing hot flue gas generated in combustion of a hot air furnace. The method provided by the invention utilizes solid waste produced in calcium carbide production, and environmental pollution is avoided; and the composite adhesive is added, so that heat intensity of the pellets is improved, and organic adhesive improves cold intensity of the pellets.

Owner:北京柯林斯达科技发展有限公司

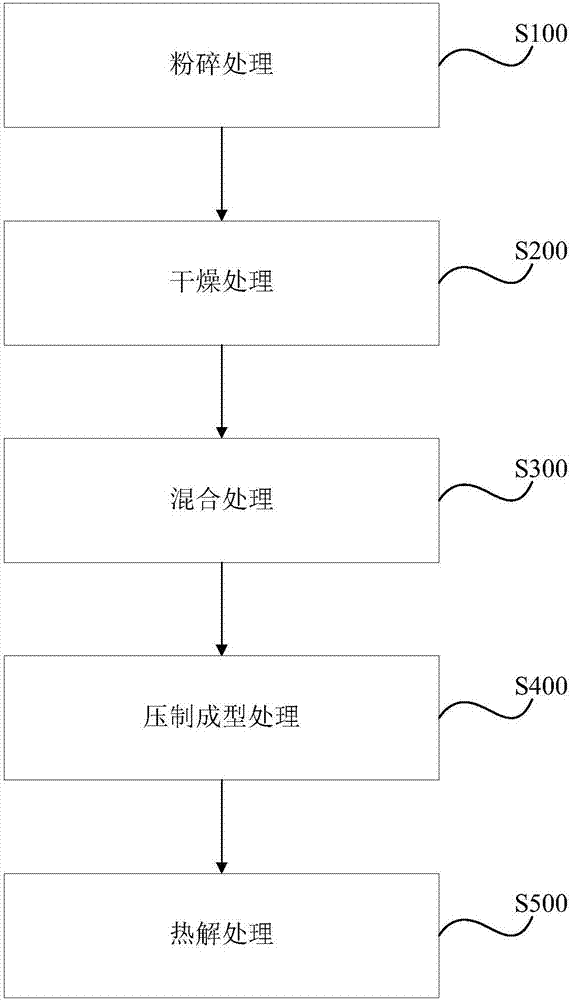

Method for molding raw material for production of calcium carbide

InactiveCN107189796AIncrease cold strengthHigh strengthCalcium carbideSpecial form destructive distillationEffective solutionUranium carbide

The invention discloses a method for molding a raw material for the production of calcium carbide. The method comprises the following steps: (1) respectively pulverizing semicoke, quick lime, coal and a binder to obtain a semicoke powder, a quick lime powder, a coal powder and a binder powder; (2) respectively drying the semicoke powder, the quick lime powder, the coal powder and the binder powder; (3) mixing the dried semicoke powder, the dried quick lime powder, the dried coal powder and the dried binder powder at the preset ratios to obtain a mixed material; (4) compressing and molding the mixed material to obtain the prepared molding material; and (5) pyrolyzing the prepared molding material to obtain the raw material for the production of calcium carbide. By using the method, the molding material with excellent cold strength, heat strength and fall strength is effectively prepared, and in addition, an effective solution is found for the recycle of the powdery semicoke.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

Environment-friendly industrial briquette composite binder and preparation method thereof

The invention discloses an environment-friendly industrial briquette composite binder and a preparation method thereof. Humic acid, alumina, common seepweed herb seed cake meal, water and the like are used as raw materials; the preparation process is simple and convenient; the briquette prepared by the method has the advantages of little drop of the solid carbon content, good binding property, high pelletizing rate, high cold / hot strength, good thermal stability, low cost, short production cycle and the like.

Owner:GUANGXI LIUZHOU JUNYE TECH

High-ore-matching-ratio brown iron ore sintering technology

The invention relates to a high-ore-matching-ratio brown iron ore sintering technology. The weight ratio of brown iron ore and powdered iron in raw material proportion is (5-19):1, the moisture content of the first mixing is controlled to be 7%-8%, the mixing time lasts for 2-3minutes, and the temperature of the mixture is 50-62 DEG C; the moisture content of second mixing pelletizing is controlled to be 7-9%, the pelletizing time lasts for 2-3.5minutes, and the temperature of materials is 52-65 DEG C; the thickness of grate-layer materials in distribution is 20mm, and a sintering material layer is 780-900mm thick; the ignition temperature for sintering is1050-1150 DEG C, and the ignition time lasts for 1.8-2.2minutes; and the negative pressure for sintering is 12-15kpa, the machine speed is 0.9-1.2m / min, the vertical sintering speed is 29-34mm / min, the air leakage rate is no more than 40%, the cooling negative pressure is 11-14kpa, the temperature of a cooling section of a sintering machine is reduced to 250 DEG C below. By using the high-ore-matching-ratio brown iron ore sintering technology, energy is saved, consumption is reduced, cost is decreased and benefit is increased.

