Hot melt adhesive for cable accessories in nuclear island of nuclear power plant and preparation method thereof

A cable accessory, hot melt adhesive technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the hot-melt adhesive for cable accessories in the nuclear island of the nuclear power plant of the present invention comprises the following steps:

[0031] Step 1: Mix ethylene copolymer hot melt adhesive, polyolefin elastomer, and composite antioxidant according to a certain ratio, knead with an internal mixer at 100~200°C for 20 minutes, and press the kneaded hot melt adhesive piece;

[0032] Step 2: The pressed hot melt adhesive is irradiated with an electron beam or a cobalt source, and the irradiation dose is 20-150 kGy. After irradiation, the hot melt adhesive is partially cross-linked, the ring and ball softening point is increased, and the fluidity is reduced.

[0033] The following examples will help to understand the present invention, but can not limit the content of the present invention.

Embodiment 1

[0035] Take 100 parts of ethylene copolymer hot melt adhesive (ethylene-vinyl acetate copolymer hot melt adhesive), 30 parts of polyolefin elastomer (POE 8150), composite antioxidant ([β-(3',5'-di-tert-butyl Base-4'-hydroxyphenyl) propionate] pentaerythritol ester (antioxidant 1010), dioctadecyl pentaerythritol bisphosphite (antioxidant 618), dilauryl thiodipropionate (antioxidant DLTDP ) at a ratio of 2:1:1) to 5 parts, the above materials were mixed repeatedly for 20 minutes at 150°C using an internal mixer, and the materials were pressed into thin sheets and then cross-linked under electron beam irradiation with a radiation dose of 100 kGy .

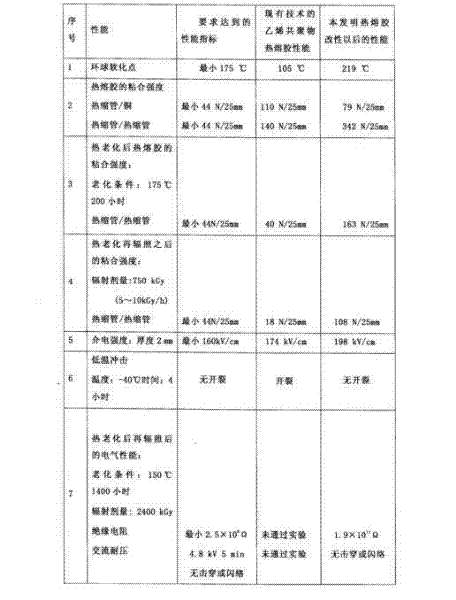

[0036] The properties of hot melt adhesive are as follows:

[0037]

Embodiment 2

[0039] Take 100 parts of ethylene copolymer hot melt adhesive (ethylene-vinyl acetate copolymer hot melt adhesive), 100 parts of polyolefin elastomer (POE 8150), composite antioxidant ([β-(3',5'-di-tert-butyl Base-4'-hydroxyphenyl) propionate] pentaerythritol ester (antioxidant 1010), dioctadecyl pentaerythritol bisphosphite (antioxidant 618), dilauryl thiodipropionate (antioxidant DLTDP ) at a ratio of 2:1:1) to 10 parts, the above materials were mixed repeatedly for 20 minutes at 150°C using an internal mixer, and the materials were pressed into thin sheets and then cross-linked under electron beam irradiation with a radiation dose of 20 kGy .

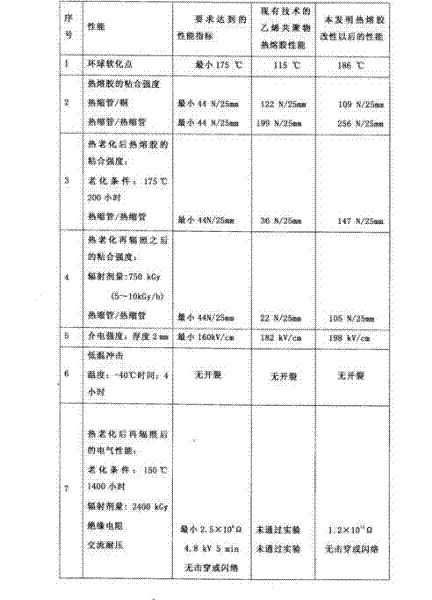

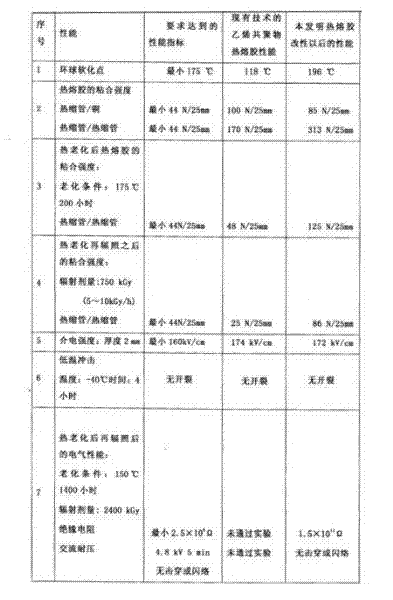

[0040] The properties of hot melt adhesive are as follows:

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com