Low-cost blast furnace iron-smelting method

A blast furnace ironmaking, low-cost technology, applied in the field of iron and steel metallurgy, can solve the problems of low indirect reduction degree of iron ore, less CO2 production, low calorific value, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

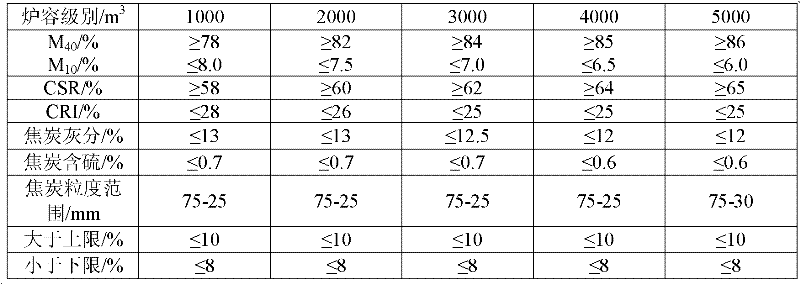

[0018] A low-cost blast furnace ironmaking method, using semi-coke (semi-coke) and stamped coke for blast furnace ironmaking. Lump semi-coke (semi-coke) is evenly mixed with ore, then layered with tamped coke and loaded into the blast furnace for blast furnace ironmaking. After the small particle size or powdery semi-coke (semi-coke) is crushed to the injection particle size requirement, it can replace the high-quality anthracite (or lean coal, lean coal) for injection with high price and tight resources and inject it into the blast furnace alone or mixed with coal powder . In the process of blast furnace ironmaking, the quality indicators of stamped coke required by blast furnaces with different volumes can be referred to in Attached Table 1.

[0019] The weight ratio of the massive semi-coke of the present invention to the ore is about 1:20~1:200, and the quality index of the described massive semi-coke satisfies A d ≤13%; S t,d ≤0.8%; M 25 ≥30%; M 10 ≤30%; CSR 35 (wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com