Owner:唐山瑞丰钢铁(集团)有限公司

Method for preparing high-strength formed coke through cold press molding

ActiveCN111154278ARealize cold press formingIncrease cold strengthBuilding insulationsMetallurgyEthyl acetate

The invention relates to a formed coke forming process, and discloses a method for preparing high-strength formed coke through cold press forming. A used binder is prepared from the following components in parts by mass: 0 to 20 parts of corn starch, 60 to 80 parts of asphalt, 0 to 5 parts of artificial graphite or a boron compound, 0 to 10 parts of cement or magnesium oxide, 0 to 20 parts of ethyl acetate and 0 to 2 parts of sodium hydroxide. The binder accounts for 8.6%-10.7% of the mass of the coke powder. The mixed binder and coke powder (metallurgical coke or petroleum coke) are premixeduniformly, a certain amount of water is added, and the formed coke is obtained through normal-temperature cold press molding. The formed coke prepared by the method has the excellent characteristics of high cold and hot strength, good thermal stability, high forming rate, low cost and the like.

Owner:孝义诚远环保科技有限公司

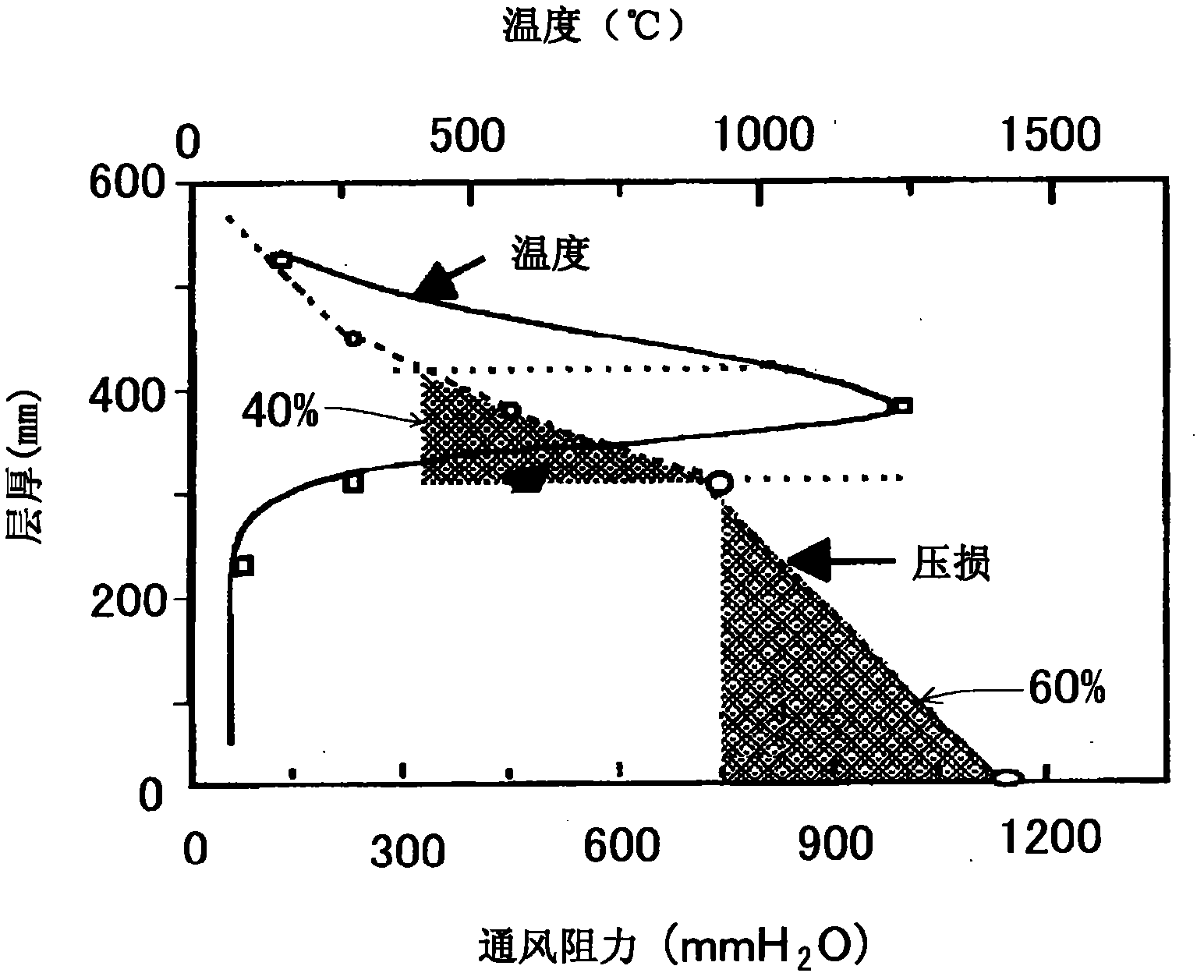

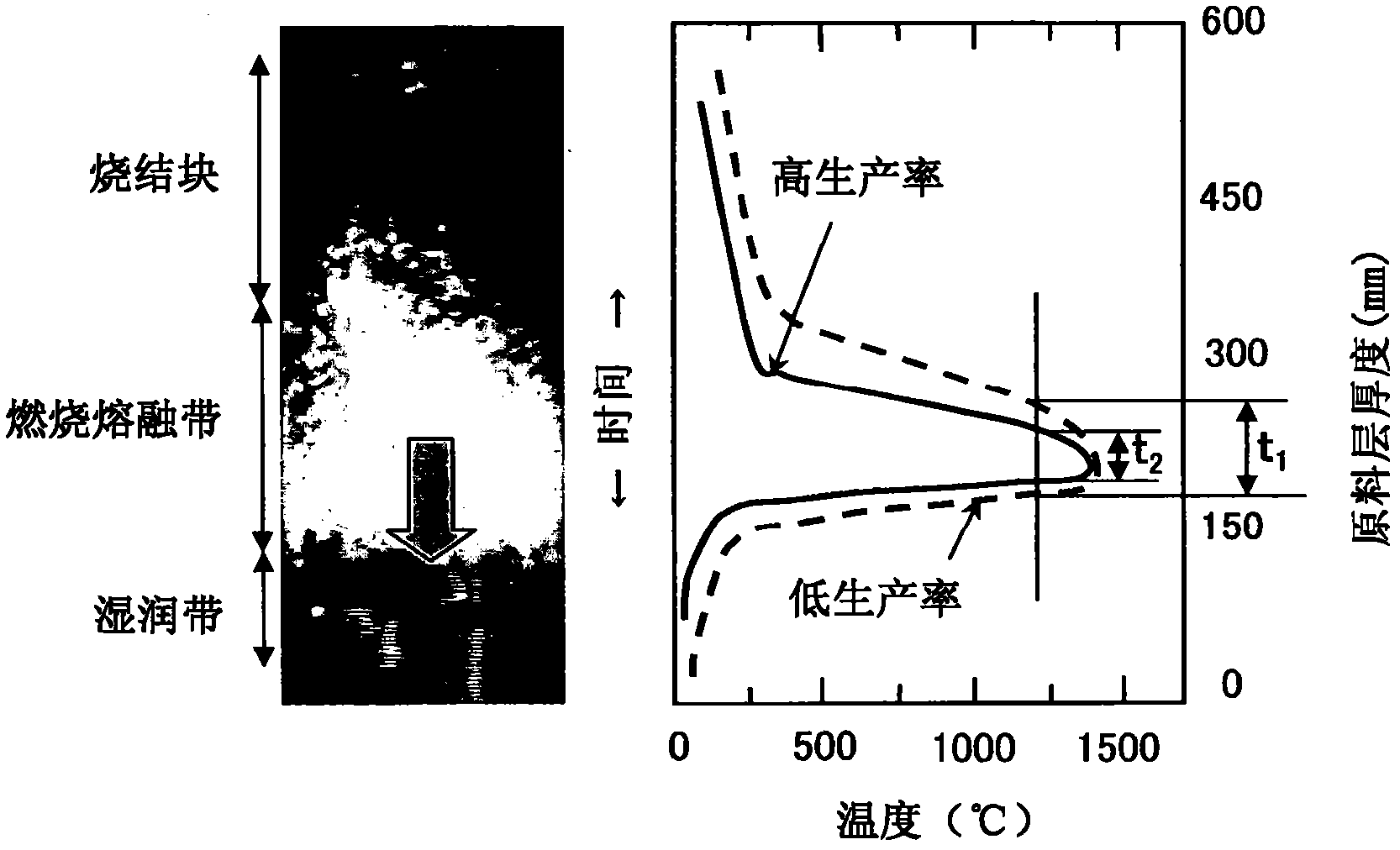

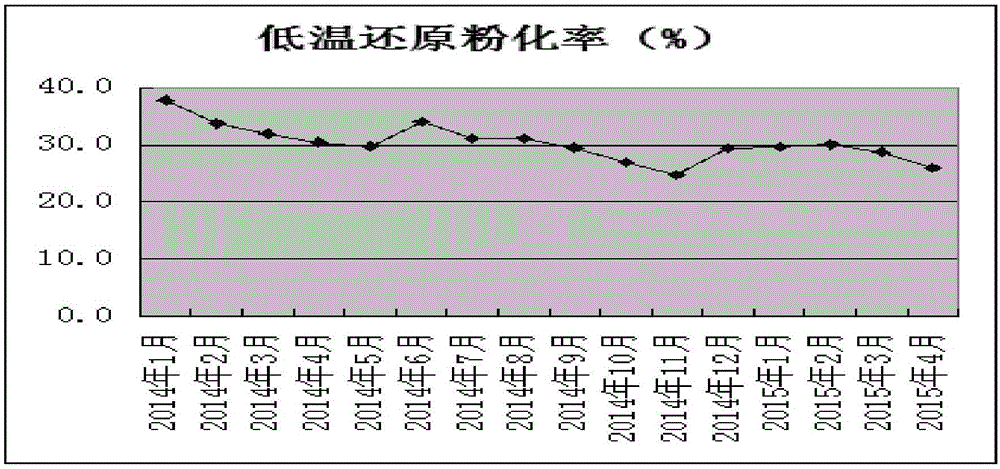

