Ore blending method based on high-temperature metallurgical performance of iron ore powders

A high-performance, high-temperature technology, applied in the field of iron and steel smelting, can solve the problems of poor sintering performance, high randomness, and rising costs, and achieve the effects of improving reducibility, facilitating cold strength, and reducing fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

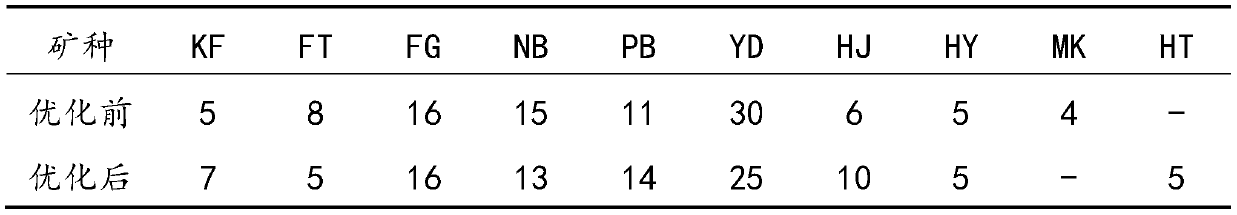

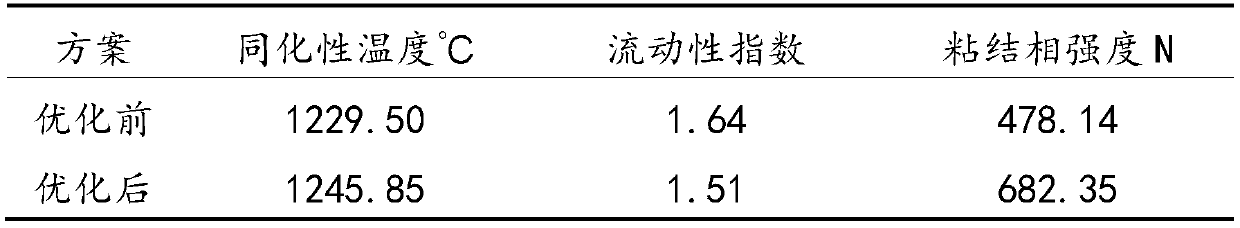

[0030] The method proposed by the present invention is based on the pyrometallurgical properties of different iron ore powders, through reasonable optimization of ore blending, so that the pyrometallurgical properties of the mixed ore can be kept within a suitable range, which is beneficial to reduce the liquid phase formation temperature during the sintering process, Improve the strength of the binder phase during the sintering process, increase the amount of composite calcium ferrite in the sintered ore, improve the reducibility of the sintered ore, increase the cold-state strength of the sintered ore, reduce fuel consumption, and reduce the cost of mixed ore raw materials.

[0031] Concrete, the ore blending method based on iron ore pyrometallurgical performance of the present invention, comprises the steps:

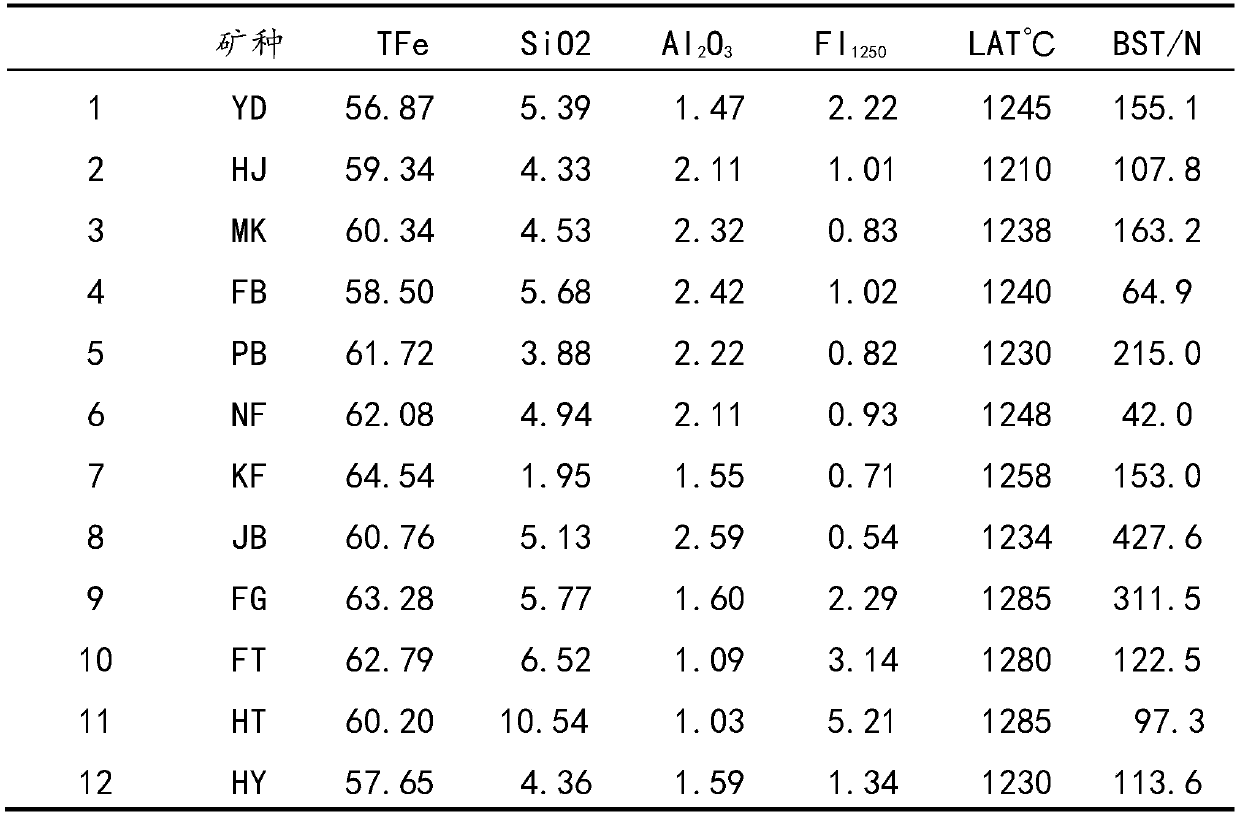

[0032] S1, iron ore powder selection step, select 10 or more iron ore powders from different origins, and measure the content of chemical components of different iron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com