Method for molding raw material for production of calcium carbide

A molding method and raw material technology, which is applied in the petroleum industry, special forms of dry distillation, carbide, etc., can solve the problems of waste of resources, backlog of powdered semi-coke, difficulty in using powdered semi-coke, etc., and achieve the goal of protecting the environment and saving resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

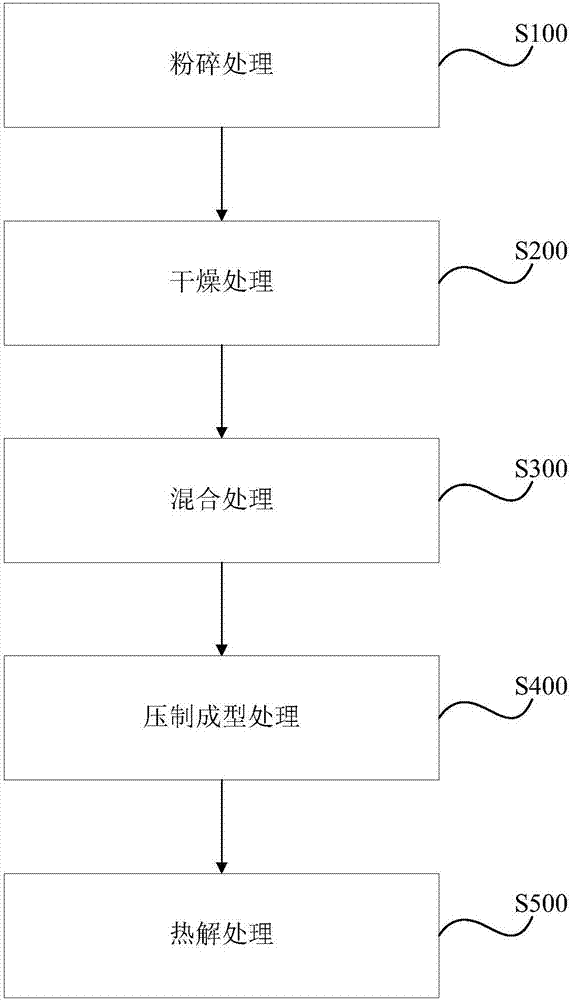

Method used

Image

Examples

Embodiment 1

[0051] Crush Gangyuan semi-coke, quicklime, and Outer Mongolia coal to less than 1mm, among which the semi-coke is crushed to a size less than 100 mesh and more than 55%. , all raw materials were dried at 105°C (moisture content less than 5%). Weigh 1600g of Gangyuan semi-coke, 2800g of quicklime, 320g of Outer Mongolian coal, 50g of polyacrylamide, and 150g of high-temperature asphalt, put them into a mixer and mix them evenly, press them into balls with a briquetting machine, and heat them at 900°C for 0.5h. Solution, measure its cold strength, hot strength and drop strength, see Table 1.

[0052] Table 1 Molding raw material strength

[0053] project

Embodiment 2

[0055] Crush Gangyuan semi-coke, quicklime, and six-mine coal to less than 1mm, among which the semi-coke is crushed to a particle size of less than 100 mesh and greater than 55%; starch and humic acid are crushed to a size below 100 mesh (particles smaller than 100 mesh are greater than 70%), All raw materials were dried at 105°C (moisture content less than 5%). Weigh 1600g of Gangyuan semi-coke, 2800g of quicklime, 320g of Outer Mongolian coal, 50g of starch, and 150g of humic acid, put them into a mixer and mix them evenly, press them into balls with a briquetting machine, and heat them at 900°C for 0.5h for pyrolysis , measure its cold strength, hot strength and drop strength, see Table 2.

[0056] Table 2 Molding raw material strength

[0057] project

Embodiment 3

[0059] Crush Gangyuan semi-coke, quicklime, and coking coal to less than 1mm, among which semi-coke is crushed to a size less than 100 mesh and more than 55%; polyacrylamide, starch and high-temperature asphalt are crushed to less than 100 mesh (more than 70% of particles smaller than 100 mesh) , all raw materials were dried at 105°C (moisture content less than 5%). Weigh 1600g of Gangyuan semi-coke, 2800g of quicklime, 320g of Outer Mongolia coal, 30g of polyacrylamide, 30g of starch, and 150g of high-temperature asphalt, put them into a mixer and mix them evenly, press them into balls with a briquetting machine, and keep warm at 900°C for 0.5 h to carry out pyrolysis, measure its cold strength, hot strength and drop strength, see Table 3.

[0060] Table 3 Molding raw material strength

[0061] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com