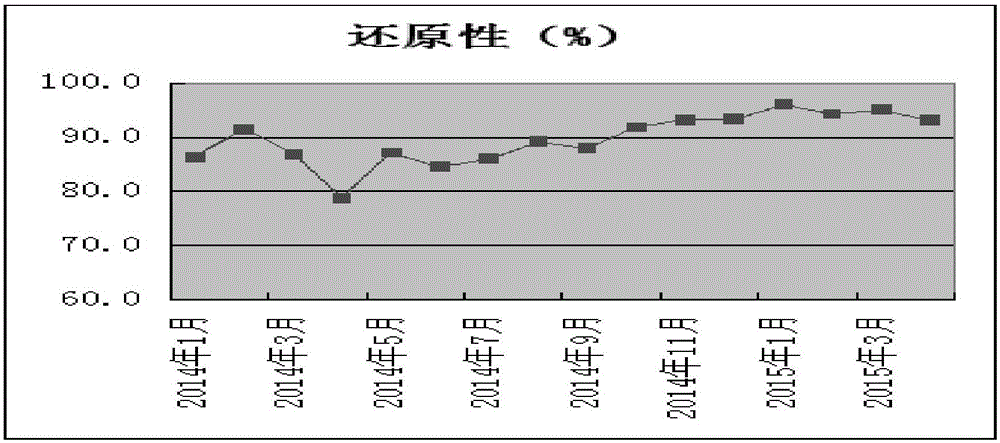

Method for improving quality of sintered ore

The invention discloses a method for improving quality of sintered ore. According to the method, the content of MgO in the sintered ore is reduced, and the content of MgO is enabled to account for 1.75%-2.05% of the total mass of the sintered ore; preferably, the content of MgO in the sintered ore accounts for 1.75%-1.81% of the total mass of the sintered ore. The content of MgO of the sintered ore is properly reduced, sintering and blast furnace production are better, and indexes get better; the sintering production efficiency and the cold strength of the sintered ore are improved, the low-temperature reduction degradation index of the sintered ore is increased, the temperature interval of a soft melting zone of the sintered ore is reduced, and the grade of the sintered ore is improved. Therefore, the permeability of a massive zone and the soft melting zone of a blast furnace is improved, the quantity of slag in the blast furnace is reduced, the smooth operation condition of the blast furnace is improved, and blast furnace smelting strengthening and coke ratio reduction are facilitated.

Owner:XINXING DUCTILE IRON PIPES CO LTD

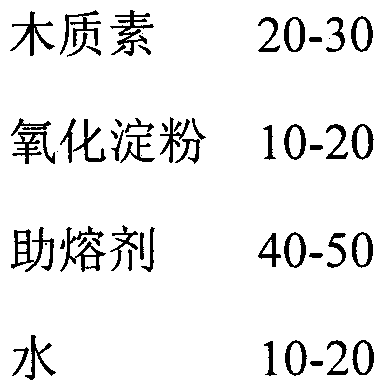

Lignin iron powder ball compound adhesive and preparation method thereof

The invention discloses a lignin iron powder ball compound adhesive and a preparation method thereof. The iron powder ball adhesive is prepared from the following ingredients of sulfur-free large molecular weight lignin, oxidized starch and an inorganic fluxing agent. The adhesive is added into an iron powder raw material according to a certain proportion to be fully and evenly stirred, the defined amount of water is sprayed to form a mixture with viscosity, and the mixture is put into a ball pressing machine to be manufactured into iron powder balls. The iron powder balls are sent into a drying stove and pass through a low-temperature area, a middle-temperature area and a high-temperature area to be dried and roasted to be solidified into the iron powder balls with certain strength. As the iron powder adhesive use amount is larger, the large molecular weight lignin without sulfur and alkali metal is utilized as a main ingredient of the iron powder ball adhesive disclosed by the invention; thus, an effective path is provided for application of bulk lignin raw materials.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

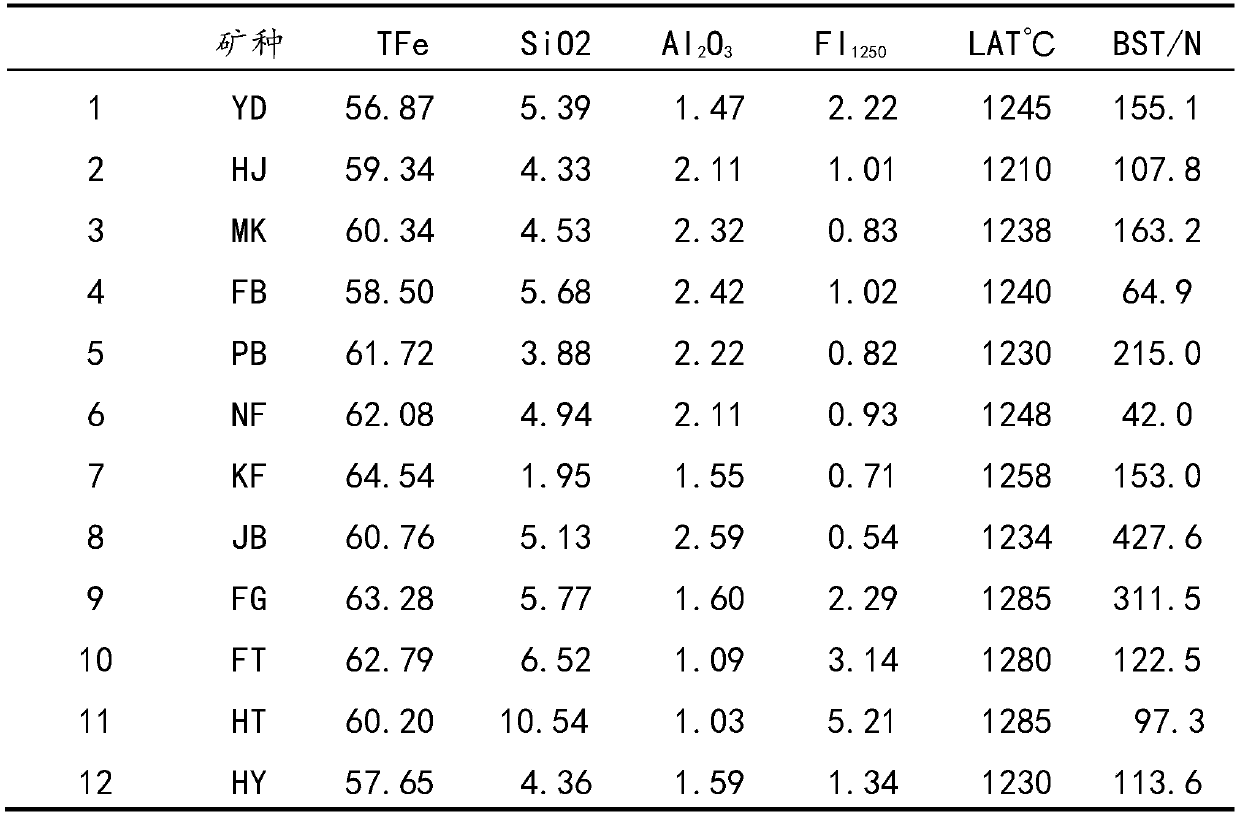

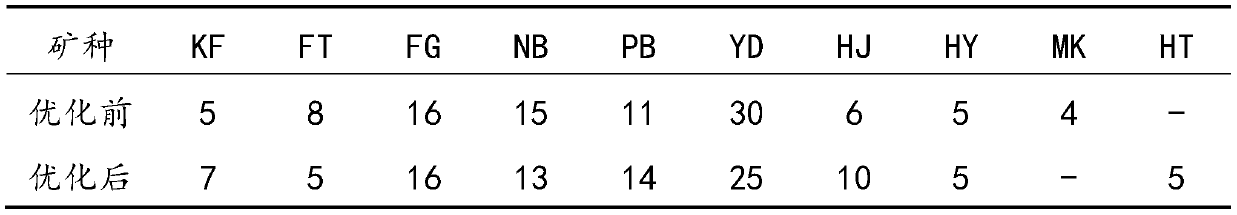

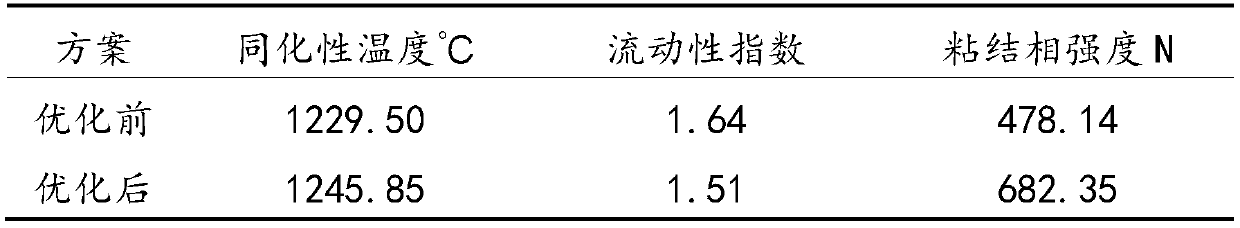

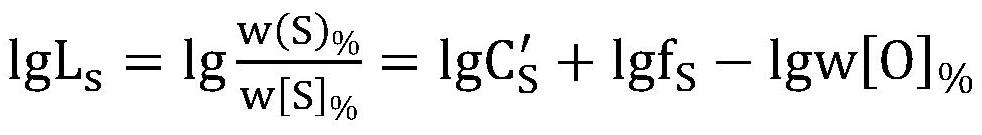

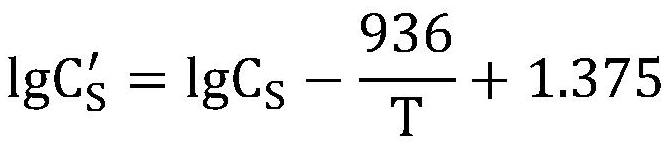

Ore blending method based on high-temperature metallurgical performance of iron ore powders

ActiveCN110600086AReduce liquidityThe fluidity is 1.4-1.8, and the strength of the binder phase slows downChemical property predictionProcess efficiency improvementChemical compositionMaterials science

The invention discloses an ore blending method based on the high-temperature metallurgical performance of iron ore powders. The method comprises selecting a plurality of iron ore powders of differentorigins to test and analyze the high-temperature metallurgical performance of the different iron ore powders; obtaining a mathematical model of high-temperature metallurgical performance values and chemical components through data analysis; matching the advantages and disadvantages of the high-temperature metallurgical performance of the iron ore powders to obtain mixed powders with excellent high-temperature metallurgical performance and suitable for sintering. The method of the invention reveals a relation between the high-temperature metallurgical performance values and the chemical components of the single ore and the mixed ore, optimizes the ore blending based on this, and can obtain mixed ore with excellent high-temperature metallurgical performance, contributes to sintering and an increase in yield, and improves sintering ore quality. In addition, when mixing ore, by means of the complementation of the high-temperature metallurgical performance of different iron ore powders, themethod increases the proportion of non-mainstream low-priced ore, and reduces the cost of sintering raw materials.

Owner:美匡冶金技术研究院(苏州)有限公司

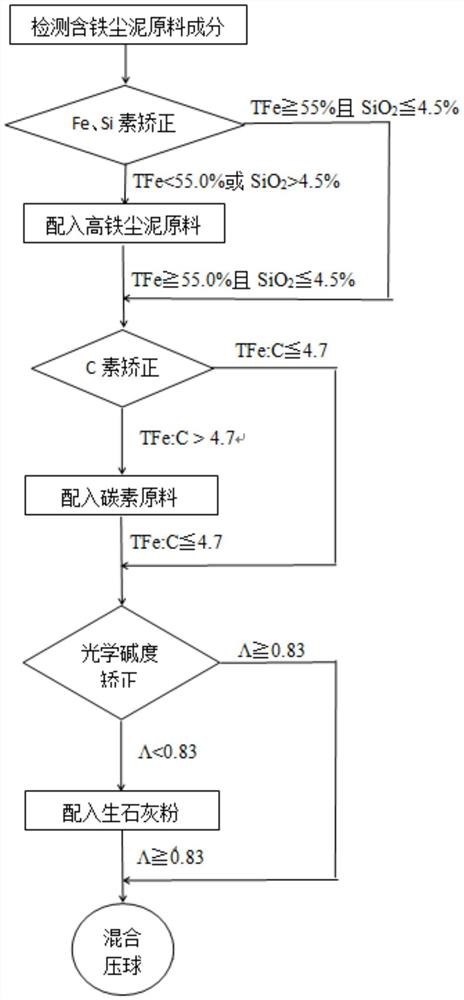

Preparation method of iron-containing dust sludge pellets

The invention relates to the technical field of metallurgy, and discloses a preparation method of iron-containing dust sludge pellets, which optimizes the components and preparation technique of the iron-containing dust sludge pellets by controlling the types of raw material dust sludge and combining the metallurgical thermodynamics theory. According to the preparation method of the iron-containing dust-mud pellets, recovery of iron elements can be achieved, meanwhile, S elements possibly entering molten iron are effectively controlled, the S elements are reserved in slag and removed in the slag falling process of the molten iron, and the quality of the molten iron is guaranteed.

Owner:武汉钢铁有限公司

Humolite composite adhesive for producing gas making coal rods and preparation method thereof

InactiveCN103436316AImprove energy savingReduction of coal consumption per ton of ammoniaSolid fuelsSmokeless powderSodium Bentonite

The invention relates to a humolite composite adhesive for producing gas making coal rods and a preparation method thereof. The humolite composite adhesive is prepared from the following raw materials in parts by weight: 1400-1800 parts of humolite powder, 40-60 parts of maize powder, 200-400 parts of calcium bentonite and 140-160 parts of sodium hydroxide. The preparation method comprises the following steps: adding water into a reaction tank, adding the raw materials, and carrying out chemical composite reaction under heating conditions. When smokeless powder coal and the composite adhesive are used for producing the gas making coal rod, the cold state compression strength of the coal rod is 60-70 kilograms, the hot strength and heat stability of the coal rod are high, and the heat stability is 70% above; and the coal rod has high chemical activity and obvious energy-saving effect.

Owner:张时能

Adhesive for zinc-containing fly ash pellets of rotary hearth furnace and preparation method

The invention relates to an adhesive for zinc-containing fly ash pellets of a rotary hearth furnace and a preparation method. The adhesive comprises raw materials mixed according to a certain proportion, and the adhesive is characterized in that the raw materials comprise the following components in percentage by mass: 0-2% of amide, 0-8% of CMC, 40-50% of pregelatinized starch, 0-5% of sodium carbonate, 0-5% of baking soda, 20-30% of alumina powder and 15-25% of bentonite; the raw materials are mixed, specifically, 0-2% of amide, 0-8% of CMC, 40-50% of pregelatinized starch, 0-5% of sodium carbonate, 0-5% of baking soda, 20-30% of alumina powder and 15-25% of bentonite in percentage by weight are prepared and uniformly mixed and stirred; and the adhesive for the zinc-containing fly ash pellets of the rotary hearth furnace is small in dosage, small in ash content and high in strength, harmful substances capable of reducing the iron grade are not introduced, the pellets do not disintegrate and do not pulverize at high temperature, and the prepared pellets are high in dezincification rate, resistant to high temperature, good in reducibility and high in metallization rate.

Owner:河南建杰实业有限公司

Magnetite-based sintered ore and method of producing same

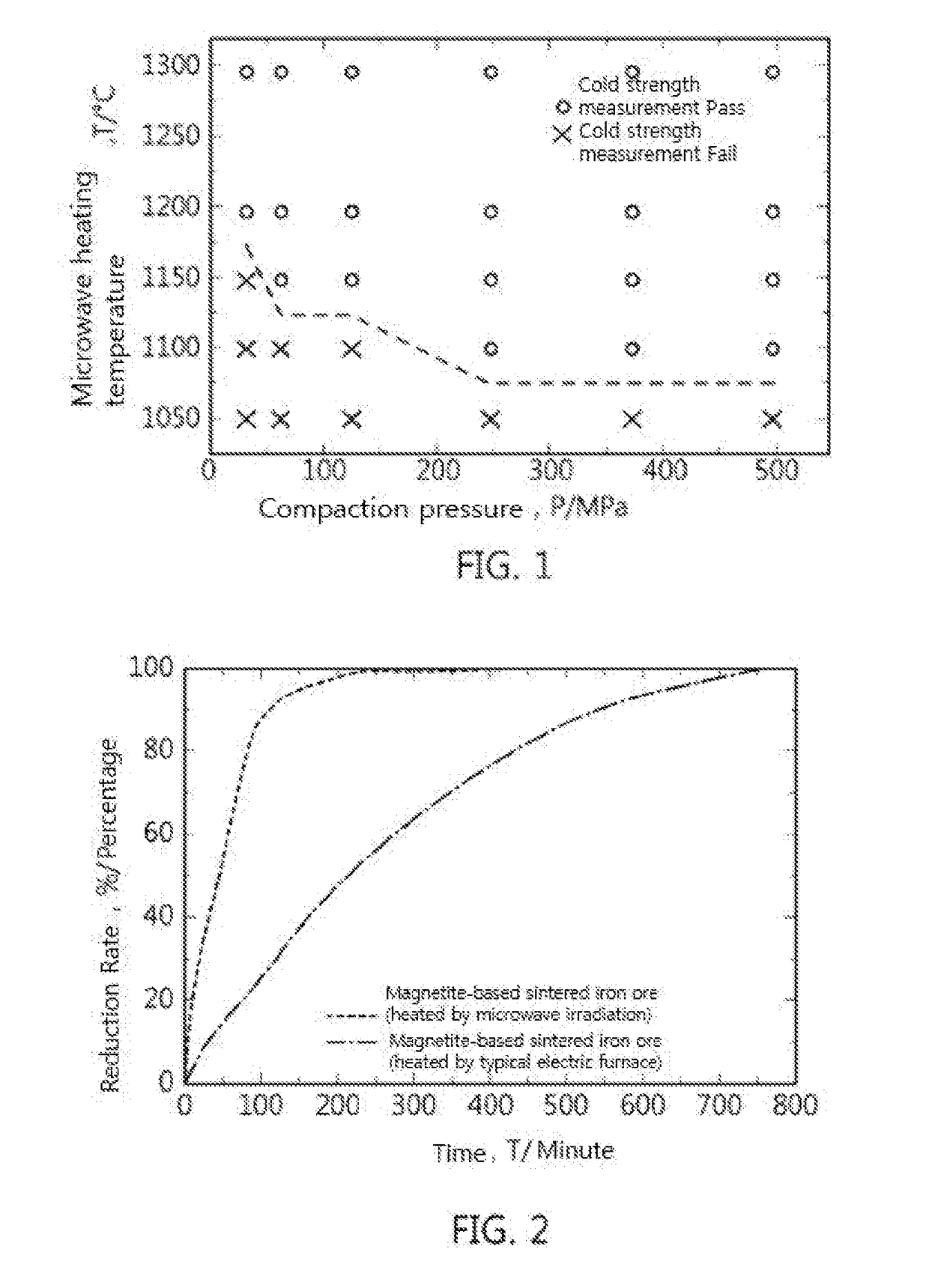

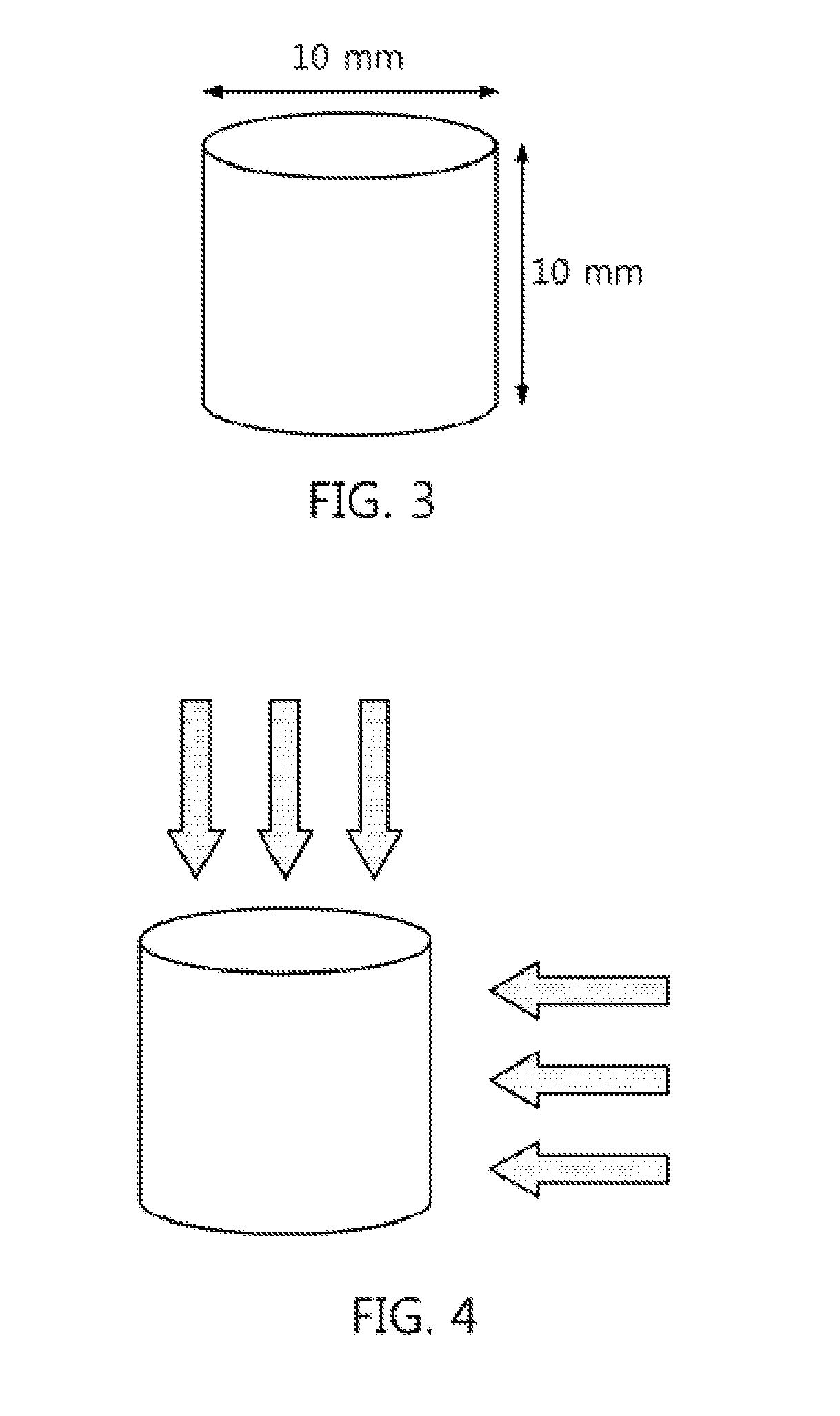

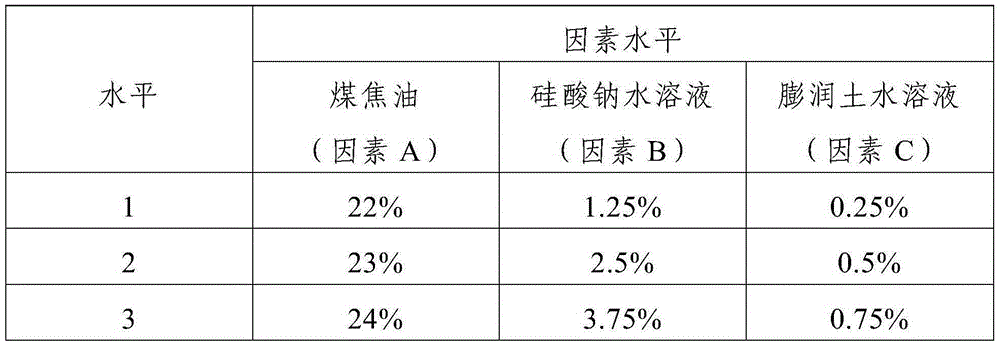

ActiveUS20180002779A1Increase cold strengthImprove reducibilityGas emission reductionMagnetiteIron ore

This invention relates to magnetite-based sintered iron ore wherein a magnetite ore powder, which is not currently utilized owing to its low reducibility index among iron ore materials serving as a main material in iron-making processes, is improved so as to have a high reducibility index, and to a method of manufacturing the same.

Owner:KOREA UNIV RES & BUSINESS FOUND

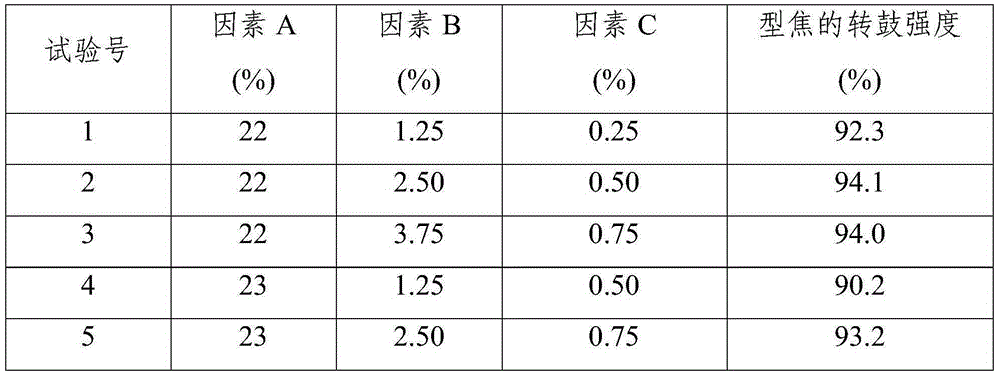

Method for preparing formed coke

The invention provides a method for preparing formed coke. The method comprises the following steps: 1, preparing a sodium silicate aqueous solution and a sodium bentonite aqueous solution; 2, adding coal tar, the sodium silicate aqueous solution and the sodium bentonite aqueous solution into pulverized coal, uniformly mixing, filling a steel mold with the mixture, performing cold press molding by utilizing a hydraulic press, and demolding to obtain a blank material; and 3, drying the blank material in a drying oven, and naturally cooling to obtain the formed coke. The formed coke prepared by adopting the method is an organic-inorganic composite material, and novel formed coke with high cold strength can be produced by adopting the cold press molding method; and the type of coal mines can be selected without strict requirements, and formed coke with high tumbler strength can be prepared by utilizing lean coal, meager lean coal and other weak caking coal.

Owner:XIAN UNIV OF SCI & TECH

Briquette and its making process

The present invention is one kind of briquette and its making process. The briquette is made with coal powder and adhesive in the weight ratio of 100 to 20-25, and features the coal powder of grain size 100-270 mesh and the adhesive is powder of glutinous rice or millet. The making process of the briquette includes superfine crushing coal, mixing the coal powder with adhesive through stirring, rolling into flat circular or square form, and drying. The briquette has the advantages of no pollution to air, capacity of replacing lump coal, high cold strength, high burning effect, etc.

Owner:郁永喜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com